Page 1

HA/HAB Fiberglass

Wall Mount Ventilators

INSTALLATION, OPERATION & MAINTENANCE MANUAL

Receiving

The HA/HAB ventilator is shipped in two parts:

1. Fan housing assembly complete with fiberglass inlet

venturi to the wheel and complete motor and drive

assembly.

2. Flanged extruded aluminum louver assembly.

Duct adapter and companion angles are shipped loose

if unit is for inline application.

Inspect cartons or crates carefully before signing a delivery receipt for the carrier. If any damage is apparent,

note it on the carrier’s receipt so that a claim can be

filed against the carrier through your usual channels.

Handle the units carefully while delivering to installation

location. Use ordinary care in unpacking the units. If the

units, when unpacked, appear to be damaged in a way

that could not be determined at the time of delivery,

notify the carrier that concealed damage has been discovered and insist on inspection by the carrier. Obtain

a copy of carrier’s inspection report showing the concealed damages so that a claim can be filed through

your usual channels.

Study the attached installation prints carefully. Inspect

the units carefully for identification marks, fan rotation

symbols, etc.

IM-3100

August 2014

Check, Test & Start Procedure

WARNING

Installation

Wall Application

1. Remove wood shipping supports from fan assembly

(see Figure 1).

1

2. Locate and provide hole in the wall

the fan housing (see Figure 2). This will provide an

opening for the electrical wiring into the unit.

3. Anchor the box in the wall, keeping a minimum of

23⁄8" between the outside wall and any part of the

box or the power assembly.

4. Fasten the flanged extruded louver to the exterior

wall.

Inline Application

1. Remove wood shipping supports from fan assembly

(see Figure 1).

2. Attach duct adapter and companion angles to unit

per Figure 3 with fasteners supplied.

3. Before anchoring the unit to the ductwork, check line

voltage and current characteristics outlined in previous section.

4. Fasten the flanged extruded louver to the exterior wall

wherever the outlet of the ductwork ends.

For easy maintenance of the ventilator inline, provide a

drop-out section between ductwork and duct adapter

(see Figure 3).

⁄2" larger than

©1997 Twin City Fan Companies, Ltd.

Electric shock hazard. Could cause severe injury or

death. Failure to bond the frame of this equipment

to the building electrical ground by use of the

grounding terminal provided or other acceptable

means may result in electrical shock. Disconnect

electric power before servicing equipment. Service to

be performed only by qualified personnel.

BEFORE START-UP: Disconnect power to this unit

before servicing the unit.

1. Check to verify that the wheel is free to rotate.

2. Verify that supply voltage on the line side of disconnect agrees with voltage on unit identification plate

and is within the utilization voltage range as indicated

in Table 1.

Table 1.

SYSTEM VOLTAGE/

UNIT NAMEPLATE MIN. MAX.

115/60/1 104 127

208-230/60/1 or 208-230/60/3 187 253

230/60/1 or 230/60/3 207 253

277/60/1 249 305

200/60/3 180 220

380/60/3 342 418

460/60/3 414 506

575/60/3 517 633

110/50/1 99 121

220/50/1 198 242

380-415/50/3 342 456

440/50/3 396 484

UTILIZATION VOLTAGE

Page 2

3. On three-phase units check and calculate phase unbalance as follows:

% Voltage Unbalance = 100 x max. voltage deviation

from avg. voltage ÷ avg. voltage

Given example: With voltage of 220, 216 and 213

How To Use The Formula:

a. Avg. Voltage = 220 + 216 + 213 = 649 ÷ 3 =

216

b. Max. Voltage Deviation From Avg. Voltage =

220 – 216 = 4

c. % Voltage Unbalance = 100 x (4 ÷ 216) = 1.8%

Voltage unbalance should not exceed 2%.

4. Apply power to unit and check rotation of wheel with

the directional arrow on the unit.

WARNING: Especially check three-phase units for rota-

tion. For three-phase, rotation can be changed by

interchanging any two of the three line leads. If unit is

check on temporary wiring, it should be rechecked

when permanently installed. Motor burn-out or tripped

overload protection devices are usually the result of

wrong rotation.

5. Electrical Input Check: Perform check of fan ampere

draw and verify that motor nameplate amps are not

exceeded. Take account of the service factory range

if motor is nameplated above a 1.0 service factor.

6. Fan RPM Check: Fan RPM should be checked and

verified with a tachometer. Refer to Table 2 for maximum fan RPM values.

WARNING: Running fan at an RPM greater than the

maximum RPM value in Table 2 will overload the fan

motor and lead to premature motor failure.

