THE WORLD MODELS

MANUFACTURING CO., LTD.

FACTORY PRE-FABRICATED

ALMOST-READY-TO-FLY (ARF) SERIES

MADE IN CHINA

www.theworldmodels.com

Wing Span

Wing Area

Flying Weight

Fuselage Length

36 in / 920 mm

225 sq in / 14.5 sq dm

28 oz / 790 g

32.5 in / 830 mm

Warning! This model is not a toy.

It is designed for maximum performance. Please seek advice if one is not familiar with this kind

of electric powered precision model. Operating this model without prior preparation may cause

injuries. Remember, safety is the most important thing. Always keep this instruction manual at

hand for quick reference.

Outrunner Motor

Requires : 4-channel radio w/ 4 micro servos,

30A (burst 35A) brushless ESC, 3 cells

11.1V 15C discharge 2100 mAh Li - Po

battery & charger.

Specifications

*Specifications are subject to change without notice.*

INSTRUCTION MANUAL

HIGH

PERFORMANCE

KM0283110KM0283110

Outrunner Motor Included!

Kv (rpm/ V) 3600

Operating Power 350 W

Operating Voltage 6-15 V

Operating Current 30 A

Peak Current 35 A (max 15 s)

Shaft Diameter 3 mm (0.118”)

Diameter 28 mm (1.10”)

Length 31 mm (1.22”)

Weight 60 g (2.1 oz)

P. 1

INDEX

BEFORE YOU BEGIN

P. 1

PARTS LIST

P.2

SAFETY PRECAUTIONS

P.10

BEFORE YOU BEGIN

Cut off shaded portion.

Ensure smooth non-binding

movement while assembling.

Apply instant glue

(C.A.glue, super glue.)

Assemble left and right

sides the same way.

Peel off shaded portion

covering film.

Pay close attention here!

Apply epoxy glue.

Must be purchased separately !

Drill holes with the specified

diameter (here: 3mm).

ASSEMBLY

P.3-P.10

Check all parts. If you find any defective or missing parts contact your local dealer. Please DRY FIT

and check for defects for all parts that will require CA or Epoxy for final assembly. Any parts you

find to be defective after the gluing process may be difficult to remove for warranty replacement. The

manufacturer will replace any defective parts, but will

not

extend to the parts that are good before

gluing to defective parts during assembly.

Warranty will not cover any parts modified by customer.

Read through the manual before you begin, so you will have an overall idea of what to do.

Symbols used throughout this instruction manual comprise of the following : -

1

2

3

Pierce the shaded portion

covering film.

3mm

Do not overlook this symbol !

Warning!

