Twose Opticut 220, Opticut 300, Opticut 260 Operator And Parts Manual

OPTICUT

DISC MOWERS

Models 220, 260 & 300

OPERATOR & PARTS MANUAL

Publication 655 Part No.22674.55

Twose of Tiverton Limited

6 Chinon Court,

Lower Moor Way,

Tiverton Business Park,

Tiverton,

Devon. EX16 6SS.

Telephone: (01884) 253691

Fax: (01884) 255189

Email sales@twose.com

Web: www.twose.com

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION

It is imperative that the selling dealer registers this machine with Twose of Tiverton Limited

before delivery to the end user – failure to do so may affect the validity of the machine

warranty.

To register machines go to the Twose web site at www.twose.com, log onto ‘Dealer

Inside’ and select the ‘Machine Registration button’ which can be found in the Service

Section of the site. Confirm to the customer that the machine has been registered in the

section below.

Should you experience any problems registering a machine in this manner please contact

the Twose Office on 01884 253691.

Registration Verification

Dealer Name: ……………………..…………………………………………………………….

Dealer Address: …….………………………………………………………………………….

Customer Name: ……………………..…………………………………………………………

Date of Warranty Registration: ……/……/...…… Dealer Signature: ………………..……

NOTE TO CUSTOMER / OWNER

Please ensure that the above section above has been completed and signed by the selling

dealer to verify that your machine has been registered with Twose of Tiverton Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s responsibility

to regularly inspect all nuts, bolts and hose connections for tightness and re-tighten if required. New

hydraulic connections occasionally weep small amounts of oil as the seals and joints settle in – where

this occurs it can be cured by re-tightening the connection – refer to torque settings chart below. The

tasks stated above should be performed on an hourly basis during the first day of work and at least

daily thereafter as part of the machines general maintenance procedure.

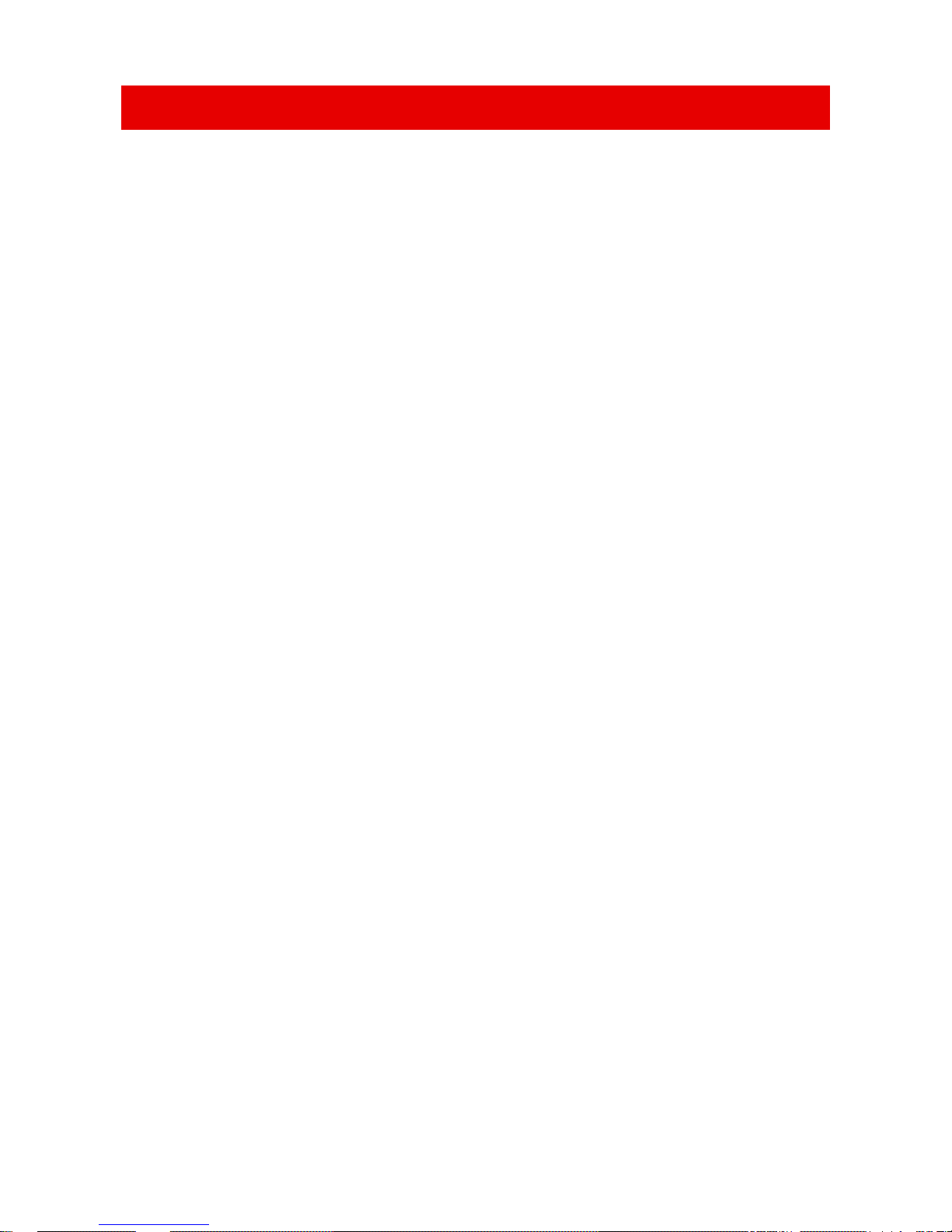

TORQUE SETTINGS FOR HYDRAULIC FITTINGS

HYDRAULIC HOSE ENDS PORT ADAPTORS WITH BONDED SEALS

BSP Setting Metric BSP Setting Metric

1/4” 18 Nm 19 mm 1/4” 34 Nm 19 mm

3/8” 31 Nm 22 mm 3/8” 47 Nm 22 mm

1/2” 49 Nm 27 mm 1/2” 102 Nm 27 mm

5/8” 60 Nm 30 mm 5/8” 122 Nm 30 mm

3/4” 80 Nm 32 mm 3/4” 149 Nm 32 mm

1” 125 Nm 41 mm 1” 203 Nm 41 mm

1.1/4” 190 Nm 50 mm 1.1/4” 305 Nm 50 mm

1.1/2” 250 Nm 55 mm 1.1/2” 305 Nm 55 mm

2” 420 Nm 70 mm 2” 400 Nm 70 mm

WARRANTY POLICY

WARRANTY REGISTRATION

All machines must be registered, by the selling dealer with Twose of Tiverton Ltd, before delivery

to the end user. On receipt of the goods it is the buyer’s responsibility to check that the Verification

of Warranty Registration in the Operator’s Manual has been completed by the selling dealer.

