Wing Span 49 in / 1240mm

Wing Area

818sq in / 52. 8 sq dm

Flying Weight 8.1 lbs / 3700 g

Fuselage Length

52. 5 in / 1330 mm

Warning !This model is not a toy.

It is designed for maximum performance. Please seek advice if one is not familiar with this kind

of engine powered precision model. Operating this model without prior preparation may cause

injuries. Remember, safety is the most important thing. Always keep this instruction manual at

hand for quick reference.

* Specifica tion s are su bjec t to cha nge wi thou t noti ce.*

Specifications

INSTRUCTION MANUAL

0.91 cu.in. displacement 4-stroke

Radio required : 4 channels, 5 servos airplane radio

E

A

D

R

-

Y

T

-

T

S

O

O

-

F

M

L

L

Y

A

- 90- 90

FACTORY PRE-FABRICATED

ALMOST-READY-TO-FLY (ARF) SERIES

MADE IN CHINA

P.2

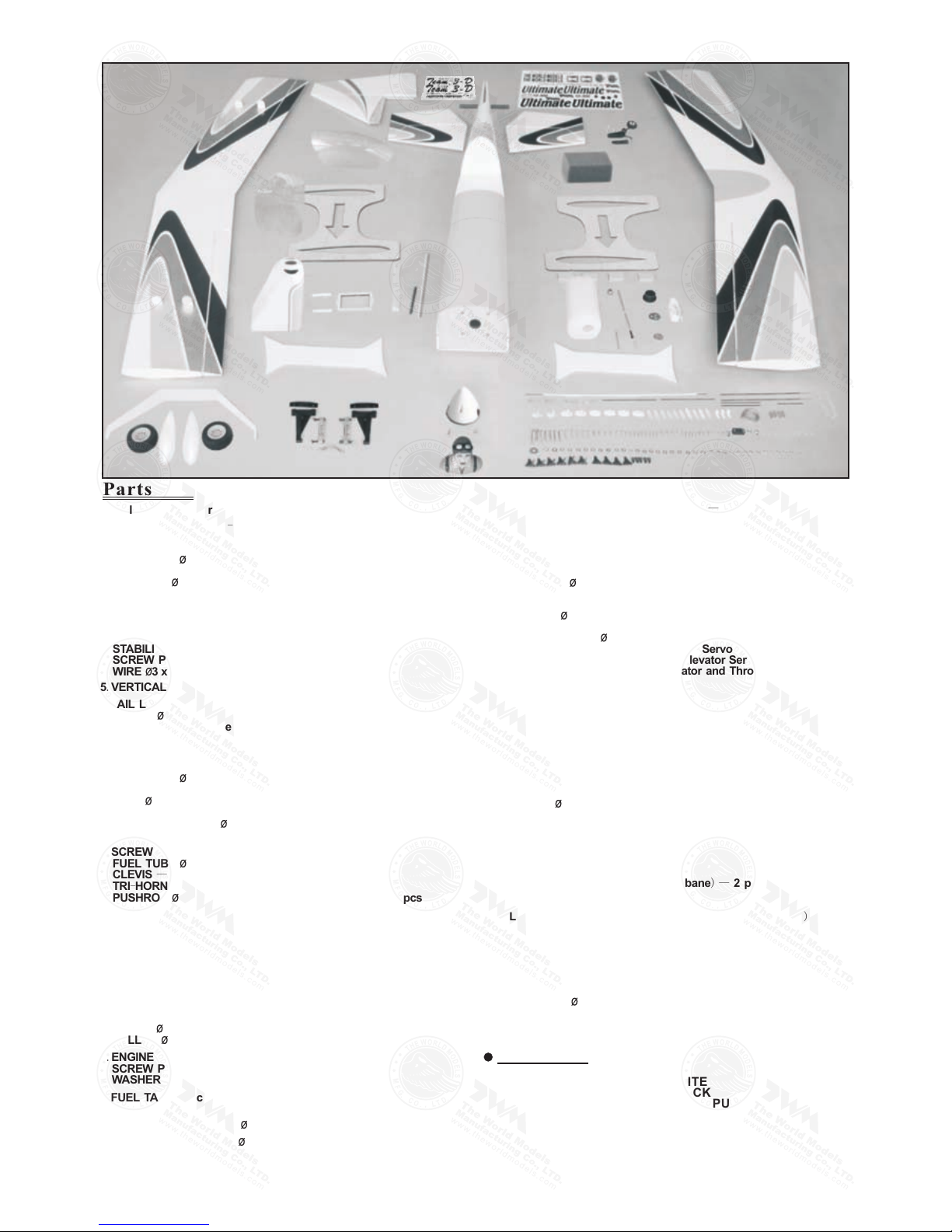

Parts List

COVERING:--

PURPLE COLOR SCHEME:

