Page 1

CRD encoder as a subscriber in the PROFIBUS-DP

Accompanying data sheet: CRD 10534

User manual no.: CRD 10617 FE

Datum: 10.07.2012

User manual

Certificate Certificate

Z00358 Z00359

TWK-ELEKTRONIK GmbH D-40041 Düsseldorf Tel. +49 211 96117-0 info@twk.de

Heinrichstrasse 85 Postbox 10 50 63 Fax +49 211 637705 www.twk.de

Page 2

COPYRIGHT: The Operating Instructions CRD 10617

is owned by TWK-ELEKTRONIK GMBH and is

protected by copyright laws and international treaty provisions.

© 2012 by TWK-ELEKTRONIK GMBH

POB 10 50 63 ■ 40041 Düsseldorf ■ Germany

Tel. +49/211/63 20 67 ■ Fax +49/211/63 77 05

info@twk.de ■ www.twk.de

Date: 10.07.2012 Page 2 of 28 user manual no. CRD 10617 FE

Page 3

Structure

1. Safety instructions ............................................................................................................. 5

1.1 Scope of validity ........................................................................................................................... 5

1.2 Documentation ............................................................................................................................. 5

1.3 Proper use ...................................................................................................................................5

1.4 Commissioning ............................................................................................................................5

2 General ................................................................................................................................. 6

3. Installation instructions for PROFIBUS-DP - RS 485 ...................................................... 7

3.1 Connection of encoder with RS plug ...........................................................................................8

3.2 Connection of encoder with connecting cap ................................................................................8

4. Conguration function (DDLM_Chk_Cfg) ........................................................................ 9

5. Data exchange function (DDLM_Data_Exchange) ........................................................ 10

5.1 Actual position value .................................................................................................................. 10

5.2 Set preset value ......................................................................................................................... 10

5.3 Example: Setting the preset value in 32 bit data format ............................................................ 11

6. Programming parameters for class 1/2 encoder (DDLM_Set_Prm) /4/........................ 12

6.1 Denition of the programming parameters ................................................................................12

6.1.1 Operating mode ...................................................................................................................12

6.1.2 Measuring units per revolution (Octet 10-13) ....................................................................... 13

6.1.3 Total measuring range in units (Octet 14-17) ....................................................................... 13

6.2 Examples for parametration (User_Prm_Data) .........................................................................14

7. Diagnosis messages (DDLM_Slave_Diag) ..................................................................... 15

7.1 Standard diagnosis information (Octet 1-6): ..............................................................................15

7.2 Device-related diagnosis ...........................................................................................................15

7.2.1 Extended header byte (Octet 7): ......................................................................................... 15

7.2.2 Alarm messages (Octet 8):...................................................................................................16

7.2.3 Operating mode (Octet 9) ....................................................................................................16

7.2.4 Encoder type (Octet 10) ....................................................................................................... 16

7.2.5 Single turn resolution (Octet 11-14) .....................................................................................16

7.2.6 Measuring range (Octet 15, 16) ...........................................................................................16

7.2.7 Additional alarm messages (Octet 17) ................................................................................16

7.2.8 Supported alarm messages (Octet 18,19) ...........................................................................17

7.2.9 Warning messages (Octet 20,21) ........................................................................................17

7.2.10 Supported warnings (Octet 22,23) .....................................................................................17

7.2.11 Prole version (Octet 24,25) ...............................................................................................17

7.2.12 Software version (Octet 26,27) ..........................................................................................17

7.2.13 Operating time (Octet 28-31) .............................................................................................17

7.2.14 Offset value (Octet 32-35) ..................................................................................................17

7.2.15 Manufacturer offset value (Octet 36-39) ............................................................................17

Date: 10.07.2012 Page 3 of 28 user manual no. CRD 10617 FE

Page 4

Structure

7.2.16 Single turn resolution (Octet 40-43) ...................................................................................18

7.2.17 Total measuring steps (Octet 44-47) .................................................................................. 18

7.2.18 Serial number (Octet 48-57) ..............................................................................................18

7.2.19 Reserved for future use (Octet 58,59) ...............................................................................18

7.2.20 Manufacturer-specic diagnosis (Octet 60-63) .................................................................18

7.2.21 Example of diagnosis message .........................................................................................19

8. Simatic Step7 .................................................................................................................... 20

8.1 Integration of the TWK probus encoder ...................................................................................20

8.1.1 Installation of the GSD le ...................................................................................................20

8.1.2 Installation of the TWK encoder symbol ...............................................................................20

8.1.3 Selection of the TWK encoder from the Step7 hardware catalogue ....................................20

8.1.4 Conguration of the encoder ................................................................................................ 20

8.1.5 Allocation of probus address .............................................................................................. 21

8.1.6 Setting the I/O addresses (S7 addresses) ...........................................................................22

8.1.7 Parameterisation of the encoder .......................................................................................... 22

8.1.8 Setting the diagnosis address .............................................................................................. 23

8.2 Setting the subscriber address in the case of the plug-version encoder ...................................23

8.3 Example programmes ................................................................................................................ 24

8.3.1 The TWKDPCL1 project ....................................................................................................... 24

8.3.2 The TWKDPCL2 project ....................................................................................................... 25

8.3.3 Installation of the example programmes ..............................................................................25

8.3.4 Explanations regarding the example programmes ..............................................................27

9. Scope of delivery .............................................................................................................. 28

10. Literature ......................................................................................................................... 28

Appendix A: Encoder terms ................................................................................................ 28

Date: 10.07.2012 Page 4 of 28 user manual no. CRD 10617 FE

Page 5

Safety instructions

1. Safety instructions

1.1 Scope of validity

This user manual applies exclusively to the following rotary encoders with PROFIsafe interface:

- CRDxx-xxxxRxxxxC2Z01

- CRDxx-xxxxRxxxxC2L01

1.2 Documentation

The following documents must be noted:

- The owner's system-specic operating instructions

- This user manual

- Data sheet number CRD 10534

- The pin assignment enclosed with the device

- Installation instruction TZY 10206 enclosed with the device

1.3 Proper use

TWK-ELEKTRONIK GmbH's rotary encoders and linear transducers are used to record rotary and linear positions,

and make their measured values available as an electric output signal. As part of a system, they must be connected

to the downstream electronics and must only be used for this purpose.

1.4 Commissioning

• The relevant device must only be set up and operated using this document and the documentation specied

in point 1.2.

• Protect the device against mechanical damage during installation and operation.

• The device must only be commissioned and set up by a specialist electrician.

• Do not operate the device outside of the limit values which are specied in the data sheet.

• Check all electrical connections before commissioning the system.

Date: 10.07.2012 Page 5 of 28 user manual no. CRD 10617 FE

Page 6

General

DP slaves

DP master (class 1)

PROFIBUS-DP

2 General

The PROFIBUS is a eld bus standard according to EN 50170. The technical and functional characteristics of the eld

bus system are dened in this standard. The protocol architecture is based on the OSI reference model, in accordance

with the international ISO 7498 standard. Layer 1 (Physical Layer) denes the transmission physics, layer 2 (Data Link

Layer) the bus access protocol, and layer 7 (Application Layer) the application functions. This document is based on

the Prol description for encoders which can be obtained from the PNO /1/. The Probus protocol chip SPC 3 from

Siemens is used as the interface module between the encoder electronics and the bus system.

For PROFIBUS-DP, data exchange between SPS/PC and the decentralised periphery (e.g. encoder) is carried out in

a predominantly cyclical manner. For parameterisation, diagnosis and alarm handling purposes, acyclical communi-

cation functions are also required for intelligent eld devices. In this case, reference must be made to the DIN 19245

Part 1 and 3 or to the EN 50170 standards.

In the case of PROFIBUS-DP, communication in the data back-up layer (layer 2) is carried out via the SRD (Send and

Request Data with Reply) and SDN (Send Data with no Acknowledge) functions.

Mono or multi-master systems may be implemented with PROFIBUS-DP. A maximum of 126 devices (master or

slaves) may be connected to one bus. The denition of the system conguration contains the number of stations,

the allocation of the station address to the I/O addresses, data consistency of the I/O data, format of the diagnosis

messages and the bus parameters which are used.