1. LIMITED WARRANTIES

1.01. All machines supplied by Twose of Tiverton Ltd are warranted to be free from defects in

material and workmanship from the date of sale to the original purchaser for a period of 12

months, unless a different period is specified.

1.02. All spare parts supplied by Twose of Tiverton Ltd and purchased by the end user are

warranted to be free from defects in material and workmanship from the date of sale to the

original purchaser for a period of 6 months. All parts warranty claims must be supported by a

copy of the failed part invoice to the end user. We cannot consider claims for which sales

invoices are not available.

1.03. The warranty offered by Twose of Tiverton Ltd is limited to the making good by repair or

replacement for the purchaser any part or parts found, upon examination at its factory, to be

defective under normal use and service due to defects in material or workmanship. Returned

parts must be complete and unexamined. Pack the component(s) carefully so that any transit

damage is avoided. All ports on hydraulic items should be drained of oil and securely plugged

to prevent seepage and foreign body ingress. Certain other components, electrical items for

example, may require particular care when packing to avoid damage in transit.

1.04. This warranty does not extend to any product from which Twose of Tiverton Ltd’s serial

number plate has been removed or altered.

1.05. This warranty does not apply to any part of the goods, which has been subjected to improper

or abnormal use, negligence, alteration, modification, fitment of non-genuine parts, accident

damage, or damage resulting from contact with overhead power lines, damage caused by

foreign objects (e.g. stones, iron, material other than vegetation), failure due to lack of

maintenance, use of incorrect oil or lubricants, contamination of the oil, or which has served

its normal life. This warranty does not apply to any expendable items such as blades, belts,

clutch linings, filter elements, flails, flap kits, skids, soil engaging parts, shields, guards, wear

pads, pneumatic tyres or tracks.

1.06. Temporary repairs and consequential loss - i.e. oil, downtime and associated parts are

specifically excluded from the warranty.

1.07. Warranty on hoses is limited to 12 months and does not include hoses which have suffered

external damage. Only complete hoses may be returned under warranty, any which have

been cut or repaired will be rejected.

1.08. Machines must be repaired immediately a problem arises. Continued use of the machine

after a problem has occurred can result in further component failures, for which Twose of

Tiverton Ltd cannot be held liable, and may have safety implications.

1.09. If in exceptional circumstances a non Twose of Tiverton Ltd part is used to effect a repair,

warranty reimbursement will be at no more than Twose of Tiverton Ltd‘s standard dealer cost

for the genuine part.

1.10. Except as provided herein, no employee, agent, dealer or other person is authorised to give

any warranties of any nature on behalf of Twose of Tiverton Ltd.

1.11. For machine warranty periods in excess of 12 months the following additional exclusions

shall apply:

1.11.1. Hoses, exposed pipes and hydraulic tank breathers.

1.11.2. Filters.

1.11.3. Rubber mountings.

1.11.4. External electric wiring.

1.11.5. Bearings and seals.

1.12. All service work, particularly filter changes, must be carried out in accordance with the

manufacturer’s service schedule. Failure to comply will invalidate the warranty. In the event of

a claim, proof of the service work being carried out may be required.

1.13. Repeat or additional repairs resulting from incorrect diagnosis or poor quality previous repair

work are excluded from warranty.

NB Warranty cover will be invalid if any non-genuine parts have been fitted or used. Use of nongenuine parts may seriously affect the machine’s performance and safety. Twose of Tiverton Ltd

cannot be held responsible for any failures or safety implications that arise due to the use of nongenuine parts.

2. REMEDIES AND PROCEDURES

2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the Twose

of Tiverton Ltd web site and confirms the registration to the purchaser by completing the

confirmation form in the operator’s manual.

2.02. Any fault must be reported to an authorised Twose of Tiverton Ltd dealer as soon as it

occurs. Continued use of a machine, after a fault has occurred, can result in further

component failure for which Twose of Tiverton Ltd cannot be held liable.

2.03. Repairs should be undertaken within two days of the failure. Claims submitted for repairs

undertaken more than 2 weeks after a failure has occurred, or 2 days after the parts were

supplied will be rejected, unless the delay has been authorised by Twose of Tiverton Ltd.

Please note that failure by the customer to release the machine for repair will not be

accepted as a reason for delay in repair or submitting warranty claims.

2.04. All claims must be submitted, by an authorised Twose of Tiverton Ltd Service Dealer, within

30 days of the date of repair.

2.05. Following examination of the claim and parts, Twose of Tiverton Ltd will pay, at their

discretion, for any valid claim the invoiced cost of any parts supplied by Twose of Tiverton Ltd

and appropriate labour and mileage allowances if applicable.

2.06. The submission of a claim is not a guarantee of payment.

2.07. Any decision reached by Twose of Tiverton Ltd is final.

3. LIMITATION OF LIABILITY

3.01. Twose of Tiverton Ltd disclaims any express (except as set forth herein) and implied

warranties with respect to the goods including, but not limited to, merchantability and fitness

for a particular purpose.

3.02. Twose of Tiverton Ltd makes no warranty as to the design, capability, capacity or suitability

for use of the goods.

3.03. Except as provided herein, Twose of Tiverton Ltd shall have no liability or responsibility to the

purchaser or any other person or entity with respect to any liability, loss, or damage caused

or alleged to be caused directly or indirectly by the goods including, but not limited to, any

indirect, special, consequential, or incidental damages resulting from the use or operation of

the goods or any breach of this warranty. Notwithstanding the above limitations and

warranties, the manufacturer’s liability hereunder for damages incurred by the purchaser or

others shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this

warranty may be brought more than one (1) year after the cause of the action has occurred.

4. MISCELLANEOUS

4.01. Twose of Tiverton Ltd may waive compliance with any of the terms of this limited warranty,

but no waiver of any terms shall be deemed to be a waiver of any other term.