TOUGHLON STL 100 WHITE

TOUGHLON STL 201 BLACK

TOUGHLON STL 561 PEARL PURPLE

TOUGHLON STL 370 SILVER

YELLOW COLOR SCHEME:

TOUGHLON STL 100 WHITE

TOUGHLON STL 201 BLACK

TOUGHLON STL 330 CADMIUM YELLOW

TOUGHLON STL 370 SILVER

1.MAIN WING(Lower) -- 1 pc

.

2.SCREW PM2x20mm -- 6 pcs

STRAPER -- 2 pcs

CLEVIS -- 2 pcs

FUEL TUBE 6x5mm -- 4 pcs

TRI-HORN M3x14mm(L) -- 2 sets

PUSHROD 1.8x70mm w/Threads(For Aileron) -- 2 pcs

WOOD BLOCK 9x10x21mm(For Aileron) -- 2 pcs

3.MAIN WING(Upper) -- 1 pc.

4.STABILIZER & ELEVATOR -- 1 set

F

USELAGE

-- 1 p c.

STABILIZER TUBE 9.6x250mm -- 1 pc.

SCREW PWA3x12mm -- 2 pcs

WIRE 3 x141mm

--

1 pc.

5.VERTICAL FIN & RUDDER -- 1 set

6.TAIL LANDING GEAR -- 1 set

WHEEL 25mm -- 1 pc.

COLLAR 2.6mm w/set screw -- 1 set

SCREW PA3x12mm -- 2 pcs

7.SCREW PM2x20mm -- 3 pcs

M2 NUT -- 3 pcs

FUEL TUBE 6x5mm -- 2 pcs

CLEVIS -- 2 pcs

WIRE 1x534mm(For Rudder) -- 2 pcs

TRI-HORN M3x22mm (L)(w/o-Base For Rudder) -- 2 sets

RIGGING COUPLER 1.8x27mm w/Threads(For Rudder) -- 2 pcs

COPPER TUBE d2.5xD3.2x8mm(For Rudder) -- 2 sets

8.SCREW PM2x20mm -- 6 pcs

FUEL TUBE 6x5mm -- 2 pcs

CLEVIS -- 2 pcs

TRI-HORN M3x22mm(L) -- 2 sets

PUSHROD 1.8x480mm w/Threads(For Elevator) -- 2 pcs

9.MAIN LANDING GEAR -- 1 pair

WHEEL PANTS -- 1 pair

SCREW PM5x50mm -- 2 pcs

M5 NUT -- 2 pcs

M3 NUT -- 2 pcs

NYLON BOLT M3x18mm -- 2 pcs

PLASTIC COLLAR d5.1xD9x3mm -- 2 pcs

SCREW PM4x16mm -- 4 pcs

WASHER d4xD9mm -- 4 pcs

WASHER d5xD12mm -- 2 pcs

WHEEL 76mm -- 2 pcs

COLLAR 5.1mm w/set screw -- 4 sets

10.ENGINE MOUNT PL5111080 -- 1 set

SCREW PM4x30mm -- 4 pcs

WASHER d4xD12mm -- 4 pcs

11.FUEL TANK 450cc -- 1 set

B ALSA 8 x8x

129

mm(For F ixing F uel T ank) --1 p c.

12.LINKAGE CONNECTOR 2.1mm -- 1 set

13.THROTTLE PUSHWIRE 1.2x480mm -- 1 set

w/Plastic tube d2xD3x370mm -- 1 pc.

ALUMINUM PLATE(For Engine Mount) -- 1 pc.

ANTI-VIBRATION MOUNT PL5214094 -- 1 set

INCLUDE:SOCKET HEAD SCREW M4x35mm -- 4 pcs

S CREW K M3x20mm -- 8 p cs

W ASHER d 4xD12mm

--

8 p cs

M 3 N YLON I NSERT L OCK U T --8 pc s

M 4 N YLON I NSERT L OCK U T --4 pc s

14.FUEL TUBE 6x5mm -- 1 pc.

STRAPER -- 1 pc .

