Page 1

V.A.L.E.

2008 Yamaha

V A R I A B L E A X I S L O C K I N G E X H A U S T

RHINO 700

V. A.L.E. ™ Com plete D UAL Exha ust Sys tem wit h M-7 Caniste rs

Part # 0 05-2170106D

Installation Instructions

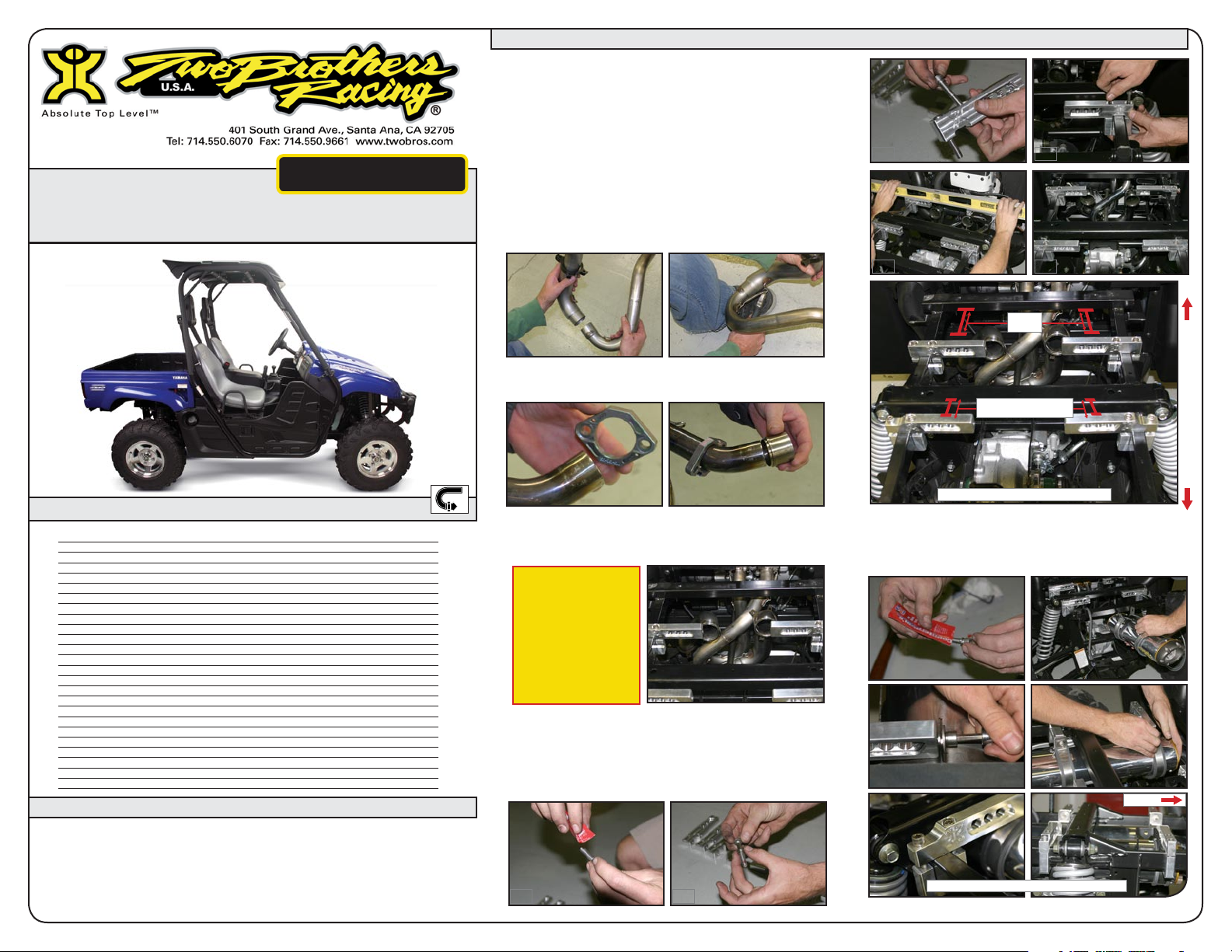

Make sure the ATV is completely cool before starting

1.

the installation. Make sure the ATV is secure and the

wheels are choked to prevent rolling during installation.