The parameters of the PROFIBUS subscribers are described in a GSD le (device data sheet). The specications

are executed in accordance with DIN 19245 Part 3 /4/.

Differentiation of the services, and an exact knowledge of these, are especially important for understanding the

PROFIBUS-DP philosophy. A distinction is made between the following in the manual:

Check_Conguration: Conguration of the encoder

Integration of the encoder into the network with various data formats,

or as a programmable or non-programmable slave, is possible.

(Example: F1: programmable (32 bit input/output data) multitour encoder

Data_Exchange: Position data of the encoder

Cyclical enquiry regarding the encoder position. The position value is

depicted as a 16 bit or 32 bit value depending on the conguration.

Setting the preset value

Set_Parameter: Programming parameters

Denition of the operating mode of the encoder and denition of the values

for single turn resolution and total measuring range in units.

Slave_Diagnosis: Diagnosis of the slave subscriber (encoder)

Date: 10.07.2012 Page 6 of 28 user manual no. CRD 10617 FE

Page 7

Installation instructions

Station 1 Station 2

RxD/TxD-P (3)

DGND (5)

VP (6)

RxD/TxD-N (8) (8) RxD/TxD-N

(5) DGND

(3) RxD/TxD-P

(6) VP

Abschirmung

Schutz-

erde erde

Schutz-

Verkabelung

Busabschluß

Datenleitung B

Datenleitung A

VP (6)

390

220

RxD/TxD-N (8)

390

DGND (5)

RxD/TxD-P (3)

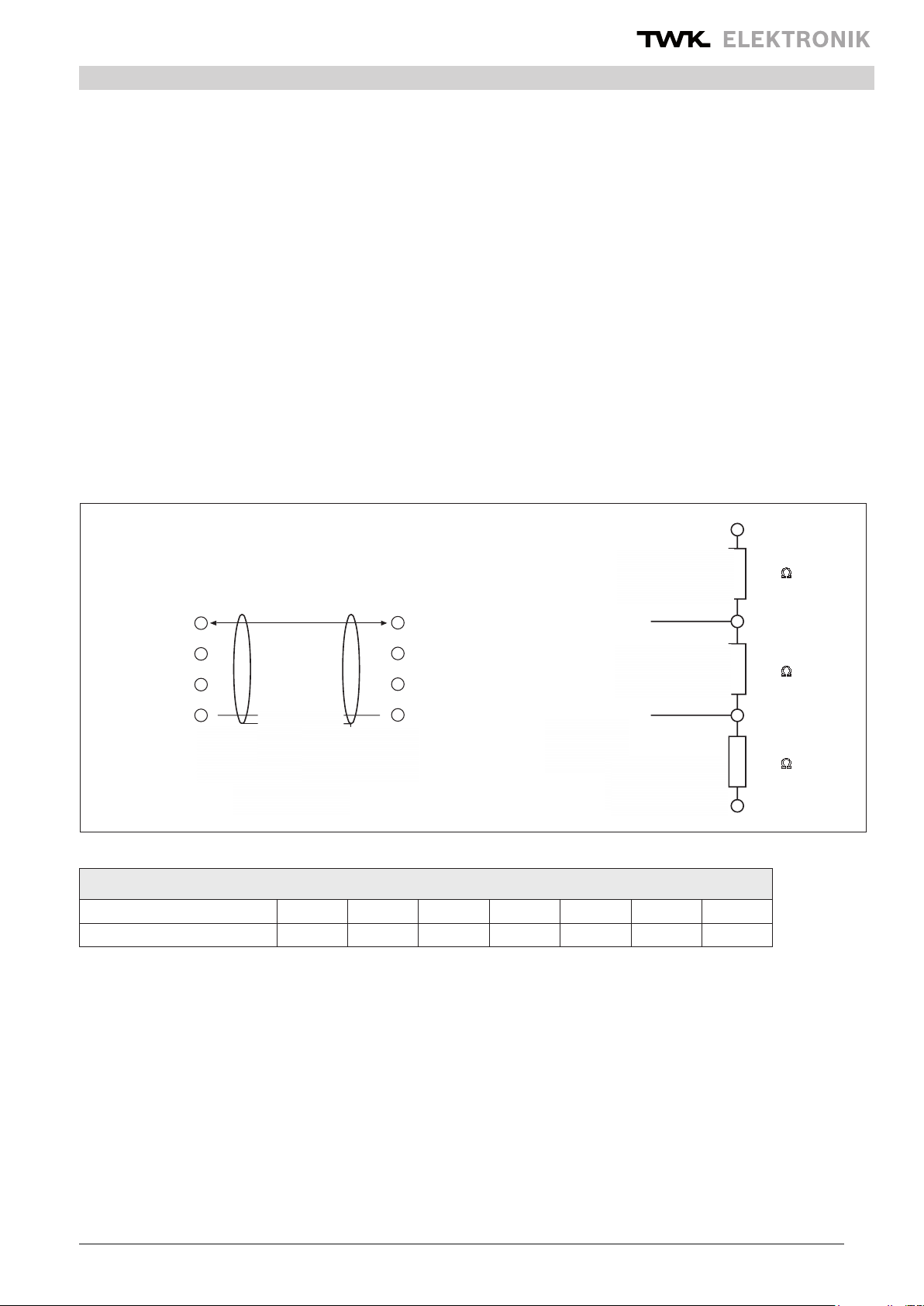

3. Installation instructions for PROFIBUS-DP - RS 485

Basic characteristics of RS-485 transmission technology /2/:

Network topology: Linear bus, terminating resistors for bus termination

Stub lines are only permissible in the case of baudrates < 1.5 MBit/s

Lead: Sheathed, twisted pair cable

Number of stations: 32 stations in each segment without repeaters

Can be extended up to 126 with repeaters.

Plug-type connector: Variants implemented in the case of the CRD model series:

Connecting cap, Round plug RS 25, 12-pin

DESINA (LWL and Cu-version)

(pin assignment according to /1/)

Wiring and bus termination for PROFIBUS-DP /2/, (Note: 9-pin Sub-D plug)

Transmission length depending on transmission speed for cable type A

Baud rate (kBit/s) 9,6 19,2 93,75 187,5 500 1.500 12.000

Transmission length in (m) 1200 1200 1200 1000 400 200 100

Cable type A specications: Characteristic impedance: 135...165 Ohm

Capacitance per unit length coating: < 30 pF/m

Loop resistance: 110 Ohm /km

Core diameter: 0.64 mm

Core cross-section: > 0.34 mm²

Shield

Connection

Data line B

Data line A

Terminating

resistance of the bus

also see: Installation guideline for PROFIBUS -FMS/DP (PNO No. 2.111/2)

Implementation guide DIN 19245 Part 3 (PNO No. 2.001/2)

