Twin Eagles Txbq-26g-t, Txbq-26r-t, Txbq-32g-t, Txbq-32r-t Owner's Manual

EXTREME GAS GRILL

INSTALLATION, USE & CARE MANUAL

MODELS TXBQ-26R-T, TXBQ-26G-T

TXBQ-32R-T, TXBQ-32G-T

P/N: 18557C 3-07

FOR YOUR RECORDS

Please record the following information and refer to them when contacting the

company or an authorized service agent. This information is found on the data plate,

located on the panel behind the control panel of the grill. Remove the drip tray to

visually access the nameplate label from the front of the grill.

Model #: ________________________________

Serial #: _________________________________

Date of Purchase: __________________________

Place of Purchase: __________________________

Type of Gas: NG LP

FOR YOUR SAFETY FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open Lid.

4. If odor continues, immediately call

your gas supplier or fire

department.

1. Do not store or use gasoline or other

flammable vapors and liquid in the

vicinity of this or any other appliance.

2. An LP (liquefied propane) cylinder not

connected for use shall not be stored in

the vicinity of this or any other appliance.

1

TABLE OF CONTENTS – EXTREME GAS GRILL

IMPORTANT SAFETY INFORMATION 3

GAS REQUIREMENTS

o LP GAS SAFETY REQUIREMENT

o LP GAS HOOKUP

o PORTABLE LP CONNECTION

o PLUMB-IN LP INSTALLATION (LP SYSTEM)

o NATURAL GAS INSTALLATION

LOCATING THE GRILL

o CLEARANCE TO COMBUSTIBLE CONSTRUCTION

o CLEARANCE TO NONCOMBUSTIBLE CONSTRUCTION

CABINET CUT-OUT DIMENSIONS FOR BUILT-IN APPLICATION

LEAK TESTING

ASSEMBLY INSTRUCTIONS

o RADIANTS AND GRATE ASSEMBLY

o TO SECURE POWER TRANSFORER

o ROTISSERIE ASSEMBLY

OPERATION INSTRUCTIONS

o LIGHTING INSTRUCTIONS

o REPLACING BATTERY

4

5

6

7

8

9

9

10

11

12

13

14

15

16

o AIR SHUTTER ADJUSTMENT

o ROTISSERIE

CLEANING AND MAINTENANCE

o STAINLESS STEEL

o GRILL GRATES

o WARMING RACK

o RADIANTS

o BURNERS

o CLEANING PAN

o SPIDER AND INSECT WARNING

TROUBLE SHOOTING GUIDE

PARTS LIST

o EXPLODED VIEW

o PARTS LIST

WARRANTY

WARRANTY REGISTRATION CARD

16

17

18

18

18

19

19

19

19

20

21

22

23

2

IMPORTANT SAFETY INFORMATION – EXTREME GAS GRILL

IMPORTANT: PLEASE READ MANUAL CAREFULLY BEFORE USING YOUR GRILL TO

ENSURE PROPER OPERATION AND TO REDUCE THE RISK OF FIRE, BURN HAZARD AND

OTHER INJURY.

General Safety Requirements:

1. The installation of this appliance must conform with local codes or, in the absence of local codes, either

the National Fuel Gas Code, ANZI Z223.1/NFPA 54, or CAN/CGA-B149.1, Natural Gas Installation

Code or CAN/CGA-B149.2, Propane Installation Code.

2. This outdoor cooking gas appliance is not intended to be installed in or on recreational vehicles and /or

boats.

3. This outdoor cooking gas appliance is intended for use outdoors and shall not be used in a building,

garage or any other enclosed area.

4. Minimum clearance of 18 inches from the back and 20 inches from the sides of the grill to adjacent

combustible construction must be maintained. This outdoor cooking gas appliance shall not be located

under overhead-unprotected combustible construction.

5. The utilization of an external electrical source requires that when installed, this outdoor cooking gas

appliance must be electrically grounded in accordance with the local codes or, in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1.

Keep any electrical supply cord, or the rotisserie motor cord and the fuel supply hose away from any

heated surfaces.

6. Keep y our grill in an area clear and free from co mbustible materials, gasoline and other flammable vapors

and liquids.

7. DO NOT obstruct the flow of combustion and ventilation air to this appliance. Keep the ventilation

openings of the cylinder enclosure free and clear from debris.

