Page 1

BCFS Belt Driven

Centrifugal Filtered Supply Fans

INSTALLATION, OPERATION & MAINTENANCE MANUAL

Models BCFS 140A through 240A

IM-4300

January 2006

Receiving, Inspection & Unpacking

When the equipment is received all items should be carefully checked against the bill of lading to be sure all crates

and cartons have been received. Before accepting delivery, carefully inspect each carton or crate for visible shipping

damage. If any damage is noticed, the carrier should make the proper notation on the delivery receipt acknowledging

the damage. Make notations of all damage on all copies of the bill of lading and have all copies countersigned by

the delivering carrier. The carrier should also fill out a Carrier Inspection Report. The factory Traffic Department should

then be contacted. File claim for damage with the carrier. Physical damage to the unit after acceptance is not the

responsibility of Twin City Fan Companies, Ltd.

Unpack each carton or crate and verify that all required parts and proper quantities of each item have been received.

Refer to drawings for part descriptions. Report shortages or missing items to your local representative to arrange for

replacement parts.

Due to availability of carriers and truck space, it is not possible to guarantee that all items will be shipped together.

Verification of shipments must be limited to only those items on the bill of lading.

The unit nameplate must be checked to make sure the voltage agrees with the power supply available.

Installation

CAUTION: Sheet metal parts, screws, clips and similar

items inherently have sharp edges, and it is necessary

that the installer and service personnel exercise

caution.

The installation of this equipment shall be in accordance

with the regulations of authorities having jurisdiction and

with all applicable codes.

This equipment is to be installed by an experienced

installation company and fully trained personnel.

The mechanical installation of the exhaust ventilator

consists of making final connections between the unit,

building services, and duct connections.

1. Before setting unit on curb (if damper is to be used),

make sure that the damper is installed correctly and

that it is operative. See diagram, page 6.

2. Position unit on roof curb so that the wiring can be

run through one of the knockouts provided. Wiring to

the unit may be run through knockouts provided in

the curb cap or the side of the unit. Provide enough

slack in the wiring to the unit to allow lifting, and

removal for cleaning, and inspection.

3. Connect supply leads to the disconnect switch.

4. Check line voltage with the motor nameplate and the

attached instruction cards.

5. Determine if wheel is free to rotate and has not been

subject to misalignment in shipping or installation.

6. Apply power and check rotation of wheel with directional label in motor compartment.

7. Lag bolt the unit to the roof curb using a minimum

of four bolts, one at each corner. Replace unit top

panel and fasten all latches securely.

©2006 Twin City Fan Companies, Ltd.

Page 2

Check, Test and Start Procedure

WARNING

Electric shock hazard. Could cause severe injury

or death. Failure to bond the frame of this equipment to the building electrical ground by use of

the grounding terminal provided or other acceptable

means may result in electrical shock. Disconnect

electric power before servicing equipment. Service

to be performed only by qualified personnel.

BEFORE STARTUP: Disconnect power to this unit before

servicing the unit.

1. Check to verify that the wheel is free to rotate.

2. Verify that supply voltage on the line side of disconnect agrees with voltage on unit identification plate and

is within the utilization voltage range as indicated in

Table 1.

3. On three-phase units check and calculate phase

unbalance as follows:

% Voltage Unbalance = 100 x max. voltage deviation

from avg. voltage ÷ avg. voltage

Example: Determine the percent voltage unbalance

given voltages of 220, 216 and 213.

How To Use The Formula:

a. Avg. Voltage = 220 + 216 + 213 = 649 ÷ 3 = 216

b. Max. Voltage Deviation From Avg. Voltage =

220 – 216 = 4

c. % Voltage Unbalance = 100 x (4 ÷ 216) = 1.8%

Voltage unbalance should not exceed 2%.

4. Apply power to unit and check rotation of wheel with

the directional arrow on the unit.

WARNING: The BCFS centrifugal wheels run in a counterclockwise direction when viewed opposite the air

intake. If the wheel is run in the wrong direction, the

motor will overload and burn out.

WARNING: Check three-phase units for rotation. For

three-phase, rotation can be changed by interchanging

any two of the three line leads. If unit is installed on

temporary wiring, it should be rechecked when permanently installed. Motor burn-out or tripped overload

protection devices are usually the result of incorrect

rotation.

