Page 1

DETAIL

SCALE 1 : 2

MPLFN, MPLFS, MPLQN, MPLQS

Modular Plenum Fans

INSTALLATION, OPERATION & MAINTENANCE MANUAL

IM-495

May 2014

Contents

Introduction .........................................................................1

Shipping and Receiving .....................................................1

Handling .............................................................................. 1

Short Term Storage ...........................................................1

Long Term Storage............................................................1

Foundations and Supporting Structures .......................... 2

Fan Installation ...................................................................3

Assembly of Fans ..............................................................3

Fan Operation – Safety .....................................................3

Operation Checklist ............................................................ 4

Maintenance of Fans ......................................................... 4

General Motor Maintenance ......................................... 4

Wheel and Shaft Maintenance ..................................... 5

Structural Maintenance ................................................. 5

Troubleshooting Guidelines................................................ 5

Troubleshooting Performance Problems

Air Capacity Problems ..................................................5

Noise Problems .............................................................5

Vibration Problems ........................................................ 5

Motor Problems ............................................................. 5

Limitation of Warranties and Claims ............................... 6

Introduction

The purpose of this manual is to provide instructions that

complement good general practices when installing or operating fans manufactured by Twin City Fan & Blower. It is the

responsibility of the purchaser to provide qualified personnel

experienced in the installation, operation, and maintenance

of air moving equipment.

Handling

Handling of all air moving equipment should be conducted by trained personnel and be consistent with safe

handling practices. Verify the lift capacity and operating condition of handling equipment. Maintain handling

equipment to avoid serious personal injury.

