TxPORT 1558A Reference Manual

Introduction

1558A

APS

®

TRANSPORT

Reference Manual

34-00228

2nd Edition

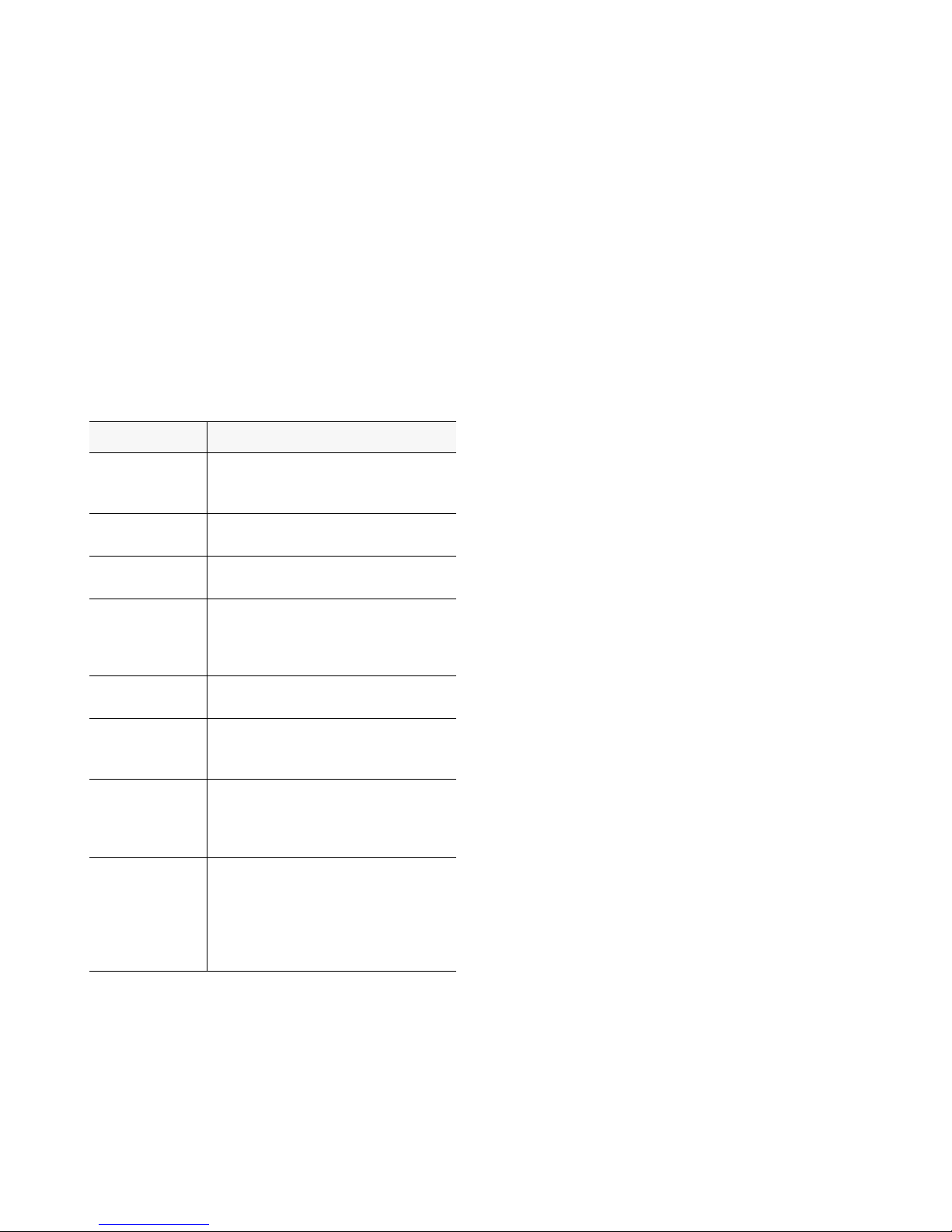

Table of Contents

General

Introduction ................................................................ 1-1

Design Highlights ....................................................... 1-1

Specifications ............................................................. 1-1

FCC Requirements....................................................... 1-2

Canadian Emissions Requirements ............................. 1-3

Warranty ..................................................................... 1-3

Ordering Numbers ...................................................... 1-4

TxPORT Customer Service ........................................ 1-4

Installation

Introduction ................................................................ 2-1

Site Preparation .......................................................... 2-1

Unpacking and Inspection .......................................... 2-1

Mounting ................................................................... 2-1

Wiring and Connections .............................................. 2-2

Chassis Ground Connection ................................. 2-2

DC Power Connection ......................................... 2 -2

Alarm Connection ................................................ 2-2

T1 Connection ..................................................... 2- 2

COM Bus Connection .......................................... 2-3

Configuration Modes ................................................... 2-3

Switch Configuration ........................................... 2-3

ROM Configuration ............................................. 2- 4

RAM Configuration ............................................. 2- 5

Manager Configuration ........................................ 2 - 5

Preservice Testing .................................................. ..... 2-5

Path A Preservice Testing .................................... 2-5

Path B Preservice Testing .................................... 2-6

Results .................................................................. 2- 7

End-to-End Pre-Service Testing .......................... 2-7

Bypass Test ................................................................. 2-8

Operation

Introduction ................................................................. 3- 1

Applications ................................................................ 3-1