8. Check all gas connections for leaks with soapy water solution and brush. Never use an open flame.

9. Check flexible hoses for cuts and wear that may affect the safety before each use.

10. Never use charcoal in the grill.

11. Never use the grill in a windy area.

12. Never use the grill without the cleaning pan installed and push all the way to the back of the grill.

Without the pan, hot grease and debris could leak downward and produce a fire hazard.

13. The pressure regulator and hose assembly supplied with this appliance must be used. Replacement

pressure regulators and hose assemblies must be those specified by Twin Eagles, Inc.

CALIFORNIA PROPOSITION 65-WARNING: The burning of gas cooking fuel generates

14.

some by-products which are on the list of substances known by the State of California to cause cancer or

reproductive harm. California law requires businesses to warn customers of potential exposure to such

substances. To minimize exposure to these substances always operate this unit according to the use and

care manual, ensuring you provide good ventilation when cooking with gas.

3

GAS REQUIREMENTS – EXTREME GAS GRILL

Each appliance is set and tested at the factory for the type of gas supply to be used. Identify the type of gas,

either natural gas or L.P. gas and make sure that the marking on the data plate (rating plate) matches the gas

supply. The data plate is located on the panel behind the control panel of the grill. Remove the drip tray to

visually access the nameplate label from the front of the grill.

L.P. Gas

If your grill is factory built for L.P., the regulator supplied is set for 11” water column and is for use with L.P.

gas only. The factory-supplied regulator and hose must be used with a 20 lb. L.P. cylinder. For plumb-in

installation (system L.P. installation), the regulator must be changed and a main gas shutoff valve must be

installed. Contact your Twin Eagles, Inc. dealer for a system L.P. regulator.

L.P. Gas Safety Requirement

NEVER USE A RUSTY OR DENTED L.P. CYLINDER.

NEVER USE A CYLINDER WITH A DAMAGED VALVE.

The LP-gas supply cylinder must be constructed and marked in accordance with the Specifications for LP-gas

Cylinders of the U.S. Department of Transportation (D.O.T.) or the National Standards of Canada CAN/CSAB339, Cylinders, Spheres and Tubes for the Transportation of Dangerous Goods, and Commission, as

applicable; and

1. Provided with a listed overfilling prevention device.

2. Provided with a cylinder connection device compatible with the connection for outdoor cooking

appliances.

It must be provided with a shut-off valve terminating in gas tank valve outlet. It must include a collar to

protect the cylinder valve. The cylinder supply system must be arranged for vapor withdrawal.

Do not operate the gas grill indoors or in any enclosed area. If the gas grill is not in use, the gas must be

turned off at the supply cylinder. If the grill is to be stored indoors, disconnect the gas supply cylinder and

leave the cylinder outdoors.

When checking for gas leaks, do not use open flame. Use a soapy water solution and apply to pipe joints and

fittings with a brush and check for bubbles. Check flexible hoses for cuts and wear that may affect the safety

before each use. Only the factory supplied hose and regulator must be used. Use only replacement regulator

and hose assemblies specified by Twin Eagles, Inc.