Date: 10.07.2012 Page 7 of 28 user manual no. CRD 10617 FE

Page 8

Installation instructions

OFF

ON

1234

5

678910

DIP-Schalter

2 : 1

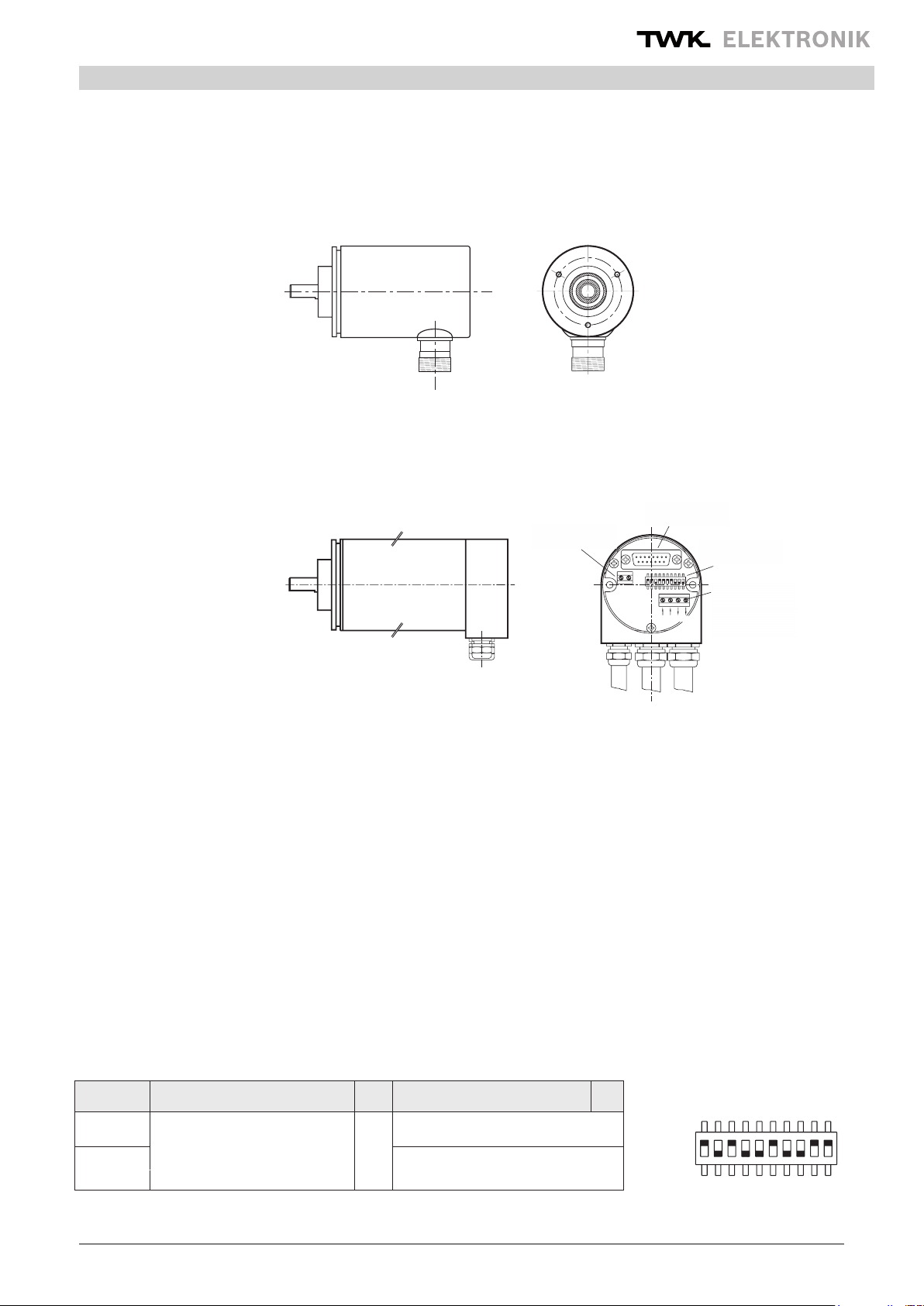

3.1 Connection of encoder with RS plug

The-pin assignment for the 12-pin RS plug (Note: Numeration of the-pins in clockwise direction (view facing contact

side of the bushing), encoder: Bushing) conforms to the prole denition for encoders /1/. The terminating resistors

must be implemented in the counterplug or in the subsequent electronics. For this connection type attention should

be paid to the length of the branch lines in the bus system and the total bus length.

When delivered, each encoder with RS plug has the default address 123. Via the DP master, it is possible to change

the address of a DP slave. The slave address which is to be newly assigned must lie within the range 1-126 (DDLM_

Set_Slave_Add).

3.2 Connection of encoder with connecting cap

Terminal 1

Anschlußklemme 1

Sub-D - Connector

Sub D Stecker

15 poles / sockets

15 polig/Buchse

DIP-Switch

DIP-Schalter

BAA’ B’

+ UB -

ON

OFF

Terminal 2

Anschlußklemme 2

(PROFIBUS)

(PROFIBUS)

The connecting cap for triple connection technology is a T-coupler, which is installed in the PROFIBUS.

It is equipped with three PG connections, which are subdivided as follows:

PG 7: Voltage supply for the encoder (24 VDC +/-)

PG 9: Bus in (Receive/transmit data A,B)

PG 9: Bus out (Receive/transmit data A’,B’)

The encoder is connected via the 15-pin SUB-D plug. In the event of an error, the encoder can be replaced without

time-consuming installation. The connecting cap is disconnected from the encoder by undoing 2 fastening screws

(Note: O-ring seal)

Setting the station/subscriber address is carried out via the DIP switches in the connecting cap.The address range lies

between 1 and 126 (Default address: 123). The address cannot be changed via the DDLM_Set_Slave_Add service.

(Note: GSD le in accordance with encoder version).

Setting the terminating resistors is carried out via the 10-fold DIP switch (9,10) in the connecting cap, which ay be

activated as lead termination as required.

DIP switch – address setting/terminating resistors

Switch 1 2 3 4 5 6 7 8 9 10

0 21

ON = 1 2

... 2

OFF = 0 Address 1 - 126 can be set

(123: Default address)

7

Termination resistors on

n.c.

Termination resistors off

DIP switch

Date: 10.07.2012 Page 8 of 28 user manual no. CRD 10617 FE

Page 9

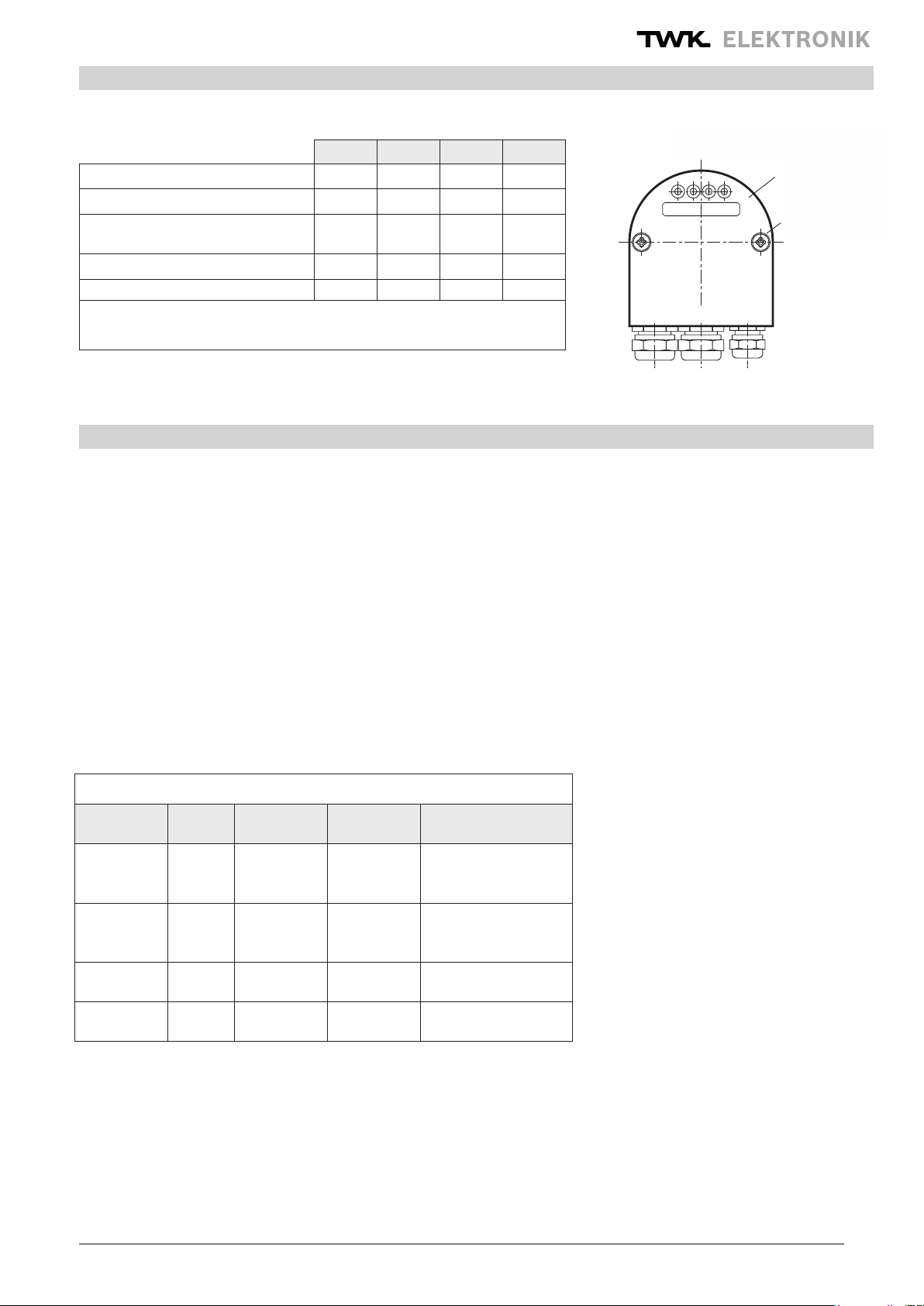

Installation

PG9PG9 PG7

SRD

LED-Statusanzeigen

UB

Befestigungs-

schrauben M4

C Err

Status LED (connecting cap)

