Page 1

BACKWARD INCLINED HINGED

RESTAURANT EXHAUST FAN

INSTALLATION, OPERATION & MAINTENANCE MANUAL

IM-610

August 2014

Twin City Fan & Blower Catalog 610 provides additional information on this equipment, fan performance,

optional accessories and construction features. This

catalog can be found at www.tcf.com or by contacting

your local Twin City Fan & Blower sales representative.

HEAVY DUTY RESTAURANT EXHAUST

Belt Drive Model: BHRE

Type: Centrifugal Roof Exhaust

CFM to 9,043 (15,365 m³/hr)

Static Pressure to 5.00 in. w.g. (1,245 Pa)

Maximum Continuous Operating Temperature:

400°F (204.4°C)

Available in nine sizes: 105 - 245, nominal wheel

diameter 10.5 to 24.5 inches (267-622 mm)

General Installation

CAUTION: Sheet metal parts, screws, clips and similar

items inherently have sharp edges, and it is necessary

that the installer and service personnel exercise caution.

The installation of this equipment shall be in accordance

with the regulations of authorities having jurisdiction and

all applicable codes.

This equipment is to be installed by an experienced

installation company and fully trained personnel. The

mechanical installation of the exhaust ventilator consists

of making final connections between the unit and building services.

CAUTION: Disconnect power and lock out power source

before installing or servicing. Failure to disconnect power

can result in electric shock, fire or serious injury.

1. Do not operate the fan beyond the maximum cataloged RPM. The current should be verified any time

the RPM is adjusted to ensure it is below the

nameplate amperage value.

2. Verify the equipment is compatible with the power source.

3. Allow motor to cool down before servicing to avoid

injury.

Receiving

When the equipment is received, all items should be

carefully checked against the bill of lading to ensure all

items have been received. Inspect each package for

shipping damage before accepting delivery.

If any damage occurred, notify the carrier, who will make

proper notation on the delivery receipt acknowledging

the damage. Damages should be noted on all copies of

the bill of lading and have all copies countersigned by

the delivering carrier. A Carrier Inspection Report should

be filled out and forwarded to the Traffic Department.

If units are damaged in transit, it is the responsibility of

the receiver to make all claims against the carrier. Twin

City Fan is not responsible for damages incurred during

shipment or after acceptance.

Short Term Storage

If fan installation is to be delayed, store the unit in a

protected area, preferably indoors. Protect fan bearings

and motor from moisture and vibration.

Long Term Storage

Prior to storage, grease fan bearings and motor bearings

per manufacturer's specifications. Note, motors which

contain ball bearings are permanently lubricated as built.

No additional lubrication is required. On belt drive units,

belts should be removed or at least the belt tension

reduced to prevent a sag/set from forming in the fan

shaft and belts. Rotate wheel and shaft monthly and

leave in a different position. When unit is to be removed

from storage and activated, check for corrosion and

damage. All bearing grease should be purged and

replaced with fresh grease.

Unpacking

Verify that all required parts and proper quantities have

been received for each item. Report shortages or missing items to your local representative to arrange for

replacement parts.

Sometimes it is not possible for all items to ship together due to availability of carriers and truck space.

Verification of shipments must be limited to only items

on the bill of lading.

©2012 Twin City Fan Companies, Ltd.