4

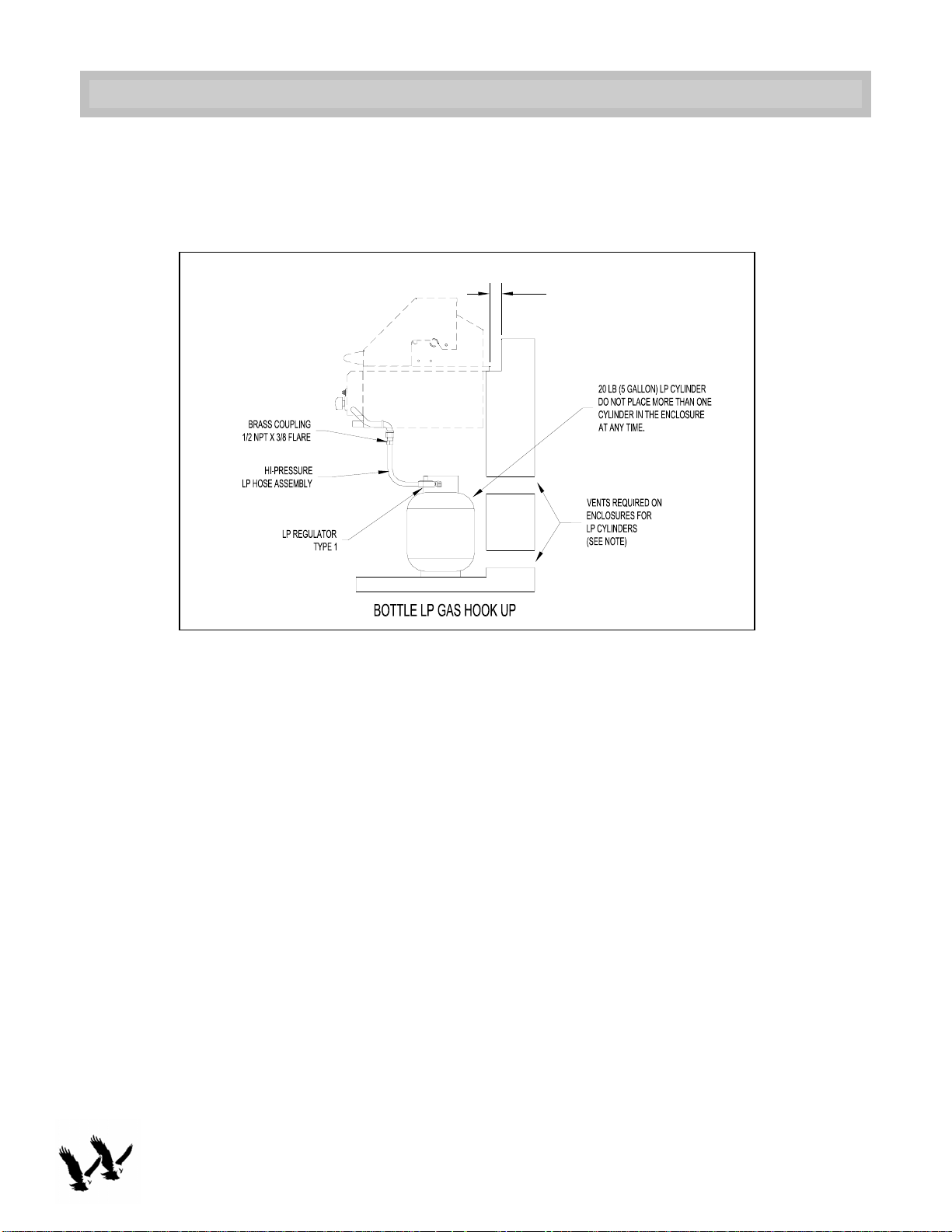

LP GAS HOOKUP – EXTREME GAS GRILL

Install the factory-supplied hose and regulator assembly as shown. Connect the 3/8”-flare end of the hose to

the grill coupling using a ¾” open wrench. Do not apply pipe sealant to the 3/8-flare connection. Connect

the regulator to the LP cylinder. Do not use a wrench but hand tighten the regulator. Check for leaks using

soapy water solution.

2 1/2" MINIMUM CLEARANCE

TO ALLOW LID TO

FULLY OPEN

Note: An enclosure for LP gas cylinder must be vented on the level of the cylinder valve and at floor level. The

effectiveness of the opening(s) for purposes of ventilation shall be determined with the LP gas supply cylinder in place.

This shall be accomplished by one of the following:

a. One side of the enclosure shall be fully open; or

b. For an enclosure having four sides, a top and a bottom:

1. At least two ventilation openings at cylinder valve level shall be provided in the sidewall, equally

sized, spaced at 180 degrees (3.14 rad), and unobstructed. Each opening shall have a total free

area of not less than 1/2 square inch per pound (7.1 cm

than a total free area of 10 square inches (64.5 cm

Ventilation opening(s) shall be provided at floor level and shall have a total free area of not less than 1/2

2

2

/kg) of stored fuel capacity and not less

).

square inch per pound (7.1 cm2/kg) of stored fuel capacity and not less than a total free area of 10 square

inches (64.5 cm2). If ventilation openings at floor level are in a sidewall, there shall be at least two openings.

The bottom of the openings shall be at floor level and the upper edge no more than 5 inches (127 mm) above

the floor. The openings shall be equally sized, spaced at 180 degrees (3.14 rad) and unobstructed.