4.02. If any provision of this limited warranty shall violate any applicable law and is held to be

unenforceable, then the invalidity of such provision shall not invalidate any other provisions

herein.

4.03. Applicable law may provide rights and benefits to the purchaser in addition to those provided

herein.

EC DECLARATION OF CONFORMITY

Conforming to EEC Directive 89/392/EEC

We,

TWOSE OF TIVERTON LIMITED,

6 Chinon Court, Lower Moor Way,

Tiverton Business Park, Tiverton, Devon, EX16 6SS.

Declare under our sole responsibility that:

The product (type) ………………………………………………………………………

…………………………………………………………………………………………...

Product Code ……………………………………………………………………………

Serial No. & Date ……………………………………. Type …………………………..

Manufactured by the above company/* …………………………………………………

…………………………………………………………………………………………...

(* insert business name and full address if not stated above)

Complies with the required provisions of the Machinery Directive 98/37/EC, *

previously Directive 89/392/EEC as amended by Directives 91/368/EEC, 93/44/EEC

and 93/68/EEC.

For the relevant implementation of the safety and health requirements mentioned in the

Directives, the following standards have been respected:

EN 292-1/1991 EN292-2/1991 EN294/1992 EN349/1993

EN 1553/1999 EN 1152/1994 EN 953/1997 EN 982/1996

Signed …………………………..…………………………………………………….....

on behalf of TWOSE OF TIVERTON Responsible Person

Status: Chief Design Engineer Date: August 2010

Rotary Disc Mower

O

p

ticut 220 / 260 / 300

LIST OF CONTENTS

Page No.

Technical Data 1

Machine Description 2

Safety Information 3

Safety Decals 5

Tractor Requirements 6

Attachment to Tractor 7

Setting of Side Position 7

Vertical Adjustment 8

Frame Height 9

PTO Shaft 10

Hydraulic Connection 11

Post Attachment Checks 12

Spring Assisted Weight Distribution 13

Moving into Transport Position 14

Moving into Work Position 15

Mowing Instructions 16

Breakback Protection System 18

Machine Removal 18

General Maintenance 19

Storage 29

OPTICUT 220/260/300

Rotary Disc Mowers

1

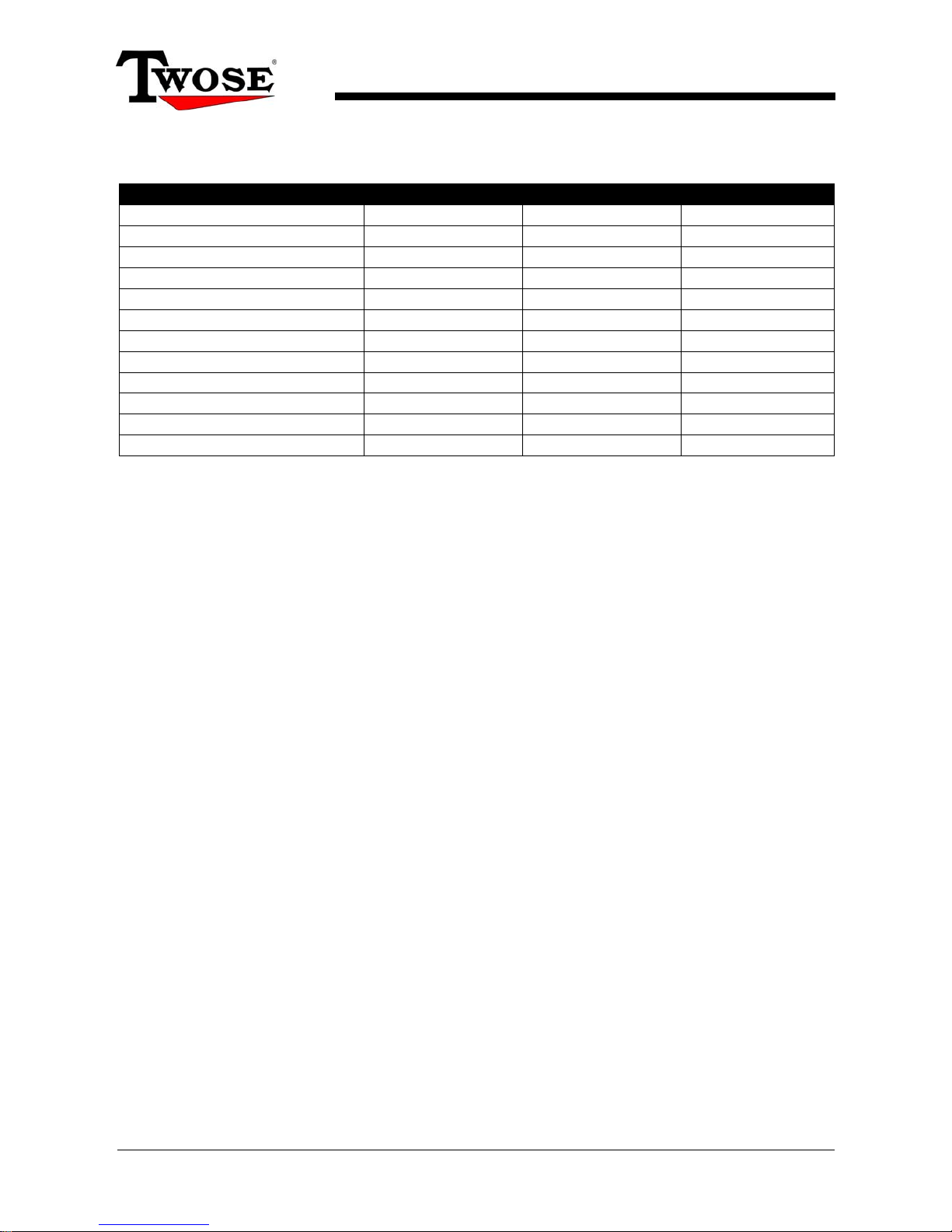

TECHNICAL DATA

SPECIFICATION OPTICUT 220 OPTICUT 260 OPTICUT 300

Attachment (3-point hitch)

Cat. II Cat. II Cat. II

Working width

2119mm 2472mm 2895mm

Weight

520kg 560kg 590kg

Transport height

2745mm 3100mm 3530mm

Transport width

1935mm 1935mm 1935mm

Maximum PTO speed

540RPM 540RPM 540RPM

Disc rotation speed

3000RPM 3000RPM 3000RPM

No. of discs

5 6 7

No. of blades

10 12 14

Minimum power requirement

30Kw/40HP 38Kw/50HP 48Kw/60HP

Cutting capacity

2.6 ha/h 3 ha/h 3.5 ha/h

Working speed

Up to 18 km/h Up to 18 km/h Up to 18 km/h

MACHINE SERIAL NUMBER PLATE

All machines will have a serial number plate fitted to them stating; the machine model, serial

number of the machine, and the machine’s weight. When ordering replacement parts or

requesting service information always quote the machine model and serial number as

stated on its serial number plate.

