Page 1

http://www.tyan.com

1

FT48-B8812

Version 1.2 Rev

Service Engineer’s Manual

Page 2

http://www.tyan.com

2

Page 3

http://www.tyan.com

3

PREFACE

Copyright

This publication, including all photographs, illustrations, and software, is

protected under international copyright laws, with all rights reserved.

Neither this manual, nor any material contained herein, may be reproduced

without written consent of manufacturer.

Copyright 2011 MiTAC International Corporation. All rights reserved. TYAN® is

a registered trademark of MiTAC International Corporation.

Version 1.2

Disclaimer

Information contained in this document is furnished by MiTAC Computer

Corporation and has been reviewed for accuracy and reliability prior to printing.

TYAN

®

assumes no liability whatsoever, and disclaims any express or implied

warranty, relating to sale and/or use of TYAN® products including liability or

warranties relating to fitness for a particular purpose or merchantability. TYAN®

retains the right to make changes to produce descriptions and/or specifications

at any time, without notice. In no event will TYAN

®

be held liable for any direct

or indirect, incidental or consequential damage, loss of use, loss of data or

other malady resulting from errors or inaccuracies of information contained in

this document.

Trademark Recognition

All registered and unregistered trademarks and company names contained in

this manual are property of their respective owners including, but not limited to

the following.

TYAN® is a trademark of MiTAC Computer Corporation

Intel

®

is a trademark of Intel® Corporation.

AMI

®

, AMIBIOS® and combinations thereof are trademarks of AMI

Technologies.

Microsoft®, Windows® are trademarks of Microsoft Corporation.

Winbond

®

is a trademark of Winbond Electronics Corporation.

Page 4

http://www.tyan.com

4

FCC Declaration

Notice for the USA

Compliance Information Statement (Declaration of Conformity

Procedure) DoC FCC Part 15: This device complies with part 15

of the FCC Rules

This device complies with Part 15 of the FCC Rules. Operation is subject

to the following conditions:

·This device must not cause harmful interference.

·This device must accept any interference received, including

interference that may cause undesirable operation.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Notice for Canada

This Class A digital apparatus complies with Canadian ICES-003. Cet

appareil numérique de la Classe A est conforme à la norme NMB-003

du Canada.

Notice for Europe (CE Mark)

This product is in conformity with the Council

Directive 2004/108/EC..

CAUTION: Lithium battery included with this board. Do not puncture,

mutilate, or dispose of battery in fire. There will be danger of explosion if

battery is incorrectly replaced. Replace only with the same or equivalent

type recommended by manufacturer. Dispose of used battery according

to manufacturer instructions and in accordance with your local regulations.

Page 5

http://www.tyan.com

5

About this Manual

This manual provides you with instructions on supporting your

FT48-B8812 barebones system. This manual is intended for

experienced users and integrators with hardware knowledge of

personal computers.

This manual consists of the following parts:

Chapter 1:

Provides an introduction to the FT48-B8812, standard

parts list, external components, motherboard block

diagram and FRU part listings.

Chapter 2:

A complete introduction to the motherboard with

detailed descriptions about jumpers, It also covers

procedures on installing the CPU’s and memory

modules.

Chapter 3:

Explanation of FT48-B8812 barebones LED definitions.

Chapter 4:

Explanation on installing the HDD’s and server rack

installation.

Chapter 5:

Covers removal and replacement procedures for

Barebones system components.

Chapter 6:

Explanation of the S8812 motherboard BIOS settings.

Appendix:

Reference lists for BIOS, cable connections, FRU

Parts, system setup, and technical support

contact

information.

Page 6

http://www.tyan.com

6

SAFETY INFORMATION

Before installing and using the FT48-B8812, take note of the following

precautions:

·Read all instructions carefully.

·Do not place the unit on an unstable surface, cart or stand.

·Do not block the slots which are provided for system ventilation.

·Only use the proper power source rated for the systems power supply.

·The PSU uses a three-wire ground cable, which is equipped with a third pin to

ground the unit and prevent electric shock. Do not use any power

connection that does not 100% support this design.

·Place the power cord where it will not be in the way of foot traffic.

·Follow all warnings in this manual and stickers attached to the chassis.

·Do not place objects in the ventilation slots as they may touch high voltage

components and result in shock and damage to the components.

· When replacing parts, ensure that you use original FRU parts specified by

the manufacturer.

·When service or repairs have been done, perform routine safety checks

to verify that the system is operating correctly.

·Avoid using the system near water, direct sunlight or near a heating device.

·Cover the unit when not in use.

Page 7

http://www.tyan.com

7

Table of Contents

Chapter 1: Overview......................................................................... 9

1.1 About the TYAN FT48-B8812 .................................................. 9

1.2 Product Models......................................................................... 9

1.3 Features.................................................................................. 10

1.4 Standard Parts List................................................................. 12

1.4.1 Box Contents ....................................................................... 12

1.4.2 Accessories ......................................................................... 13

Chapter 2: Motherboard Details.................................................... 15

2.1 Board Image ........................................................................... 16

2.2 Sensors on the board ............................................................. 17

2.3 Block Diagram ........................................................................ 18

2.4 Board Parts, Jumpers and Connectors .................................. 19

2.5 Installing the Processor and Heat sink ................................... 31

2.6 Thermal Interface Material...................................................... 34

2.7 Tips on Installing Motherboard in Chassis ............................. 35

2.8 Lights on the Motherboard...................................................... 37

2.9 Installing the Memory ............................................................. 38

2.10 Attaching Drive Cables......................................................... 45

2.11 Installing Add-In Cards ......................................................... 46

2.12 Connecting External Devices ............................................... 47

2.13 Installing the Power Supply .................................................. 48

2.14 Finishing Up.......................................................................... 49

Chapter 3: About the Barebones Chassis Features.................... 51

3.1.1 System Front View .............................................................. 51

3.1.2 System Rear View ............................................................... 52

3.1.3 LED Definitions.................................................................... 52

3.1.4 Internal View........................................................................ 54

Chapter 4: Setting Up..................................................................... 55

4.0.1 Before you Begin ................................................................. 55

4.0.2 Work Area............................................................................ 55

4.0.3 Tools.................................................................................... 55

4.0.4 Precautions.......................................................................... 56

4.1 Installing Motherboard Components ...................................... 57

4.1.1 Removing the Chassis Cover.............................................. 57

4.1.2 Installing the PCI-E Cards ................................................... 58

4.2 Installing Hard Drives ............................................................. 60

4.3 Installing DVD Drive ............................................................... 62

4.4 Rack Mounting........................................................................ 68

4.4.1 Installing the Server in a Rack............................................. 68

Page 8

http://www.tyan.com

8

4.5 Opening the Chassis Front Bezel........................................... 71

Chapter 5: Replacing Pre-Installed

Components ................................................................................... 73

5.1 Introduction............................................................................. 73

5.2 Disassembly Flowchart........................................................... 73

5.3 Removing the Cover............................................................... 74

5.4 Replacing the System Fan and Fan Board ............................ 74

5.4.1 M1801F77 Fan Board Features .......................................... 76

5.4.2 M1801F77 Fan Board Connector Pin Definition ................. 77

5.5 Replacing the M1237F48 SATA/SAS Backplane................... 78

5.5.1 M1237F48 SATA/SAS Backplane Features........................ 79

5.6 Replacing the Front Panel Control Board............................. 81

5.6.1 M1018 LED Control Board Features................................... 82

5.6.2 M1018 LED Control Board Connector Pin Definition .......... 83

5.7 Replacing Power Supply and M7025 PDB........................... 84

5.7.1 Replacing Power Supply ..................................................... 84

5.7.2 Replacing M7025 Power Distribution Board........................ 85

5.7.3 M7025 Power Distribution Board Features ......................... 87

5.7.4 M7025 PDB Connector Pin Definition ................................. 88

5.8 Replacing S8812 System Board........................................... 90

Chapter 6: BIOS Setup................................................................... 91

6.1 About the BIOS....................................................................... 91

6.2 Main Menu.............................................................................. 93

6.3 Advanced Menu...................................................................... 94

6.4 PCI/PnP Menu...................................................................... 121

6.5 Boot Menu ............................................................................ 123

6.6 Security Menu....................................................................... 125

6.7 Chipset Menu ....................................................................... 127

6.8 Exit Menu.............................................................................. 138

Appendix I: S8812 / FT48 B8812 BIOS Comparisons................ 141

Appendix II: Cable Connection Tables....................................... 149

Appendix III: FRU Parts Table ..................................................... 151

Appendix IV: Technical Support ................................................. 152

Page 9

http://www.tyan.com

9

Chapter 1: Overview

1.1 About the TYAN FT48-B8812

Congratulations on your purchase of the TYAN

®

FT48-B8812, a highly optimized

rack-mountable 4U barebones system. The FT48-B8812F48W8HR is designed to

support AMD 32nm 16-Core/12-Core/8-Core/4-Core Opteron 6200 Series

processors and up to 256GB of 800/1066/1333/1600MHz

UNB or REG/ECC DDR3

memory. There are 16 channels with 32 DDR3 DIMM slots, providing a rich feature

set and incredible performance. Leveraging advanced technology from AMD

®

, the

FT48-B8812 server system is capable of offering scalable 32 and 64-bit computing,

high-bandwidth memory design, and lightning-fast PCI-E Gen2 bus implementation.

The FT48-B8812 not only empowers your company in today’s demanding IT

environment but also offers a smooth path for future application usage. The

FT48-B8812 uses TYAN

®’

s latest rack-mountable 4U chassis featuring a robust

structure and a solid mechanical enclosure. All of this provides the FT48-B8812 the

power and flexibility to meet the needs of nearly any server application.

1.2 Product Models

Model HDD Bays Power supply

FT48-B8812F48W8HR

(4) 3.5" Hot-Swap HDD

Bays; Extra (8) hot-swap

trays available

ERP1U

hot-swap / (2+1)

Page 10

http://www.tyan.com

10

1.3 Features

TYAN FT48B8812 (B8812F48W8HR)

Form Factor

4U Rackmount

Chassis Model

FT48

Dimension (D x W x H)

27.5" x 16.8" x 6.9" (700 x 427 x 176mm)

Motherboard

S8812WGM3NR

Board Dimension

MEB, 13"x16.2" (330x411mm)

System

Gross Weight

50 kg

Buttons

(1) PWR / (1) RST / (1) NMI / (1) ID

LEDs

(1) PWR / (1) HDD / (2) LAN / (1) ID / (1) Warning

Front Panel

I/O Ports

(2) USB ports

Type / Q'ty

3.5" Hot-Swap / (8) / (3) 5.25" device bays

External Drive

Bay

Supported HDD

Interface

SAS 3.0Gb/s / SATA-II 3.0Gb/s

System Cooling

Configuration

FAN

(6) 12cm fans

Type

ERP1U

Efficiency

PFC

Redundancy

2+1

Input Range

Full-range AC(100-240V)

Frequency

60 Hertz

Power Supply

Output Watts

1,540W (2 x 770W)

Supported CPU Series

AMD 32nm 16-Core/12-Core/8-Core/4-Core Opteron

6200 Series Processors (Interlagos) / (4) HT3; 16M

L3 per socket

Socket Type / Q'ty

G34 / (4)

Average CPU Power

(ACP) wattage

Up to 80W

Processor

System Bus

Up to 6.4 GT/s Hyper-Transport link support

Chipset

AMD SR5690 + SP5100

Chipset

Super I/O

Winbond W83627DHG

Supported DIMM Qty

(32) DIMM slots

DIMM Type / Speed

U/RDDR3 & LV RDDR3, 800/1066/1333/1600 MHz

Capacity

Up to 256GB

Memory channel

4 Channels per CPU

Memory

Memory voltage

1.5V to1.35V

Expansion Slots PCI-E

(2) PCI-E Gen.2 x8 slots(open-end) / (1) PCI-E Gen.2

x16 slot (w/ x16 or x8 link) / (1) PCI-E Gen.2 x8 slot

(open-end, / x0 or x8 link)

Port Q'ty

(3)

LAN

Controller

Intel 82574L / Intel 82576EB

Connector type

D-Sub 15-pin

Resolution

1600x1200@60Hz

Graphic

Chipset

Aspeed AST2050

Page 11

http://www.tyan.com

11

USB

(4) ports (2 at front, 2 at rear)

COM

(1) DB-9 COM port

PS/2

(1) PS/2 connector (for Keyboard and Mouse)

VGA

(1) D-Sub 15-pin port

I/O Ports

RJ-45

(3) ports

Chipset

Winbond W83795G

Voltage

Monitors voltage for CPU, memory, chipset & power

supply

Temperature

Monitors temperature for CPU & system environment

LED

Fan fail LED indicator / Over temperature warning

indicator

System

Monitoring

Others

Chassis intrusion detection / Watchdog timer support

Onboard Chipset

Onboard Aspeed AST2050

AST2050 IPMI Feature

IPMI 2.0 compliant baseboard management controller

(BMC) / Supports storage over IP and remote

platform-flash

Server

Management

AST2050 iKVM Feature

24-bit high quality video compression / Dual 10/100

Mb/s MAC interfaces

Brand / ROM size

AMI / 4MB

BIOS

Feature

Plug and Play (PnP) /PCI2.3 /WfM2.0 /SMBIOS2.3

/PXE boot / ACPI 2.0 power management /Power on

mode after power recovery / User-configurable H/W

monitoring / Auto-configurable of hard disk types

Operating System OS supported list

Please refer to our OS support list.

FCC (DoC)

Class A

Regulation

CE (DoC)

Yes

Operating Temp.

10° C ~ 35° C (50° F~ 95° F)

Non-operating Temp.

- 40° C ~ 70° C (-40° F ~ 158° F)

Operating

Environment

In/Non-operating

Humidity

90%, non-condensing at 35° C

RoHS RoHS 6/6 Complaint

Yes

Barebones

(1) FT48 B8812 Barebones

Manual

(1) FT48 B8812 System Engineer Guide

Installation CD

(1) TYAN installation CD

Heatsink / Cooler

(4) G34 CPU heatsinks

Rail kit

(1) CRAL-0070, sliding rail kit for KFT48

Mounting Ear

(1) CRBK-0021, Rack mounting handle bracket, right /

(1) CRBK-0020, Rack mounting handle bracket, left

Package Contains

Cable Power Cord

(3) CCBL-0310, US type power cords / (3)

CCBL-0300, EU type power cords

Page 12

http://www.tyan.com

12

1.4 Standard Parts List

This section describes FT48-B8812 package contents and accessories. Open

the box carefully and ensure that all components are present and undamaged.

The product should arrive packaged as illustrated below.

