TYAN S2895 User Manual

http://www.tyan.com

1

Thunder K8WE

///

S2895

Version 1.01

Copyright

Copyright © TYAN Computer Corporation, 2004-2005. All rights reserved. No

part of this manual may be reproduced or translated without prior written

consent from TYAN Computer Corp.

Trademark

All registered and unregistered trademarks and company names contained in

this manual are property of their respective owners including, but not limited to

the following.

TYAN, Taro and Thunder K8WE are trademarks of TYAN Computer

Corporation.

AMD, Opteron, and combinations thereof are trademarks of AMD Corporation.

Microsoft, Windows are trademarks of Microsoft Corporation.

SuSE,is a trademark of SuSE AG.

Linux is a trademark of Linus Torvalds

IBM, PC, AT, and PS/2 are trademarks of IBM Corporation.

Winbond is a trademark of Winbond Electronics Corporation.

Notice

Information contained in this document is furnished by TYAN Computer

Corporation and has been reviewed for accuracy and reliability prior to printing.

TYAN assumes no liability whatsoever, and disclaims any express or implied

warranty, relating to sale and/or use of TYAN products including liability or

warranties relating to fitness for a particular purpose or merchantability. TYAN

retains the right to make changes to product descriptions and/or specifications

at any time, without notice. In no event will TYAN be held liable for any direct or

indirect, incidental or consequential damage, loss of use, loss of data or other

malady resulting from errors or inaccuracies of information contained in this

document.

http://www.tyan.com

2

Table of Contents

Chapter 1: Introduction

1.1 Congratulations Page 3

1.2 Hardware Specifications Page 3

1.3 Software Specifications Page 5

Chapter 2: Board Installation

2.1 Board Image Page 8

2.2 Block Diagram Page 9

2.3 Board Parts, Jumpers and Connectors Page 10

2.4 Installing the Processor(s) Page 18

2.5 Heatsink Retention Frame Installation Page 19

2.6 Thermal Interface Material Page 20

2.7 Heatsink Installation Procedures Page 21

2.8 Finishing Installing the Heatsink Page 23

2.9 Tips on Installing Motherboard in Chassis Page 24

2.10 Installing the Memory Page 25

2.11 Attaching Drive Cables Page 28

2.12 Installing Add-In Cards Page 30

2.13 Connecting External Devices Page 31

2.14 Installing the Power Supply Page 32

2.15 Finishing Up Page 33

Chapter 3: BIOS

3.1 BIOS Setup Utility Page 35

3.2 BIOS Menu Bar Page 36

3.3 BIOS Legend Bar Page 36

3.4 Getting Help Page 36

3.5 BIOS Main Menu Page 37

3.6 BIOS Advanced Menu Page 38

3.7 BIOS Memory Menu Page 52

3.8 BIOS Boot Menu Page 54

3.9 BIOS Exit Menu Page 56

Chapter 4: Diagnostics

4.1 Beep Codes Page 57

4.2 Flash Utility Page 57

4.3 BIOS Post Code Page 58

Glossary

Page 61

Technical Support

Page 67

http://www.tyan.com

3

Chapter 1: Introduction

1.1 - Congratulations

You have purchased one of the most powerful workstation mainboard solutions.

The Thunder K8WE (S2895) is a high-end workstation mainboard, based on

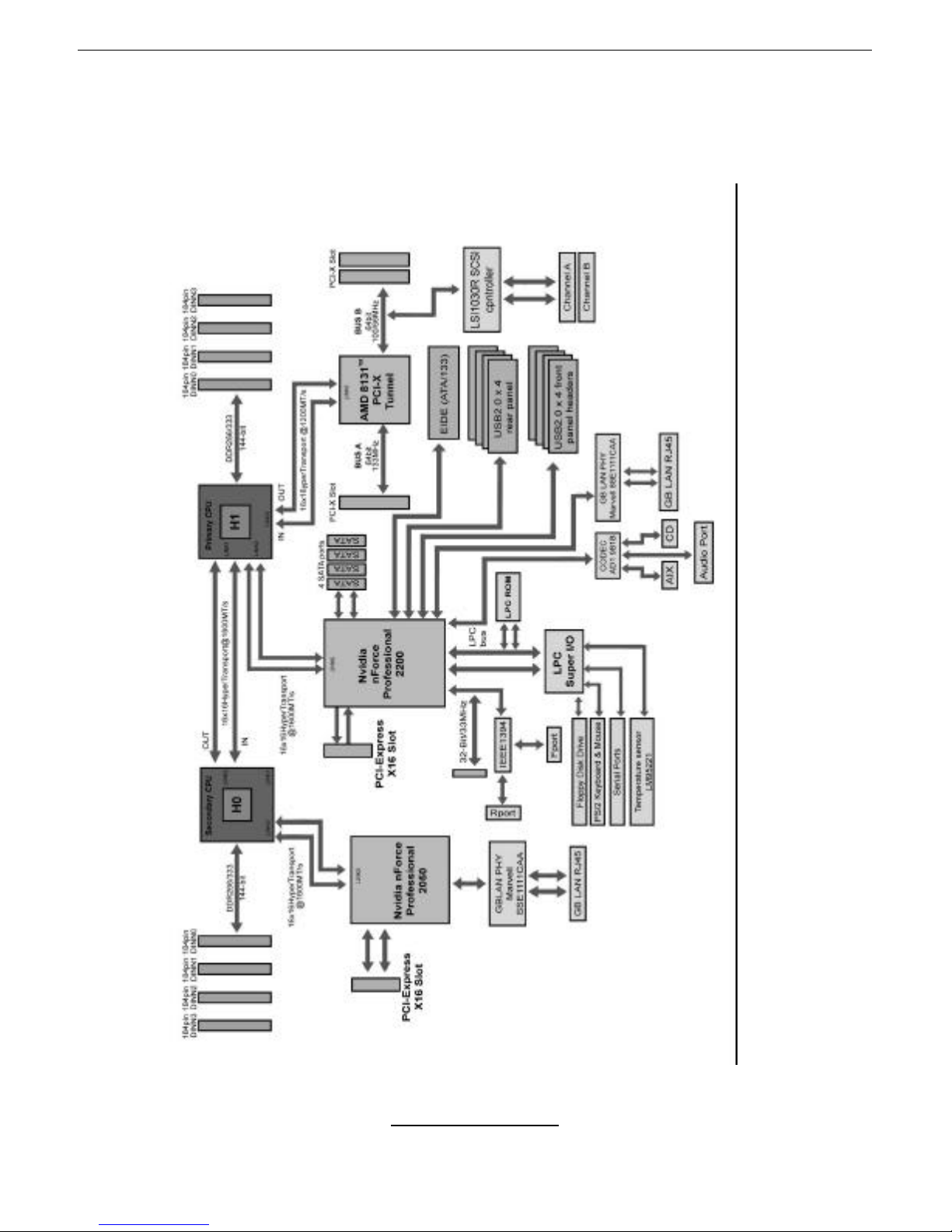

Nvidia nForce Professional 2200 Media and Communications Processor (MCP),

Nvidia nForce Professional 2050, and AMD 8131 PCI-X HyperTransport™

Tunnel.

Designed to support up to two AMD Opteron™ (Opteron 2xx) processors and

16GB of DDR333 or DDR400 memory, the S2895 is ideal for CPU, memory,

and video intensive applications such as CAD, Graphics Design, High

Bandwidth Video Editing, etc.

Remember to visit TYAN’s Website at http://www.TYAN.com

. There you can

find information on all of TYAN’s products with FAQs, online manuals and BIOS

upgrades.

