Warning ! This model is not a toy.

It is designed for maximum performance. Please seek advice if one is not familiar with

this kind of engine powered precision model. Operating this model without prior

preparation may cause injuries. Remember, safety is the most important thing. Always

keep this instruction manual at hand for quick reference.

* Spec if icati on s are sub je ct to cha ng e witho ut n otice .*

Specifications

INSTRUCTION MANUAL

1/3 SUPER CUB

1/3 SUPER CUB

Wing Span 141 in / 3580 mm

Wing Area 2821 sq in / 182 sq dm

Flying Weight 28.5 lbs / 13000 g

Fuselage Length 91 in / 2310 mm

Requires: 80 c.c. gasoline engine,

5-channel radio w/ 8 high

torque servos

.

E

A

D

R

-

Y

T

-

T

S

O

O

-

F

M

L

L

Y

A

FACTORY PRE-FABRICATED

ALMOST-READY-TO-FLY (ARF) SERIES

MADE IN CHINA

Manufacturing Co.,Ltd.

A186SRPO248 010 09

P. 3-12

Check all parts. If you find any defective or missing parts contact your local dealer. Please DRY FIT

and check for defects for all parts that will require CA or Epoxy for final assembly. Any parts you

find to be defective after the gluing process may be difficult to remove for warranty replacement. The

manufacturer will replace any defective parts, but will

not

extend to the parts that are good before

gluing to defective parts during assembly. Warranty will not cover any parts modified by customer.

