Page 1

DV-5 Deluge Valve, Diaphragm Style,

1-1/2 thru 8 Inch (DN40 thru DN200),

Deluge System — Electric Actuation

General

Description

The DV-5 Deluge Valve (described in

Technical Data Sheet TFP1305) is a

diaphragm style valve that depends

upon water pressure in the Diaphragm

Chamber to hold the Diaphragm closed

against the water supply pressure.

When the DV-5 Valve is set for service,

the Diaphragm Chamber is pressurized

through the trim connections from the

inlet side of the system’s main control valve, for example an O.S.&Y. gate

valve or buttery valve (Ref. Figures 1

and 4).

Operation of an electrical device such

as a heat sensitive thermostat, smoke

detector, or electrical manual control

station signals the Deluge Valve Releasing Panel to energize the Solenoid

Valve. In turn, the energized Solenoid

Valve opens to release water from the

Diaphragm Chamber faster than it can

be replenished through the 1/8 inch

(3,2 mm) restriction provided by the

Model ASV-1 Automatic Shut-Off Valve

in the diaphragm supply connections

(Item 5 - Fig. 3A and 5, also described

in Technical Data Sheet TFP1384). This

results in a rapid pressure drop in the

Diaphragm Chamber and the force

differential applied through the Diaphragm that holds it in the set position

is reduced below the valve trip point.

The water supply pressure then forces

the Diaphragm open permitting water

to ow into the system piping, as well

as through the Alarm Port to actuate

the system alarms.

As water ows into the system, the pilot chamber of the Model ASV-1 Automatic Shut-Off Valve (Item 5 - Fig. 3A

and 5) becomes pressurized and the

ASV-1 automatically shuts off the diaphragm chamber supply ow to the

DV-5 Diaphragm Chamber. Shutting

off the diaphragm chamber supply ow

prevents the DV-5 Diaphragm Chamber

from becoming re-pressurized, thereby preventing inadvertent closing of the

DV-5 during a re (as may be the case

should the Solenoid Valve become deenergized after its initial operation).

NOTICE

The DV-5 Deluge Valve with Electric

Actuation Trim described herein must

be installed and maintained in compliance with this document, as well as

with the applicable standards of the

National Fire Protection Association, in

addition to the standards of any other

authorities having jurisdiction. Failure

to do so may impair the performance

of these devices.

The owner is responsible for maintaining their fire protection system

and devices in proper operating condition. Contact the installing contractor or product manufacturer with any

questions.

Worldwide

Contacts

www.tyco-fire.com

Page 1 of 14 OCTOBER 2014 TFP1320

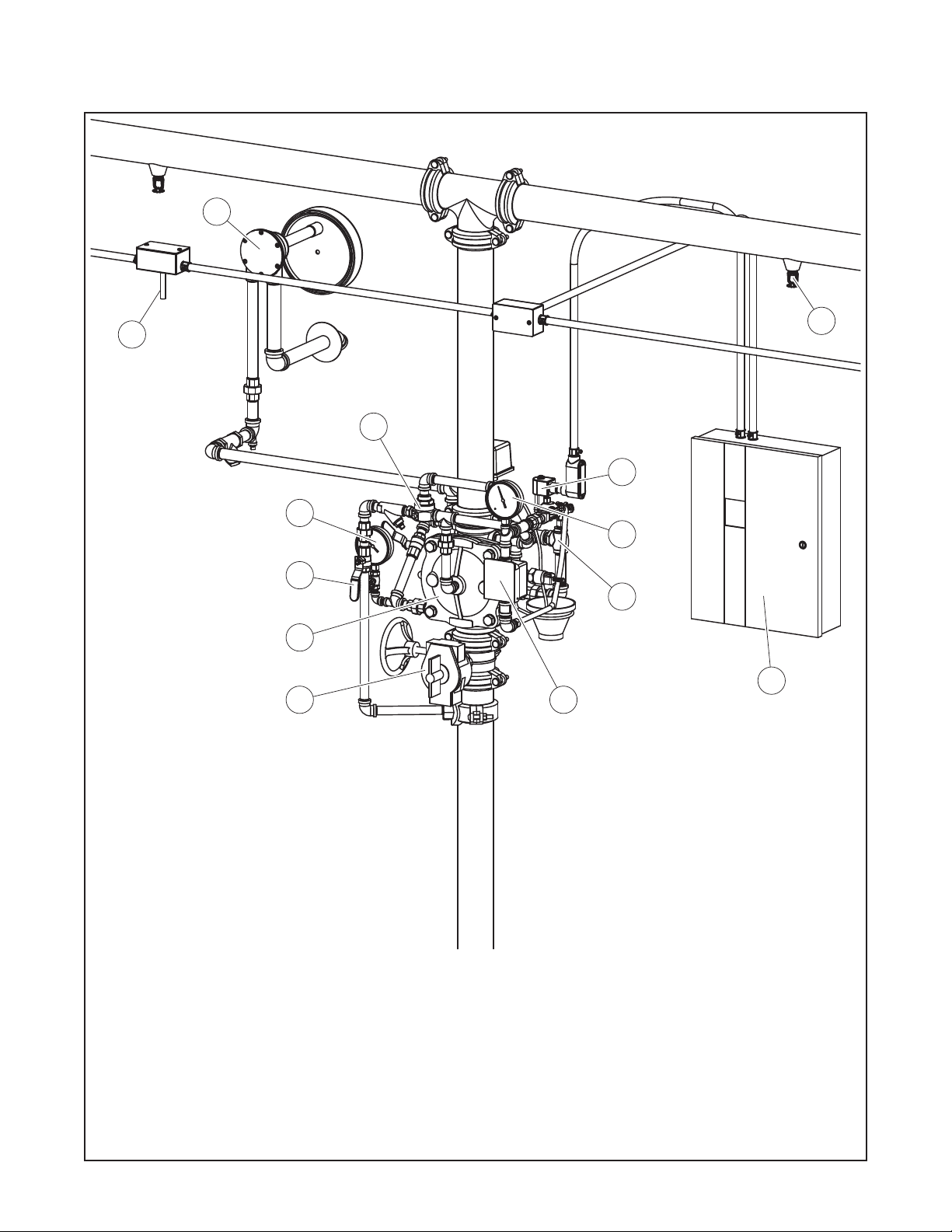

Page 2

TFP1320

etc. (Fire Detection)

Page 2 of 14

13

6

5

11

14

7

8

3

9

1

15

2

4

-

1

DV-5 Deluge Valve

-

2

Main Control Valve (N.O.)

-

3

Diaphragm Chamber Supply

Control Valve (N.O.)

-

4

Local Manual Control Station

-

5

Open Nozzles or Sprinklers

-

6

Heat Detectors, Smoke Detectors,

-

7

Water Supply Pressure Gauge

-

8

Diaphragm Chamber Pressure

Gauge

-

9

System Drain Valve (N.C.)

-

10

Main Drain Valve (N.C.)

(Shown at Rear of Valve)

-

11

Diaphragm Chamber Automatic

Shut-Off Valve

FIGURE 1 (1 OF 2)

SYSTEM SCHEMATIC (FRONT VIEW)

ELECTRIC ACTUATION

-

12

Waterow Pressure Alarm Switch

(Shown at Rear of Valve)

-

13

Water Motor Alarm (Optional)

-

14

Solenoid Valve

-

15

Deluge Valve Releasing Panel

Page 3

TFP1320

-

12

etc. (Fire Detection)

Waterow Pressure Alarm Switch

Page 3 of 14

6

5

15

14

12

13

11

9

3

10

1

2

-

1

DV-5 Deluge Valve

-

2

Main Control Valve (N.O.)

-

3

Diaphragm Chamber Supply

Control Valve (N.O.)

-

4

Local Manual Control Station

(Shown at Front of Valve)

-

5

Open Nozzles or Sprinklers

-

6

Heat Detectors, Smoke Detectors,

-

7

Water Supply Pressure Gauge

(Shown at Front of Valve)

-

8

Diaphragm Chamber Pressure

Gauge (Shown at Front of Valve)

-

9

System Drain Valve (N.C.)

-

10

Main Drain Valve (N.C.)

