Twin City IM-1080 User Manual

Inline Fume Exhaust Fans

INSTALLATION, OPERATION & MAINTENANCE MANUAL

IM-1080

August 2014

INTRODUCTION

This manual has been prepared to guide the users of TFE, QFE, QIFE, and TVIFE Fume Exhaust Fans in the proper

installation, operation and maintenance procedures to insure maximum equipment life with trouble-free operation.

TFE and QFE QIFE TVIFE

CONTENTS

Inspection and Receiving ...........................................................................................................................................................2

Handling and Rigging .................................................................................................................................................................2

Storage .........................................................................................................................................................................................2

Installation

• Pre-Installation Checklist ................................................................................................................................................... 2

• Roof Curb Installation .......................................................................................................................................................3

• Mixing Box Assembly Installation.....................................................................................................................................3

• Fan and Windband Installation .........................................................................................................................................3

• Drain Connections .............................................................................................................................................................4

• Damper and Actuator Installation .....................................................................................................................................4

Operation Checklist .....................................................................................................................................................................5

Maintenance

• Fan ......................................................................................................................................................................................5

• Motor ..................................................................................................................................................................................5

• Bearing ................................................................................................................................................................................5

• Drive ....................................................................................................................................................................................6

Jib Crane Operation ....................................................................................................................................................................6

Troubleshooting ...........................................................................................................................................................................7

Caution:

Fan systems include rotating components and electrical devices. Proper care must be taken during installation

and maintenance of all fan system components to protect personnel. This includes, but is not limited to the use

of protective enclosures, guards, locking devices to stop rotating parts, and electrical disconnect lock-outs. Refer

to applicable local codes to ensure compliance for all protective devices.

Fans create a suction at the inlet. Care should be taken around the inlet of the fan, whether it is in operation

or not. Make sure the inlet area is clear prior to energizing the system. This includes all personnel and loose,

foreign objects.

©2012 Twin City Fan Companies, Ltd.

INSPECTION AND RECEIVING

All Twin City Fan & Blower products are carefully constructed and inspected before shipment to insure the highest standards of quality and performance. Compare all

components with the bill of lading or packing list to verify

that the proper unit was received. Check each unit for any

damage that may have occurred in transit. Any damage

should be reported immediately to the carrier and the

necessary damage report filed.

UNIT STORAGE

If fan installation is to be delayed, store the unit in an

environmentally stable and protected area. During storage,

the fan should not be subjected to vibration from external

sources or bearing damage may occur. The unit should be

reasonably protected from any accidental impacts. Cover

the fan to protect coatings and to prevent any foreign

material or moisture from entering the inlet or discharge.

Take care to protect the motor, drives and bearings.

HANDLING AND RIGGING

Handling of all air moving equipment should be conducted

by trained personnel and be consistent with safe handling

practices. Verify the lift capacity and operating condition of

handling equipment. Maintain handling equipment to avoid

serious personal injury.