INDEX

BEFORE YOU BEGIN

PARTS LIST

ASSEMBLY

SAFETY PRECAUTIONS

P. 1

P. 2

P.12

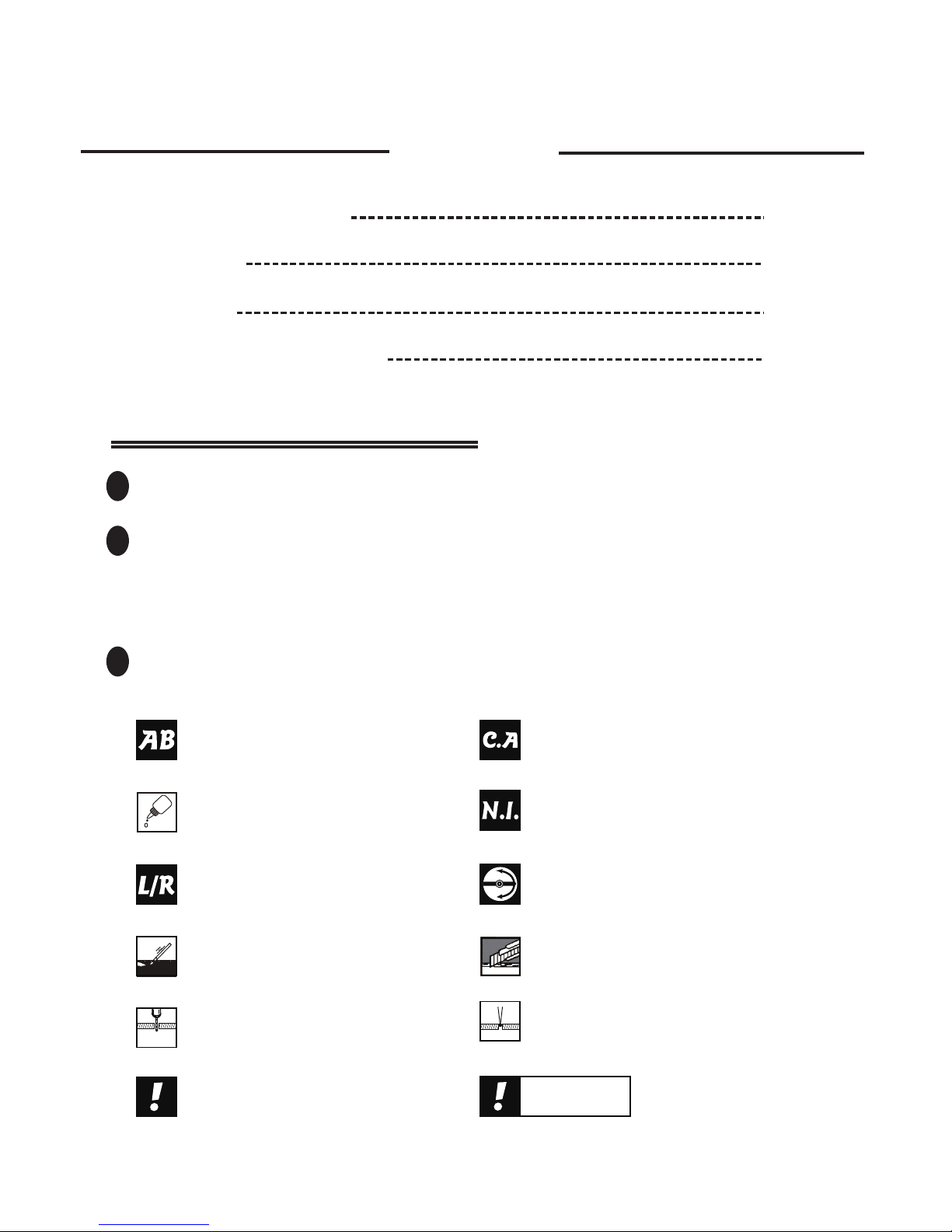

BEFORE YOU BEGIN

Read through the manual before you begin, so you will have an overall idea of what to do.

Symbols used throughout this instruction manual comprise of the following : -

1

2

3

1/3 SUPER CUB

1/3 SUPER CUB

3mm

Do not overlook this symbol!

Cut off shaded portion.

Peel off shaded portion

covering film.

Pay close attention here!

Pierce the shaded portion

covering film.

Must be purchased separately!

Drill holes with the specified

diameter (here: 3mm).

Ensure smooth non-binding

movement while assembling.

Apply instant glue

(C.A. glue, super glue.)

Assemble left and right

sides the same way.

Apply epoxy glue.

Apply thread locker

Warning!

P.1

A186SRPO248 010 09

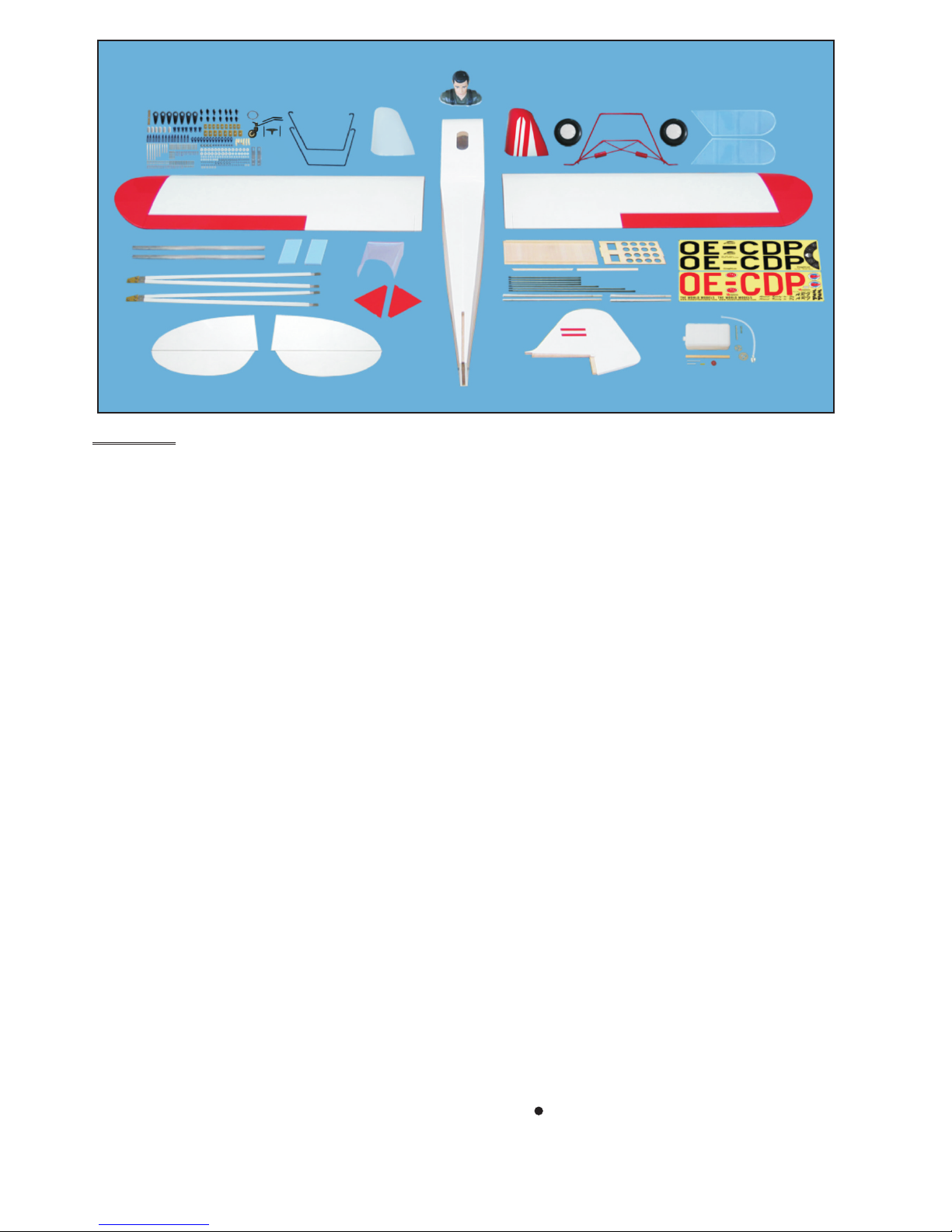

Parts List

COVE RING:

TOUGHL ON ST L 10 0 WHITE

TOUGHL ON ST L 31 2 BRIGH T RED

1. MAIN WING -- 1 pair

2. SERVO MOUNTING PANEL (For Aileron) -- 2 pairs

HEAVY DUTY CLEVIS PL4112200 -- 8 sets

SCREW PM4x60mm -- 4 pcs

SCREW PWA2.3x8mm -- 16 pcs

M4 NYLON INSERT LOCK NUT -- 4 pcs

HEAVY DUTY HORN BRACKET PL4112400 -- 4 sets

HEAVY DUTY SERVO HORN PL4120300 -- 4 sets

PUSHROD Ø2.3x129mm w/ Threads (For Aileron) -- 2 pcs

PUSHROD Ø2.3x108mm w/ Threads (For Flap Servo) -- 2 pcs

SWIVEL CLEVIS HORN FAIRING PL4610010 -- 4 sets

3. SCREW HM4x20mm -- 12 pcs

COPPER CLIPPER 0.5mm -- 8 pcs

MAIN WING STRUTS -- 1 pair

WING STRUT WIRE D4mm -- 2 pcs

M4 NYLON INSERT LOCK NUT -- 4 pcs

WASHER d4xD9mm -- 4 pcs

WASHER d4xD12mm -- 4 pcs

4. FUSELAGE -- 1 pc.

STABILIZER & ELEVATOR -- 1 set

SCREW PWM2.5x12mm -- 2 pcs

STABILIZER WIRE Ø4x200mm -- 2 pcs

5. VERTICAL FIN & RUDDER -- 1 set

6. TAIL GEAR ASSEMBLY (PL3410022) --1 set

COPPER PLATE (For Stays on Tail Fueslage Bottom) 1x12x60mm -- 1 pc.

SCREW PA3x18mm -- 3 pcs

SCREW PWA2.5x12mm -- 2 pcs

7. MAIN LANDING GEAR -- 1 set

SCREW HM4x18mm -- 2 pcs

SCREW PA3x14mm -- 12 pcs

SCREW PA4x20mm -- 2 pcs

WASHER d4xD12mm -- 2 pcs

WASHER d4xD9mm -- 2 pcs

MOUNTING PLATE 12x20mm -- 6 pcs

ALUMINUM PLATE 3x15x77mm -- 2 pcs

8. SCREW PA1.7x8mm -- 6 pcs

SCREW PM3x10mm -- 8 pcs

WASHER d3xD7mm -- 16 pcs

M3 NUT -- 8 pcs

COLLAR Ø6.1mm w/ set screw -- 4 sets

LARGE SCALE CAPTIVE AIR WHEELS Ø140mm(PL3115140) -- 2 sets

PLYWOOD 2x211.5x193.5mm (Main Langing Gear Cover) --1 pair

COPPER CLIPPER 0.5x12x20mm -- 8 pcs

9. BLIND NUT M6 -- 4 pcs

WASHER d6xD15mm -- 4 pcs

SOCKET HEAD SCREW M6x30mm -- 4 pcs

10. COWLING -- 1 pc.

TRANSPARENT 3D TEMPLATE -- 1 pc.

SCREW PA3x12mm -- 4 pcs

WASHER d3xD7mm -- 4 pcs

SILICON GROMMET d2.5xD8.5mm -- 4 pcs

11. FUEL TANK 1500cc (PL1121500G-gasoline) -- 1 set

CABLE TIE (For Fuel Tank) 1.5x8x500mm -- 1 pc.

DOUBLE-SIDED TAPE 40x160mm -- 1 pc.

12. PUSHROD Ø2.3x215mm w/ Threads (For Elevator) -- 2 pcs

SCREW PM4x50mm -- 2 pcs

M4 NYLON INSERT LOCK NUT -- 2 pcs

SWIVEL CLEVIS HORN FAIRING PL4610010 -- 2 sets

HEAVY DUTY HORN BRACKET PL4112400 -- 2 sets

HEAVY DUTY SERVO HORN PL4120250 -- 2 sets

HEAVY DUTY CLEVIS PL4112200 -- 4 sets

13. PUSHROD Ø2.3x170mm w/ Threads (For Rudder) -- 1 pc.

SCREW PM4x50mm -- 1 pc.