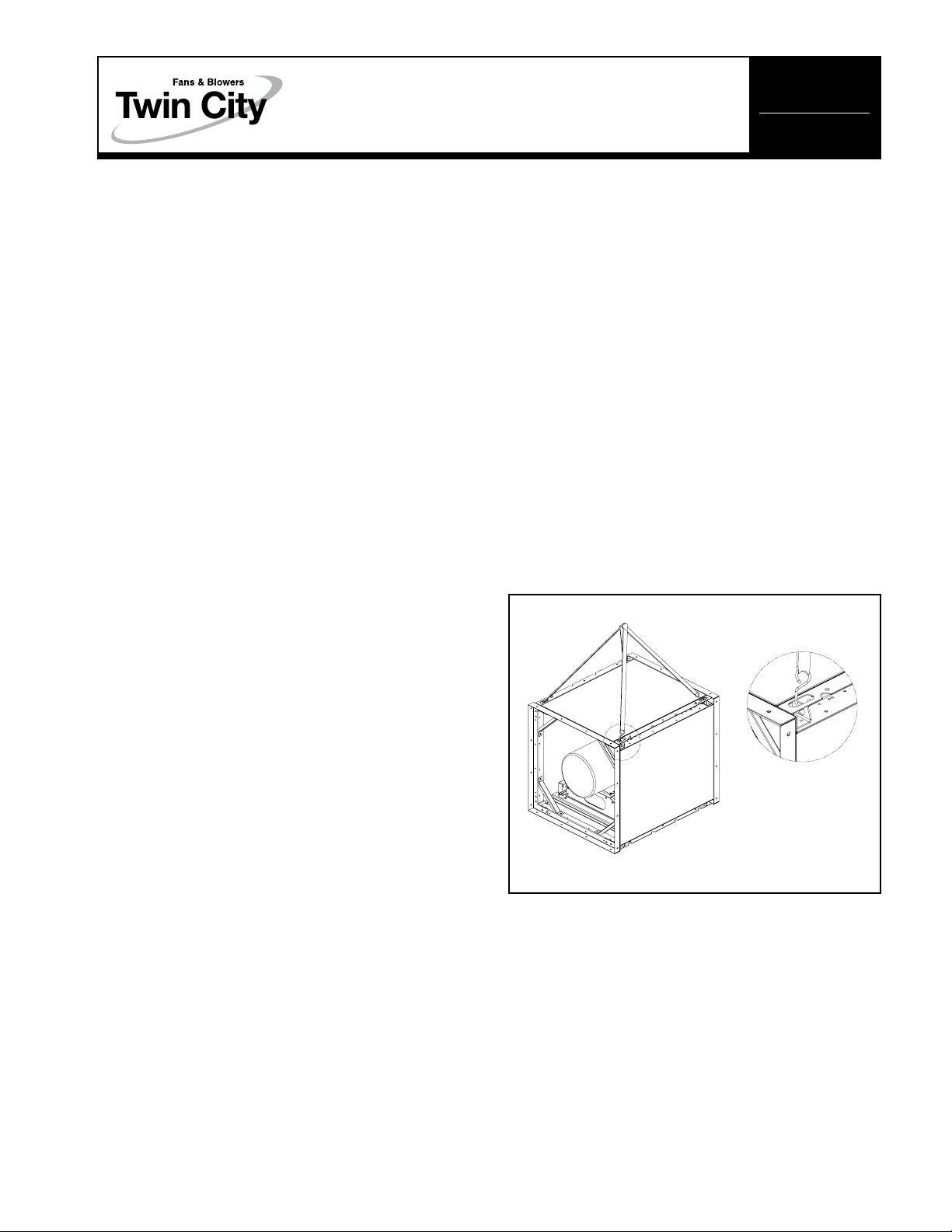

Units shipped completely assembled may be lifted with

slings and spreader bars. Use well-padded chains, cables

or nylon straps. On most units, lifting lugs are provided

for attaching chains (see Figure 1). Lift the fan in a fashion that protects the fan and fan coating from damage.

Never lift a fan by the inlet or discharge flange, shafting

or drives, wheel or impeller, motor or motor base, or in

any other manner that may bend or distort parts.

Partial or disassembled units require special handling. All

parts should be handled in a fashion which protects the

coatings and parts from damage. Components should

be handled such that forces are not concentrated and

bending or distortion cannot occur.

Figure 1. Lifting Lug Locations

Instructions given in the body of this manual are general in

nature and apply to a variety of models manufactured by

Twin City Fan & Blower. Most units can be installed and

maintained with the instructions given. Additional product

and engineering information is available at www.tcf.com.

Special applications may require additional information. These

instructions are supplied in the form of attached appendices.

Use the instructions in the appendix if the directions in this

manual differ from instructions in the appendix.

As always, follow good safety practices when installing,

maintaining and operating your air moving equipment. A

variety of safety devices are available. It is the user’s

responsibility to determine adequate safety measures and

to obtain the required safety equipment.

Shipping and Receiving

All Twin City Fan & Blower products are carefully constructed and inspected before shipment to insure the highest standards of quality and performance.

Compare all components with the bill of lading or packing

list to verify that the proper unit was received.

Check each unit for any damage that may have occurred in

transit. Any damage should be reported immediately to the

carrier and the necessary damage report filed.

NOTE: When lifting, the

straps/chains should be at a

minimum angle of 45°

Housing should be lifted using straps and spreaders. Do

not distort housing or side plates when lifting.

Short Term Storage

If fan installation is to be delayed, store the unit in a

protected area. Protect the fan and motor bearings from

moisture and vibration (or shock loading).

Long Term Storage

Prior to Storage – Motor bearings are to be greased at

the time of going into extended storage per the motor

manufacturer’s specifications.

©2014 Twin City Fan Companies, Ltd.

Page 2

Storage Procedure – Fans should be stored indoors

whenever possible where control over temperature,

shock and dust is reasonably maintained. If units are to

be stored outside in the elements, they should be covered with a water-resistant material. Stored equipment

should be stored on a clean, dry floor or blocked up

off the ground on blocks to prevent unit from setting in

any water or directly on the ground. If shock or vibration

will be present during storage, the unit may need to be

placed on some type of vibration dampening material

to aid in preventing brinelling of the bearing surfaces.