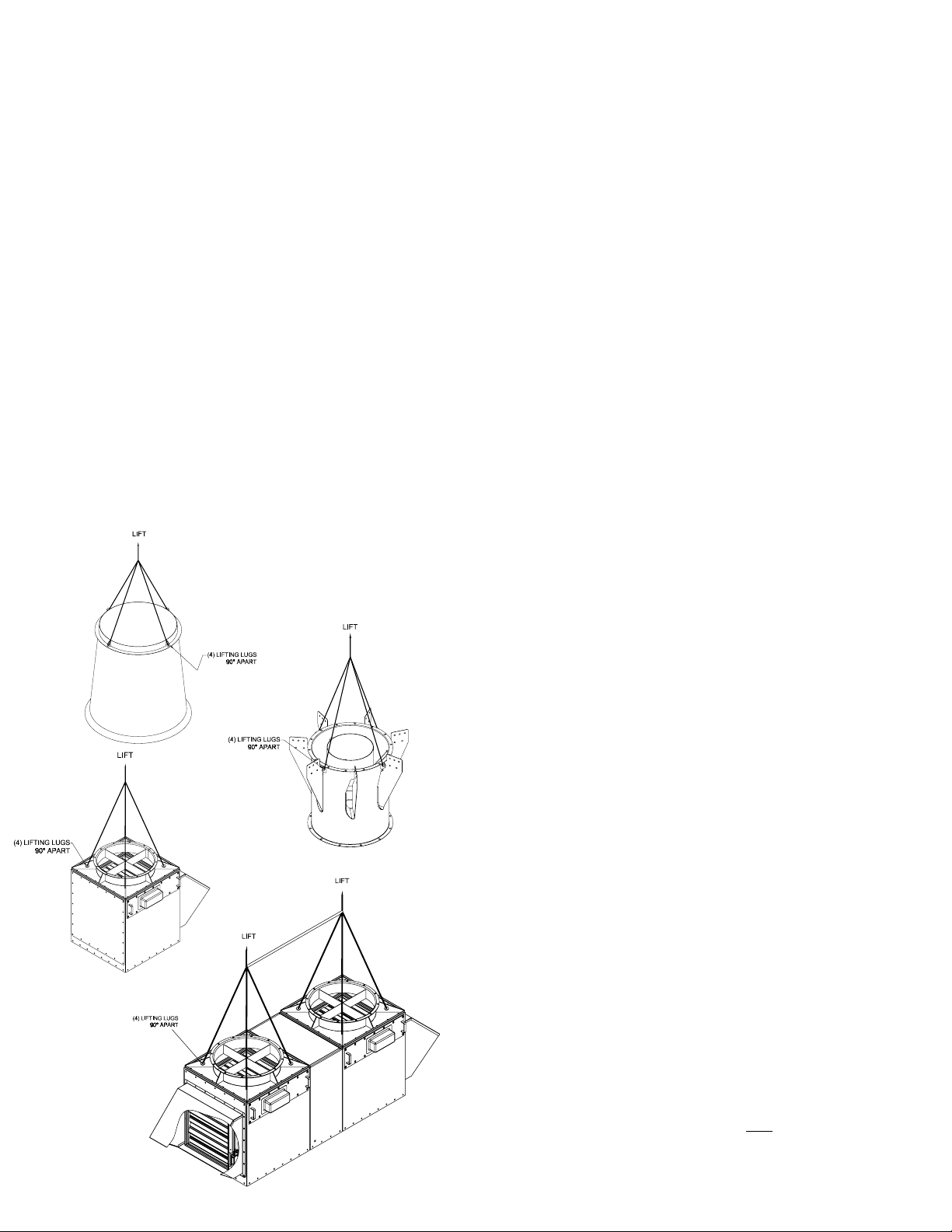

Units shipped may be lifted with slings and spreader bars.

Use well-padded chains, cables or nylon straps (see Figure

1). On most units, lifting lugs are fashioned to protect the

fan and fan housing from damage. Never lift a fan by the

inlet or discharge flange, shafting or drives, wheel, motor

or motor base, or in any other manner that may bend or

distort parts.

Mixing plenum boxes configured for multiple fans mounted

on a common unit are modular in design and may be

broken down into smaller segments for ease of installation

and handling.

Figure 1. Lifting Locations

Extended storage requires monthly inspections. Check for

corrosion or damage to the unit and for debris within the

fan.

Bearings tend to take on moisture if the atmosphere in

which they are stored is not at a constant temperature. To

avoid corrosion, it is necessary to keep the bearings full

of grease and to rotate them periodically. Even when full

of grease, bearings will take on moisture, so it is necessary

to purge the bearings with new grease to expel moisture

every thirty days. It is recommended that the bearings be

purged with grease while being rotated by hand. Do not

use high pressure greasers as they may ruin the bearing

seals.

The drives and belts should be removed if the fan is to

be stored for a prolonged period. The drives should be

labeled for service and stored in a dry place. Belts should

be removed, coiled without kinks, placed in a heavy carton, and stored in a dry, well-ventilated place. To prevent

belt deterioration storage conditions should not exceed

85°F and 70% humidity. If belts show signs of deterioration, they should be replaced prior to startup.

Motors should be stored in a clean, dry, vibration-free

location. The packaging should be opened up enough to

allow air circulation around the motor. The winding temperature should be kept slightly above that of the surroundings to prevent condensation. This can be accomplished by energizing the internal heaters, if the motor is

so equipped, or by using space heaters. If it is impossible

to heat the windings, the motor should be wrapped

tightly with a waterproof material which also encloses several bags of desiccant. Replace the desiccant regularly to

prevent moisture problems. The motor rotor should also be

rotated regularly (monthly) to assure the bearing parts are

well greased.

