Wing Span

Wing Area

Flying Weight

Fuselage Length

63.0 in / 1600 mm

688 sq in / 44 sq dm

6.8 lbs / 3100 g

59.0 in / 1500 mm

Warning ! This model is not a toy.

It is designed for maximum performance. Please seek advice if one is not familiar with this kind

of engine powered precision model. Operating this model without prior preparation may cause

injuries. Remember, safety is the most important thing. Always keep this instruction manual at

hand for quick reference.

* Speci ficatio ns are subj ect to chan ge withou t notice.*

Specifications

INSTRUCTION MANUAL

E

A

D

R

-

Y

T

-

T

S

O

O

-

F

M

L

L

Y

A

INTRUDER 90RINTRUDER 90R

FACTORY PRE-FABRICATED

ALMOST-READY-TO-FLY (ARF) SERIES

MADE IN CHINA

Required :

0.91 cu.in. displacement 4-stroke

4-channel radio w/ 5 standard servos

0.60-0.75 cu.in. displacement 2-stroke

A050RPO28881306

INTRUDER 90RINTRUDER 90R

Apply thread locker

Apply epoxy glue.

Pierce the shaded portion

covering film.

Appl

(C.A.glue, super glue.)

y instant glue

Ensur

movement while assembling.

e smooth non-binding

Do not overlook this symbol !

P. 3 -11

Check all parts. If you find any defective or missing parts contact your local dealer. Please DRY FIT

and check for defects for all parts that will require CA or Epoxy for final assembly. Any parts you

find to be defective after the gluing process may be difficult to remove for warranty replacement. The

manufacturer will replace any defective parts, but will

not

extend to the parts that are good before

gluing to defective parts during assembly. Warranty will not cover any parts modified by customer.

INDE X

BEFORE YOU BEGIN

PARTS LIST

ASSEMBLY

SAFETY PRECAUTIONS

P. 1

P. 2

P.11

BEFORE YOU BEGIN

Read through the manual before you begin, so you will have an overall idea of what to do.

Symbols used throughout this instruction manual comprise of the following : -

1

2

3

Assembl

sides the same way.

e left and right

Pee

covering film.

l off shaded portion

Drill holes with the specified

diameter (here:3mm).

Pay close attention here!

Cut off shaded portion.

Must be purchased separately !

Warning!

3mm

P.1

A050RPO28881306

Parts List

P.2

COVE RIN G:

TOUGHLON

STL 100 WHITE

TOUGHLON

STL 201 BLACK

TOUGHLON

STL 320 ORANGE

1. MAIN WING -- 1 pair

2. SCREW PB2x16mm -- 2 pcs

SCREW PB2x18mm -- 4 pcs

SCREW PWA2x8mm -- 8 pcs

FUEL TUBE Ø6x5mm -- 4 pcs

STRAPER PL4112102-- 2 pcs

CLEVIS PL4112103 -- 2 pcs

TRI-HORN M3x14mm PL4111185 -- 2 sets

PUSHROD Ø1.8x115mm w/ Threads (For Aileron) -- 2 pcs

SERVO MOUNTING PANEL PL5310000 -- 1 pair

3. WING TUBE Ø25.4x234mm -- 1 pc.

4. MAIN LANDING GEAR --1 set

SCREW PA3x12mm -- 8 pcs

WHEEL Ø52mm PL3111520 -- 2 pcs

COLLAR Ø4.1mm w/ set screw -- 4 sets

PLATE 12x

20mm (For Main Landing Gear) PL4114020 -- 4 pcs

5. FUSELAGE -- 1 pc .

STABILIZER & ELEVATOR -- 1 set

SCREW PWA3x12mm -- 2 pcs

STABILIZER TUBE D9.5x296mm -- 1 pc.

WIRE Ø3x97mm -- 1 pc.