Periodic Check – On a monthly interval, the equipment

should be checked to ensure that it has remained in

an acceptable stored condition. After verifying the fan is

disconnected from the electrical supply, the fan wheel

should be rotated several times by hand while adding

enough grease to replenish the bearing surfaces with

fresh grease and to maintain a full bearing cavity. Grease

used must be compatible with that already supplied in

the motor and fan bearings. The fan impeller should

be left at approximately 180 degrees from that of the

previous month to prevent the shaft and impeller from

taking a set in one position. Storage records should

be maintained which indicate the above requirements

have been followed. Consult the motor manufacturer for

proper storage, space heater connection and lubrication

if the unit was supplied with one.

Start-Up – When the unit is removed from storage, all

bearing grease should be purged and replenished with

fresh grease as per the lubrication decal. The motor

resistance should be measured to verify it is still at a

satisfactory level compared to the value recorded prior

to storage.

Foundations and Supporting Structures

Floor mounted fans should be installed on a flat, level

surface with sufficient structure support. Support shall

be suitable for static and dynamic loads and foundation

frequencies be separated at least 20% from the rotational speed/speed ranges.

If the fans are mounted in a structure, the support

should be placed under the enclosure inlet and outlet

edges as a minimum. The fan mounting surfaces or

beams must be flat and level. Structural resonance

should be at least 20% from the fan operating speed,

when considering the weight of all fans and accessories.

Any ducting and/or dampers with sleeves should have

independent support; do not use the fan for support.

Isolating the fan from ductwork with flex connections

eliminates transmission of vibration.

