TWT TWT-POUS-300, TWT-POUE-400 Owner's Manual

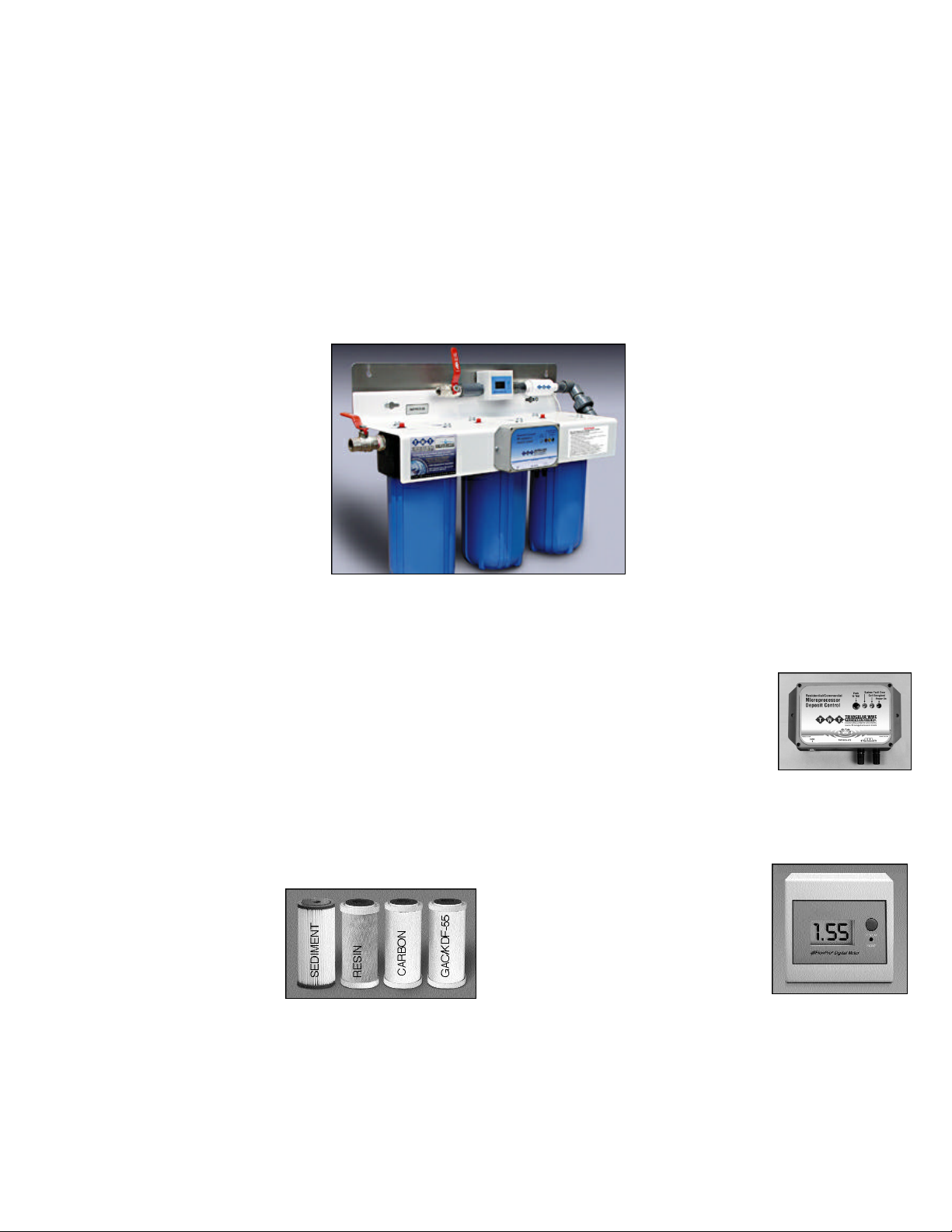

System1.

FACTORY ASSEMBLED WATER TREATMENT

SYSTEM OWNERS MANUAL

TWT-POUS-300 Point-of-Use (P.O.U)

Integrated Water Softening, Treatment and Conditioning System

Filtration • Water Softening • Patented Deposit Control Technology

Ideal for the Beverage (Coffee) Dispensing Industry

M62

System 2.

TWT-POUE-400 Point-of-Use (P.O.U) Point-of-Entry (POE)

Integrated Water Treatment and Conditioning System

Filtration • Patented Deposit Control Technology

Ideal for Cottages, Mobile Homes, RV ’s, Boats & More .

System Design and Installation Guidelines

Please take the time and read the following suggestions before installation

TWT®YOUR SIMPLE AND SAFE

SOLUTION

You have now purchased a technologically advanced

water treatment system that with proper maintenance, will insure cleaner water for decades to

come. Providing end-to-end treatment and conditioning with consistent results.