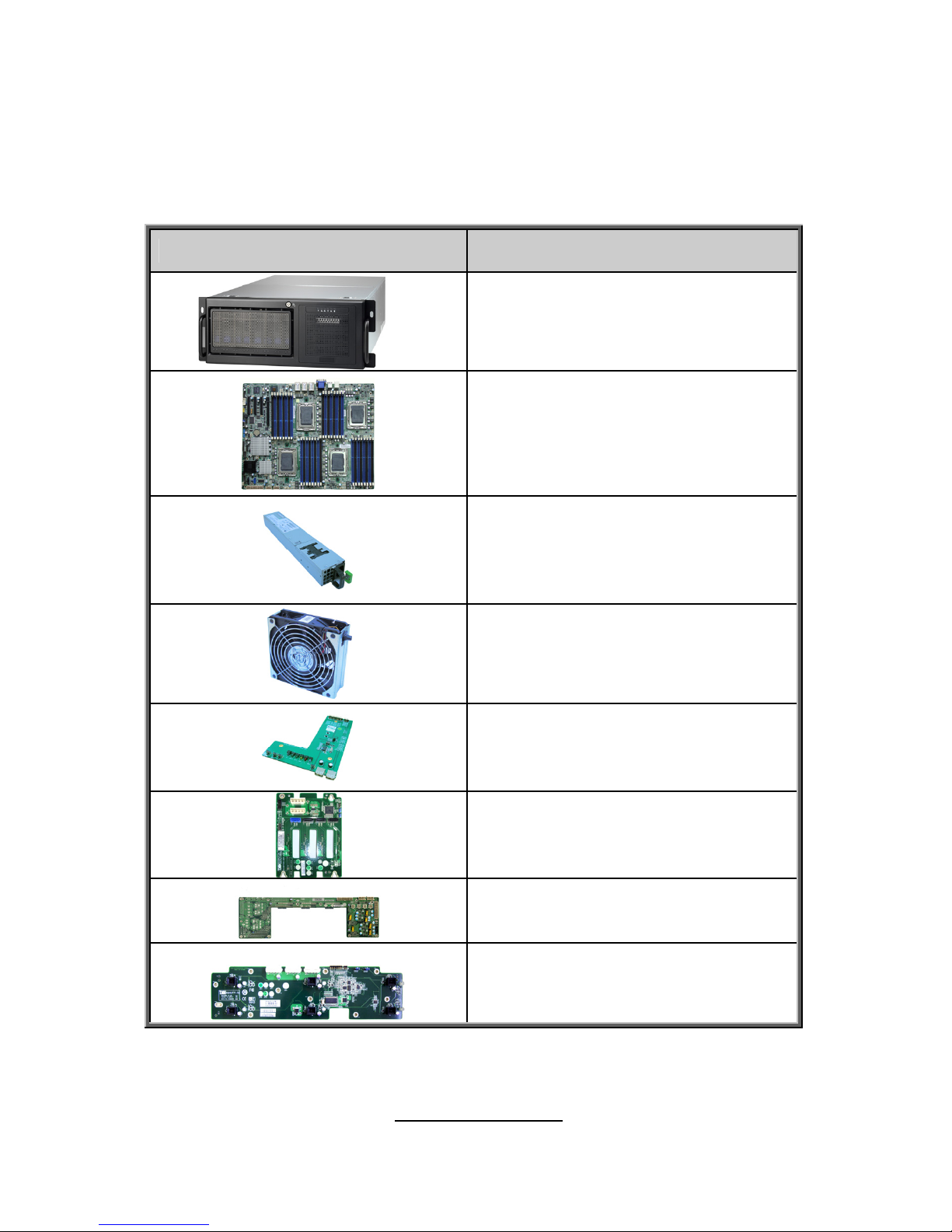

1.4.1 Box Contents

Component Description

4U Rackmount FT48 Chassis

S8812 Motherboard

(3) 770W,DPS-770AB B

DELTA,EPR1U-MODULE

(6)120X120X38mm FAN

12V/4800RPM/Delta 4-pin

Front Panel board, Antrada

(2) M1237 SAS Backplane board

Power distribution board

M7025-PDB-HE

M1801F77-FAN board

Page 13

http://www.tyan.com

13

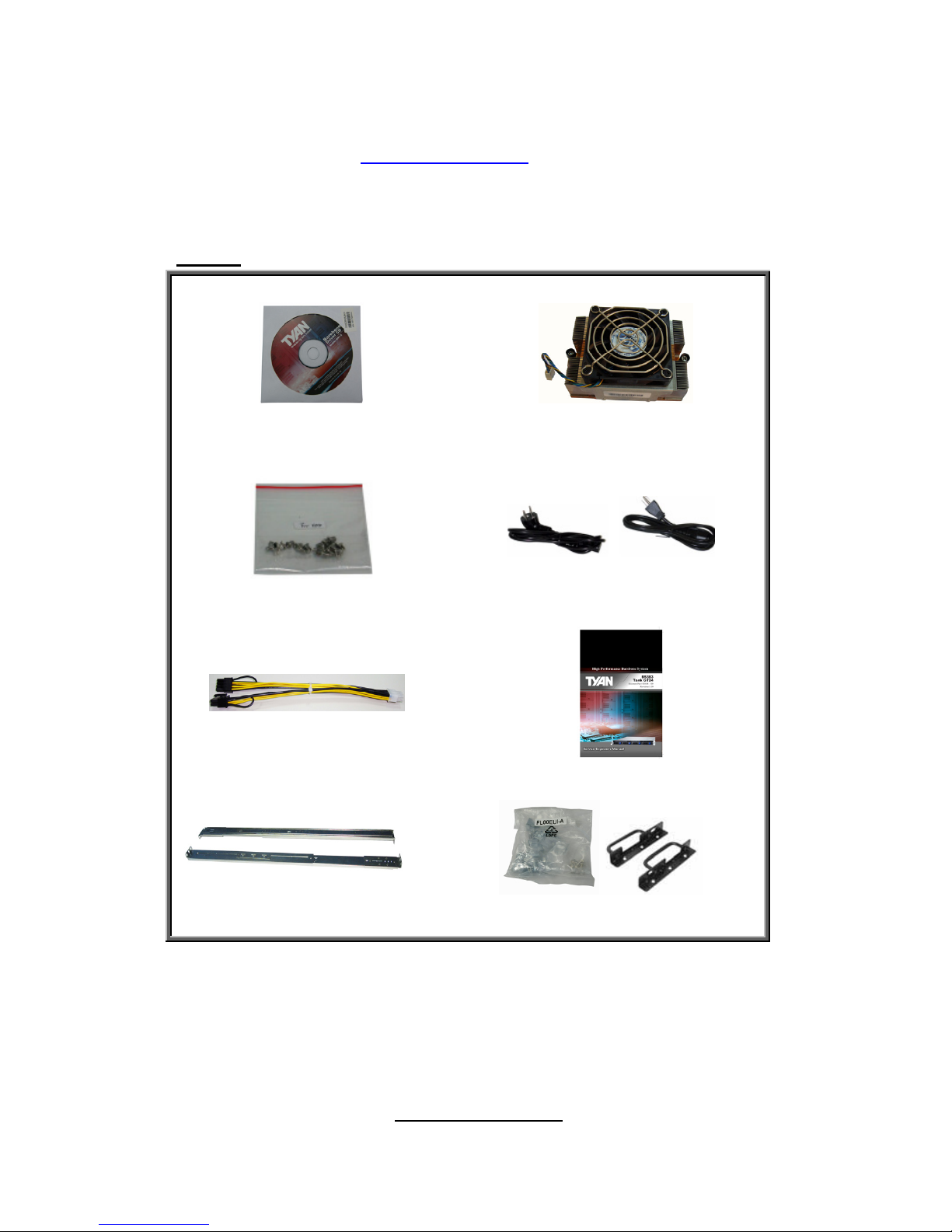

1.4.2 Accessories

If any items are missing or appear damaged, contact your retailer or browse to

TYAN’s website for service: http://www.tyan.com

The web site also provides information of other TYAN

®

products, as well as

FAQs, compatibility lists, BIOS settings, etc.

Rail Kit

1 x TYAN®

Motherboard Drive CD

4 x Heatsinks

HDD Screws

Power Cables

Left to right: Europe, US

2 x GPU PWR CABLE 2*4Pin System Engineer Guide

2 x Rail with Bracket Mounting Ears & Screw Sack

Page 14

http://www.tyan.com

14

NOTE

Page 15

http://www.tyan.com

15

Chapter 2: Motherboard Details

You are now ready to install your motherboard.

How to install our products right… the first time

The first thing you should do is reading this user’s manual. It contains important information that

will make configuration and setup much easier. Here are some precautions you should take

when installing your motherboard:

(1) Ground yourself properly before removing your motherboard from the antistatic bag.

Unplug the power from your computer power supply and then touch a safely

grounded object to release static charge (i.e. power supply case). For the safest

conditions, MiTAC recommends wearing a static safety wrist strap.

(2) Hold the motherboard by its edges and do not touch the bottom of the board, or flex

the board in any way.

(3) Avoid touching the motherboard components, IC chips, connectors, memory

modules, and leads.

(4) Place the motherboard on a grounded antistatic surface or on the antistatic bag that

the board was shipped in.

(5) Inspect the board for damage.

The following pages include details on how to install your motherboard into your chassis, as

well as installing the processor, memory, disk drives and cables.

NOTE: Do not apply power to the board if it has been damaged.

Page 16

http://www.tyan.com

16

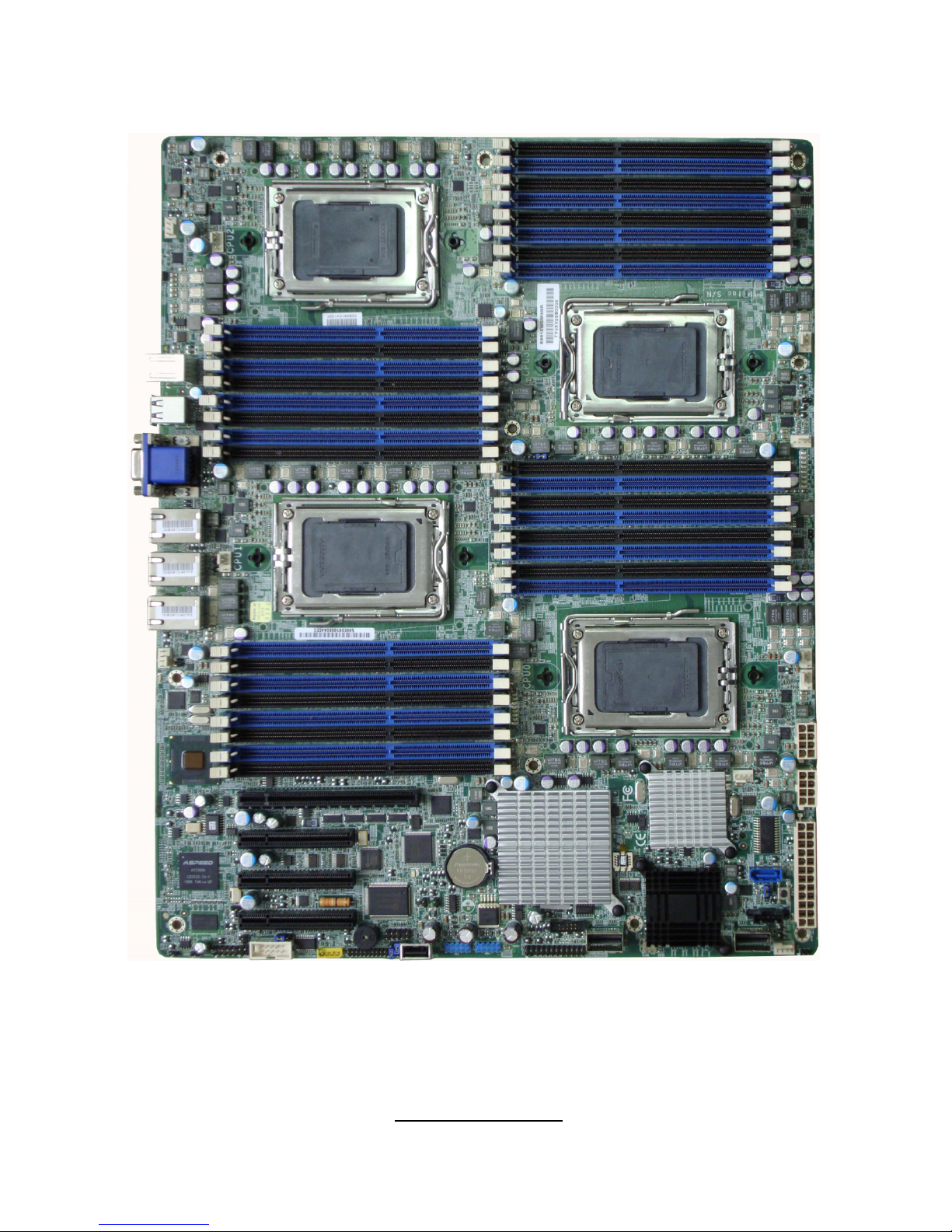

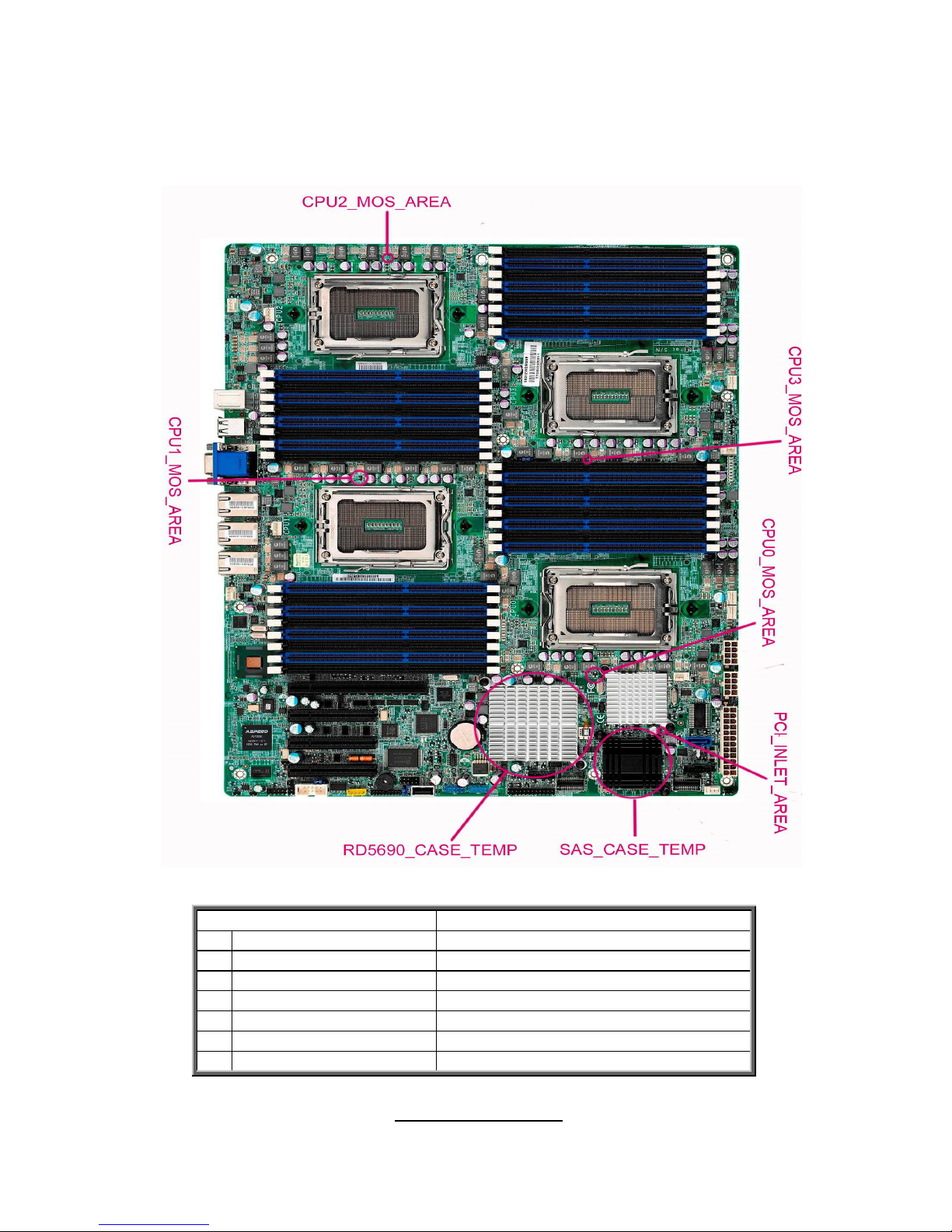

2.1 Board Image

This picture is representative of the latest board revision available at the time of publishing. The

board you receive may not look exactly like the above picture.