6. VERTICAL FIN & RUDDER -- 1 set

7. ENGINE MOUNT (PL5111070) -- 1 set

SOCKET HEAD SCREW M4x25mm -- 4 pcs

WASHER d4xD12mm -- 4 pcs

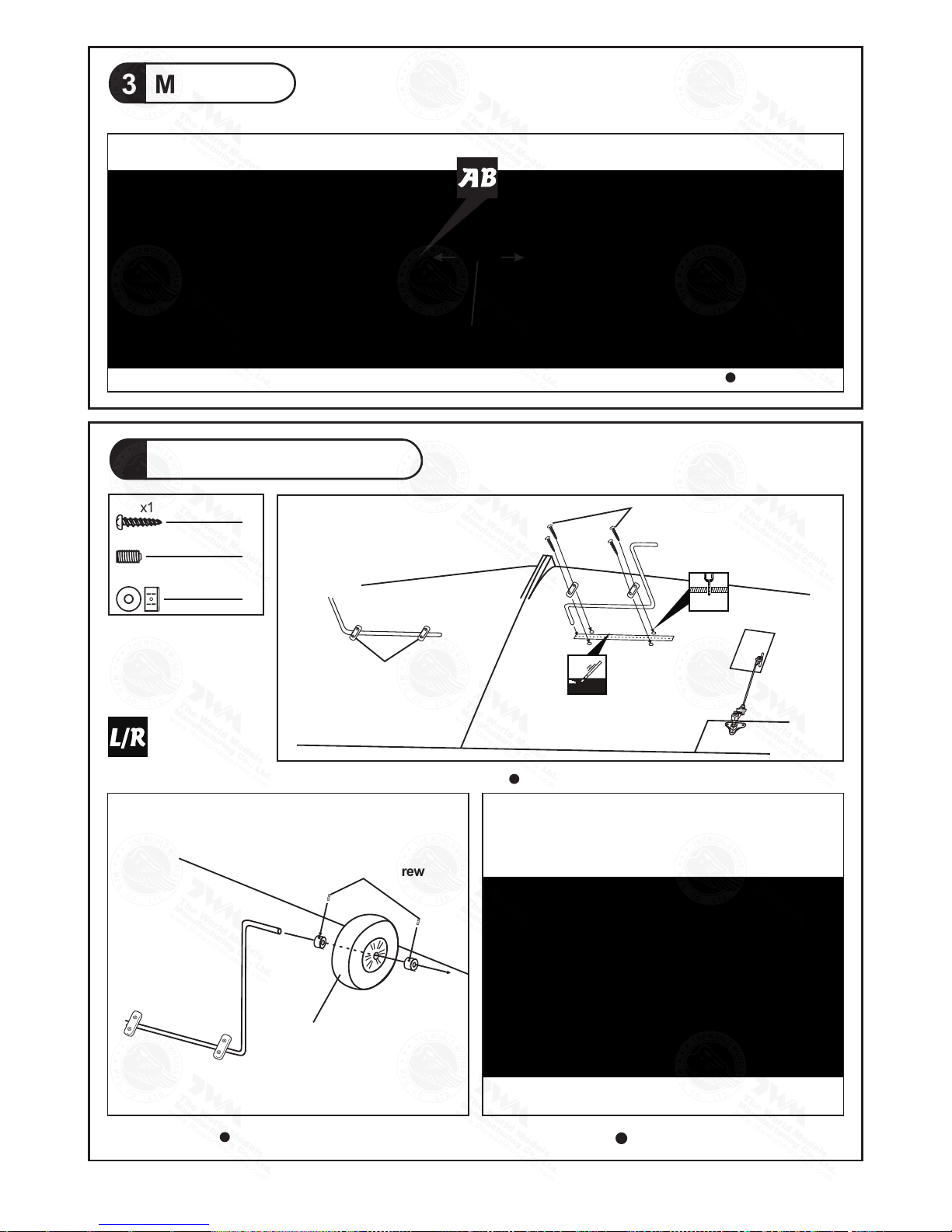

8. FRONT LANDING GEAR -- 1 set

COLLAR Ø4.1mm w/ set screw -- 4 sets

WHEEL Ø52mm PL3111520 -- 1 pc.

STEERING ARM Ø4.1mm PL4112401 -- 1 set

9. FUEL TANK 320cc PL1

111320 -- 1 set

BALSA 10x10x89mm(For Fuel Tank Position Fixing) -- 1 pc.

10. SOCKET HEAD SCREW M4x30mm -- 4 pcs

WASHER d4xD9mm -- 8 pcs

M4 NUT -- 8 pcs

11. SCREW PB2x22mm -- 6 pcs

CLEVIS PL4112103 -- 2 pcs

FUEL TUBE Ø6x5mm -- 2 pcs

TRI-HORN M3x14mm (L) PL4111185 -- 2 sets

PUSHROD Ø1.8x760mm w/ Threads (For Elevator) -- 2 pcs

12. SCREW PB2x16mm -- 3 pcs

FUEL TUBE Ø6x5mm -- 1 pc.