WARNING: Motor overloading is usually the result of

incorrect rotation, high voltage, or low voltage. The NEC

states that motors used in devices such as filtered roof

supply units must be protected by a separate overload

device that is responsive to motor current or a thermal

protector integral with the motor. Refer to Sections 43022 of the NEC for additional information.

5. Electrical Input Check: Perform check of fan ampere

draw and verify that motor nameplate amps are not

exceeded. Take account of the service factor range

if motor is nameplated above a 1.0 service factor.

6. Fan RPM Check: Fan RPM should be checked and

verified with a tachometer. Refer to Table 2 for maximum fan RPM values.

WARNING: Running fan at an RPM greater than the

maximum RPM value in Table 2 will overload the fan

motor and lead to premature motor failure.

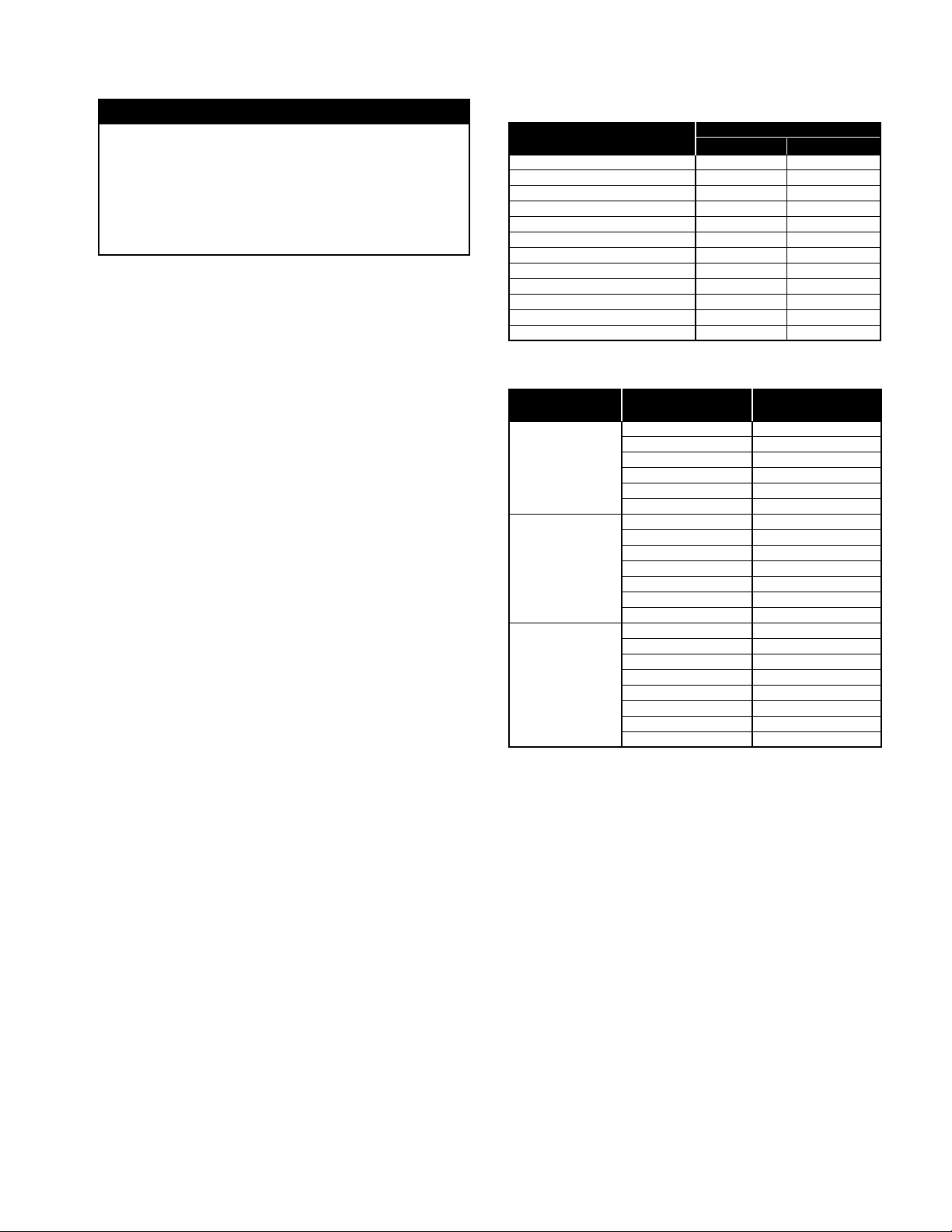

Table 1. Utilization Voltage Ranges

SYSTEM VOLTAGE/ UTILIZATION VOLTAGE

UNIT NAMEPLATE MIN. MAX.