PUSHROD CONNECTOR

-- 1

set

PUSHROD 1 .8x70mm(For Elevator

Servo) --

1 pc .

COPPER TUBE d2 .5xD3 .2x8mm(For Rudder) -- 2 pcs

RIGGING Z BEND 1 .8x27mm(For Rudder) -- 2 pcs

PLYWOOD

5x61x121

mm For Rudder Servo) -- 1 pc .

(

BALSA 6x6x61mm(For Rudder &

Elevator

Servo Stand) -- 4 pcs

PLYWOOD

5x61x126mm

(For Elevator and Throttle

Servo

) -- 1 pc.

SPONGE

60x70x120

mm

--

1 pc .

15.CANOPY -- 1 pc.

SCREW PM3x16mm

--

2 pcs

WASHER d3xD7mm 2 pcs

- SCREW PWA2 .3x8mm -- 4 pcs

DOUBLE-SIDED TAPE -- 1 pc.

SILICON GROMMET d1.5xD6.5mm -- 4 pcs

PILOT PC001085A/B -- 1 set

16.COWLING -- 1 set

TRANSPARENT DUMMY COWLING -- 1 pc.

SPINNER 62mm(w/alu.back plate) -- 1 set

SCREW PWA2 .6x12mm -- 4 pcs

SILICON GROMMET d1.5xD6.5mm --

4

pcs

17.SCREW PM4x40mm -- 1 pc.

SCREW PM4x30mm

-- 2

pcs

WASHER d4xD15mm

-- 3

pcs

18.PLYWOOD 6x133x243mm Side Cabane) -- 2 pcs

(

PLYWOOD 6x20x36.6mm -- 4 pcs

CENTER WING CABANE -- 1 set

PLYWOOD 3x282x309mm(Wing Incidence Angle Template) -- 2 pcs

SCREW PM3x16mm -- 13 pcs

SCREW PM3x20mm -- 1 pc.

WASHER d3xD7mm -- 28 pcs

M3 NYLON INSERT LOCK NUT -- 14 pcs

19.SCREW PM2x10mm -- 8 pcs

CLEVIS -- 4 pcs

FUEL TUBE 6x5mm -- 4 pcs

HORN -- 4 sets

PUSHROD

M2xD4x212

mm w /Threads(For Aileron) -- 2 pcs

20.DECALS -- 1 set

P. 1

- 90- 90

P. 3 - 11

Do not overlook this symbol!

Cut off shaded portion.

Peel off shaded portion

covering film.

Pay close attention here!

Pierce the shaded portion

covering film.

Must be purchased separately!

Drill holes with the specified

diameter (here: 3mm).

3mm

Check all parts. If you find any defective or missing parts contact your local dealer. Please DRY FIT

and check for defects for all parts that will require CA or Epoxy for final assembly. Any parts you

find to be defective after the gluing process may be difficult to remove for warranty replacement. The

manufacturer will replace any defective parts. but will

not

extend to the parts that are good before

gluing to defective parts during assembly.

I N D E X

BEFORE YOU BEGIN

PARTS LIST

ASSEMBLY

SAFETY PRECAUTIONS

P. 1

P. 2

P. 11

BEFORE YOU BEGIN

Read through the manual before you begin, so you will have an overall idea of what to do.

Symbols used throughout this instruction manual comprise of the following : -

Ensure smooth non-binding

movement while assembling.

Apply instant glue

(C.A.glue, super glue.)

Assemble left and right

sides the same way.

Apply epoxy glue.