VS SRD C Err

Status LED

Incorrect conguration x x x

Impermissible parameter x x x

Code error

(see diagnosis bytes 62 - 63)

x x

Screw M4

Class 1 Gerätekonguration i.O. x x

Class 2 Gerätekonguration i.O. x x x

VS - power supply, Err - error, C - class, SRD - data trafc

Conguration

4. Conguration function (DDLM_Chk_Cfg)

The absolute encoders with PROFIBUS-DP are classied as follows:

Encoder with Class 1 functionality

Class 1 devices are characterised by the fact that only the position value (16 bit or 32 bit) of the encoder is transmitted

via the bus. No parameterisation of encoder parameters is carried out. In this case, a distinction is made between

the D0 and D1 congurations. The D0 conguration contains the data format: 1 word input data, consistency and D1

contains 2 word input data, consistency.

Encoder with Class 2 functionality

Class 2 devices are characterised by the fact that they can be parameterised via the bus. In this case, a distinction

is made between the F0 and F1 congurations. The F0 conguration has the data format 1 word input data, 1 word

output data, consistency and F1 contains 2 word input data, 2 word output data, consistency .

Possible conguratons of the encoder:

Conguration function (DDLM_Chk_Cfg)

Selection Class Data

Class 2 32

Bit In/ Out

Class 2 16

Bit In/ Out

Class 1 32

Bit In

Class 1 16

Bit In

2

2

1

1

32 Bit In/

Output data

16 Bit In/

Output data

32 Bit Input

data

16 Bit Input

data

Identier

byte

F1

F0

D1

D0

Assignment Octet-

No. and MSB/LSB

Octet 1/Bit 7: MSB

Octet 4/Bit 0: LSB

Octet 1/Bit 7: MSB

Octet 2/Bit 0: LSB

Octet 1/Bit 7: MSB

Octet 4/Bit 0: LSB

Octet 1/Bit 7: MSB

Octet 2/Bit 0: LSB

Date: 10.07.2012 Page 9 of 28 user manual no. CRD 10617 FE

Page 10

Data exchange function

5. Data exchange function (DDLM_Data_Exchange)

Input data are data which are transmitted from the peripheral devices to the master or into the bus. The control of

the preset value (see below) is listed as an example of output data at this point.

5.1 Actual position value

The actual position value is output in 16 or 32 bit data format (input data), Please refer to the conguration of the

encoder in the previous chapter.

Actual position value (DDLM_Data_Exchange) 16 bit data format

Input-Data

Octet 1 2

Bit (MSB) 15 - 8 7 - 0 (LSB)

15

8

2

Data

- 2

position value

Actual position value (DDLM_Data_Exchange) 32 bit data format

Input-Data

27 - 2

0

Octet 1 2 3 4

Bit

Data

(MSB) 31 24

31

24

2

- 2

position value

23 - 16 15 - 8 7 - 0 (LSB)

223 -2

16

215 - 2

8

27 - 2

0

5.2 Set preset value

The set preset value function should only be executed when the encoder shaft is stationary!

In order to compare machine position values and the absolute position of the encoder, setting the preset value

is unavoidable in certain cases. The preset value is the position value which is displayed in the reference point.

The possibility of setting the preset value is available in the case of the TWK encoder with class 2 functionality.

The user must note the fact that the preset value must lie within the total measuring range in units. In particular,

this must be taken into consideration when changing the total measuring range in units.

The preset value (binary code) is transmitted in data exchange mode by setting bit 31 (32 bit data format) or bit

15 (16 bit data format).

The following explanations refer to the 32 bit data format.

Setting the preset value in 32 data format

Output-Data

Octet 1 2 3 4

Bit 31 (MSB)30 - 24 23 - 16 15 - 8 7 - 0 (LSB)

30

Data

1/0 2

- 2

24

Preset Control reference value

223 - 2

16

215 - 2

8

27 - 2

0

Date: 10.07.2012 Page 10 of 28 user manual no. CRD 10617 FE

Page 11

Data exchange function

5.3 Example: Setting the preset value in 32 bit data format

Output-Data

Octet 1 2 3 4

Bit 31

Data 1

Preset Control reference value: 8

Following the receipt of this message, an offset value (from the current actual position value and preset value) is calculated by the encoder. If the output position value is equal to the preset value, bit 31 can be reset by the master, as

the preset mode is terminated. The timing diagrams are specied in a separate TY sheet.

Return to normal operation mode, 32 bit data format

Output-Data

Octet 1 2 3 4

Bit 31

Data

0

Preset Control position value: 8

30 - 0

00.0000.0000.0000.0000.0000.0000.1000

30 - 0

00.0000.0000.0000.0000.0000.0000.1000

After bit 31 = 0 has been reset, the encoder operates in normal operating mode. The offset value is stored in the diagnosis data and can be read in the event of a power failure and restarting (Also see Diagnosis messages in Chapter 7).

Date: 10.07.2012 Page 11 of 28 user manual no. CRD 10617 FE

Page 12

Programming parameters

6. Programming parameters for class 1/2 encoder (DDLM_Set_Prm) /4/

The parameterisation data are comprised from bus-specic data and DP slave-specic data.

Bus-specic data: Octet 1-7 Octet 1 – Station status

Octet 2 - WD_Fact_1

Octet 3 - WD_Fact_2

Octet 4 - Min. station delay responder (min T

Octet 5 - Ident_Number 19

Octet 6 - Ident_Number 62H

Octet 7 - Group_Ident

DP slave-specic data: Octet 8-9 Class 1 encoder ( 2 byte User_Prm_Data)

Octet 8-29 Class 2 encoder (22 byte User_Prm_Data)

(See below for description)

Overview ot the encoder programming parameters

Octet number parameter data class remarks

8

SDR

)

9 operating status 1/2

10(MSB) - 13(LSB) Singleturn resolution

14(MSB) - 17(LSB) Total measuring steps

18 - 29

1 to 8192 steps/revolution

(1.000hex)

1 to 16.777.216 steps

(1.000.000hex)

2

2

6.1 Denition of the programming parameters

6.1.1 Operating mode

Logic table for Octet 9 (Operating parameters)

bit number parameter data class remarks

0: CW: Increasing clockwise

Bit 0 Code sequence

Bit 1 Class 2 functionality

Bit 2

Commissioning diagnosis

control

1: CCW: Increasing counter

clockwise

0: not supported

1: supported

0: not supported optional not supported

1,2

1,2

0: disabled

Bit 3 Scaling function status

1: enabled

Date: 10.07.2012 Page 12 of 28 user manual no. CRD 10617 FE

2

enables the scaling

for resolution and total

measuring range

Page 13

Programming parameters

Denition of the operating parameters:

Code sequence: The code sequence denes the direction of rotation in which the position value corre-

sponds to increasing values (viewed in the direction of the shaft).

CW - clockwise

CCW - counter clockwise

Class 2: This operating parameter serves to distinguish between encoders with class 1 or class 2

functions.

Class 1 - Code sequence, release of the class 2 functions

Class 2 - Contains class 1 functions Scaling function control (see below)

Diagnosis: The diagnosis routine enables the extensive examination of all encoder components to ensure

routine: perfect functional capability. The routine is run through each time the device is switched on. If

faults are determined by the diagnosis routine, these are displayed with the alarm bit.

This function is not currently supported.

Scaling function: The scaling function control releases the parameterisation of the single turn resolution

and the total measuring range in units. This function is only effective when changing

the single turn resolution and total measuring range in units parameters. Following the

execution of scaling function control, the position value is recalculated and output.