-

11

Diaphragm Chamber Automatic

Shut-Off Valve

SYSTEM SCHEMATIC (REAR VIEW)

ELECTRIC ACTUATION

FIGURE 1 (2 OF 2)

-

13

Water Motor Alarm (Optional)

-

14

Solenoid Valve

-

15

Deluge Valve Releasing Panel

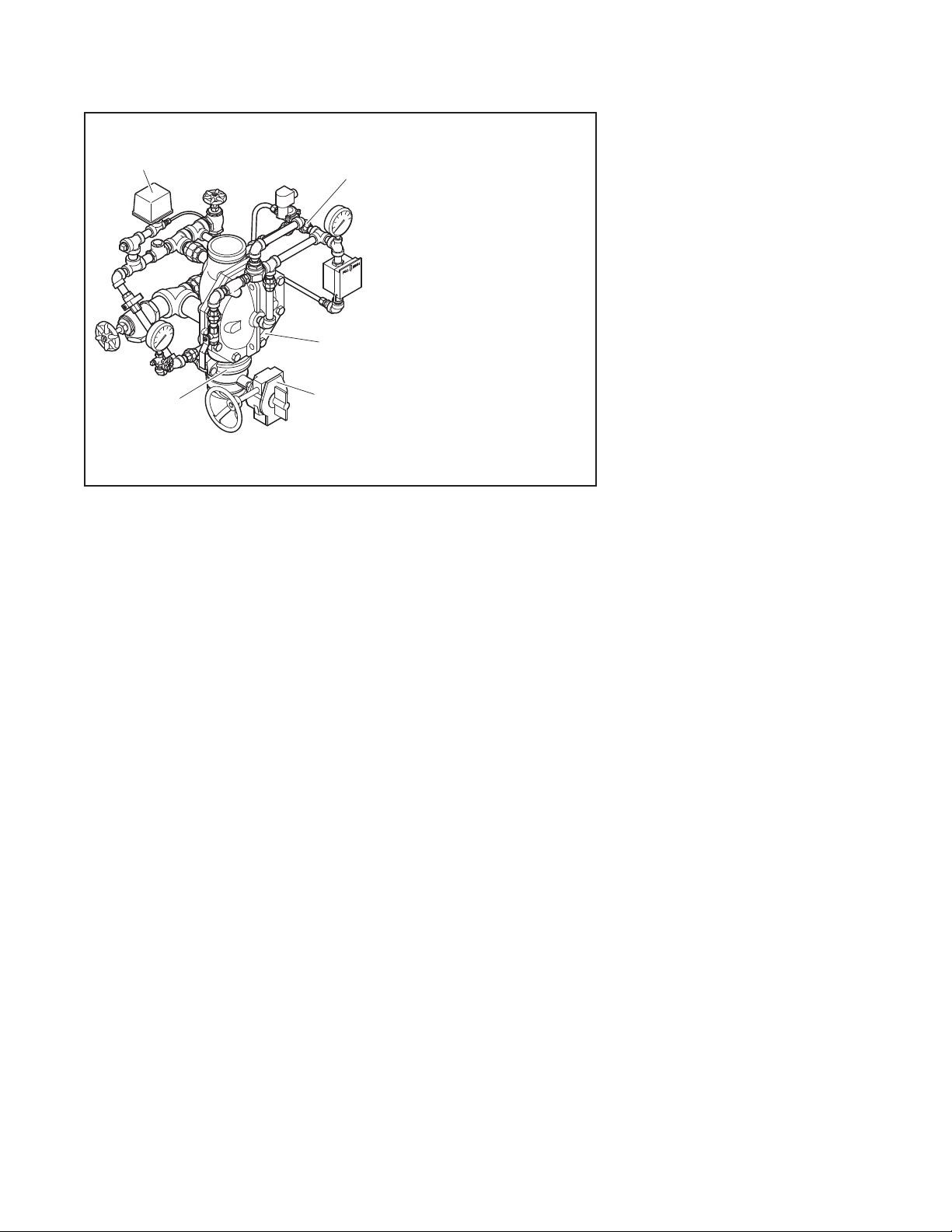

Page 4

TRIM SHOWN FULLY ASSEMBLED;

COMPONENTS SUCH AS GAUGES

WATERFLOW

TFP1320

Page 4 of 14

PRESSURE

ALARM

SWITCH

DELUGE

SYSTEM

GROOVED

COUPLING

SHUT-OFF

FIGURE 2

DV-5 PRE-TRIMMED DELUGE VALVE

ELECTRIC ACTUATION

Technical

Data

Approvals

UL and C-UL Listed

FM Approved.

Valve Trim

The Vertical Electric Actuation Trim

(Fig. 3A/3B) and Horizontal Electric

Actuation Trim (Fig. 5) form a part of

the laboratory listings and approvals

for the DV-5 Valve and are necessary

for its proper operation.

Each package of trim includes the following items:

• Water Supply Pressure Gauge

• Diaphragm Chamber

Pressure Gauge

• Diaphragm Chamber Connections

• Manual Control Station

• Main Drain Valve

• System Drain Valve

• Alarm Test Valve

• Automatic Drain Valve

The following items are included in the

Pre-trimmed Valve Assembly and can

be ordered separately for the valve

trim:

• Model BFV-N Buttery Valve

• Waterow Pressure Alarm Switch

(PS10-2)

• Figure 577 Grooved Coupling

To ease eld assembly of the trim arrangement, the vertical trim components are provided partially assembled

as shown in Figure 3B.

DELUGE

ELECTRIC

ACTUATION

TRIM

NOTES:

1. SEE FIGURE 3, PER VALVE SIZE

AS APPLICABLE, FOR TRIM

ARRANGEMENT WITH BILL OF

MATERIALS AND COMPONENT

PART NUMBERS.

2.

DV-5

VALVE

VALVE

AND SWITCHES MAY REQUIRE

ASSEMBLY IN TRIM AT VALVE

INSTALLATION.

The trim arrangement is provided with

galvanized, black, or brass nipples and

ttings. The galvanized and brass trim

are intended for non-corrosive or corrosive conditions, whereas the black

trim is principally intended for use with

AFFF systems.

NOTE: When the system pressure is

greater than 175 psi (12,1 bar), provision

is to be made to replace the standard

order 300 psi (20,7 bar) Water Pressure

Gauges, shown in Figure 3A/3B and 5

with separately ordered 600 psi (41,4

bar) Water Pressure Gauges.

The Electric Actuation Trim is required

for electric operation of the DV-5 Valve

by a detection system consisting of

electrical devices such as heat sensitive thermostats, smoke detectors,

and/or electric manual pull stations.

Information on the various types of

separately ordered Solenoid Valves

that may be used with this trim package is given in Technical Data Sheet

TFP2180. Nominal installation dimensions for the Vertical Electric Actuation

Trim are shown in Figure 4.

NOTE: Approval by Factory Mutual is contingent on the use of an FM

Approved 24VDC Solenoid Valve. FM

only approves solenoid valves for use

in non-hazardous locations.

Consult with the authority having jurisdiction regarding installation criteria pertaining to electric actuation

circuitry.

The Electric Actuation Trim is provided

with a Model ASV-1 Automatic Shut-Off

Valve (Item 5 - Fig. 3A and 5); consequently, the release circuit of the Releasing Panel need only provide the

standard ten minutes of alarm condi-

tion intended to energize the Solenoid

Valve to open. After the ten minute duration, at which point should the Solenoid Valve become de-energized and

close (especially while operating under

battery back-up), the Automatic ShutOff Valve will have already automatically closed, thereby preventing the DV-5

Diaphragm Chamber from becoming

re-pressurized, and preventing an inadvertent closing of the DV-5 during a

re event.

Materials of

Construction

NOTES: The galvanized or brass nipples and fittings for the Valve Trim

provide corrosion resistance and are

intended to extend the life of the installation of the DV-5 Valve when exposed

to internal and external corrosive conditions. Although these selections are

intended to resist corrosion, it is recommended that the end user or other technical expert familiar with conditions at the proposed installation be

consulted with respect to these selections for a given corrosive condition.

Systems using a seawater or brackish

water supply require special considerations in order to extend the life of

the valve and trim. This type of system

ideally should be configured with a primary source of clean fresh water (e.g.,

a pressurized water tank) and that only

upon system operation is the secondary water supply (seawater or brackish water) allowed to enter the system.

After the system operation, the system should be thoroughly flushed with

clean fresh water. Following this recommendation will increase the service

life of the DV-5 Valve and Valve Trim.

Pressure Gauges. Bronze bourdon

tube with brass socket.

Gauge Test Valve. Bronze body per

ASTM B584.

Manual Control Station. Corrosion

resistant copper alloys and glass lled

PTFE seals. Thermoplastic enclosure.

Automatic Drain Valve. Brass body

per ASTM B584, Type 440 stainless

steel or brass per ASTM B134 Ball, and

galvanized steel inlet.

Automatic Shut-Off Valve. Brass

body, cover, and center seat per UNS

C36000, Type 316 stainless steel

spring, and Nylon fabric reinforced,

natural rubber diaphragm per ASTM

D2000.

Ball Valve. Corrosion resistant copper

alloys and glass lled PTFE seals.

Spring Loaded Check Valve. Brass

body and buna-n seal.

Page 5

TFP1320

Item 14.

2.

3.

4.

5.

1.

NOTES:

Page 5 of 14

NO.

DESCRIPTION P/N

1

2

3

Model MC-1 Manual Control Station 52-289-2-001

4

Model AD-1 Automatic Drain Valve 52-793-2-004

5

6

Item No. Not Used

7

8

9

10 31

11

12

Drip Funnel Connector

Drip Funnel Bracket

13

Drip Funnel

14

15

16

1/4" x 18" Tubing CH

1/2" Tubing Connector CH

17

1/2" x 12" Tubing CH

18

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

1/4" Plug CH

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

3/4" Plug CH

21

1/2" Union CH

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

QTY.

. .

2

92-343-1-005300 psi/ 2000 kPa Water Pressure Gauge

1

46-005-1-0021/4" Gauge Test Valve

1

. . . . . .

1

. . . . . . .

. . .

1

92-343-1-021Model ASV-1 Automatic Shut-Off Valve

2

. . . . . . . . .