Table 2. Maximum Fan RPM (Belt Drive Units)

MAXIMUM

MODEL

12HA1B, 2B, 3B 1/4 1740

14HA1B, 2B, 3B 1/4 1470

14HA4B 1/3 1615

14HA5B 1/2 1850

18HA1B, 2B 1/4 945

18HA3B 1/3 1040

18HA4B 1/2 1200

18HA5B 3/4 1365

24HA1B 1/4 575

24HA2B 1/3 633

24HA3B 1/2 725

24HA4B 3/4 830

24HA5B 1 915

30HA1B 1/3 440

30HA2B 1/2 500

30HA3B 3/4 575

30HA4B 1 630

30HA5B 1

30HA6B 2 795

MOTOR HP

FAN RPM

1

⁄2 725

Table 3. Bearing Lubrication Interval

(Belt Drive Model HAB Only)

OPERATING CONDITION GREASING INTERVAL

FAIRLY CLEAN 6 TO 12 MONTHS

MODERATE TO

EXTREMELY DIRTY 1 MONTH

1. Frequency or regreasing will vary, depending on the hours of

operation, temperature and surrounding conditions.

2. Bearings have been prelubricated from factory with NLGI Grade

No. 2 lithium-12 hydroxysterate base grease.

Belts on belt-drive units should be readjusted after 24

hours of operation. Loosen motor base bolts and apply

15 lbs. pull per belt for proper belt tensions. Tighten

motor base bolts.

Check contact surfaces of belt for excessive wear. If

belts have a slick, glazed look or are cracked, belts are

slipping. Replace belts as required.

Motors require no lubrication for 10 years of normal

operation.

The inlet venturi is molded shock-resistant, bonded,

reinforced fiberglass and will require no maintenance.

Wall Application

1. Servicing or inspecting the unit can be accomplished

from the exterior by removing the flanged extruded

louver and from the interior of the building by removing the fiberglass inlet (see Figure 2).

2. To remove the motor assembly for servicing, unplug

the motor from the provided outlet and unfasten the

four vibro-isolator bolts. The entire motor assembly,

including the wheel and bearing (belt drive units), will

slide out of the housing.

Inline Application

For easy maintenance of the inlet unit, provide a dropout section between the ductwork and duct adapter (see

Figure 3).

Servicing or inspection can then be accomplished by

removing the dropout section, then removing the fiberglass inlet. The motor assembly can then be removed

by disconnecting the motor from the provided outlet and

unfastening the four vibro-isolator bolts. Periodic inspection and cleaning of the fan will insure smooth operation.

