Page 1

Rev: 2013.10.19.v002b

1

Superlite

Superlite Superlite

Superlite Indoor Series

Indoor SeriesIndoor Series

Indoor Series

13g - 18g motor / 30

-

50 watts

6 - 10 amp ESC

4 channel radio

2x 4g - 6g servos

1x 8g - 11g servo

7in - 8in prop

USA

Distributor

Twisted Hobbys

www.twistedhobbys.com

YAK

Wingspan = 32"

Length = 31"

AUW= 12

6g -

135g

INFERNO

Wingspan = 34"

Length = 35"

AUW= 126g - 135g

Page 2

Rev: 2013.10.19.v002b

2

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

Page

WARNING INFORMATION ........................................................................................................................................................3

SHIPPING DAMAGE..................................................................................................................................................................... 3

OUR MISSION ................................................................................................................................................................................3

SAFETY NOTES.............................................................................................................................................................................4

IMPORTANT: PRIOR TO ANY ASSEMBLY....................................................................................................................4

KIT CONTENTS.............................................................................................................................................................................5

OPTIONAL PARTS........................................................................................................................................................................ 6

TOOLS & ADHESIVES NEEDED ............................................................................................................................................... 7

THE BUILD ..................................................................................................................................................................................... 8

CENTER OF GRAVITY .............................................................................................................................................................. 34

EXTREME & 3D SET UP PRECAUTIONS 34

CONTROL THROWS ..................................................................................................................................................................34

THROTTLE CURVE....................................................................................................................................................................34

PRE-FLIGHT & TESTING .........................................................................................................................................................35

P

REFLIGHT CHECKS

35

Motor 35

Flight Controls 35

Batteries 35

Radio 35

Range Check 35

F

LIGHT TESTING

35

S

TORAGE

35

NOTES & S/U SHEET.................................................................................................................................................................. 36

TIPS AND TRICKS....................................................................................................................................................................... 37

Page 3

Rev: 2013.10.19.v002b

3

TWISTED HOBBYS

Website: www.twistedhobbys.com – email: sales@twistedhobbys.com

Thank you for your purchasing a Twisted Hobbys’ model. Please read through the entire manual before beginning to

build this model. If you have any questions please contact us at the above indicated email address.

WARNING INFORMATION

WARNING INFORMATIONWARNING INFORMATION

WARNING INFORMATION

This R/C Aircraft is not a toy! Read and understand the entire manual before assembly. If misused, it can cause serious bodily harm and

property damage. Fly only in open areas, and AMA (Academy of Model Aeronautics) approved flying sites. Do not over look the warnings

and instructions enclosed or those provided by other manufactures’ products. If you are not an experienced pilot and airplane modeler you

must use the help of an experienced pilot or an authorized flight instructor for the building and flying of this model aircraft.

These instructions are suggestions only on how to assemble this model. There are other ways and methods to do so. Twisted Hobbys has

no control over the final assembly, the materials and accessories used when assembling this kit, or t he manner in which the assembled

model, installed radio gear and electronic parts are used and maintained. Thus, no liability is assumed or accepted for any damage

resulting from the use of the assembled model aircraft or from this instruction manual including but not limited to direct, indirect,

incidental, special, and consequential damages. By the act of using this user-assembled product, the user accepts all resulting liability. In

no event shall Twisted Hobbys’ liability exceed the original purchase price of the kit.

SHIPPING DAMAGE

SHIPPING DAMAGESHIPPING DAMAGE

SHIPPING DAMAGE

Twisted Hobbys checks each plane before shipping to ensure that each kit is in fine condition. We have no bearing on the condition of any

component parts damaged by use, modification, or assembly of the model. Inspect the components of this kit upon receipt. If you find any

parts damaged or missing, contact Twisted Hobbys immediately. We will not accept the return or replacement of parts on which assembly

work has already begun. Twisted Hobbys reserves the right to change this warranty at anytime without notice.

OUR

OUR OUR

OUR MISSION

MISSIONMISSION

MISSION

To provide the best products and service to our customers at the lowest prices possible. We take great pride in

our company, our commitment to customer service and in the products we sell. Our online store is designed

to provide you with a safe and secure environment to browse our product catalog.

Thank you for shopping with Twisted Hobbys!

Page 4

Rev: 2013.10.19.v002b

4

SAFETY NOTES

SAFETY NOTESSAFETY NOTES

SAFETY NOTES

Before assembling and flying this model, read carefully any instructions and warnings of other

manufacturers for all the products you installed or used on your model, especially radio

equipment and power source.

Check thoroughly before every flight that the airplanes’ components are in good shape and

functioning properly. If you find a fault do not fly the model until you have corrected the

problem.

Radio interference caused by unknown sources can occur at any time without notice. In such a

case, your model will be uncontrollable and completely unpredictable. Make sure to perform a

range check before every flight. If you detect a control problem or interference during a flight,

immediately land the model to prevent a potential accident.

Youngsters should only be allowed to assemble and fly these models under the instruction and

supervision of an experienced adult.

Do not operate this model in a confined area.

Do not stand in line with, or in front of a spinning propeller and never touch it with any object.

IMPORTANT: PRIOR TO ANY ASSEMBLY

Please Note: after removing kit from shipping box, lay each piece flat on a

hard surface, this will allow the airframe to straighten out if lightly bent

from shipping. Do not worry since EPP is very pliable and can be bent back

if out of shape.