1.2 - Hardware Specifications

Processor

•Supports one or two AMD

Opteron™ 2xx processors

•Two onboard 4-phase VRMS

•Three HyperTransportTM links per

CPU, support up to 6.4GB/s data

transfer rate each link

•144-bit DDR interface (128-bit

data + 16 bit ECC)

•Scalable 32bit and 64bit

computing

•Secure computing with Nx register

support

Chipset

•Nvidia nForce Professional 2200

(CK8-04)-connected to CPU1

•Nvidia nForce Professional 2050#

(I/O-4)-connected to CPU2

•AMD 8131™ PCI-X Tunnel

•SMsC Super I/O

#Optional

Integrated ATA-133 (from nForce

Professional 2200)

•One ATA-133 IDE Channel for up

to two devices

Integrated SATAII Generation 1

Controllers (from nForce

Professional 2200)

•Two integrated dual port SATA II

controllers

•Four SATA connectors support up

to four drives

•3 Gb/s per direction per channel

•NvRAID v2.0 support

•Supports RAID 0, 1, 5, 0+1 and

JBOD

Integrated Secure Network

Processor

• Two IEEE 802.3 Nvidia MAC

1000/100/10 Ethernet (First from

PRO 2200, Second from PRO

2050)

http://www.tyan.com

4

Memory

•128-bit dual channel (interleaved)

memory bus

•Total Eight DDR-1 DIMM sockets

(Four per CPU)

•Supports up to 16GB Registered

DDR

•Supports ECC with CHIPKil

technology

•Supports DDR400, DDR333, or

DDR266

Expansion Slots

•Two x16 PCI Express full speed

expansion slots

- Slot 1 PCI-E x16 from nForce

PRO 2200

- Slot 3 PCI-E x16 from nForce

PRO 2050

•Two independent 64-bit PCI-X

buses

- Slot 4 and slot 5 support PCI-X

100MHz max

- Slot 6 supports PCI-X 133MHz

max

•One 32-bit 33Mhz PCI v2.3 (Slot

2)

•Total of six usable slots

Integrated I/O

•One floppy connector

•One serial port connector

•Eight USB 2.0 EHCI ports (four

rear connectors & four pin

headers)

•PS/2 mouse and keyboard

connectors

•Two FireWire (IEEE 1394a) ports

(one rear connector and one

internal pin header)

System Management

•Total six 4-pin fan headers with

PWM and tachometer monitoring

•Watchdog Timer support

•Two Marvell Gigabit PHY

•Supports WOL and PXE

•Supports Ethernet Jumbo Frames

(9018 Bytes)

•Full Duplex Gigabit Ethernet

support

•Nvidia Firewall for secure network

communications

Integrated FireWire (IEEE

1394a) Controller

•TI TSB43AB22A IEEE 1394a

PCI controller

•Two FireWire ports (one rear

connector and one internal pin

header)

Integrated Audio

•Enhanced AC’97 2.3 compliant

audio link

•Analog Devices 1981B codec

•16 bit Stereo Full Duplex

•CD-in/Aux-in connectors

Integrated SCSI Controller

(Mfg. Option)

•LSI 53C1030 U320 SCSI

controller

- Two U320 68-pin SCSI

connectors

- Connected to PCI-X Bridge B

Form Factor

•SSI EEB v3.5 Footprint (12” x 13”,

304.8x330.2mm)

•EPS 12V/SSI v3.5 Wo rkstation

(24 + 8) power connectors

(Split Plane design

recommended)

•Serial (one)

•Stacked PS/2 keyboard and

mouse connectors

•Two dual port USB2.0 connectors

(total 4 ports)

•Two RJ-45 LAN connectors with

LEDs

http://www.tyan.com

5

•Temperature, voltage and fan

monitoring

•Audio Line-in, Line-out, Mic-in

jacks

•One IEEE 1394a port

BIOS

•PhoenixBIOS on 8Mbit LPC

Flash ROM

•ACPI 2.0

•Serial Console Redirect

•USB device boot

•WOL and PXE support

•48-bit LBA support

1.3 - Software Specifications

OS (Operating System) Support

Microsoft Windows XP (32-bit/64-bit)

Microsoft Windows Server 2003 (32-bit/64-bit)

SUSE Professional 9.x and SLES 9 SP2

RHEL3 Update 4

RHEL4 Update 1

TYAN reserves the right to add support or discontinue support for any OS with

or without notice.

http://www.tyan.com

6

NOTES:

http://www.tyan.com

7

Chapter 2: Board Installation

You are now ready to install your motherboard. The mounting hole pattern of

the Thunder K8WE matches the SSI EEB 3.51 specification. Before continuing

with installation, confirm that your chassis supports an SSI EEB v3.51

motherboard.

How to install our products right… the first time

The first thing you should do is read this user’s manual. It contains important

information that will make configuration and setup much easier. Here are some

precautions you should take when installing your motherboard:

(1) Ground yourself properly before removing your motherboard from the

antistatic bag. Unplug the power from your computer power supply and

then touch a safely grounded object to release static charge (i.e. power

supply case). For the safest conditions, TYAN recommends wearing a

static safety wrist strap.

(2) Hold the motherboard by its edges and do not touch the bottom of the

board, or flex the board in any way.

(3) Avoid touching the motherboard components, IC chips, connectors,

memory modules, and leads.

(4) Place the motherboard on a grounded antistatic surface or on the

antistatic bag that the board was shipped in.

(5) Inspect the board for damage.

The following pages include details on how to install your motherboard into your

chassis, as well as installing the processor, memory, disk drives and cables.