Page 2

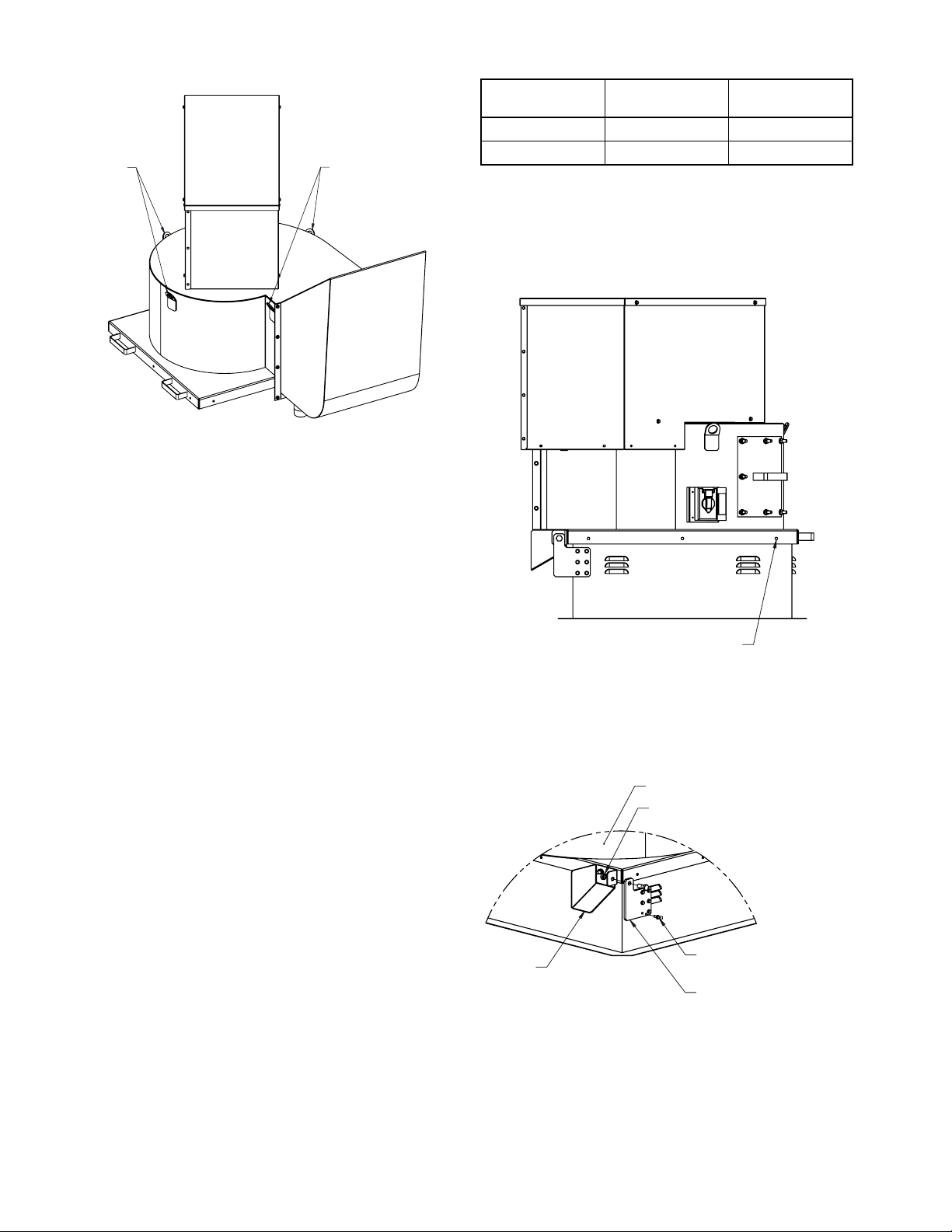

Fan

Lifting Lug

Figure 1.

Table 1. Fan Mounting to Roof Curb

Lifting Lug

Handling

Lift fan using all lift points. Use spreader bars to ensure

straps do not come in contact with unit. See Figure 1.

BHRE Size

Fasteners per

Side

105 2 8

122 - 245 3 12

Figure 2.

Total

Fasteners

Installation

Refer to Table 2 for appropriate size roof opening.

Follow curb manufacturer's recommended installation.

1. For lifting locations, see Fig. 1.

2. Position the fan with its wiring conduit in line with

the wiring or external disconnect, towards the power

supply. The location and placement of any supply

fans should be considered.

3. Center fan on roof curb, allow 3/4" (19 mm) space

all around.

4. Attach hinge bracket to fan with 1/2" cap screw and

nut. Adjust curb stop (bolted to fan) so hinge is

flush with roof curb.

5. Rotate hinge bracket such that mounting holes are

vertical and fasten curb hinge with hardware pack

(p/n HWPACK-1) according to Fig. 3.

6. Screw fan to the roof curb using #12-14 dril-flex or

equal 3" (76 mm) from each corner and one fastener centered. Add additional fasteners equally

spaced to satisfy. See Figure 2 and Table 1.

7. Verify the power is de-energized. Run wires to the

disconnect switch. Leave some slack in the wire in

the motor compartment so the motor and wheel

assembly can be lifted for inspection and cleaning.

8. Verify power source is compatible with the fan.

Make connection to the disconnect switch.

9. Check tightness of all fasteners.

10. Verify wheel is centered and spins freely.

11. Restaurant fan installation must be in compliance

with local codes and National Fire Protection

Association's standard NFPA 96.

#12-14 Dril-Flex self drilling

Figure 3.

Nut, 1/2-13

Curb Stop

All hardware found in package HWPACK-1

screw or equal

1/4-11 x .75 Dril-ex screw or equal

6 Locations

Hinge Bracket

(Both Sides)