Page 5

Rev: 2013.10.19.v002b

5

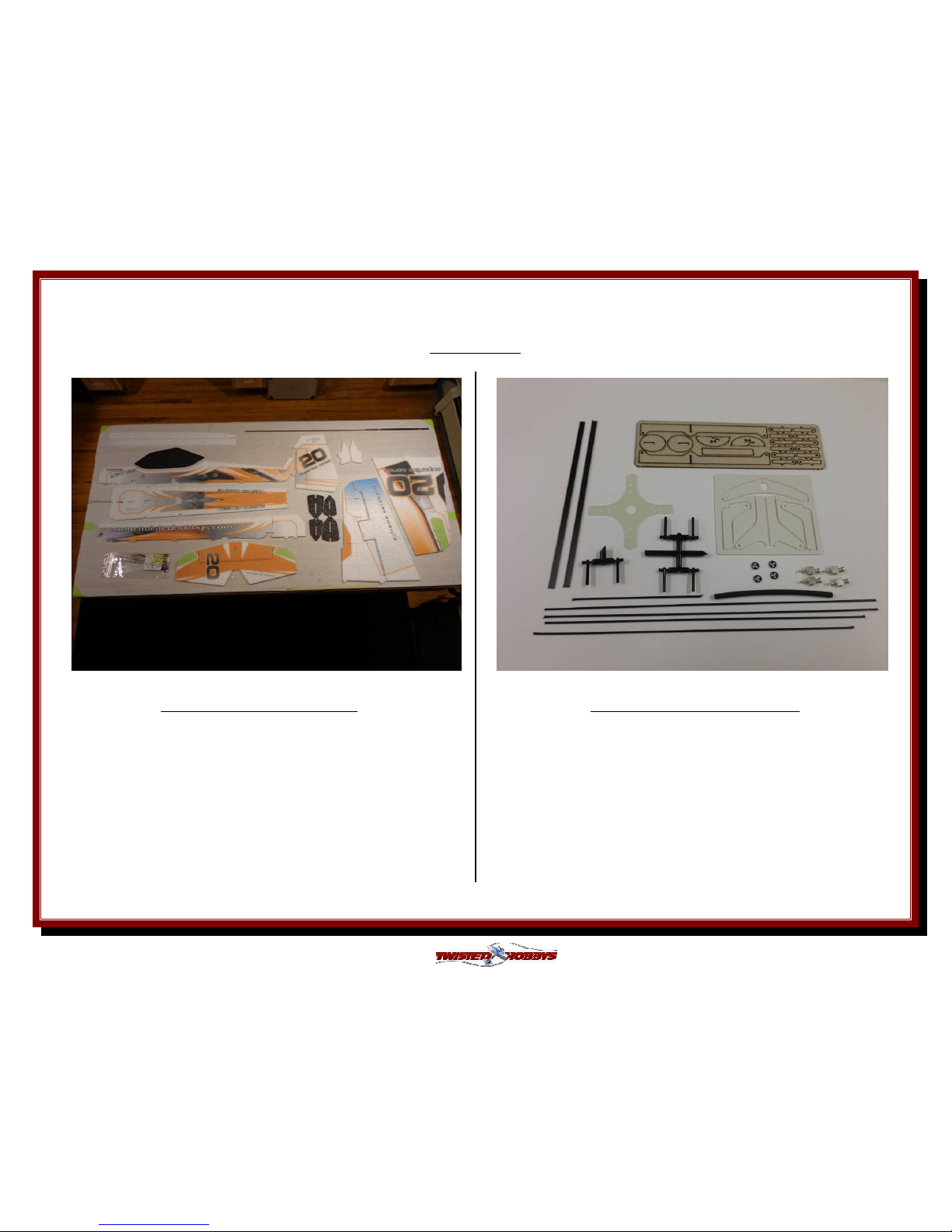

kit contents

kit contentskit contents

kit contents

PARTS LIST

AIRFRAME COMPONENTS

1x Wing (2pcs) 2x 1mm x 500mm Round

1x Top Fuse (elev. & rudder control rods)

1x Bottom Fuse 4x 0.75mm x 225mm Round

1x Rudder (aileron stiffeners)

1x Elevator 4x 1mm x 200mm Round

1x Canopy (wing-fuse stiffeners)

2x Wheel/Pant 2x 1mm x 3mm x 198mm Rec

1x Wing SFG Kit (landing gear struts)

2x Fuse Truss 1x 0.5mm x 4 x 667mm Rec

1x Horizontal Fuse (wing spar)

1x Hardware - see detail

DETAIL - HARDWARE PACK

2x 1mm Dia x 150mm Round (Aileron Control Rod)

1x 1mm Dia x 50mm Round

1x 1mm Dia x 60mm Round ( Tail Skid)

2x 0.5mm x 3mm x 100mm Rectangle (Tail Stiffeners)

1x Fiberglass Motor Mount

1x Plastic Kit

1x Wood Horn Kit

6x Snap Link Ends

4x Quick Links with Screws and Keeper Rings

1x Heat Shrink Tube for Z-Bends (approx 65mm long)

Page 6

Rev: 2013.10.19.v002b

6

Perfect choice for building and

repairing your Twisted Hobbys

EPP planes! This is the only

adhesive you will ever need.

Welder virtually bonds anything

to anything! Clear, heavy-duty,

flexible and water-proof when

dry. Use indoors or out. (1) 1 oz

tube

Note: many of these “optional parts” shown

or similar items, may be available from the

Twisted Hobbys’ web store.

Crack Power Combo

(Recommended by Twisted Hobbys)

(1) Crack Series 14g - 19g Motor

(1) Crack Series 6A ESC

(2) CS-40D Digital Micro Servos

(1) CS-70D Digital Micro Servo

(1)

7 x 3.5 GWS DD Prop

OPTIONAL PARTS

OPTIONAL PARTSOPTIONAL PARTS

OPTIONAL PARTS

CA and Kicker

Various thickness CA glues

and

Activator available from

Twisted Hobbys’