5

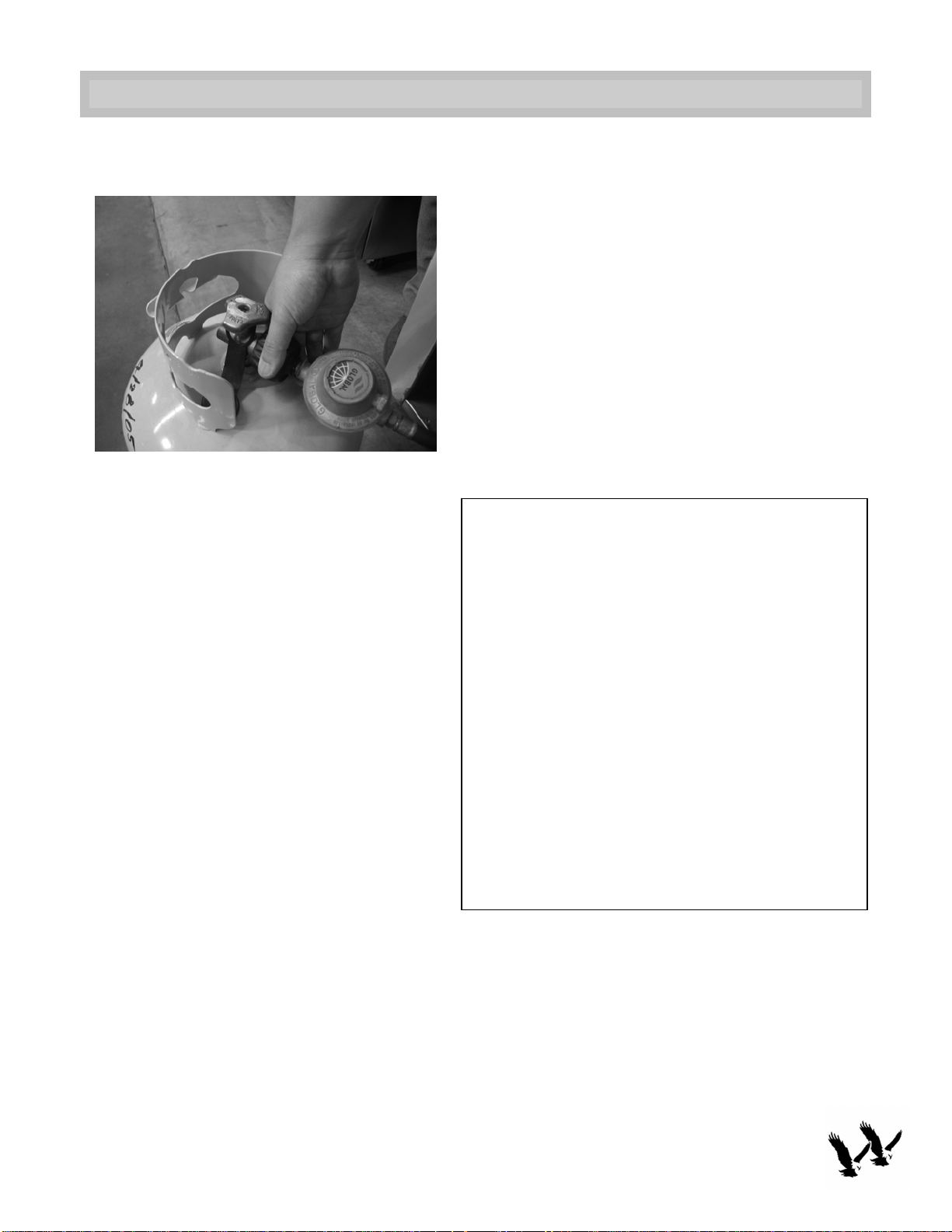

FOR PORTABLE LP CONNECTION – EXTREME GAS GRILL

The cylinder used must include a collar to protect the

cylinder valve.

The cylinder supply system must be arranged for vapor

withdrawal.

Make sure the gas valve, on top of the cylinder, is

closed. Connect the Type 1 cylinder connection

device, installed in the regulator, to the cylinder and

hand-tighten only. Open the tank valve and make sure

all connections are leak tight using a soapy water

solution and a brush.