General Operation ....................................................... 3-1

Revertive and Non-Revertive Switching ............. 3-1

Default Power-Up Path ........................................ 3 -1

Loss of Signal / Loss of Frame ............................ 3-1

Bipolar Violations ................................................ 3-1

CSU Loopbacks ................................................... 3- 2

Forced/Locked Capability ................................... 3-2

APS Switching Time ........................................... 3-3

APS Switching Parameters .................................. 3-3

Line Availability Timer ....................................... 3-4

Status and Performance Information .................... 3-4

Configuration Modes ........................................... 3-4

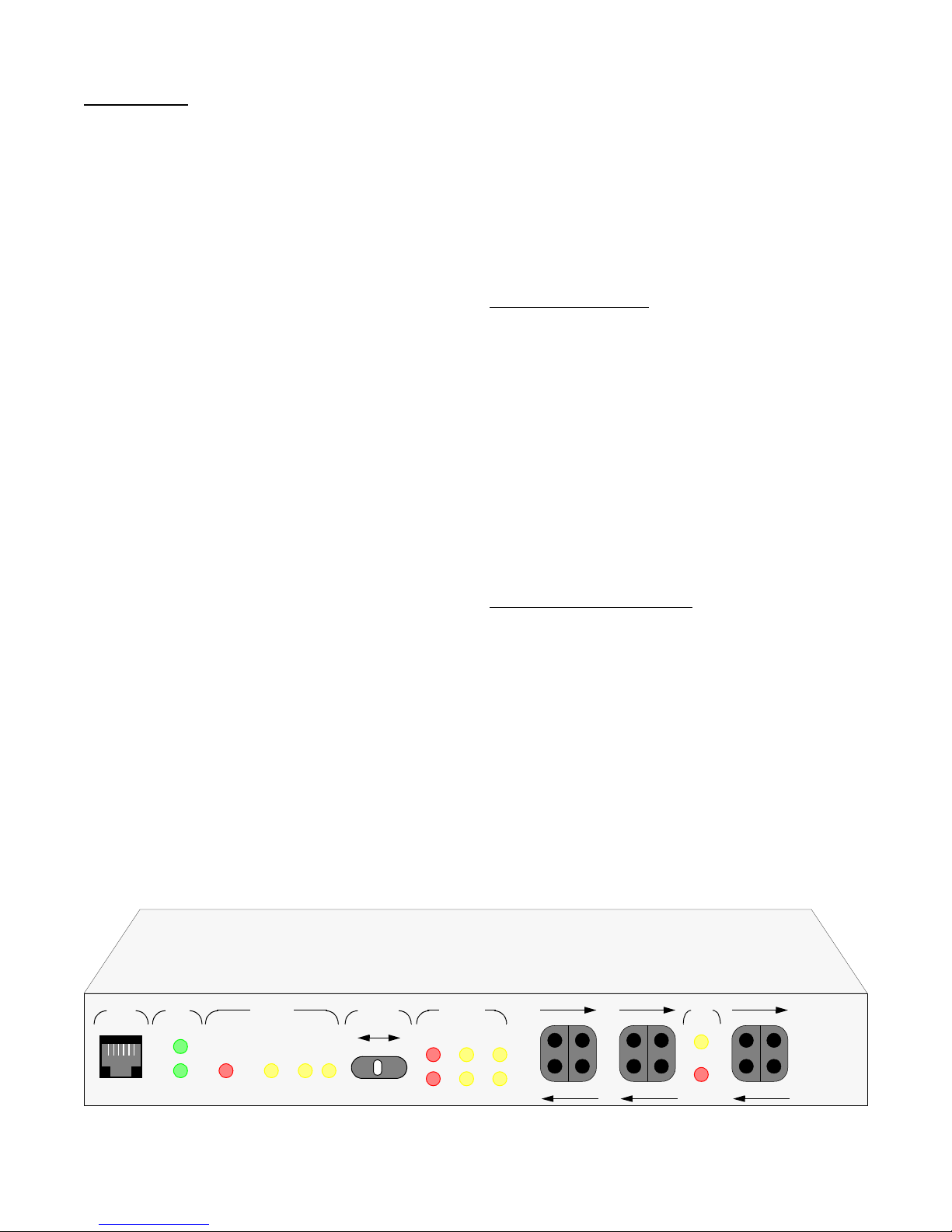

Front Panel Controls and Indicators ........................... 3-4

Supervisory Port .................................................. 3-4

Power Indicators .................................................. 3-5

Bypass Indicator .................................................. 3-5

Locked Indicator .......................... ...... ..... ............. 3-5

Status Indicators .................................................. 3-5

Manual Path Selector Switch ............................... 3-6

Path Status Alarm Indicators ............................... 3-6

Path Status LOS Indicators .................................. 3-6

Path Status Loop Indicators ................................. 3-6

Bantam Test Access Jacks ................................... 3-6

DTE Loop Indicator ............................................ 3-6

DTE Loss of Signal Indicator .............................. 3-6

Rear Panel Connections .............................................. 3-7

COM Bus Connections ........................................ 3-7

Network T1 Connections ..................................... 3-7

DTE T1 Connection ............................................ 3 - 7

Screw Terminal Connections ............................... 3-7

Option Switch Functions ............................................ 3-8

LAPS Operation

Introduction ................................................................. 4 -1

LAPS Installation ....................................................... 4 - 1

Screens and Menus ..................................................... 4-1

Common Screen Elements ................................... 4-1

Cursor Controls .................................................... 4-2

User Log On ........................................................ 4-2

Main Menu Screen ...................................................... 4-2

Circuit List Screens ..................................................... 4-3

Circuits in Alarm Screen ..................................... 4-3

Circuits in Test Screen ......................................... 4-3

Circuit List Screen ............................................... 4-3

Screen Manipulation ............................................ 4-3

Performance Screen ............................................. 4-4

Maintenance Screen .................................................... 4-6

Configuration Screen .................................................. 4-7

Utilities Screens .......................................................... 4-9

Loopback Operations .................................................. 4-10

Near CO Payload Loop ........................................ 4-10

CO Line Loop ...................................................... 4-10

CO Facility Loop ................................................. 4-11

CO Equipment Loop ............................................ 4-12

CPE Payload ....................................................... . 4-12

CPE Line ............................................ ..... ............. 4-12

CSU Loop ............................................................ 4-13

NET Loop ............................................................ 4-13

NPC Payload Loop .............................................. 4-13

BERT Testing ............................................................. 4- 14

Copyright/Liability

Copyright

1996 TxPORT, All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, stored

in a retrieval system, or translated into any language in any form by any means without the written permission of TxPORT.

Reorder # 34-00228

2nd Edition, February 1996

TxPORT shall not be liable for errors contained herein or for incidental or consequential damages in connection with

the furnishing, performance, or use of this material. TxPORT reserves the right to revise this publication from time to

time and make changes in content without obligation to notify any person of such revision changes.

Contents of this publication may be preliminary and/or may be changed at any time without notice and shall not be

regarded as a warranty.

Documentation Disclaimer

TxPOR T mak es no representation or w arranties of an y kind whatsoe v er with respect to the contents her eof and specifically disclaims any implied warranties of merchantability or fitness for any particular purpose.

Acknowledgment

The software used in the SNMP function of this product contains material derived from the following source:

Copyright 1989 by the Regents of the University of California. All rights reserved.

Redistributions in binary form must reproduce the above copyright not ice, this list of conditions, and the fol lowing

disclaimer in the documentation and/or other materials provided with the distribution. All advertising materials

mentioning features or use of this software must display the following acknowledgment:

This product includes software developed by the University of California, Berkeley and its contributors.

Neither the name of the University nor the names of its contributors may be used to endorse or promote products

derived from this software without specific prior written permission.

This software is provided by the regents and contributors ‘as is’ and any express or implied warranties, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose are disclaimed. In no

event shall th e re gents or contribut ors be liable for any dir ect, indir ect, incidental, s pecial, exempla ry , or consequential

damages (including, but not limited to, procurement of substitute goods or services; loss of use, data, or profits; or

business interruption) however caused a nd on any theor y of liability, whether in contract, strict liability, or tort (including negligence or otherwise) arising in any way out of the use of this software, ev en if advised of the possibility of

such damage.