115/60/1 104 127

208-230/60/1 or 208-230/60/3 187 253

230/60/1 or 230/60/3 207 253

277/60/1 249 305

200/60/3 180 220

380/60/3 342 418

460/60/3 414 506

575/60/3 517 633

110/50/1 99 121

220/50/1 198 242

380-415/50/3 342 456

440/50/3 396 484

Table 2. Maximum Fan RPM

BCFS MAXIMUM

MODEL

1/6 1100

1/4 1250

1/2 1590

3/4 1810

1.0 2000

1/6 730

1/4 840

1/3 930

180 1/2 1060

3/4 1220

1.0 1300

1.5 1530

1/3 580

1/2 660

3/4 760

1.5 960

2.0 1060

3.0 1180

5.0 1350

1/3 1380

140

1.0 840

240

MOTOR HP

FAN RPM

Maintenance

FILTERS: To gain access to filters, unlatch top panel

and slide top back approximately 2 inches. Lift filters out

from top. Filters may be cleaned with soap and water

or replaced. Filters should be cleaned regularly, as dirty

filters will cause performance to be reduced. Frequency

of cleaning depends upon the local environment and

frequency of use of the fan.

1. The motors in these units are equipped with prelubricated ball bearings which are considered to be

permanently lubricated.

2. Fan shaft pillow block bearings are equipped with

grease gun fittings. These bearings are factory lubricated and, with normal operation, will need no lubrication for 3 to 6 months.

3. For pillow block bearings, use a low pressure grease

gun with Alvania #2 or #3 grease or equivalent. Only

a few strokes of the gun are required. Excess grease

will be forced out through the bearing pressure relief

holes. Use of a high pressure gun, however, is liable

to blow the bearing seals.

2 Twin City IM-4300

Page 3

4. Belt tension is adjusted at the factory. It should be

readjusted after a break-in period of 24 hours of

actual operation.

5. To adjust belt tension, loosen the hex head screw in

the tab of the motor plate. Snug belts by pulling on

the motor until the belt is tight. Tension is correct if

the belt can be twisted from

1

⁄4 to 1⁄2 turn with mod-

erate pressure at a point midway between sheaves.

6. Belt condition and tension should be checked every

3 to 6 months depending on service. If belt tension

is too tight, there is a possibility of overloading the

motor as well as causing undue belt wear. If the belt

tension is too slack, then the wheel will fall off in

RPM, air delivery will decrease and the belts will wear

quite rapidly.

7. If the air handled by the unit is dust or grease laden,

a regular inspection and cleaning of the backdraft

damper and the wheel will ensure smooth, efficient

operation.

WARNING: Do not replace motor sheave with one larger

in diameter. Do not replace fan sheave with one smaller

in diameter. The sheave ratios are set so that the motor

will not be overloaded within the range of the adjustable sheave.

CHECK: Belt tension is adjusted at the factory, but it

should be readjusted after a break-in period of approximately 24 hours of actual operation.

Figure 2. Opening Location of Duct Adapter AccessoryFigure 1. Typical Installation

Apply foam tape to seal duct

to unit to prevent leakage

Duct Adapter

(Align this side with

inlet side of curb)

L

W

Y

Duct

(Customer

Supplied)

Damper*

X

Figure 3. Location of Fan Outlet

Top View of Roof Curb Showing Duct Location

L

Curb

Sq.

Fan Outlet

Y

Roof

Curb

Nailer

Duct Flange

By Customer

Strip

Position duct adapter as shown and secure to nailer strip

with nails in holes provided in duct adapter.

*For a standard gravity (spring return) damper, recess the

damper a minimum of 2" inside the duct in order to clear the

fan outlet. For an optional motorized damper, the damper must

be recessed 12" to allow for clearance between the actuator

and fan outlet.