CLEVIS PL4112103 -- 1 pc.

TRI-HORN M3x14mm (L) PL4111185 -- 1 set

PUSHROD Ø1.8x870mm w/ Thr

eads (For Rudder) -- 1 pc.

13. LINKAGE CONNECTOR Ø2.1mm HW7111060 -- 2 sets

14. STRAPER PL4112102 -- 2 pcs

FUEL TUBE Ø6x5mm -- 2 pcs

SPONGE 60x70x90mm (For Radio Equipment) -- 1 pc.

FRONT WHEEL PUSHROD Ø1.4x375mm -- 1 pc.

PLASTIC TUBE d2.5xD4x330mm -- 1 pc.

THROTTLE PUSHWIRE Ø1.2x425mm -- 1 pc.

PLASTIC TUBE d2xD3x330mm -- 1 pc.

PUSHROD Ø1.8x80mm (For Elevator) -- 1 pc.

PUSHROD CONNECTOR 4x9x20mm PL4410010 -- 1 set

15. SOCKET HEAD SCREW M4x30mm -- 2 pcs

WASHER d4

xD15mm -- 2 pcs

SCREW PWM3x13mm -- 1 pc.

PLYWOOD 2x24x68mm (Wing Protection) -- 1 pc.

BELLY PAN -- 1 pc.

16. COWLING -- 1 pc.

TRANSPARENT 3D TEMPLATE --1 pc.