General

1.0 Introduction

The TxPORT 1558A APS (Automatic Protection Switch)

unit provides automatic T1 service restoration from a

degraded or failed T1 facility to a stand by T1 facility. See

the ‘Operation’ chapter for a typical APS application.

Switching from the failed line (Path A or Path B) to the

standby (Path A or Path B) is based upon user definable

switching alarm thresholds (errored seconds, consecutively

severely errored seconds, loss of signal, loss of frame). The

1558A APS is fully compatible with all industry standard

APS equipment that complies with PUB 54017, 1991.

• Redundant Power Configurations (AC or DC)

• Bantam Test Access Jacks

• Complies with AT&T 54017 Automatic Protection

Switching, 1991

• FCC, DOC, UL, and CSA Compliant

1.2 Specifications

T1 Network Interface

Line Rate: 1.544 Mbps

Framing: ESF

Line Code: AMI or B8ZS

1.1 Design Highlights

The APS unit is designed so that it can be configured to support a wide variety of user applications. The key features

and functions are:

• Mission-Critical Automatic Protection Switching from a

Fail or Impaired T1 Facility to a Standby T1 Facility

• D4 or ESF Framing,

• AMI or B8ZS Line Coding

• Integral ESF CSUs (TR 54016 compliant)

• 24 Hour Performance History

• Revertive and Non-revertive Operation

• User -Definable Alarm Switching Thresholds

• Proactive Call-on-Alarm Reporting (requires manager)

• Desk Top or Rack Mount

1558A Automatic Protection Switch for customer premise

DS1 Interface: +1 to -27 dB ALBO, 100 Ω (± 5%)

Connector: RJ48 jack

Overvoltage Primary and Secondary lightning

Protection: fusing for line cross

ESF Mode: Pass/Block Facility Data Link

to/from Network

CPE (Equipment Interface)

Line Rate: 1.544 Mbps

Framing: D4 or ESF

Line Code: AMI or B8ZS

DSX Interface: DSX -1 to -6 dB (ALBO), RJ48

jack, 100 Ω (± 5%), 0 to 655 ft.

Connector: RJ48 jack

SUPV PWR

A

B

STATUS

ABYPASS LOCKED B

SELECT

A

PATH

AUTO

PATH

STATUS

B

ALM LOS LP

A

B

N

E

T

A

RX BRDG

TX BRDG

N

E

T

B

RX BRDG

TX BRDG

DTE

LP

LOS

RX BRDG

TX BRDG

General 1-11558A APS

TxPORT

D

T

1558A

E

ESF Mode: Pass/Block Facility Data Link

!

to/from DTE

TR 62411: T1 interface and CSU specifications

PUB 54016: ESF requirements

Diagnostics

Line Loop: Signal regeneration only (bidirectional)

Payload Loop: Signal regenerated with new frame

synchronization, CRC6, and data.

Loop Activation Industry standard formats

and De-activation: (54016, 62411, T1-403)

Jack Access

Network Side: Bantam jacks Tx, Rx, & Bridging

for Transmit and Receive paths

DTE Side: Bantam jacks Tx, Rx, & Bridging

for Transmit and Receive paths

Alarms

Contacts: Normally Opened (NO) and

Normally Closed (NC)

Rating: 0.6A @ 125 VAC

2.0A @ 30 VDC

UL 1549, Part 2: Electrical

Industry Listings

FCC Registration: FXK USA-22709-XB-N

UL/CSA File Number: LR 62298

1.3 FCC Requirements

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and

if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user is

required to correct the interference at his own expense.

Power

Unit: Dual Inputs (Power A and Power B bus)

Range: -20 to -56 VDC, ≤150 mA, 10 W,

35 BTUs

Mechanical

Mounting: Desk, wall, or rack installation (comes

with 19” rack mount hardware)

Dimensions: 17.25" W, 1.75" H, 12" D

Weight: 5 lbs.

Environmental

Operating Temp: 0° to 50° C(32° to 122°F)

Storage Temp: -20° to 85° C(-4° to 185°F)

Humidity: 95% maximum (non- condensing)

Compatibility

Shielded cables must be used to ensure compliance with the

Class A FCC li mits.

WARNING: Changes or modifications to this

unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the

equipment.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditi ons:

1) This device may not cause harmful interference.

2) This device must accept any interference received,

including interference that may cause undesired operation.

Notice to Users of 1.544 Mb/s Service: The following

instructions are provided to ensure compliance with FCC

Rules, Part 68:

1) All direct connections to T1 lines must be made using

standard plugs and jacks.

PUB 54017: Automatic Protection Switching

Equipment, 1991

2) The following information may be required by the local

telephone company when applying for leased line facilities:

1558A APS1-2 General

Port ID REN / SOC FIC USOC

P/N/12 - 00635 6.0 N 04DU9-BN

04DU9-DN

04DU9-IKN

04DU9-ISN

RJ48C

1.5 Warra nty

TxPORT warrants each unit against defects in material and

workmanship for a period of five years from the date the

unit was shipped to the customer. If the unit malfunctions at

any time during the warranty period, TxPORT will repair, or

at TxPORT’s option, replace the unit free of charge.

3) If the unit appears to be malfunctioning, it should be

disconnected from the telephone lines until you learn

whether the source of trouble is your equipment or the telephone line. If your equipment needs repair, it should not be

reconnected until it is repaired.

4) The unit has been designed to prevent harm to the T1

network. If the telephone company finds that the equipment

is exceeding tolerable parameters, they can temporarily disconnect service. In this case, the telephone company will

give you advance notice, if possible.

5) Under FCC rules, no customer is authorized to repair

this equipment. This restriction applies regardless of

whether the equipment is in or out of warranty.

6) If the telephone company alters their equipment in a

manner that will affect the use of this device, they must give

you advance warning so that you can have the opportunity

for uninterrupted service. You will be advised of your right

to file a complaint with the FCC.

7) The attached affidavit must be completed by the

installer.

8) In the event of equipment malfunction, all repairs

should be performed by our company or an authorized

agent. It is the responsibility of users requiring service to

report the need for service to our company or to one of our

authorized agents.

1.4 Canadian Emissions Requirements

This digital apparatus does not exceed the Class A limits for

radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department

of Communications.

The remedies listed herein are the users sole and exclusive

remedies. TxPORT shall not be liable for any indirect,

direct, incidental or consequential damages. The owner must

return the unit to the factory, shipping prepaid and packaged

to the best commercial standard for electronic equipment.