Blenderm tape is one of the

best know tapes used for

hinging and repairing your

Depron or Epp models. Each

roll consists of 1/2" wide x 4m

in length

Specifications

6 Channel / DSM2 / 2.4GHZ

25mm X 19mm X 11mm

Weight: 3.0g / Input: 3.5–9.6V

Bind plug included

Page 7

Rev: 2013.10.19.v002b

7

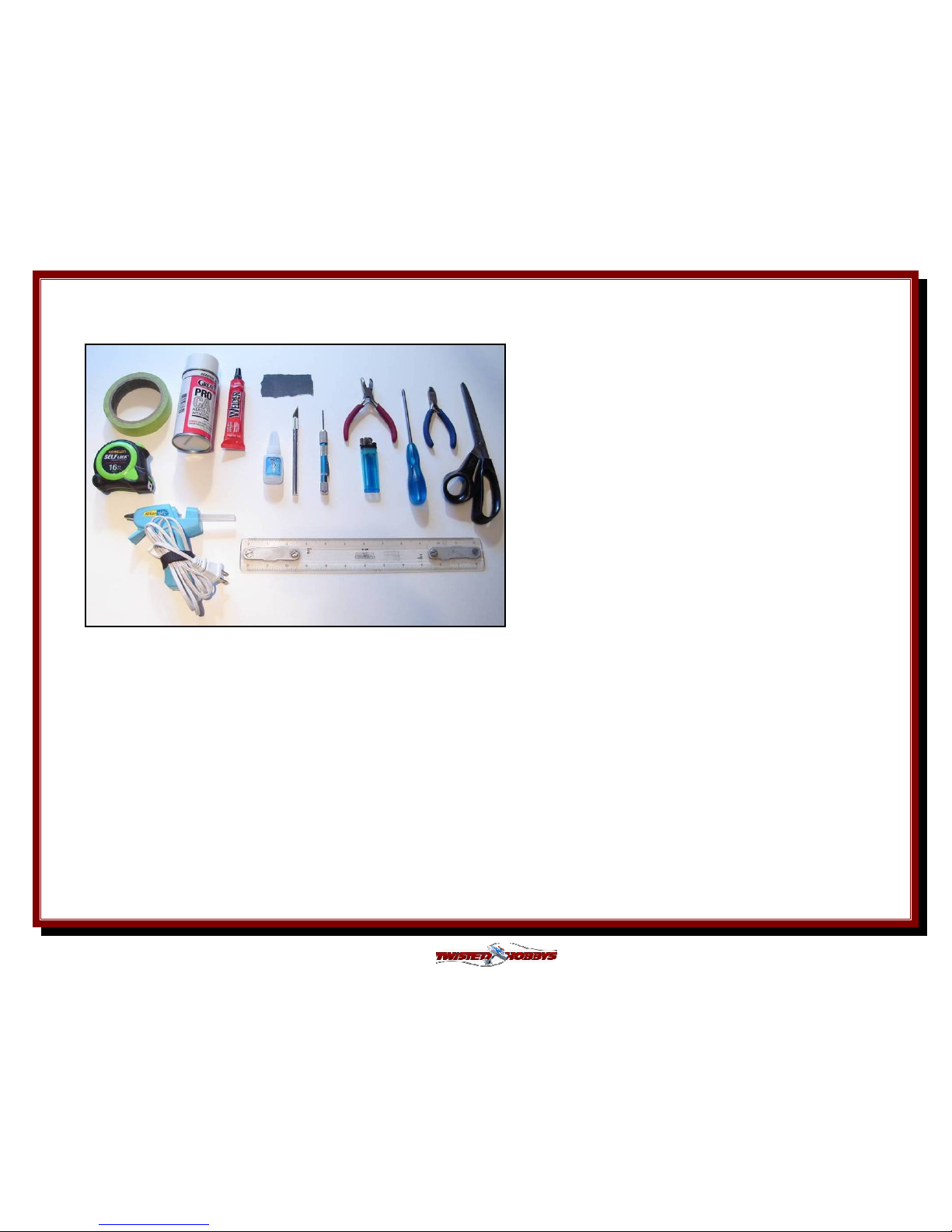

Tools

Tools Tools

Tools &&&& Adhesives Needed

Adhesives Needed Adhesives Needed

Adhesives Needed

• Lighter

• Small drill bits

• Tape Measure and Ruler

• Black Sewing Thread

• Welders Glue

• Hobby Knife w/new Blade

• Needle Nose Pliers

• Wire Cutters

• Low Temp Hot Glue Gun

• Course Sand Paper

• Scissors

• Small Phillips Screw Driver

• Thin & Medium CA

• CA Applicator Tips

• Activator

Tools shown and listed are suggestions only. Depending

on your building technique you may not need everything

indicated – and/or – you may find that other tools

available to yourself may be of benefit to your Build.

It is also recommended that you have a flat building

surface, one that will accept stick pins and push pins.

An Acrostic Ceiling panel from your local hardware store

fits this bill nicely, and will lay flat on your work table.

Over size / long push pins are available at your local

craft store. These two items are by no means required,

but will aid in the building process, and can be used for

future projects.

Page 8

Rev: 2013.10.19.v002b

8

THE BUILD

THE BUILDTHE BUILD

THE BUILD

CONSTRUCTION METHODS:

Building surface should be at least 2ft x 4ft and flat. Weights or some small heavy objects will be handy for holding things in place during

the time glue is setting.

Welders glue is the primary adhesive used for this build. The Rod Guides and End Links use thin CA with Applicator and Activator. When

using the Welders glue for a butt joint, apply a thin film to each surface, allow to sit for approx five minutes and then assemble.

Note that this method will create a nearly instant bond, so locate carefully when bringing the two pieces together. If alignment is

necessary or a slip joint, do not allow the glue to tack up, simple apply and join immediately, you will have several minutes to locate the

two parts before the glue sets up. In most cases the parts being glued can be handled with care in 30 minutes, full cure is approx 24

hours.

Open up your kit and inspect for damage and / or missing parts.

Use the Parts List on page 5 to verify that your kit is complete.

Do the same with the Power Set, confirm that you have all your

items and that they appear to be in sound condition. Testing of

functionality will be one of the first steps that will follow shortly.