SCREW PWA2.6x12mm -- 4 pcs

SILICON GROMMET d1.5xD6.5mm -- 4 pcs

SPINNER Ø70 PL2111070 -- 1 set

17. CANOPY -- 1 pc.

SCREW PWA2.3x8mm -- 3 pcs

SILICON GROMMET d1.5xD6.5mm -- 3 pcs

18. DECALS A050RDEC -- 1 set

A050RPO28881306

P.3

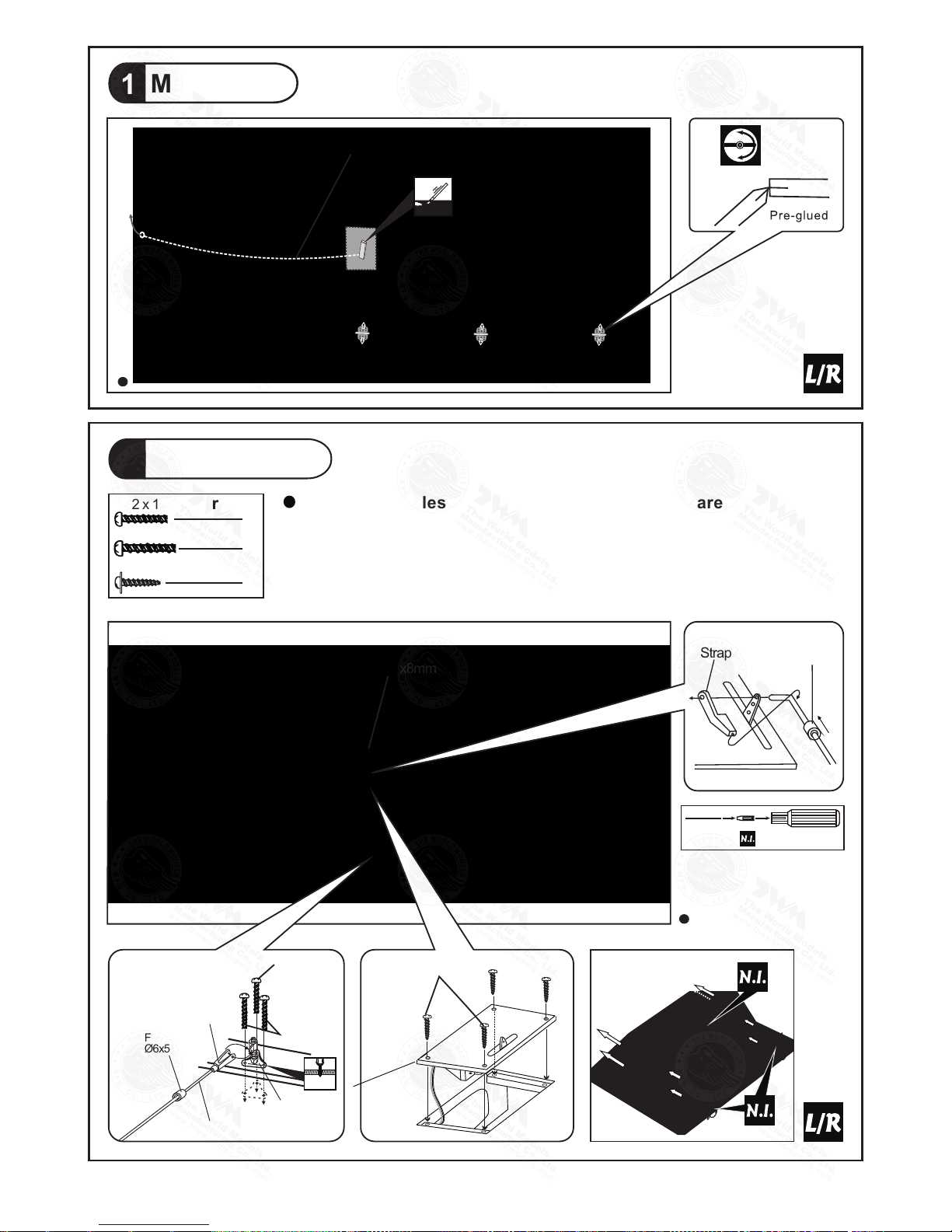

1

Main Wing

Aile ron S erv o Lead

Aileron Servo

2

Botto m View

2

PB2 x 16mm Screw

4

PB2 x 18mm Screw

8

PWA2 x 8mm Screw

Fuel Tube

Ø6x5mm

PB2x16mm

Tri-horn

M3x14mm

Clevis

Pushrod

Ø1.8x115mm

PB2x18mm

Fuel Tube

Ø6x5mm

Straper

PWA2x8mm

Botto m View

PWA2x8mm

Ø1mm pilot holes for The World Models tri-horn are pre-drilled.

Please look for pin-hole marks at under side of control surfaces.

2mm

TWM PL 82100 10

CLE VIS WREN CH

A050RPO28881306

P.4

3

Main Wing

Tube

Ø25.4x234mm

Wing

Botto m View

4

Main Landing Gear

PA3x12mm Screw

8

4

4

4.1mm

Wheel Collar

3mm Set Screw

Completed

One side only for

detachable wing.

Botto m View

3mm Set Screw

Wheel 52mmØ

Botto m View

Plate

PA3x12mm

1mm

A050RPO28881306

D9.5x296mm

1

2

5

m

m

65mm

PWA 3 x 12mm

P.5

Bottom View

6

Vertical Fin & Rudder

Completed

B=B'

B

B

5

Stabilizer & Elevator

PWA 3 x 12mm Screw

2

Botto m View

Ø3x97mm

Botto m View

PWA3 x 12mm

M3 x 6mm Set Screw

M3 x 6mm Set Screw

A

A’

A=A’

Botto m View

2mm

2mm

Botto m View

Botto m View

M3 x 6mm Set Screw

M3 x 6mm Set Screw

Top View

A050RPO28881306

P.6

Fuel Tank

9

Inst al l Ba lsa 10x10 x8 9m m

(For Fue l Tan k Po si tion Fixi ng )

Fuel Tank

320c c

Botto m View

Front View

Wheel 52mmØ

3mm Set Screw

Botto m View

8

Front Landing Gear

4

4

3mm Set Screw

4.1mm Wheel Collar

Engine Mount

7

4

4

d4 x D12mm

Washer

Engine Mount

PL5111070

M4x mm

SOCKET HEAD SCREW

25

M4x25mm Socket Head Screw

d4 x D12mm Washer

Fuel Tank

320cc

UP

Completed

Steering Arm

A050RPO28881306

P.7

11

Elevator Pushrod

6

PB2 x 22mm Screw

42m

m

17

0

m

m

Botto m View

Fuel Tube

Ø6x5mm

PB2x22mm

Tri-horn

M3x14mm

Clevis

Pushrod

Ø1.8x760mm

Elevator Pushrod

Ø1.8x760mm

Ø

Please look for pin-hole marks at under side of control surfaces.

1mm pilot holes for The World Models tri-horn are pre-drilled.