46-050-1-0041/2" Ball Valve

1

92-322-1-0021/2" Spring Loaded Check Valve

1

52-353-1-0051/2" Y-Strainer

1 2

46-049-1-0053/4" Swing Check Valve 1/4" x Close Nipple CH

2

46-048-1-0053/4" Angle Valve

1

92-211-1-005

1

92-211-1-003

1

92-343-1-007

1

92-032-1-0023/32" Vent Fitting

1

1

1

1

1

5

A1

16

27

LOCATION

FOR OPTIONAL

ELECTRICALLY

SUPERVISED

N.O. ALARM

CONTROL

VALVE

29

20

35

43

33

24

29

(GREEN

TINT)

28

42

42

10

42

38

7

35

Electric Actuation Trim is

comprised of Items 1-45

19

plus Items E2-E4. Item E1

ordered separately. Items

A1-A3 included only in

pre-trimmed valve assemblies

as applicable; otherwise

ordered separately.

31

31

23

All Fittings and Nipples are

galvanized (Standard Order).

CH: Common Hardware.

See Figure 2 of TFP1305 for

Valve Port identication.

Route all Tubing to Drip Funnel,

NO. NO.

DESCRIPTION P/N DESCRIPTION P/N

22

23

24 45

25

26

27

28

29

30

32

33

34

35

36

37

38

39

40

41

42

. . . . . . . . . . . . . . . . . . . . . . . . . . .

3/4" Union CH

1/4" 90° Elbow CH

1/2" 90° Elbow CH

3/4" 90° Elbow CH

1/2" Tee CH

1/2" x 1/4" x 1/2" Tee CH

3/4" Tee CH

3/4" x 1/2" x 3/4" Tee

3/4" x 3/4" x 1/2" Tee CH

1/2" x Close Nipple CH

1/2" x 1-1/2" Nipple CH

1/2" x 2" Nipple CH

1/2" x 2-1/2" Nipple

1/2" x 5" Nipple CH

1/2" x 7" Nipple CH

Select Nipple per Table CH

Select Nipple per Table CH

Select Nipple per Table CH

3/4" x Close Nipple CH

3/4" x 1-1/2" Nipple

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

30

15

42

42

22

42

42

42

28

11

44

1

21

2

36

39

27

2" (DN50)

GROOVE x GROOVE

DV-5 DELUGE VALVE

QTY. QTY.

2

1

8

1

3

3

2

2

CH

1

3

10

1

4

CH

2

1

1

1

1

1

8

CH

41

11

43

3/4" x 2" Nipple CH

44

3/4" x 4" Nipple CH

Select Nipple per Table CH

E1

Solenoid Valve Ordered Separately

Per Data Sheet TFP2180

E2

1/2" Tubing Connector CH

E3

1/2" x 24" Tubing CH

E4

1/2" x 1-1/2" Nipple CH

A1

Waterow Pressure Alarm Switch,

Model PS10-2 25710

A2

Buttery Valve, Power Ball 300:

A3

Figure 577 Coupling:

Nipple

Number

38

45

35

24

4

33

E3

25

22

26

12

24

35

24

14

33

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

COMPONENTS INCLUDED ONLY IN

PRE-TRIMMED VALVE ASSEMBLIES:

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1/2" (DN40)

1/2" x 1-1/2"

3/4" x 1-1/2"45

E2

36

21

40

26

32

13

A3

A2

5

8

24

9

33

33

33

21

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

Select Appropriate Nipple Sizes

per DV-5 Deluge Valve Size

1/2" x 2"39 1/2" x 1-1/2"

1/2" x 5"40

SEPARATELY)

32

24

37

33

21

34

18

24

SHOWN

33

7

1

1

1

1

1

1

1

1

1

1

1

1

2" (DN50)

1/2" x 5-1/2"

3/4" x 2-1/2"

E1

(ORDERED

E4

21

26

33

3

17

Refer to

Data Sheet

51024A1-1/2" (DN40)

51021A2" (DN50)

57715ACP1-1/2" (DN40)

57720ACP2" (DN50)

1/2" x 2"

33

1

27

32

24

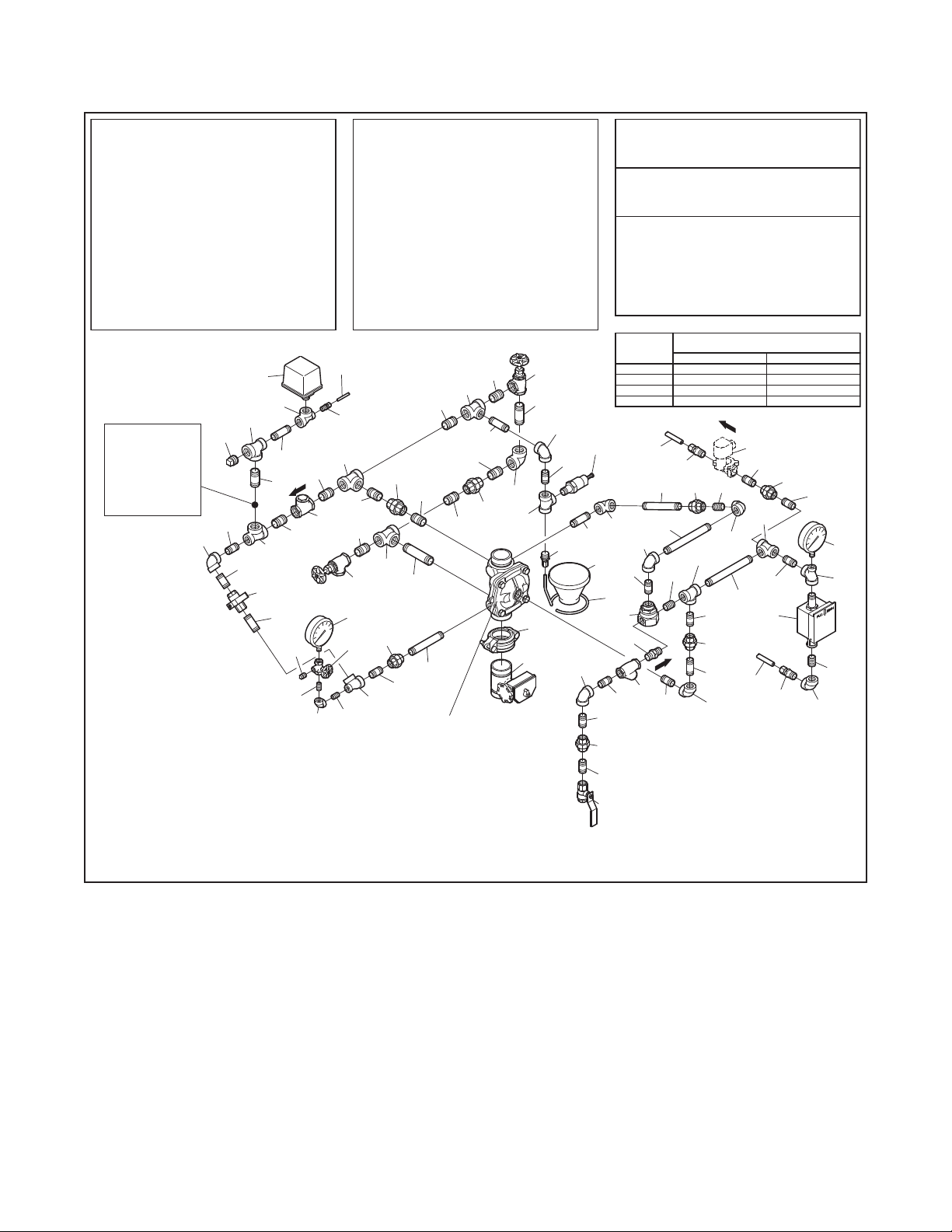

1-1/2 AND 2 INCH (DN40 AND DN50) DV-5 DELUGE VALVES

EXPLODED VIEW OF VERTICAL ELECTRIC ACTUATION TRIM

Y-Strainer. Bronze body per ASTM

B584 and Type 304 stainless steel

screen.

Swing Check Valve. Bronze body per

ASTM B584 and buna-n seal.

Angle Valve. Bronze body per ASTM

B584 and nitrile disc (TEFLON disc for

2 inch size valve).

3/32” Vent Fitting. Brass per ASTM

B16.

Tubing Connector. Brass per ASTM

B16.

Tubing. Type L copper per ASTM B88.

FIGURE 3A (1 OF 3)

Pipe Fittings. Galvanized malleable iron per ANSI B16.3 or cast iron

per ANSI B16.4; black malleable iron

per ANSI B16.3 or cast iron per ANSI

B16.4; or, bronze per ANSI B16.15.

Pipe Nipples. Schedule 40 galvanized

steel per ASTM A53 or A135; Schedule 40 black steel per ASTM A53 or

A135; or, Schedule 40 red brass pipe

per ASTM B43.

Page 6

TFP1320

Item 15.

2.

3.

4.

5.

1.

NOTES:

Page 6 of 14

DESCRIPTION P/N

NO.

1 19

2

Model MC-1 Manual Control Station 52-289-2-001

3

Model AD-1 Automatic Drain Valve 52-793-2-004

4

5

Item No. Not Used

6

7

8

9

10

11

12

Drip Funnel Connector

13

Drip Funnel Bracket

14

Drip Funnel

15

16

1/4" x 18" Tubing CH

17

1/2" Tubing Connector CH

18

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

QTY.