NOTE

DO NOT APPLY POWER TO THE BOARD IF IT HAS BEEN

DAMAGED

http://www.tyan.com

8

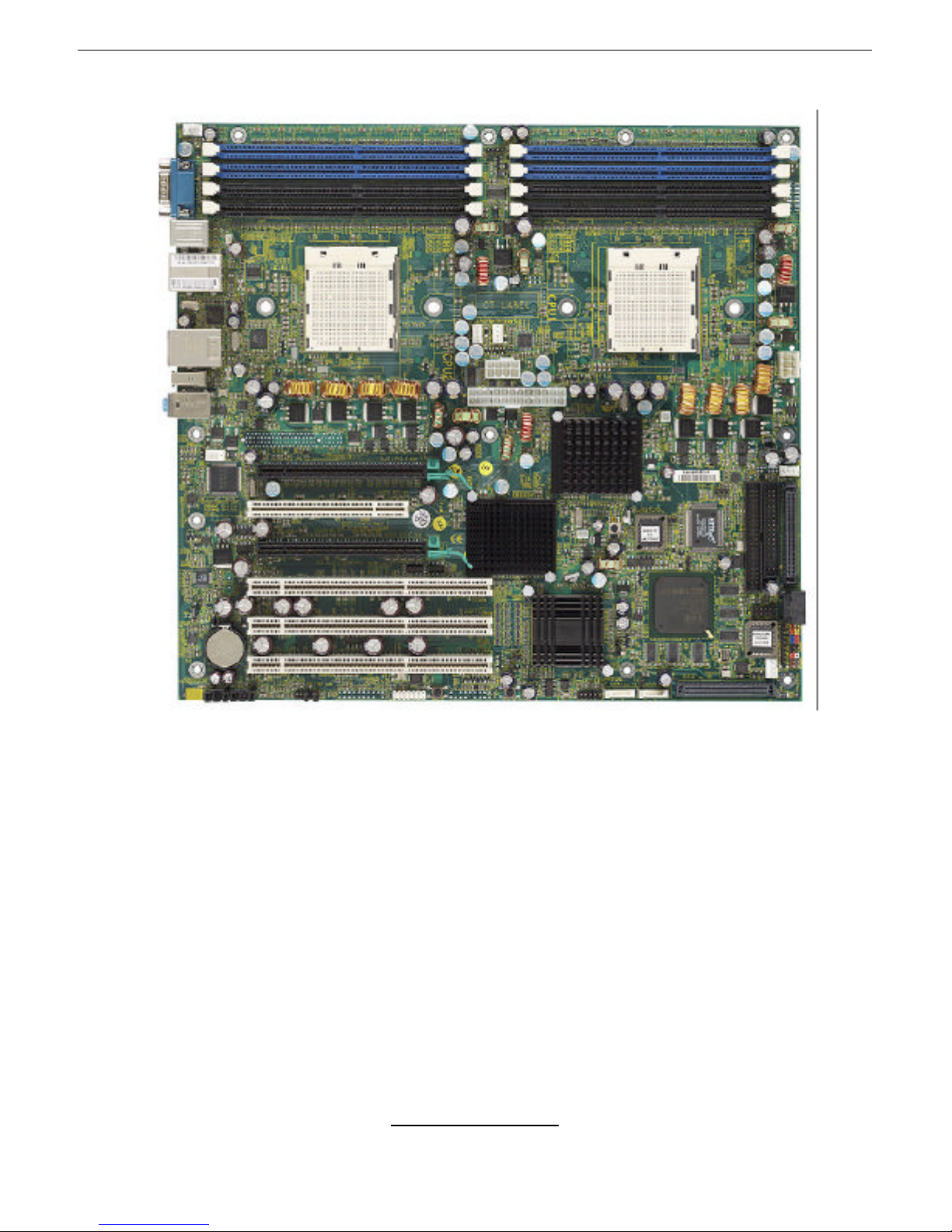

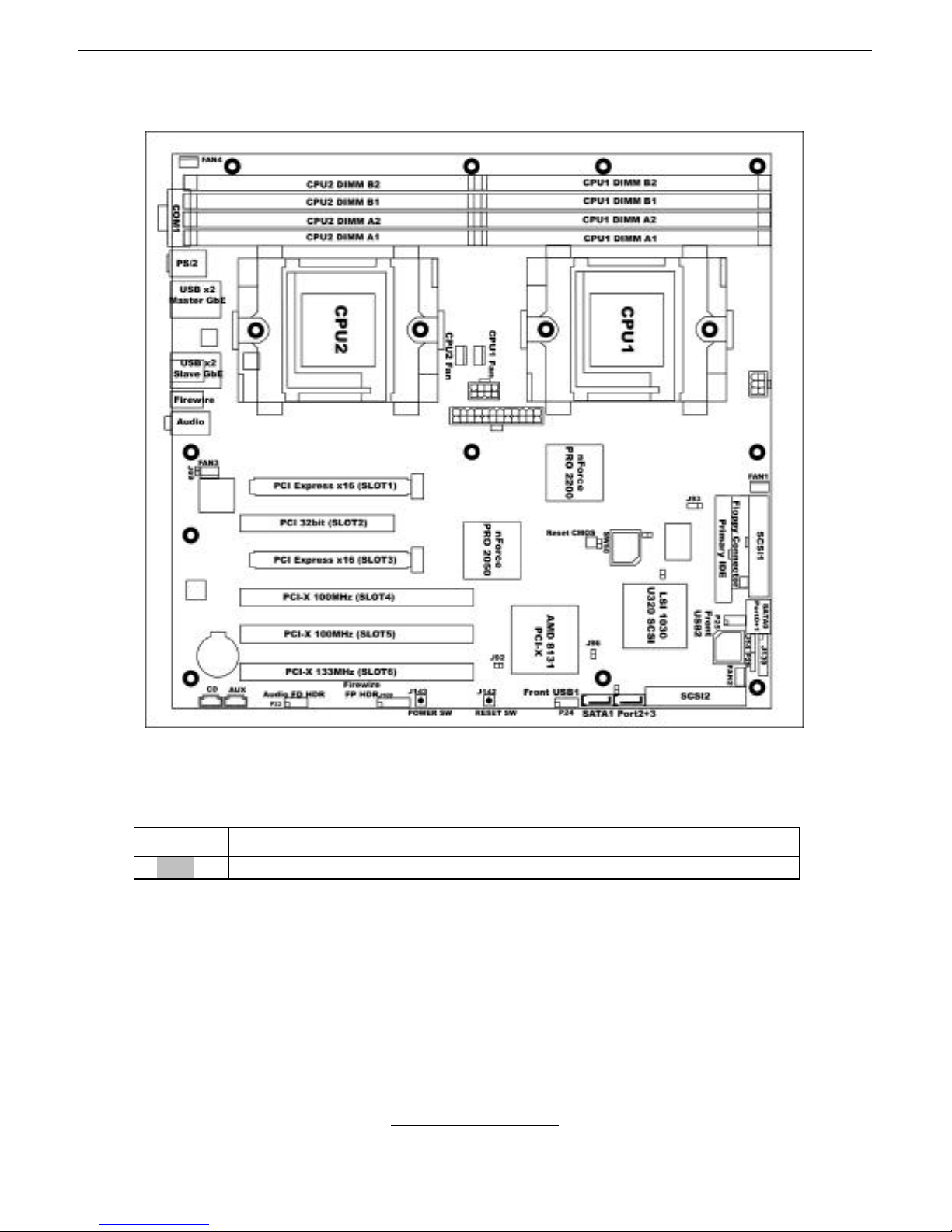

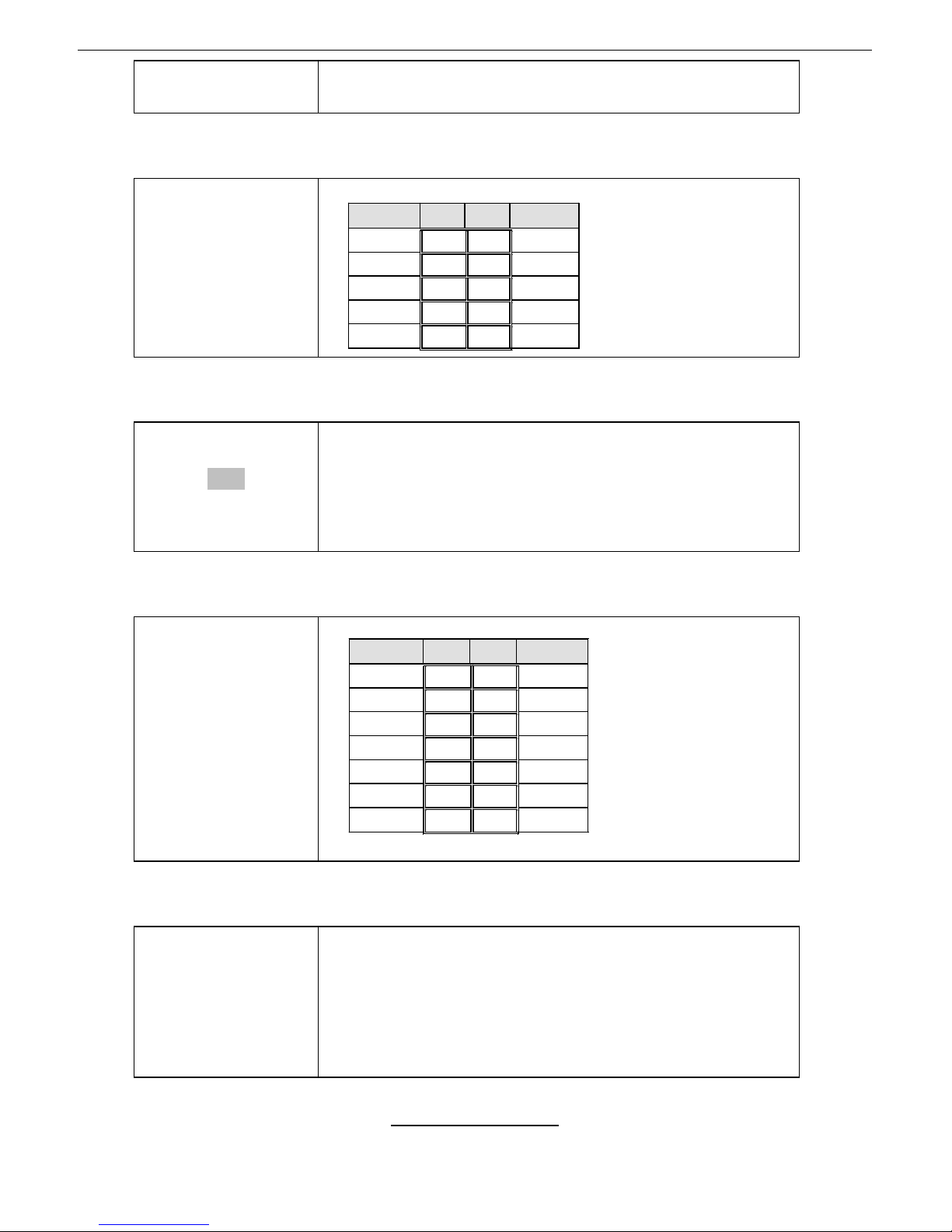

2.1- Board Image

This picture is representative of the latest board revision available at

the time of publishing. The board you receive may or may not look

exactly like the above picture.