Apply thread locker

P.2

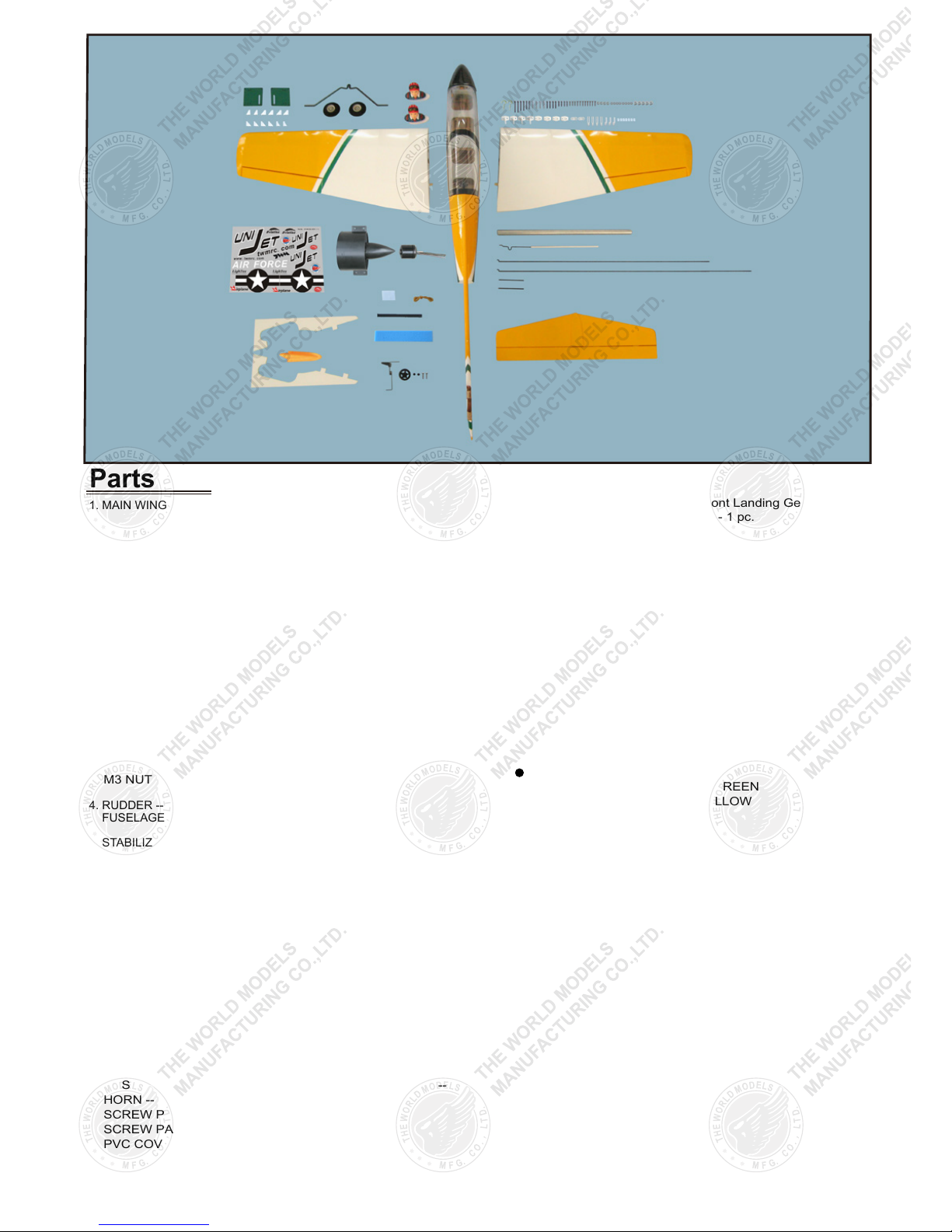

Parts List

1. MAIN WING -- 1 pair

2. SERVO MOUNTING PANEL -- 1 pair

PUSHROD Ø1.4x50mm w/ Threads (For Aileron Servo) -- 2 pcs

STRAPER -- 2 pcs

FUEL TUBE

d2xD4x4mm -- 4 pcs

CLEVIS -- 2 pcs

HORN -- 2 sets

SCREW PM2x16mm -- 4 pcs

SCREW PA1.7x8mm -- 8 pcs

3. DUCTED FAN PROPULSION UNIT WITH 28/31 MOTOR -- 1 set

PLYWOOD 3x67.8x217.8mm -- 1 pair

CABLE TIE -- 4 pcs

SOCKET HEAD SCREW M3x6mm -- 4 pcs

SCREW PM2x5mm -- 3 pcs

SCREW PM3x12mm -- 4 pcs

SCREW PWA2.3x8mm -- 4 pcs

WASHER d3xD7mm -- 4 pcs

M3 NUT -- 4 pcs

4. RUDDER -- 1 pc.

FUSELAGE -- 1 pc.

5. STABILIZER & ELEVATOR -- 1 set

6. MAIN LANDING GEAR -- 1 set

LANDING WIRE STRAPS (PL4114030) -- 2 pcs

MAIN WHEEL

Ø40mm -- 2 pcs

COLLAR Ø2.6mm w/ set screw -- 4 sets

SCREW PA2x8mm -- 4 pcs

7. FRONT LANDING GEAR -- 1 set

PLASTIC COLLAR d1.1xD5x2mm -- 2 pcs

FRONT WHEEL Ø23mm -- 1 pc.

SCREW PA2x8mm -- 2 pcs

8. PUSHROD Ø1.2x440mm

w/ Threads

(For Rudder Servo) -- 1 pc.

HORN -- 1 set.

SCREW PM2x12mm -- 2 pcs

9. PUSHROD Ø1.2x533mm

w/ Threads

(For Elevator Servo) -- 1 pc.

HORN -- 1 set

SCREW PM2x8mm -- 2 pcs

SCREW PA2x5mm -- 3 pcs

PVC COVER 0.5mm -- 1 pc.

10. PUSHROD

Ø0.8x206mm (For Front Landing Gear) -- 1 pc.

PLASTIC TUBE d2xD3x140mm -- 1 pc.

CLEVIS (d1.2mm) -- 2 pcs

FUEL TUBE d2XD4x4mm -- 2 pcs

PLYWOOD 2x9.4x15mm -- 1 pc.

BATTERY TIE 200mm -- 1 pc.

SPONGE 10x50x150mm -- 1 pc.

11. EYE SCREW PA2.5x10x23mm -- 2 pcs

WING TUBE d9.6x284mm -- 1 pc.