TO CONNECT LP CYLINDER

6

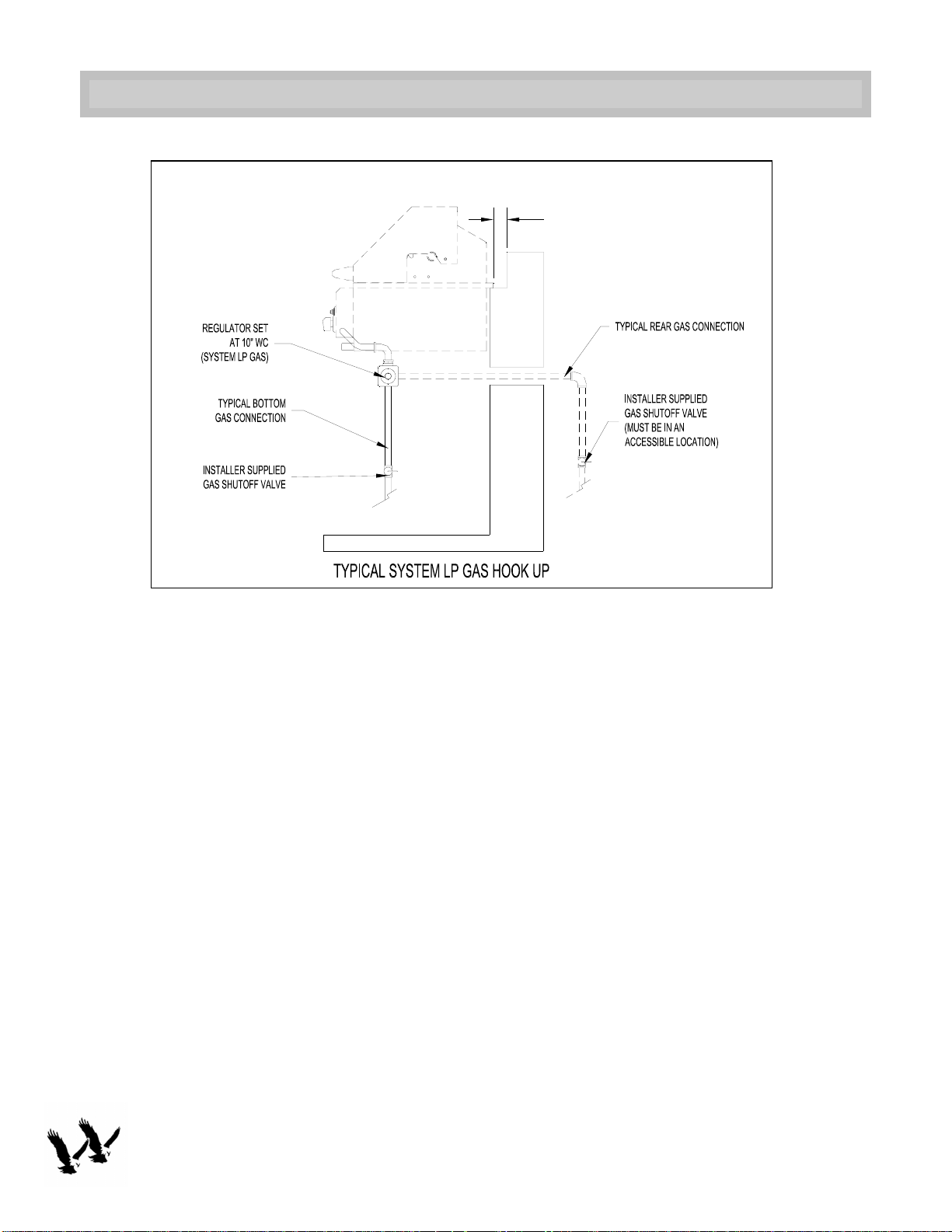

PLUMB-IN LP GAS INSTALLATION (LP-SYSTEM) – EXTREME GAS GRILL

The installation must conform with local codes or, in the absence of local codes, with either the national Fuel

2 1/2" MINIMUM CLEARANCE

TO ALLOW LID TO

FULLY OPEN

Gas Code, ANSI Z223.1/NFPA 54, or CAN/CGA-B149.1, Natural Gas Installation Code or CAN/CGAB149.2, Propane Installation Code.

1. This gas appliance and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at the test pressures in excess of 1/2 psi

(3.5 kPa).

2. This appliance must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psi (3.5 kPa). Use 1/2” diameter pipe (minimum) for up to 25’ of piping.

Use 3/4” diameter for longer runs.

IMPORTANT: When connecting or replacing any gas pipe or fittings, all joints must be sealed with

leak-proof sealing compound approved for use with natural and propane gases. After making

connections, check all joints for leaks using a soapy water solution and brush.

WARNING: Never use an open flame when testing for gas leaks. Use of an open flame could result in

a fire, explosion and bodily harm.

7

Loading...

Loading...