6.1.2 Measuring units per revolution (Octet 10-13)

Operating parameter resolution

Octet 10 11 12 13

Bit (MSB) 31-24 23-16 15-8 7-0 (LSB)

Data 2

31-224

223-2

16

215-2

8

27-2

0

6.1.3 Total measuring range in units (Octet 14-17)

Operating parameter total measuring steps

Octet 14 15 16 17

Bit (MSB) 31-24 23-16 15-8 7-0 (LSB)

Data 2

31-224

Note: It must be noted that the calculation of the number of revolutions is carried out in 2n powers internally within

the encoder. Regardless of this requirement, the user may programme the desired total measuring range in units

and the desired single turn resolution in accordance with the application. During calculation, the encoder accesses

the next highest 2n power if required. In this case, the values are designated as the actual single turn resolution or

as the actual total measuring range in units, and are displayed as the output value.

Example: desired total measuring range in units : 20480

desired single turn resolution : 4096

desired number of

revolutions : 5

internal encoder calculation

actual total measuring range in units : 32768

actual single turn resolution : 4096

223-2

16

215-2

8

27-2

0

calculated number of

revolutions : 8

Date: 10.07.2012 Page 13 of 28 user manual no. CRD 10617 FE

Page 14

Programming parameters

(Note: The above mentioned note must be taken into consideration in the event of irreversible operation. In the example

which is described, the position 0 is only achieved after 32767 steps and not, as desired, after 20479 steps.)

6.2 Examples for parametration (User_Prm_Data)

Class 1 encoder ( 9 parameter bytes, inclusive 7 bytes bus specid data)*

Class 1 encoder

bus specic data

octet 01 - 07 08 09

data 00 00

data 00 01

operating

status

remarks

Bit 0=0 code sense: CW

Bit 1=0 class1

Bit 0=1 codesense: CCW

Bit 1=0 class1

Class 2 encoder ( 29 parameter data, inclusive 7 bytes bus specic data)*

Class 2 encoder

bus specic

data

octet 01 - 07 08 09 10 - 13 14 - 17 18 - 29

data 00 0A

data 00 0B

operating status

Bit 0=0 code sense: CW

Bit 1=1 class 2

Bit 2=0 no diagnosis

Bit 3=1 scaling on

Bit 0=1 code sense: CCW

Bit 1=1 class 2

Bit 2=0 no diagnosis

Bit 3=1 scaling on

steps/

turn

1.000 1.000.000

100 10.000

total steps

* example contains only DP-slave specic parameter data (see DIN 19245-3)

Date: 10.07.2012 Page 14 of 28 user manual no. CRD 10617 FE

Page 15

Diagnosis messages

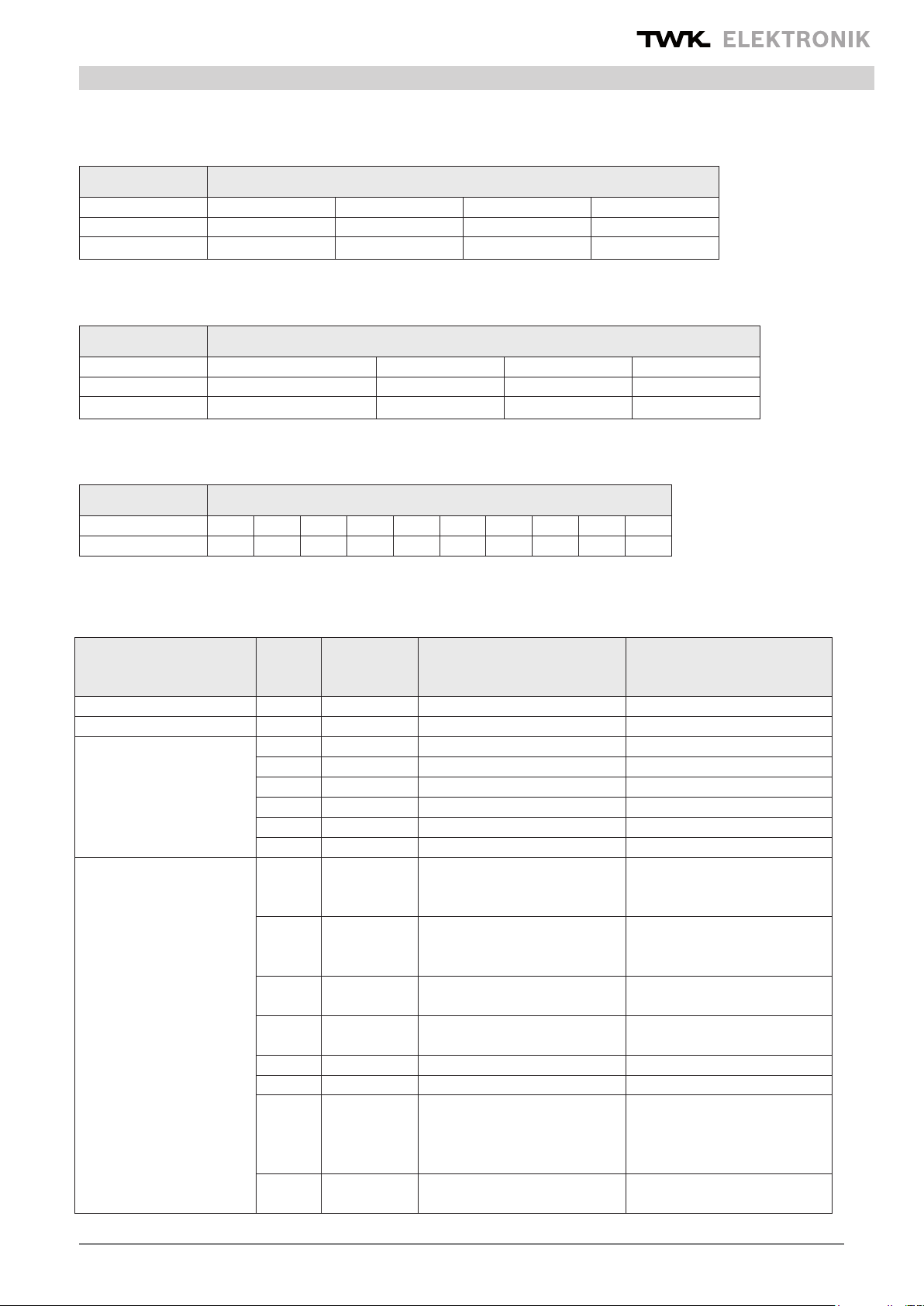

7. Diagnosis messages (DDLM_Slave_Diag)

Overview of diagnosis information

Diagnosis octet

number

1 - 6 standard diagnosis information 1, 2

7 extended headerbyte 1, 2

8 alarm messages 1, 2

9 operating parameters encoder 1, 2

10 encoder type 1, 2

11(MSB) - 14 (LSB) resolution 1, 2

15 - 16 measuring range 1, 2

End of diagnosis data for class 1 encoder!

17 additional alarm messages 2

18 - 19 supported alarm messages 2

20 - 21 warning messages 2

22 - 23 supported warnings 2

24 - 25 prol version 2

26 - 27 software version 2

28 - 31 operating time 2

32 - 35 offset 2

36 - 39 manufacturer offsetwert 2

40(MSB) - 43(LSB) resolution 2

44(MSB) - 47(LSB) total measuring steps 2

48 - 57 serial number 2

58 - 59 reserved 2

60 - 63 manufacturer specic diagnosis 2

diagnosis function class

device specic diagnosis

Explanations regarding the diagnosis information:

7.1 Standard diagnosis information (Octet 1-6):

For detailed description, see DIN 19245-3 /4/

(Note: Octet 5,6: Manufacturer identication: 1962H)

This manufacturer identication number is stored in the PNO, and identies the subscriber as a TWK encoder.

7.2 Device-related diagnosis

In the range from Octet 7 up to max. 244 (according to standard /4/), the DP slave may store its specic diagnosis.

7.2.1 Extended header byte (Octet 7):

In the header diagnosis (Octet 7), the length of the extended diagnosis bytes, including the header, is specied.