The following page includes details on the vital components of this

motherboard.

http://www.tyan.com

9

2.2 - Block Diagram

S2895 Thunder K8WE Block Diagram

http://www.tyan.com

10

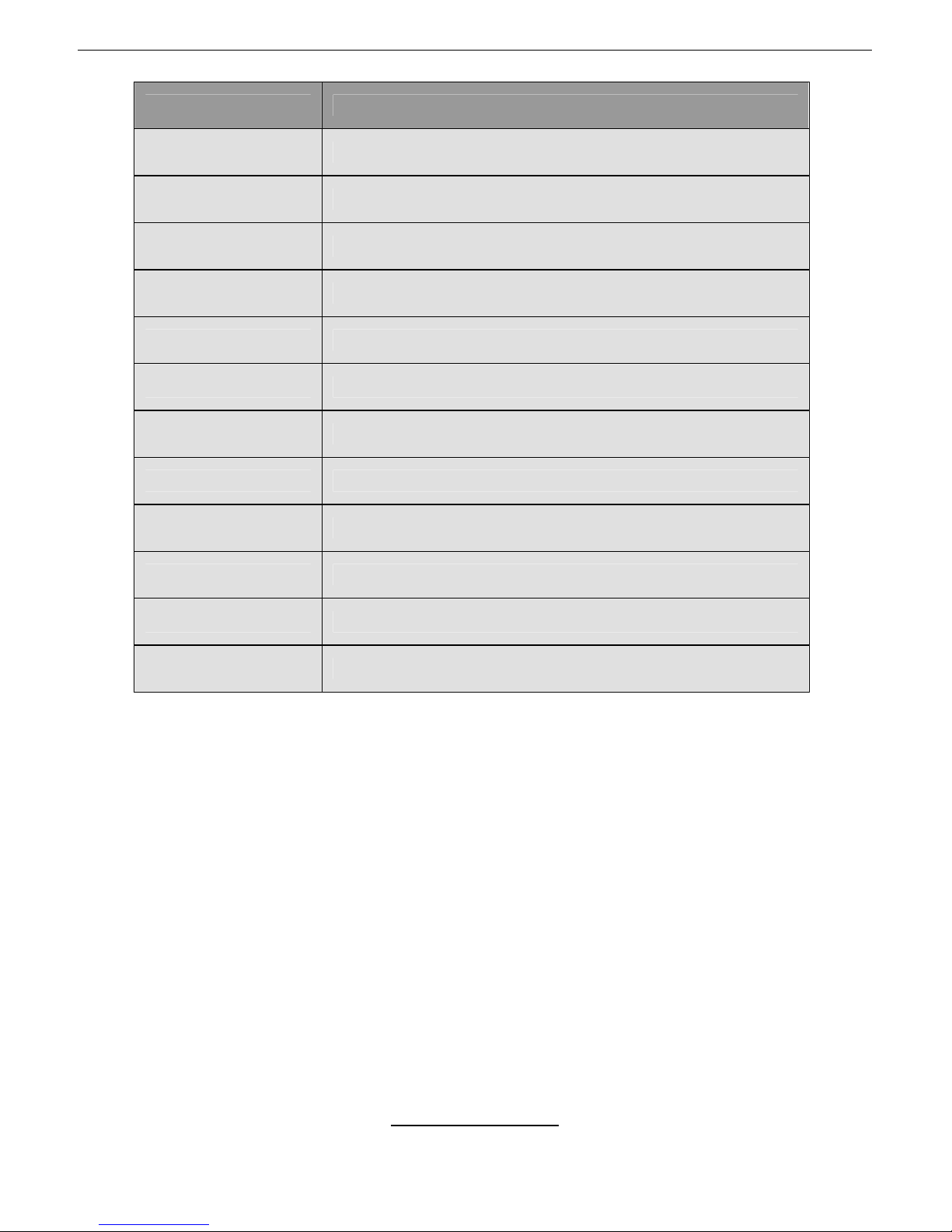

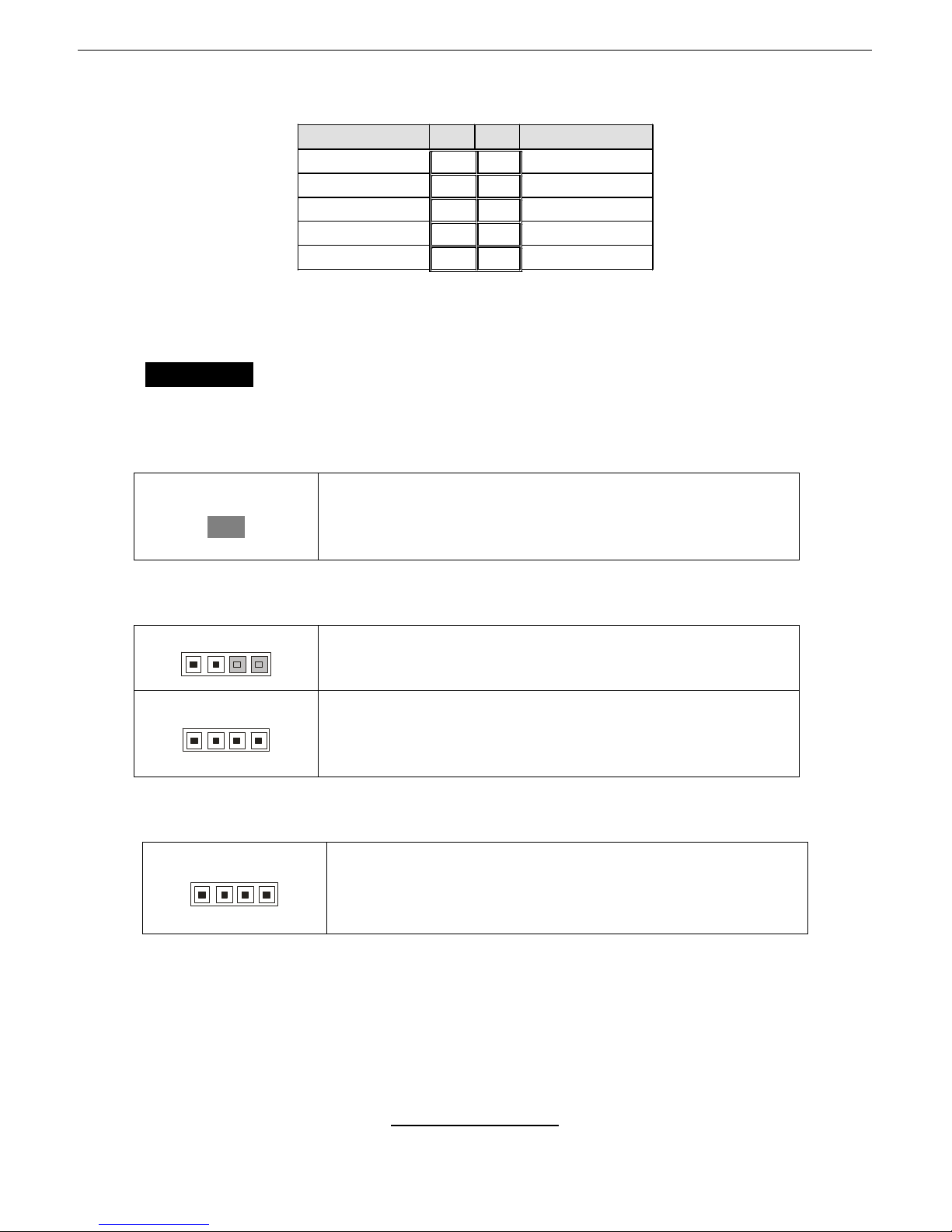

2.3 - Board Parts, Jumpers and Connectors

This diagram is representative of the latest board revision available at the time of

publishing. The board you receive may not look exactly like the above diagram.

Jumper Legend

©©

OPEN - Jumper OFF, without jumper cover

©©

CLOSED – Jumper ON, with jumper cover

http://www.tyan.com

11

Jumper/Connector

Function

J14 Chassis Speaker Header

J69 FireWire Disable Jumper

J92 PCI-X-Bridge B Bus Speed Override

J93 COM2 Header

J109 FireWire (IEEE 1394A) Pin Header

J139 Front Panel Header

J142 Reset Button

J143 Power Button

P23 Front Audio Header

P24/P25 USB Front Panel Header

P29 External SCSI LED Header

SW50 Reset CMOS Button

http://www.tyan.com

12

J139: Front Panel Header

SW50: Reset CMOS Button

?

In certain cases it may be necessary to reset system

CMOS. Follow these steps:

1) Power off system

HDDLED+

1¾ ¾2

PWR LED+

HDDLED-

3¾ ¾4

PWR LED-

Reset SW

5¾ ¾6

PWR SW

Reset SW

7¾ ¾8

PWR SW

+5V

9¾

¾10

SLEEP SW

NC

11¾ ¾12

SLEEP SW

+5V Standby

13¾ £14

NC (KEY)

SMBUS DATA

15¾ ¾16

GND

SMBUS CLOCK

17¾ ¾18

Chassis Intr# (Active

Low)

SW50

J92 J109

P24

J93

P25

J139

http://www.tyan.com

13

2) Press SW50 for 5 seconds

3) Power system and enter BIOS setup

P24, P25: USB Front Panel Header

©©

©©

©©

©©

£©

Signal Pin Pin Signal

VCC

1 2

VCC

Data -

3 4

Data -

Data +

5 6

Data +

GND

7 8

GND

KEY

9 10

GND

J92: PCI-X Bridge Bus Speed Override

©©

©©

Open-(Default) Allows PCI Bridge B (Slots 4, 5 &

Devices) to operate at up to 100MHz

Closed- Force PCI Bridge B (Slots 4, 5 & Devices) to

operate at a maximum 66MHz

NOTE: This jumper affects integrated SCSI on the

same bus.