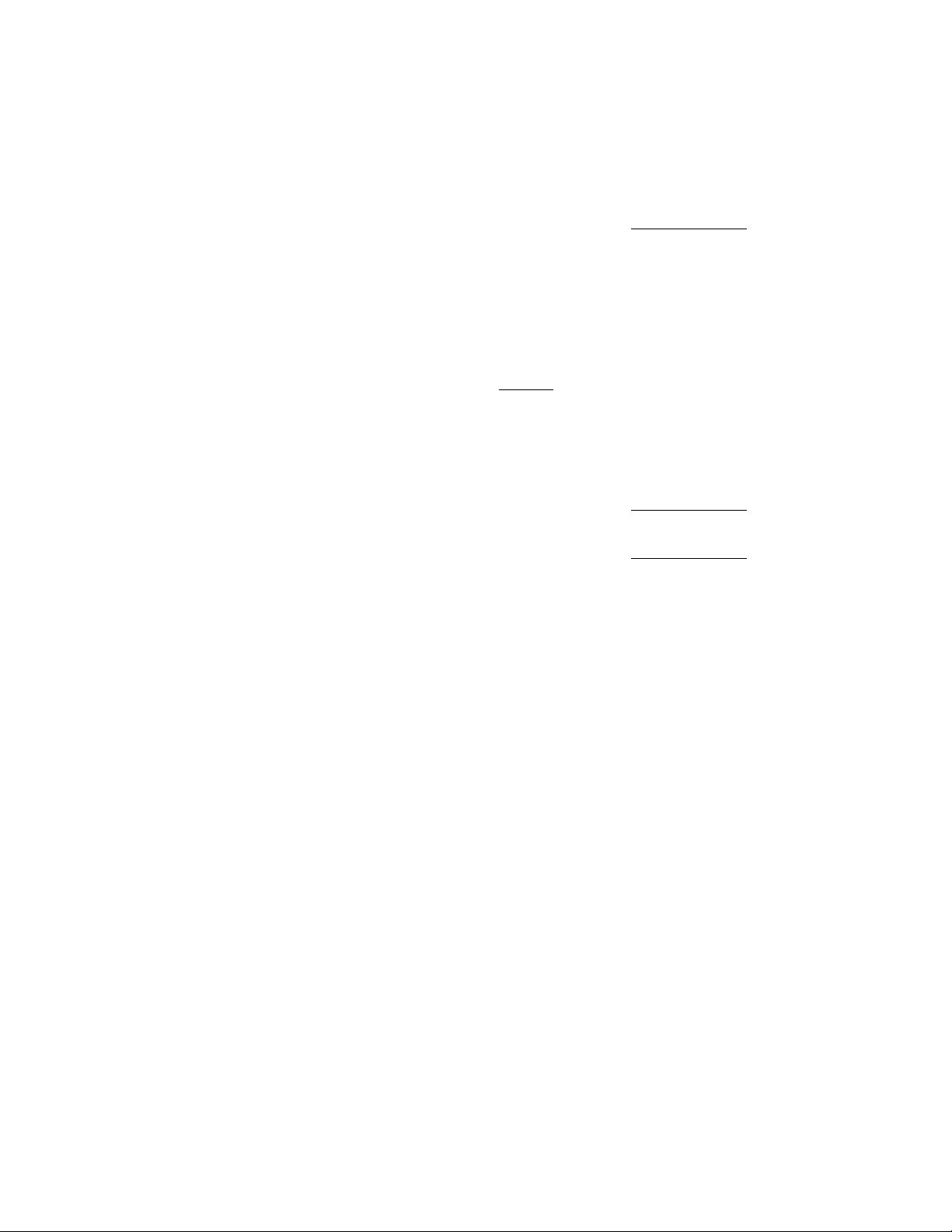

1. Sufficient structure must be provided to support

weight of fan assembly.

2. Sufficient restraint must be provided to resist the

pressure force against the fans. Typically fans are

assembled in an application in a modular fashion with

multiple fans working in parallel. The cumulative thrust

force must be restrained to prevent the fan assemblies

from leaning or tipping forward. The force acting on

the fan assemblies is calculated as shown below.

Thrust force (lb

27.68

H x W x N x P

f) =

s

Where

P

s = Maximum operating static pressure (in. w.g.)

W = Width of each individual fan (in.)

H = Height of each individual fan (in.)

N = Quantity of fans in system

27.68 = conversion factor for in. w.g. to PSI

Example

Parallel fan system employing nine (9) – Size 182 fans

in a 3 x 3 configuration. (3 fans high x 3 fans wide)

System pressure is 5 inches of water column.

Outside dimension of fan housing = approx. 38 in. by

38 in.

Thrust force (lb

27.68

Thrust force (lb

27.68

NOTE:

The thrust force is distributed evenly across

H x W x N x P

f) =

38 x 38 x 9 x 5

f) =

s

= 2348 (lbf)

the front surface of the parallel fan system.

3. Recommend attachments to the sides and top of the

parallel fan system incorporating some form of spring

support, i.e. rubber snubbers/isolators or springs. Such

devices should be attached to prevent significant point

loading on an individual fan. They should be located

on the side of the parallel fan system at the top corner and along the top every 2 fans or less.

a. When the fans are rigidly mounted to the base, an

assumption can be made that half of the thrust

load will be supported at the base, and the supports added at the top of the fan need to carry a

minimum of one half of the thrust load.

b. When the fans are supported on an isolation base

or isolators, it will be necessary to add thrust

restraints around the periphery of the fan assembly

to support the entire thrust load. Flex connections are required when using isolators or isolation

base.

c. Attachments to the fan can be made utilizing the

factory mounting holes. Recommend that the gage

of the materials be checked for tear out strength

in thrust applications. If necessary utilize multiple

mounting hole locations to distribute the load.