1. TWT-POUS-300 Application

The TWT Integrated system should be installed at

point-of-use, on or near the beve rage dispensing

machines requiring treatment (for water-fed lines 3/4" in

d i a m e t e r or less) . Select a location near water fe e d

line in an area allowing enough room on all sides of

system for filter(s) replacement, visual inspection,

keeping it out of harm’s way (i.e., appropriate service

clearances).depending upon model purchased.This

will allow most maintenance procedures to be accomplished without removing the unit and filters from its

mounting bracket.

2. TWT-POUE-400 Application

The TWT Integrated system should be installed at P.O.U./P.O.E., near water-fed

line (for water-fed lines 3/4" in diameter or less). Select a location near water

feed line in an area allowing enough room on all sides of system for filter(s)

replacement, visual inspection, keeping it out of harm’s way (i.e., appropriate service clearances). This will allow most maintenance procedures to be accomplished without removing the unit and filters from its mounting bracket.

FILTRATION-

Traps & Removes Harmful Pollutants, prevents restriction and keeps

water in the plumbing system flowing

Filters are designed to trap various kinds of debris, dirt and organic particles

that will otherwise enter your equipment and/or plumbing system, restrict your

water flow and create a breeding ground for bacteria. The first step in achieving

clean water is to install a filtration

matter and similar debris.

Filters used in TWT-POUS-300 system

1. Sediment 5-10 Micron: Pl e a t e d

Washable and reusable for sediment

r e d u c t i on/r e m o v a l

2. Resin Filter: Water softening resin filter

3. GAC: Granulated activated carbon for

taste, odor, organic chemicals and chlo-

rine reduction/removal.

Filters used in TWT-POUE-400 system

1. Sediment 5-10 Micron: Pleated Washable and reusable for sediment

r e d u c t i on/r e m o v a l

2. GAC: Granulated activated carbon for taste, odor, organic chemicals and

chlorinereduction / removal

3. GAC/KDF-55:

copper/zinc alloy media designed to remove chlorine, lead, volatile organic

chemicals,hydrogen sulfide, sulfur, herbicides, pesticides, chemical fertilizer

residues and trihalomethanes

Note: See maintenance calender

Granulated activated carbon with KDF-55, specially formulated

device that effectively removes particulate

Email: info@triangularwave.com • triwaveinc@aol.com • Websites:www.Triangularwave.com • www.twtwatertreatment.com

All though simular in design, the TWT-POUS-300 (above) uses a

Sediment, Resin and Carbon filter. The TWT-POUE-400 uses a

Sediment, Carbon and GAC-KDF-55 Filter (1-2 GPM System)

DEPOSIT CONTROL-

TWT®Patented Deposit Control Technology

The basic component in the TWT systems is

the deposit contr o l l e r.It is comprised of a

m i c r o p r o c e s s o r, solenoid coil fa c t o ry wrapped

reaction chamber. The microprocessor is a

patented controller that functions like a compute r to relay a continuous electrical power supply to the solenoid coil reaction chamber. The

reaction chamber is part of the system, and

provides a factory wrapped wire coil forming a

solenoid. The solenoid conveys the triangular

wave signal at the appropriate power level

(as allowed by the model chosen) to the water

passing through the chamber. This signal constantly changes the polari t y, freq u e n c y, and

amplitude of the current entering the water.

al benefits.It increases the capability of the water to hy d rate scale

ions and other c o lloidal particles. In effect, the s u r face charge of

the hydrogen molecules is enhanced and the water is made “ we t t er”.

T h i s “ hy d ra te d ” water can dissolve unw a n t e d

p a rt i c l e s, s u s pend them in solution, and allow

them to be easily filtered out or flushed from the

s y s t e m .A c c o r d i n g l y, the mineral and b i o l o g i c a l

p a rticles that cause scale, deposits, and corrosion are d i s s o l ved and washed away.

This means that the breeding environments fo r

b a c t e ri a , such as bio-film and corrosion, are

e l i m i n a t e d .The agitation created in the reaction chamber also disrupts

the conditions essential for the normal reproduction of bacteria and they

die, thus allowing them to be harmlessly flushed out of the sy s t e m .

This triangular wave treatment produces seve r-

TWT Deposit Controller

FLOW METER-

Battery operated digital flow meter with ability

to reset so users may track total flow in gallons. Offers ability to monitor multiple functions,

with capacity settings 100 to 19,900 gallons.

Audible alarm indicates cartridge/ media

replacement.

When the TWT systems are properly installed and

maintained, the effects of the Triangular Wave

Technology Treatment Last Downstream. In effect, a clean, corrosion-free

delivery systems restored and maintained in a safe manner. The result is

clean tanks, pipes and tubing with no bio-film and reduced bacterial

contamination.