Remove the bed from the rear section of the Rhino.

2.

First remove the pins in the hinges, unhook the

hydraulic shocks, then disconnect the electronics.

Remove the heat shield from the top of the motor.

Remove the stock headpipe and remove the mounting

3.

TM

bolts hardware and brackets holding the stock muffler.

You will need to twist and rotate the stock muffler

4.

3 4

assembly in order to remove it from the chassis.

Connect both left and right header and slip tubes, join

5.

together with the 80mm springs.

5 6

5 “

Parts List

Qty. Description Part Number

1 Left Muffler Canister M-7 005-217-206ML

1 Right Muffler Canister M-7 005-217-206MR

1 Left Header 005-21701H-L

1 Right Header 005-21701H-R

4 Heavy Duty Muffler Clamp 005-2C4

1 HARDWARE KIT 005-217-4

4 X-Ring (half) 005-7-2-3

2 Header Collar 005-152-17-2

2 Steel Header Flange 005-152-15S-2

4 80mm Spring 005-S-80

2 Billet Bolt-on Muffler Mount (Front) 005-217-21

2 Billet Bolt-on Muffler Mount (Back w/ radius) 005-217-21B

4 Billet Bolt-on Muffler Mount “U” Brackets 005-217-21U

8 8x40mm Socket Head Cap Screws 005-SH840

12 M8 Split High Collar Lock Washers 005-WL8

8 M6 Split High Collar Washers 005-WL6

4 8x1.25mm Pitch Metal Locking Flange Nuts 005-FNL8

4 8mm Large Flat Washers 005-WO8

4 8x20mm Socket Head Cap Screws 005-SH820

2 Spark Arrester Screen (Installed) 005-106S

8 6x14mm Socket Head Cap Screws 005-SH614

1 5mm Long Handle Ball end hex key 005-9-18610

1 Permatex High Strength Threadlock 031-P09179

1 TBR Sticker Kit 015-10212

IMPORTANT - PLEASE READ CAREFULLY

Slide the flange over the header tube with the part number

6.

edge going on first. Then slide the collar over the end of the

exhaust tube that will connect to the cylinder head.

Install the new TBR head pipes making sure that the OEM

7.

sealing gasket is between header collar and cylinder head.

Use the supplied 8mm lock nuts to secure header flange to

cylinder head. Leave loose for now.

IMPORTANT:

The driver’s side

header system has less

bend when compared

to the passenger side.

Both exhaust will go

under the drive shaft.

Install the passenger

side first. The driver’s

side goes in front of the

passenger side.

Install mounting brackets to frame as shown. The rear

8.

brackets have a radius for bed hydrolic shock clearance.

Use threadlock and lock washers on all hardwarre. Make

sure brackets are level with each other. Because of the

differences with every Rhino, this bracket may fit tighter on

some frame rails due to paint and/or heat from production

welds and twisting. This is normal.

1” or Less

Bracket Spacing Measurements

Slide rubber clamp liner inside the 4 muffler clamps.

9.

Carefully slide rubber lined clamps over the muffler and

10.

loosely secure to mounting brackets. Use threadlock, lock

washers and large OD washers. Leave loose for now.

Front

Front

Rear

We recommend that this performance part be installed by a qualied motorcycle technician.

If you have any doubts as to your ability to install this performance part, please consult with

your local motorcycle dealer. Read all instructions rst before starting installation. Make sure

the motorcycle and exhaust system are completely cool before starting the installation. Also,

make sure the bike is secure on a centerstand or ideally a service lift during installation. Be

sure to save all stock components for possible use later.

1 2

Rear brackets have radial bends.

NOTE: Instructions continued on Page 2...

Page 2

Installation Instructions

Attach header tubes to mufflers using supplied 6x16mm

11.

socket head screws and lock washers using threadlocker

and loosely secure both mufflers.

Check wires and cables to make sure they are clear from

18.

header tubes.

V.A.L.E.