2

Twin City IM-610

Page 3

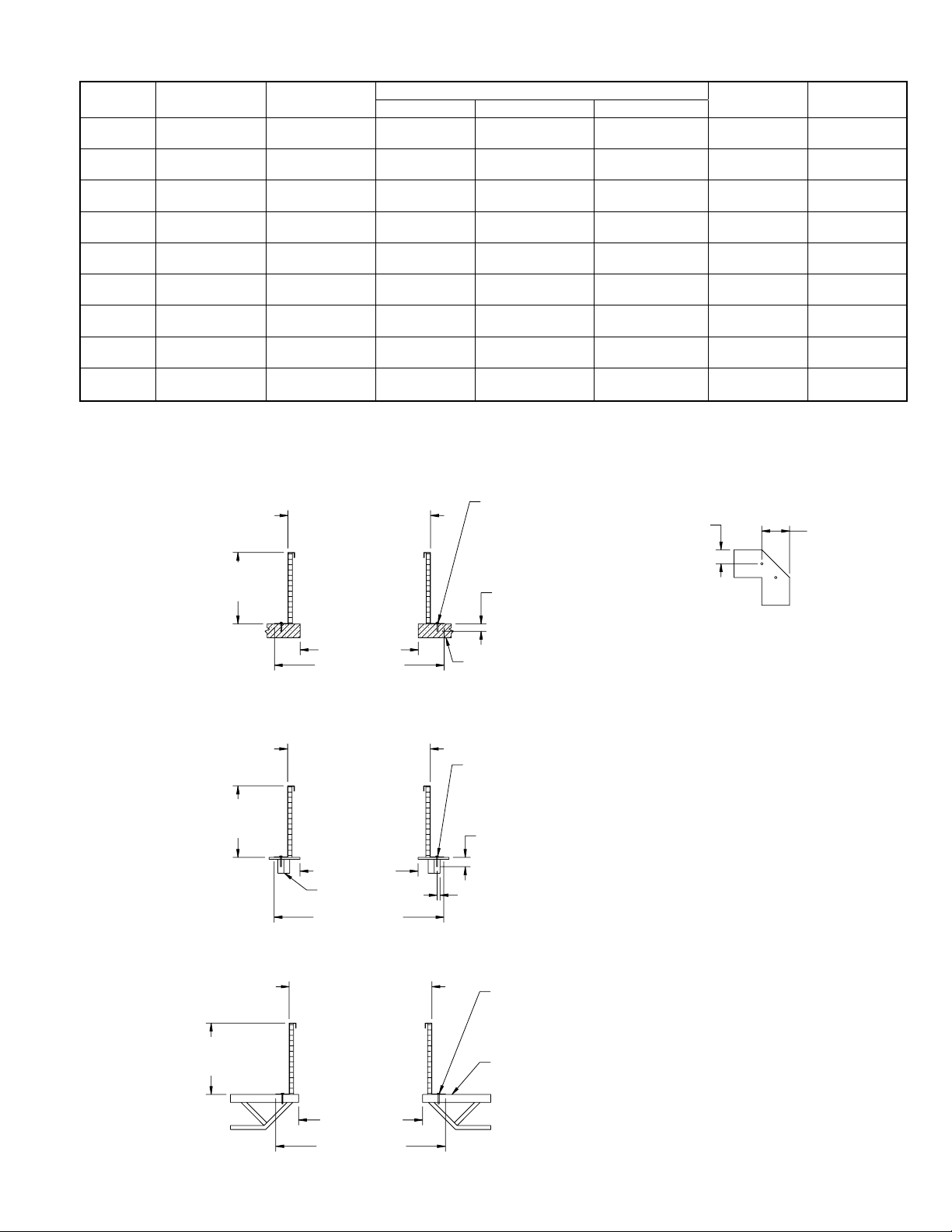

Table 2. Roof Curb Mounting to Building Structure

Concrete Anchoring Instructions for Roof Curbs

BHRE Size Curb Cab Roof Curb

105

122

135

150

165

182

200

222

245

20 x 20

(508 x 508)

23 x 23

(584 x 584)

25 x 25

(635 x 635)

27 1/2 x 27 1/2

(698 x 698)

29 x 29

(737 x 737)

31 1/2 x 31 1/2

(800 x 800)

34 x 34

(864 x 864)

38 x 38

(965 x 965)

41 1/2 x 41 1/2

(1054 x 1054)

18 1/2 x 18 1/2

(470 x 470)

21 1/2 x 21 1/2

(546 x 546)

23 1/2 x 23 1/2

(597 x 597)

26 x 26

(660 x 660)

27 1/2 x 27 1/2

(698 x 698)

30 x 30

(762 x 762)

32 1/2 x 32 1/2

(825 x 825)

36 1/2 x 36 1/2

(927 x 927)

40 x 40

(1016 x 1016)

Figure 4.

Outside of Roof Curb

Curb Height

8" - 18"

(203 - 457 mm)

1 1/2" (38 mm)

less than Fan Curb

[3/4" (19 mm) per side]

Minimum Fasteners

Steel Anchoring Concrete Anchoring Timber Anchoring

3 3 3

3 3 3

3 3 3

3 3 3

3 3 3

3 3 4

3 3 4

3 4 5

4 4 5

1/4" Dia. S.S. Hilti Kwik bolt expansion

anchors or equal.

4-1/2" (114 mm) min. spacing.