2

Twin City IM-495

Page 3

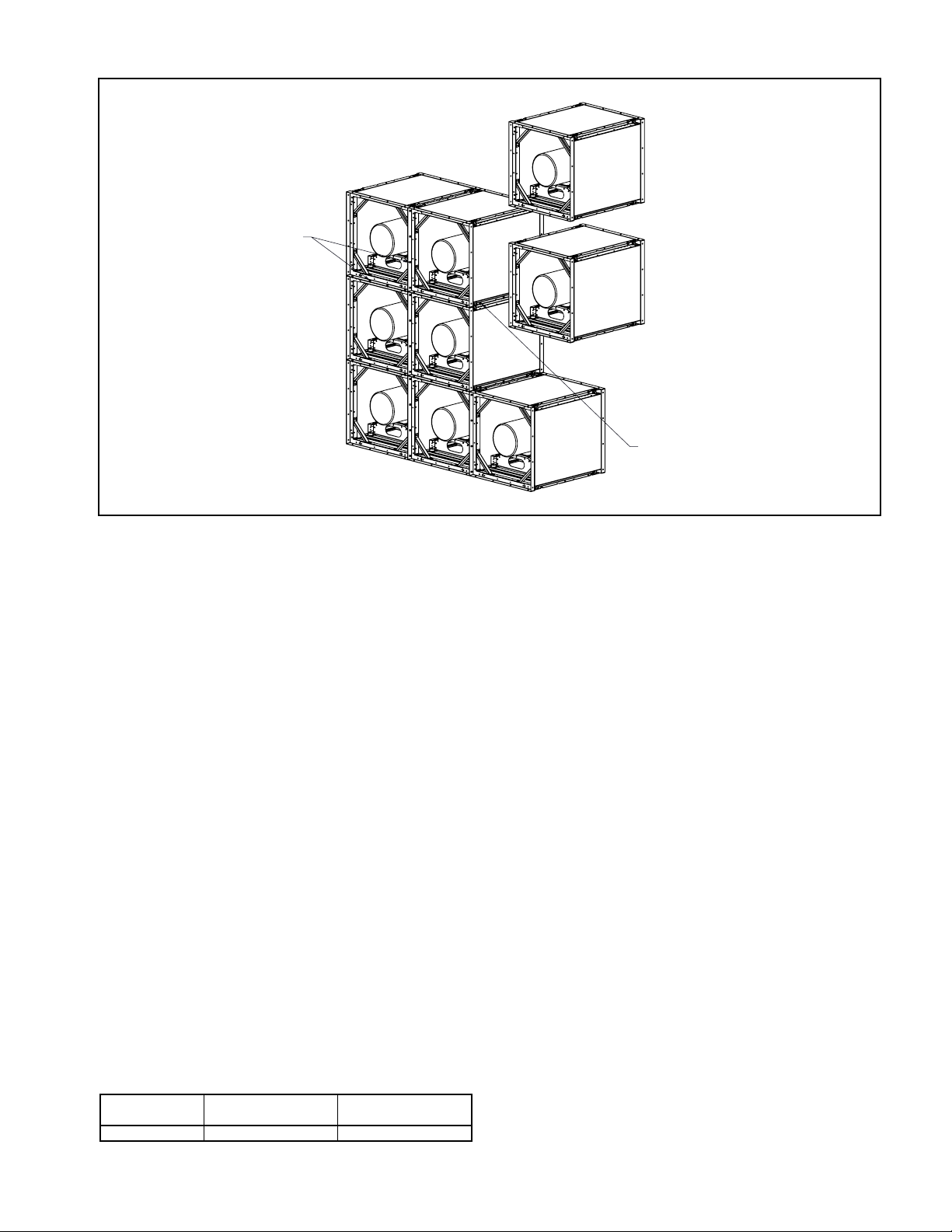

Figure 2.

3/8-16 x 0.75 Screws & Nuts

axial anges where accessable

front and back anges

3/8-16 x 0.75 Screws & Nuts

Fan Installation – Factory Assembled Units

Follow proper handling instructions given earlier.

1. Move the fan to the final mounting position.

2. Remove skid, crates, and packing materials carefully.

3. If supplied, place vibration pads or isolation base on

mounting bolts. Line up holes in fan base with bolts.

4. Place fan on mounting structure. Carefully level unit

using shims as required at all mounting hole locations. Bolt down the unit.

Assembly of Fans

1. Fans must be securely bolted to a base either directly

through the factory mounting holes or with a properly

designed clip. Final bolting of each individual row of

fans to the support structure or base should be done

after the individual fans are bolted together as a row.

NOTE: A thin gasket or caulk may be used to prevent

undesired air leakage and noise

2. The bolts to be snugged up on vertical sections for the

first row. Once all fasteners are in place, the bolts shall

be tightened to torque values in table. See Table 1.

3. The bolts holding the fan to the supporting structure

can now be torqued.