Page 9

Rev: 2013.10.19.v002b

9

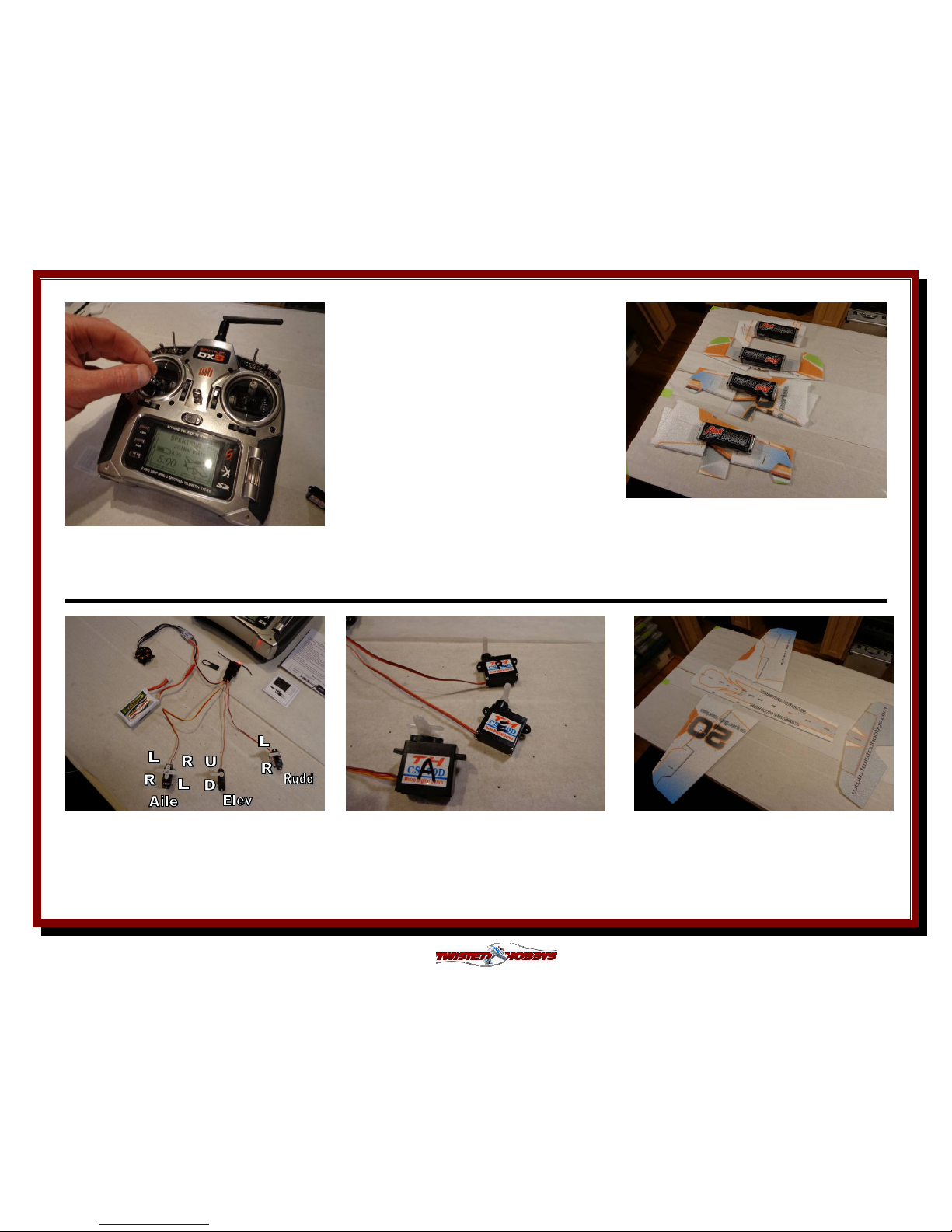

Program the Throttle End Points per the

ESC Instructions and next couple steps….

Identify the porper pins for the; Throttle,

Aileron, Elevator and Rudder Channels.

Carefully compare to the diagram to make

sure you have the correct orientations.

Compare your Reciever to the included

diagram from the side as shown above.

Make a note of the polarity of the pins. In

most cases, either Black or Brown is used

to identify Negative (-).

Make a new program in your Radio. Zero all

the Trims and Subtrims. For starters all the

ATVs can be set to 100% . Adjustment of

additional settings will be done at the end

of the build.

Plug Motor wires into the ESC, the ESC into

the Throttle Channel, and the servos to

their appropriate channel. Bind per your

Radio’s Instructions.

turn on your radio and move the throttle

stick to "full throttle" position...

Page 10

Rev: 2013.10.19.v002b

10

…. reconnect the battery to the ESC

and listen for two quick short beeps,

immediately following the beeps,

move the Throttle stick to low

position.

Next you should hear a series of

tones to indicate that programing is

complete.

Re-

bind the system and double check

correct operation of all components.

Center all servos as close to 90 deg

as possible. Install the Longest single

arms on the servos.