RUBBER BAND D30x1mm -- 2 pcs

12. COOKPIT -- 1 pc.

PILOT (PC101042A) -- 2 pcs

13. DECAL -- 1 set

COVERING:- LIGHTEX SGX 540 PEARL GREEN

LIGHTEX SGX 331 CUB YELLOW

LIGHTEX SGX 100 WHITE

P.3

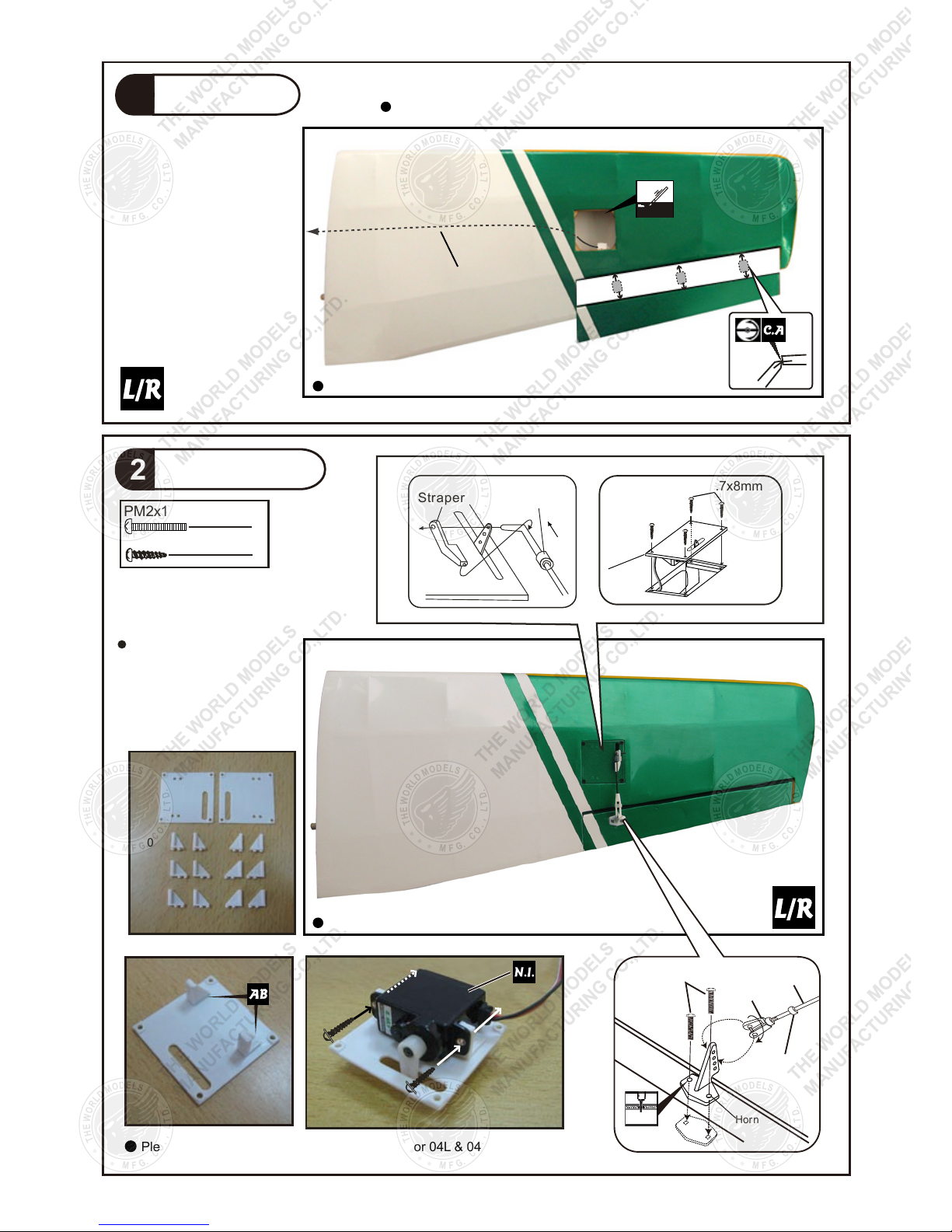

Main Wing

1

Aileron Servo

2

Aileron Servo Lead

Ø1mm pilot holes for World

Models tri-horn are pre-drilled.

Please look for pin-hole marks

at under side of control surfaces.

4

8

PA1.7x8mm Screw

PM2x16mm Screw

Str aper

Fuel Tube

d2xD4x4mm

Please choose either 02L & 02R or 03L & 03R or 04L & 04R that suits your servo.

02L

03L

04L

02R

03R

04R

Apply instant type CA glue to both sides of each hinge.

Bottom View

Bottom View

Fuel Tube

Clev is

PM2x 16mm

Horn

Pushrod

Ø1.4x50mm

d2xD4x4mm

PA1.7x8mm

2mm

P.4

Ducted Fan Propulsion Unit with 28/31 Motor

3

3

4

4

4

4

PM3x12mm Screw

d3xD7mm Washer

PM2x5mm Screw

PWA2.3x8mm Screw

M3x6mm Socket Head Screw

M3 Nut

Make sure TWM logo on ducted

fan stay on left side of fuselage.