OPTICUT 220/260/300

Rotary Disc Mowers

2

DESCRIPTION

The Twose Opticut Series disc mowers are three-point linkage tractor mounted agricultural

implements specifically designed for the mowing of grass and clover on even terrain. The

machines feature belt driven cutterbars fitted with rotating discs each equipped with 2

cutting knives that perform efficient cutting of vegetation.

Mower components are protected by a mechanical breakback system and the machines are

equipped with a hydraulic ‘fold up’ system for ease of transportation.

These machines must only be used to perform the designated task for which they were

designed. Use of these machines for any other function may cause damage to the machine

and possible injury to the operator or other persons.

OPTICUT 220/260/300

Rotary Disc Mowers

3

SAFETY INFORMATION

In the interest of safety it is important that great care is adopted at all times during the attachment,

transportation, operation and maintenance of this machine. Both the owner and the operator of the

machine should read and understand the following section to ensure the safety of themselves and all

other persons who enter into the close proximity of these machines.

In addition to the instructions stated here always abide by general safety and accident

regulations.

Safety and warning decals placed on the machine give important instructions for safe

work - take them into consideration for your safety and the safety of others.

While driving on public roads always abide by traffic signs and road regulations.

Familiarise yourself with the controls and functions of the machine and practice them in

a safe location before attempting to start work.

Never approach this machine whilst it is working or running – switch off the machine

and wait until it has stopped fully before approaching.

Do not wear loose fitting clothes in the vicinity of this machine - clothes should fit tight

to the user's body.

Check no one is near to, or on, the machine before attempting to start or transport it.

Ensure your visibility is kept clear at all times.

Never permit anyone to ride on this machine.

Implements should always be attached according to the manufacturer’s instructions

and fastened correctly to the prescribed devices using the correct components.

When disconnecting the machine from the tractor select a firm level site and use the

support leg.

Take care when connecting or disconnecting the implement to the tractor – keep

onlookers at a safe distance.

Ensure controls for the machine are positioned such that the machine cannot

accidentally be started during transport.

For transportation on the road, prepare and secure the machine according to the

manufacturer's instructions.

Never leave the driver seat whilst the tractor or the machine is running.

OPTICUT 220/260/300

Rotary Disc Mowers

4

Always adjust the driving speed to suit the driving conditions. Avoid fast turning

when driving uphill, downhill or across a slope. Braking performance and turning ability

will be affected when implements are connected or mounted to the tractor - allow

extra time for turning and braking.

Never attempt to operate a machine without its safety devices fitted or incorrectly

secured.

Ensure all bystanders are kept at a safe distance from a moving or working machine.

Even when the machine is unattached some hydraulic or mechanical components on

the machine are able to be rotated or moved by hand and are therefore capable of

causing injury to fingers or hands due to trapping. Wherever possible secure these

components during storage to prevent accidental injuries.

Always place the machine in a safe position before leaving the tractor - lower the

implement completely, switch off the engine and remove the ignition key.

Never permit anyone between the machine and the tractor whilst either is working or

when the machine is in a raised position.

Only use machines on a tractor that is capable of taking its weight - use weights or

ballast as required ensuring stability of the unit.

Be aware at all times of the width, height and length of any machinery you are

operating – especially when transporting on the public highway or near obstructions.

Ensure the work area is clear of obstructions before starting work – clear stones, wire,

glass or any other dangerous objects from the work site before attempting to start work.

Although the information given here covers a wide range of safety subjects it is impossible to predict

every eventuality that can occur under differing circumstances whilst operating this machine. No

advice given here can replace ‘good common sense’ and ‘total awareness’ at all times but will go a

long way towards the safe use of your Twose machine.

OPTICUT 220/260/300

Rotary Disc Mowers

5

SAFETY DECALS

1. WARNING! Always ‘Read the Operator Manual’.

2. DANGER! Pinch & Crush Zone – Keep hands and limbs clear whilst machine is

working.

3. DANGER! Wait until machine has stopped completely before approaching.

4. DANGER! Keep clear of mower knife area whilst tractor or machine is running.

5. DANGER! Keep clear of machine whilst tractor or machine is running.

6. WARNING! Switch off tractor engine & remove key before performing

maintenance or repair.

7. DANGER! Keep clear of danger area between tractor and machine.

8. DANGER! Keep clear of raised machine.

9. WARNING! Maximum RPM – 540RPM machines only (where applicable).

10. WARNING! Maximum RPM – 1000RPM machines only (where applicable).

11. INFORMATION! Blade Information

12. INFORMATION! Check tightness of nuts & bolts every couple of working hours.

OPTICUT 220/260/300

Rotary Disc Mowers

6

TRACTOR REQUIREMENTS

The tractor to which this machine is to be fitted must meet the following criteria:

o 3-point linkage connection – Cat. II.

o Minimum power requirement of: 38kW (50HP) for Opticut 260 machines

48kW (60HP) for Opticut 300 machines

o PTO shaft speed: Maximum 540RPM

o Hydraulic service connection.