Fold all the hinged parts over onto

themselves and let sit for approx ten

minutes

Mark the Servos with their channel and

install the horn screws

Locate and position the four pieces

shown above

Program your radio so that the

channels & directions match the

picture above. Installed horns as

shown, dbl check that subtrims - arms

should be at 90 deg

Page 11

Rev: 2013.10.19.v002b

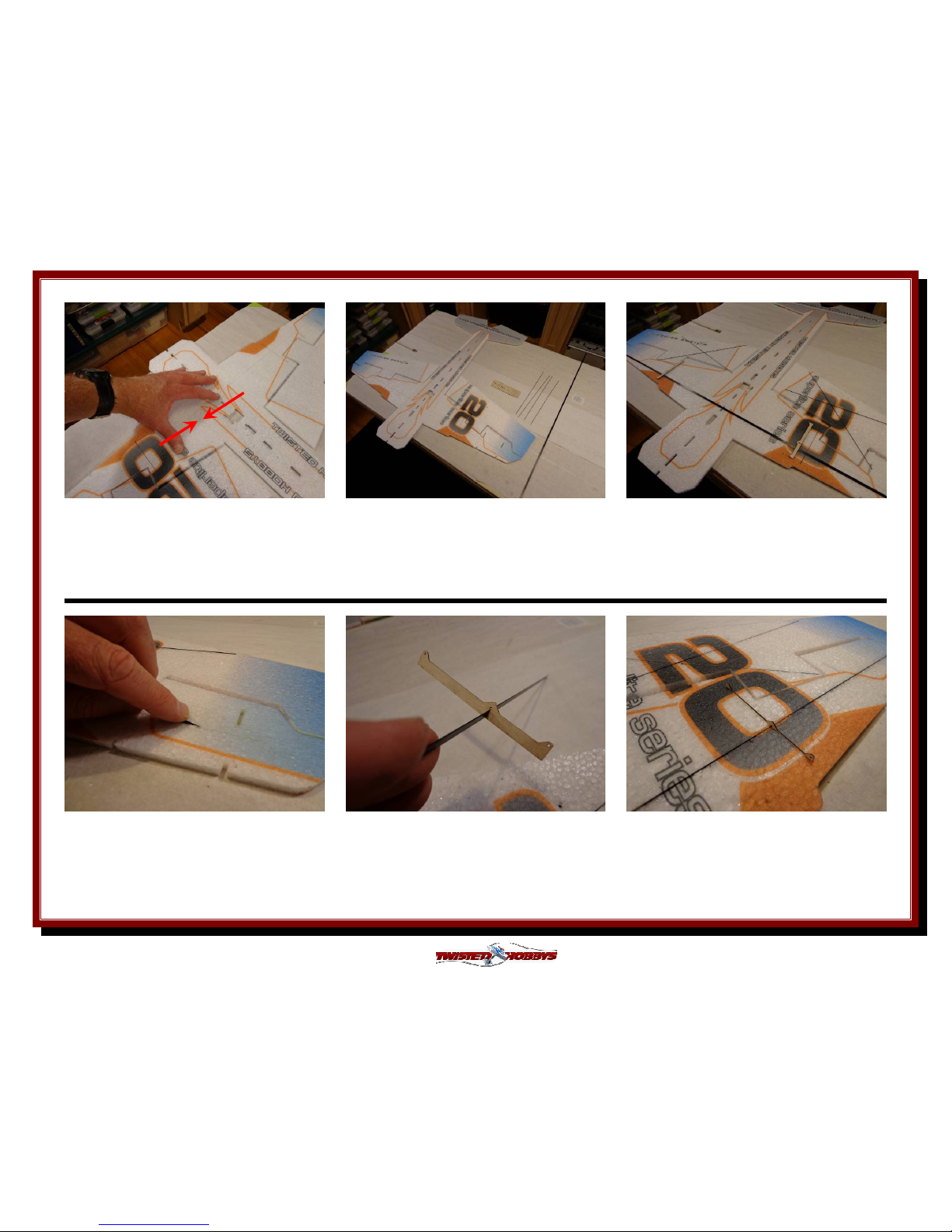

11

Remove the webs from the areas where

the Side force generators will install

Apply a medium bead of Welders to one

of the pieces of each joint

Join and separate each joint a couple

times to evenly distribute the glue onto

both surfaces, set aside to tack up

While this is tacking up, do the same

with the canopy and fuselage. Also

locate the short carbon strips and test

fit them into their slots.

It may be that the slots need to be

made a little deeper for a flush fit.

Apply some glue into the slot and

install the strips. Weigh down flat and

let dry

Set these aside for while the glue tacks

up for the canopy joint

Page 12

Rev: 2013.10.19.v002b

12

Test / Dry fit the rib and spar pieces,

with the exception of the bumped

areas, everything should be flush with

the bottom of the wing.

By now the glue for the fuselage

horizontal fuselage sections should be

tacked up. Carefully bring them

together, the bond will be instant

Next is the carbon inlays. Locate the

longest strip, the four 225mm rounds

and the wood kit

Find the pre-made slo

ts and cuts for all

the pieces. Notice how the wood rib is

different from front to back

Check that the slot for the Wing Spar is

deep enough, should sit flush. If not

you can gently drag the end of the spar

across the slit to increase the depth

until deep enough

Make sure the slot in the rib allows for

an easy fit of the spar. Enlarge if

necessary with a hobby knife if

necessary

Page 13

Rev: 2013.10.19.v002b

13

Next test fit the "X" brace pieces into

the slits of the aileron. Note, at the

intersection point one will be a little

deeper then flush

By now the Welder's should be tacked

up on the Canopy. Carefully bring the

two pieces together, lining up the front

and rear points

Back to the wing... remove the pieces

for the "X" brace, and with the tip of the

Welder's tube as show, force a small

amount of Welders into the slit.

Repeat this process for the other aileron

and the wing spar/rib parts. Weigh

down the assembly and allow to dry

Long Push pins could also be used if

you building surface allows for it.

Shown here is an acoustic ceiling tile

on flat surface covered with Parchment

paper

Lay the rod in, and press to flush, wipe

away any extra glue that is forced out

Page 14

Rev: 2013.10.19.v002b

14

Test fit your aileron servo into the

provided cut out. You may need to

enlarge it slightly

If your building board allows for it,

make a small pocket so that the servo

will sit flush on it's ears, otherwise just

hang this part over the edge of the table

Locate the Differential horn from the

plastic kit and 2 sets of the quick links.

Install the quick links into the holes

and secure with the keepers

Once the quick links are installe

d apply

a generous amount of Welders to the

top surface of the servo arm and then

attach the Diff Horn on top of, and

centered as shown, allow to dry.

Locate the small halve moon wood

parts. Note that the notch in the wood

will line up with the notch in the foam.