MODEL DIMENSION (IN.)

BCFS W L X Y

140A 8

180A 10

240A 13

X

MODEL DIMENSION (IN.) CURB SUPPLY

BCFS W L X Y SQ. DAMPER

140A 8 19 2

W

180A 10 22 2

240A 13

DIMENSIONS ARE NOT TO BE USED FOR CONSTRUCTION.

1

⁄2 191⁄2 2

1

⁄2 221⁄2 1

11

⁄16 291⁄2 1

1

⁄2 71⁄4 30 x 30 8 x 19

1

3

⁄16 29 2 113⁄4 47 x 47 13 x 29

⁄8 91⁄4 36 x 36 10 x 22

1

⁄4 7

7

⁄8 9

3

⁄4 111⁄2

Inlet Side of Fan (Provide a min. of 15"

between inlet side and nearest obstruction)

3 Twin City IM-4300

Page 4

Motor Installation

To prevent damage during shipment, the motor of this

unit has been installed at the factory, tested, then

removed and shipped separately. Please follow the

instructions below to reinstall the motor.

1. Fasten the motor plate to the bearing plate by inserting the hinge pin in the holes and then putting a

hitch pin in the hole of the hinge pin.

See Figure 4.

2. Install the belts on the sheaves, apply tension and

tighten the bolt at the top of the motor plate or the

nut on the jacking bolt to maintain tension. The ideal

Figure 4. Motor Plate Assembly Figure 5. Sheave Alignment

HINGE PIN

TENSION

HOLD BOLT

HITCH PIN

belt tension is to be enough so that the belt does

not slip under peak load. Do not over-tighten the belt

as it will severely reduce the life of the bearings.

3. Check the sheave alignment as shown in Figure 5

below and align sheaves with a straightedge if necessary. Be sure the belt tension is rechecked if the

sheave alignment is changed.

Note: The belt tension will need to be rechecked after

the fan has been operating for a few days. There is an

initial break-in period for the belts in which they may

stretch.

Limitation of Warranties and Claims

Seller warrants to the original purchaser that the goods

sold hereunder shall be free from defects in workmanship and material under normal use and service (except

in those cases where the materials are supplied by the

buyer) for a period of one year from the date of original

installation or eighteen (18) months from the date of shipment, whichever occurs first. The liability of seller under

this warranty is limited to replacing, repairing, or issuing

credit (at cost, F.O.B. factory and at seller’s discretion)

for any part or parts which are returned by buyer during

such period provided that:

a. seller is notified in writing within ten (10) days follow-

ing discovery of such defects by buyer, or within ten

(10) days after such defects should reasonably have

been discovered, whichever is less;

b. the defective unit is returned to seller, transportation

charges prepaid by buyer.

c. payment in full has been received by seller for said

products; and

d. seller’s examination of such unit shall disclose to its

satisfaction that such defects have not been caused

by misuse, neglect, improper installation, repair,

alteration, act of God, or accident.

No warranty made hereunder shall extend to any seller

product whose serial number is altered, effaced or

removed. Seller makes no warranty, express or implied,

with respect to motors, switches, controls, or other

components of seller’s product, where such components

are warranted separately by their respective manufacturers. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, WHETHER

STATUTORY OR OTHERWISE, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. In no event shall seller be liable

to buyer for indirect, incidental collateral, or consequential

damages of any kind. (BUYER’S FAILURE TO PAY THE

FULL AMOUNT DUE WITHIN SIXTY (60) DAYS OF DATE

OF INVOICE SHALL OPERATE TO RELEASE SELLER

FROM ANY AND ALL LIABILITY OR OBLIGATION ARISING

PURSUANT TO ANY WARRANTY, EXPRESS OR IMPLIED,

WHETHER STATUTORY OR OTHERWISE, INCLUDING

ANY IMPLIED WARRANTY OR MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE, MADE

IN CONNECTION WITH ANY CONTRACT FORMED

HEREUNDER. BUYER AGREES THAT SUCH FAILURE TO

PAY SHALL CONSTITUTE A VOLUNTARY WAIVER OF

ANY AND ALL SUCH WARRANTIES ARISING PURSUANT

TO SUCH CONTACT.)

Twin ciTy fan & blower | www.Tcf.com

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601

1MPP11/09

Loading...

Loading...