M4 NYLON INSERT LOCK NUT -- 1 pc.

SWIVEL CLEVIS HORN FAIRING PL4610010 -- 1 set

HEAVY DUTY HORN BRACKET PL4112400 -- 1 set

HEAVY DUTY SERVO HORN PL4120250 -- 1 set

HEAVY DUTY CLEVIS PL4112200 -- 2 sets

14. SCREW PM2x18mm -- 12 pcs

WASHER d2xD5mm -- 24 pcs

M2 NUT -- 12 pcs

CLEVIS -- 12 pcs

WIRE Ø1x4200mm -- 1 pc.

FLYING WIRE BRACKET -- 12 pcs

CLIP PIN -- 12 pcs

EYE SCREW -- 6 pcs

COPPER TUBE d2.5xD3.2x8mm (For Rudder) -- 16 pcs

15. SIDE WINDOWS -- 1 pair

16. LINKAGE CONNECTOR Ø2.1mm w/ set screw -- 1 set

17. PLYWOOD 3x196x304mm (For Fuselage Servos) -- 1 pc.

PLYWOOD 3x10x160mm (For Fuselage Servo Stand) -- 2 pcs

BALSA 10x10x288mm (For Fuselage Servo Stand) -- 2 pcs

SPONGE 10x80x200mm -- 2 pcs

THROTTLE PUSHWIRE Ø1.2x480mm -- 1 pc.

PLASTIC TUBE d2xD3xd300mm -- 1 pc.

18. PILOT PC101110A -- 1 set

SCREW PWA2x12mm -- 4 pcs

COCKPIT BASE PANEL 3x196x444mm -- 1 pc.