2

. .

92-343-1-005300 psi/ 2000 kPa Water Pressure Gauge

1

46-005-1-0021/4" Gauge Test Valve

1

. . . . . .

1

. . . . . . .

1 1

92-343-1-021Model ASV-1 Automatic Shut-Off Valve

. . . . . . . . . . . . . . . . . . . . . . .

2

A1

46-050-1-0041/2" Ball Valve

1

92-322-1-0021/2" Spring Loaded Check Valve

1

52-353-1-0051/2" Y-Strainer

1

46-049-1-0053/4" Swing Check Valve

1

46-048-1-0053/4" Angle Valve

1

46-048-1-0071-1/4" Angle Valve

1

92-211-1-005

1

92-211-1-003

1

92-343-1-007

1

92-032-1-0023/32" Vent Fitting

1

1

17

. . . . . . . . .

28

LOCATION

FOR OPTIONAL

ELECTRICALLY

SUPERVISED

N.O. ALARM

CONTROL

VALVE

30

21

36

45

35

25

30

(GREEN

29

44

10

44

35

7

12

Electric Actuation Trim is

40

comprised of Items 1-48

plus Items E2-E4. Item E1

ordered separately. Items

20

A1-A3 included only in

pre-trimmed valve assemblies

as applicable; otherwise

ordered separately.

All Fittings and Nipples are

galvanized (Standard Order).

33

24

CH: Common Hardware.

See Figure 2 of TFP1305 for

Valve Port identication.

Route all Tubing to Drip Funnel,

DESCRIPTION P/N DESCRIPTION P/N

NO. NO.

1/2" x 12" Tubing CH

1/4" Plug CH

20

21

3/4" Plug CH

1/2" Union CH

22

3/4" Union CH

23

1/4" 90° Elbow CH

24

1/2" 90° Elbow CH

25

3/4" 90° Elbow CH

26

1/2" Tee CH

27

1/2" x 1/4" x 1/2" Tee

28

3/4" Tee CH

29

30

3/4" x 1/2" x 3/4" Tee

3/4" x 3/4" x 1/2" Tee CH

31

32

1-1/4" x 3/4" x 1-1/4" Tee CH

1/4" x Close Nipple CH

33

1/2" x Close Nipple CH

34

1/2" x 1-1/2" Nipple CH

35

1/2" x 2-1/2" Nipple

36

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

31

16

TINT)

44

36

QTY. QTY.

1

1

1

5

2

1

8

1

3

3

CH

1

2

CH

1

1

2

2

13

2

CH

43

11

46

25

26

37

1/2" x 3-1/2" Nipple CH

1/2" x 4" Nipple CH

38

39

1/2" x 4-1/2" Nipple CH

1/2" x 5" Nipple CH

40

1/2" x 5-1/2" Nipple CH

41

1/2" x 7" Nipple CH

42

43

3/4" x Close Nipple CH

3/4" x 1-1/2" Nipple

44

3/4" x 2" Nipple CH

45

3/4" x 4-1/2" Nipple CH

46

1-1/4" x 2" Nipple CH

47

1-1/4" x 4" Nipple

48

E1

Solenoid Valve Ordered Separately

Per Data Sheet TFP2180

1/2" Tubing Connector CH

E2

1/2" x 24" Tubing CH

E3

1/2" x 1-1/2" Nipple CH

E4

A1

Waterow Pressure Alarm Switch,

Model PS10-2 25710

A2

Model BFV-N Buttery Valve, 3" (DN80) 59300F030N

A3

Figure 577 Coupling, 3" (DN80) 57730ACP

35

E3

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

COMPONENTS INCLUDED ONLY IN

PRE-TRIMMED VALVE ASSEMBLIES:

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

E2

4

23

44

44

23

43

27

43

38

13

15

32

47

48

1

22

2

39

35

28

33

3" (DN80)

A2

A3

25

35

22

41

22

35

42

25

25

25

27

35

14

5

35

34

42

35

8

9

35

22

37

19

25

GROOVE x GROOVE

DV-5 DELUGE VALVE

SHOWN

35

7

1

1

1

1

2

3

5

1

1

1

1

1

1

1

1

1

1

. . .

1

. . . . . . . . . .

E1

(ORDERED

SEPARATELY)

E4

22

27

35

3

18

CH

CH

Refer to

Data Sheet

35

34

25

1

28

3 INCH (DN80) DV-5 DELUGE VALVE

FIGURE 3A (2 OF 3)

EXPLODED VIEW OF VERTICAL ELECTRIC ACTUATION TRIM

Page 7

TFP1320

Item 15.

2.

3.

4.

5.

1.

NOTES:

28

Page 7 of 14

. . . . . .

. . . . . . .

. . . . . . . . .

. . .

A1

QTY.

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

5

2

1

8

1

3

3

2

92-343-1-005300 psi/ 2000 kPa Water Pressure Gauge

46-005-1-0021/4" Gauge Test Valve

92-343-1-021Model ASV-1 Automatic Shut-Off Valve

46-050-1-0041/2" Ball Valve

92-322-1-0021/2" Spring Loaded Check Valve

52-353-1-0051/2" Y-Strainer

46-049-1-0053/4" Swing Check Valve

46-048-1-0061" Angle Valve

46-048-1-0092" Angle Valve

92-211-1-005

92-211-1-003

92-343-1-007

92-032-1-0023/32" Vent Fitting

CH

CH

17

DESCRIPTION P/N

NO.

1

2

3

Model MC-1 Manual Control Station 52-289-2-001

4

Model AD-1 Automatic Drain Valve 52-793-2-004

5

Item No. Not Used

6 35

7

8

9

10

11

12

13

Drip Funnel Connector

14

Drip Funnel Bracket

15

Drip Funnel

16

17

Select Tubing per Table CH

18

1/2" Tubing Connector CH

19

1/2" x 24" Tubing CH

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

1/4" Plug CH

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

3/4" Plug CH

22

1/2" Union CH

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

1" Union CH

24

1/4" 90° Elbow CH

25

1/2" 90° Elbow CH

26

1" 90° Elbow CH

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

1/2" Tee CH

28

1/2" x 1/4" x 1/2" Tee

3/4" x 1/2" x 3/4" Tee

29

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

28

LOCATION

FOR OPTIONAL

ELECTRICALLY

SUPERVISED

N.O. ALARM

CONTROL

VALVE

29

21

36

45

35

25

29

16

(GREEN

TINT)

44

10

46

41

7

Electric Actuation Trim

is comprised of Items 1-52

plus Items E2-E4. Item E1

ordered separately. Items

A1-A3 included only in

40

20

pre-trimmed valve assemblies

as applicable; otherwise

ordered separately.

All Fittings and Nipples are

galvanized (Standard Order).

CH: Common Hardware.

33

24

See Figure 2 of TFP1305 for

Valve Port identication.

Route all Tubing to Drip Funnel,

NO.

DESCRIPTION P/N

1" x 1" x 1/2" Tee CH

30

1" x 3/4" x 1" Tee

31

2" x 1" x 2" Tee CH

32

33

1/4" x Close Nipple CH

1/2" x Close Nipple CH

34

1/2" x 1-1/2" Nipple CH

1/2" x 2-1/2" Nipple

36

37

Select Nipple per Table

1/2" x 5" Nipple CH

38

39

1/2" x 6" Nipple CH

40

1/2" x 7" Nipple CH

Select Nipple per Table CH

41

42

Select Nipple per Table CH

43

Select Nipple per Table CH

44

3/4" x 1-1/2" Nipple

45

3/4" x 2" Nipple CH

46

Select Nipple per Table CH

47

1" x Close Nipple CH

48

1" x 3" Nipple CH

49

Select Nipple per Table CH

50

2" x 3" Nipple CH

51

2" x 5" Nipple CH

52

Select Nipple per Table CH

E1

Solenoid Valve Ordered Separately

Per Data Sheet TFP2180

E2

1/2" Tubing Connector CH

E3

1/2" x 24" Tubing CH

E4

1/2" x 1-1/2" Nipple CH

. . . . . . . . . . . . . . . . . . . . .. .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

30

47

23

31

23

47

47

48

32

50

51

12

1

22

2

38

35

28

33

4" (DN100)

GROOVE x GROOVE

DV-5 DELUGE VALVE

SHOWN

QTY.

1

1

CH

1

2

2

10

3

CH

1

CH

2

1

2

1

1

1

1

CH

1

1

5

1

1

1

1

1

Refer to

1

Data Sheet

1

1

1

47

11

NO.

A1

A2

A3

49

36

26

47

25

37

27

36

25

13

15

9

25

A3

A2

35

COMPONENTS INCLUDED ONLY IN

PRE-TRIMMED VALVE ASSEMBLIES:

DESCRIPTION P/N

Waterow Pressure Alarm Switch,

Model PS10-2 25710

Model BFV-N Buttery Valve:

Figure 577 Coupling:

Tube

No.

17

Nipple

No.