Center Line

1

2

3

5

4

Make sure rotating motor casing

is not in contact with wiring or anything.

PM2x5mm

PM3x12mm

PM3x12mm

M3 Nut

M3x6mm

Rear View

4

PWA2.3x8mm

Cable Tie

1. 5m m

d3xD7mm

Washer

d3xD7mm

Washer

Plywood

3x67.8x217.8mm

TWM

TWM

TWM

TWM

TWM

6

30A Brushless ESC

Stabilizer & Elevator

4

Rudder

5

(Stabil izer)

(Main Wi ng)

B B'

B=B'

P.5

Completed

Completed

Apply instant type CA glue to both sides of each hinge.

Temporary install the main

wing, adjust leveling of the

stabilizer to make it as

parallel to the main wing as

possible.

Bottom View

Main Landing Gear

6

PA2x8mm Screw

2.6mm C o llar

4

4

PA2x8m m

1mm

Front

A A'

A= A'

C=C'

C

C'

3mm Set Screw

2.6mm Collar

Apply instant type CA glue to both sides of

each hinge.

Bottom View

P.6

Front Landing Gear

7

Rudder Pushrod

PA2x8mm Screw

2

PM2x12mm Screw

2

Plas tic Collar

d1.1xD5mm

1. 3m m

PA2x8m m

1.5 mm

8

Elevator Pushrod

9

PA2x5mm Screw

3

PM2x8mm Screw

Horn

2

PA2x5m m

1. 5m m

2mm

Bottom View

Bottom View

Ø1mm pilot holes for World Models horn are pre-drilled. Please look for

pin-hole marks at side of control surfaces.

Ø1mm pilot holes for World Models horn are pre-drilled. Please look

for pin-hole marks at under side of control surfaces.

2mm

Rudder Pushrod

Ø

1.2x440mm

Horn

PM2x12mm

120mm

55mm

PM2x8mm

Elevator Pushrod

Ø1.2x533mm

Ø1mm pilot hole is pre-drilled. Please look for pin-hole marks at

under side of fuselage.

P.7

10

Radio Equipment

Install and arrange the equipment as

shown in the picture.

Front Landing Gear

Front Landing Gear

Pushrod

Front Landing Gear

Pushrod

Ø0.8x206mm

Front

Plywood

2x9.4x15mm

w/ Plastic Tube

d2xD3x140mm

Elevator Servo

Elevator Pushrod

Ø1.2x533mm

Fuel Tube

d2xD4x4mm

Rudder Pushrod

Ø1.2x440mm

Rudder Servo

Fuel Tube

d2xD4x4mm

Clevis

Clevis

Bottom View

Front

Battery

Battery Tie

Sponge

Receiver

30A Brushless ESC Lead

Main Wing

11

Lead To Aileron Servo

Wing Tube Ø9.6x284mm

Rubber Band

Eye Screw

PA2.5x10x23mm

1. 5 mm

P.8

Front

Front

Bottom View

P.9

Wing Setting

13

Adjust the wing and fuselage configuration as shown in the diagrams.

A=A' B=B' C=C'

A

A'

B

B'

C

C'

Cookpit

12

Completed

Pilot

P.10

E2720 709

C.G.

15

Important Safety Precautions

# First time flyer should never fly by himself / herself. Assistance from experienced flyer is

absolutely necessary.

# Pre-flight adjustment must be done before flying, it is very dangerous to fly a badly

pre-adjusted aircraft.

# is designed for high speed flying. Too low an air speed during take off or landing

may canuse tip stall. Point the UniJet towards the wind, use full throttle and let the UniJet

gain enough ground speed before pulling the elevator gently for take off. For landing,

approach against the wind, maintain power to the ducted fan to keep enough air speed

before touch down.

# Make sure the air field is spacious, never fly the plane too close to people and neverget

too close to a running propeller.

# If you find wrinkles on the covering as a result of weather changes, you can use hot iron

to remove the wrinkles. Please begin with lower temperature setting and gradually raise

the temperature until the wrinkles are gone. Too hot an iron may damage the covering.

# Check and re-tighten up all factory assembled screws, use thread locker if necessary.

Warning!

The ideal C.G. position is 57mm ( 2.25in ) behind the leading

edge measured at where the wing meets the fuselage. In order to obtain

the C.G. specified, add weight to the fuselage or move the battery

position. Check the C.G. before flying.

57mm

C.G.

2.25in

Control Throws

14

6mm

6mm

El e vator

12mm

12mm

Rudder

6mm

6mm

Ailerons

Adjust the control throws as shown in the diagram. These throws are good for general

flying. You can adjust according to your personal preference.

http://www.theworldmodels.com

E2720 709

Loading...

Loading...