J109: FireWire (IEEE1394A) Pin Header

©£

©©

©©

©©

©©

©©

©£

Signal Pin Pin Signal

NC1

1 2

Key

TPA +

3 4

TPA -

GND

5 6

GND

TPB +

7 8

TPB -

+12V

9 10

+12V

GND

11 12

GND

NC2

13 14

Key

J93: COM2 Header

©©©

Use these pin definitions to connect a port to

COM2*

Pin1 COM2 Receive

Pin2 COM2 Ground

Pin3 COM2 Transfer

*TYAN does NOT provide cable for this header. It is

designed for OEM use only.

http://www.tyan.com

14

P23

J69 J14 P29

http://www.tyan.com

15

P23: Front Audio Header

Signal Pin Pin Signal

MIC_L

1 2

GND

MIC_R

3 4

VCC-

LINE_FPOUT_R

5 6

LINE_OUT_R

7 8

KEY

LINE_FPOUT_L

9 10

LINE_OUT_L

The front panel Audio comes preinstalled with jumpers on pins 5-6 and 9-10.

Remove these jumpers to place a front panel audio cable

WARNING: Do not place jumper covers on this header in any other

configuration. Doing so could result in damage to the motherboard

J69: FireWire Disable Jumper

©©

©©

Open- (Default) Enables onboard FireWire controller

Closed- Disables onboard FireWire controller

J14: Onboard Buzzer/Speaker Header

4

1

Close Pin-3 and 4 (Default)-Onboard buzzer enabled.