Off center hole in the wood is to the

rear of the plane

Glue the wood pieces to the fuselage

using the tack up method, making sure

the orientation and notches are correct

and lined up

Page 15

Rev: 2013.10.19.v002b

15

Once the glue is dry on the aileron

differential horn, fit the lower fuselage

section as shown

It may be necessary to slightly enlarge

some areas to allow for a nice fit

Do the same for the for the rudder

servo. Make sure the cut is deep

enough and notch to allow clearance for

the servo wires

Apply a thin bead of Welders to the butt

joint areas on the bottom of the

horizontal fuselage sections. Note - no

glue in the slots at this time

With a small piece of paper or thin

cardboard, spread the bead out into a

thin even layer

Apply glue in the same fashion to the

butt joint area of the lower vertical

fuselage section. Note - no glue on the

tabs at this time

Page 16

Rev: 2013.10.19.v002b

16

Spread the glue bead out as you did on

the mating part, avoiding the tabs. Set

aside and let both parts tack up

While those parts are tacking up, locate

the ailerons control rods (150mm) and

tail control rods (500mm)

as well as the

two tail servos, horns and snap links as

shown above

Start by clipping the snaps links from

the molded tree. Use a small pair of

flush cutters or hobby knife

Dress up the end of the push rod that

you will be gluing the snap link to.

Make sure that the end is nice and

round, not crushed out from the

cutting process

Check to verify a nice fit of the rod into

the saddled area of the snap link

Take the finished end of the rod and

poke it into the glue nozzle to coat with

glue, it may be necessary to do this a

time or two for an even coat of glue

Page 17

Rev: 2013.10.19.v002b

17

Once there is an even coat of glue,

attach it to the saddle area of the snap

link and set aside to dry. Repeat with

the other three control rods

Test fit the aileron control horns. Make

sure and use the one that is shown

above and that the hole will be inline

with the hinge/pivot point

Force some glue into the slit with the

tip of the glue nozzle

Install the horn, making is flush with

the bottom surface and making sure

that the hole is directly above the hinge

line. Wipe away any extra glue. Repeat

for the other side

Install a quick link into the outer most

hole of the longest single sided servo

arm.

Press the keeper ring on, make sure the

quick link can rotate freely. Repeat for

the other tail servo

Page 18

Rev: 2013.10.19.v002b

18

Back to the Fuselage pieces... add some

glue to the tabs and slots

While the glue is still wet on the tabs

and in the slots, join the two pieces

together. Make sure the nose area is

flush

Since part of the joint was tacked up,

the bond here will be instant. Press the

pieces together firmly and make sure

there are no gaps

Wipe away any extra glue. Remember,

for this airframe, the lighter the better,

so remove any extra glue

Make sure everything is square. It can

still be tweaked a little from side to side

if necessary

Next is the foam trusses. Start with the

right underside truss, add a thin bead

of Welders to the entire length of the

beveled edges

Page 19

Rev: 2013.10.19.v002b

19

Install the right under side truss as

shown... use stick pins if necessary to

hole the truss in place while the glue

dries

Repeat for the Left under side truss,

but do not put glue all the way to the

pointed end, see next picture

Leaving this area free of glue will allow

you to tuck all the radio wires away and

out of site later in the build

Bottom Carbon Trussing is next. Find

the four 200mm rods and the two

165mm rods. A .040" dia drill and pin

vise will come in real handy. Read the

next couple steps before proceeding

Dress up both ends of all the rods so

that they are sharply pointed

With the drill, chase the holes in the

wing rib as shown, using the approx

angle that the rod will be installed in for

best results and fit

Page 20

Rev: 2013.10.19.v002b

20

Repeat for the other wing rig hole

Do the same for the mating holes on

the doubler on the fuselage

Once far enough in, line the other end

up with the mating hole in the fuse

double, then back out slightly so that

the fuse end is engaged about half the

foam thickness

Repeat for the other three long pieces.

Note - no glue yet at this point.

Sight down the fuselage, and adjust for

squareness if needed

Stick the carbon rod thru the hole in

the rib, and while holding at the right

angle, twist and poke that end into the

foam far enough to clear the fuse hole

Page 21

Rev: 2013.10.19.v002b

21

Repeat with the rod that angles

backwards. Make sure there is enough

clearance in the doubler hole so that it

can be installed freely.....

.... stick it thru the about 3/16" extra,

then prick the other end into the foam

and feed back into the horz fuse section

approx 3/16". Repeat for the other side

Look every thing over, make sure that

there is about 1/8" or so sticking thru

the doubler in the fuselage, and that

other ends have good bite in the foam

Close up, notice how the rods are

sticking thru the rib and into the foam.

Still no glue at this time

Close up of the other side

Double check that everything is still

square and that all the rod ends are

engaged as they should be

Page 22

Rev: 2013.10.19.v002b

22

Now.. time for glue, back each end in

and out a little so that the glue can

work it's way in and around the rib and

doubler on the other side. Repeat for all

ends and double check squareness

Landing Gear - Locate the two 200mm

strips and the wood pieces shown above

Dry fit everything as shown, make sure

there is clearance for the aileron

differential horn

The wood doubler is in the middle, with

one strut in the front and one in back

Remove the items once satisfied with

the fit. Put a little Welders in the

thinner, top and bottom, area of the

slot...

Re-install the wood doubler and gear

struts, force glue into the area. Make

sure the one end of the strut goes into

the slot on the underside of the

fuselage with some Welders.

Page 23

Rev: 2013.10.19.v002b

23

Make sure that the struts are

intersecting the fuselage symmetrically

and that the horz fuse section is still

square. Wipe away any extra glue

Wheels/Pants are next, cut the foam

apart, and make sure the slit in the

wood pieces is wide enough to clear the

landing gear struts

Glue the wood pieces on as shown. Wet

or tack up method can be used, if time

is critical, use the tack method

While the glue dries on the

Wheel/Pants, prepare the Side Force

Generators

Slit the one end approx in the location

shown above. There are little "v" marks

to help get it split right in the middle

Ready for installation later in the build,

repeat for the other three

Page 24

Rev: 2013.10.19.v002b

24

Once the glue has dried, slit all the way

thru in the area defined by the slot in

the wood doubler

Test fit onto the end of the landing gear

strut. Note, the strut should not stick

out beyond the far side

When both are installed the should be

perpendicular to the work surface and

parallel to each other in the direction of

flight

In this view, the bottoms of the wheel

pant should be parallel with the work

surface, and each other.