OPTICUT 220/260/300

Rotary Disc Mowers

7

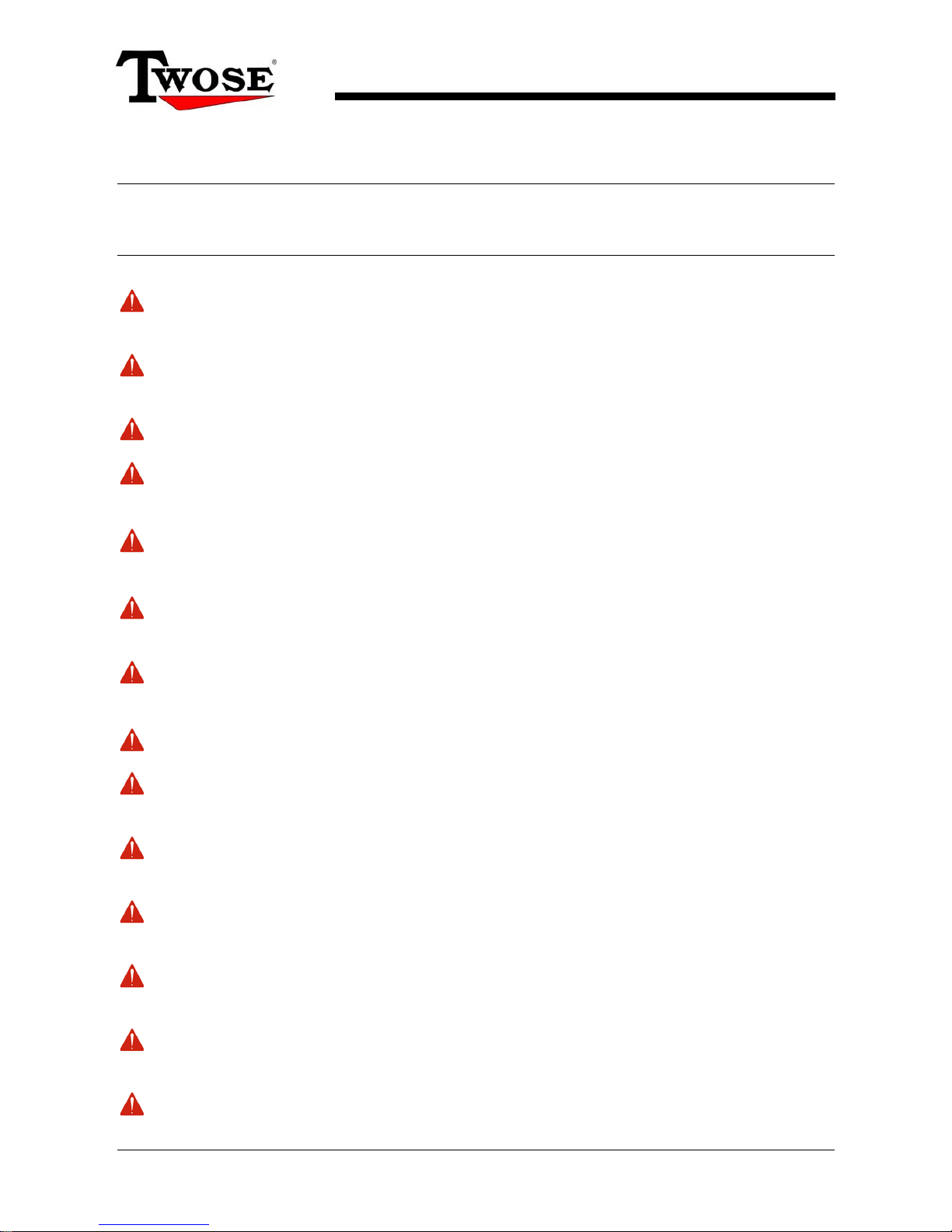

Attachment to Tractor

Select a firm level site on which to attach the

mower to the tractor.

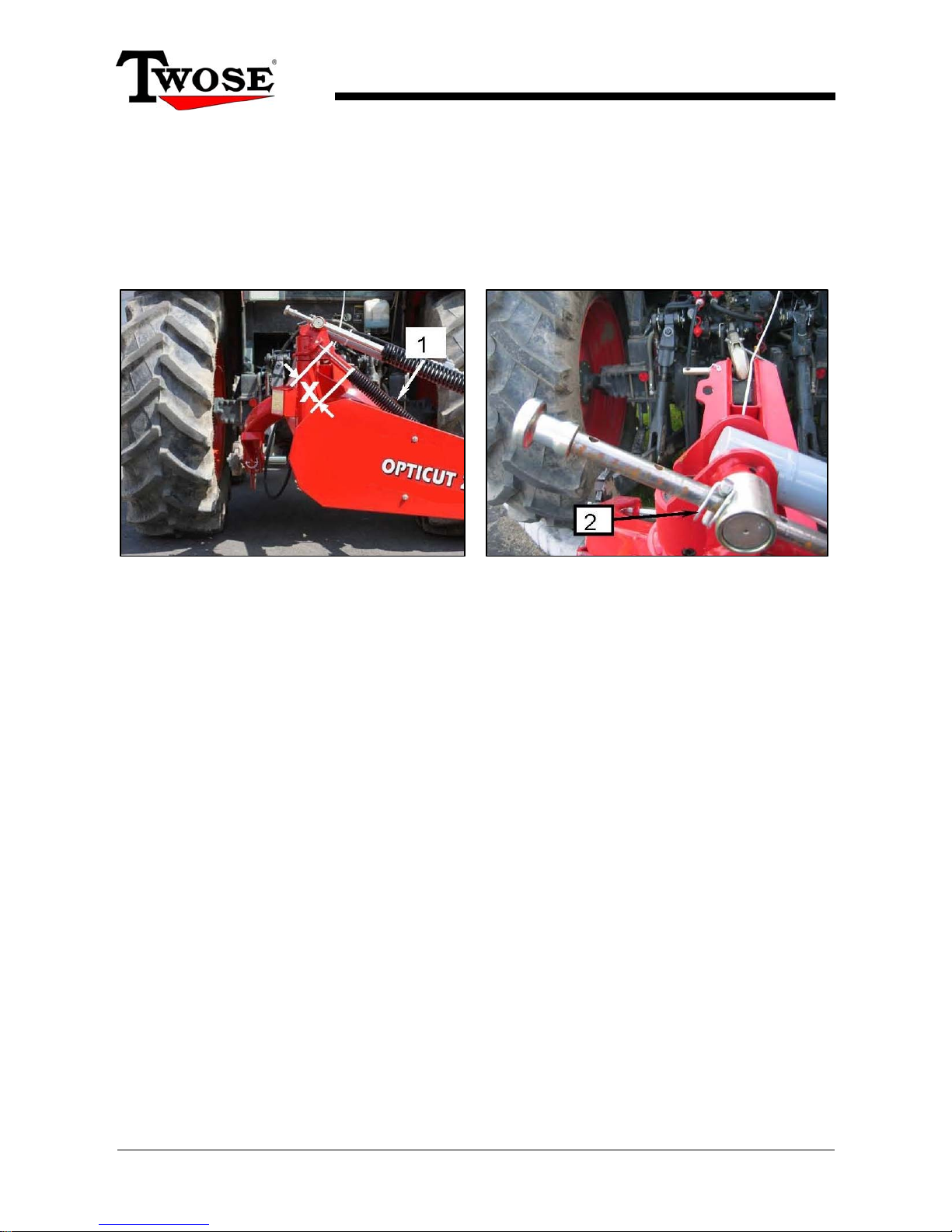

Reverse tractor up to machine positioning

linkage arms (1) at a suitable height for

attachment, secure in position with locking pins

(2).