4

1

Open Pin-3 and 4-Disable onboard buzzer or connect

to chassis speaker

P29: External SCSI LED Header

4

1

Use to connect external SCSI LED

Pin 1: NC, Pin 2: LED, Pin 3: LED, Pin 4: NC

http://www.tyan.com

16

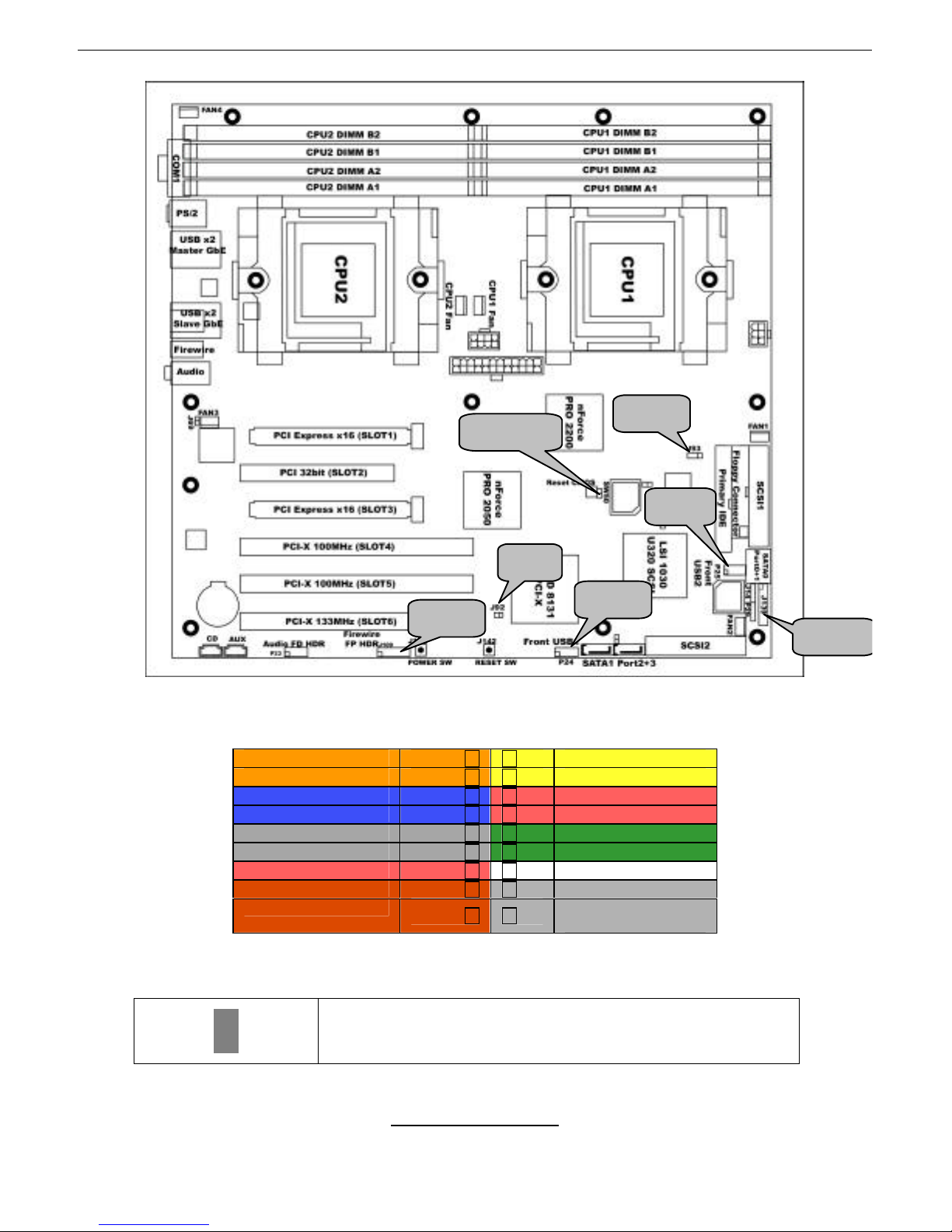

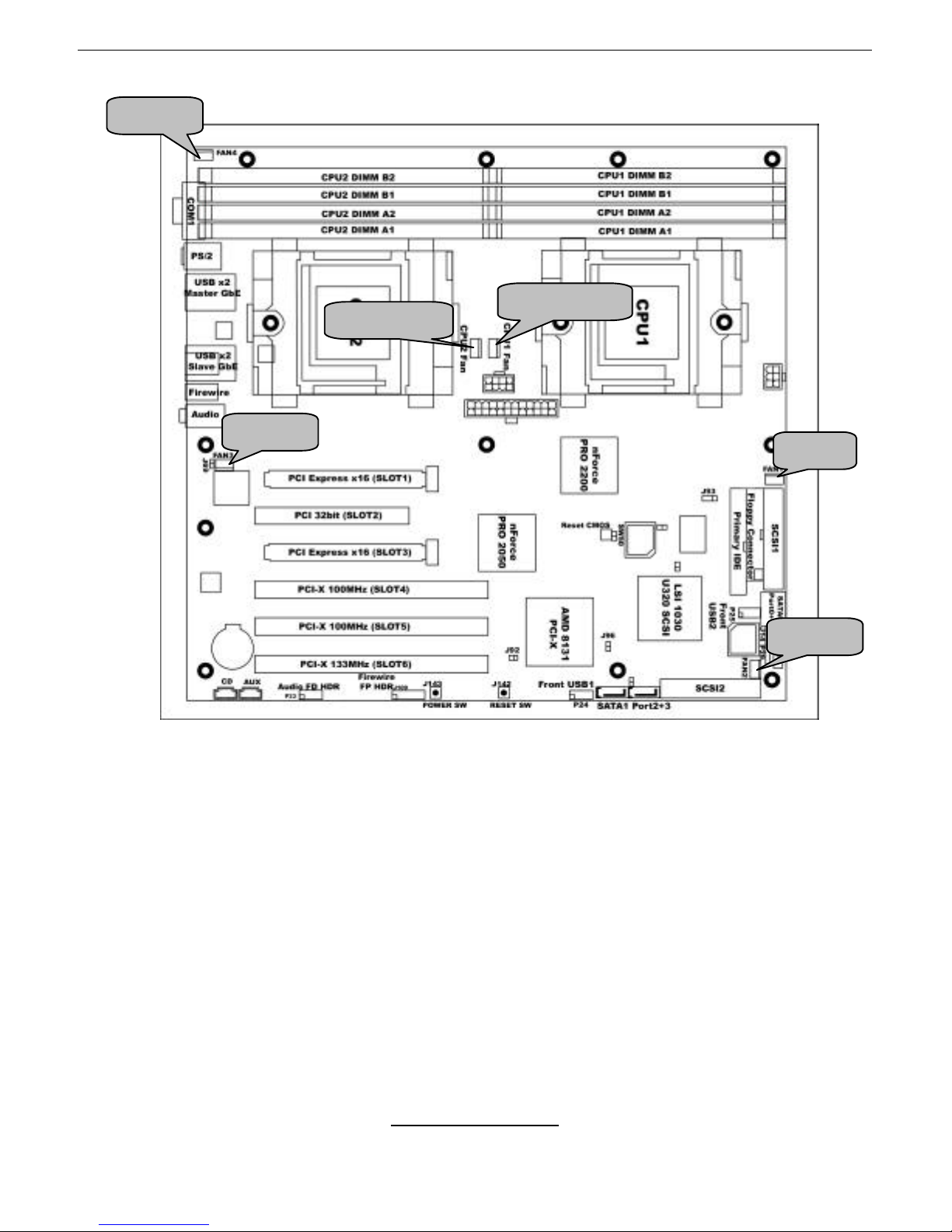

FAN4

FAN3

FAN2

CPU1 Fan

CPU2 Fan

FAN1

http://www.tyan.com

17

Fan Connectors

The S2895 uses the standard 4-wire cooling fan connector pin-out. The

connector is keyed to prevent damage to the mainboard and fan due to

misalignment during insertion. Fans are 12V nominally rated with fan speed

modulated by the control signal. The Sense signal is a fan tachometer output

signal with two pulses per revolution. The Control signal is a 25KHz Pulse Width

Modulated (PWM) signal from the baseboard control circuitry.

The 4-wire fan is forward and backward compatible to the 3-wire fan. This

means an older 3-wire fan will plug into a 4-wire fan header. However, there is

no speed control for a wire fan. It will always run at full RPM

1 2 3 4

©©©©

Pin1=GROUND

Pin2= +12v

Pin3= Tachometer

Pin4= Speed Control

Use these headers to connect the processor or

chassis cooling fan to your motherboard to keep the

system stable and reliable.

* For 3-pin fans connect to pin 1-3.

Hardware Monitor

Temperature senor

Senor chip: LM95221 (SMB address: 010 1011x)

CPU1 temperature: U92 pin1, 2

CPU2 temperature: U92 pin3, 4

FAN speed detect and control

CPU1 FAN

CPU1 FAN PWM: SIO PIN34 GP11

CPU1 FAN TACH: SIO PIN7 GP85

CPU2 FAN

CPU2 FAN PWM: SIO PIN43 GP22

CPU2 FAN TACH: SIO PIN110 FAN_TACH4

FAN 1

FAN1 PWM: CK804 PINAB4 FANCTL1

FAN1 TACH: CK804 PINAA3 FANRPM

FAN 2

FAN2 PWM: SIO PIN104 GP74

FAN2 TACH: SIO PIN35 FAN_TACH2

FAN 3

FAN3 PWM: SIO PIN104 GP74

FAN3 TACH: SIO PIN103 FAN TACH3

FAN 4

FAN4 PWM: CK804 PINAA2 FANCTL0

FAN4 TACH: CK804 PINAA3 FANRPM

http://www.tyan.com

18

2.4 - Installing the Processor(s)

Your brand new Thunder K8WE supports the latest 64-bit processor technology

from AMD. Only AMD Opteron

™

processor 200 series are certified and

supported with this motherboard.

Check our website for latest processor support. http://www.tyan.com

NOTE

If using a single processor, it MUST be installed in socket

CPU1. When using a single processor only CPU1 memory

banks are addressable.

TYAN is not liable for damage as a result of operating an unsupported

configuration.

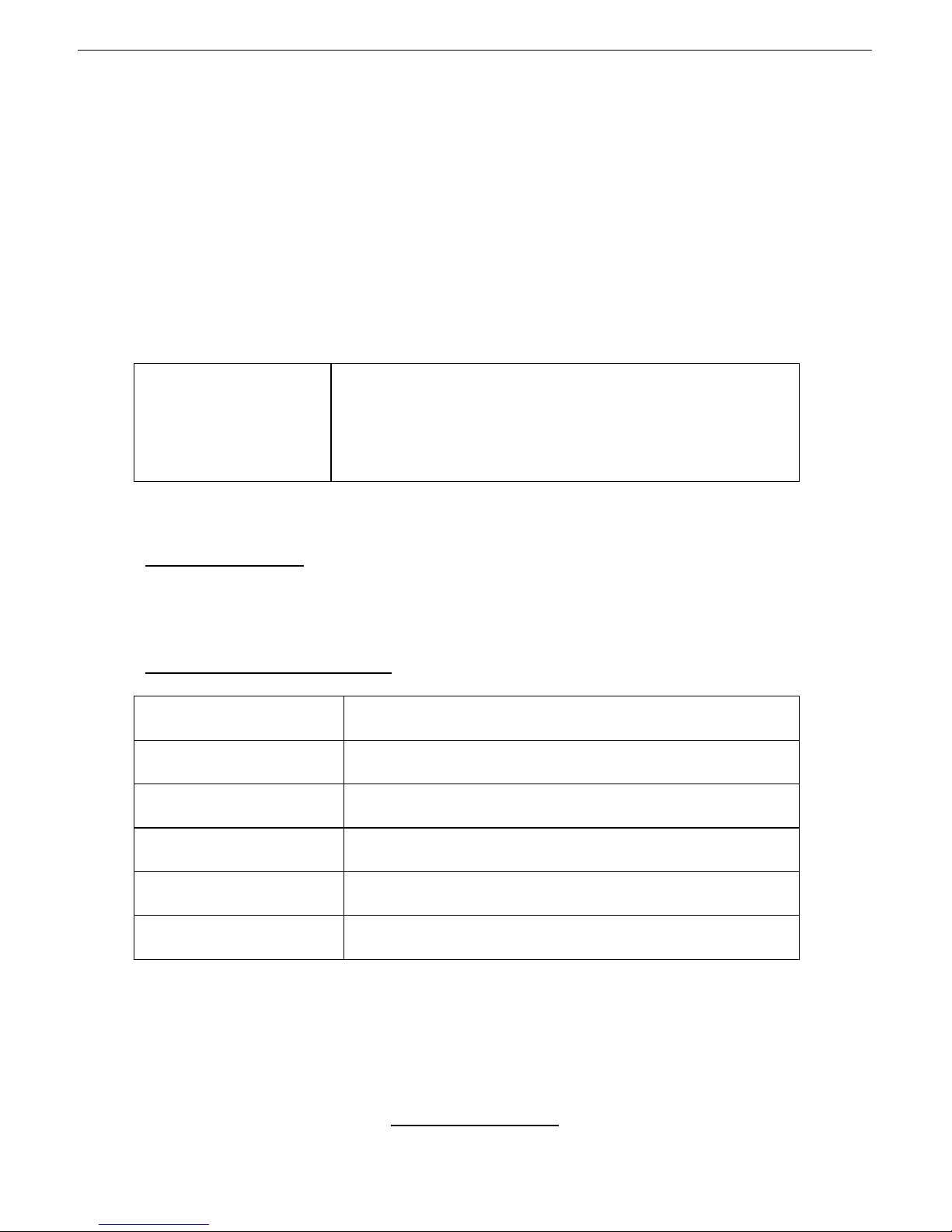

The diagram is provided as a visual guide to help you install socket processors

and may not be an exact representation of the processors you have.

Step 1: Lift the lever on the socket until it is approximately 90o or as far back as

possible to the socket.

Step 2: Align the processor with the socket. There are keyed pins underneath

the processor to ensure that the processor’s installed correctly.

Step 3: Seat the processor firmly into the socket by gently pressing down until

the processor sits flush with the socket.

Step 4: Place the socket lever back down until it locks into place. The

installation is finished.

Repeat these steps for the second processor if you are using two processors.

Take care when installing processors as they have very fragile connector pins

below the processor and can bend and break if inserted improperly.

NOTE

In order to access PCI Express x16 slot 3 and second Nvidia

MAC, TWO CPUs must be installed.

http://www.tyan.com

19

2.5 - Heatsink Retention Frame Installation

After you are done installing the processor(s), you should proceed to installing

the retention frame and heatsink. The CPU heatsink will ensure that the

processors do not overheat and continue to operate at maximum performance

for as long as you own them. Overheated processors are also dangerous to the

motherboard.