TxPORT will pay shipping charges for delivery on return.

The customer is responsible for mode and cost of shipment

to TxPORT. This warranty does not apply if the unit has

been damaged by accident, misuse or as a result of service

or modification by othe r than TxPORT personnel.

When returning the unit for warranty work, a Return Material Authorization (RMA) number must be obtained from

customer service at the address/ phone number given at the

end of this chapter. When calling TxPORT to obtain a

Return Material Authorization number or to arrange service,

please have the following information available:

• Model number(s) and serial number(s) for the unit(s).

• Reason for return and symptoms of problem.

• Warranty status (if known).

• Purchase order number to cover charges for out-of-war-

ranty items.

• Name and phone number of person we can contact if we

have questions about the unit(s).

• Mode of shipment required (second day air is the normal

mode of shipment for all returned material unless otherwise specified).

As soon as TxPORT has the above information, the RMA

that must accompany the item(s) returned can be issued.

NOTE: End users should use existing 48 VDC battery

sources or a CSA certified power supply.

Le present appareil numerique n’emet pas de bruits

radioelectriques depassant les limites applicables aux

appareils numeriques (de la class A) prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communication s du Canada .

General 1-31558A APS

1.6 Ordering Numbers

1.7 TxPORT Customer Service

The 1558A is shipped from the factory with the following

standard items:

• The 1558A unit (the part number is F-1558-001A-1111)

• The 1558A reference manual

• 19" rack mount hardware

• Local Access PC software

• One PC to 1558A data interface cable

• AC to DC wall power transformer

• Three 10' RJ48 modular T1 cables

The following is a list of the standard and optional equip-

ment which may also be needed.

Part Number Equipment

F-1558-001A-1111 1558A unit with Dual Integral ESF CSU’s,

-20 to -56 VDC operation or

110 VAC operation.

6-3030-035-1 19" Rack Mount Hardware for 1558A.

Standard with 15 58A unit.

6-3030-036-1 23" Rack Mount Hardware for 1558A.

Ordered as an option to the 1558A.

9-1558A-003-1 PC DOS Local Access software on 3.5”

Disk. Allows the user to access unit performance, status, and configuration in formation and to perform local loop testing.

9-1001-029-2 PC to 1558A data cable, 10 ' DB9 to 6-pin

modular. Standard with 1558A unit.

30-00087 110 VAC to -48 VDC ( 200 mA max.) wall

transformer uni t, 10' po wer c able. Stand ard

with 1558A unit.

9-1001-004- 010 RJ48 8-pin modular 10' cable. Three

cables come standard with the 1558A unit.

Contact the factory for additiona l cable

lengths and types.

F-1559-000-XXXX 1559 APSM Manager. Used for central site

management of one or more co-located

1558A units. Can be ordered as AC or DC

power, one or two inte rna l mo de m s , 19’ or

23’ rack hardware. Contact the factory for

additional information.

Address: TxPORT

127 Jetplex Circle

Madison, Alabama 35758

Telephone: 800-926-0085 or

205-772-3770

Sales /Administration FAX: 205 -772-3388

Manufacturing FAX: 205 -772 - 8280

Customer Service Returns: 800-926-0085, ext. 227

Product Technical Support

Normal Hours - 8 a.m. to 5 p.m. Central, Monday – Friday

Telephone: 800-285-2755 or

205-772-3770

Emergency - Nights / Weekends / Holidays:

Telephone: 800-285-2755

E-Mail (Internet address): support@txport.com

1558A APS1-4 General

Installation

2.0 General

Proper installation of the 1558A unit involves the following

key steps:

• Site Survey and Preparation

• Unpacking and Inspecting Equipment

• Equipment M ounting

• T1, Alarm, and Power Connections

• Setting Equipment Options

• Preservice Testing

The following paragraphs contain information and instruc-

tions to assist the user in preparing the 1558A for operation.

It is recommended that the user sequen tially follow the site

preparation and unit installation steps described.

2.1 Site Preparations

The following site preparations should be performed before

starting installation of the 1558A APS unit. First, determine

the location of 1558A unit and perform the following:

A) Determine the distance from the APS unit to the AC

outlet, or if connecting to a DC external power source, the

distance to this source. The 1558A is shipped from the factory with a 110 VAC to -48 VDC wall transformer (10 ft.

cord). If external DC is being used, insure that 26 gauge

wire is on hand to wire the external DC power source to the

1558A unit. The maximum current draw of the 1558A is

≤80 milliamps at -48 VDC.

B) Determine the distance from the T1 facility demark and

the actual location of the 1558A. After determining distance, verify that the proper cable lengths and types have

been ordered to connect from the T1 demark to the 1558A

unit. The 1558A is shipped with three RJ48 modular T1

cable, 10 feet in length.

1558A DTE DSX receive will operate is 1,400 feet (using

ABAM cable, 26 gauge, shielded wiring).

E) Verify that the T1 line is operating properly before you

attempt to install the 1558A unit. Both of the T1 lines

should be checked for error free operation for at least 1 hour

to insure that they are performing error free.

F) If the unit is going to installed in a 19’ equipment be

rack, verify that there is enough rack space available in the

rack (requires 1.75 inches per 1558A unit). Four pan head

(type 12-24 x 1/2 inch) screws are provided for mounting

the unit. An optional 23” rack mount kit is available for

applications using this size rack.

G) Verify that no external CSUs (channel service units) are

installed at the location where the 1558A is being installed.

NOTE: The 1558A unit provides intern al ESF CSU functions and cannot operate properly if another CSU is also

co-located with the 1558A.

2.2 Unpacking and Inspection

This unit is carefully packaged to prevent damage in shipment. Upon receipt, inspect the shipping container for damage. If the shipping container or cushioning material is

damaged, notify the carrier immediately and make a notation on the delivery receipt that the container was damaged

(if possible, obtain the signature and name of the person

making delivery). Retain the packaging material until the

contents of the shipment have been checked for completeness and the instrument has been checked both mechanically

and electrically.

If the contents of the shipment are incomplete or, if there is

mechanical damage or defect, notify TxPORT. If the shipping container is also damaged, or the cushioning material

shows signs of stress, notify the carrier of the damage as

well as TxPORT. Keep the shipping materials for carrier’s

inspection. TxPORT will arrange for repair or replacement

without waiting for claim settlement.

C) Normally, the provider of the T1 facility will provide

the required LBO setting (trans mit signal level) required for

connection to the T1 facilities. This value should be used

when setting the 1558A LBO transmit values (0, 7.5, 15, or

22 db) in the 1558A unit. If the value cannot be obtained

from the provider, the LBO transmit values for Path A and

Path B should be set to 0 db.