Start-Up – When the unit is removed from storage, all fan

bearing grease should be purged and replenished with

fresh grease as per the lubrication decal. The motor should

be measured to verify that the resistance is still at a satisfactory level compared to the value recorded prior to

storage.

INSTALLATION

Pre-Installation Checklist

Prior to fully assembling and installing, inspect the fan and

ancillary components to ensure it is in working order.

• Check all external and internal hardware on the fan,

wheel, bearings, drive motor base and accessories for

tightness.

• Rotate the fan wheel by hand and assure no parts are

rubbing. Adjust components prior to installation as adjustments are easier while lower to grad.

• Check proper wheel clearances to be sure near tolerance. The wheel will need to be realigned after installation, therefore, clearances should be near tolerance.

2

Twin City Fan IM-1080

Roof Curb Installation

Caution: Roof curbs should be square and level to ensure

safe fan installation and proper sealing of gas stream to

the fan.

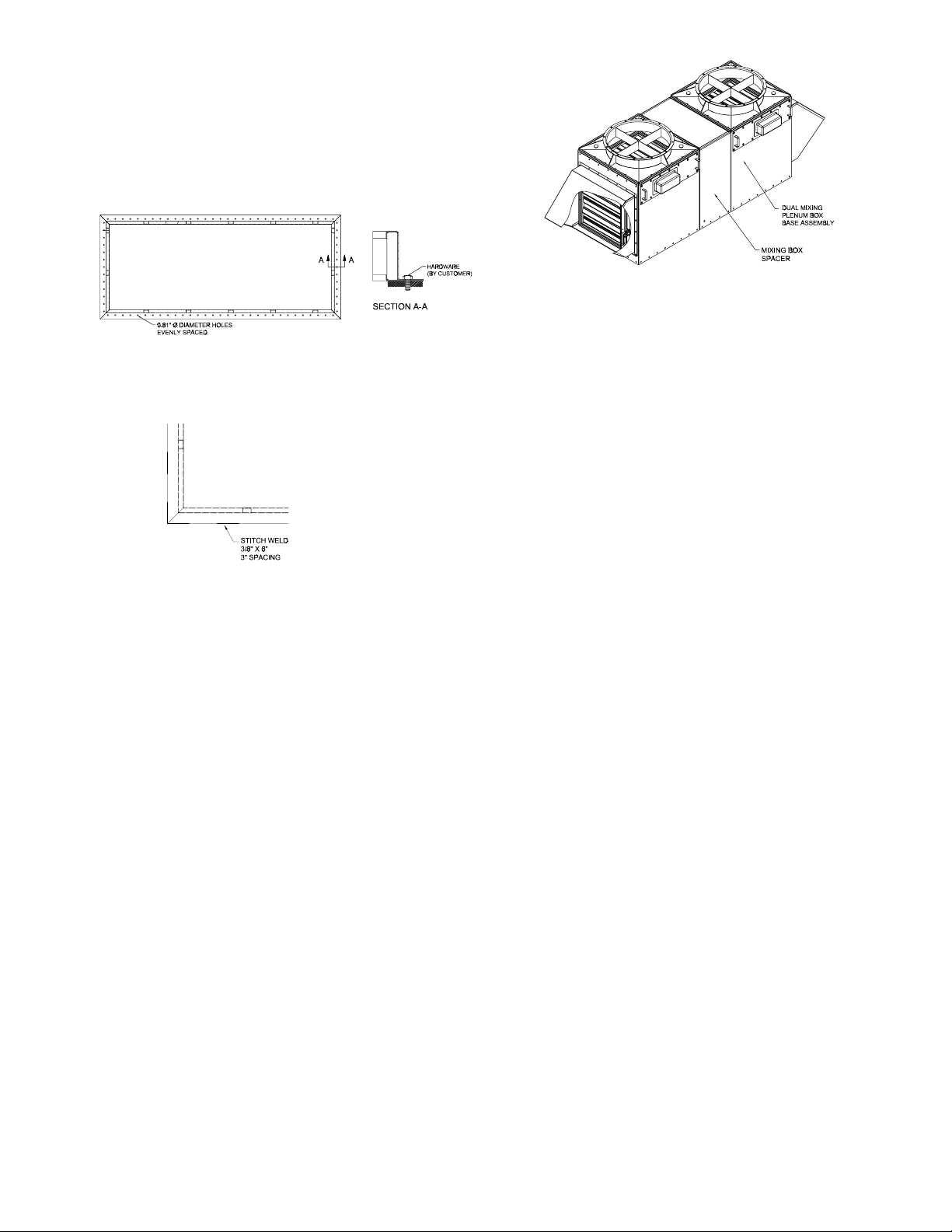

Roof curbs shall be installed and fully attached to structural support (by others) which is typically steel or concrete

using 1/2" diameter bolts w/ 1-3/8" washers (by others)