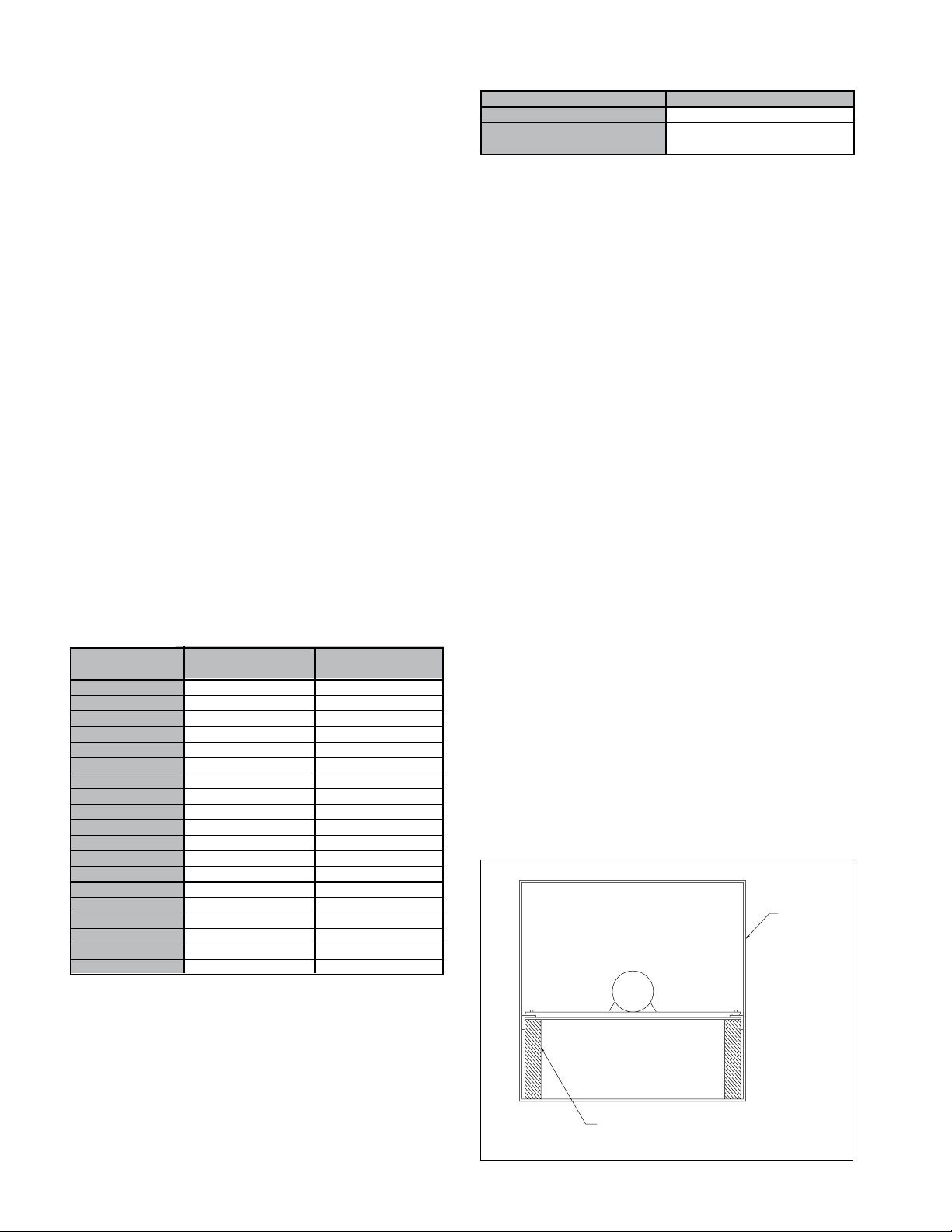

Figure 1. Removal of Wood Shipping Supports

Housing

Maintenance

General

Fan shaft bearings on belt drive units are factory lubricated and require no lubrication for the first 3-6 months

of operation. Lubricate at intervals shown in Table 3

thereafter. With fan running and with a low pressure

grease gun, add grease slowly until a slight bead forms

between the seals. Use Sinclair Litholene, Shell Gadus

S2 V100 2, Socony Vacuum Armvac 781, Sinclair Oil

Stranolith 57 or equal.

2

Instructions: Remove wood shipping supports

frame before installing unit

.

Twin City Fan & Blower IM-3100

Page 3

Figure 2. Wall Application

Louver

Assembly

Fan

Housing

Assembly

Electrical Wiring By Others

Hole Provided for Electrical Entrance Into Unit

Electrical Junction Box With Outlet

Belt Drive Motor

Assembly

Figure 3. Inline Application

Louver Assembly

on Exterior Wall

Direct Drive Motor

Assembly

Wiring By

Others

Ductwork By Others

Trim Angle Assembly

Access To Power Pack of Ventilator

By Removing 4 Fasteners (Interior Side)

or Louvers (Exterior Side)

Duct Adaptor

(Shipped Loose

With Fasteners)

Fiberglass Inlet Venturi

Ductwork By Others

Companion Angles (Shipped Loose)

With Fasteners)

Access to Power Pack of Inline

Unit By Removing 4 Fasteners

Twin City Fan & Blower IM-3100

Dropout Section of Duct For

Easy Maintenance (By Others)

3

Page 4

Limited Warranty

Seller warrants to the original purchaser that the goods

sold hereunder shall be free from defects in workmanship and material under normal use and service (except

in those cases where the materials are supplied by the

buyer) for a period of one year from the date of original

installation or eighteen (18) months from the date of

shipment, whichever occurs first. The liability of seller

under this warranty is limited to replacing, repairing, or

issuing credit (at cost, F.O.B. factory and at seller’s

discretion) for any part or parts which are returned by

buyer during such period provided that:

a. seller is notified in writing within ten (10) days follow-

ing discovery of such defects by buyer, or within ten

(10) days after such defects should reasonably have

been discovered, whichever is less;

b. the defective unit is returned to seller, transportation

charges prepaid by buyer.

c. payment in full has been received by seller or said

products; and

d. seller’s examination of such unit shall disclose to its

satisfaction that such defects have not been caused

by misuse, neglect, improper installation, repair,

alteration, act of God, or accident.

No warranty made hereunder shall extend to any seller

product whose serial number is altered, effaced or

removed. Seller makes no warranty, express or implied,

with respect to motors, switches, controls, or other

components of seller’s product, where such components

are warranted separately by their respective manufacturers. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, WHETHER

STATUTORY OR OTHERWISE, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. In no event shall seller be

liable to buyer for indirect, incidental collateral, or consequential damages of any kind. (BUYER’S FAILURE TO

PAY THE FULL AMOUNT DUE WITHIN SIXTY (60) DAYS

OF DATE OF INVOICE SHALL OPERATE TO RELEASE

SELLER FROM ANY AND ALL LIABILITY OR OBLIGATION

ARISING PURSUANT TO ANY WARRANTY, EXPRESS

OR IMPLIED, WHETHER STATUTORY OR OTHERWISE,

INCLUDING ANY IMPLIED WARRANTY OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, MADE IN CONNECTION WITH ANY

CONTRACT FORMED HEREUNDER. BUYER AGREES

THAT SUCH FAILURE TO PAY SHALL CONSTITUTE A

VOLUNTARY WAIVER OF ANY AND ALL SUCH

WARRANTIES ARISING PURSUANT TO SUCH CONTACT.)

TWIN CITY FAN & BLOWER | WWW.TCF.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601

Loading...

Loading...