Located at each corner as shown.

Each side at center of unit.

Add additional fasteners to satisfy.

1.00

2" (51 mm) Min. Embedment

Outside

Flange

22 1/2 x 22 1/2

(571 x 571)

25 1/2 x 25 1/2

(648 x 648)

27 1/2 x 27 1/2

(698 x 698)

30 x 30 (762 x

762)

31 1/2 x 31 1/2

(800 x 800)

34 x 34 (864 x

864)

36 1/2 x 36 1/2

(927 x 927)

40 1/2 x 40 1/2

(1029 x 1029)

44 x 44 (1118 x

1118)

Corner Detail Of

All Structures - Typ

Roof

Opening

13 1/2 x 13 1/2

(343 x 343)

16 1/2 x 16 1/2

(419 x 419)

18 1/2 x 18 1/2

(470 x 470)

21 x 21

(533 x 533)

22 1/2 x 22 1/2

(571 x 571)

25 x 25

(635 x 635)

27 1/2 x 27 1/2

(698 x 698)

31 1/2 x 31 1/2

(800 x 800)

35 x 35

(889 x 889)

2.00

Curb Height

8" - 18"

(203 - 457 mm)

Curb Height

8" - 18"

(203 - 457 mm)

Roof Opening

Outside Flange

2000 PSI Min. Concrete Strength

Wood Anchoring Instructions for Roof Curbs

Outside of Roof Curb

1 1/2" (38 mm)

less than Fan Curb

[3/4" (19 mm) per side]

#10 Zinc plated wood screw or equal.

Located at each corner as shown.

Each side at center of unit.

3/4" (19 mm) min. spacing, 14-1/2" (368 mm) max. spacing.

Add additional fasteners to satisfy.

1-1/2" (38 mm) Min. Embedment

Roof Opening

Wood Buck

Min. S.G. = .55

Center fasteners

Outside Flange

Steel Anchoring Instructions for Roof Curbs

Outside of Roof Curb

1 1/2" (38 mm)

less than Fan Curb

[3/4" (19 mm) per side]

#12-14 Dril-ex self drilling screw or equal.

Located at each corner as shown.

Each side at center of unit.

3/4" (19 mm) min. spacing, 14-1/2" (368 mm) max. spacing.

Add additional fasteners to satisfy.