D) Determine the distance between the 1558A unit and the

terminating DTE equipment. This distance will be used

when you set the DSX transmit LBO value for the DTE T1

port on the 1558A unit. The maximum distance that the

2.3 Mounting

If the 1558A is to be installed in an equipment rack, simply

mount the 1558A in the equipment rack using the provided

mounting screws and rack mount adaptors (the 1558A can

be ordered with either 19” or 23” rack mount adaptors). If

the equipment is to be desk top installed, the user may

remove the provided rack mount adaptors and set the unit on

any flat surface. Once the equipment has been physically

located, the following rear panel wiring connections should

be performed.

Installation 2-11558A APS

2.4 Wiring & Connections

There are several wiring connections that must be performed

to install the APS unit. The following paragraphs describe

how to attach the APS unit to the associated T1 lines, power

connections, alarm connections, and COM BUS connections. Figure 2- 1 should be used as a reference for the fol-

lowing paragraphs concerning installation of the 1558A

APS unit.

2.4.1 Chassis Ground Connection

The 1558A unit should be connected to a good earth ground.

To connect ground to the unit, attach a 26 gauge or larger

wire from the rear panel screw terminal labeled ‘GND’ to a

good earth ground.

!

Caution: Voltages in excess of 100 VDC may

be present on the T1 telecommunications lines. Before

connecting the APS unit to telecommunication lines,

insure that the rear panel screw terminal labeled ‘GND’

has been connected to a good earth ground.

2.4.2 DC Power Connections

The rear panel screw terminal labeled ‘-DC’ and ‘RTN’ are

used to connect -20 to -56 VDC to the 1558A. The 1558A

may be wired with redundant power inputs by wiring an

external source to both the PWR A and PWR B -DC/RTN

terminals. To connect power to the APS unit, perform the

following.

PWR A Wiring: Connect an external power source (-20 to

56 VDC) to the rear panel screw terminal labeled PWR A

‘DC’ and ‘RTN’. If using the provided AC to DC wall

power transformer, connect the RED

minal, the BLACK

GREEN

wire to the ‘GND’ terminal.

wire to the ‘-DC’ terminal and the

PWR B Wiring: Connect an external power source (-20 to

56 VDC) to the rear panel s crew terminal labeled PWR B

wire to the ‘RTN’ ter-

‘DC’ and ‘RTN’. If using the provided AC to DC wall

power transformer, connect the RED

minal, the BLACK

GREEN

wire to the ‘GND’ terminal.

wire to the ‘-DC’ terminal and the

wire to the ‘RTN’ ter-

2.4.3 Alarm Connections

The 1558A has alarm contacts provided at the rear panel

screw terminals labeled ‘COMMON’, ‘NC’, and ‘NO’. The

alarm relay is operated when power is present to the 1558A.

To connect the APS alarm relay to an external customer

alarm surveillance system, perform the following:

• Connect a 26gauge wire to the rear panel screw terminal

labeled ‘COMMON’ to the external alarm system.

• Connect a 26gauge wire to the rear panel screw terminal

labeled ‘ALARM NO’ (normally open) or to ‘ALARM

NC (normally closed) to the external alarm system. Note

that the alarm relay is normally operated when power is

connected to the unit.

2.4.4 T1 Connections

All T1 lines are connected to the APS unit using modular 8pin RJ48 cables (three 10' cables come with the unit). Insert

the RJ 48 connectors into the rear panel receptacles labeled

NET A, NET B, and DTE. Connect the other ends of the

cable to the appropriate T1 A and B facility equipment and

to the DTE equipment. The DTE port is not designed for

direct connection to a TELCO T1 facility. The modular pin

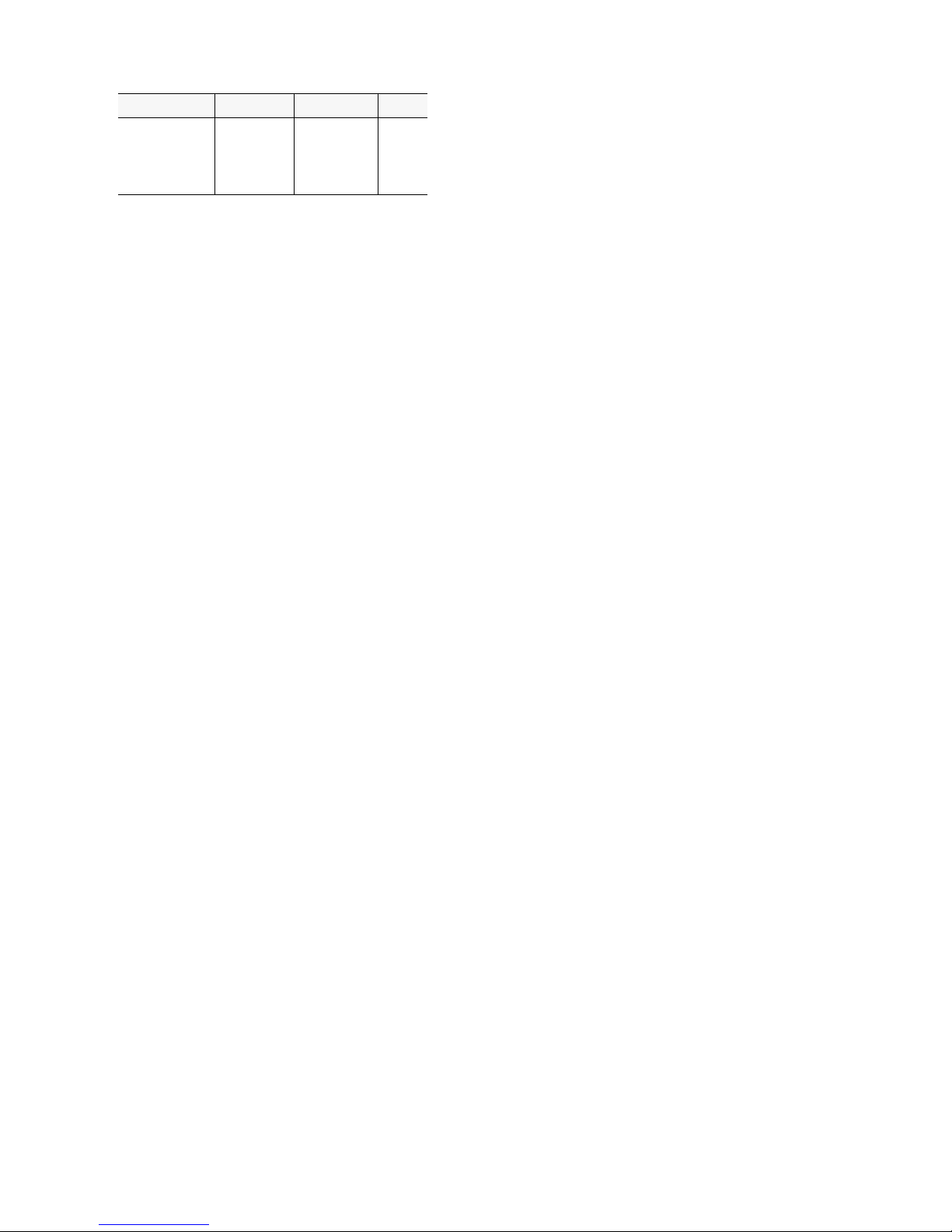

outs and their functions are shown in the following table.