2008 Yamaha

V A R I A B L E A X I S L O C K I N G E X H A U S T

RHINO 700

V. A.L.E. ™ Com plete D UAL Exha ust Sys tem wit h M-7 Caniste rs

Part # 0 05-2170106D

005-2170106D

Qty. Description Part Number

1 Left Muffler Canister M-7 005-217-206ML

1 Right Muffler Canister M-7 005-217-206MR

1 Left Header 005-21701H-L

1 Right Header 005-21701H-R

4 Heavy Duty Muffler Clamp 005-2C4

1 HARDWARE KIT 005-217-4

4 X-Ring (half) 005-7-2-3

2 Header Collar 005-152-17-2

2 Steel Header Flange 005-152-15S-2

4 80mm Spring 005-S-80

2 Billet Bolt-on Muffler Mount (Front) 005-217-21

2 Billet Bolt-on Muffler Mount (Back w/ radius) 005-217-21B

4 Billet Bolt-on Muffler Mount “U” Brackets 005-217-21U

8 8x40mm Socket Head Cap Screws 005-SH840

12 M8 Split High Collar Lock Washers 005-WL8

8 M6 Split High Collar Washers 005-WL6

4 8x1.25mm Pitch Metal Locking Flange Nuts 005-FNL8

4 8mm Large Flat Washers 005-WO8

4 8x20mm Socket Head Cap Screws 005-SH820

2 Spark Arrester Screen (Installed) 005-106S

8 6x14mm Socket Head Cap Screws 005-SH614

1 5mm Long Handle Ball end hex key 005-9-18610

1 Permatex High Strength Threadlock 031-P09179

1 TBR Sticker Kit 015-10212

TM

Re-install the bed and hydrolic shock. Check to make sure

Align mufflers from rear of the vehicle.

12.

19.

that the shocks clear the brackets.

Before you run the bike, clean off all fingerprints and dirt, as

20.

any oily residue will etch the metal and become somewhat

permanent when the system gets hot. Run the bike and

enjoy. It is normal for some white smoke to appear the first

time you start the bike. This is packing/manufacturing oil

from inside the pipe burning off. Check for gaps or leaks.

If you find a leak, a little high temperature silicon sealant

should fix it. After 1 to 2 hours of riding recheck all fasteners

Tighten the 4 6x16mm socket head screws that attach the

13.

muffler to the header joint on both mufflers.

Tighten the muffler clamps, making sure the alignment is good.

14.

Tighten header flange nuts.

15.

for tightness.

Maintenance

Check your hardware every 10 hours of operation,

•

including the bolts on the muffler assembly.

Packing should be replaced every 15 hours of operation.

•

Quiet inserts are also available. P1 Powertip (005-P1), P1-

•

R Powertip (005-P5) and P4 Powertip (005-P4)

In order to maintain optimal performance, it is

•

recommended that this spark arrestor be cleaned after

every 30 hours of use. (Our U.S. Forestry Service approved

Spark Arrester is included with all M-7 V.A.L.E. stainless/aluminum

exhaust systems. These tips prevent broadcasting sparks with no

appreciable loss of horsepower. Additionally this tip prevents the

introduction of foreign matter into the exhaust system.)

Care & Cleaning

Care & Cleaning

Keep system free of dirt and moisture. Store in a cool, dry place. Make sure vehicle is

Install one spring per side on each header at flange.

16.

Re-install heatshield.

17.

completely cool before maintenance.

Stainless Header System: Polished stainless steel pipes will turn a light golden hue

after a few heat cycles, this is a normal characteristic of high quality stainless steel.

Clean using a mild water based spray cleaner. Always apply cleaner or polish with a soft,

clean cloth.

Polished Aluminum Canisters: Use an aluminum or mag wheel polish to restore the

bright finish to factory spec.

Repack all road canisters every 3,000 miles. Part #005-10038

Repack all offroad canisters after every 10 hours of use. Part #005-10038MX

NEVER dyno test your bike with carbon fiber or titanium canisters installed - the

intense heat and lack of cooling air can quickly burn through the canister material. Two

Brothers Racing does not provide a warranty for burned canisters.

Warranty

Two Brothers Racing products are intended for closed course

competition purposes only, and therefore are sold “as is” without

warranty. Two Brothers Racing specifically disclaims any warranties

of merchantability or fitness for a particular purpose and disclaims all

responsibility for consequential and incidental damages or any other

losses arising from the use of these products or parts.

Loading...

Loading...