4. The second row and succeeding rows can be installed

using the same assembly steps as the first row.

5. Sealing around the perimeter should be accomplished

using a flexible material.

Table 1. Torque Values MPLFN/MPLFS/MPLQN/MPLQS

Fasteners

Size

3/8 – 16 UNC

Net Type

Nylock 16 – 17

Torque Values

(ft lbs)

Electrical Wiring of Fans

The customer is required to investigate and install

equipment in compliance with all local electrical and

safety codes for the equipment location. Twin City Fan &

Blower requires all power cabling be located away from

the rotating impeller and fastened to the inside of the

fan housing. Wiring must be routed away from the motor

to reduce potential contact with hot or greasy surfaces.

When a fan is supplied with an outlet damper, wiring

the electrical supply to the motor requires routing the

supply through the damper housing frame. Knockouts of

various sizes are provided in the damper housing frame to

accommodate cable connectors or raceway (see figure 3).

Fan Operation - Safety

For general safety practices for air moving equipment,

see AMCA Catalog 410.

Twin City Fan & Blower has many safety accessories

available. These safety devices include (but are not

limited to) inlet and discharge screens. The use, abuse,

or non-use of safety devices is the responsibility of the

purchaser.

Facility-related safety conditions include fan accessibility and location. How easily can non-service personnel

access the unit? Is the fan in a hazardous duty environment? Was the unit ordered for this duty? Other

concerns must also be addressed. All fans should be

powered through switches which are easily accessible

to service personnel from the fan. Every switch should

have the ability to be “locked-off” by the service person

and the key to be retained by this person to prevent

accidental power of the fan while service is in process.

Twin City IM-495 3

Page 4

Operation Check List

Verify that proper safety precautions have been followed:

□ Electrical power must be locked off.

Check fan mechanism components:

□ System connections are properly made and tightened. □

□ Bearings are properly lubricated.

□ Wheel, drives and fan surfaces are clean and free

of debris.

□ Rotate the impeller by hand to verify it has not shifted

in transit.

□ Check fan/wheel overlap. (See Figure 4.)

Figure 4. Wheel-Funnel Overlap

A

DIA

B

MPLFN/MPLFS/MPLQN/MPLQS

Size

1

15

165

182/18

200/200C

222/222C

Check fan electrical components:

□ Motor is wired for proper supply voltage.

□ Motor was properly sized for power and rotational

inertia of rotating assembly.

□ Motor is properly grounded.

□ All leads are properly insulated.

Trial “bump”:

□ Turn on power just long enough to start assembly

rotating.

□ Check rotation for agreement with rotation arrow.

Does the assembly make any unusual noise?

(See Figure 5.)

□ Correct any problems which may have been found.

(Follow safety guidelines - shut power off.) Perform

checklist again until unit is operating properly.

□ Run unit up to speed.

A B Size A B

22

0

2C

12.75 0.130

15.62 0.172

17.18 0.203

19.00 0.38

20.82 0.41

23.16 0.45

2

45/245

270/270C

300/300C

330/330C

365/365C

C

25.51 0.50

28.11 0.55

31.23 0.61

34.36 0.67

38.00 0.75

Verify fastener tightness. These may have loosened during shipment or installation.

□ Setscrews attaching wheel hub to shaft.

□ Nuts on inlet funnel.

□ Nuts and bolts holding motor.

□ Nuts holding housing frame to base and base to

ground.

□ Bolts in taper-lock bushings.

□ Grease line connections.

After one week of operation, check all nuts, bolts and

setscrews and tighten if necessary.

Figure 5. Proper Wheel Rotation

a

t

i

t

o

o

n

R

MPLFN, MPLFS,

MPLQN, & MPLQS

Wheels

Maintenance of Fans

This section contains general maintenance instructions

for your Twin City Fan & Blower unit. For specific information about maintenance of components, particularly

for special application fans, see the attached documents.

General Motor Maintenance

The three basic rules of motor maintenance are keep the

motor clean, dry and properly lubricated.