Pin NET A & B, RJ48 DTE RJ48

1 Data In, Tip Data Out, Tip

2 Data In, Ring Data Out, Ring

3 Not Used Not Used

4 Data Out, Tip Data In, Tip

5 Data Out, Ring Data In, Ring

6 Not Used Not Used

7 Not Used Not Used

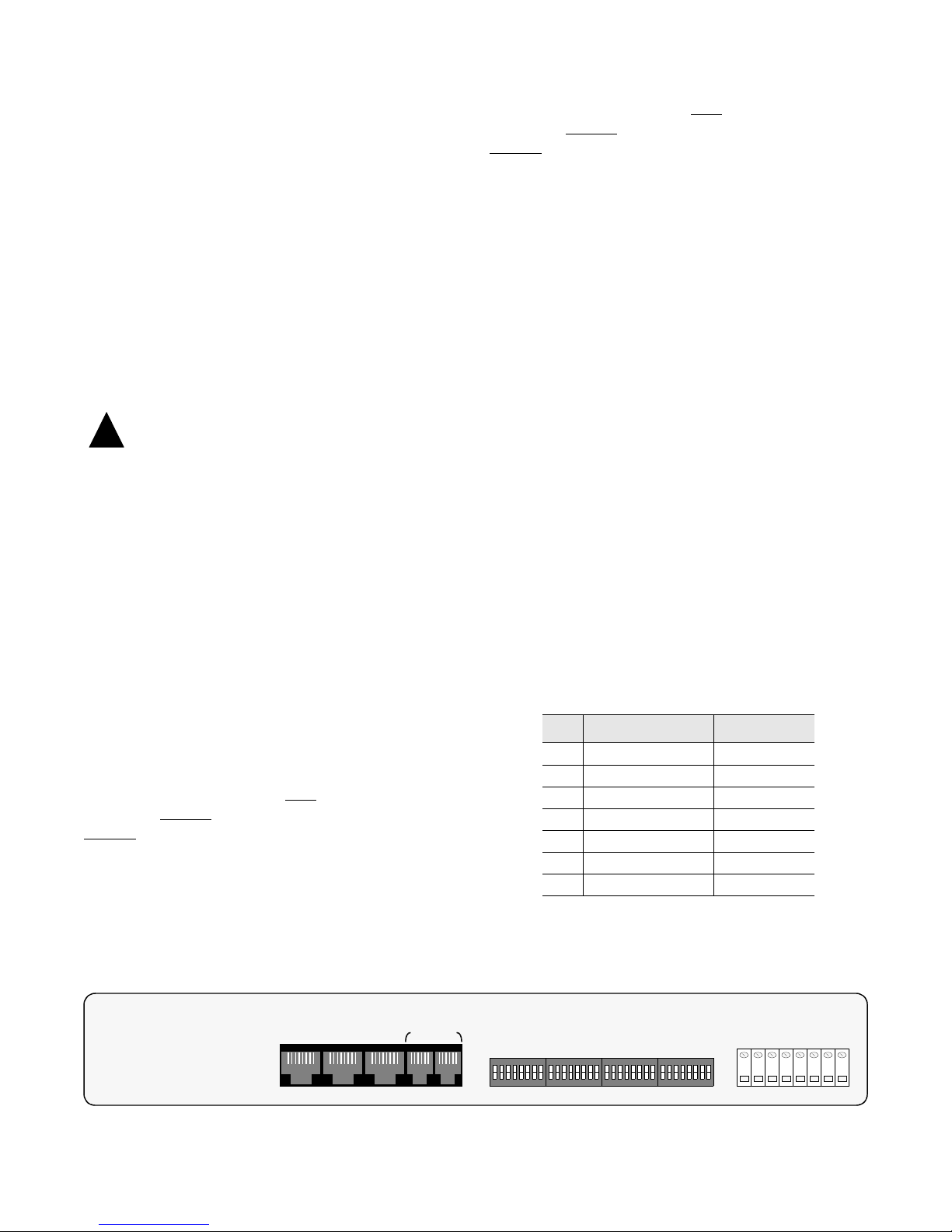

Figure 2-1 1558A Rear View

DTE COM BUSNET BNET A

S1

IN OUT

S2 S3 S4

GND

–VDC (A)

RTN (A)

–VDC (B)

RTN (B)

Alarm NO

Common

-20 to -56 VDC, 200 MA

1558A APS2-2 Installation

Alarm NC

Pin NET A & B, RJ48 DTE RJ48

8 Not Used Not Used

2.4.5 COM Bus Connections

The rear panel COM BUS connectors (IN/OUT) are used to

communicate to/from the optional APS 1559 site m anager.

These connections are only used when a 1559 Network

manager is co-located with the 1558A(s). Bus connections

from the manager to one or more 1558A units is done in a

daisy chain fashion. That is, the COM BUS Out from the

1559 is connected to the COM BUS IN of the 1558A and

the COM BUS OUT of the 1558A is connected to the COM

BUS IN of the 1559. Physically, the connections to the

COM Bus IN/OUT are RJ11, 6-pin miniature modular

jacks. The function of the six pins associated with the jacks

are shown below.