Min. 12 ga. or 1/8" (3 mm) thick steel member

Twin City IM-610

Roof Opening

Outside Flange

Fig. 3

3

Page 4

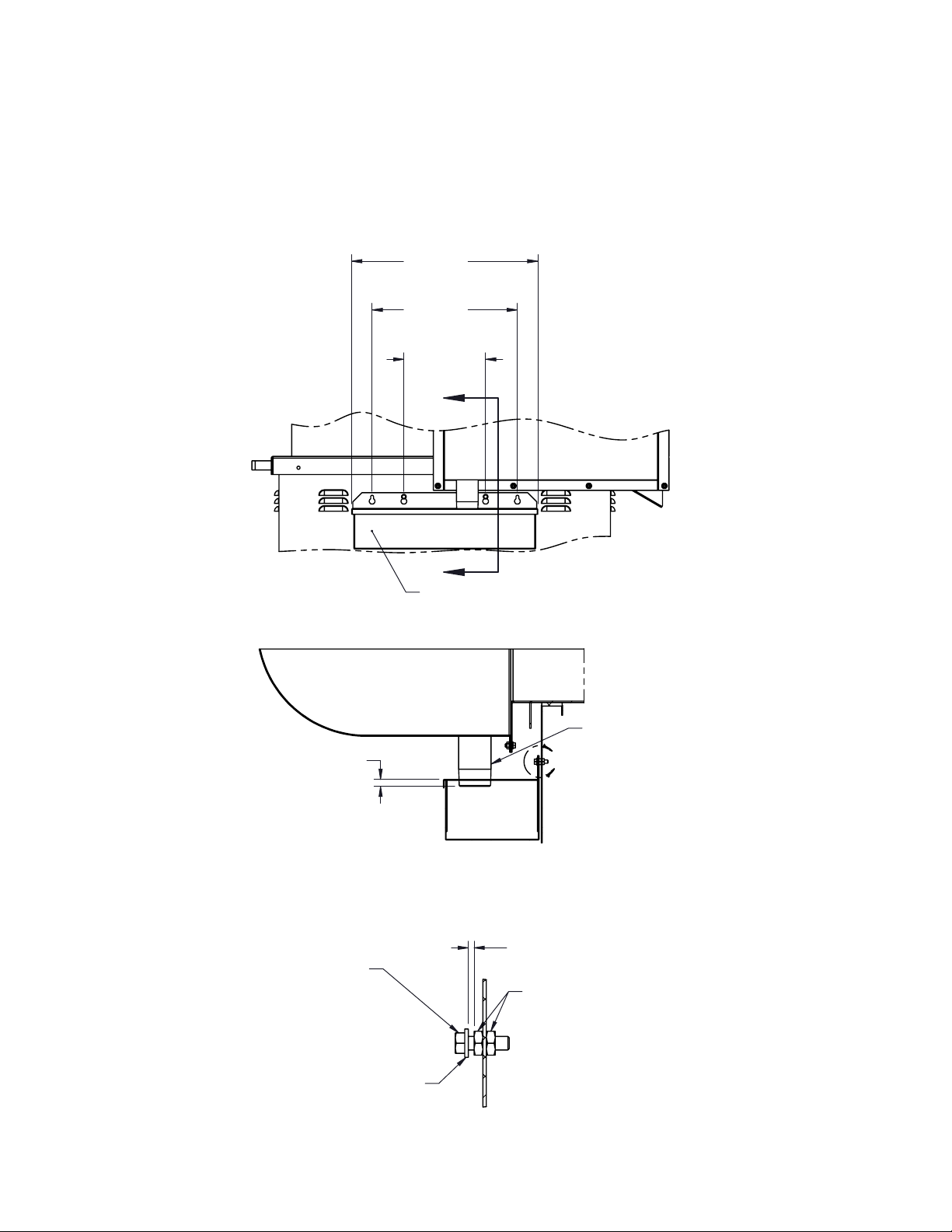

Grease Box Installation

1. Position Grease Box under the 2" NPT pipe with

approximately 1/2 - 3/4 in. (13-19 mm) overlap using

the inside or outside hole patterns.

2. Mark mounting hole locations on curb cap.

3. Drill two 5/16 in. (8 mm) diameter holes in marked

location.

4. Install 1/4 in. (6 mm) hardware to detail shown.

Figure 5.

20.48

(520 mm)

16.00

(406 mm)

9.00

(229 mm)

A

A

Grease Pad

(Inside box)

.50 - .75

(13 - 19 mm)

Cap Screw

1/4-20 x 3/4

Flat Washer, 1/4

Drain Pipe

B

SECTION A-A

.13

(3 mm)

Hex Nut, 1/4-20

DETAIL B

4

Twin City IM-610

Page 5

Table 3.

BHRE

Size

105 25.74 11.57 21.14 11.21 20.00 17.69 12.05 26.90 1.00 2 173

122 26.87 13.24 24.44 13.02 23.00 20.13 12.12 29.29 1.00 2 193

135 28.93 14.43 26.76 14.34 25.00 22.11 14.10 32.61 1.00 3 251

150 30.05 15.86 29.58 15.90 27.50 24.36 14.35 34.72 1.00 3 267

165 31.30 17.28 31.85 17.43 29.00 26.67 14.74 36.17 1.00 5 294

182 32.68 18.94 35.08 19.40 31.50 29.38 14.75 38.11 1.19 5 348

200 34.08 20.62 38.14 21.21 34.00 32.09 15.28 40.38 1.19 5 380

222 35.77 22.76 42.52 23.59 38.00 35.45 16.04 43.98 1.44 5 446

245 38.64 24.90 46.64 25.96 41.50 38.87 17.84 50.09 1.44 7.5 573

A B C D E F G H

Dimensions

Bearing

Size

Max

HP

Figure 6.

D

H

Approx.

Weight

(lbs)

A

MAX

2.00

G

E SQ.

INSIDE

C

B

F

2" NPT DRAIN

Twin City IM-610

5

Page 6

Electrical Connection

Standard Fan

1. Connect supply wiring to the disconnect switch (nonfused standard).

2. The motor is factory set at the voltage marked on the

fan nameplate. Check the line voltage with the nameplate voltage.

3. The main power wiring should be sized for the ampacity shown on the dataplate. Size wires in accordance

with the ampacity tables in Article 310 of the National

Electrical Code. If long wires are required, it may be

necessary to increase wire size to prevent excessive

voltage drop. Wires should be sized for a maximum

of 3% voltage drop.

CAUTION: Use copper conductors only.

any two of the three line leads. If the unit is checked with

temporary wiring, it should be rechecked when permanently installed. Motor burn out or tripped overload protection devices are usually the result of wrong rotation.

6. Electrical Input Check: Perform check of fan ampere

draw and verify that motor nameplate amps are not

exceeded. Take into account the service factor of the

motor if it is above 1.0 S.F.

7. Fan RPM should be checked and verified with a

tachometer.

CAUTION: Protect wiring from sharp edges. Leave some

slack in the line to prevent damage.

4. Disconnect switches are not fused. The power leads

must be protected at the point of distribution in accordance with the fan dataplate.