Fit top link (3) and secure with link pin and

locking pin (4).

Ensure linkage lift rods on both sides are set at

the same height and secured.

Note: The top link should be adjusted to an angle of

at least 3° greater than the lower links arms – refer

to diagram below.

Raise support leg (5) into the stowed position

and secure in place with its lock pin (6). Do not

remove the support leg.

Setting of Side Position

The working position of the machine (side position) is set by sideways adjustment of the

lower link arms to a point where the cutting area of the machines is just beyond the tractor

wheel on its working side – see illustrations below.

Shift the mower sideways on the lower link arms (2) to achieve the required distance (A),

secure in position with stabiliser arms (3). Additional shift (±

100mm) is available by altering

the position of the lower linkage pins.

OPTICUT 220/260/300

Rotary Disc Mowers

8

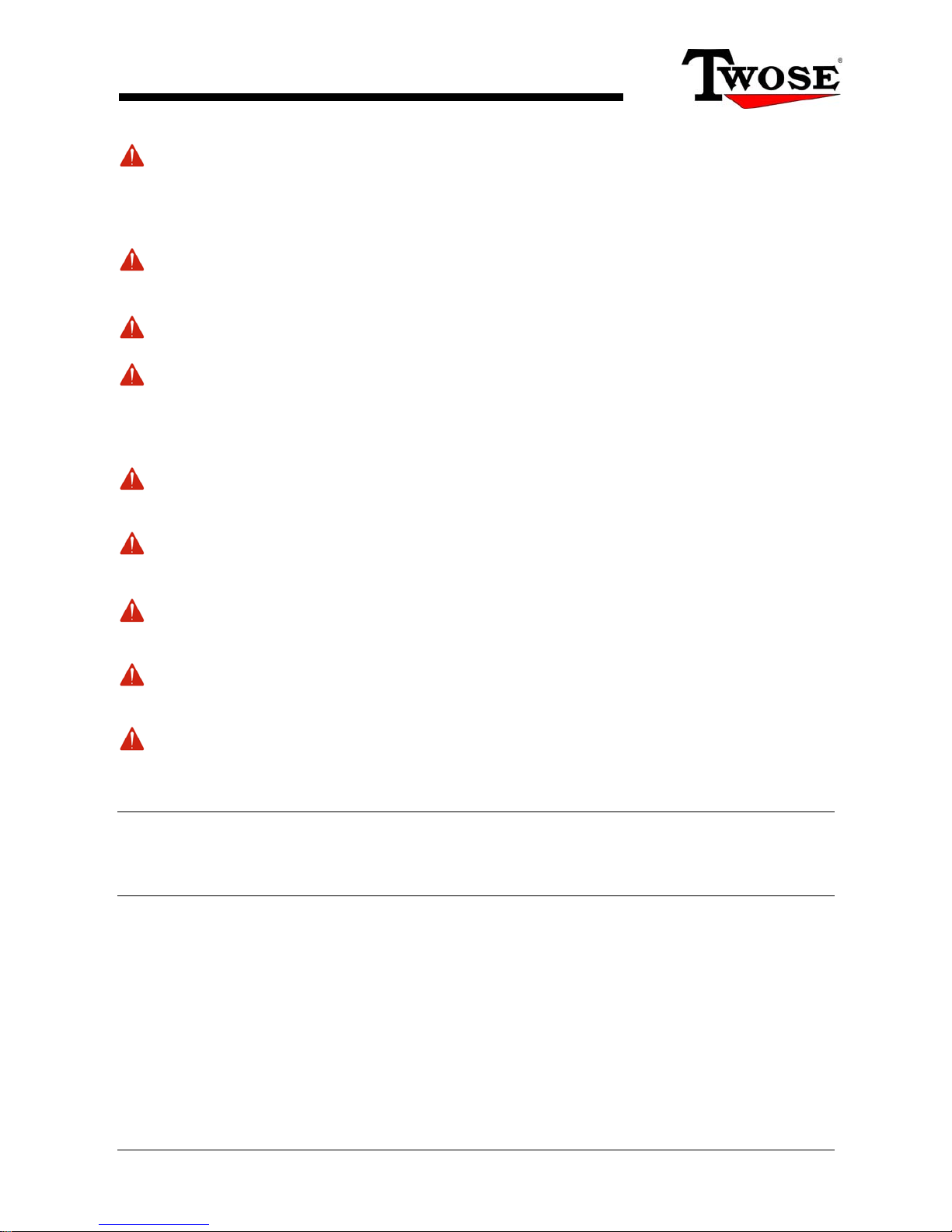

Vertical Adjustment (Side to Side)

Ensure the frame of the machine is

vertical as shown opposite ►

◄ If required, adjust the lower links (1) and lift rods

(2) to bring the frame into the vertical (side to side)

position.

Vertical Adjustment (Front to Back)

The correct vertical position of the frame, front to back, is with the frame tilted forward by 2°

in the direction of travel, this can be gauged by viewing the protection curtain (1); all the

lower edges should be equidistant to the ground when the machine is set correctly.

Rotate the adjuster nut (3) on top link (2) to achieve this setting – refer to illustrations below.

Note: This 2° inclination of the machine will produce a grass cut height of 50 – 55mm. The

tilt angle may be adjusted to suit individual preference but under no circumstances should it

exceed 7°.

The support leg is designed so the machine is automatically leaned forward by 2° when the

machine is disconnected.