(Class 1 encoder: 0AH = 10 d

-> 6 (Standard diagnosis) + 1(Octet 7)+ 9 (Octet 8-16) = 16 diagnosis bytes,

Class 2 encoder: 39H = 57d

-> 6 (Standard diagnosis) + 1(Octet 7)+ 56 (Octet 8-63) = 63 diagnosis bytes)

Parameter extended headerbyte

Diagnosis octet 7

Bit 0-5 6 7

Data xxhex 0 0

Denition

length inclusive

header

display of device

diagnosis

Date: 10.07.2012 Page 15 of 28 user manual no. CRD 10617 FE

Page 16

Diagnosis messages

7.2.2 Alarm messages (Octet 8):

Output of the current alarm status. TWK currently supports memory errors only.

Parameter alarm messages

Diagnosis octet 8

Bit 0 1 2 3 4 5-7

Data 0=no /1=yes 0=no /1=yes 0=no /1=yes 0=no /1=yes 0=no /1=yes

Denition Position error

Supply voltage

error

Current to high

Remarks not supported not supported not supported not supported supported

7.2.3 Operating mode (Octet 9)

Current encoder status. This byte is described via the parameterisation of the master, and is read by the

diagnosis string.

Parameter operating mode

Diagnosis octet 9

Bit 0 1 2 3 4-7

Data 0=CW /1=CCW 0=no /1=yes 0=no /1=yes 0=no /1=yes

Denition code sense

class2

functionality

Remarks not supported

diagnosis

function

Commissioning

diagnosis

scaling

function

Memory

error

currently not

assigned

currently not

assigned

7.2.4 Encoder type (Octet 10)

The encoder type is set to multitour absolute. The code is stored in hexadecimal form (00-FFH)

Parameter encoder type

Diagnosis octet 10

Bit 0-7

Data 01hex

Denition Multiturn absolut

7.2.5 Single turn resolution (Octet 11-14)

The maximum possible selection of measuring units per revolution, specied via the single turn resolution of the

encoder shaft. The value is stored in the binary code.

Parameter resolution

Diagnosis octet 11 12 13 14

Bit (MSB) 31-24 23-16 15-8 7-0 (LSB)

Data 2

31-224

223-2

16

215-2

8

27-2

0

7.2.6 Measuring range (Octet 15, 16)

The maximum possible number of revolutions, specied via the single turn resolution of the multitour section.

Depiction in hexadecimal form, e.g. 4096 revolutions = 1000H.

Parameter measuring range

Diagnosis octet 15 16

Bit (MSB) 15-8 7-0 (LSB)

Data 2

15-28

27-2

0

End of diagnosis data for class 1 encoder !

7.2.7 Additional alarm messages (Octet 17)

Not currently assigned.

Date: 10.07.2012 Page 16 of 28 user manual no. CRD 10617 FE

Page 17

Diagnosis messages

7.2.8 Supported alarm messages (Octet 18,19)

The error entitled memory error is currently supported (10H).

Parameter supported alarm messages

Diagnosis octet 18 - 19

Bit 0 1 2 3 4 5-15

Data 0=no /1=yes 0=no /1=yes 0=no /1=yes 0=no /1=yes 0=no /1=yes

Denition Position error

Supply voltage

error

Current to high

Remarks not supported not supported not supported not supported supported

7.2.9 Warning messages (Octet 20,21)

This function is not currently supported.

7.2.10 Supported warnings (Octet 22,23)

This function is not currently supported.

7.2.11 Prole version (Octet 24,25)

Prole version: e.g. 01.00

Commissioning

diagnosis

Memory

error

currently not

assigned

Parameter prol version

Diagnosis octet 24 25

Bit 15-8 7-0

Data 2

15-28

27-2

0

Denition revision number index

7.2.12 Software version (Octet 26,27)

Software version: e.g. 01.00

Parameter software version

Diagnosis octet 26 27

Bit 15-8 7-0

Data 2

15-28

27-2

0

Denition revision number index

7.2.13 Operating time (Octet 28-31)

This function is not currently supported. The operating time default is set as FFFF FFFF

encoder prole.

in accordance with the

hex

7.2.14 Offset value (Octet 32-35)

The offset is the shift in the zero point on setting the reference point, with reference to the output

(according to the calculation).

Parameter offset value

Diagnosis octet 32 33 34 35

Bit (MSB) 31-24 23-16 15-8 7-0 (LSB)

Data 2

31-224

223-2

16

215-2

8

27-2

0

7.2.15 Manufacturer offset value (Octet 36-39)

The manufacturer offset is the shift in the zero point of the encoder with regard to its physical zero point.

The manufacturer offset value is not currently supported (Assignment: 00 00 00 00H).

Date: 10.07.2012 Page 17 of 28 user manual no. CRD 10617 FE

Page 18

Diagnosis messages

7.2.16 Single turn resolution (Octet 40-43)

In this case, the single turn resolution set in the parameter programme is reected.

Parameter single turn resolution

Diagnosis Octet 40 41 42 43

Bit (MSB) 31-24 23-16 15-8 7-0 (LSB)

Data 2

31-224

7.2.17 Total measuring steps (Octet 44-47)

In this case, the total measuring units per revolution set in the parameter programme is reected.

Parameter total measuring steps

Diagnosis Octet 44 45 46 47

Bit (MSB) 31-24 23-16 15-8 7-0 (LSB)

Data 2

31-224

7.2.18 Serial number (Octet 48-57)

This parameter is not currently supported.

Parameter serial number

Diagnosis Octet 48 49 50 51 52 53 54 55 56 57

Data 2A 2A 2A 2A 2A 2A 2A 2A 2A 2A

223-2

16

223-2

8

215-2

16

215-2

8

27-2

0

27-2

0

7.2.19 Reserved for future use (Octet 58,59)

7.2.20 Manufacturer-specic diagnosis (Octet 60-63)

Octet Nummer Bit Deniton Function Remarks

60 0 - 7 reserved

61 0 - 7 reservied

62 0 ErrEE EEPROM error reset encoder

1 ErrMSA MSA error reset encoder

2 ErrXRAM error external RAM reset encoder

3 ErrExp error connectiong cap reset encoder

4 IniFlg initialising EEPROM

5 - 7 reserved

63 0 ErrCRCO CRC0 error re-program and restart

encoder

1 ErrCRC1 CRC1 error re-program and restart

encoder

2 ErrPar parameter value error re-program encoder

3 ErrSkal scaling error

4 ErrMem ROM-Code error reset encoder

5 ErrInt internal controler error reset encoder

6 ErrPre referenz value error reference value must be

in the range of: 0 - total

measuring steps - 1

7 ErrStat unknown command

Date: 10.07.2012 Page 18 of 28 user manual no. CRD 10617 FE

Page 19

Diagnosis messages

* If a faulty preset value is input, control bit 31 must be set to zero before inputting the correct preset value in order to eradicate

the error. The preset value can subsequently be reset after setting control bit 31 to 1. After resetting bit 31 to the value zero, the

position value may then be output.

7.2.21 Example of diagnosis message

Octet 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

01-16 00 0C 00 02 19 62 39 00 0A 01 00 00 10 00 10 00

17-32 00 00 10 00 00 00 00 01 00 01 70 FF FF FF FF 00

33-48 00 0A D4 00 00 00 00 00 00 10 00 01 00 00 00 2A

48-63 2A 2A 2A 2A 2A 2A 2A 2A 2A 00 00 00 00 00 00

Explanation:

Octet:

1 - 6

7 Extended header byte 39 hex 63 diagnosis bytes

8 Alarm messages 00 hex No alarms are present

9 Operating mode 0A hex

10 Encoder type 01 hex Multitour, absolute

11 - 14 Single turn resolution 1000 hex 4096 S/U

15 - 16 Measuring range 1000 hex 16.777.216 Total measuring range

17

18-19

20-21 Warning messages 0000 hex wird nicht unterstützt

22-23

24-25 Prole version 01.00 Hardware version: 1.00

26-27 Software version 01.70 Software version: 1.70

28-31 Operating time FFFFFFFF hex

32-35 Offset value 00000AD4 hex Offsetwert

36-39

40-43 Single turn resolution 00001000 hex 4096 S/U

44-47

48-57 Serial number 2A2A2A2A2A2A2A2A2A2A hex

58-59

60-63

Parameter Data Remarks

01 00 hex

Response monitoring activated,

bit 2 set to 1

Parameterisation via master with

address 02

CW, class 2, diagnosis: no, scaling

yes

Standard diagnosis

information

Additional

alarm messages

Supported

alarm messages

Supported

alarm messages

Manufacturer

offset value

Total measuring units

per revolution

Reserved

for future use

Manufacturer-

specic diagnosis

02 0C hex

03 00 hex

04 02 hex

05 - 06 1962 hex Ident_Number CRD

00 hex No alarms are present

0010 hex Memory error is supported

0000 hex wird nicht unterstützt

00000000 hex Is not currently supported

01000000 hex 16.777.216 Schritte

0000 hex

00000000 hex No errors are present

Date: 10.07.2012 Page 19 of 28 user manual no. CRD 10617 FE

Page 20

Simatic Step7

8. Simatic Step7

This Chapter explains the procedure for integrating the TWK encoder into the probus of Siemens S7 control system,

and the set up and the utilisation of the example programmes for Step7. The basis of the documentation is Step 7

Version 5.1.