Once satisfied with the dry fit, remove

the wheel/pants and force some glue

into the slit with the tip of the tube

Re-install and adjust accordingly in all

directions as was done on the dry fit.

Let all this dry over night

Page 25

Rev: 2013.10.19.v002b

25

Once all the carbon bracing and

landing gear pieces have had time to

dry, remove the assembly from the

bench and flip over onto its wheels

Stick the servos into their appropriate

holes. Note the elevator servo is laying

down with horn sticking up and rudder

servo as shown with arm to the left

Test fit the top half of the fuselage.

Check to make sure that the firewall

surfaces are all flat and square to the

direction of flight

Apply a thin bead of Welders to the butt

joint area as you did on the bottom side

and

spread to a thin layer. Allow to tack

up

Same for the vert fuse section, thin

bead of Welders on the butt joint

surfaces, spread thin and allowed to

tack up. Note no glue in the tabs and

slots at this time

Page 26

Rev: 2013.10.19.v002b

26

Once the butt joint areas are tacked,

add wet glue to the slots in the fuse

assembly...

... and to the tabs on the vert fuse

section...

... carefully bring the two pieces

together. The bond will be instant, so

make sure you have good alignment

Prepare the Rudder. Apply a skim coat

of Welders to both surfaces and allow to

tack up

While waiting for the rudder to tack up,

locate the motor mount

Rough up the glue side with a file or

rough sandpaper

Page 27

Rev: 2013.10.19.v002b

27

Apply a coat of Welders to the roughed

up side of the motor mount...

... and to the mating surface on the

front of the aircraft. Let the glue tack

up

While in this area, add small fillet

(about an inch long) of Welders in the

areas where the two fuse sections come

together, all four corners

Once the glue is tacked up on the

motor mount, attach it to the nose of

the airframe

Locate the 60mm long carbon rod,

dress up one end to a point and insert

into the rear of the plane, approx where

shown. Leave enough hanging out to

keep the rudder off the ground

Glue joint for the rudder should be

tacked up by now as well. Align the top

edge of the fin with the slit cut on the

rudder

Page 28

Rev: 2013.10.19.v002b

28

Tail skid installed

Next up is the control horns for the tail

and the control rod guides

Test fit the horn into the slot, it may

need to be cut thru with a hobby knife.

Hole in the horn should be directly

above the hinge line. Picture shows the

horn but not full seated yet

Once the horn is completely flush on

the top side the profile of the horn

should match the profile of the hinge

cut out area

When happy with the fit, remove the

horn and squeeze some glue into the

slit, re-install the horn, check

alignment and wipe away any extra

glue

Repeat with the Rudder

Page 29

Rev: 2013.10.19.v002b

29

Find the two longest control rods and

the twelve guides. Slide six guides onto

each rod

Poke the ends of the guides into the

provided holes, you may need to hold

the fuse up to a light to see the holes

Adjust them so that they are all lined

up nice and straight

Do the same for the rudder side

Once happy with the location of the

guides apply a little Welders to the hole

and base of the guide. Thin CA could

also be used here, just make sure that

the CA runs away for the carbon rod

Blender Mod (optional) - cut ten pieces

one inch long, these will be installed in

the areas indicated, and the top and

bottom of the rudder hinge line.

Page 30

Rev: 2013.10.19.v002b

30

Lay down a tiny bead of Welders about

one inch long in each of the spots, and

spread thin with a piece of paper or

thin cardboard

Once the Welders has tacked up lay the

Blenderm pieces on top of the glue spot

and press together

Do the same on the eight different

surfaces directly behind the motor

mount

Once the Blenderm is stuck down, it is

barely visible, but adds lots of strength

to the area used.

On the motor mount, the long pieces will

fold back on to each surface directly behind

the mount, stick down all the edges

completely

Install the Snap links into the

appropriate control horns, this is easily

done by lining up the

link with the hole

in the horn, and gently squeezing with

your finger tips, you will here it snap

Page 31

Rev: 2013.10.19.v002b

31

Grab your motor of choice and decide

what side you want the wires to be on

Locate the screw that were included in

your motor hardware packet

Mount the motor. Use care when

installing the screws, support the motor

mount with your fingers so that all the

twisting will not damage the glue joint

Install the ESC approx where shown,

run all your wires underneath the open

end of the foam truss, then glue down

the opening

Plug all the servos and ESC into the

receiver,

attach with a drop of low temp

hot glue. Servos should be secured at

this time as well with a couple small

beads of low temp hot glue

Close up of the receiver wiring and

location

Page 32

Rev: 2013.10.19.v002b

32

Route the ESC/Battery lead to the

general area where you will mount the

battery

Now that all the work is done in this

area, install the aileron push rods.

Find the four tiny screws that are used

to lock the rods to the quick links

Turn on your radio with the SuperLite

program, plug in a battery, double

check that all servos are centered. Hold

the control surface neutral and

GENTLY TIGHTEN the set screw

Clip off any extra rod. Leave about 1/4"

stick out. Repeat the process for the

elevator and ailerons. Again, be gentle

with the tighten of the set screws, it is

easy to crush the rod if not careful

Side Force Generators will be installed

next....