Keeping motors and windings clean is important because

dirt and dust serve as thermal insulators. Heat normally

dissipated by the motor is trapped causing overheating

and/or premature failure. Blow dust and dirt out of windings and off the motor periodically. Use low pressure (50

psig) airstream so that winding damage does not occur.

Keep the area surrounding the motor open so the air can

circulate through the motor cooling fan. Follow normal

maintenance schedule given to the right.

Motors should be kept dry to avoid electrical short circuits. Motors kept in storage for long periods of time

can have moisture condense on the windings. Be certain

the motor is dry before using.

Some smaller motors are lubricated for life. Motor bearing lubrication, if required, must follow a rigorous schedule. Motors less than 10 hp running about eight hours

a day in a clean environment should be lubricated once

every five years; motors 15 to 50 hp, every 3 years;

and motors 50 to 150 hp, yearly. For motors in a dusty

or dirty environment or running 24 hours a day, divide

the service interval by 2. If the environment is very dirty

or high temperatures exist, divide the service interval by

4. Lubrication requirements are normally attached to the

motor. Do not overlubricate.

4

Twin City IM-495

Page 5

Wheel and Shaft Maintenance

Periodically inspect the shaft and wheel for dirt buildup,

corrosion, and signs of excess stress or fatigue. Clean

the components and, when appropriate, apply new coatings. (Any addition of coatings or weld can create an

imbalance.) Check the balance of the assembly.

Structural Maintenance

All structural components or devices used to support or

attach the fan to a structure should be checked at regular intervals. Vibration isolators, bolts, foundations, etc.,

are subject to failure from corrosion, erosion, and other

causes. Improper mounting can lead to poor operation

characteristics or fan fatigue and failure.

Check metallic components for corrosion, cracks, or

other signs of stress. Concrete should be checked to

ensure the structural integrity of the foundation.

Troubleshooting Guidelines

Use current safety practices when investigating fan or

system performance problems. General safe practices

and performance troubleshooting guidelines can be

found in AMCA Publications 410 and 202, respectively.

Fan application and field measurement procedures can

be found in AMCA Publications 201 and 203.

Troubleshooting Performance Problems

The lists below indicate possible areas to check when air

or sound values do not match expectations. Most fan problems can be pinpointed to one of these common causes.

Vibration Problems:

1. Misalignment of drive components.

2. Poor foundations or mounting structure (resonances).

3. Foreign material attached to rotating components.

4. Damaged rotating components (bearings, shaft, fan,

wheel).

5. Broken, loose or missing setscrews.

6. Loose bolts.

7. Vibration transmitted by another source.

8. Water accumulating in airfoil blades.

9. Fan is operating in stall or unstable flow region.

NOTE: All fans manufactured by Twin City Fan &

Blower are factory balanced prior to shipment. Handling

and movement of the fan during shipment may cause

the rotating assembly to shift. Balance should be

checked once the fan is installed. If a final trim balance

is required, it is the end user's responsibility to bring the

fan back to factory specifications. Final trim balancing is

not the responsibility of Twin City Fan & Blower.

Motor Problems:

1. Incorrect wiring.

2. Speed of fan too high.

3. Parts improperly installed - binding.

4. Bearings improperly lubricated.

2

5. WR

capability of motor too low for application.

6. Protection devices may be improperly sized.

Air Capacity Problems:

1. Resistance of system not at design rating. If resistance is lower than expected, both airflow and

horsepower may be up. If resistance is higher than

anticipated, air volume will be down.

2. Fan speed is not at design speed.

3. Air density not at design values. Also check air performance measurement techniques/procedures.

4. Devices for air modulation are closed or plugged.

Also check filters.

5. Wheel mounted improperly or is rotating in reverse.

6. Parts of system or fan have been damaged or need

cleaning.

Noise Problems:

1. Air performance is incorrect and fan is not at design

point of operation. Fan forced to operate in an

unstable flow region.

2. Bearing failure. Check bearings (lubrication).

3. Supply voltage high or inconsistent supply frequency.

Adjustable frequency controllers can generate motor

noise.