8.1 Integration of the TWK probus encoder

Prerequisites: You have congured your hardware in accordance with the structure of your control system, and

have installed a probus subnetwork.

8.1.1 Installation of the GSD le

- The GSD-le and the encoder symbols (bitmaps) are available under www.twk.de menu Documentation

- Close all projects in the hardware conguration.

- In the hardware conguration, select Install new GSD under Options.

- Select the GSD le which corresponds to your encoder:

Version with connecting cap: TWKZ1962.GSD

Version with plug connection: TWKL1962.GSD

- Update the Step7 hardware catalogue via Options, Update Catalog.

8.1.2 Installation of the TWK encoder symbol

Via the installation of the TWK encoder symbol, your encoder is not depicted as an unknown subscriber in the

hardware conguration, but assumes the appearance of your encoder. This is not, however, of signicance as

regards the function of the encoder.

In order to install the symbol (bitmap), copy the two les: CRD_Z_an.BMP and CRD_L_an.BMP into the C:\Siemens\

Step7\S7Data\NSBMP\ directory (if C: is your S7 drive). The symbols rst appear after restarting the Simatic Manager.

8.1.3 Selection of the TWK encoder from the Step7 hardware catalogue

- After opening the hardware catalogue, you will nd, under Probus-DP, Additional Field Devices, General,

the TWK Probus encoder "Encoder CRD plug" (encoder in plug version) or "Encoder CRD cap" (encoder

with connecting cap).

- Now open your project, mark the bus and integrate the encoder into the bus by double-clicking onto the

corresponding line in the hardware catalogue (Encoder CRD plug or Encoder CRD cap).

8.1.4 Conguration of the encoder

After the appropriate encoder type has been selected in the (hardware) Catalog, the following window appears for

the selection of encoder functionality and single turn resolution.

In this case, select class 1 or class 2 functionality and 16 or 32 bit single turn resolution in accordance with your

requirements. (See Chapter 4)

Date: 10.07.2012 Page 20 of 28 user manual no. CRD 10617 FE

Page 21

Simatic Step7

8.1.5 Allocation of probus address

If you have selected your nominal conguration, the following window, in which you must specify the probus address

set in the encoder, appears. For the example programmes, please select address 123 for the rst and address 122

for the second encoder here.

Note: The probus address of the encoder is set, in the case of the cap version, via dip switches (See Chapter 3.2)

and, in the case of the plug version, via software (See Chapter 8.2).

In addition, select your planned Probus in the Subnet, and quit the window with OK.

The encoder subsequently appears as a subscriber in your probus. Depending on the conguration and address,

this may appear as follows:

Double-clicking for

the diagnosis address

configuration (

Double-clicking for the

address configuration and

parameter programming

(

See 8.1.6 und 8.1.7)

See 8.1.8)

The value for Module / DP-ID results from the conguration which is selected. The values for I/O address are default

values which may vary depending on the control system.

Date: 10.07.2012 Page 21 of 28 user manual no. CRD 10617 FE

Page 22

Simatic Step7

8.1.6 Setting the I/O

addresses (S7 addresses)

Double-clicking onto the “Slot

0” line opens the Properties

- DP slave window with the

Address / ID and Parameter

Assignment registers. In the

Address / ID registers, under

output (in the case of class 2

encoder only) and input, the

addresses under which the

encoder is to be addressed

in S7 must be allocated. The

other entries in this register

should not be changed. The

following Figure depicts an

example of this register for a

class 2 encoder with 32 bit

single turn resolution.

For the example programme,

please input address 100 for

outputs and inputs.

8.1.7 Parameterisation of

the encoder

Via the Parameter Assignment

register, the following window,

in which the characteristics of

the encoder can be dened, is

accessed. The parameters of a

class 2 slave are shown. In the

case of a class 1 slave, only the

code sequence parameter can

be set here.

(See Chapter 6)

Date: 10.07.2012 Page 22 of 28 user manual no. CRD 10617 FE

Page 23

Simatic Step7

8.1.8 Setting the diagnosis address

Setting the diagnosis address is only required if the special probus diagnosis functions are used within the S7

programme.

So that the diagnosis range of the encoder can be accessed within the S7 programme, a special S7 diagnosis address

must be allocated to this. This address may lie within the entire peripheral range of the control system. It does not,

therefore, occupy any input/output addresses.

By double-clicking onto the encoder symbol, the Properties - DP slave window appears with the General register.

For the example programme please specify diagnosis address 200 for the rst encoder and 202 for the second encoder.

Following conrmation with OK, the encoder is congured and parameterised. The hardware conguration can

now be translated and transferred into S7.

8.2 Setting the subscriber address in the case of the plug-version encoder

According to Siemens, the prerequisites for allocating a new address are as follows:

1. No further DP master is contained in the PROFIBUS network.

2. At least one DP slave exists in the PROFIBUS network.

3. A PROFIBUS address has already been directly allocated to each DP slave in the

PROFIBUS network (either via software via PG - DP slave direct connection

or via setting the switches on the DP slave; Assignment is DP slave-dependent,

therefore consult the DP slave manual)

4. You have connected the programming device to the PROFIBUS network via a stub line

(See the manual regarding the DP master).

(See on-line help under Assignment of probus address” in the Simatic Manager)

Date: 10.07.2012 Page 23 of 28 user manual no. CRD 10617 FE

Page 24

Simatic Step7

I.e. if the encoder is not the only slave on the probus/MPI card, all slaves contained in the bus must possess a

unique (allocated only once) address, and the master (S7-CPU) must be disconnected from the bus. It is therefore

impossible, for example, to simultaneously connect two encoders with address 123 to the bus and to then assign a

new address to one of the two.

If the encoder whose address is to be changed has already previously been used in bus operation, this must be

rendered potential-free before it can be set to a new address.

Address setting is carried out in the Simatic Manager under “PLC , Assign PROFIBUS Address”. If the encoder is

connected to the probus/MPI interface of your programming device, the depicted dialogue appears.

This displays the current address of the encoder, and requests the input of the new probus address. If this is conrmed

with Apply, the new address is stored in the encoder in a zero-voltage-protected manner. The dialogue subsequently

displays the new address as the current address.

8.3 Example programmes

In the internet several S7 archive les are available, which contain S7 example programmes which have been

generated by TWK for working with the TWK probus encoder. The programmes have been developed for a CPU3152DP, and have been designed such that no periphery other than a TWK probus encoder is required. There is one

project for encoders with class 1 functionality and one for encoders with class 2 functionality. Each project contains

several programme folders for different application cases. The standard ”Sources” and ”Blocks” folders are located

beneath the programme folders.

The TWK examples only contain modules which have been generated with the KOP/FUP/AWL Editor. The generation

language was FUP. Within the modules, comprehensive documentation is made available on the basis of network

comments.

TWK cannot undertake to provide any guarantee for the function of these programmes on customers’

systems/control systems.

Programmes in the archive les:

- TWKDPCL1.ARJ : Class 1 project with Diagnosis and Istwert programme folders, comments in German

- TWKDPCL2.ARJ : Class 2 project with Diagnosis, IstRef and Istwert programme folders, comments in German

- DP_C1_GB.ARJ : Class 1 project with Diagnosis and Istwert programme folders, comments in English

- DP_C2_GB.ARJ : Class 2 Project with Diagnosis, IstRef and Istwert programme folders, comments in English

Because of a modication in the handling of the used system function SFC13 the examples for the diagnosis in the

above programmes do not work with actual CPUs. Therefore a new programm example is available (please refer to

the additional information in document no. 12532).