TWT systems make sense from operational, economic, and safety points of

v i e w. Ownership of the TWT System will afford you and/or your customers

significant savings over a short period of time and even greater savings over

the life cycle of the equipment.

BASIC INSTALLATION GUIDELINES

TWT-POUS-300 / TWT-POUE-400

• Securely mount system using pre-drilled holes on beverage dispensing machine(s) or near

water feed line (POU/POE) in an area a l l owing enough room on all sides of system for filter

replacement, visual inspection, keeping it out of harms way (i.e., appropriate service c l e a r a n c e s ) .

• Shut off water before you start installation at Point-of-Use

• Plumb system into to water feed line

• Test System

• Do not plug in system

• Close drain ports

• Open shut-off valves, test for leaks

• Tighten all connectors

• System should now be ready for operation

• Plug into VAC outlet, make sure manual shut off valves and drain ports are in

proper position for water flow

• Allow system to operate for several minutes before using or drinking water

COMPONENTS

One- factory assembled and mounted system

One- spanner filter wrench for filter replacement

One- owner’s installation and maintenance manual (read before installation )

4. Press down pressure release valve on top of filter assembly, allowing

additional drainage

5. Allow enough time for system to drain fully– It is now safe to perform mainten-

ance, after performing maintenance, take these necessary and important steps:

6. Close drain port

7.Open inflow and outflow valves

8. Plug in Power Cord

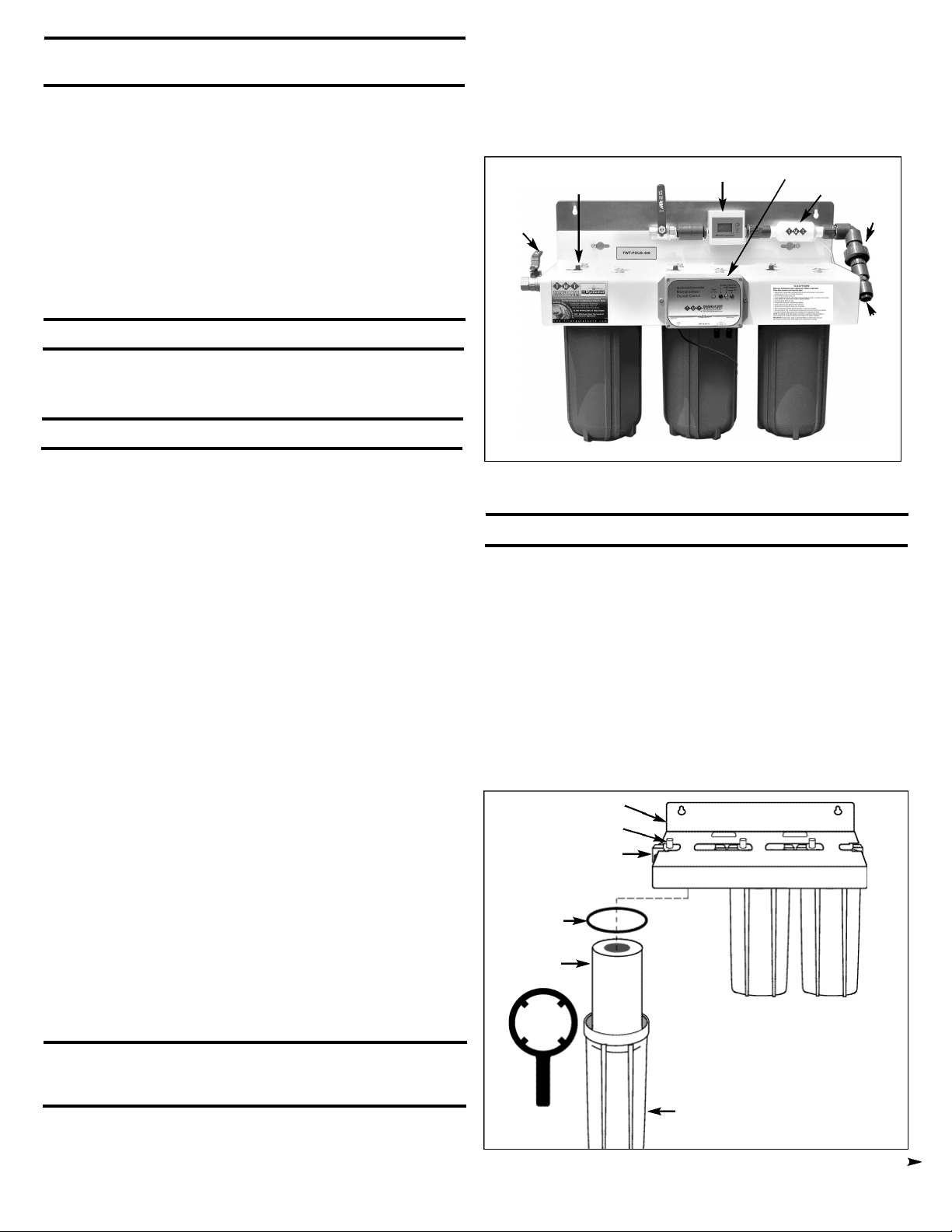

TWT Deposit Controller

TWT Reaction Chamber

1/2" In & Out

Piping

Manual Shut-Off

Valves

Pressure Release

Valves

Flow Meter

Drain

Port

THINGS TO DO PERIODICALLY Not less than weekly

1. TWT-POUS-300 Unplug AC power cord(s) before any repairs and/or replace

ments are performed

• Visually inspect deposit controller to ensure continuous operation

• Deposit control system LED lights should be on

• Make sure the filters are free flowing, if they become clogged you must clean or

replace them

• Replace sediment and/or carbon filters when needed, generally 2 to 3 times a year,

depending on water use, quality, and conditions.*

• Replace resin filter and reset meter every 150 to 200 gallons of processed fluid (up

to 20 grains), above 20 grains hardness to be determined* (will vary based on

equipment operating conditions, water quality in different areas of country.

Manufactures suggest equipment owners replace resin filters more frequently until

they have established appropriate usage and time tables). See flow meter next page

• Water Source (municipal/well), condition and GPM determines need (hard water

areas of the country may require more frequent filter replacements).

• Use filter wrench (shipped with system) when replacing filters

2. TW T-POUE-400 Unplug AC power cord(s) before any repairs and/or

replacements are performed:

• Visually inspect deposit controller to ensure continuous operation

• Deposit control system LED lights should be on

• Make sure the filters are free flowing, if they become clogged you must clean or

replace them

• Replace filters when needed, generally 2 to 3 times a year, depending on water

use, quality, and conditions.*

Meter Setting Guidelines POUE-400 (Non-Resin Filter Use):

• Set meter to max 19,900 gallons of processed water, based on a family of 4 or

less, you should be able to reset meter to 19,900 again before filter replacement is

needed. It is estimated the average person uses between 60 to 100 gallons of

water per day (will vary based on equipment operating conditions, water quality in

different areas of country. Manufactures suggest equipment owners replace filters

more frequently until they have established appropriate usage and time tables).

• Water Source (municipal/well), condition and GPM determines need (hard water

areas of the country may require more frequent filter replacements).

• Use filter wrench (shipped with system) when replacing filters

*TWT Inc. recommends that owners periodically test their water and that an initial supply of replacement

products e.g., replacement filters, be stored at owners facility at all times, that will insure uninterrupted

service and treatment.

SYSTEM MAINTENANCE

Before any maintenance and/or replacement of filters

is performed, follow these necessary and important steps:

1. Unplug Power Cord

2. Close inflow & outflow shut-off valves

3. Open drain port, allowing water to drain

Staged Filtration

TW T-POUS-300 & POUE-400 Integrated Treatment System

Ap p r ox Size 26"L X 20"H X 10"D • Approx weight 40 lbs.(will va ry based on filtrs used)

Systems engineering design, weight, size and system component assembly may vary based on TWT engineering review.

FILTER REPLACEMENT

1. Replace filters when needed

2. Replace sediment, carbon and/or GAC/KDF-55 filters when needed, generally 2 to 3

times a year, depending on water use, quality, and conditions.*

3. Replace resin filter every 150 to 200 gallons of processed fluid (up to 20 grains),

above 20 grains hardness to be determined (will vary based on equipment operating

conditions, water quality in different areas of country. Manufactures suggest

equipment owners replace resin filters more frequently until they have established

appropriate usage and time tables).

4. Shut down system before performing any maintenance. READ CAUTION LABEL

5. Turn off water supply to system.

6. Depress pressure release button to relieve pressure in filter housing.

7. Unscrew filter housings using spanner wrench (shipped with system). N OT E :

When opening filter housing (see diagram below)to change cartridge, it is

common for O-ring/Gasket to lift out of housing and stick to cap (remove carefully.)

Mounting Bracket

Pressure Release

Filter Head

O-Ring

Gasket

Filter

Cartridge

Filter systems, sizes and cartridges

will vary based on capacity and

application needs.

Basic procedures for replacement of

cartridges are the same as illustrated

Spanner

Wrench

Filter Housing

Continue Filters

Email: info@triangularwave.com • triwaveinc@aol.com • Websites:www.Triangularwave.com • www.twtwatertreatment.com

Loading...

Loading...