41

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Select Appropriate Tube Size

per DV-5 Deluge Valve Size

4" 6"

(DN100)

1/4" x 24"

Select Appropriate Nipple Sizes

per DV-5 Deluge Valve Size

4" 6"

(DN100)

1/2" x 3"37 1/2" x 3" 1/2" x 5"

1/2" x 2-1/2"

1/2" x 2"42

1/2" x 6-1/2"43

3/4" x 2-1/2"46

1" x 6"49 1" x 9"

1/2" x 7"52 1/2" x 7" 1/2" x 9"

E3

E2

4

39

22

42

43

25

25

(DN150)

1/4" x 24"

(DN150)

1/2" x 5-1/2"

1/2" x 3"

1/2" x 7-1/2"

3/4" x 3-1/2"

(ORDERED

SEPARATELY)

E4

27

QTY.

1

1

1

1

1

1

1

E1

22

27

35

14

5

35

34

35

52

35

8

22

38

25

3

19

18

35

59300F040N4" (DN100)

59300F060N6" (DN150)

59300F080N8" (DN200)

57740ACP4" (DN100)

57760ACP6" (DN150)

57780ACP8" (DN200)

8"

(DN200)

1/4" x 32"

8"

(DN200)

1/2" x 8-1/2"

1/2" x 3-1/2"

1/2" x 9"

3/4" x 4-1/2"

1" x 12"

35

25

1

34

22

35

7

4, 6, AND 8 INCH (DN100, DN150 AND DN200) DV-5 DELUGE VALVES

FIGURE 3A (3 OF 3)

EXPLODED VIEW OF VERTICAL ELECTRIC ACTUATION TRIM

Page 8

TFP1320

WATER SUPPLY

DIAPHRAGM

Page 8 of 14

WATERFLOW

PRESSURE ALARM

SWITCH, ORDERED

SEPARATELY

3/4 INCH NPT

CONNECTION FOR

WATER MOTOR

ALARM

LOCATION

FOR OPTIONAL

ELECTRICALLY

SUPERVISED

N.O. ALARM

CONTROL

VALVE

NIPPLE

Nipple

Number

Main Drain

1

DRAIN VALVE

(NORMALLY

CLOSED)

ALARM

TEST VALVE

(NORMALLY

CLOSED)

SYSTEM

WATER

SUPPLY

PRESSURE

GAUGE

1

Size

MAIN

1-1/2" (DN40)

1/2" x Close

1/2" x Close2

1/2" x 5"3

3/4" x 1-1/2"4

3/4" x 1-1/2"5 3/4" x 2-1/2"

1/2" x 1-1/2"6 1/2" x 1-1/2" 1/2" x 3" 1/2" x 3"1/2" x 1-1/2" 1/2" x 5"

1/2" x 7"7 1/2" x 7" 1/2" x 7" 1/2" x 7"1/2" x 7" 1/2" x 9"

3/4" NPT 3/4" NPT 2" NPT 2" NPT1-1/4" NPT

1/4" x 18"Tube 1 1/4" x 18" 1/4" x 24" 1/4" x 24"1/4" x 18" 1/4" x 32"

NIPPLE

1-1/4 INCH NPT

Select Appropriate Nipple and Tube Sizes per DV-5 Deluge Valve Size

VENT FITTING

(GREEN TINT)

B

4

NIPPLE

6

DRIP

FUNNEL

CONNECTION

TO DRAIN

A

C

2" (DN50)

1/2" x 2"

1/2" x Close

1/2" x 5-1/2"

3/4" x 1-1/2"

TUBE 1

DRAIN VALVE

(NORMALLY

AUTOMATIC

DRAIN VALVE

MAIN DRAIN

CONNECTION

(SIZED PER

TABLE)

3" (DN80)

1/2" x 1-1/2"

1/2" x 1-1/2"

1/2" x 7"

3/4" x 1-1/2"

3/4" x 4-1/2"

SYSTEM

CLOSED)

NIPPLE

DIAPHRAGM

CHAMBER SUPPLY

CONTROL VALVE

(NORMALLY

5

4" (DN100)

1/2" x 2-1/2"

1/2" x 2"

1/2" x 6-1/2"

3/4" x 2-1/2"

1" x 6" 1" x 9"

NOTES:

Install subassemblies in alphabetical order.1.

2.

See Figure 2 of TFP1305 for Valve Port

identication.

Route all Tubing to Drip Funnel.3.

When DV-5 trips, Automatic Shut-Off Valve

4.

shuts off diaphragm chamber supply.

5. Nipples 1-7 and Tube 1 vary in length relative

to DV-5 size. Select per table. All other nipples

and tubing packed unassembled shall be

installed per appropriate trim exploded view,

Figure 3A Part 1, 2, or 3.

4" (DN100)

FLANGE x FLANGE

DV-5 DELUGE

VALVE SHOWN

OPEN)

1/2 INCH NPT

CONNECTION FROM

6" (DN150)

1/2" x 5-1/2"

1/2" x 3"

1/2" x 7-1/2"

3/4" x 3-1/2"

D

SHUT-OFF VALVE

8" (DN200)

1/2" x 8-1/2"

1/2" x 3-1/2"

1/2" x 9"

3/4" x 4-1/2"

1" x 12"

2" NPT

1/2 INCH CONDUIT

CONNECTION FOR

"ELECTRIC DETECTION"

ORDERED SEPARATELY

NIPPLE

7

AUTOMATIC

(NORMALLY

OPEN)

SOLENOID VALVE,

(NORMALLY CLOSED)

NIPPLE

2

NIPPLE

3

CHAMBER

PRESSURE

GAUGE

MANUAL

CONTROL

STATION

1-1/2 THRU 8 INCH (DN40 THRU DN200) DV-5 DELUGE VALVES

FIGURE 3B

OPERATIONAL COMPONENTS OF VERTICAL ELECTRIC ACTUATION TRIM

EXPLODED ARRANGEMENT OF SEMI-PREASSEMBLED TRIM

Page 9

Nominal Installation Dimensions in Inches and (mm)

Valve

LEFT VIEW FRONT VIEW

Size

1-1/2"

DN40

2"

DN50

3"

DN80

4"

DN100

6"

DN150

8"

DN200

A

7.00

(177,8)

7.13

(181,0)

7.81

(198,4)

10.00

(254,0)

11.38

(289,0)

12.00

(304,8)

B

8.88

(225,4)

9.13

(231,8)

10.44

(265,1)

11.75

(298,5)

14.31

(363,5)

16.00

(406,4)

C

13.19

(335,0)

13.19

(335,0)

13.19

(335,0)

14.31

(363,5)

15.31

(388,9)

16.25

(412,8)

D

10.50

(266,7)

10.50

(266,7)

10.50

(266,7)

10.50

(266,7)

10.50

(266,7)

10.50

(266,7)

E

15.25

(387,4)

15.56

(395,3)

19.13

(485,8)

22.13

(562,0)

23.31

(592,1)

25.50

(647,7)

MINIMUM CLEARANCE

*

F

1.25

(31,8)

0.94

(23,8)

1.63

(41,3)

1.75

(44,5)

3.50

(88,9)

1.75

(44,5)

(147,6)

(152,4)

(170,0)

(217,5)

(252,4)

10.75

(273,1)

G

5.81

6.00

6.69

8.56

9.94

H

1.81

(46,0)

2.00

(50,8)

2.69

(68,3)

4.44

(112,7)

5.81

(147,6)

6.50

(165,1)

J

3.00

(76,2)

3.00

(76,2)

4.25

(108,0)

6.25

(158,8)

6.25

(158,8)

6.25

(158,8)

K

7.00

(177,8)

7.00

(177,8)

7.00

(177,8)

7.13

(181,0)

7.13

(181,0)

7.13

(181,0)

L

3.88

(98,4)

3.00

(76,2)

0.88

(22,2)

0.63

(15,9)

1.81

(46,0)

7.38

(187,3)

Page 9 of 14

M

8.00

(204,0)

8.63

(220,0)

12.75

(324,0)

15.75

(400,0)

18.13

(460,4)

22.50

(570,0)

TFP1320

N

4.02

(102,1)

4.09

(103,9)

3.85

(98,0)

4.56

(116,0)

5.86

(149,0)

5.26

(134,0)

* * *

F

H K

G

B

N

J

DCA

L

FIGURE 4

1-1/2 THRU 8 INCH (DN40 THRU DN200) DV-5 DELUGE VALVES

VERTICAL ELECTRIC ACTUATION / NOMINAL INSTALLATION DIMENSIONS

*

E

M

Page 10

TFP1320

SEPARATELY)

Page 10 of 14

NO. NO.

DESCRIPTION P/N DESCRIPTION P/N

10

11

12

Drip Funnel Connector

13

Drip Funnel Bracket

14

Drip Funnel

15 24

16

1/4" x 18" Tubing CH

17

1/2" Tubing Connector CH

18

1/2" x 12" Tubing CH

33

5

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

24

E4

40

26

32

33

21

24

37

32

26

33

35

21

. . . . . .

. . . . . . .

. . . . . . . . .

33

QTY.

. .

2

92-343-1-005300 psi/ 2000 kPa Water Pressure Gauge

1

46-005-1-0021/4" Gauge Test Valve

1

1

. . .

1

92-343-1-021Model ASV-1 Automatic Shut-Off Valve

2

46-050-1-0041/2" Ball Valve

1

92-322-1-0021/2" Spring Loaded Check Valve

1

52-353-1-0051/2" Y-Strainer

33

NO.