WOOD 10x10x443mm (For Cockpit Base Panel) -- 2 pcs

19. WIND SHIELD -- 1 pc.

M2 NYLON INSERT LOCK NUT -- 2 pcs

SCREW PM2x14mm -- 2 pcs

WASHER d2xD5mm -- 4 pcs

MOUNTING PLATE 5x15mm -- 2 pcs

BALSA ROD Ø8x220 -- 2 pcs

20. WING TUBE Ø22x931mm -- 2 pcs

SCREW HM3x30mm -- 2 pcs

SCREW PA3x30mm -- 2 pcs

WASHER d3xD7mm -- 4 pcs

21. SCREW HM4x15mm -- 2 pcs

WASHER d4xD12mm -- 2 pcs

M4 NYLON INSERT LOCK NUT -- 2 pcs

22. DECALS: A186SRDEC -- 1 set

P.2

A186SRPO248 010 09

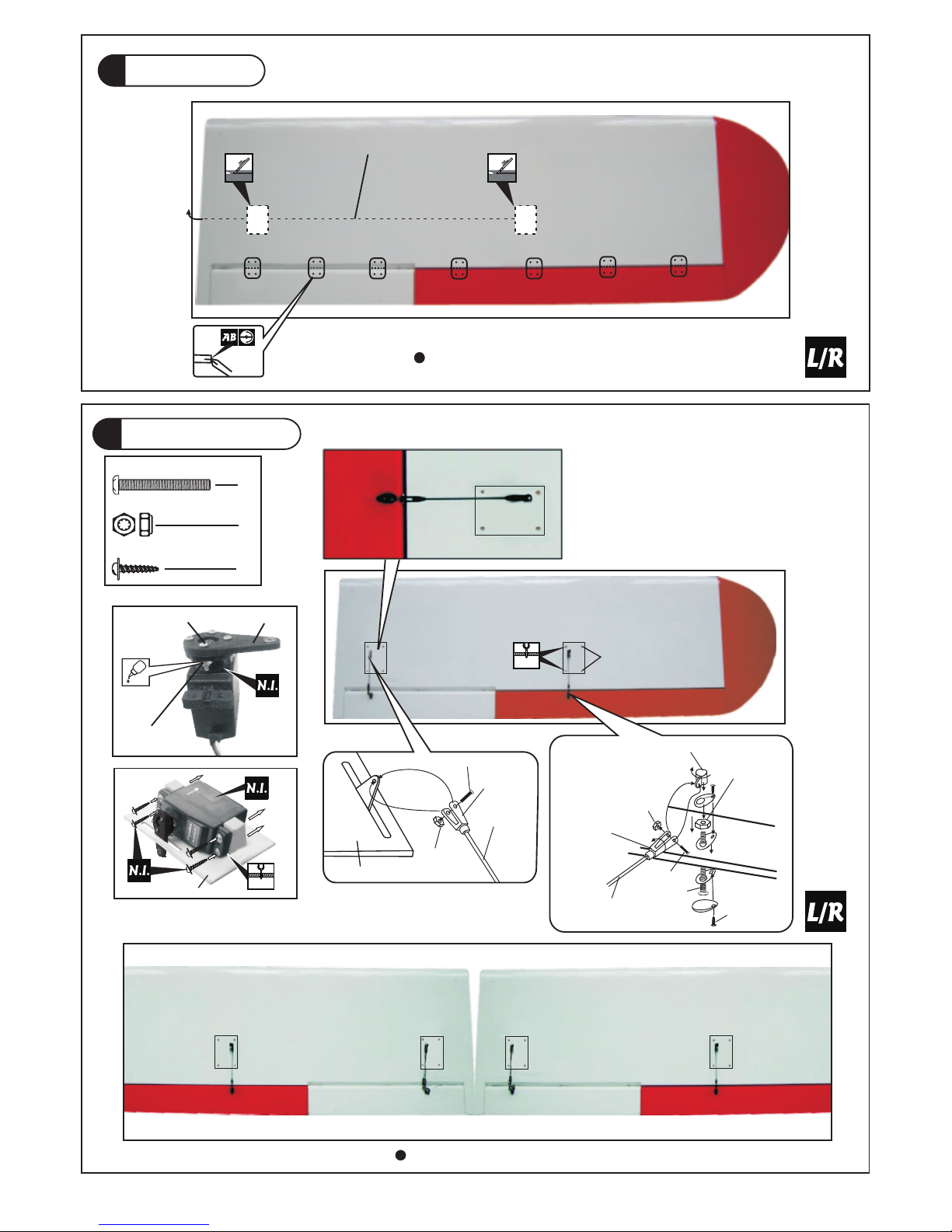

2

Aileron & Flap servo

1

Main Wing

Pre -glue d

PM4x 60 mm Scre w

M4 N YL ON I NS E RT LO C K NU T

4

4

Aile ron & Flap Ser vo Lead

Bottom View

Bottom View

16

PWA2.3 x 8mm Screw

PWA 2.3 x 8mm

M2

x

10

mm

H

e

a

vy Du t

y

Cl

evi s

SER VO M OUN TI NG PAN EL

M2 NY LON

INS ERT LOC K NUT

Pushrod

Ø2. 3x108 mm

SER VO MOUN TING PANE L

1mm

1.5mm

Pushrod

Ø2.3x12 9m m

PM4 x 60m m

M4 Nyl on I nsert

Lock N ut

PM2x10m m

Heavy Duty

Clevis

Heav y Du ty H or n

Bracke t

PA1. 7x 8mm

M2 Nyl on I nsert

Lock N ut

M2 NUT

M2x8mm

PL4120300

P.3

A186SRPO248 010 09

Stabilizer & Elevator

COMPLETE D

5

Vertical Fin & Rudder

COMPLETED

Pre-g lu ed

(St abili zer)

(Ma in Wing )

B B'

B=B'

HM4x20mm

Washer d4xD9mm

3.5mm

HM4 x 20mm

M4 Nylon Insert Lock Nut

Main Wing Strut

d4xD 12mm Wash er

HM4x20mm Screw

12

4

d4xD 9mm Washe r

4

4

M4 N YLON I N SE R T LOCK N UT

3

4

Bottom View

Tempor a r y i nstall t h e main w i n g , adjust

leveling o f the s t a b i l i z e r to m a k e it a s

parallel t o the m a i n wing a s possible.