The backplate assembly prevents excessive motherboard flexing in the area

near the processor and provides a base for the installation of the heatsink

retention bracket and heatsink.

Because there are many different types of heatsinks available from many

different manufacturers, a lot of them have their own method of installation. For

the safest method of installation and information on choosing the appropriate

heatsink, use heatsinks validated by AMD. Please refer to AMD’s website at

www.amd.com

.

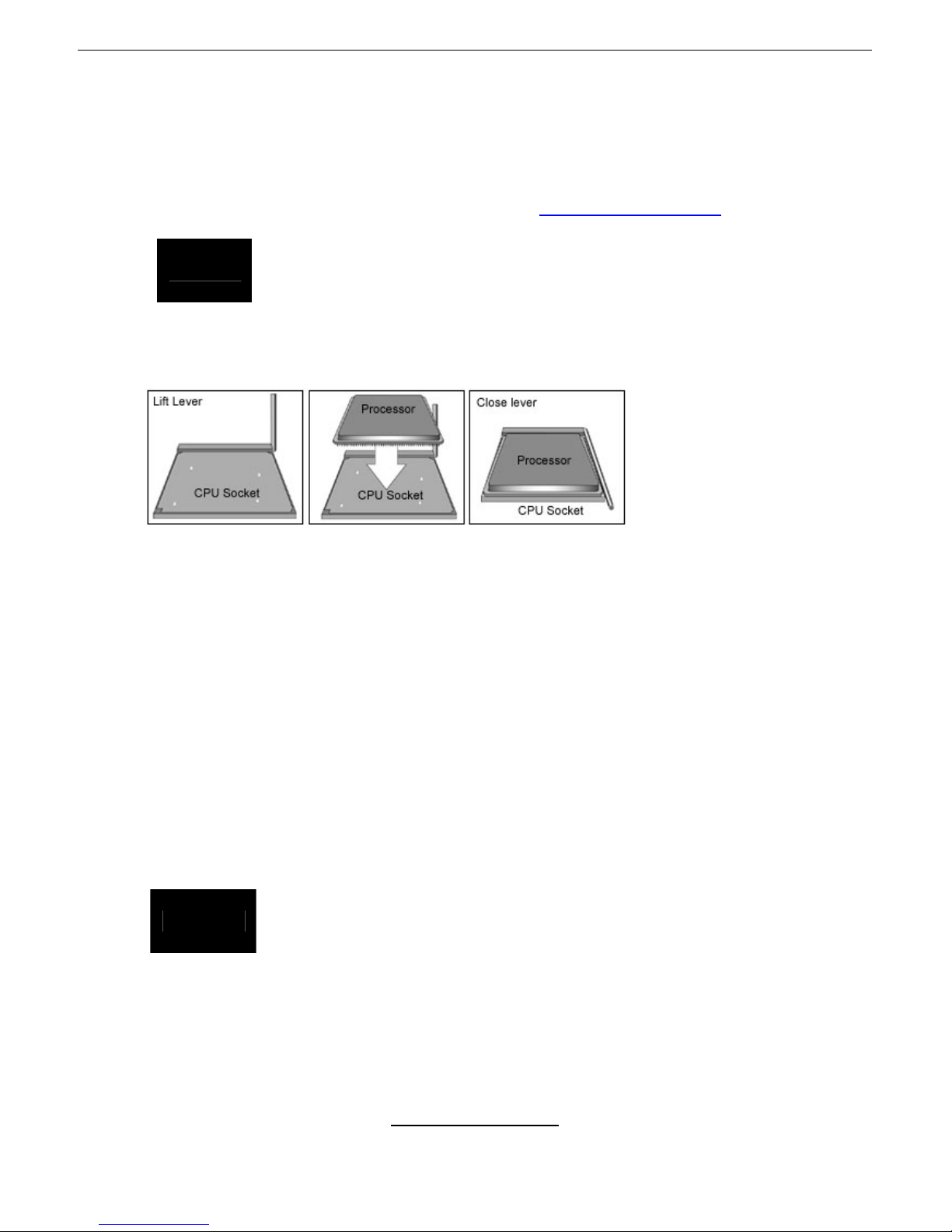

The following diagram will illustrate how to install the most common CPU back

plates:

1. Mounting screws

2. Heatsink retention frame

3. CPU socket

4. Motherboard PCB

5. Adhesive insulator

material

6. Backplate assembly

NOTE: Please see next

section for specific

instructions on how to install

mounting bracket.

http://www.tyan.com

20

2.6 - Thermal Interface Material

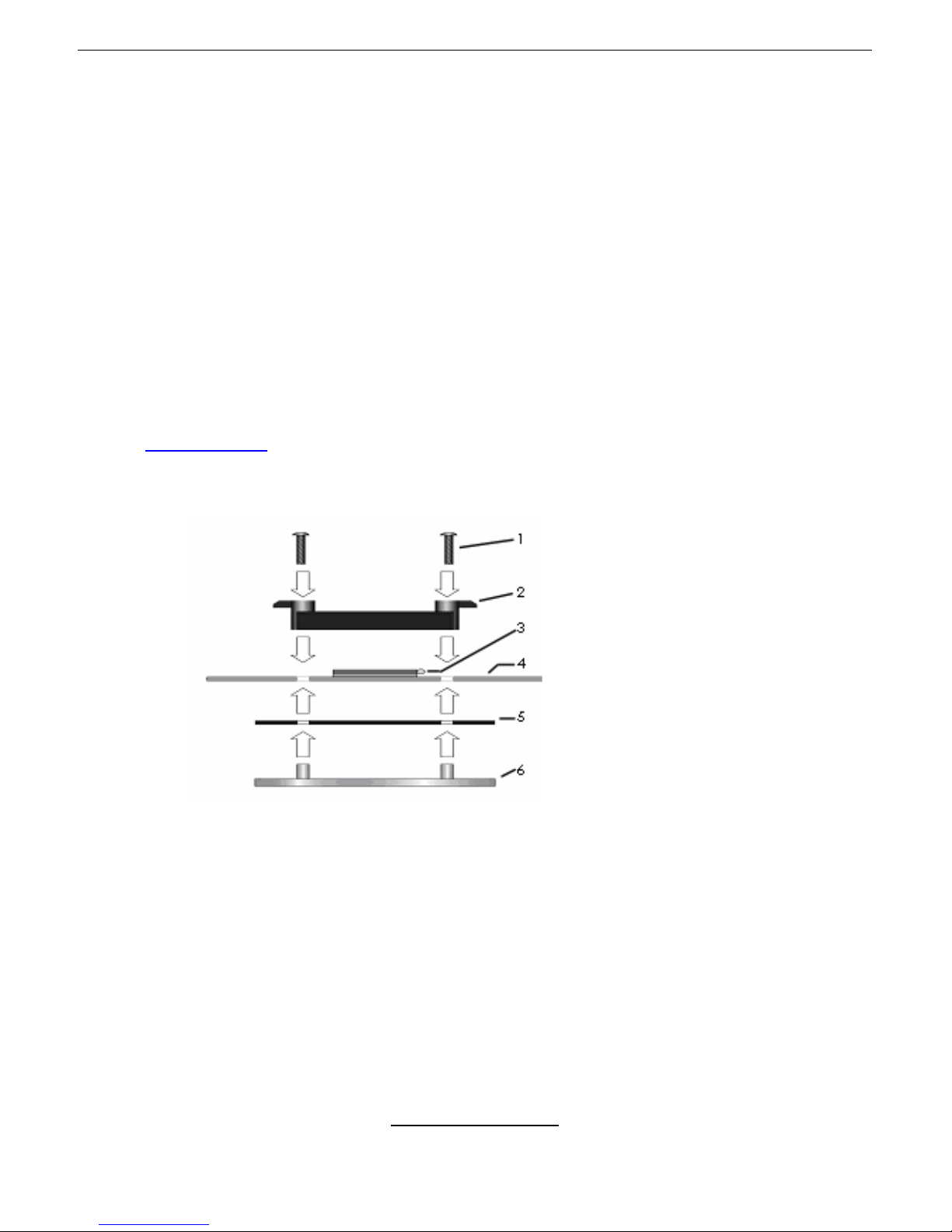

There are two types of

thermal interface materials

designed for use with the

AMD Opteron processor.

The most common material

comes as a small pad

attached to the heatsink at

the time of purchase. There

should be a protective cover

over the material. Take care

not to touch this material.

Simply remove the protective

cover and place the heatsink

on the processor.