OPTICUT 220/260/300

Rotary Disc Mowers

9

Adjusting Frame Work Height

Place the machine into the working position; the optimal working position is when the base

end of the support arm (1) is located midway within its guide slot – an indicator ‘notch’ (2)

marks this position. Raise or lower the machine on the tractors three-point linkage to

achieve this central position. Secure the linkage in position when the working height has

been set.

Note: This machine has the ability to work with the cutterbar at angles of between -30° and

+45°; when working at these angles the cutterbar should be brought back into the parallel

position every 15 minutes or so and run for 4 minutes to ensure continuous lubrication.

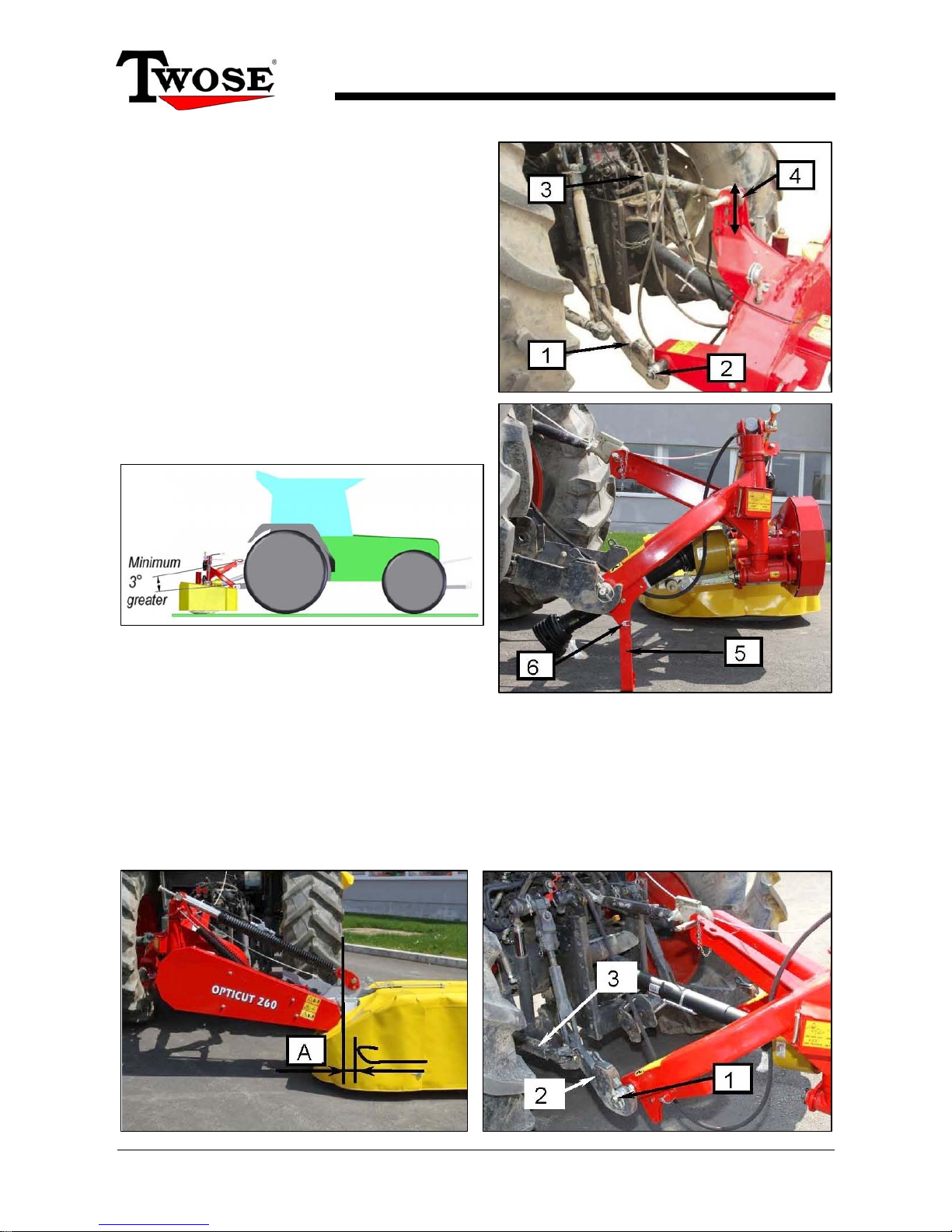

PTO Shaft Fitment

On initial fitment the PTO shaft halves (1 & 2) will need to be measured and cut to suit the

particular application – refer to following page for details.

Install PTO shaft (3) and fit torque chains to PTO guard (4) at each end of the shaft to

prevent them from rotating with the shaft.

Check the PTO shaft does not foul on the tractor or machine during normal operation and

manoeuvring; failure to observe this can result in damage to components.

OPTICUT 220/260/300

Rotary Disc Mowers

10

PTO Driveshaft

The PTO driveshaft attaches between the tractor and the machine gearbox to transfer the

power required to the run and operate the machine – it is important to achieve the correct

shaft length to avoid risk of it ‘bottoming out’ when raising or lowering the machine.

The procedure for measuring and cutting the shaft is as follows:

Measuring the PTO Shaft

With the machine attached to the

tractor in the working position measure

the horizontal distance ‘A’ from the

tractor’s PTO to the input shaft on the

machines gearbox and subtract 75mm

(3”) – this figure is the required shaft

length.

Place the fully closed PTO shaft on the

ground and measure its overall length,

if the shaft is shorter than the required

length you can use it without the need

to shorten - providing it allows for a

minimum 150mm (6”) overlap when

fitted.

If the shaft is longer subtract the

required shaft length plus an additional

75mm (3”) - the resulting figure is the

excess length that will need to be

removed from each half of the shaft.

Cutting the PTO Shaft

Separate the two halves and using the

measurement obtained above shorten

both the plastic guarding and the inner

steel profile tubes of each shaft by this

same amount. De-burr the cut tubes

with a file to remove rough or sharp

edges and thoroughly clean to remove

swarf before greasing, assembling and

fitting the shaft.

Always secure the PTO guards with torque chains to prevent them from rotating with the

shaft. Check to ensure the shaft does not contact or foul tractor or machine components

during normal operation - failure to observe this can result in damage to the tractor and/or

machine.