Wing Struts

465 mm 481 mm

174 mm

280 mm

184 mm

260 mm

d4xD12 mm

Was he r

Pre -glue d

P M mm W 2.5x12 Screw

2

P M mm W 2.5x12

Ø4x200mm

P.4

A186SRPO248 010 09

Bottom View

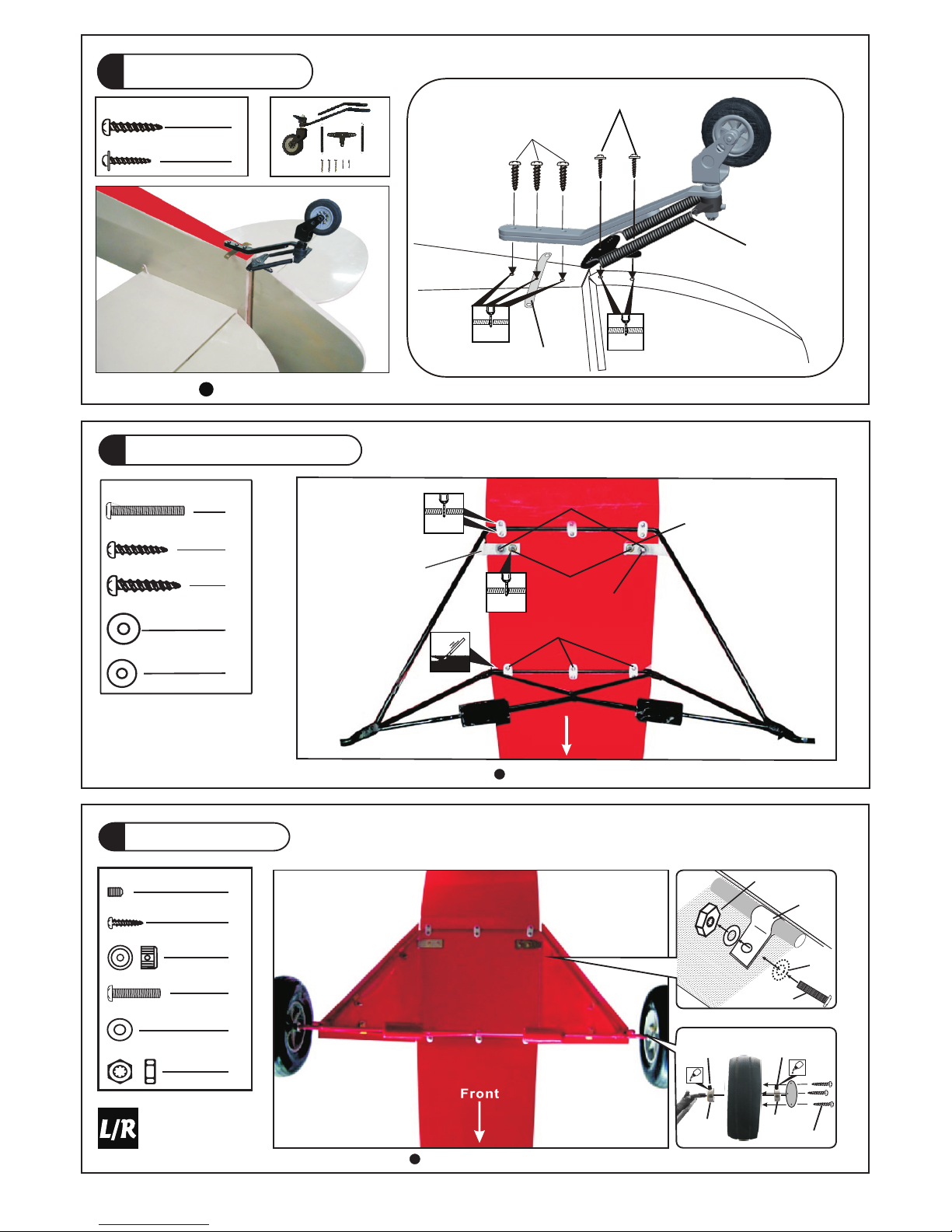

Tail Landing Gear

6

8

Landing Gear

PA1. 7x 8m m

Collar

M3x3mm

Set Screw

M3x3mm

Set Screw

Collar

PM3x10mm Screw

PA1.7X8mm Screw

d3xD7mm Washer

M3 Nut

8

6

16

8

4

3mmSet Screw

4

6.1mm Collar

d4xD12mm Washer

HM4x18mm S cre w

2

2

PA3x14mm S cre w

12

d4xD9mm Washer

2

PA4x20mm S cre w

2

Bottom View

Bottom View

PM3 x10mm

d3x D7mm

Was her

Coppe r Plate

0.5 x12x2 0mm

M3 Nut

7

Main Landing Gear

Fron t

PA3x14mm

PA4x20mm

HM4x 18 mm

d4xD 9m m

Was he r

d4xD 12 mm

Was he r

Alum inum Pla te

3x15 x7 7mm

1.5mm

2.5mm

P.5

3

2

PWA2.5 x 12mm

PA3 x18mm

Copper Plate

1x12x60mm

Spring

2.5mm

1.5mm

Bottom View

PA3x18mm Screw

PWA2.5x12mm Screw

A186SRPO248 010 09

Engine

9

d6xD15mm Washer

M6 Blind Nut

4

4

4

M6x30mm Socket Head Screw

Cowling

10

PA3x1 2mm S crew

d2.5 x8.5mm Sil icon Gr ommet

4

4

207mm

8.15 in.

COMPLETED

First i nsert the grom met to the cowli ng then apply sc rew.

Plea se re fer to th e attac hed

shee t for usage of t he

tran sparent 3D t empla te.