Page 17

http://www.tyan.com

17

2.2 Sensors on the board

There are seven different hardware health and IPMI sensors on the S8812 motherboard.

Name Function

1 PCI_INLET_AREA Thermometer on board

2 RD5690_CASE_TEMP integrated in the SR5690 chip

3 SAS_CASE_TEMP integrated in the SAS controller chip

4 CPU0_MOS_AREA embedded part

5 CPU1_MOS_AREA embedded part

6 CPU2_MOS_AREA Thermometer on board

7 CPU3_MOS_AREA Thermometer on board

Page 18

http://www.tyan.com

18

2.3 Block Diagram

S8812 Block Diagram

Page 19

http://www.tyan.com

19

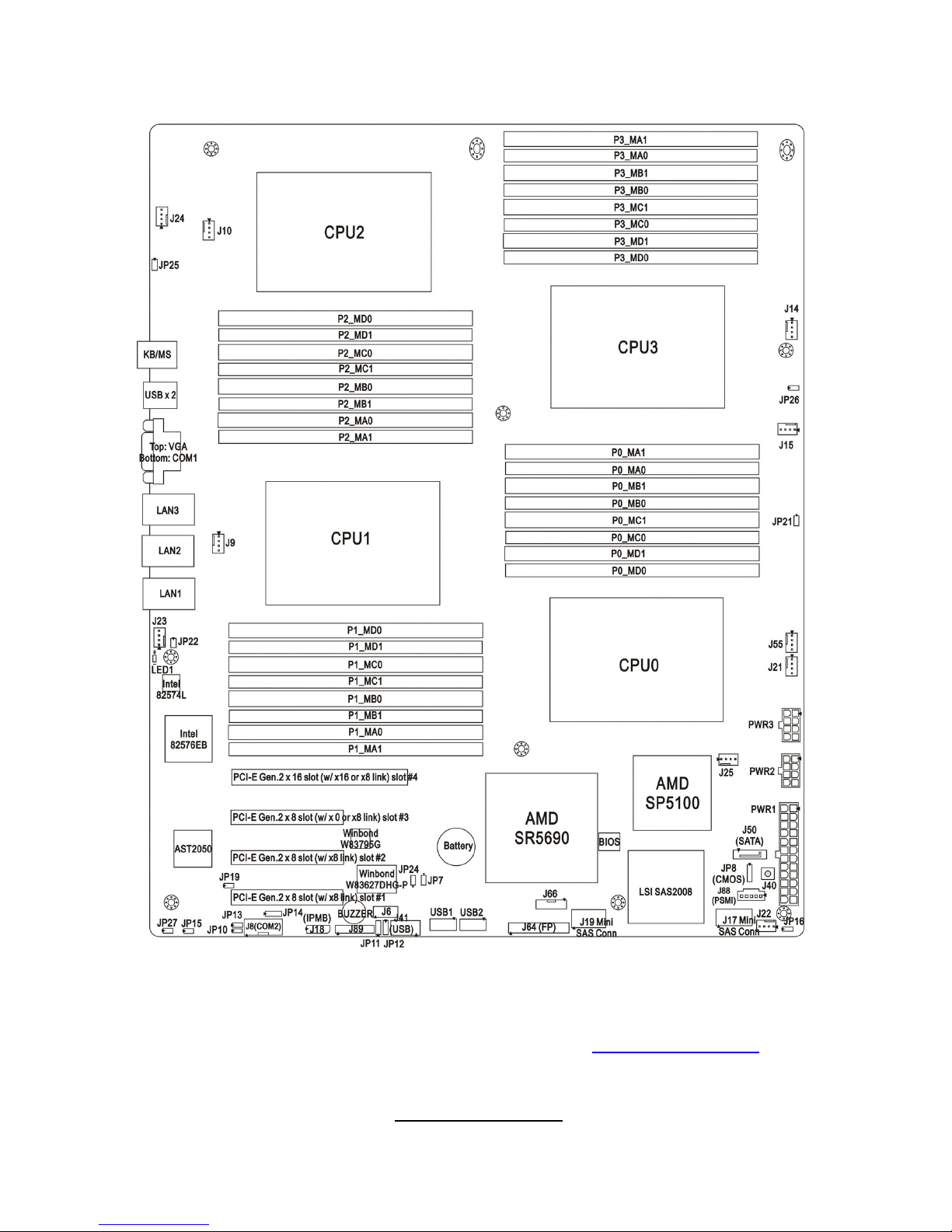

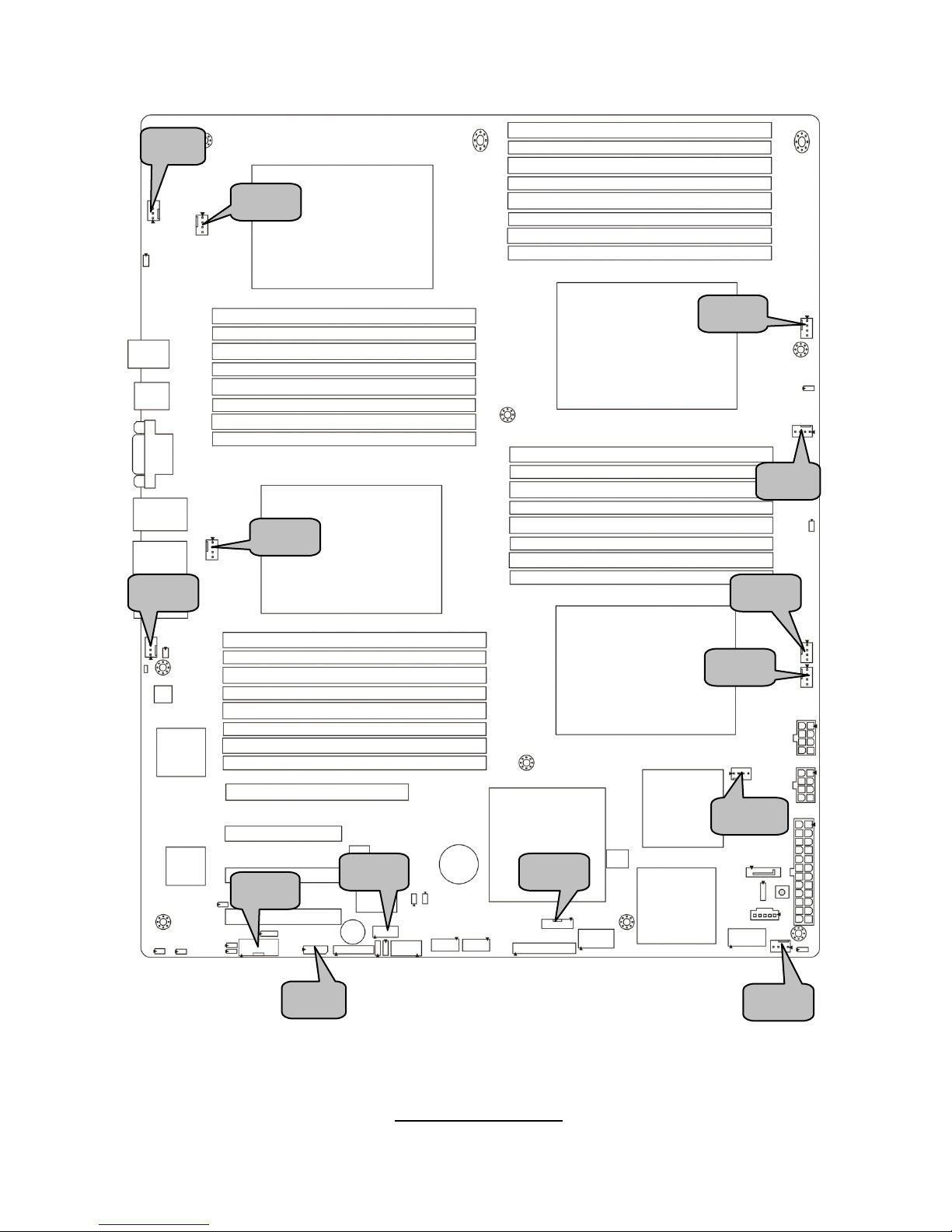

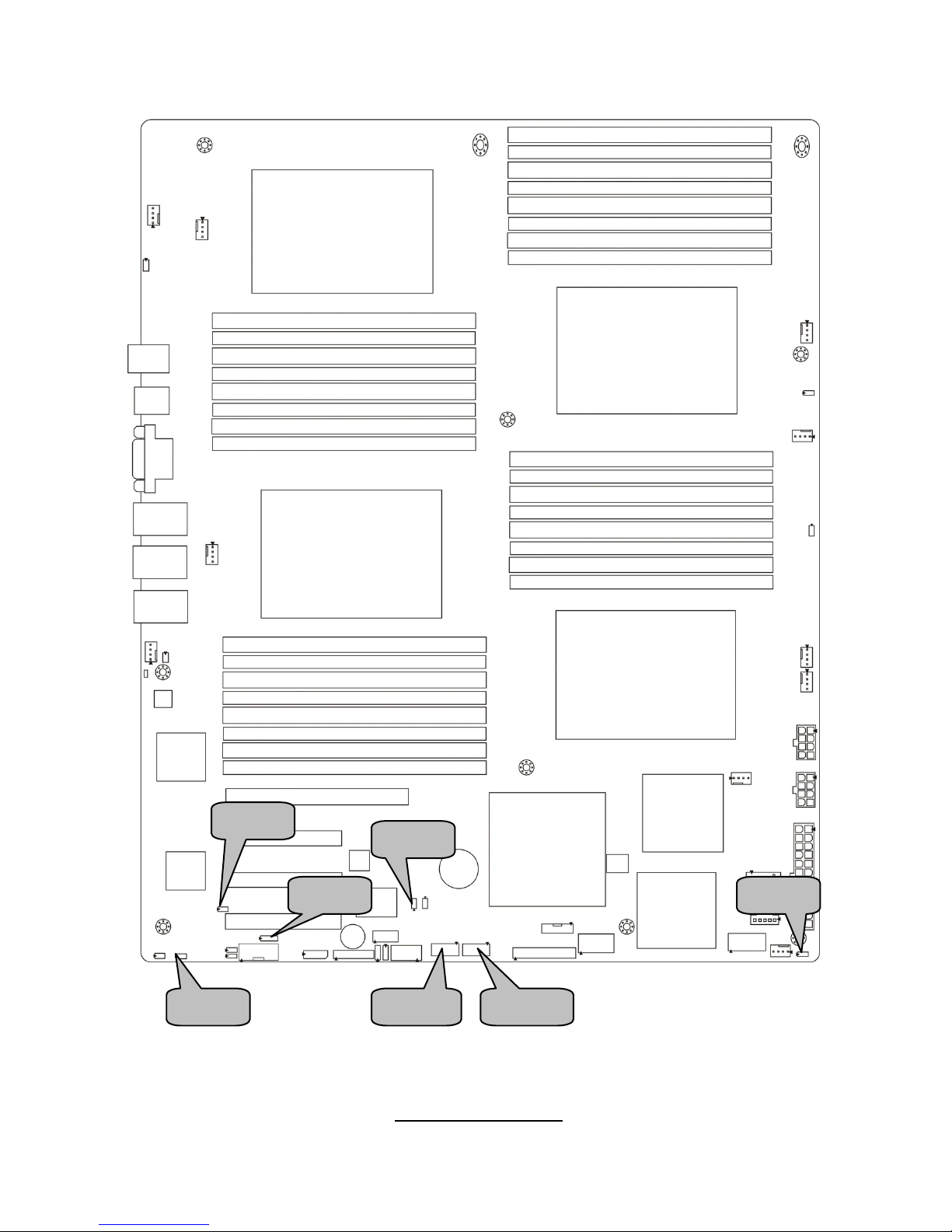

2.4 Board Parts, Jumpers and Connectors

This diagram is representative of the latest board revision available at the time of

publishing. The board you receive may not look exactly like the above diagram. But

for the DIMM number please refer to the above placement for memory installation.

For the latest board revision, please visit our web site at http://www.tyan.com

.

Page 20

http://www.tyan.com

20

Jumpers & Connectors

Jumper/Connector Function

J6

CPLD JTAG Connector

J8 (COM2)

COM2 Header

J9/J10/J14/J15/J21/

J22/J23/J24/J25/J55

4-pin Fan Connectors

J17

Mini SAS Connector (For HDD 0/1/2/3)

J19

Mini SAS Connector (For HDD 4/5/6/7)

J18 (IPMB)

IPMB Connector

J40

Power Switch

J41 (USB)

Vertical (Type A) USB Connector

J50 (SATA)

Serial ATA Connector

J64 (FP)

Front Panel Connector

J66

SAS Fault LED Connector

J88 (PSMI)