PIN COM BUS IN COM BUS OUT

1 Not Used Not Used

2 Signal Ground Signal Ground

3 Data, output Data, Output

4 Data, input Not Used

5 Signal Ground Signal Ground

6 Not Used Not Used

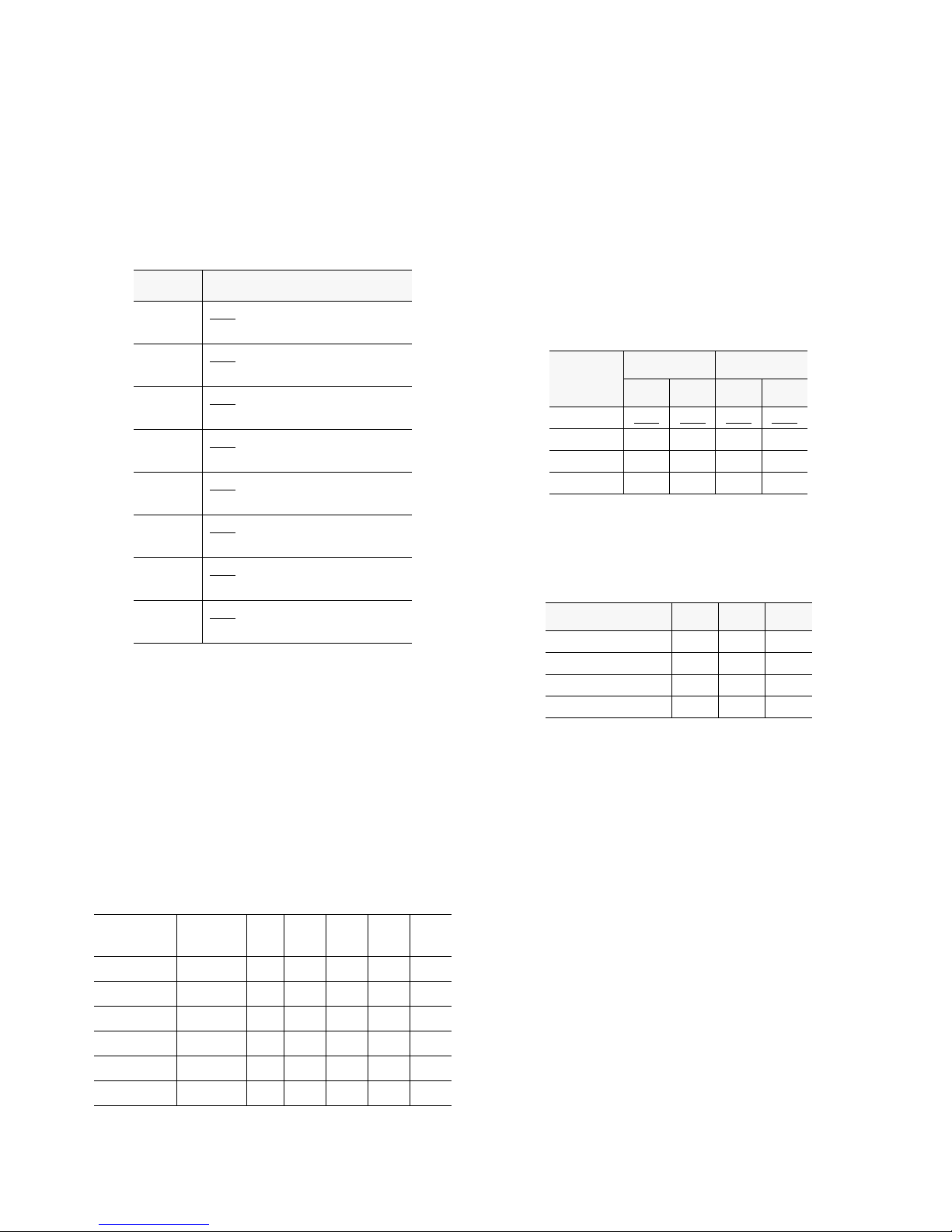

2.5.1 Switch Configuration

After the equipment has been unpacked and inspected and

mounted, the next step is to configure the unit. All unit

options are set by the switch positions on four 8- position

DIP switches (S1, S2, S3 and S4) on the rear of the 1558A

unit. The 1558A is shipped from the factory with all option

switches in the OFF (factory defaul t) position. The following paragraphs briefly describe the 1558A option switches.

NOTE: After all of the option switches have been set to

the desired mode of operation, recycle the power to the

unit. At power up, the CPU will read and implement the

switch settings selected by the user.

Option Switch S1

This 8-position DIP switch is used to set the following unit

options:

• Block/Pass ESF data link configurations

• Regeneration or Pass CRC

• Master or Slave Card Operation

• Boot alarm parameters from ROM or RAM

• Boot general parameters from Switches, ROM, RAM, or

Manager

The following table describes the DIP switch settings co ntrolled by Switch S1.

2.5 Configuration Modes

Any time that the 1558A unit is initi alized (power removed,

then reapplied), all key configuration data is read by the

1558A CPU and implemented based upon the particular

configuration boot mode options selected by the user. There

are four possible configuration boot modes:

• Configure/Boot from Switches

• Configure/Boot from ROM (refer to Section 2.5.2).

• Configure/Boot from RAM (refer to Section 2.5.3).

• Configure/Boot from Manager. This requires the optional

1559 manager (refer to Section 2.5.4).

The following sections describe how to set up the 1558A to

boot using one of the above modes as well as other general

operating parameters.

NOTE: All factory default settings in this manual are

shown underlined.

(refer to Section 2.5.1).

Position Switch S1 Description

1OFF

2OFF= NET/DTE, Block Data Link

3OFF

4OFF

5OFF

6OFF

7,8 OFF

= DTE/NET, Block Data Link

ON= DTE/NET, Pass Data Link

ON= NET/DTE, Pass Data Link

= DTE/NET, Reg en. CRC

ON= DTE/NET, Pass CRC

= NET/DTE, Regen. CRC

ON= NET/DTE, Pass CRC

= Card Function, Slave

ON= Card Function, Master

= ARM from ROM

ON= ARM from RAM

,OFF = Boot from Switches

OFF,ON = Boot from Manager

ON,OFF = Boot from RAM

ON,ON = Boot from ROM

Option Switch S2

This 8-position DIP switch is used to set the following unit

options:

• Alarm on Framing Errors

Installation 2-31558A APS

• Alarm on Loss of Signal

• AMI/B8ZS Line Coding for DTE and NET

• CSU Functions Enabled/Disabled

• Path Revert, Enabled/Disabled

• DTE Framing ESF/D4 (NET framing is fixed as ESF)

The following table describes the DIP switch settings con-

trolled by Switch S2.

Position Switch S2 Description

1OFF

2OFF

3OFF

4OFF

5OFF

6OFF

7OFF

8OFF

= Framing Errors, Enabled

ON = Framing Errors, Disabled

= LOS, Enabled

ON= LOS, Disabled

= NET/B, B8ZS

ON = NET /B, AMI

= NET/A, B8ZS

ON = NET /A, AMI

= DTE/B8ZS

ON = DTE /AMI

= CSU Mode, Enabled

ON = CSU Mode, Disabled

= Revert, Disabled

ON = Revert, Enabled

= DTE, ESF

ON = DTE, D4

Option Switch S3

This is an 8-position DIP swi tch. It is used to s et the 1558A

unit address ID for the NET A hardware and the NET B

hardware. Unique addresses must be optioned for each

1558A unit when multiple units are co-located and a 1559

Site Manager is being used. If no manager is being used, the

user should leave the DIP switches in the factory default

positions (all in the OFF or DOWN position). This configures the unit for NET A address 1 and NET B address 2.