Engine

10

8

8

132mm

5.2 in

Installed Engine Position

Botto m View

d4 x D9mm Washer

M4 Nut

M4 Nut

d4 x D9mm

Washer

M4x30mm Socket Head Screw

4

M4x30 mm

4mm

2mm

TWM P L8 21 0010

CLE VIS WRE NC H

A050RPO28881306

P.8

Servo Set

13

3 x 3mm Set Screw

Linka ge Stopper

2mm

Nut

2mm Washer

2

2

2

4

3

PB2 x 16mm Screw

3

4m

m

1

7

0

m

m

Botto m View

Fuel Tube

Ø6x5mm

PB2x16mm

Tri-horn

M3x14mm

Clevis

Pushrod

Ø1.8x870mm

Rudder Pushrod

Ø1.8x870mm

12

Rudder Pushrod

Ø

Please look for pin-hole marks at under side of control surfaces.

1mm pilot holes for The World Models tri-horn are pre-drilled.

14

Radio Equipment

Install and arrange the servo as shown

in the diagram.

Front

Sponge

60x70x90mm

Throttle Pushwire

Ø1.2x425mm

Elevator Servo

Elevator Pushrod

Rudder Pushrod

Rudder Servo

Front Wheel Pushrod

Ø1.4x375mm

Botto m View

d2xD3x330

Plastic Tube

mm

d2.5xD4x330

Plastic Tube

mm

KM 2x 8mm

M2 Nu t

Ele vator P ushro d

Ø1.8 x80mm

Battery

Receiver

Throttle Servo

Switch Harness

Elevator Servo

Push ro d Conne ct or

J1( P us hr od Ø1.8 x8 0m m)

J2( P us hr od Ø1. 8x 76 0mm)

J1

J2

2mm

Pleas e refer to th e attache d sheet for l inkage co nnector i nstalla tion.

Throttle Pushwir e

3x3mm Set Screw

Throttle Serv o.

2mm

2mm

Washer

M2 Nut

2mm

Washer

TWM PL8 21 00 10

CLEVIS WRE NC H

Charg e Recepta cles

KP004 1300

A050RPO28881306

P.9

17

Canopy

Cowling

16

3

3

d1.5 x D6.5 mm Silicon Grommet

PWA2.3 x 8mm Screw

4

4

d1.5 x D6.5 mm Silicon Grommet

PWA2.6 x 12mm Screw

Spinner

Ø70mm

PWA2.3 x 8mm

d1.5 x D6.5 mm Silicon Grommet

PWA2.6 x 12mm

d1.5 x D6.5 mm Silicon Grommet

Main Wing

15

Bottom View

Complet ed

d4xD15mm

M4x30mm

Wing Protection

2x24x68mm

2

d4 x D15mm Washer

2

PWM3 x 13mm Screw

1

PWM3x13mm

First insert the grommet to the cowling then apply screw.

Wing Protection

2x24x68mm

Plea se refer to attached sheet fo r usa ge of the transparent

3D template.

First insert the grommet to the c

anopy then apply screw.

4mm

1.5mm

1.5mm

M4x30mm Socket Head Screw

Fue l Fille r

PL8 110030

A050RPO28881306

P.10

Adjust the wing and fuselage configuration as shown in the diagrams.

18

Wing Setting

B B'

C C

'

A =A'

B =B'

C

=C

'

A

A'

Stabilizer Setting

TO INC RE AS E I NC ID EN CE ANGLE, LO OSE BO TTO M S ET SCREW AN D T HE N T IG HT EN

TOP SE T S CR EW. TO REDUCE IN CIDE NC E A NG LE , LOOSE TOP SE T S CR EW A ND

THE N T IG HT EN B OT TOM S ET SCREW. DON 'T OVER TI GH TE N S ET S CR EW S AS TH E

INC ID EN CE AN GL E ADJUSTER AR E M AD E OF PL AS TI CS .

TOP

BOTTOM

M3X6mm Set Screw

A050RPO28881306

P.11

Adjust the control throws as shown in the diagram

These throws are good for general flying. Yon can

adjust according to your personal preference.

.

Control Throws

19

C.G.

20

6.14in

156mm

Elev ato r

Rudd er

Aile ron

35mm

35mm

20mm

20mm

8mm

8mm

INTRUDER 90RINTRUDER 90R

Important Safety Precautions

Warning!