1

2

3

P.3

1

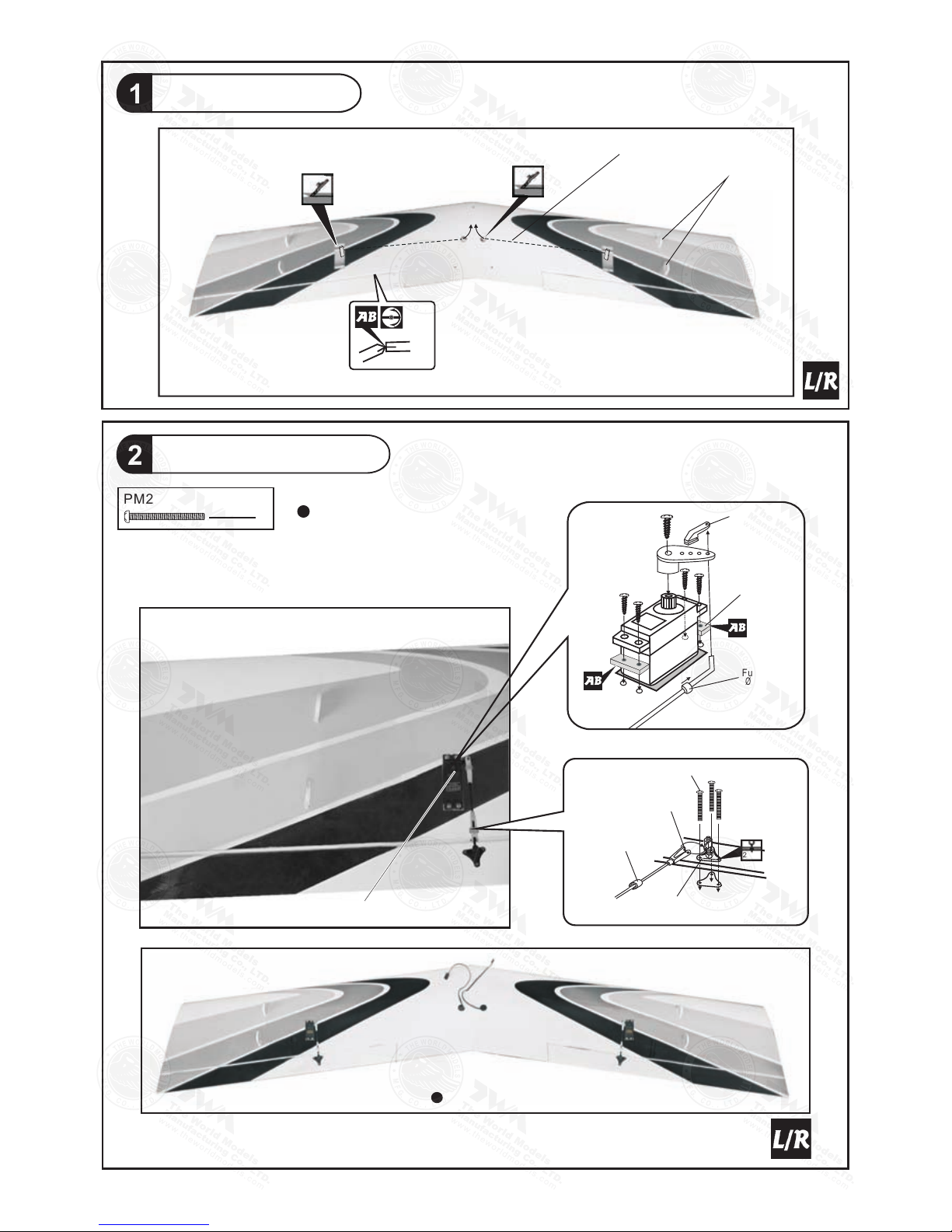

Aileron Servo (Lower)

2

Main Wing (Lower)

CABA NE MO UNT

Aile ron S erv o Lea d

PM2x2 0mm Screw

6

Fuel Tu be

Ø6x5m m

PM2x 20 mm

Tri-h or n

M3x1 4m m(L )

Clev is

Compl eted

Pushr od Ø1.8 x70mm

Pre-g lued

Ø1mm pilot holes for World Models

tri-horn are pre-drilled. Please look

for pin-hole marks at under side of

control surfaces.

2mm

Fuel Tu be

Ø6x5mm

Stra pe r

Woo d Block

9x10 x2 1m m

P.4

3

Stabilizer & Elevator

4

Main Wing (Upper)

Vertical Fin & Rudder

5

Bottom View

B=B

B

B

Completed

CABA NE MO UNT

Bottom View

PWA 3x 12 mm

42m m

98m m

PWA 3 x 12 mm

M3 x 6mm S et S crew

M3 x 6mm S et S crew

M3 x 6mm S et S crew

M3 x 6mm S et S crew

Wire Ø3 x1 41 mm

PWA 3 x 12mm Screw

2

2mm

2mm

Bottom View

Bottom View

Stabilizer Tube

D9.6 x2 50 mm

A

A'

A=A'

Pre-glued

Pre-g lued

Pre-glued

P.5

Tail Landing Gear

6

1.5mm

PA3x1 2mm Screw

2.6mm Collar

M3x3 mm S et Sc re w

PA3x12m m

2.6m m Co lla r

1

Bottom View

2

7

Rudder Pullwire

PM2x2 0mm Screw

3

M2 Nut

3

Bottom View

190m m

50mm

M2 Nut

PM2x2 0mm

Clev is

Rigg in g Co upl er

1.8 x 27 mm

2mm

Ring

Cop per Tube

Fuel Tu be

6 x 5mm

Wire Ø1 x5 34 mm

8

Elevator Pushrod

PM2x2 0mm Screw

6

Ø1mm pilot holes for World Models tri-horn

are pre-drilled. Please look for pin-hole marks

at side of control surfaces.