The following table indicates how to configure the address

settings for the first six 1558A units.

NOTE: When connecting to the SUPV port using the APS

local access software, the 1558A NET A/B address es are

viewed as a single unit address and are displayed as 1.01

for addresses 1 and 2, 1.02 for addresses 3 and 4, etc.

Option Switch S4

This is an 8 -position DIP switch. The following tables indicate how to set the DIP switches for the various LBO and

DSX level settings. Note that S4-8 is not used (spare).

Positions 1 - 4 are used to set the LBO transmit level for the

NET A and NET B T1 signals. The factory default is 0 db

for the LBO settings.

LBO

0.0 DB OFF

7.5 DB OFF ON OFF ON

15.0 DB ON OFF ON OFF

22.5 DB ON ON ON ON

NET A NET B

S1 S2 S3 S4

OFF OFF OFF

Positions 5 - 7 are used to set the DSX signal level (in feet)

for the DTE port. The factory default is 0 to 133 feet for the

DTE DSX setting.

DTE DSX V alue S5 S6 S7

1 to 133 ft.* OFF O FF OFF

134 to 266 ft. OFF OFF ON

267 to 533 ft. OFF ON OFF

534 to 655 ft. ON OFF OFF

2.5.2 ROM Configuration

The 1558A may be configured to boot operational parameters from the internal ROM (read only memory). To configure the 1558A to boot from ROM, set S1 -7 and S1 -8 to the

ON position and S1 - 6 to the OFF position. With these settings, the 1558A will always boot (at power up) the unit

configuration parameters from the internal ROM settings.

The ROM unit parameters are listed below:

*APS Mgr.

Unit Pos.

1.01 1 /2 ON OFF OFF OFF OFF

1.02 3 /4 ON ON OFF OFF O FF

1.03 5 /6 ON OFF ON OFF O FF

1.04 7 /8 ON ON ON OFF OFF

1.05 9/10 ON OFF OFF ON OFF

1.06 11/12 ON ON OFF ON OFF

NET A/B

Address

Pos1Pos2Pos3Pos4Pos

5 - 8

• Block ESF data link, both directions

• Regenerate CRC6, both directions

• Slave Operation

• B8ZS line coding, both directions

• ESF framing, both directions

• Revert mode, disabled

• Availability timer set to 60 seconds

• Errored seconds set to 20

• Consecutively errored seconds set to 2

1558A APS2-4 Installation

• Loss of frame set to Enabled

• Loss of signal set to Enab led

illustrates the testing describe d in the following preservice

steps. Testing will verify:

In addition to setting the ROM configuration options, the

user must also manually configure the following options:

• LBO transmit level setting for both NET A and NET B

• DSX transmit level/distance setting for the DTE T1 port

• 1558A unit address ( if optional 1559 manager is install ed)

2.5.3 RAM Configuration

The 1558A can be optioned to boot all alarm and operating

parameters from the battery backed RAM at power up. To

configure the 1558A for this mode of operation simply set

S1 - 7 to ON, and S1-8 to OFF. Note that the following unit

options must still be manually configured by the user:

• LBO transmit level setting for both NET A and NET B

• DSX transmit level/distance setting for the DTE T1 port

• 1558A unit address ( if optional 1559 manager is install ed)

2.5.4 Manager Configuration

The 1558A may be configured and controlled using the

optional 1559 APS M site m anag er. The manager, co-located

with one or more 1558A units (up to 56), provides both

local and remote access and control/ alarm reporting to one

or more remote locations. When the 1558A has been configured to ‘Boot from Manager’, the 1559 can access and

change all options except the following:

• 1558A Address

• 1558A LBO and DSX Levels

• Boot Mode (Switches, RAM, ROM, Manager)

To configure the 1558A to ‘Boot from Manager’, set S1- 7

to OFF and S1-8 to ON. For additional information concerning the use and operation of the 1559 manager, refer to

the TxPORT 1559 APSM reference manual.

• Path Integrity for Path A and Path B (local)

• Path Integrity for Path A and Path B (end-to-end)

The following T1 test equipment and miscellaneous cables

will be required to perform the preservice tests:

• Two T1 test sets (one required at each APS location)

• Two cables to go from t he T1 test sets to the unit RJ 48

DTE connectors at both ends.

Before proceeding, the user should read and understand the

background information presented in the following paragraphs concerning the basic operation theory of an APS service (also refer to Figure 3-1 on page 3-2).

APS service is different from “normal” point- to- point T1

service. The 1558A APS unit accepts a single source signal

from the attached DTE equipment, verifies signal density,

duplicates the signal, and then transmits it on two T1 lines

(Path A, Transmit and Path B, Transmit). This duplication

and dual transmission is also done at the far end APS equipment (if applicable).

In addition to the u nique transmitti ng functi on p erform ed by

the APS, the unit also performs a unique receiving function.

There are two identical signals being received from two T1

lines by the APS equipment (Path A, Receive and Path B,

Receive). The 1558A constantly monitors both of these lines

for satisfactory signal performance. In the event that the

present active receive line exceeds an alarm value, the APS

will automatically switch the service from the failed receive

path to the standby receive path. The active receive signal is

the path connected to the DTE equipment.

Once a path has declared an alarm condition from Errored

Seconds, Consecutively Severely Errored Seconds, Loss of

Frame, or Loss Of Signal, it will not be available for service

until a 2- minute interval has been detected that was completely error free. At that time, the path alarm circuitry will

be reset and then the path will be ready to accept service.

Unit configuration of the 1558A APS is now complete. The

final steps to complete installation is to perform the 1558 A

pre service testing steps describe in the following sections.

2.6 Preservice Testing

The preservice test checks the operational integrity of the

1558A unit. The local pre-service testing is made independently of any DTE or T1 connections. The end-to-end testing requires that the T1 facilities be connected to the unit

and that the user has a T1 test set. Figure 2- 2 on page 2 -6

2.6.1 Path A Preservice Testing

Perform the following test steps to verify that the 1558A can

run error free data from the DTE port to the NET A port and

back (local loop test). The test setup for performing this test

is depicted in Figure 2-2 on page 2-6.

1) Connect a T1 test set to the DTE RJ 48 jack at the rear

of the 1558A unit. The test set should be configured to generate a T1 signal that matches the options previously set in

the 1558A unit (D4 or ESF, AMI or B8ZS) and configured

to supply clock to the 1558A.

Installation 2-51558A APS

Loading...

Loading...