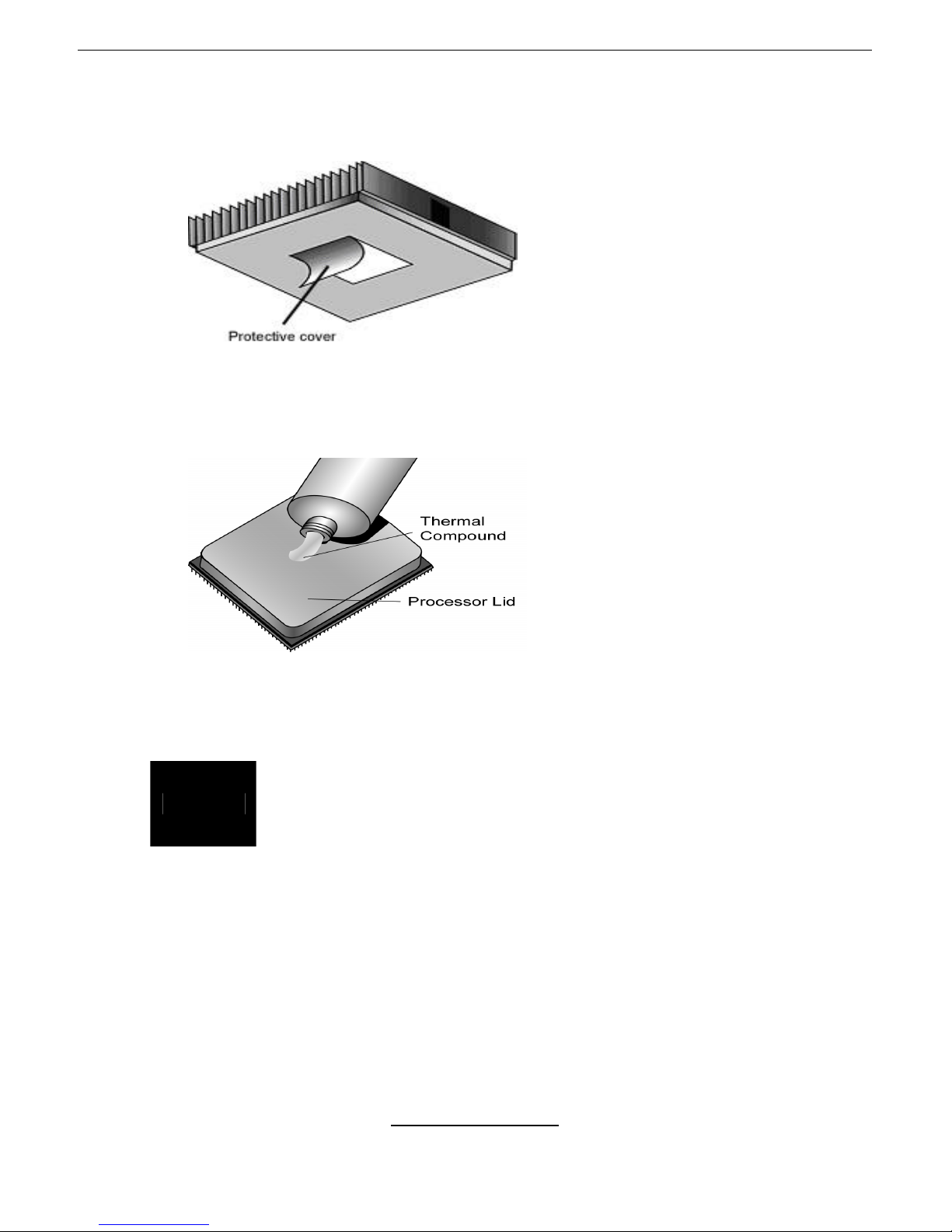

The second type of interface

material is usually packaged

separately. It is commonly

referred to as ‘thermal

compound’. Simply apply a

thin layer on to the CPU lid

(applying too much will

actually reduce the cooling).

NOTE

Always check with the manufacturer of the heatsink &

processor to ensure the Thermal Interface material is

compatible with the processor & meets the manufacturer’s

warranty requirements

http://www.tyan.com

21

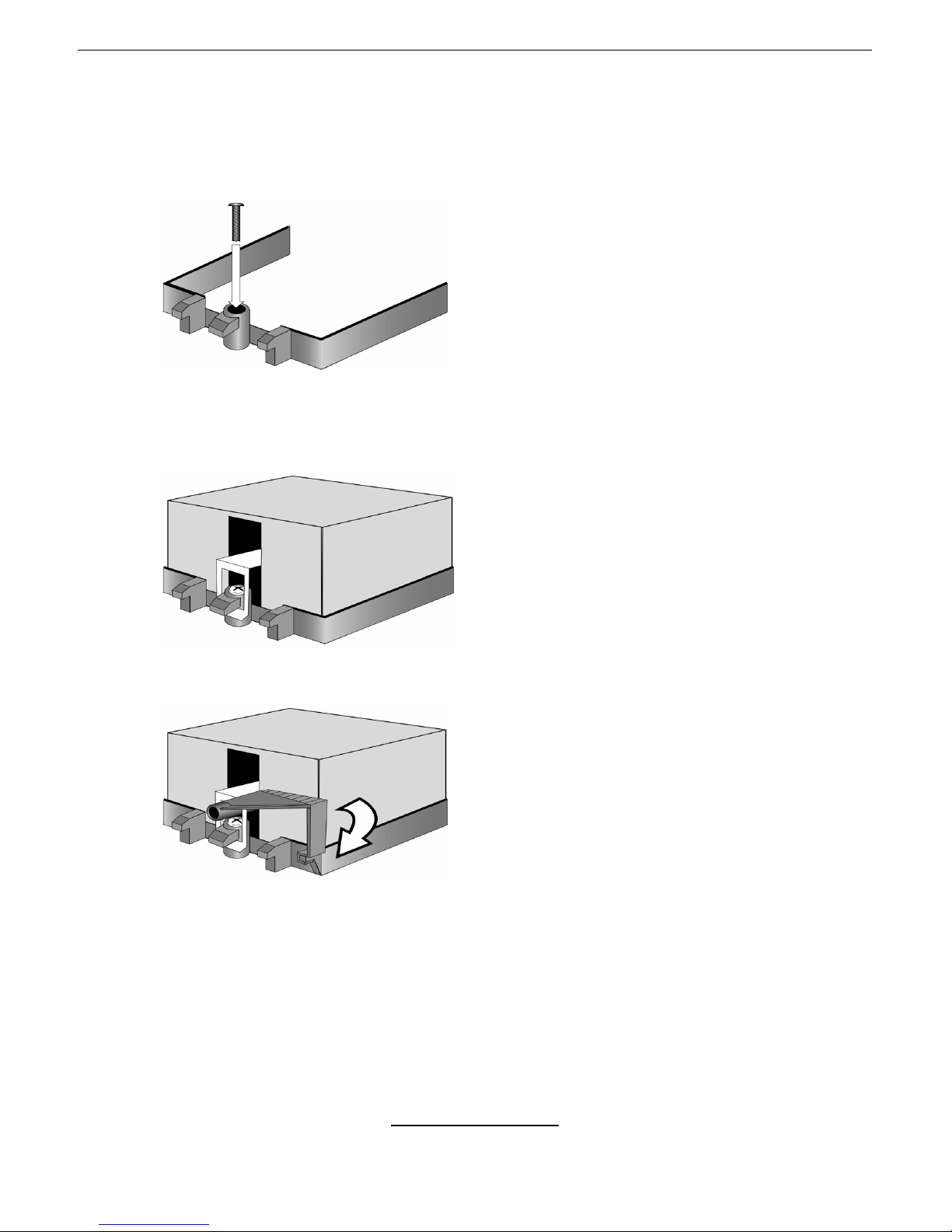

2.7 - Heatsink Installation Procedures

Type A: CAM LEVER (TYPE) INSTALLATION

1. After placing backplate and

interface material under motherboard

place heatsink retention frame on top

of motherboard. Align plastic retention

bracket screw holes with CPU backplate standoffs.

Tighten screws to secure plastic

retention bracket. Repeat for the other

side. DO NOT OVER TIGHTEN.

2. After tightening screws secure

metal clip to plastic retention bracket

center tab. Repeat for the other side

of heatsink.

3. After securing metal clip to plastic

retention bracket center tab, push

down on plastic clip to lock plastic clip

to side tab.

Loading...

Loading...