Ø1mm pilot holes for World Models tri-horn are pre-drilled.

Please look for pin-hole marks at under side of control surfaces.

Elevator Pushrod

1.8x 4 80 mm

Fuel Tu be

Ø6x5m m

PM2x 20 mm

Tri -h orn

M3x2 2m m(L )

Cop per Tube

Wir e

Press d ow n th e

cente r 1/ 3 po rt io n

Bottom View

Bottom View

155m m

72mm

2.5mm

2mm

P.6

11

Fuel Tank

Install Balsa 8x8x129mm

(For Fixing Fu el Ta nk)

Fuel Tank

450cc

Fuel Tank

450cc

Install Balsa 8x8x129mm

Engine Mount

PM4x30mm Screw

4

PM4x30mm

d4xD12mm Washer

d4xD12mm

Washer

Blind nuts are off-centered to keep

the spinner at the fuselage axis.

Engi ne M oun t

PL5111 08 0

Apply t hread loc ker to s crews.

9

Main Landing Gear

PM4x16mm

Bottom View

d4xD 9mm

Was her

PM5x50 mm Screw

2

M5 Nut

5.1mm Collar

PM4x16mm Screw

4

4

d4xD9mm Washer

4

10

2

d5xD12 mm Washer

M3x18mm NYLON BOLT

M3 Nut

2

2

2

4

5.1

mm Col

lar

d5. 1x D9x3m m

Plastic Collar

PM5x 50 mm

M5 Nut

d5xD 12

mm

Was he r

Nyl o

n Bolt

M3x 18 mm

M3x3 mm

Se

t Sc

rew

M3 Nut

Compl eted

P.7

13

Engine

M4x35mm SOCKET HEAD SCREW

4

M4 NYL ON IN SER T LOCK NUT

4

8

d4xD12mm Washer

d4xD12mm Washer

Throttle Pushwire

Ø1.2x480mm

w/Plastic Tube d2xD3x370mm

137mm

5.39 in.

Install Engine p osition

Throttle pushwire

3mm

Included with the radio Set.

Throttle Servo.

2mm

Servo Set

2mm

3x3mm Set Screw

Linkage Con nect or

M2 Nut

2mm Washer

1

1

1

2

LINKAGE CONNECTOR

12

2mm

Please refer to attache d shee t for li nkag e conn ecto r inst alla tion .

d4xD12mm

Washer

M4x35mm

SOCKET HEAD SCREW

M4 NYLON INSERT LO CK NUT

4mm N ylon In sert

Loc k Nut

M4x 35mm

Soc k Head Sc rew

1

2

Make sure the rounded

edges are facing the

shock absorbing

SILICON PAD.

KM3 x20mm S crew

Cop per Tube

d3. 1xD4x 7.2mm

M3 Ny lon Ins ert

Loc k Nut

d4x D12mm

Was he r

ANTI -VI BR ATION MO UNT I NSTALLATION

d4x D12mm

Was he r

Cop per Tube d 4.1xD 5x7.2 mm

Apply double-sided tape

Sp o n ge

PLYW OOD

5x61 x1 21 mm

Str aper

Fuel Tu be

Ø6x5m m

Throttle Pushwire

1.2x480mm

BALS A

6x6x 61 mm

Thro tt le S er vo

Rudd er S er vo

Front

Elev at or S er vo

P.8

14

16

Cowling & Spinner

PWA2.6x1 2mm Screw

4

4

First insert the grommet to the cowling then apply screw.

15

Canopy

First insert the grommet to the canopy then apply screw.

PWA 2.3x 8mm Sc rew

4

d1.5xD6 .5m m Sil ico n Gro mme t

4

Pilot

Radio Equipment

Spinner Ø62mm

d1.5 xD6.5 mm

Sili con Gro mme t

PWA 2.3x8 mm

d1.5 xD6 .5m m

Sili con G rom met

PWA 2.6 x12mm

1.5mm

Install and arrange the servo as shown in the diagram.