Was he r

d6xD 15 mm

M6 Bli nd N ut

Socket Head Screw

M6x30mm

7.5mm

1.5mm

d3xD7mm Washer

4

P.6

Cowling

Fuselage

d2.5x8.5mm

Silicon Grommet

PA3x12mm

d3xD7mm

A186SRPO248 010 09

Rudder

Pushrod

Elevator Pushrod

Fuel Tank

11

Bottom View

Bottom View

13

12

P.7

PM4x 50mm Screw

2

2

Elevator Pushrod

PM4x5 0m m

M4 Nylon In se rt L oc k Nu t

M2 Nylon In se rt L oc k Nu t

M2x10 mm

Heavy Dut y Cl ev is

Heavy Dut y Ho rn B ra ck et

PA1. 7 x8 mm

M4 Nylon Insert Lock Nut

M2 Nut

M2x8mm

PL41202 50

Hea vy Duty H orn

Bra cket

M2 Nylo n In sr t

Lock Nu t

Heavy Duty

Clevis

PM4x50mm

M2x 10mm

M4 Nylon Insert

Lock Nut

PA1. 7 x8 mm

Pus hrod

PM4x 50mm Screw

1

1

M4 Nylon Insert Lock Nut

M2 Nut

M2x8mm

PL41202 50

Fuel Tank

1500cc

Completed

UP

CABLE TIE

1.5x8x500mm

DOUBLE-SIDED

40x160mm

1 2 3

A186SRPO248 010 09

Servo Set

16

14

Flying Wire

Windows

Securely glue the windows to the fuselage.

COMPL ETED

Window A

Wind ow B

15

COMPLETED

1

1

3x3mm Set Screw

Linkage Connector

M2 Nut

2mm Washer

1

2

Please refer to t he a ttached sheet for linkage c onn ector installation.

T

h

rott

l

e Pu

s

hw

ir

e

3x3m m Set S crew

Throttle Servo.

2m m

2mm

Washer

M2 Nut

2mm

Washer

P.8

PM2x18mm Screw

12

12

d2xD5mm Washer

24

M2

PM2x18mm

PM2x18mm

d2.5xD3.2x8mm

3mm

3mm

d2xD5mm

Washer

M2 N UT

Cop per Tub e

Pre ss down t he cent er

1/ 3 po rtion

A186SRPO248 010 09

M2 Nut

18

Pilot

Wind Shield

19

PWA 2x 12mm Screw

M2 NYLON INSERT LOCK NUT

2

PM2x 14mm Screw

2

d2xD5mm Washer

4

17

Radio Equipment

lnstall and a rrange the servos as shown in the diagra m.

PC10 11 10 A

PWA 2x 12mm Screw

Bottom View

M2 NYLON INSERT LOCK NUT

PM2 x14mm

d2x D5mm

Was her

Bals a Rod

Ø8X2 20mm

Thro ttl e Servo

Spong e

Receive r

Thro tt le P us hrod

D1.2x480mm

Plas ti c Tube

d2xD 3x 30 0mm

Battery

Char ge R ec ep tacles

KP00 41 30 0

P.9

A186SRPO248 010 09

Appl y thick CA or

Cano py glue.

Main Wing

20

d3xD 7mm Washe r

2

4

PA3x30m m Scr ew

2

Step 1. Insert the aluminum wing tube with the pre-drilled hole end into the right wing. Align

the lines marked at the wing root and wing tube and apply the PM3 x 30mm machine screw

through the pre-drilled hole on top of the wing. ( please confirm the alignment of the hole by

putting a 2.5mm diameter rod through the pre-drilled wing hole before applying the screw )

The hole on the wing tube is pre-threaded, do not over tighten the PM3mm screw, the set up is for

future removal of the wing.

Step 2. Install the right wing to the fuselage by inserting the wing tube (now attached to

the right wing) through the fuselage, then install the left wing.

Step 3. Make sure the wings are resting against the fuselage tightly. Locate the pre-drilled 2.5mm

hole at top of left wing, and drill along with 2.5mm drill bit until it passes through the wing tube.

Apply the PA3 X30mm self-tapping screw.

Note : It is recommended that the wing tube stays with the left wing. Removal of the wings could

be acheived by removing the right wing machine screw, the right wing then the left wing with

wing tube. If removal of wing tube from left wing is also required, it is recommended that

instead of applying self-tapping screw in step 3, you pre-tap with M3 thread cutter and apply M3

machine screw.

Top Vi ew

Right

Left

PA 3x30mm

d3xD7mm

Wing Tube

D22x931mm

345m m

345m m

70mm

185m m

HM 3x3 0m m

d3xD 7mm

2.5mm

2.5mm

P.10

HM3x 30mm Screw

A186SRPO248 010 09

Wing Setting

Adjust the w ing a nd fuselage confi gur ation as shown

in the diagr ams .

Wing Struts

d4xD 12mm Wash er

2

2

M4 N YLON I N SE R T LOCK N UT

2

B'

C'

B

C

21

22

A

A'

HM4x 15 mm

Wash er

d4 xD1 2m m

M4 N YLON I N SE R T LOCK N UT

P.11

HM4x 15mm Screw

A186SRPO248 010 09

23

Control Throws

Adjust the control throws as shown in

the diagram. These throws are good for

general flying. You can adjust according

to your personal preference.