- Diag_neu: reading of diagosis data with SFC13 with german comments

- Diag_new: reading of diagosis data with SFC13 with english comments

8.3.1 The TWKDPCL1 project

The following Figure shows the class 1 project programme folders:

Date: 10.07.2012 Page 24 of 28 user manual no. CRD 10617 FE

Page 25

Simatic Step7

Program Istwert: The program Istwert is comprised only of an OB1 and is intended to briey show the manner in

which the actual position value of the encoder is accessed within the S7 programme.

Program Diag1: In addition to the program Istwert, the Diag1 programme also contains error handling for a class 1

encoder. It contains, amongst other things, OB86 for detecting the failure of the encoder, and OB82 for detecting a

diagnosis request on the part of the encoder. Step7 system function SFC13 is used to read the diagnosis range out.

(The diagnosis range of the class 1 encoder is 16 bytes. See Chapter 7)

Program Diag2: The Diag2 programme provides the same functionality as Diag1, but is designed for two encoders.

Within each programme, a selection may be made between functions for a 16 or 32 bit-wide encoder input. To achieve

this, either the 16 or the 32 bit function is simply provided with a ”1” signal (one-marker M 0.1) at the EN input, and

the non-required function with a ”0” signal (zero-marker M 0.0).

8.3.2 The TWKDPCL2 project

The class 2 project contains the following programme folders:

Program Istwert: Identical to class 1 programme

Program IstRef: The program IstRef contains the reading out of the actual position value and, in addition, the

setting of a preset value, which is possible in the case of class 2 functionality.

Program Diag1: In the same manner as Diag1 from the class 1 project, the Diag1 programme contains the error

handling of a class 2 encoder. In this case, the scope of the diagnosis range is 63 bytes.

Program Diag2: Once again, Diag2 is the variant of Diag1 which is extended to encompass two encoders.

8.3.3 Installation of the example programmes

Prerequisites:

- You have generated a project and have inserted a control system into this with its hardware conguration.

This may appear as follows, for example:

· In the hardware conguration, you have connected one or two encoders with the following settings to a

probus subnetwork:

First encoder: Probus address 123

Inputs/outputs: From address 100

Diagnosis address: 200

Poss.: Second encoder: Probus address 122

Inputs/outputs: From address 110

Diagnosis address: 202

Date: 10.07.2012 Page 25 of 28 user manual no. CRD 10617 FE

Page 26

Simatic Step7

Installation:

- In the Simatic Manager, select File, Retrieve. Change the le type to *.arj and select the downloaded le

- In the next window, specify your project directory (normally S7proj).

- Via integration with OK, the dearchiving programme is started. After terminating this, you will nd your

selected TWK example project in your S7 project directory.

- If you now select File, Open, User project, you will be provided with a list of the projects available on your

system. If the example project is not yet available here, select Browse and search for the TWKDPCL1.s7p

(or TWKDPCL2.s7p) le under the TWK example project.

- Open the example project so that you now have both projects, your own and the example project, open. This

may then, for example, look like the Figure on the next Page.

- Select a subordinate S7 programme folder of the TWK example project. (In this case, either Diag1, Diag2, IstRef

or Istwert. Also see: Chapter 8.3.1)

- Copy all of the module container’s modules from the selected programme folder ( e.g. Diag1 from

TWKDPCL2 ) into your own project’s still empty module container (e.g. S7 programme (1) from DP_CLAS2 ).

(Note: Each module container, even an empty one, contains at least one OB1; this is, of course, also empty,

and can therefore be overwritten.)

- If you have installed a class 2, 16 bit encoder, and have selected the ActualRef or Diag1/2 programme, you

must, in order to set the preset value, release the FB10 in the OB1, i.e. supply the EN input with M 0.1 and

block the FB11 (s), i.e. supply the EN input with M 0.0.

- If necessary, replace the M 1.0 – Acknowledge message and the M 10.0 (and M 10.1 in the case of two

encoders) – Set the preset value, with your signals.

- Transfer all modules into the control system.

- Now call up the OB1 in the on-line view, and switch Test, Observe on, in order to have the current values of

the encoder displayed on the monitor.

- For ActualRef and Diag1/2 programme only: Enter a preset value into DB100 data doubleword 0 (for the

second encoder, DB100 data doubleword 8), and set this with the M 10.0 (or M 10.1). If the preset value lies

outside of the parameterised measurement range of the encoder, the corresponding error message is set in

OB1.

Date: 10.07.2012 Page 26 of 28 user manual no. CRD 10617 FE

Page 27

Simatic Step7

8.3.4 Explanations regarding the example programmes

Each programme folder contains a symbol table, which contains all global variables of the maximum expansion (class

2 project, Diag2 programme).

The programme structure of this maximum expansion is explained in the following. The reference data provide the

following overview: (The symbolic name is always contained in the round brackets)

Cyclical programme:

- Reading the actual value in

- Setting the preset value (class 2 only) for

16 bit (FB10) or 32 bit (FB11)

- Error messages from OB82

- Error messages from OB 86

OB82 is run through as soon as a DP slave

places a diagnosis request (in the case of an

incoming and outgoing event). In OB82, the

diagnosis data are collected by FB13 or SFC13.

The errors are reported in OB1.

OB86 is called up by the system in the event of

the failure of a DP slave (e.g. power failure), etc.

(in the case of an incoming and outgoing event).

The failed encoder is determined in FC16 and

is displayed in OB1.

The entire diagnosis range of the disturbed encoder is always read out via system function SFC13 (16 bytes in the

case of class 1 and 63 bytes in the case of class 2). The address of this slave is provided by OB82 in its local data.

Only the manufacturer-specic error message bits are evaluated, and of these, only those which may occur in Data

Exchange Mode (in normal bus operation). Errors which can occur during bus initialisation cannot be detected by

OB82. In this case, the error messages must be read out via the Diagnosing hardware function of the Step7 package.

Date: 10.07.2012 Page 27 of 28 user manual no. CRD 10617 FE

Page 28

Scope of delivery

9. Scope of delivery

The scope of delivery includes: - Encoder with DP interface

- Pin assignment TY XXXXX (depending on the device variant)

Remark:

The GSD-le, the complete documentation and the example programms are available for download in the internet

www.twk.de under documentation

Literature

10. Literature

/1/ PROFIBUS Prole for Encoders

Order No. 3.062

1997, PROFIBUS User Organisation Regd. Assoc.

Haid-und-Neu-Str. 7

D-76131 Karlsruhe

/2/ PROFIBUS

Brief Technical Description

Version: April 1997

PROFIBUS User Organisation

/3/ DIN 19245 Part 1 PROFIBUS

Process Field Bus Transmission Technology, Bus Access and Transmission Protocol,

Service Interface for Application Layer, Management

/4/ DIN 19245 Part 3 PROFIBUS

Process Field Bus Decentralised Periphery (DP)

/5/ SIEMENS SINEC L2

SPC 3 Siemens PROFIBUS Controller

User Description Order No.: 6ES7 195-0BD00-8AA0

Appendix A

Appendix A: Encoder terms

Parameter: Explanation

Measuring units per revolution: The single turn resolution species the number of measuring units per

revolution (360°).

Measuring range: The measuring range species the maximum number of revolutions.

Specication of the revolutions must be carried out in 2

Total measuring range in units: The total measuring range in units is revealed as follows:

Total measuring range in units = Single turn resolution x Measuring range

Code sequence: The code sequence species the direction of rotation in which the output code

of the encoder corresponds to increasing values.

A distinction is made between the following depending on the direction of rotation:

CW - clockwise, clockwise direction of rotation

CCW - counter clockwise, anti-clockwise direction of rotation

(viewed in the direction of the shaft)

Preset value: The preset value is the value which appears in the encoder’s output value

parameter according to the preset function.

n

powers.

Date: 10.07.2012 Page 28 of 28 user manual no. CRD 10617 FE

Loading...

Loading...