PSMI Connector

J89

Fan TACH Connector

JP7

PCI-E x8/x16 Select Jumper

JP8

Clear CMOS Jumper

JP10

BMC Disable Jumper

JP11/JP12

COM2 Switch Jumper

JP13

TPM Disable Jumper

JP14

COM Power Select Jumper

JP15

WDT Trigger NMI Jumper

JP16

Chassis Intrusion Header

JP19

VGA Disable Jumper

JP21/JP22/JP25/JP26

DDR3 VDDIO Voltage Select Jumper

JP24

LAN2 LED Connector

JP27

ID LED Connector

LED1

ID LED

USB1/USB2

USB Front Panel Header

Jumper Legend

OPEN - Jumper OFF Without jumper cover

CLOSED - Jumper ON With jumper cover

Page 21

http://www.tyan.com

21

J22

J15

J24

J21

J8

J25

J23

J6

J14

J18

J55

J9

J10

J66

Page 22

http://www.tyan.com

22

J6: CPLD JTAG Connector

Signal Pin Pin Signal

TCK 1 2 GND

TDO 3 4 V3DU

TMS 5 6 NC

NC 7 8 KEY

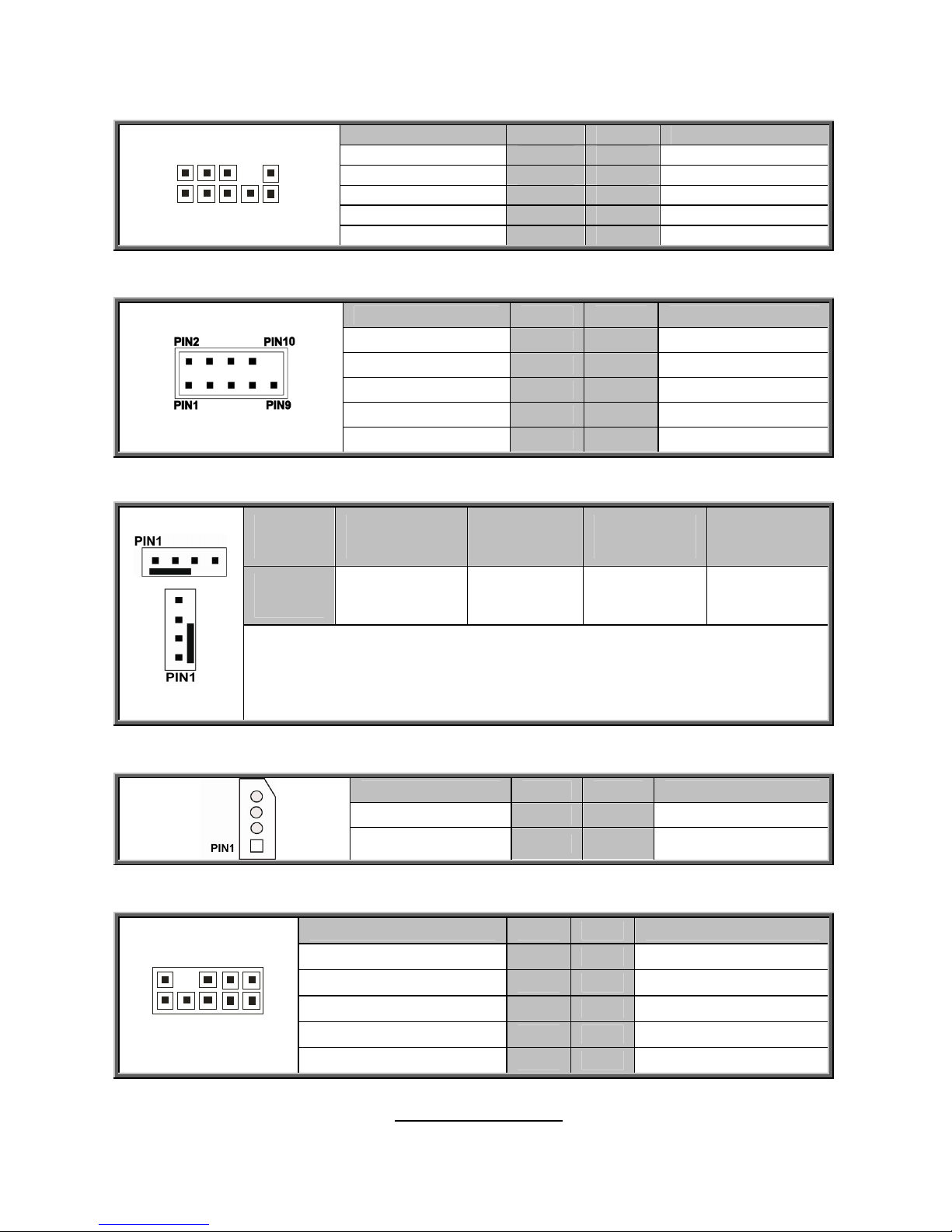

1

0

9

2

1

TDI

9 10 GND

J8: COM2 Connector

Signal Pin Pin Signal

DCD 1 2 DSR

RXD 3 4 RTS

TXD 5 6 CTS

DTR 7 8 RI

GND 9 10 NC

J9/J10/J14/J15/J21/J22/J23/J24/J25/J55: 4-Pin FAN Connectors

Pin 1 2 3 4

Signal GND +12V TACH PWM

Use this header to connect the cooling fan to your motherboard to keep the

system stable and reliable.

CPU0 Fan : J55 CPU2 Fan : J10 CPU1 Fan : J9 CPU3 Fan : J14

J18: IPMB Connector

Signal Pin Pin Signal

IPMB DATA 1 2 GND

IPMB CLK 3 4 NC

J66: SAS Fault LED

Signal Pin Pin Signal

LED_SAS_FAULT-0 1 2 LED_SAS_FAULT-1

LED_SAS_FAULT-2 3 4 LED_SAS_FAULT-3

LED_SAS_FAULT-4 5 6 LED_SAS_FAULT-5

KEY 7 8 LED_SAS_FAULT-7

1

092

1

LED_SAS_FAULT-6

9 10 GND

Page 23

http://www.tyan.com

23

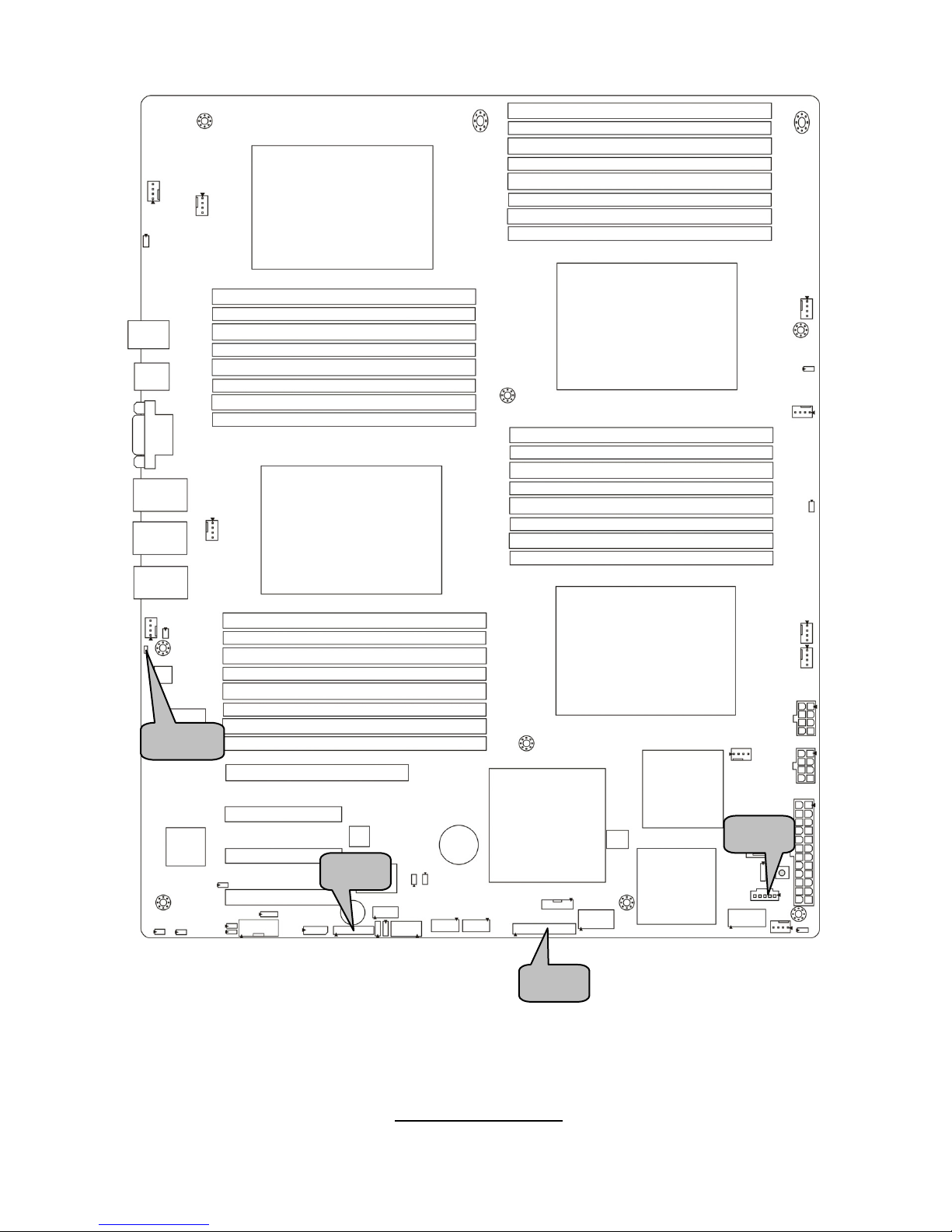

J64

J88

J89

LED1

Page 24

http://www.tyan.com

24

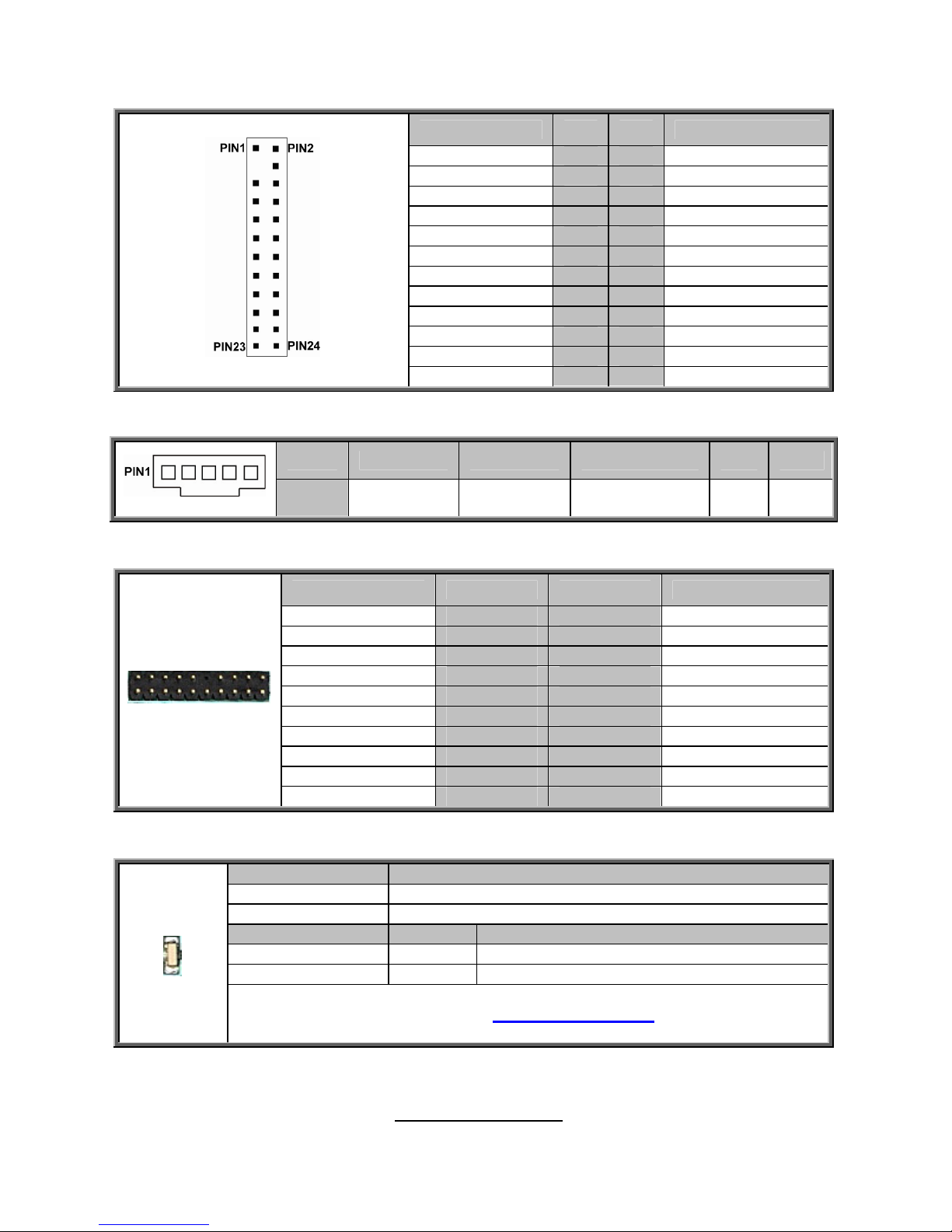

J64: Front Panel Connector

Signal Pin Pin Signal

PWR_LED+ 1 2 FP_PWR

KEY 3 4 IDLED+

Power LED - 5 6 IDLED-

HD LED+ 7 8 WARN_LEDHD LED - 9 10 PSU_ALERT-

Power SW 11 12 LAN1_LED+

GND 13 14 LAN1_LED-

Reset SW 15 16 SDA

GND 17 18 SCL

ID SW 19 20 INTRUDER_L

TEMP Sensor 21 22 LAN2_LED+

NMI

23 24 LAN2_LED-

J88: PSMI Connector

Pin 1 2 3 4 5

Signal SMB_SCLK SMB_SDAT SMB_ALERT_L GND VCC3

J89: Fan TACH Connector

Signal Pin Pin Signal

Taco 1 1 2 Taco 6

Taco 2 3 4 Taco 7

Taco 3 5 6 Taco 8

Taco 4 7 8 Taco 9

Taco 5 9 10 Taco 10

GND 11 12 KEY

PWM2 13 14 PWM1

Taco 11 15 16 NC

Taco 12 17 18 NC

NC

19 20 PWM3

LED1: ID LED

Pin Signal

+ P3V3_AUX

- ID_SW_L

State Color Description

On Blue System identified

Off Off System not identified

+

_

NOTE: IPMI can activate ID LED from remote site.

Please visit the TYAN Web Site at http://www.tyan.com

to download the latest

AST2050 Software Configuration Guide for IPMI settings.