5. All units must be electrically grounded in accordance

with local codes or, in the absence of local codes,

with the latest edition of the National Electrical Code

(ANSI/NFPA 70). A ground lug is provided as standard

in the unit terminal box. Size grounding conductor in

accordance with Table 250-95 of the National Electrical

Code. DO NOT use the ground lug for connecting a

neutral conductor.

6. Supply voltage to the power ventilator should not vary

by more than 10% of the value indicated on the unit

dataplate. Phase unbalance must not exceed 2%.

Check, Test & Start Procedures

Warning: Electric shock hazard. Could cause severe

injury or death. Failure to bond the frame of this equipment to the building electrical ground by use of the

grounding terminal provided or other acceptable means

may result in electrical shock. Disconnect electric power

before servicing equipment. Service to be performed only

by qualified personnel.

Before Start-up: Disconnect power before servicing unit

Figure 7.

.44 Overlap,

Figure 8.

.13

Gap, Swingout Fan

.00

6

1. Check all fasteners and setscrews for tightness.

Note: The wheel position is set at the factory and the fan

was balanced and vibration tested prior to shipment.

Movement may have occurred during transport and realignment may be necessary.

2. Check that the wheel is centered and free to rotate.

Centering can be changed by loosening isolator

mounts and repositioning the drive frame.

3. For optimum fan performance make sure that the

wheel to inlet venturi gap or overlap is maintained per

Figure 7. Height can be adjusted by loosening set

screws on the wheel and reposition on the fan shaft,

per the table.

4. Verify that the power supply matches the voltage on

the fan data plate and is within the 10% utilization

rate.

5. Apply power to unit and check rotation of wheel with

the directional arrow on the unit. All fans are clockwise, as viewed from drive side, per Figure 8.

Warning: Rotation is critical. If allowed to operate in the

wrong direction, the motor will overload and burn out. For

three-phase units, rotation can be changed by switching

View from drive side

Twin City IM-610

Page 7

Inspection

Inspection of the fan should be completed at the first

30 minutes, 8 hour and 24 hour intervals of satisfactory operation.

30 Minute Interval

Inspect tightness of all hardware, setscrews and motor

mounting bolts. Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. See Belt Adjustment

and tension as necessary

24 Hour Interval

Inspect belt tension, adjust as necessary.

Maintenance

A maintenance program should be established to maintain the reliability and performance of the fan. The

frequency of inspection depends on the location and

operating conditions of the fan.

Maintenance is to be performed only by qualified personnel who are familiar with local codes and regulations and experienced with this type of equipment.

Routine maintenance should cover the following:

a. Tighten all setscrews and hardware.

b. Check belt tension and sheaves for wear.

c. Lubricate fan bearings (see Table 4 for recom-

mended interval and Table 5 for grease types.

d. Cleaning of unit, wheel and grease box.

1. Before performing any maintenance on the fan, be

sure power is turned off and locked in the off

position at the service entrance.

2. Ventilators should be carefully checked at least

once a year. For critical or rugged applications, a

routine check every two or three months is suggested.

3. Always follow the bearing manufacturer's recom-

mended lubrication schedule. If not available, below

is a general guideline:

Table 4.

Bearing Greasing Intervals

Fan RPM Interval (months)

Up to 500 6

500 - 1,000 6

1,000 - 1,500 5

1,500 - 2,000 3

2,000 - 2,500 3

2,500 - 3,000 2

Divide the listed interval by 2 for vertical shaft applications or for 24 hour operation.

Relubricate while running, if safety permits, until some

purging occurs at seals. Adjust lubrication frequency

depending on condition of purged grease. Hours of

operation, temperature and surrounding conditions will

affect the relubrication frequency required.

4. All motors supplied with Twin City Fan & Blower

ventilators carry a one year limited warranty from

date of shipment. For repairs within the warranty

period, the motor must be taken to the motor man-

ufacturer's authorized service dealer. Contact your

TCF representative for additional warranty details.

5. A periodic motor check should consist of removing

the belt, then spinning the motor shaft with the

power off to be sure the motor turns freely and

the bearings run smoothly.

6. When removing or installing a belt, do not force

the belt over the sheave. Loosen the motor mount

so that the belt can be easily slipped over the

sheave. See Belt Adjustment, on page 8.

7. The belt should be removed and carefully checked

for glazing, cracks, ply separation or irregular wear.

A small irregularity in the contact surface of the

belt will result in noisy operation. If any defects are

apparent, the belt should be replaced.

8. Check sheaves for chipping, dents or rough surfaces which could damage the belt. Always replace

sheaves with identical size and type.

9. If the unit is left idle for an extended period, the

belts should be removed and stored in a cool, dry

place to avoid premature belt failure.

10. Check sheave setscrews to ensure tightness.

Proper keys must be in keyways.

11. Check for proper belt alignment. See Figure 10.

Improper alignment leads to excessive belt wear,

vibration, noise and power loss.