Page 33

Rev: 2013.10.19.v002b

33

Lay down a small bead of Welders in

the contact area and in the slots

Spread the SFG, being careful to not

make a mess out of the glue bead

Bring the open together into the slotted

area and hold in place for a minute or

two until the glue is holding on its own

Repeat for the other three SFG's. Make

sure they are square and stuck down

good

Install a small piece of Velcro

somewhere between the aileron servo

and firewall. Once the battery location

has been determined after flying, a hole

can be cut to hole the battery

Balance the prop. Set max control

throws to 60 degrees on the Elevator,

Rudder and Ailerons, Expo 60% on all.

Adjust from there to taste after flying

Page 34

Rev: 2013.10.19.v002b

34

Center of

Center of Center of

Center of

Gravity

GravityGravity

Gravity

Locate all the electronic to achieve indicated CG point.

Use Velcro for initial flights for battery mounting and

experiment with it's position until you have

determined the best spot for your flying style. For best

3D performance a slight touch of down elevator may

be needed for inverted flight, and power off down line

should be straight down without any pull or tuck

EXTREME & 3D SET UP PRECAUTIONS

In order to achieve the control throws as suggested above

described for “Extreme & 3D”, it is imperative that the

control surface, linkages, rod ends, etc, all move freely over

the entire range, including range end points.

Failure to do so will result in damage to either the

servos or mechanical components

Control Throws

Control ThrowsControl Throws

Control Throws

Throttle curve

Throttle curveThrottle curve

Throttle curve

Throttle Curve can be set-up as pictured below.

Move the 50% point so that hover is at mid-stick

on your transmitter and flatten out the 25% and 75%

points to smooth out throttle response at Hover

Extreme

&

3D

:

Ailerons - approx +/- 60 deg

Rudder - approx +/- 60 deg

Elevator - approx +/- 60 deg

Expo to suit

Beginner

& Sport

:

Ailerons - approx +/- 30 deg

Rudder - approx +/- 40 deg

Elevator - approx +/- 40 deg

Expo to suit

Page 35

Rev: 2013.10.19.v002b

35

PRE

PREPRE

PRE----FLIGHT

FLIGHT FLIGHT

FLIGHT &&&& testing

testing testing

testing

Preflight Checks

Motor

:

Should run smoothly at all stick positions, and

transition smoothly from low to high RPM. If the motor is

turning backwards, reverse two of the three wires between

the motor and ESC. Check that the screws holding the

motor to the airframe are tight and secure.

Flight Controls

:

Set all to neutral or level positions with

sticks in the neutral positions. Ensure that all controls and

linkages move freely. Double check that all hinged areas are

free from rips or tears. Verify proper control surface

directions. Right Roll is – right aileron up, left aileron down,

Left Roll is left aileron up and right aileron down.

Batteries

:

Should be fully charged prior to each flight.

Watch transmitter battery level and follow manufactures

recommendations. Motor battery should not be drained any

further than recommended by the manufacture, use a timer

to prevent an over discharged condition.

Radio

:

All trims should be set to neutral and throttle in

the low position. Check that rate switches and mixes are

set properly.

Range Check

:

With and without the motor running per

radio manufactures instructions. If there is insufficient

range or significant reduction with the motor running,

resolve and re-test before flying.

Flight Testing

The first flights should be done with the CG at the

recommended position, and reduced control rates until

comfortable with your handling of the aircraft. As your

experience with the aircraft grows experiment with different

CG points and control rates. After all flights, check the

aircraft over for damage and/or other items that may

adversely affect flight performance.

This Extreme 3D Plane is a full performance aircraft and

will provide hours of entertainment, including the

occasional crash. If, as the result of a crash, the foam

tears, simply glue with Welders or CA. Many pilots prefer

Welders because it remains flexible after drying. CA

however, is more suited for the “quick” repair.

This aircraft can be flown indoors or outdoors. It is the

perfect size for the local park or school yard.

Storage

This EPP plane should be stored resting on the Bottom Pod.

Storing in other fashions that put stress on the airframe

could cause the airframe to distort. Storage in a hot car

could also cause damage.

Be safe and enjoy, thank you again for purchasing a Twisted Hobbys’ Product!

Page 36

Rev: 2013.10.19.v002b

36

NOTES

NOTESNOTES

NOTES &&&& s/u Sheet

s/u Sheet s/u Sheet

s/u Sheet

Page 37

Rev: 2013.10.19.v002b

37

TIPS AND TRICKS

TIPS AND TRICKSTIPS AND TRICKS

TIPS AND TRICKS

• A good building surface is “drop ceiling” panel from a local hardware store on a nice flat board

• Use parchment paper between the areas being glued and your work surface

• Heavy flat objects (like books, batteries, etc.) could be used to hold everything flat

• When resetting your radio, start with all the ATV’s or throw volumes at 100%.

• Make sure you have set the direction of the servos correctly before attempting to trim for zero position.

• If possible try the servo horns in different locations to determine which position will require the least amount of

sub trim.

• Installing the servo horns in their final location and attaching quick links to the servos may make servo

installation much easier later.

• On the Orange Rx, the negative pin is the one closest to the flat side of the circuit board.

• Keep a good supply of sharp knife blades handy when building a foamie airplane.

• Use low temp hot glue for gluing electronics, this will allow for easy removal later if necessary. The low temp hot

glue can be “released” by painting” the glue bead with an alcohol soaked cotton swab a couple times.

• A business card with the corners clipped off can be used as a small square.

• Allowing the Welders glue to set for five minutes before assembly will shorten the tack up time, just be sure if

doing it this way that you get the parts into position quickly, as the glue will start to bond on contact. Any joints

that you feel are going to require adjustment, it is best to assembly the pieces while the glue is wet. The Green

(high tack) masking tape works the best when used to clamp things together on an EPP foam airplane.

• When gluing the rudder to the fuselage, stick pins could be used to hold in position if wanting to handle the

airframe before it is completely dry

• A rotary tool with a cutting wheel could be used to produce grooves in fiber glass parts instead of coarse sand

paper. Use a hatch pattern. This creates more bonding area for the glue.

Loading...

Loading...