Page 25

http://www.tyan.com

25

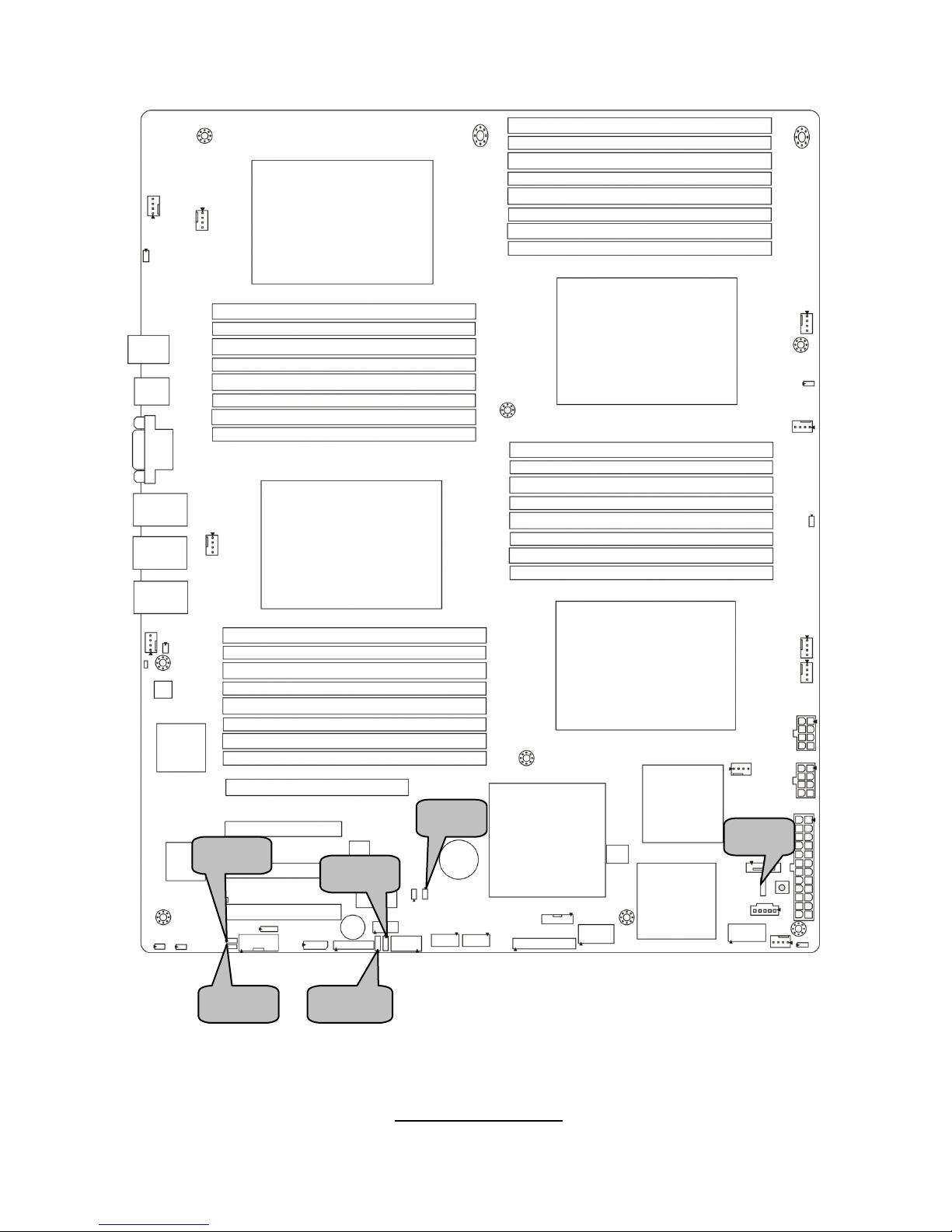

JP11

JP12

JP10

JP8

JP7

JP13

Page 26

http://www.tyan.com

26

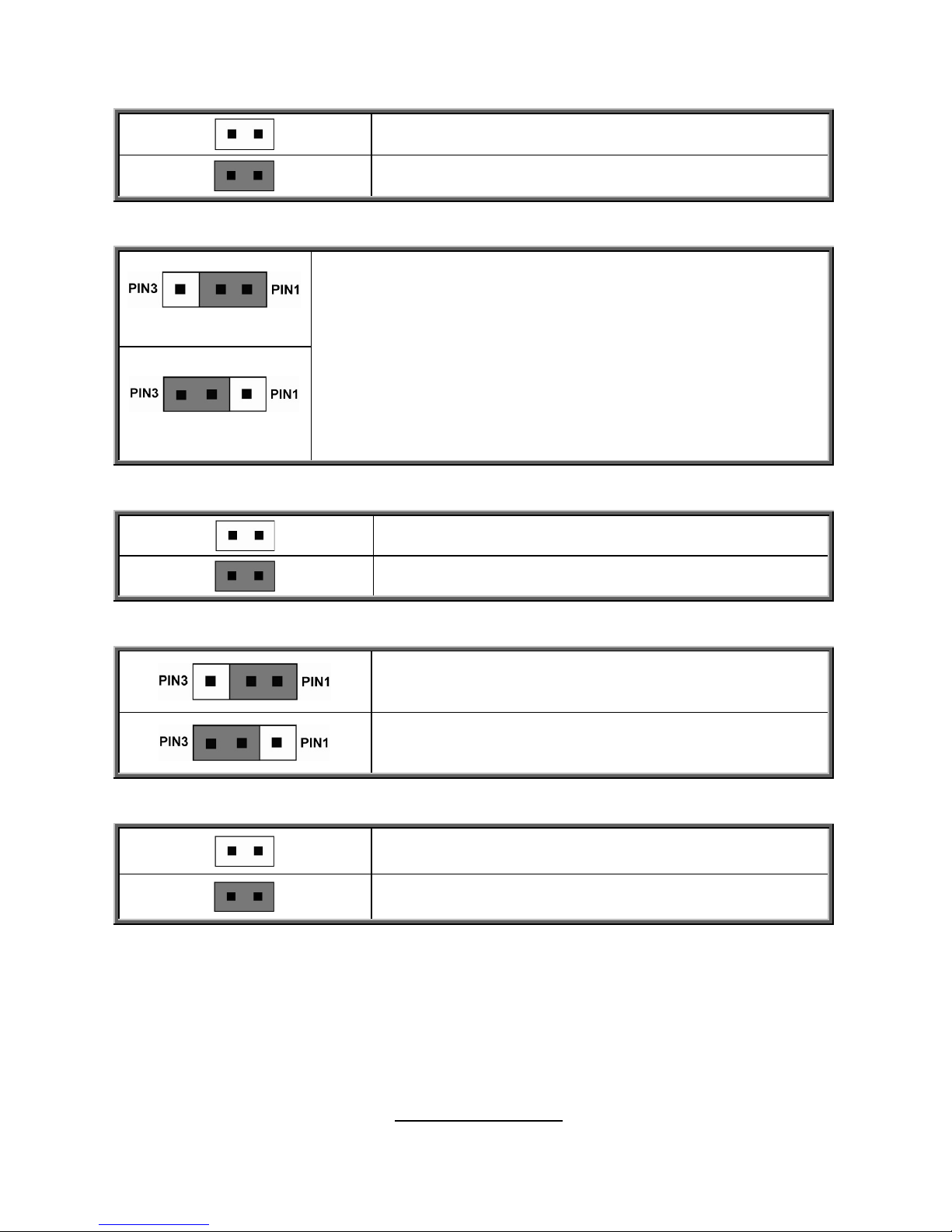

JP7: PCI-E x8/x16 Select Jumper

Open: PCI-E x16 (slot #4) (Default)

Closed: PCI-E x8 (slot #4) + PCI-E x8 (slot #3)

JP8: Clear CMOS Jumper

Normal (Default)

Clear CMOS

You can reset CMOS by using this jumper if you have forgotten your

system/setup password or need to clear BIOS setting.

1. Power off system and disconnect both power connectors from

the motherboard.

2. Put jumper cap back to Pin_1 and Pin_2 (default setting).

3. Use jumper cap to close Pin_2 and Pin_3 for seconds to Clear

CMOS.

4. Reconnect power & power on system.

JP10: BMC Disable Jumper

Open: Normal (Default)

Closed: BMC Disable

JP11/JP12: COM2 Switch Jumper

Pin 1-2 Closed: SIO to COM2 (Default)

Pin 2-3 Closed: BMC UART2 to COM2

JP13: TPM Disable Jumper

Open: Enable TPM (Default)

Closed: Disable TPM

Page 27

http://www.tyan.com

27

JP15

JP14 JP16

JP19

JP24

USB1 USB2

Page 28

http://www.tyan.com

28

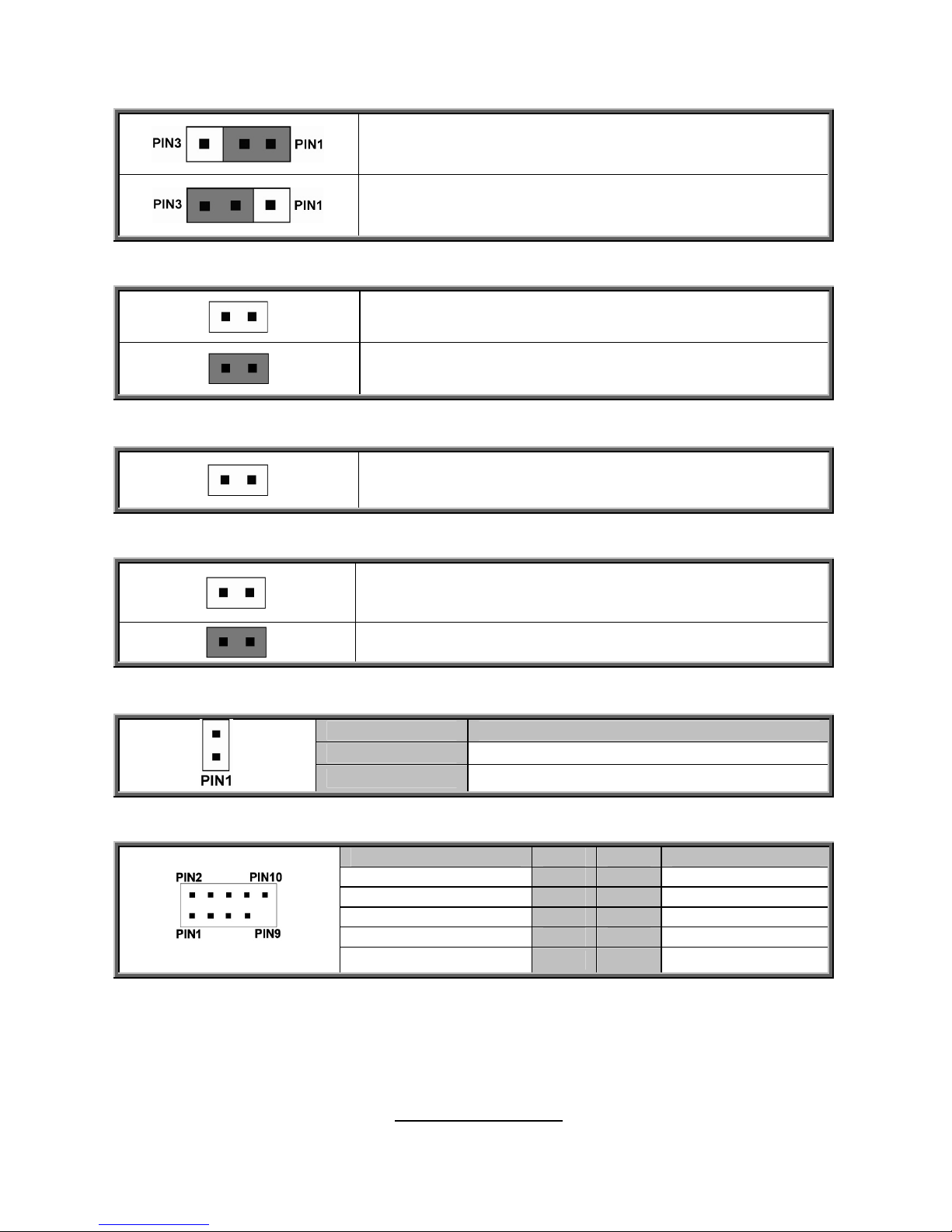

JP14: COM Power Select Jumper

Pin 1-2 Closed: VCC (Default)

Pin 2-3 Closed: V5SB

JP15: WDT Trigger NMI Jumper

Open: WDT Reset System (Default)

Closed: WDT Trigger NMI

JP16: Chassis Intrusion Header

Use this header to trigger the system chassis intrusion alarm.

JP19: VGA Disable Jumper

Open: Enable VGA (Default)

Closed: Disable VGA

JP24: LAN3 LED Header

Pin Signal

1 LAN3 LED+

2 LAN3 LED-

USB1/USB2: USB Front Panel Connector

Signal Pin Pin Signal

VCC 1 2 VCC

USB0- 3 4 USB1USB0+ 5 6 USB1+

GND 7 8 GND

KEY

9 10 NC

Page 29

http://www.tyan.com

29

JP26

JP27

JP25

JP22

JP21

Page 30

http://www.tyan.com

30

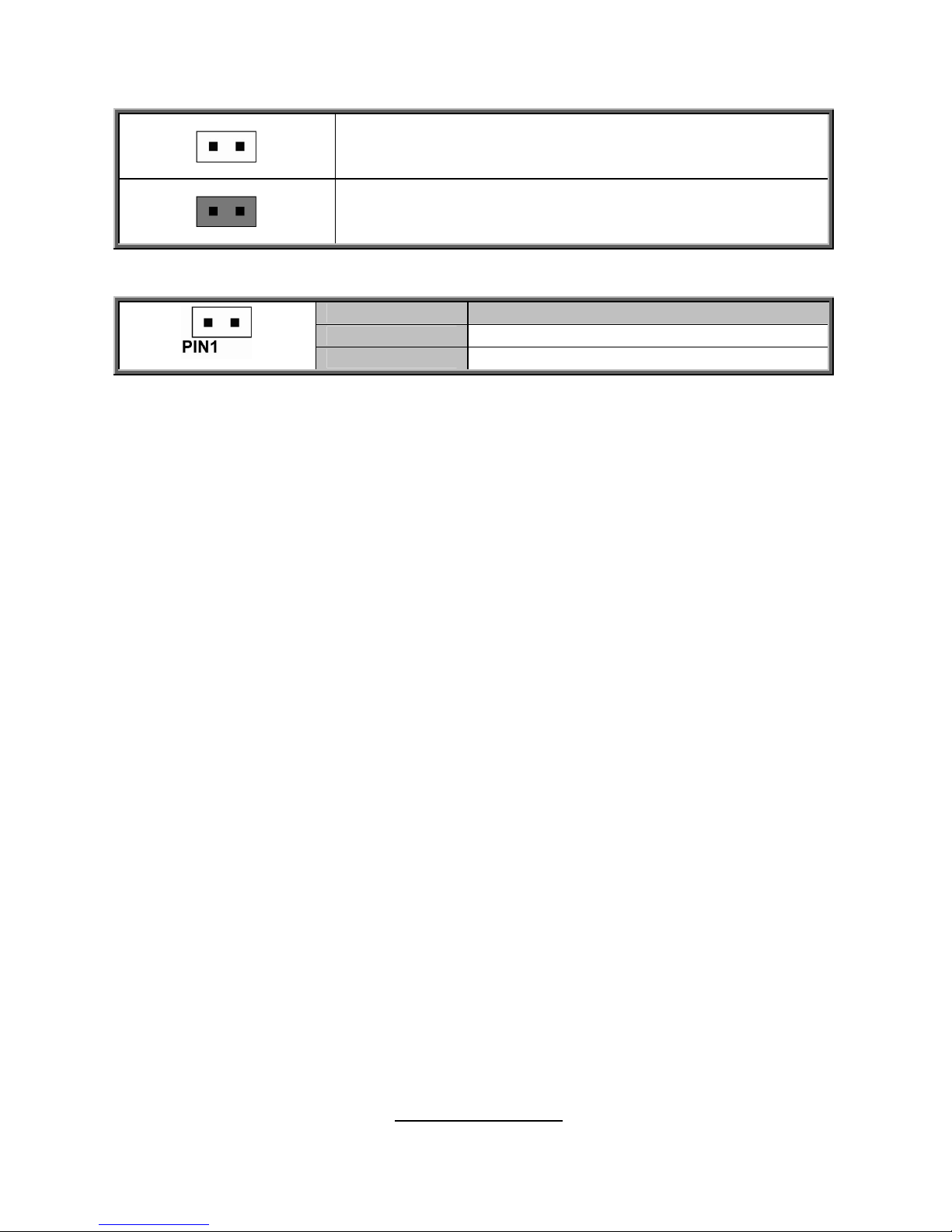

JP21/JP22/JP25/JP26: DDR3 VDDIO Voltage Select Jumper

Open: Support regular 1.5V DDR3 memory (Default)

Closed: Support for Low Voltage 1.35V DDR3 memory

JP27: ID LED Connector

Pin Signal

1 ID LED+

2 GND

Page 31

http://www.tyan.com

31

2.5 Installing the Processor and Heat sink

The S8812 supported AMD® class of processors are listed on Page 10. Check our website at

http://www.tyan.com for latest processor support.

NOTE: MiTAC is not liable for damage as a result of operating an unsupported

configuration.

Processor Installation (G34 1944-pin Socket)

Follow the steps below to install the processors and heat sinks.

Please note that the illustrations are based on a G34 1944-pin Socket which may be look

exactly like the motherboard you purchased. Therefore, the illustrations should be held for your

reference only.

1. Locate the CPU socket.

2. Pull the CPU lever slightly away from the socket and then push it to a fully open position.

Page 32

http://www.tyan.com

32

3. Lift the socket cover to a fully open position.

4. Take off the CPU protection cap.

5. Place the CPU in the CPU socket.

Page 33

http://www.tyan.com

33

6. Close the socket cover and press the CPU socket lever down to lock the CPU in place.

7. Repeat the same procedures to install the other CPUs.

Heat sink Installation

After installing the processor, you should proceed to install the heat sink. The CPU heat sink

will ensure that the processor do not overheat and continue to operate at maximum

performance for as long as you own them. The overheated processor is dangerous to the

motherboard.

For the safest method of installation and information on choosing the appropriate heat sink,

using heat sinks validated by AMD®. Please refer to the AMD® website:

http://www.amd.com

The following diagram illustrates how to install heat sink onto the CPU of S8812.

8. Place the heat sink on top of the CPU and secure it to the motherboard with 2 screws.

9. Connect the heat sink Fan cable to the CPU0 FAN connector J55.

10. Repeat the same procedures to install the other heat sinks (CPU1 Fan: J9, CPU2 Fan:

J10, CPU3 Fan: J14).

Page 34

http://www.tyan.com

34

2.6 Thermal Interface Material

There are two types of thermal

interface materials designed for

use with the processors.

The most common material

comes as a small pad attached

to the heat sink at the time of

purchase. There should be a

protective cover over the

material. Take care not to touch

this material.

Simply remove the protective

cover and place the heat sink on

the processor.