Ailerons(away from fuse lag e)

40mm

Elevator

50mm

Rudder

65mm

24

C.G.

The ideal C.G. position is 150mm (5.9 in ) behind the leading edge measured at where

the wing meets the fuselage. In order to obtain the C.G.specified, add weight to the

fuselage or move the battery position. Check the C.G. before flying.

.

65mm

50mm

40mm

15

0 m

m

5

.

9

i

n

.

F

la

ps (

n

e

ar f

us

ela

g

e)

60mm

C.G.

Important Safety Precautions

9

Warning!

# First t i me flye r s h ould n e v er fly by h i m self / h e r self. Assist a n ce from e x perie n c ed

flyer i s a bsolu t e ly nece s sary.

# Pre-f l i ght ad j u stmen t m u st be do n e b efore f l ying, i t i s v ery da n g erous t o f l y a badl y

pre-a d juste d a i rcraf t .

# is spec i a lly de s i gned to b e p owere d b y 8 0C.C . gasol i n e e ngine , u s ing

a more powerf u l e ngine d o e s not me a n b etter p e rform a n ce. In fa c t , over p o w ered

engin e m ay caus e s e vere d a m age and i n j urie s .

# Make su r e the air f i e ld is sp a c ious, n e v er fly t h e p lane to o c lose to p e o ple an d n e ver

get too c l ose to a ru n n ing pr o p eller.

# If you f i n d wrink l e s on the c o v ering a s a r esult o f w e ather c h anges , y o u can us e h o t

iron to r e move th e w r inkle s . Pleas e b e gin wi t h l ower te m p eratu r e setti n g a nd

gradu a l ly rai s e the te m p eratu r e until t h e w rinkl e s are gon e . Too ho t a n i ron ma y

damag e t he cove r i ng. Don ' t u se hot i r o n near t h e s eams or e d ges, ho t i r on will

melt th e g lue and s h r ink th e c o verin g a t t he sam e t i me, cau s ing the s e a ms to pu l l a way.

# Check a n d re-ti g h ten up a l l f actor y a s semb l e d screw s , u se thr e a d locke r i f n eces s a ry.

1/3 S UPER C UB

P.12

A186SRPO248 010 09

A186SRPO248 010 09

Product Registration Form (US Customers)

We would like to share with you any relevant information regarding your model, including

product news and free upgrade parts when applicable. Please fill in the following and send to

AirBorne Models, 4749-K, Bennett Drive, Livermore, CA 94551 USA.

1. Name:

2. Address:

3. Phone #: E-mail:

4. Model:

Wing QC# Fuselage QC#

(QC numbers are stamped on wing and fuselage)

5. Date of Purchase:

6. Store Name:

Please call AirBorne Models at 925 371 0922 for any assistance in filling this form.

Thank you very much for purchasing our product.

LINKAGE CONNECTOR

HW7111050 & HW7111060

After fastening the round nut, make sure that

the linkage connector can rotate freely.

Drill 2mm hole at servo horn.

Insert linkage connector

into servo horn.

Make sure shoulder of

screw is cleared from

servo horn.

Add washer to reduce

play if necessary.

Shoulder

Tighten up the round nut

against the shoulder. Apply

CA or permanent thread

locker.

1

3

4

2

Usage of the transparent 3D template

This transparent 3D template

is used for position guidance

of the actual cutting of the

pre-painted cowling.

Simply cut the transparent 3D template to fit your engine and

exhaust pipe, then slide onto the actual cowling and use as

template to mark the openings required for final cutting.

A186SRPO248 010 09

KP0041300

Special tool fo r cle vis installation.

Suitable for st and ard and small

(EP) c lev is.

Larg e Cl ev is

Smal l Cl ev is

Optional Parts

ACCESSORIES

180mm Y Cord

KW0011800 180mm 1 set

180mm Extension

KW0021800 180mm 1 pc

Charge Receptacles

Field Stand

MS9111450 600X240X350mm 1pc

Code N o. Size

Pack ag e

Code N o. Size

Pack ag e

Code N o. Size

Pack ag e

Code N o. Size

Pack ag e

Clevis Wrench

Code N o. Size

Pack ag e

PL8210010 1 set

A186SRPO248 010 09

The World Models

Manufacturing Co., Ltd.

www.the w orl d m o d e l s . c o m

Warbirds

Scale

Sports

Trainer

Ducted Fan

Pattern

Funfly

Electric

Glider

Boat

Accessories

Covering

(Lightex / Toughlon)

A186SRPO248 010 09

Loading...

Loading...