12. For two-groove drives, matched belts must be

used.

13. When replacing belts, use the same type & size as

supplied on the unit.

14. The standard pillow block bearings on belt driven

ventilators are factory lubricated and are provided

with external grease fittings. Lubrication bi-annually

is recommended, or more frequently if needed. (see

Table 5). It is recommended to add fresh grease

at start-up, but do not over-grease. Use only 1 or

2 shots of a recommended lubricant with a hand

gun in most cases (see Table 5). Maximum hand

gun rating of 40 psi. Rotate bearings during lubrication where good safety practice permits.

Caution: Greases of different soap bases (lithium,

sodium, etc.) may not be compatible when

mixed. Prevent such intermixing by completely purging the bearing of old greases.

Table 5.

Grease Manufacturers

Manufacturer Grease (NLGI #2)

Shell Gadus S2 V100 2

Exxon/Mobil Ronex MP

15. The most frequent causes of bearing failure are not

greasing often enough, using an excessive quantity

of grease or using incompatible greases. Excessive

vibration, especially if the bearing isn't rotating, will

also cause bearings to fail. Bearings must also be

protected from water and moisture to avoid internal

corrosion.

16. During the first few months of operation, it is recommended to periodically check the bearing setscrews to ensure tightness.

17. Wheels require attention when moving dirty or

grease laden air. Regular cleaning is required to

avoid imbalance caused by accumulation of grease

or dust.

18. All fasteners should be checked for tightness during each maintenance.

Twin City IM-610

7

Page 8

Motor Lubrication:

Fasteners

(Both Sides)

C

Lid

Standard Fan

(Both Sides)

Motor Cover

Motors which contain ball bearings are permanently lubricated from the factory. No additional maintenance is

required. Motors supplied with grease fittings should be

lubricated according to the manufacturer's recommendation.

Figure 9.

Access for Drive Inspectionk, Fig 9:

1. For inspection and belt tightening, remove motor

cover lid.

2. For unrestricted access to motor and drives, remove

motor cover.

Belt Adjustment, Detail C

1. Loosen screws (A) on motor plate; do not remove.

2. Turn jacking bolts (B) equally to proper belt tension.

(Ref Fig. 11).

3. Tighten screws (A).

Motor

Cover

Fasteners

(Both Sides)

Lid

V-Belts

V-belts are oil, heat and static resistant type and oversized for continuous duty.

The condition and the amount of belt deflection should

be checked prior to start-up. Do not over-tension as

bearing damage may occur. Recommended belt tension

C

is 1/64" multiplied by the center distance of sheaves (in

inches). (See Figure 11.)

Extreme care must be exercised when adjusting V-belts

as not to mis-align sheaves. Any misalignment will cause

a reduction in belt life and will increase the likelihood of

noise & vibration.

Figure 10.

Standard Fan

Fasteners

Figure 11.

Deection = 1/64 x Distance

Swingout Fan

A

B

Distance

(inches)

DETAIL C

8

Twin City IM-610

Page 9

Access for Cleaning:

Curb Stops

Remove Wingnuts

(Qty 1) Sizes 105-150

(Qty 2) Sizes 165-245

All models - Hinge fan open or remove outlet scoop held

on by screw/nut. See Fig. 12. It is recommended to use

two people to open the fan.

Swingout - Remove wingnut(s). Lift handle and rotate prop

rod onto stud. Secure with wingnut. See Fig. 13.

Figure 12. Hinged Fan

Handle

Screw

Hex Nut

Figure 13. Swingout Fan

Handle

Prop Rod

Stud/Wingnut

Twin City IM-610

9

Page 10

Lid

Curb Hinge

Motor

Cover

Gasket

Prop Rod

Gasket

(All models)

Swingout Fan

Roof Curb

Outlet

Scoop

Fan

Sheave

Bearing

Plate

Disconnect

Switch

Inlet Funnel

Wheel

Grease

Box

Motor

Cover

Prop

Rod

Retaining

Cable

Gasket

(All Models)

Parts List

Gasket

Motor

Cover

Prop

Rod

Retaining

Cable

Gasket

(All Models)

Gasket

Motor

Cover

Parts List

Fan Sheave

Bearing Plate

Motor

Sheave

Motor

Mounting Rail

Disconnect

Switch

Standard Fan

Wheel

Inlet Funnel

Roof Curb

(Optional)

Outlet

Scoop

Grease Box

(Optional)

Swingout Fan

Motor

Cover

Gasket

Prop Rod

Gasket

(All models)

10

Parts List

Refer to the TCF nameplate for model number and serial number to assist in ordering the correct replacement parts.

Be sure the unit is locked out/tagged out before repairing.

Twin City IM-610

Page 11

Table 6.