DESCRIPTION P/N

1 19

2

3

Model MC-1 Manual Control Station 52-289-2-001

4

Model AD-1 Automatic Drain Valve 52-793-2-004

5

6

Item No. Not Used

7

8

9

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

33

1

19

7

2

GROOVE x GROOVE

DV-5 DELUGE VALVE

31

31

39

23

21

27

35

21

2" (DN50)

SHOWN

36

7

24

9

8

34

24

QTY. QTY.

1

46-049-1-0053/4" Swing Check Valve

2

46-048-1-0053/4" Angle Valve

1

92-211-1-005

1

92-211-1-003

1

92-343-1-007

1

92-032-1-0023/32" Vent Fitting

1

1

1

E2

E3

E1

(ORDERED

SEPARATELY)

33

1

21

33

27

3

36

LOCATION

FOR OPTIONAL

ELECTRICALLY

SUPERVISED

N.O. ALARM

CONTROL

VALVE

20

A1

(ORDERED

38

24

32

33

24

43

27

29

42

35

44

10

15

(GREEN

TINT)

22

42

42

18

42

26

28

35

30

16

29

24

17

4

14

12

42

11

42

22

42

28

41

45

25

11

13

42

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1/4" Plug CH

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

3/4" Plug CH

21

22

23

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

E1

E2

E3

E4

A1

. . . . . . . . . . . . . . . . . . . . . . . . . . .

1/2" Union CH

. . . . . . . . . . . . . . . . . . . . . . . . . . .

3/4" Union CH

1/4" 90° Elbow CH

1/2" 90° Elbow CH

3/4" 90° Elbow CH

1/2" Tee CH

1/2" x 1/4" x 1/2" Tee CH

3/4" Tee CH

3/4" x 1/2" x 3/4" Tee

3/4" x 3/4" x 1/2" Tee CH

1/4" x Close Nipple CH

1/2" x Close Nipple CH

1/2" x 1-1/2" Nipple CH

1/2" x 2" Nipple CH

1/2" x 2-1/2" Nipple

1/2" x 5" Nipple CH

1/2" x 7" Nipple CH

Select Nipple per Table CH

Select Nipple per Table CH

Select Nipple per Table CH

3/4" x Close Nipple CH

3/4" x 1-1/2" Nipple

3/4" x 2" Nipple CH

3/4" x 4" Nipple CH

Select Nipple per Table CH

Solenoid Valve Ordered Separately

Per Data Sheet TFP2180

1/2" Tubing Connector CH

1/2" x 24" Tubing CH

1/2" x 1-1/2" Nipple CH

Waterow Pressure Alarm Switch,

Model PS10-2 25710

Nipple

Number

38

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

COMPONENTS ORDERED SEPARATELY:

. . . . . . . . . . . . . . . . . . . . . . . .

Select Appropriate Nipple Sizes

per DV-5 Deluge Valve Size

1-1/2" (DN40)

1/2" x 1-1/2"

1/2" x 2"39 1/2" x 1-1/2"

1/2" x 5"40

3/4" x 1-1/2"45

1

1

5

2

1

8

1

3

3

2

2

CH

1

2

3

10

1

4

CH

2

1

1

1

1

1

8

CH

1

1

1

Refer to

1

Data Sheet

1

1

1

1

2" (DN50)

1/2" x 2"

1/2" x 5-1/2"

3/4" x 2-1/2"

NOTES:

Electric Actuation Trim is comprised of

1.

Items 1-45 plus Items E2-E4. Items A1

and E1 ordered separately.

All Fittings and Nipples are galvanized

2.

(Standard Order).

CH: Common Hardware.

3.

See Figure 2 of TFP1305 for Valve Port

4.

identication.

Route all Tubing to Drip Funnel, Item 14.

5.

6. Horizontal Arrangement uses only 7 out of

8 of Item 24, and 9 out of 10 of Item 33.

Discard unused material.

1-1/2 AND 2 INCH (DN40 AND DN50) DV-5 DELUGE VALVES

EXPLODED VIEW OF HORIZONTAL ELECTRIC ACTUATION TRIM

Installation

General Instructions

Proper operation of the DV-5 Deluge

Valves depends upon their trim being

installed in accordance with the instructions given in this Technical Data

Sheet. Failure to follow the appropriate trim diagram may prevent the DV-5

Valve from functioning properly, as well

as void listings, approvals, and the

manufacturer’s warranties.

The DV-5 Valve must be installed in a

readily visible and accessible location.

The DV-5 Valve, associated trim, and

wet pilot lines must be maintained at

a minimum temperature of 40°F (4°C).

FIGURE 5 (1 OF 3)

Heat tracing of the DV-5 Valve or its

associated trim is not permitted. Heat

tracing can result in the formation of

hardened mineral deposits that are capable of preventing proper operation.

The DV-5 Deluge Valve is to be installed in accordance with the following criteria:

Step 1. All nipples, ttings, and devices must be clean and free of scale

and burrs before installation. Use pipe

thread sealant sparingly on male pipe

threads only.

Step 2. The DV-5 Valve must be

trimmed in accordance with Figure

3A/3B or 5.

Step 3. Care must be taken to ensure

that check valves, strainers, globe

valves, etc. are installed with the ow

arrows in the proper direction.

Step 4. Drain tubing to the Drip Funnel

must be installed with smooth bends

that will not restrict ow.

Step 5. The main drain and Drip Funnel

drain may be interconnected provided

a check valve is located at least 12

inches (300 mm) below the Drip Funnel.

Step 6. Suitable provision must be

made for disposal of drain water. Drainage water must be directed such that

it will not cause accidental damage to

property or danger to persons.

Step 7. Connect the Diaphragm Cham

ber Supply Control Valve to the inlet

side of the system’s Main Control Valve

in order to facilitate setting of the DV-5

Valve (Ref. Figure 4).

Step 8. Unused pressure alarm switch

connections must be plugged.

-

Page 11

. . . . . .

SEPARATELY)

Discard unused material.

. . . . . . .

QTY.

. .

2

1

1

1

. . .

1

NO.

DESCRIPTION P/N

1

2

3

Model MC-1 Manual Control Station 52-289-2-001

4

Model AD-1 Automatic Drain Valve 52-793-2-004

5

. . . . . . . . . . . . . . . . .

35

25

22

35

1

20

33

24

28

LOCATION

FOR OPTIONAL

ELECTRICALLY

SUPERVISED

N.O. ALARM

CONTROL

VALVE

7

2

33

3" (DN80)

GROOVE x GROOVE

DV-5 DELUGE VALVE

SHOWN

35

22

40

25

45

21

39

7

35

35

30

28

30

36

A1

(ORDERED

48

12

47

NO. NO.

DESCRIPTION P/N DESCRIPTION P/N

92-343-1-005300 psi/ 2000 kPa Water Pressure Gauge Item No. Not Used

46-005-1-0021/4" Gauge Test Valve

92-343-1-021Model ASV-1 Automatic Shut-Off Valve

35

6

7

8

9

10

25

35

9

8

34

5

37

25

22

35

27

35

38

23

44

10

44

44

16

(GREEN

TINT)

44

29

17

44

23

32

43

46

26

43

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . .

E4

42

25

35

42

27

35

35

22

41

25

19

27

36

31

13

43

11

Page 11 of 14

QTY. QTY.

2

46-050-1-0041/2" Ball Valve

1

92-322-1-0021/2" Spring Loaded Check Valve

1

52-353-1-0051/2" Y-Strainer

1

46-049-1-0053/4" Swing Check Valve

E2

E1

(ORDERED

SEPARATELY)

1

22

28

34

25

18

4

15

11

12

13

Drip Funnel Connector

14

Drip Funnel Bracket

15

Drip Funnel

16

17

1/4" x 18" Tubing CH

18

1/2" Tubing Connector CH

19

1/2" x 12" Tubing CH

20

1/4" Plug CH

21

E3

3

3/4" Plug CH

1/2" Union CH

22

23

3/4" Union CH

1/4" 90° Elbow CH

24

25

1/2" 90° Elbow CH

3/4" 90° Elbow CH

26

1/2" Tee CH

27

28

1/2" x 1/4" x 1/2" Tee

3/4" Tee CH

29

30

3/4" x 1/2" x 3/4" Tee

31

3/4" x 3/4" x 1/2" Tee CH

32

1-1/4" x 3/4" x 1-1/4" Tee CH

33

1/4" x Close Nipple CH

34

1/2" x Close Nipple CH

35

1/2" x 1-1/2" Nipple CH

1/2" x 2-1/2" Nipple

36

1/2" x 3-1/2" Nipple CH

37

1/2" x 4" Nipple CH

38

1/2" x 4-1/2" Nipple CH

39

1/2" x 5" Nipple CH

40

1/2" x 5-1/2" Nipple CH

41

1/2" x 7" Nipple CH

42

3/4" x Close Nipple CH

43

3/4" x 1-1/2" Nipple

44

3/4" x 2" Nipple CH

45

3/4" x 4-1/2" Nipple CH

46

1-1/4" x 2" Nipple CH

47

1-1/4" x 4" Nipple

48

E1

Solenoid Valve Ordered Separately

Per Data Sheet TFP2180

E2

1/2" Tubing Connector CH

E3

1/2" x 24" Tubing CH

E4

1/2" x 1-1/2" Nipple CH

Waterow Pressure Alarm Switch,

A1

Model PS10-2 25710

NOTES:

Electric Actuation Trim is comprised of

1.