The second type of interface

material is usually packaged

separately. It is commonly

referred to as ‘thermal

compound’. Simply apply a thin

layer on to the CPU lid (applying

too much will actually reduce the

cooling).

NOTE: Always check with the manufacturer of the heat sink & processor to ensure that

the thermal interface material is compatible with the processor and meets the

manufacturer’s warranty requirements.

Page 35

http://www.tyan.com

35

2.7 Tips on Installing Motherboard in Chassis

Before installing your motherboard, make sure your chassis has the necessary motherboard

support studs installed. These studs are usually metal and are gold in color. Usually, the

chassis manufacturer will pre-install the support studs. If you are unsure of stud placement,

simply lay the motherboard inside the chassis and align the screw holes of the motherboard to

the studs inside the case. If there are any studs missing, you will know right away since the

motherboard will not be able to be securely installed.

Page 36

http://www.tyan.com

36

Some chassis include plastic studs instead of metal. Although the plastic studs are usable,

MiTAC recommends using metal studs with screws that will fasten the motherboard more

securely in place.

Below is a chart detailing what the most common motherboard studs look like and how they

should be installed.

Page 37

http://www.tyan.com

37

2.8 Lights on the Motherboard

1. Memory Error LED

When a DIMM exists on the DIMM slot and it works normally, the LED which relative to this slot

is off. The purpose of the red LED is that it shows which DIMM is failed among many DIMMs

when we can not find out in a short time.

2. Blue Error LED / Green LED

The action of the blue LED is to show the work status of the motherboard in S5 Mode (standby

State). The blue LED will light because the S5 power has been supplied in S5 Mode. It will blink

slowly when the MB works normally in S5 Mode. If it does not blink, it shows that the MB has

died in S5 Mode.

Green LED (Still): Initializing BMC/Being updated BMC firmware

Green LED (Blink): Monitoring hardware health

Page 38

http://www.tyan.com

38

2.9 Installing the Memory

Before installing memory, ensure that the memory you have is compatible with the

motherboard and processor. Check the TYAN Web site at http://www.tyan.com

for details of

the type of memory recommended for your motherboard.

The following diagram shows common types of DDR3 memory modules.

Supports up to 256GB total of U/RDDR3 and LV RDDR3 at 800,1066 or 1333MHz

speeds

All installed memory will automatically be detected and no jumpers or settings need

changing

All memory must be of the same type and density

Always populate the memory starting from P0_DIMMA1 first

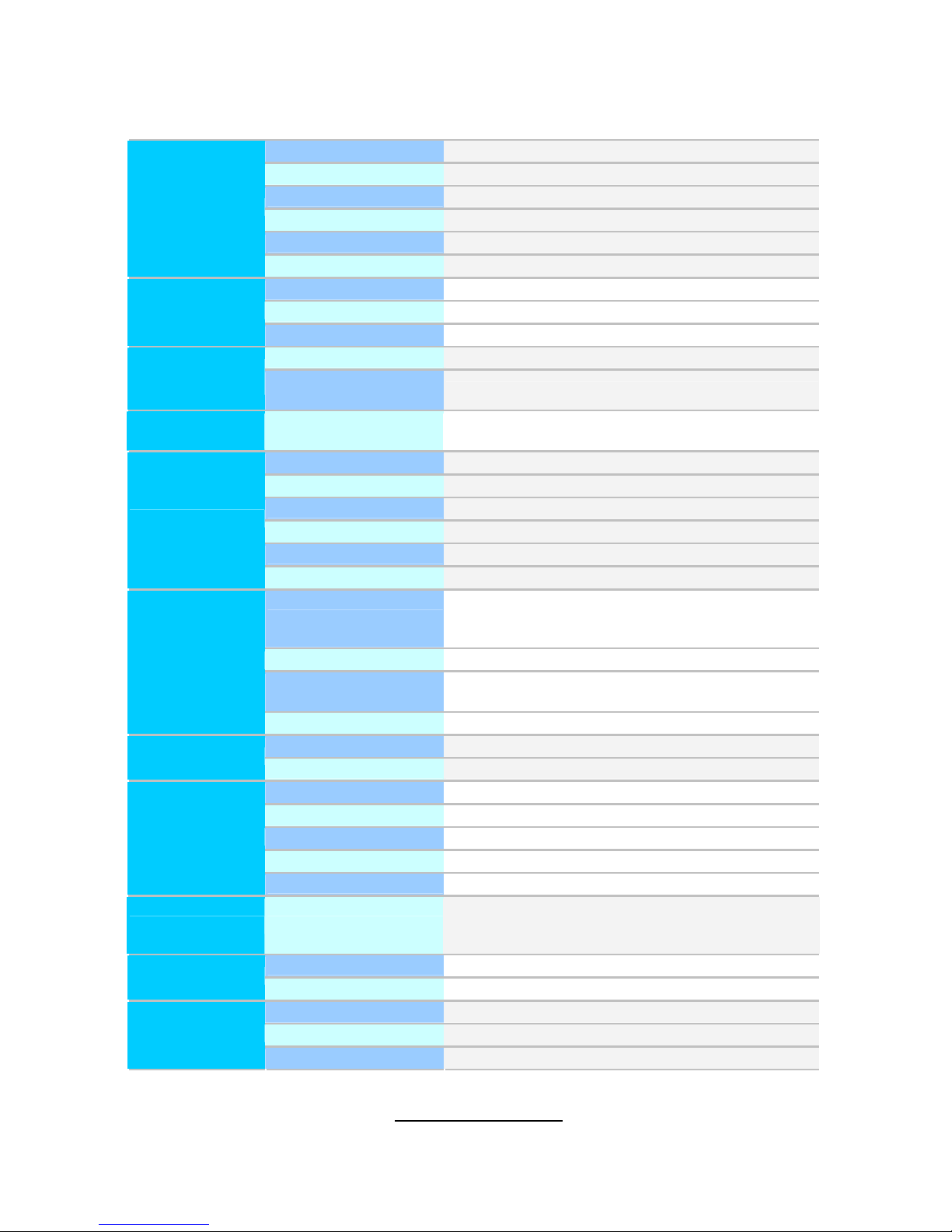

Recommended Memory Population Table

Single CPU

Installed

(CPU0 only)

Dual CPU

installed

(CPU0 and CPU1)

Dual CPU

installed

(CPU0 and CPU3)

Quantity of

memory installed

11112248 8 16 8 16

P0_DIMM(1)D0 √ √ √

P0_DIMM(2)D1 √ √ √ √ √ √ √ √

P0_DIMM(3)C0 √ √ √

P0_DIMM(4)C1 √ √ √ √ √ √ √ √

P0_DIMM(5)B0 √ √ √

P0_DIMM(6)B1 √ √ √ √ √ √ √ √

P0_DIMM(7)A0 √ √ √

P0_DIMM(8)A1 √ √ √ √ √ √ √ √

P1_DIMM(9)D0 √

P1_DIMM(10)D1 √ √

P1_DIMM(11)C0 √

Page 39

http://www.tyan.com

39

Single CPU

Installed

(CPU0 only)

Dual CPU

installed

(CPU0 and CPU1)

Dual CPU

installed

(CPU0 and CPU3)

Quantity of

memory installed

11112248 8 16 8 16

P1_DIMM(12)C1 √ √

P1_DIMM(13)B0 √

P1_DIMM(14)B1 √ √

P1_DIMM(15)A0 √

P1_DIMM(16)A1 √ √

P2_DIMM(17)D0

P2_DIMM(18)D1

P2_DIMM(19)C0

P2_DIMM(20)C1

P2_DIMM(21)B0

P2_DIMM(22)B1

P2_DIMM(23)A0

P2_DIMM(24)A1

P3_DIMM(25)D0 √

P3_DIMM(26)D1 √ √

P3_DIMM(27)C0 √

P3_DIMM(28)C1 √ √

P3_DIMM(29)B0 √

P3_DIMM(30)B1 √ √

P3_DIMM(31)A0 √

P3_DIMM(32)A1 √ √

NOTE:

1. √ indicates a populated DIMM slot.

2. Pair DIMM module configuration for Max performance.

3. We do not suggest or support any other memory configurations.

Page 40

http://www.tyan.com

40

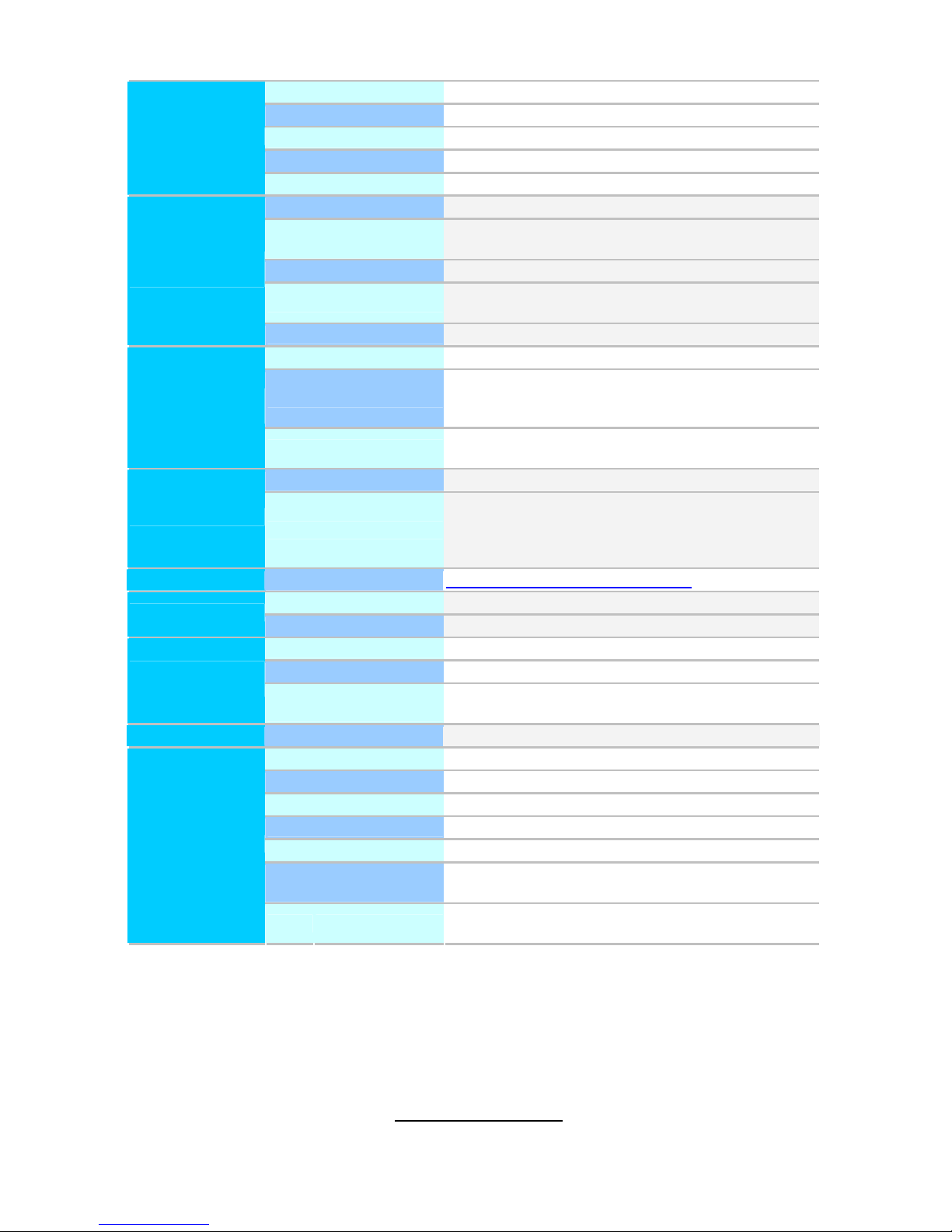

Triple CPU

installed

(CPU0, CPU1 and CPU3)

Quad CPU

installed

(CPU0, CPU1, CPU2 and CPU3)

Quantity of

memory installed

12 24 16 32

P0_DIMM(1)D0 √ √

P0_DIMM(2)D1 √ √ √ √

P0_DIMM(3)C0 √ √

P0_DIMM(4)C1 √ √ √ √

P0_DIMM(5)B0 √ √

P0_DIMM(6)B1 √ √ √ √

P0_DIMM(7)A0 √ √

P0_DIMM(8)A1 √ √ √ √

P1_DIMM(9)D0 √ √

P1_DIMM(10)D1 √ √ √ √

P1_DIMM(11)C0 √ √

P1_DIMM(12)C1 √ √ √ √

P1_DIMM(13)B0 √ √

P1_DIMM(14)B1 √ √ √ √

P1_DIMM(15)A0 √ √

P1_DIMM(16)A1 √ √ √ √

P2_DIMM(17)D0 √

P2_DIMM(18)D1 √ √

P2_DIMM(19)C0 √

P2_DIMM(20)C1 √ √

P2_DIMM(21)B0 √

P2_DIMM(22)B1 √ √

P2_DIMM(23)A0 √

P2_DIMM(24)A1 √ √

P3_DIMM(25)D0 √ √

P3_DIMM(26)D1 √ √ √ √

P3_DIMM(27)C0 √ √

P3_DIMM(28)C1 √ √ √ √

Page 41

http://www.tyan.com

41

Triple CPU

installed

(CPU0, CPU1 and CPU3)

Quad CPU

installed

(CPU0, CPU1, CPU2 and CPU3)

P3_DIMM(29)B0 √ √

P3_DIMM(30)B1 √ √ √ √

P3_DIMM(31)A0 √ √

P3_DIMM(32)A1 √ √ √ √

NOTE:

1. √ indicates a populated DIMM slot.

2. Pair DIMM module configuration for Max performance.

3. We do not suggest or support any other memory configurations.

U-DIMM Module Support

DDR3 Speed/Voltage

DDR3 Rank

Configuration

1.35v 1.5v

DIMM0

(A0, B0,

C0, D0)

DIMM1

(A1, B1,

C1, D1)

800MHz 800MHz

SR and

DR

800MHz 800MHz

SR and

DR

SR and

DR

1066MHz 1066MHz

SR and

DR

1066MHz 1066MHz

SR and

DR

SR and

DR

n/a 1333MHz

SR and

DR

n/a 1333MHz

SR and

DR

SR and

DR

Notes:

UDIMM can support up to 4GB sized DIMM’s

Maximum of 8GB per channel

SR and DR UDDR3 module support only

SR and DR 1.35v Memory MAX speed of 1066MHz in a dual channel configuration

SR and DR 1.5v Memory MAX speed of 1333MHz in a dual channel configuration

Page 42

http://www.tyan.com

42

R-DIMM Module Support

DDR3 Speed/Voltage DDR3 Rank Configuration

1.35v 1.5v

DIMM0 (A0,

B0, C0, D0)

DIMM1 (A1,

B1, C1, D1)

800MHz 800MHz n/a SR and DR

800MHz 800MHz n/a QR

800MHz 800MHz

SR, DR and

QR

SR, DR and

QR

1066MHz 1066MHz n/a SR and DR

1066MHz 1066MHz n/a QR

1066MHz 1066MHz SR and DR SR and DR

n/a 1066MHz QR

SR, DR and

QR

n/a 1066MHz

SR, DR and

QR

QR

n/a 1333MHz n/a SR and DR

n/a 1333MHz n/a QR

n/a 1333MHz SR and DR SR and DR

Notes:

RDIMM can support up to 16GB sized DIMM’s

SR and DR Memory has a MAX amount of 16GB per channel

SR and DR 1.35v Memory MAX speed of 1066MHz in a dual channel configuration

SR and DR 1.5v Memory MAX speed of 1333MHz in a dual channel configuration

QR Memory has a MAX amount of 32GB per channel

QR 1.35v Memory MAX speed of 800MHz in a dual channel configuration

QR 1.5v Memory MAX speed of 1066MHz in a dual channel configuration

Page 43

http://www.tyan.com

43

Page 44

http://www.tyan.com

44

Memory Installation Procedure

Unplug the power supply before adding or removing DIMM modules or

any other system components, Failure to do so may cause severe

damage to both the motherboard and the components.