# F ir st t ime fl ye r s h oul d ne ve r fl y by h im s el f / h ers elf . A ss is t an c e fr om e xp er i en c ed

f ly er i s ab so lu t el y n e ce s sar y.

# P re -f l ig h t ad ju st m en t m u st b e do ne b e fo r e fl yin g, i t is v ery da ng er o us t o fl y a b a dl y

p re -a d ju s te d a i rcr aft .

# i s sp e ci a ll y d e si g ne d t o b e p o we r ed b y 2C 0 .6 0 -0 . 75 / 4 C 0 . 91

en gin e, u si na m ore po we rf u l e n gin e do es n o t me an b et te r p e rf o rm a nc e . In f ac t , ov er

po wer ed e ng in e m a y ca us e s e ver e da ma ge a nd i nj ur i es .

# M ak e su re t he a i r fi el d i s s p ac i ou s ,

ne ver fl y th e pl a ne t oo c lo se t o pe o pl e a n d n e ve r

g et t o o cl ose to a r un ni n g pr ope ll er.

# I f yo u f i nd w rin kle s on t he c ove ri ng a s a r e su l t of w e ath er c ha ng e s, y ou c an u s e ho t

ir on t o re m ov e t h e wr in kl e s. P lea se b eg in w ith lo wer te mpe ra tu r e se tti ng a nd

gr adu all y ra is e th e t e mp e ra t ur e u n ti l t h e wr in kl e s a r e go ne . Too h ot a n ir on m a y

da mag e th e co v er i ng . D o n' t u s e ho t ir o n n e ar t he s e am s o r e d ge s , ho t ir on w i ll

m el t th e gl ue a n d sh rin k th e co v er i ng a t th e s a me t ime , ca us in g t h e se ams to p

ul l aw ay.

# C he ck a nd r e- ti g ht e n up a ll f ac t ory as sem ble d sc re ws , u s e th re ad l ock er i f ne c es s ar y.

The ideal C.G. position is 156mm (6.14in.) behind the leading

edge measured at where the wing meets the fuselage. In

order to obtain the C.G. specified, add weight to the fuselage

or move the battery position. Check the C.G. before flying.

If you are converting this model to electric, please move the

C.G. forward 10% of current C.G. distance from leading edge

to compensate for we

ight of fuel.

http://www.theworldmod els.com/para/i nstruction/ins tructionManual s.php

A050RPO28881306

Product Registration Form (US Customers)

We would like to share with you any relevant information regarding your model, including

product news and free upgrade parts when applicable. Please fill in the following and send to

AirBorne Models, 4749-K, Bennett Drive, Livermore, CA 94551 USA.

1. Name:

2. Address:

3. Phone #: E-mail:

4. Model:

Wing QC# Fuselage QC#

(QC numbers are stamped on wing and fuselage)

5. Date of Purchase:

6. Store Name:

Please call AirBorne Models at 925 371 0922 for any assistance in filling this form.

Thank you very much for purchasing our product.

LINKAGE CONNECTOR

HW7111050 & HW7111060

After fastening the round nut, make sure that

the linkage connector can rotate freely.

Drill 2mm hole at servo horn.

Insert linkage connector

into servo horn.

Make sure shoulder of

screw is cleared from

servo horn.

Add washer to reduce

play if necessary.

Shoulder

Tighten up the round nut

against the shoulder. Apply

CA or permanent thread

locker.

A050RPO28881306

1

3

4

2

Usage of the transparent 3D template

This transparent 3D template

is used for position guidance

of the actual cutting of the

pre-painted cowling.

Simply cut the transparent 3D template to fit your engine and

exhaust pipe, then slide onto the actual cowling and use as

template to mark the openings required for final cutting.

A050RPO28881306

Cod e No.

Siz e

Pac kage

Cod e No.

Siz e

Pac kage

Cod e No.

Siz e

Pac kage

Cod e No.

Siz e

Pac kage

Cod e No.

Siz e

Pac kage

Cod e No.

Siz e

Pac kage

Code N o SV 4031

KP0041300

Speci al tool for c levis ins tallati on.

Suita ble for sta ndard and s mall

(EP) clevis.

Larg e Cl evis

Smal l Cl evis

180mm Extension

A050RPO28881306

A050RPO28881306

Loading...

Loading...