Items 1-48 plus Items E2-E4. Items A1

and E1 ordered separately.

All Fittings and Nipples are galvanized

2.

(Standard Order).

CH: Common Hardware.

3.

See Figure 2 of TFP1305 for Valve Port

4.

identication.

14

Route all Tubing to Drip Funnel, Item 15.

5.

6. Horizontal Arrangement uses only 7 out of

8 of Item 25, and 12 out of 13 of Item 35.

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

COMPONENTS ORDERED SEPARATELY:

. . . . . . . . . . . . . . . . . . . . . . . .

13

TFP1320

1

46-048-1-0053/4" Angle Valve

1

46-048-1-0071-1/4" Angle Valve

92-211-1-005

1

1

92-211-1-003

1

92-343-1-007

1

92-032-1-0023/32" Vent Fitting

1

1

1

1

1

5

2

1

8

1

3

CH

3

1

CH

2

1

1

2

2

CH

2

1

1

1

1

1

2

3

CH

5

1

1

1

CH

1

Refer to

1

Data Sheet

1

1

1

1

3 INCH (DN80) DV-5 DELUGE VALVE

FIGURE 5 (2 OF 3)

EXPLODED VIEW OF HORIZONTAL ELECTRIC ACTUATION TRIM

Step 9. Conduit and electrical connections are to be made in accordance

with the requirements of the authority

having jurisdiction and/or the National

Electric Code.

Step 10. Before a system hydrostatic

test is performed in accordance with

NFPA 13 system acceptance test requirements, the DV-5 Diaphragm

Chamber is to be depressurized, the

Automatic Drain Valve (Item 4, Fig. 3A

and 5) is to be temporarily replaced

with a 1/2 inch NPT plug, the 3/32 inch

Vent Fitting (Item 16 - Fig. 3A and 5)

is to be temporarily replaced with a

1/4 inch NPT plug, and the Diaphragm

Cover Bolts must be uniformly and securely tightened using a cross-draw

sequence. After tightening, doublecheck to make certain that all of the

Diaphragm Cover Bolts are securely

tightened.

Page 12

TFP1320

SEPARATELY)

Page 12 of 14

DESCRIPTION P/N

NO.

1

2

3

Model MC-1 Manual Control Station 52-289-2-001

4 18

Model AD-1 Automatic Drain Valve 52-793-2-004 1/2" Tubing Connector CH

5

Item No. Not Used

6

7

8

9

10

11

12

Drip Funnel Connector

13

14

Drip Funnel Bracket

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

QTY.

2

92-343-1-005300 psi/ 2000 kPa Water Pressure Gauge

. .

1

46-005-1-0021/4" Gauge Test Valve

1

. . . . . .

1 1

. . . . . . . . . . . . . . . . . . . . . . . .

1

92-343-1-021Model ASV-1 Automatic Shut-Off Valve

. . .

2

46-050-1-0041/2" Ball Valve

1

. . . . . . . . .

35

92-322-1-0021/2" Spring Loaded Check Valve

1

52-353-1-0051/2" Y-Strainer

1

46-049-1-0053/4" Swing Check Valve

1

46-048-1-0061" Angle Valve

1

46-048-1-0092" Angle Valve

1

92-211-1-005

1

92-211-1-003

35

25

22

9

35

1

20

33

2

33

24

28

40

LOCATION

FOR OPTIONAL

ELECTRICALLY

SUPERVISED

N.O. ALARM

CONTROL

VALVE

21

7

4" (DN100)

GROOVE x GROOVE

DV-5 DELUGE VALVE

SHOWN

35

22

38

7

41

35

25

45

25

29

46

28

29

51

A1

(ORDERED

36

50

12

32

DESCRIPTION P/N

NO.

15

16

17

19

20

21

22

23

24

25

26

27

28

. . . . . . . . . . . . . . . . . . . . . . . . . .

Drip Funnel

Select Tubing per Table CH

1/2" x 24" Tubing CH

1/4" Plug CH

3/4" Plug CH

1/2" Union CH

1" Union CH

1/4" 90° Elbow CH

1/2" 90° Elbow CH

1" 90° Elbow CH

1/2" Tee CH

1/2" x 1/4" x 1/2" Tee CH

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

25

35

8

5

34

43

38

27

35

22

52

35

39

36

25

23

48

10

44

47

31

16

(GREEN

TINT)

17

30

47

23

47

47

49

26

E4

25

27

42

22

27

37

47

QTY.

1

92-343-1-007

1

92-032-1-0023/32" Vent Fitting

1

1

1

1

5

2

1

8

1

3

3

(ORDERED

SEPARATELY)

35

22

35

18

19

4

13

11

E2

E1

14

(DN150)

1/4" x 24"

(DN150)

1/2" x 5-1/2"

1/2" x 3"

1/2" x 7-1/2"

3/4" x 3-1/2"

QTY.

10

2

1

1

1

2

2

3

1

2

1

2

1

1

1

1

1

1

5

1

1

1

1

1

1

1

1

1

1

CH

CH

CH

CH

CH

Refer to

Data Sheet

8"

(DN200)

1/4" x 32"

8"

(DN200)

1/2" x 8-1/2"

1/2" x 3-1/2"

1/2" x 9"

3/4" x 4-1/2"

1" x 12"

DESCRIPTION P/N

NO.

3/4" x 1/2" x 3/4" Tee

29

1" x 1" x 1/2" Tee CH

30

1" x 3/4" x 1" Tee

31

2" x 1" x 2" Tee CH

32

1/4" x Close Nipple CH

33

1/2" x Close Nipple CH

34

1/2" x 1-1/2" Nipple CH

35

1/2" x 2-1/2" Nipple

36

Select Nipple per Table

37

1/2" x 5" Nipple CH

38

1/2" x 6" Nipple CH

39

1/2" x 7" Nipple CH

40

Select Nipple per Table CH

41

Select Nipple per Table CH

42

Select Nipple per Table CH

43

3/4" x 1-1/2" Nipple

44

3/4" x 2" Nipple CH

45

Select Nipple per Table CH

46

1" x Close Nipple CH

47

E3

1

1" x 3" Nipple CH

48

Select Nipple per Table CH

49

2" x 3" Nipple CH

50

2" x 5" Nipple CH

51

Select Nipple per Table CH

52

Solenoid Valve Ordered Separately

E1

Per Data Sheet TFP2180

1/2" Tubing Connector CH

E2

1/2" x 24" Tubing CH

E3

1/2" x 1-1/2" Nipple CH

E4

COMPONENTS ORDERED SEPARATELY:

Waterow Pressure Alarm Switch,

A1

Model PS10-2 25710

28

Tube

No.

3

34

25

17

Nipple

No.

41

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

Select Appropriate Tube Size

per DV-5 Deluge Valve Size

4" 6"

(DN100)

1/4" x 24"

Select Appropriate Nipple Sizes

per DV-5 Deluge Valve Size

4" 6"

(DN100)

1/2" x 3"37 1/2" x 3" 1/2" x 5"

1/2" x 2-1/2"

1/2" x 2"42

1/2" x 6-1/2"43

3/4" x 2-1/2"46

1" x 6"49 1" x 9"

1/2" x 7"52 1/2" x 7" 1/2" x 9"

NOTES:

Electric Actuation Trim is comprised of

1.

15

Items 1-52 plus Items E2-E4. Items A1

and E1 ordered separately.

All Fittings and Nipples are galvanized

2.

(Standard Order).

CH: Common Hardware.

3.

See Figure 2 of TFP1305 for Valve Port

4.

identication.

Route all Tubing to Drip Funnel, Item 15.

5.

6. Horizontal Arrangement uses only 7 out of

8 of Item 25, and 2 out of 3 of Item 36.

Discard unused material.

4, 6, AND 8 INCH (DN100, DN150, AND DN200) DV-5 DELUGE VALVES

FIGURE 5 (3 OF 3)

EXPLODED VIEW OF HORIZONTAL ELECTRIC ACTUATION TRIM

Page 13

TFP1320

Page 13 of 14

Valve Setting

Procedure

Steps 1 through 11 are to be performed

when initially setting the DV-5 Deluge

Valve; after an operational test of the

re protection system; or, after system

operation due to a re.

NOTE: When the system is using either a seawater or brackish water supply, it is recommended that the system

be thoroughly flushed with clean fresh

water. Following this recommendation

will increase the service life of the DV-5

Valve and Trim.

Step 1. Close the Main Control Valve.

Step 2. Close the Diaphragm Chamber

Supply Control Valve.

Step 3. Open the Main Drain Valve,

System Drain Valve, and all auxiliary

drains in the system. Close the System

Drain Valve and auxiliary drain valves

after water ceases to discharge. Leave

the Main Drain Valve open.

Step 4. Depress the plunger of the Automatic Drain Valve to verify that it is

open and that the DV-5 Valve is completely drained.

Step 5. Clean the Strainer in the Diaphragm Chamber Supply connection

by removing the clean-out plug and

strainer basket. The Strainer may be

ushed out by momentarily opening

the Diaphragm Chamber Supply Control Valve.

Step 6. Reset the actuation system.