1. Unlock a DIMM socket by Press the retaining clip outwardly in the following illustration.

2. Align the memory module with the socket, such that the DIMM NOTCH matches the KEY

SLOT on the socket.

3. Hold the DIMM by both of its ends. Insert the module vertically into the socket. Apply force

to both ends of the DIMM simultaneously until the retaining clip pop up into place. And the

DIMM cannot be pushed in any further to ensure proper sitting of the DIMM。

KEY SLOT

Unlocked

retaining clip

Unlocked

retaining

clip

DIMM NOTCH

Page 45

http://www.tyan.com

45

2.10 Attaching Drive Cables

Attaching Serial ATA Cables

The S8812 is equipped with 1 Serial ATA (SATA) channel. There is no need to set

Master/Slave jumpers on SATA drives. If you are in need of SATA/SAS cables or power

adapters please contact your place of purchase.

The following pictures illustrate how to connect an SATA drive.

1. SATA drive cable connection

2. SATA drive power connection

3. SATA cable motherboard connector

4. SATA drive power adapter

Page 46

http://www.tyan.com

46

2.11 Installing Add-In Cards

Before installing add-in cards, it’s helpful to know if they are fully compatible with your

motherboard. For this reason, we’ve provided the diagrams below, showing the slots that may

appear on your motherboard.

PCI-E Gen. 2 x 16 slot (x16 signal)

PCI-E x8 slot (x8 signal)

Simply find the appropriate slot for your add-in card and insert the card firmly. Do not force any

add-in cards into any slots if they do not seat in place. It is better to try another slot or return the

faulty card rather than damaging both the motherboard and the add-in card.

TIP: It’s a good practice to install add-in cards in a staggered manner rather than making them

directly adjacent to each other. Doing so allows air to circulate within the chassis more easily,

thus improving cooling for all installed devices.

NOTE: You must always unplug the power connector to the motherboard before

performing system hardware changes to avoid damaging the board or expansion

device.

Page 47

http://www.tyan.com

47

2.12 Connecting External Devices

Connecting external devices to the motherboard is an easy task. The motherboard supports a

number of different interfaces through connecting peripherals. See the following diagrams for

the details.

NOTE:

1. Peripheral devices can be plugged straight into any of these ports but software

may be required to complete the installation.

2. LAN3 is connected to the BMC AST2050 IPMI solution.

Onboard LAN LED Color Definition

The two onboard Ethernet ports have green and yellow LEDs to indicate LAN status. The chart

below illustrates the different LED states.

10/100/1000 Mbps LAN Link/Activity LED Scheme

Left LED Right LED

Link Green Off

10 Mbps

Active Blinking Green Off

Link Green Green

100 Mbps

Active Blinking Green Green

Link Green Yellow

1000 Mbps

Active Blinking Green Yellow

No Link Off Off

2 X USB ports

VGA Port

LAN2 (Intel 82576EB)

KB/MS

COM Port

LAN3

(Intel82574)

Share with

IPMI

LAN1

(Intel 82576EB)

Page 48

http://www.tyan.com

48

2.13 Installing the Power Supply

There are three power connectors on your S8812. It is required that you have an EPS12V

power supply which has one 24-pin and two 8-pin connectors.

24-pin (PWR1)

Signal Pin Pin Signal

+3.3V 1 13 +3.3V

+3.3V 2 14 -12V

GND 3 15 GND

+5V 4 16 PS_ON

GND 5 17 GND

+5V 6 18 GND

GND 7 19 GND

Power OK 8 20 RES

5VSB 9 21 +5V

+12V 10 22 +5V

+12V 11 23 +5V

+3.3V 12 24 GND

8-pin (PWR2, PWR3)

Signal Pin Pin Signal

GND 1 5 +12V

GND 2 6 +12V

GND 3 7 +12V

GND 4 8 +12V

NOTE: Please be aware that ATX 2.x, ATX12V and ATXGES power supplies may

not

be compatible with the board and can damage the motherboard and/or

CPU(s).

Applying power to the board:

Connect the EPS12V 8-pin power connectors. For general usage, both PW2 and PW3

are for CPU loading. For light load usage, processors like the AMD CPU HE models,

only one 8-pin connector will be required. For heavy load usage, processors like the

AMD CPU SE models, both 8-pin power connectors will be required.

Connect the EPS/12V 24-pin power connector.

Connect power cable to power supply and power outlet.

NOTE: You must unplug the power supply before plugging the power cables to

motherboard connectors.

Page 49

http://www.tyan.com

49

2.14 Finishing Up

Congratulations on making it this far! You have finished setting up the hardware

aspect of your computer. Before closing up your chassis, make sure that all cables

and wires are connected properly, especially IDE cables and most importantly,

jumpers. You may have difficulty powering on your system if the motherboard

jumpers are not set correctly.

In the rare circumstance that you have experienced difficulty, you can find help by

asking your vendor for assistance. If they are not available for assistance, please

find setup information and documentation online at our website or by calling your

vendor’s support line.

Page 50

http://www.tyan.com

50

NOTE

Page 51

http://www.tyan.com

51

Chapter 3: About the Barebones Chassis

Features

3.1.1 System Front View

The front bezel

LED control panel

Power Button

Reset Button

NMI Button

ID LED

LAN2 LED

LAN1 LED

HDD LED

Warning LED

Power LED

ID Button

USB Ports

3 * 5.25 inch device bays

Hot-swap HDD Bays

Page 52

http://www.tyan.com

52

3.1.2 System Rear View

3.1.3 LED Definitions

Front Panel

LED State Description

Power LED Green Power on

ID LED Blue ID LED

Green Link LAN1/LAN2

Activity

Green (Blinking) Activity

HDD LED Amber (Blinking) Activity

Green Normal Status

Warning LED

Red

System Failed.fan, voltage,

thermal Failed.

ID LED

LED State Color Description

On Blue System identified

ID LED

Off Off System not identified

NOTE:

Press ID button when the system is on, then the ID LED will illuminate

and the system is identified by a blue light. Users from remote site could also

activate ID LED by interfacing with the IPMI. For further details on the IPMI

software, please visit http://www.tyan.com

for the latest AST2050 user guide.

Expansion slots

PSU1/2/3

USB Ports

VGA and COM Ports

Thumb Screw

for MB Tray

LAN3(L)/LAN2(M)/LAN1(R)

Thumb Screw

for top cover

KB/ MS

I

2 3

Page 53

http://www.tyan.com

53

HDD LED

State

Activity LED Status LED Description

On Off Drive present,no activity

Green (Blinking)

Off Drive present,with activity

Off

Red

HDD Fail

Blink

Red

(Blinking 4 Hz)

Identify

Blink

Red

(Blinking 1 Hz)

Rebuild

Rear I/O

The three onboard Ethernet ports have green and yellow LEDs to indicate LAN

status. The rear I/O LED Please refer to Chapter 2.10 Connecting External

Devices Onboard LAN LED Color Definition on page 45.

Page 54

http://www.tyan.com

54

3.1.4 Internal View

①

(8) HDD trays with (2) M1237F48 SAS backplane

(Pre-installed)

②

M1018 Front Panel Board and (3) 5.25 inch media bays

③

System Fan Module

(6) 12038 hot-swap fan as pre-installed

④

System Main Board

⑤

(4) Expansion slots

①

⑤

②

③

④

Page 55

http://www.tyan.com

55

Chapter 4: Setting Up

4.0.1 Before you Begin

This chapter explains how to install the CPUs, CPU heatsinks, memory

modules, and hard drives. Instructions on inserting add on cards are also

given.

4.0.2 Work Area

Make sure you have a stable, clean working environment. Dust and dirt

can get into components and cause malfunctions. Use containers to keep

small components separated. Putting all small components in separate

containers prevents them from becoming lost. Adequate lighting and

proper tools can prevent you from accidentally damaging the internal

components.

4.0.3 Tools

The following procedures require only a few tools, including the following:

A cross head (Phillips) screwdriver

A grounding strap or an anti-static pad

Most of the electrical and mechanical connections can be disconnected

with your hands. It is recommended that you do not use pliers to remove

connectors as it may damage the soft metal or plastic parts of the

connectors.

Page 56

http://www.tyan.com

56

4.0.4 Precautions

Components and electronic circuit boards can be damaged by

discharges of static electricity. Working on a system that is connected to

a power supply can be extremely dangerous. Follow the guidelines

below to avoid damage to FT48-B8812 or injury to yourself.

Ground yourself properly before removing the top cover of the

system. Unplug the power from the power supply and then touch

a safely grounded object to release static charge (i.e. power

supply case). If available, wear a grounded wrist strap.

Alternatively, discharge any static electricity by touching the bare

metal chassis of the unit case, or the bare metal body of any

other grounded appliance.

Avoid touching motherboard components, IC chips, connectors,

memory modules, and leads.

The motherboard is pre-installed in the system. When removing

the motherboard, always place it on a grounded anti-static

surface until you are ready to reinstall it.

Hold electronic circuit boards by the edges only. Do not touch

the components on the board unless it is necessary to do so. Do

not flex or stress circuit boards.

Leave all components inside the static-proof packaging that they

ship with until they are ready for installation.

After replacing optional devices, make sure all screws, springs,

or other small parts are in place and are not left loose inside the

case. Metallic parts or metal flakes can cause electrical shorts.

NOTE:

1. All connectors are keyed to only attach one way.

2. All use the correct screw size as indicated in the procedures.

Page 57

http://www.tyan.com

57

4.1 Installing Motherboard Components

This section describes how to install components on to the motherboard, including

CPUs, memory modules and add on cards.

4.1.1 Removing the Chassis Cover

Follow these instructions to remove FT48-B8812 chassis cover.

1. Press the button on the front top cover and slide the cover off.

2. Unscrew the thumb screw securing the rear cover then slide the

rear top cover off.

Page 58

http://www.tyan.com

58

4.1.2 Installing the PCI-E Cards

FT48-B8812 has four PCIe expansion slots. Slot 1 and Slot 2 have x8 PCIe

signals. Slot 3 and Slot 4 share a single x16 PCIe signal. If cards are

installed on both Slot 3 and Slot 4, then both slots can only expect a

maximum of x8 PCIe signal strength. If only a single care is installed on Slot

4, then a maximum of x16 PCIe signal strength can be expected.

For detail information, please see follow PCI-E Configuration table.

Follow these instructions was the example to install expansion GPU cards.

1. Locate the expansion slot on the motherboard, unscrew the slot cover

from the slot you want to use.

2. Take the slot covers out from the slot, insert the card into the slot and

secure it with the screws you removed from the bracket.

PCI‐E Slot3 (x8) PCI‐E Slot4 (x16) JP7

Card InnerSignal Card InnerSignal Status

Install X8 X X8 X

NotInstall n/a X X16 Open

NotInstall X8 X X8 Close

Page 59

http://www.tyan.com

59

3. Connect the cables between the expansion card and the power

distribution board. The (CCBL-1100) power cable was designed to

support up to 2x GPU cards (each w/8-pin power connector per GPU

card).

Page 60

http://www.tyan.com

60

4.2 Installing Hard Drives

The FT48-B8812 supports up to eight 3.5” hard drives. Follow these

instructions to install a hard drive.

1. Press the locking lever latch and pull the locking lever open.

2. Slide the HDD tray out.

Page 61

http://www.tyan.com

61

3. Place a 3.5" hard drive into the HDD tray.

4. Turn over the HDD unit and secure the HDD using 4 HDD screws.

5. Reinsert the HDD tray into the chassis and press the locking lever to

secure the tray.

Page 62

http://www.tyan.com

62

4.3 Installing DVD Drive

1. prepare DVD kit material

Prepare DVD kit material as below:

1 DVD Rail-L P/N: 340746600049

2 DVD Rail-R P/N: 340746600048

3 DVD Rail Screw P/N: 452761200003 * 8pcs

4 SATA Cable P/N: 422T38700001

5 DVD PWR cable P/N: 422790900011

2. Install the DVD Rail-L and Rail-R to the DVD device and secure with the

packaged screws.

3. Open the chassis front bezel, and determine the location to insert the

DVD device.

Page 63

http://www.tyan.com

63

4. Remove the DVD cover BKT.

Page 64

http://www.tyan.com

64

5. Install the DVD device into location 1.

6. DVD rail-R needs to be locked with the chassis hook.

Page 65

http://www.tyan.com

65

7. Remove the J36 connector cable from the HDD BP-1.

8. Insert the SATA cable on the motherboard J50 and route the cable along

the side of the chassis.

Page 66

http://www.tyan.com

66

9. Connect the SATA cable to the DVD device.

10. Connect the DVD power Y cable to the HDD PWR cable.

11. Insert DVD power cable Y to the HDD BP-1 connector J36.

Page 67

http://www.tyan.com

67

12. Connect the DVD PWR cable to the DVD device.

13. The DVD device has been successfully installed.

Page 68

http://www.tyan.com

68

4.4 Rack Mounting

After installing the necessary components ,the FT48-B8812 can be

mounted in a rack using the supplied rack mounting kit.

Rack mounting kit

Rail with Bracket x 2

Mounting Ears x 2

Screw Sack x 1

4.4.1 Installing the Server in a Rack

Follow these instructions to mount the FT48-B8812 into an industry standard

19” rack.

NOTE:

Before mounting FT48-B8812 in a rack, be sure that all internal

components have been installed and the unit has been fully tested. Maintenance

can be performed on the unit while in a rack but it is preferable to install the device

in a fully operational condition.

Screw Sack Including:

A: Bracket for M6 screw--10 pcs

B: M 6--10 pcs

C: M 4-L5--16 pcs

A B C

Installing the Inner Rails to the Unit

Step1: Screw the mounting ears to each side of the FT48-B8812 as shown

using three M4-L5 screws (C) from the supplied screws kit.

Page 69

http://www.tyan.com

69

Step2: Draw out the inner rails from each rail assembly. Install the inner

sliding rails to each side of the server using five M4-L5 screws (C).

Installing the Outer Rails to the Unit

Step1: Adjust the outer rails to fit the length of the rack. The sliding brackets have

long slits to allow them to be fixed to the other part of the rails in various positions.

Step2: Secure the outer rails to the

Server rack using 4 M6 screws (B) for

each side. Secure the mounting

brackets from the outside, not the

inside of the server rack.

Page 70

http://www.tyan.com

70

Rack Mounting the Server

Step1: Draw out the middle rail to the latch position.

Step2: Lift the unit and then insert the inner slide rails into the middle rails.

Step3: Press the latch key and push the whole system in.

Page 71

http://www.tyan.com

71

Step4: Secure the mounting ears of the unit to the rack using two small

brackets (A) and M6 screws (B).

4.5 Opening the Chassis Front Bezel

1. Insert the front bezel key (packed in a bag in the accessory box) and

rotate the key 90 degrees counterclockwise to unlock the front bezel.

2. Open the front bezel.

Page 72

http://www.tyan.com

72

NOTE

Page 73

http://www.tyan.com

73

Chapter 5: Replacing Pre-Installed

Components

5.1 Introduction

This chapter explains how to replace the pre-installed components in the FT48

B8812 server chassis, including the Motherboard, four small boards (M1018

Front Panel Board, M1237-F48 HDD Backplane, M1801-F77 Fan Board,

M7025-PDB Power Distribution Board) System fan, ODD drive, PSU and etc.