KM 2x 8mm

M2 Nu t

Ele vator P ushro d

Ø1.8 x70mm

Decals

d1.5 xD6 .5 mm Si licon Grommet

Ele vator S ervo

w/Plastic tube

d2xD3x370mm

Cop per Tube

Wir e

Pre ss down t he cent er

1/3 p ortio n

BALS A

6x6x 61 mm

PLYW OOD

5x61 x1 26 mm

1.5mm

PM3x1 6mm Screw

2

2

d3xD7mm Washer

PM3x1 6mm

d3xD7mm

Washer

Str aper

17

Main Wing (Lower)

PM4x4 0mm Screw

1

d4xD1 5mm Was her

3

PM4x3 0mm

Bottom View

d4xD1 5mm Was her

P.9

PLYW OOD 3 x2 82 x309m m

PLYW OOD 6 x1 33 x243m m

SIDE C AB AN E

WING I NC ID ENC E ANG LE T EM PLATE

Oute r win g cab ane

shou ld fi t to th e outsi de

of out er wi ng ca bane

moun ts.

With the wing incidence

angle template still in place,

position the side cabanes,

mark and drill the side cabane

mounts and fasten with

PM3x16mm screw and nut.

PM3x 16 mm

d3xD 7m m

Was he r

PM3x 16 mm

M3 Nylon In se rt

Lock Nu t

M3 Nylon In se rt L oc k Nu t

3mm

3mm

d3xD 7m m

Was he r

PM4x4 0mm

d4xD1 5mm Was her

PM4x3 0mm Screw

2

PM3x1 6m m

d3xD7mm

Was he r

M3 Nylo n

Insert Lo ck N ut

d3xD7mm

Was he r

3mm

PM3x2 0m m

18

Main Wing

d3xD7 mm Washer

28

M3 Nylo n Ins ert Lock Nu t

14

PM3x1 6mm S crew

13

PM3x2 0mm S crew

1

Plyw oo d

6x20 x3 6. 6mm

Pierce the two pre-drill

holes at upper wing center

cabane mount and fasten the

center cabanes with

PM3x16mm & PM3x20mm

screw and nut. With the lower

wing fastened to the fuselage,

insert the wing incidence

angle templates to both sides

of upper and lower wing to

hold the upper wing in

position. Drill and fasten the

center wing cabane with

2

B

2

A

Horn

Clev is

Fuel Tu be

Ø6x5m m

Clev is

Horn

PM2x 10 mm

Pushrod

M2xD4x212mm

2mm

B

B'

C

C'

D

D'

P.10

19

20

Wing Setting

Main Wing

PM2x1 0mm Screw

8

A=A' B=B' C=C' D=D' E=E' F=F'

F

F'

G=G'

G G'

E E'

A

A'

Ø1mm pi lot h ole s for World Models horn ar e pre -dr ill ed. Please

look for pi n-h ole marks at under sid e of control surfaces.

Adjus t the wing an d fuse lage conf igurati on as

in the di agrams.

P.11

120m m

4.72 i n.

22

Important Safety Precautions

# First time flyer should never f ly by himself / herse lf. Assistance from experienced flyer is

absolutely necessary.

# Pre-flight adjustment mus t be done before flying, it is very dangerous to fly a ba dly

pre-

adjusted aircraft.

# is specially desig ned to be powered by 4-stroke 0. 91 engine usin g a

more powerful e ngine does not mean b etter performance. In fact, over powered engi ne

may cause severe damage and inj uries.

# Make sure the air field is spacio us, never fly the plane too close to people and never g et

too close to a running propelle r.

# If you find wrinkles on the cover ing as a result of weather changes, you can use hot iro n

to remove the wrinkles. Pleas e begin with lower temperature setting and grad ually raise

the temperature until the wri nkles are gone. Too hot an iron ma y damage the covering.

# Check and re-tighten up all fac tory assembled screws, use thread locker if app licable.

A22405 12

Adjust the control throws as s how n in th e dia gra m.

These t hro ws ar e goo d for general fl yin g. You can

adjust according to your per son al pr efe ren ce.

Elevator

Rudder

21

Ailerons

15mm

15mm

50mm

50mm

- 90- 90

The ideal C .G. position is 1 20mm (4.72 in.) b ehind

the leadi ng edge measure d at top wing center line.

In order to o btain the C.G. sp ecified, add we ight to

the fusel age or move the bat tery position. Check

the C.G. be fore flying.

80mm

80mm

Loading...

Loading...