Manual Actuation — Push the operating lever up; however, do not close the

hinged cover at this time.

Electric Actuation — Reset the electric

detection system in accordance with

the manufacturer’s instructions to deenergize the solenoid valve.

Step 7. Open the Diaphragm Chamber

Supply Control Valve and allow time

for full pressure to build up in the Diaphragm Chamber.

Step 8. Operate (open) the Manual Control Station to vent trapped air

from the Diaphragm Chamber. If necessary, rst open the hinged cover, and

then fully pull down on the operating

lever. Slowly close the operating lever,

by pushing it up, after aerated water

ceases to discharge from the Manual

Control Station drain tubing. Close the

hinged cover and insert a new break

rod in the small hole through the top of

the enclosing box.

Step 9. Inspect the drain connections

from the Manual Control Station and

Solenoid Valve. Any leaks must be corrected before proceeding to the next

step.

Step 10. Verify the ability for the DV-5

Diaphragm to hold pressure as follows:

With the diaphragm chamber pressurized per Step 8, temporarily close the

Diaphragm Chamber Supply Control

Valve, and then monitor the Diaphragm

Chamber Pressure Gauge for a drop in

pressure.

If a drop in pressure is noted, the DV-5

Diaphragm is to be replaced and/or any

leaks must be corrected before proceeding to the next step.

If the Diaphragm Chamber Pressure

Gauge indicates no drop in pressure,

re-open the Diaphragm Chamber Supply Control Valve and proceed to the

next step.

Ste p 11. Slowly open the Main Control Valve. Close the Main Drain Valve

as soon as water discharges from the

drain connection. Observe the Automatic Drain Valve for leaks. If there are

leaks, determine/correct the cause of

the leakage problem. If there are no

leaks, the DV-5 Valve is ready to be

placed in service and the Main Control

Valve must then be fully opened.

NOTE: When the Main Control Valve

is opened, the pressure on the Diaphragm Chamber may increase. This

increase in pressure is normal, and if

the pressure is greater than 250 psi

(17,2 bar), the pressure is to be relieved

by partially and temporarily opening

the Manual Control Station; however,

do not allow the pressure as indicated

on the Diaphragm Chamber Pressure

Gauge to drop below the supply pressure shown on the Water Supply Pressure Gauge, since this action may result in tripping of the DV-5 Valve.

After setting a re protection system,

notify the proper authorities and advise

those responsible for monitoring proprietary and/or central station alarms.

Care and

Maintenance

The following procedures and inspections must be performed as indicated,

in addition to any specic requirements

of the NFPA, and any impairment must

be immediately corrected.

Before closing a re protection system

Main Control Valve for maintenance

work on the re protection system that

it controls, permission to shut down the

affected re protection systems must

rst be obtained from the proper authorities and all personnel who may be

affected by this action must be notied.

Reset the DV-5 Deluge Valve in accordance with the Valve Setting Procedure

section.

The owner is responsible for the inspection, testing, and maintenance of

their re protection system and devices

in compliance with this document, as

well as with the applicable standards

of the National Fire Protection Association (e.g., NFPA 25), in addition to the

standards of any authority having jurisdiction. Contact the installing contractor or product manufacturer with any

questions.

It is recommended that automatic

sprinkler systems be inspected, tested,

and maintained by a qualied Inspection Service in accordance with local

requirements and/or national codes.

NOTICE

Some of the procedures outlined in

this section will result in operation of

the associated alarms. Consequently,

notification must first be given to the

owner and the fire department, central

station, or other signal station to which

the alarms are connected.

When the system is using either a seawater or brackish water supply, internal and external inspection of the DV-5

Valve and Trim is essential. Parts showing any signs of corrosion must be replaced to ensure the integrity of the

system.

Annual Operation Test Procedure

Proper operation of the DV-5 Valve (i.e.,

opening of the DV-5 Valve as during a

re condition) must be veried at least

once a year as follows:

Step 1. If water must be prevented

from owing beyond the riser, perform

the following steps:

• Close the Main Control Valve.

• Open the Main Drain Valve.

•

Open the Main Control Valve one turn

beyond the position at which water

just begins to ow from the Main

Drain Valve.

• Close the Main Drain Valve.

Step 2. Test the Deluge Valve Releas-

ing Panel in accordance with the manufacturer’s instructions to energize the

solenoid valve.

NOTE: Be prepared to quickly perform

Steps 3, 4, and 5, if water must be prevented from flowing beyond the riser.

Step 3. Verify that the DV-5 Valve has

tripped, as indicated by the ow of water into the system.

Step 4. Close the system’s Main Control Valve.

Step 5. Close the Diaphragm Chamber

Supply Control Valve.

Step 6. Reset the DV-5 Deluge Valve

in accordance with the Valve Setting

Procedure.

Page 14

TFP1320

Page 14 of 14

Quarterly Waterflow Alarm Test

Procedure

Testing of the system waterow alarms

must be performed quarterly. To test

the waterow alarm, open the Alarm

Test Valve, which will allow a ow of

water to the Pressure Alarm Switch

and/or Water Motor Alarm. Upon satisfactory completion of the test, close

the Alarm Test Valve.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-re.com.

Ordering

Procedure

NOTE: Part Numbers for factory pretrimmed DV-5 Valves are provided in

the Price Book.

DV-5 Semi-Preassembled Vertical

Electric Actuation Trim

Specify: (specify size and nish — galvanized is standard) Semi-Preassembled Vertical Electric Actuation Trim for

DV-5 Deluge Valves, P/N (specify):

1-1/2 & 2 Inch Galvanized ... P/N 52-477-2-309

1-1/2 & 2 Inch Black........ P/N 52-47 7-1- 30 9

1-1/2 & 2 Inch Brass........ P/N 52-477-3-309

3 Inch Galvanized ..........P/N 52- 477-2-106

3 Inch Black ...............P/N 52-477-1-10 6

3 Inch Brass .............. P/N 52-47 7-3-106

4, 6 & 8 Inch Galvanized .... P/N 52-477-2-3 03

4, 6 & 8 Inch Black ......... P/N 52-477-1-303

4, 6 & 8 Inch Brass .........P/N 52-477-3-303

DV-5 Unassembled Electric

Actuation Trim for Vertical or

Horizontal Installation

Specify: (specify size and nish — galvanized is standard) Unassembled

Electric Actuation Trim for Vertical or

Horizontal Installation of DV-5 Deluge

Valves, P/N (specify):

1-1/2 & 2 Inch Galvanized ... P/N 52-477-2-209

1-1/2 & 2 Inch Black.........P/N 52-477-1-209

1-1/2 & 2 Inch Brass........ P/N 52-477-3-209

3 Inch Galvanized ......... P/N 52-477-2-206

3 Inch Black ...............P/N 52-477-1-206

3 Inch Brass .............. P/N 52-477-3-206

4, 6 & 8 Inch Galvanized .... P/N 52-477-2-203

4, 6 & 8 Inch Black ..........P/N 52-477-1-203

4, 6 & 8 Inch Brass ......... P/N 52-477-3-203

Pre-trimmed DV-5 Assembly

Electric Actuation Trim

with Butterfly Valve

Specify: (size), G x G End Connection,

Pre-trimmed DV-5 Assembly with Buttery Valve, P/N (specify):

1-1/2 Inch G x G ...........P/N 52- 913 - 0-1AP

2 Inch G x G ..............P/N 5 2- 92 3-0 -1A P

3 Inch G X G ..............P/N 52- 9 33 - 0-1AP

4 Inch G x G ..............P/N 52 -9 43- 0 -1AP

6 Inch G x G ..............P/N 52 -9 63- 0 -1AP

8 Inch G x G ..............P/N 52-983-0-1AP

Pre-trimmed DV-5 Assembly

Electric Actuation Trim

without Butterfly Valve

Specify: (specify size), (specify) End

Connection, Pre-trimmed DV-5 Assembly without Buttery Valve, P/N

(specify):

1-1/2 Inch T x T ...........P/N 52-913-3-1AP

2 Inch T x T...............P/N 52-923-3-1AP

3 Inch F x F............... P/ N 52-93 3-1 -1AP

3 Inch F x G ..............P/N 52-933 -2-1AP

4 Inch F x F............... P/ N 52-94 3-1 -1AP

4 Inch F x G ..............P/N 52-943 -2-1AP

6 Inch F x F............... P/ N 52-96 3-1 -1AP

6 Inch F x G ..............P/N 52- 963 -2-1AP

8 Inch F x F............... P/ N 52-98 3-1 -1AP

8 Inch F x G ..............P/N 52-983 -2-1AP

Accessories

Refer to the Technical Data Sheets for

the following, as applicable, for details

and additional accessories:

600 PSI Water

Pressure Gauge . . . . . . .....P/N 92-343-1-004

Solenoid Valve for

Electric Actuation..............See TFP2180

Model PS10-2

Potter Electric

Waterow

Pressure

Alarm Switch . . . . . . . . . ...........P/N 25710

Model WMA-1 Water

Motor Alarm . . . . . . . . . ....P/N 52-6 30-1-0 01

Replacement Trim Parts

Specify: (description) for use with DV-5

Deluge Valve, P/N (see Figure 3A or 5).

Accessories

Refer to the Technical Data Sheets for