5.2 Disassembly Flowchart

The following flowchart outlines the disassembly procedure.

Page 74

http://www.tyan.com

74

5.3 Removing the Cover

Before replacing any parts you must remove the chassis cover.

Follow Chapter 2.1.1 to remove the cover of the FT48-B8812.

5.4 Replacing the System Fan and Fan Board

Follow these instructions to replace the cooling fans in your

system.

1. Refer to Chapter 1.6.7 “internal view” and locate the cooling fans.

2. Unplug all 6 installed system fans in the fan module.

3. Unscrew the fan holder and lift it up from the chassis.

Page 75

http://www.tyan.com

75

4. Unplug the cables connected to the fan board and turn over the fan

holder.

5. Remove the 10 screws and disassemble the fan board from the fan

holder.

6. Renew the fan board if it is necessary and assemble the fan module

back follow the steps above in reverse.

Page 76

http://www.tyan.com

76

5.4.1 M1801F77 Fan Board Features

J4

J1

J8

PW1

PW2

J5

J2

J6

J3

PW3

Page 77

http://www.tyan.com

77

5.4.2 M1801F77 Fan Board Connector Pin Definition

J1~J6: 4 pin Fan connector

Definition Pin Pin Definition

GND 1 2 VDD+12V

CLOCK 3 4 PWM

PW1/PW2/PW3: Big 4 pin Power connector

Definition Pin Pin Definition

VDD+12V 1 2 GND

GND 3 4 VCC+5V

J8: fan control header

Definition Pin Pin Definition

TACH1 1 2 TACH6

TACH2 3 4 NC

TACH3 5 6 NC

TACH4 7 8 NC

TACH5 9 10 NC

GND 11 12 KEY

PWM1 13 14 PWM2

NC 15 16 NC

NC 17 18 NC

NC 19 20 PWM3

Page 78

http://www.tyan.com

78

5.5 Replacing the M1237F48 SATA/SAS Backplane

To replace the SAS/SATA backplane, you need to remove all the fans and the

fan holder first. Refer to the steps given in Chapter 3.4, then, follow these

instructions to replace SATA/SAS backplane.

1. Remove the HDD trays corresponding to the SAS/SATA backplane to

be replaced from the FT48-B8812.

2. Disconnect all cables from the M1237F48 to be replaced and remove

the screw securing it.

3. Renew the backplane and secure it following the steps above in reverse.

Page 79

http://www.tyan.com

79

5.5.1 M1237F48 SATA/SAS Backplane Features

Front view:

Rear view:

Page 80

http://www.tyan.com

80

5.5.2 M1237 F48 Connector Pin Definition

J6: burning FW header

Definition Pin Pin Definition

CPLD_JTAG_TCK 1 2 GND

CPLD_JTAG_TDO 3 4 VDD_3P3_RUN

CPLD_JTAG_TMS 5 6 dummy pin

dummy pin 7 8 key pin

CPLD_JTAG_TDI 9 10 GND

J18: SGPIO header

Definition Pin Pin Definition

FPIO_SCL 1 2 SDATAIN

FPIO_SDA 3 4 SDATAOUT

GND 5 6 SAS_SIO_END_A

Key pin 7 8 SAS_SIO_CLK_A

dummy pin 9 10 HD_ERR_LED

J35/J36: Big 4 pin Power connector

Definition Pin Pin Definition

VDD+12V 1 2 GND

GND 3 4 VCC+5V

Page 81

http://www.tyan.com

81

5.6 Replacing the Front Panel Control Board

Follow these instructions to replace the M1018 LED control

board.

1. Disconnect the power cable and data cable from M1018.

2. Push aside the latch and slide the LED control board unit out of the

chassis.

Page 82

http://www.tyan.com

82

3. Remove three screws securing the LED control board to the bracket.

4. Lift the LED control board free from the chassis. After replacement,

insert the unit into the chassis following the above procedures in

reverse.

5.6.1 M1018 LED Control Board Features

1

Power Switch

8

Warning LED

2

Reset Switch

9

Power LED

3

NMI Switch

10

ID Switch

4

ID LED

11

USB 2

5

LAN2 LED

12

USB 1

6

LAN1 LED

J2

2x14 pin header

7

HDD LED

J1

2x5 pin USB header

Page 83

http://www.tyan.com

83

5.6.2 M1018 LED Control Board Connector Pin Definition

J1: 2x5 pin USB header

Definition Pin Pin Definition

VCC+5V

1 2

VCC+5V

USB1-

3 4

USB0-

USB1+

5 6

USB0+

GND

7 8

GND

Key

9 10

GND

J2: 2x14 pin header

Definition Pin Pin Definition

HD_LED+

1 2

HD_LED-

RESET+

3 4

RESET-

Power LED+

5 6

Power LED-

WLED+

7 8

WLED-

Reserved

9 10

Reserved

EXT INT

11 12

Voltages

V5SB

13 14

Reserved

Power SW+

15 16

Power SW-

LAN1 LED+

17 18

LAN1 LED+

LAN2 LED+

19 20

LAN2 LED+

Reserved

21 22

Reserved

ID LED-IN+

23 24

ID LED-IN-

ID SW+

25 26

ID SW-

KEY

27 28

Reserved

Page 84

http://www.tyan.com

84

5.7 Replacing Power Supply and M7025 PDB

5.7.1 Replacing Power Supply

You need to disconnect the power supply first before replacing the

power distribution board.

1. Press the blue button on the power supply and slide it out.

2. After replacement new ones, insert the power supply back into the

chassis.

Page 85

http://www.tyan.com

85

5.7.2 Replacing M7025 Power Distribution Board

1. Disconnect the cables on the M7025 PDB and motherboard.

Power cables, SAS cable, front panel cable:

2. Thumb the screw securing the motherboard tray, pull down the bar.

3. Slide the motherboard tray out carefully.

Page 86

http://www.tyan.com

86

4. Disconnect the cables on the PDB.

5. Locate the 12 screws on the PDB, then you can renew the board and fix

it back follow the steps above in reverse.

Page 87

http://www.tyan.com

87

5.7.3 M7025 Power Distribution Board Features

PW17

PW6

J6: Power Supply

Connector

J5: Power Supply

Connector

J4: Power Supply

Connector

J9

PW7

PW16

J2

PW12

PW13

PW15

PW14

J10

Page 88

http://www.tyan.com

88

5.7.4 M7025 PDB Connector Pin Definition

PW6/7: 2×4 Pin Power Connector

Definition Pin Pin Definition

GND 1 2 GND

GND 3 4 GND

+12V 5 6 +12V

+12V 7 8 +12V

PW12/13/14/15: 2×2 Pin Power Connector for Fan board / HDD

backplane

Definition Pin Pin Definition

GND 1 2 GND

+12V

3 4 +5V

PW16: 2×10 Pin Power Connector

Definition Pin Pin Definition

GND 1 2 GND

GND 3 4 GND

GND 5 6 GND

GND 7 8 GND

GND 9 10 GND

+12V 11 12 +12V

+12V 13 14 +12V

+12V 15 16 +12V

+12V 17 18 +12V

+12V 19 20 +12V

Page 89

http://www.tyan.com

89

PW17: 2×12 Pin Power Connector

Definition Pin Pin Definition

+3.3V 1 2 +3.3V

GND 3 4 +5V

GND 5 6 +5V

GND 7 8 PWR Good

5VSB 9 10 +12V

+12V 11 12 +3.3V

+3.3V 13 14 -12V

GND 15 16 PS_ON

GND 17 18 GND

GND 19 20 Reset

+5V 21 22 +5V

+5V 23 24 GND

J2: PSMI Header

Pin Definition

1 SMBCLK

2 SMBDAT

3 SMB_ALERT

4 GND

5 VDD3.3V

J9: Power Redundancy Select Jumper

Pin Definition

1

GND

2

5VSB

3

RSVD

Note: Connect pin1-pin2 for PSU 2+0 or 2+1;

Connect pin2-pin3 for PSU 1+0 or 1+1;

Default: connect pin1-pin2 for PSU 2+0 or 2+1.

J10: PS_ON Enable

Pin Definition

1 RSVD

2 PSON_EN

3 GND

Note: Default status: Connect J10 pin1-pin2

Page 90

http://www.tyan.com

90

5.8 Replacing S8812 System Board

1. Followed Chapter 3.7.2 to set the mother board tray free.

2. Unscrew the motherboard and carefully lift it up from the MB tray.

3. Renew the board and fix it back follow the steps above in reverse.

Page 91

http://www.tyan.com

91

Chapter 6: BIOS Setup

6.1 About the BIOS

The BIOS is the basic input/output system, the firmware on the motherboard that

enables your hardware to interface with your software. The BIOS determines what a

computer can do without accessing programs from a disk. The BIOS contains all the

code required to control the keyboard, display screen, disk drives, serial

communications, and a number of miscellaneous functions. This chapter describes

the various BIOS settings that can be used to configure your system.

The BIOS section of this manual is subject to change without notice and is provided

for reference purposes only. The settings and configurations of the BIOS are current

at the time of print and are subject to change, and therefore may not match exactly

what is displayed on screen.

This section describes the BIOS setup program. The setup program lets you modify

basic configuration settings. The settings are then stored in a dedicated,

battery-backed memory (called NVRAM) that retains the information even when the

power is turned off.

To start the BIOS setup utility:

1. Turn on or reboot your system.

2. Press <Del> during POST (F4 on remote console) to start the BIOS setup

utility.

6.1.1 Setup Basics

The table below shows how to navigate in the setup program using the keyboard.

Key Function

Tab Moves from one selection to the next

Left/Right Arrow Keys Changes from one menu to the next

Up/Down Arrow Keys Moves between selections

Enter Opens highlighted section

PgUp/PgDn Keys Changes settings.

Page 92

http://www.tyan.com

92

6.1.2 Getting Help

Pressing [F1] will display a small help window that describes the appropriate

keys to use and the possible selections for the highlighted item. To exit the Help Window, press

[ESC] or the [F1] key again.

6.1.3 In Case of Problems

If you have trouble booting your computer after making and saving the changes with the BIOS

setup program, you can restart the computer by holding the power button down until the

computer shuts off (usually within 4 seconds); resetting by pressing CTRL-ALT-DEL; or

clearing the CMOS.

The best advice is to only alter settings that you thoroughly understand. In particular, do not

change settings in the Chipset section unless you are absolutely sure of what you are doing.

The Chipset defaults have been carefully chosen either by MiTAC or your system manufacturer

for best performance and reliability. Even a seemingly small change to the Chipset setup

options may cause the system to become unstable or unusable.

6.1.4 Setup Variations

Not all systems have the same BIOS setup layout or options. While the basic look and function

of the BIOS setup remains more or less the same for most systems, the appearance of your

Setup screen may differ from the charts shown in this section. Each system design and chipset

combination requires a custom configuration. In addition, the final appearance of the Setup

program depends on the system designer. Your system designer may decide that certain items

should not be available for user configuration, and remove them from the BIOS setup program.

NOTE: The following pages provide the details of BIOS menu. Please be noticed that the BIOS

menu are continually changing due to the BIOS updating. The BIOS menu provided are the

most updated ones when this manual is written. Please visit TYAN’s website at

http://www.tyan.com

for the information of BIOS updating.

Page 93

http://www.tyan.com

93

6.2 Main Menu

In this section, you can alter general features such as the date and time.

Note that the options listed below are for options that can directly be changed within the Main

Setup screen.

AMIBIOS

It displays the core number, date of BIOS build and the version of BIOS.

Processor

This displays the CPU information.

System Memory

This displays the amount of system memory present on the system.

System Time / Date setup

System Time: Adjusts the system clock.

HH (24 hours format): MM (Minutes): SS (Seconds)

System Date: Adjusts the system date.

MM (Months): DD (Days): YYYY (Years)

Page 94

http://www.tyan.com

94

6.3 Advanced Menu

This section facilitates configuring advanced BIOS options for your system.

CPU Configuration

Configure CPU.

IDE Configuration

Configure the IDE devices.

Super IO Configuration

Configure the Super IO.

ACPI Configuration

Selection for Advanced ACPI Configuration.

Event Log Configuration

Configuration the Event Log.

Hardware Health Configuration

Configure / monitor the Hardware Health.

Page 95

http://www.tyan.com

95

IPMI 2.0 Configuration

IPMI configuration including server monitoring and event log.

MPS Configuration

Configure the Multi-Processor Table.

PCI Express Configuration

Configure PCI Express Support.

Remote Access Configuration

Configure Remote Access.

USB Configuration

Configure the USB support.

Hyper Transport Configuration

Configure the HT link.

Page 96

http://www.tyan.com

96

6.3.1 Advanced CPU Configuration

This section allows you to fine-tune the processor options.

Page 97

http://www.tyan.com

97

GART Error Reporting

This option should remain disabled for normal operation. The driver developer may

enable it for the purpose of testing.

Disabled / Enabled

Microcode Update

Enable/disable the CPU Microcode update.

Disabled / Enabled

Secure Virtual Machine Mode

Enable/disable the CPU secure virtual machine mode (SVM).

Disabled / Enabled

PowerNow

Enable/disable the generation of ACPI_PPC, _PSS, and _PCT objects.

Disabled / Enabled

PowerCap

The option can decide the highest performance P-state in OS.

P-state 0 / P-state 1 / P-state 2 / P-state 3 / P-state 4

Page 98

http://www.tyan.com

98

ACPI SRAT Table

Enable or disable the building of ACPI SRAT Table.

Disabled / Enabled

CPU DownCore Mode

Disable some Core in the CPU. Cold reset is needed after changing option.

Auto Mode / Maximum Core Level / No Leveling / 2 Cores / 4 Cores / 6

Cores / 8 Cores / 10 Cores / 12 Cores

CPU Prefetching

Enable or disable CPU prefetching.

Disabled / Enabled

IO Prefetching

Enable or disable IO prefetching.

Disabled / Enabled

Probe Filter

Initialization mode for Probe Filter.

Auto / Disable / MP Mode

HTC

HW Thermal Control.

Disabled / Enabled

HTC P-State

HTC P-State limit.

P-state 0 / P-state 1 / P-state 2 / P-state 3 / P-state 4

HTC Temperature

HTC limit Temperature, range from 52 to 115.

70

NOTE: HTC P-State & HTC Temperature is hidden and will be appear when HTC

is set to [Enabled].

Page 99

http://www.tyan.com

99

6.3.2 Advanced IDE Configuration

Onboard PCI IDE Controller

Disabled: disables the integrated IDE Controller

Primary: enables only the Primary IDE Controller

Secondary: enables only the Secondary IDE Controller

Both: enables both IDE Controller

Disabled / Primary / Secondary / Both

Hard Disk Write Protect

Disable/Enable device write protection. This will be effective only if device is

accessed through BIOS.

Disabled / Enabled

IDE Detect Time Out (Sec)

Select the time out value for detecting ATA/ATAPI device(s).

0~35 (at 5 interval)

ATA(PI) 80Pin Cable Detection

Select the mechanism for detecting 80Pin ATA(PI) Cable.

Host & Device / Host / Device

Page 100

http://www.tyan.com

100

6.3.2.1 Primary IDE Master Sub-Menu

Type

Selects the type of device connected to the system.

Auto / Disabled

LBA/Large Mode

Auto: Enabled LBA Mode if the device supports it and the device is not already

formatted with LBA Mode disabled.

Disabled: Disabled LBA Mode.

Auto / Disabled

Block (Multi-Sector Transfer)

Disabled: The Data transfer from and to the device occurs one sector at a time.

Auto: The Data transfer from and to the device occurs multiple sectors at a time

if the device supports it.

Auto / Disabled

Loading...

Loading...