4. Objects which are installed in a high velocity airstream can generate noise. This includes flow sensors, turning vanes, etc.

5. Poor fan inlet conditions.

6. Acoustics or sound measurement procedure incorrect.

Motor Lubrication – The major cause of motor bearing

failure is contamination of grease, insufficient grease, or

incompatibility of grease. If a fan is to be stored for

any length of time at the job site and the bearings are

regreasable, the motor bearings should immediately be

filled with grease while rotating the fan and then the

bearings should be regreased and rotated monthly. This

will prevent moisture, which condenses within the bearing, from corroding the raceways. Most greases used on

motor bearings are lithium base. Use the greases shown

in the motor information. Do not mix the bases without

completely purging out the initial grease.

Initially, follow the lubrication instruction in the motor

information. The frequency of lubrication should be

adjusted depending on the condition of the old grease

being purged. This is the responsibility of the user. If

the grease is dirty, the lubrication frequency should be

more often.

a. Noise – If a bearing is increasing in noise intensity

and/or vibration, it will probably result in failure.

b. Temperature – If a bearing temperature begins to

gradually rise, it will generally result in failure. A

bearing can operate up to 200 degrees and operate

satisfactorily if the temperature remains constant and

the bearing receives adequate lubrication. Remember

that a roller bearing under the same load and speed

will be somewhat more noisy and run warmer than a

ball bearing. This is normal.

Rough handling and/or dropping a fan can result in brinelling the bearing. This appears as a clicking noise at

first, then gradually worsens until failure.

Twin City IM-495 5

Page 6

Limitation of Warranties and Claims

Seller warrants to the original purchaser that the goods

sold hereunder shall be free from defects in workmanship and material under normal use and service (except

in those cases where the materials are supplied by the

buyer) for a period of one year from the date of original

installation or eighteen (18) months from the date of

shipment, whichever occurs first. The liability of seller

under this warranty is limited to replacing, repairing, or

issuing credit (at cost, F.O.B. factory and at seller’s

discretion) for any part or parts which are returned by

buyer during such period provided that:

a. seller is notified in writing within ten (10) days fol-

lowing discovery of such defects by buyer, or within

ten (10) days after such defects should reasonably

have been discovered, whichever is less;

b. the defective unit is returned to seller, transportation

charges prepaid by buyer.

c. payment in full has been received by seller or said

products; and

d. seller’s examination of such unit shall disclose to its

satisfaction that such defects have not been caused

by misuse, neglect, improper installation, repair,

alteration, act of God, or accident.

e. seller cannot guarantee sound pressure levels or

dBA.

No warranty made hereunder shall extend to any seller

product whose serial number is altered, effaced or

removed. Seller makes no warranty, express or implied,

with respect to motors, switches, controls, or other

components of seller’s product, where such components

are warranted separately by their respective manufacturers. THIS WARRANTY IS EXPRESSLY IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

WHETHER STATUTORY OR OTHERWISE, INCLUDING

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. In no event

shall seller be liable to buyer for indirect, incidental collateral, or consequential damages of any kind.

(BUYER’S FAILURE TO PAY THE FULL AMOUNT DUE

WITHIN SIXTY (60) DAYS OF DATE OF INVOICE SHALL

OPERATE TO RELEASE SELLER FROM ANY AND ALL

LIABILITY OR OBLIGATION ARISING PURSUANT TO

ANY WARRANTY, EXPRESS OR IMPLIED, WHETHER

STATUTORY OR OTHERWISE, INCLUDING ANY IMPLIED

WARRANTY OR MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE, MADE IN CONNECTION

WITH ANY CONTRACT FORMED HEREUNDER. BUYER

AGREES THAT SUCH FAILURE TO PAY SHALL

CONSTITUTE A VOLUNTARY WAIVER OF ANY AND ALL

SUCH WARRANTIES ARISING PURSUANT TO SUCH

CONTACT.)

6

Twin City IM-495

Page 7

TWIN CITY FAN & BLOWER | WWW.TCF.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601

Loading...

Loading...