NOTE: For subsequent use with different tractors the shaft should be measured again to

check suitability – there must be a minimum shaft overlap of 150mm (6”).

Maintenance

To increase the working life of the PTO shaft it should be periodically checked, cleaned and

lubricated – refer to the PTO maintenance section for further details on this subject.

OPTICUT 220/260/300

Rotary Disc Mowers

11

Hydraulic Connection

The machine requires one hydraulic

connection; this is for operation of the

hydraulic ram that raises and lowers the

cutterbar.

The minimum working pressure necessary to

operate the machine is 50bar and a maximum

of 200bar.

Before connecting the hydraulic hose (1) to the tractor ensure that the control for that

service is in the midpoint ‘off’ position and the system is not pressurised.

NOTE: Ensure all hydraulic connections are kept free from dirt and other contaminates that

can cause damage to a hydraulic system.

Transport Locking Mechanism

Route the operation cord (1) for the transport locking

mechanism (2) into the tractor cab through the rear

window – ensure sufficient slack is retained in the cord

run to avoid accidental operation of the mechanism.

Fix the cord to a suitable location in the cab that is easily

accessible to the operator.

WARNING!

The transport latch operation cord must be slack at all

times to avoid unintentional operation of the latch. Ensure

the cord is kept clear of any components on the tractor

and the machine that may cause accidental tightening of

the cord and operation of the latch.

Ballast

Add front end weights to the tractor if required to increase stability of the unit for both

transportation and work. Refer to tractor manufacturer’s handbook for advice on ballasting.

OPTICUT 220/260/300

Rotary Disc Mowers

12

Post Attachment Checks

After attaching the machine the following checks should be performed, ensure the tractor is

switched off and the starting key removed.

Check the attachment of the machine to the tractor;

Operating height of the hitch.

Hitch installation.

Frame angle (2° inclination in the direction of travel).

Check position of the support leg.

Check all guarding is correctly located and undamaged.

Check lubrication levels in all drives.

Check all vital parts are present and working correctly.

Check parts for wear, damage or looseness on used machines, particularly;

Blades.

Discs.

Quick change blades.

Belts.

Guards.

Protection curtain.

In the event of damage or excessive wear to vital parts of the machine, replacements

must be sourced and fitted before attempting to operate it. Each disc on the machine is

fitted with 2 blades; these must be new or evenly worn. For safety and long working life

always replace components with genuine parts from the manufacturer.

With all persons are kept at a safe distance from the machine, conduct a test run with the

machine running at 540RPM.

In the event of excessive noise and/or vibration, stop the machine and correct the

problem.

If the problem continues, contact authorised service centre for advice or help.

If all the above criteria are met the machine is ready for operation.

OPTICUT 220/260/300

Rotary Disc Mowers

13

Spring Assisted Weight Distribution

To aid weight distribution and reduce mechanical stress the machine is fitted with 2 spring

dampeners; the smaller spring supports the heel of the cutterbar and the larger spring

supports the whole cutterbar. These are adjustable to suit operating preference and specific

working conditions.

Factory setting for the spring is: Distance ‘X’ = 70mm

Spring Adjustments

To reduce spring tension on the cutterbar, reduce distance ‘X’ on small spring (1) and

relocate pin (2) on the large spring to the previous hole position, to increase tension,

increase distance ‘X’ and move pin (2) to the next hole.

NOTE: Adjustment to the larger spring must be performed with the machine folded into the

transport position.

OPTICUT 220/260/300

Rotary Disc Mowers

14

▲

Ensure ram tap is closed for transportation.

Moving Into Transport Position

For transportation of the machine the cutterbar must be raised into the vertical position; the

procedure for moving into transport is as follows:

With the machine in the horizontal work position, fold the

outer end of the protection curtain (1) over the top of the

cutterbar.

Pull and retain tension on the operation cord (2) to

disengage the transport locking mechanism.

Operate the hydraulic ram to raise the cutterbar.

Tension on the operation cord can be released once the

cutterbar has reached an angle in excess of 60°.

Continue operation of the ram until the cutterbar is

upright at 90° and the transport lock has fully engaged.

Close tap (4) on the ram valve.

The machine is now folded and ready for transportation.

WARNING! Always be aware of the height of the machine during transport and take extra care when

manoeuvring close to buildings and under low bridges.

OPTICUT 220/260/300

Rotary Disc Mowers

15

Moving from Transport into Work Position

The procedure for moving from transport to work position is basically a reversal of moving

from work into transport.

Open tap on ram valve.

Pull and retain tension on the operation cord to disengage the transport locking

mechanism.

Operate the hydraulic ram to lower the cutterbar.

Tension on the operation cord can be released once the cutterbar reaches an angle of

approximately 80°.

Continue operation of the ram until the cutter has reached its horizontal work position

and the latch has re-engaged.

Re-position the protection curtain.

The machine is now ready for work.

Raising and Lowering the Cutterbar in Work

Raising and lowering the cutterbar when moving between rows or turning on the headland

is performed by operation of the hydraulic ram. Do not pull the cord for the transport latch.

Raising the cutterbar during work is by operating the ram with the transport latch engaged.

CAUTION!

When raising the cutterbar with the machine running there is risk of danger from flying

objects such as stones or other hard objects; ensure persons and animals are clear of the

danger zone before raising the cutterbar when the machine is running. Always cease

working and stop the machine when persons approach, do not re-start until they are clear of

the danger zone.

OPTICUT 220/260/300

Rotary Disc Mowers

16

Instructions for Safe Mowing

Always ensure that each disc is fitted with 2 knives, either new or equally worn.

Always replace damaged or worn blades, knives, and knife holders immediately – never

attempt to operate the machine with any of these components in a damaged or overly

worn condition.

Stop the machine immediately if an increase in noise or vibration is experienced –

continue work only when the reason for the disturbance has been investigated and

resolved. Ensure both the machine and the tractor’s engines are switched off before

nearing the mower to investigate.

Only operate the machine at the correct PTO speed.

Mowing Instructions

Allow the mower to reach its maximum permitted PTO speed before entering it into the

grass to cut and keep the machine at this speed for the duration of the mowing to

ensure a clean cut.

Select a gear that will enable best mowing according to the ground conditions.

Replace worn knives – sharp knives produce a cleaner more efficient cut.

Loading...

Loading...