Symptom Cause Corrective Action

Fan does not operate

Too little air

Too much air

Excessive Noise or

Vibration

Excessive Horsepower

Motor Overloads/

Overheats

Electrical Supply

Drive

Motor

Wheel rotating in wrong direction Check wheel rotation, see Fig. 8, P.6

System resistance too high

Fan speed lower than design Tighten belt; close variable speed sheave.

Dampers closed Inspect and repair.

Improper wheel alignment

Excessive dirt/grease on wheel Clean wheel.

Fan inlet/outlet is restricted

Filters (if applicable) are dirty or clogged Clean or replace filters.

System resistance lower than expected

Fan speed higher than design Adjust fan speed.

Wheel hitting inlet

Loose sheave or wheel Align and tighten.

Wheel out of balance Clean wheel; check wheel balance.

Bearings

V-belts

Fan not properly anchored Secure fan base, see Table 2, P. 3

Loose components Tighten loose hardware.

Fan Check wheel rotation; reduce fan speed.

System resistance too high

Motor improperly wired

Incorrect wheel rotation Change wiring leads to correct rotation.

Undersized motor

Fan rpm too high

Over/Under line voltage Contact power company.

Fan

Check disconnect switch, fuses/breakers.

Check for correct supply voltage.

Check for broken belts. Tighten loose belts,

see Belt Adjustment

Check overload protection on motor. Verify

correct motor horsepower.

Check system backdraft dampers, ductwork

and filters.

Center wheel on inlet, check wheel gap/over

lap against Fig. 7, P.6

Remove obstruction, check for damage or

unbalance.

Reduce fan speed to reach required operat

ing point.

Center wheel on inlet, check wheel gap/over

lap against Fig. 7, P. 6

Lubricate bearings, replace defective bear

ings; tighten setscrew or bearing bolt, align

bearings.

Mismatched belts, replace with matched

belts; Adjust belt tension, replace worn belt.

Check dampers; re-size ductwork; check fan

inlet conditions; check filter.

Check motor wiring against wiring diagram

on motor nameplate.

Check motor ratings against cataloged performance.

Check fan rpm; open variable pitch sheave

on motor.

Check for bent shaft; check for proper belt

tension; check for damaged bearings.

-

-

-

-

It is recommended that the users and installers of this equipment familiarize themselves with AMCA Publication

#201, "Fans and Systems" and publication # 202 "Troubleshooting" which are published by the Air Movement

and Control Association (AMCA), 30 West University Drive, Arlington Heights, Illinois 60004. www.amca.org

Twin City IM-610

11

Page 12

LIMITATIONS OF WARRANTIES and CLAIMS

Seller warrants to the original purchaser that the goods

sold hereunder shall be free from defects in workmanship and material under normal use and service (except

in those cases where the materials are supplied by the

buyer) for a period of one year from the date of original

installation or eighteen (18) months from the date of

shipment, whichever occurs first. The liability of seller

under this warranty is limited to replacing, repairing, or

issuing credit (at cost, F.O.B. factory and at seller’s

discretion) for any parts which are returned by buyer

during such period provided that:

a. Seller is notified in writing within ten (10) days

following discovery of such defects by buyer, or

within ten (10) days after such defects should

be reasonably have been discovered, whichever

is less;

b. The defective unit is returned to seller, trans portation charges prepaid by buyer.

c. Payment in full has been received by seller or

said products; and

d. Seller’s examination of such unit shall disclose

to its satisfaction that such defects have not

been caused by misuse, neglect, improper installation,

repair, alteration, act of God, or accident.

e. Seller cannot guarantee sound pressure levels or

dBA.

No warranty made hereunder shall extend to any seller

product whose serial number is altered, effaced, or

removed. Seller makes no warranty, express or implied,

with respect to motors, switches, controls, or other

components of seller’s product, where such components

are warranted separately by their respective manufacturers. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, WHETHER

STATUTORY OR OTHERWISE, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. In no event shall seller be

liable to buyer for indirect, incidental collateral, or consequential damage of any kind. (BUYER’S FAILURE TO

PAY THE FULL AMOUNT DUE WITHIN SIXTY (60) DAYS

OF DATE OF INVOICE SHALL OPERATE TO RELEASE

SELLER FROM ANY AND ALL LIABILITY OR OBLIGATION

ARISING PURSUANT TO ANY WARRANTY, EXPRESS

OR IMPLIED, WHETHER STATUTORY OR OTHERWISE,

INCLUDING ANY IMPLIED WARRANTY OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, MADE IN CONNECTION WITH ANY

CONTRACT HEREUNDER. BUYER AGREES THAT SUCH

FAILURE TO PAY SHALL CONSTITUTE A VOLUNTARY

WAIVER OF ANY AND ALL SUCH WARRANTIES

ARISING PURSUANT TO SUCH CONTRACT.)

TWIN CITY FAN & BLOWER | WWW.TCF.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601

Loading...

Loading...