Figure 2. Bolted Installation

For attachment to structural steel the curb can be continuously welded or stitch welded using 3/8" x 6" welds

with a maximum of 3" spacing between welds. Welds

should be evenly spaced along curb side and corners

Figure 3. Welded Installation

Mixing Plenum Box Assembly and Installation

The modular plenum mixing boxes are designed to allow

for easy installation and future expandability. Single mixing

plenum boxes are fully assembled (less any dampers) to

expedite installation. Depending on the size, multi-unit mixing boxes may or may not be assembled. When installing

the mixing box(es), it is important to follow the guidelines

for lifting and rigging on page 2.

When a single-unit mixing plenum box is installed, prepare

the roof curb or mounting structure. Lay gasket material

on the top edge of the roof curb. Lift mixing box onto

curb and square (level) mixing box.

Depending on the air intake (side or bottom), the mixing

box must be oriented to allow for direct duct connection

into the mixing plenum box. Match drill roof curb to mixing plenum box. Attach mixing plenum box to curb using

1/2” diameter bolts with 1 3/8” washers (by others).

For multi-unit configurations, some assembly may be

required. There are at least two different assemblies in a

multi-unit configuration. There is the mixing plenum box

assembly and the mixing box spacer. See figure 4. There

will be one less spacer than the quantity of mixing plenum

boxes.

To assemble, space the mixing boxes a distance apart that

is slightly more than the width of the spacer section. Utilize

a gasket between the mixing box and the spacer section

to provide a tight seal.

Install 316 stainless steel bolts to attach the spacer and

the mixing box. Repeat as necessary for each section.

When the multi-unit mixing plenum box is assembled, rig

the mixing box system into place in accordance with

Figure 1 to avoid any damage.

Install mixing plenum box assembly onto a prepared (gasket material on mating surface) roof curb or mounting

structure. Lay Square (level) mixing box. Install lag bolts

into the mixing plenum box to roof curb as indicated.

Figure 4. Mixing Box

Fan and Windband Installation

• Follow proper handling instructions as provided earlier.

• Identify each fan and component and match the equip-

ment up with the supplied customer drawing(s).

• Move the fan to the final mounting location.

• Remove skid, crates and packing materials carefully.

• For fans mounted directly to roof curb (supplied with a

curb cap), place the fan on properly installed roof curb.

Fans mounted on a mixing plenum box (supplied with

mixing plenum box transition) require the installation of

the mixing plenum box prior to installing fan.

• Fans shipped as a single unit shall be broken down

into several parts. Install each item individually in the

following order:

1. Fan and curb cap onto the installed roof curb

-orFan and mixing plenum box transition onto installed mixing box.

2. Stack extension, if in the scope of supply (TFE/

QFE Only)

3. Windband

Note: When installing the components, lifting lugs shall be utilized for safe installation. Lifting lugs are designed for the weight

of the component they are welded to and should not be used

to lift assemblies.

Fan Housing Installation

1. Place supplied gasket around the perimeter of the mixing plenum box or roof curb.

2. Lower fan housing onto roof curb or mixing plenum box

aligning the bolt holes on the two components. Allow

for gasket to compress naturally prior to securing fan

housing to the adjacent component.

3. Install 316 stainless steel hardware (provided) in all

mounting holes. Use a commercially available antiseizing compound formulated for 316 stainless steel to

hardware. Carefully level the unit on the roof curb or

mixing plenum box. Be careful not to force the fan to

the mounting structure. This may cause misalignment

which may unsafe operating conditions, cause vibration

and premature failure.

4. Check the alignment of the bearings. Shim or reposition

the bearings if necessary.

5. Check face alignment of sheaves on belt driven fans.

Check tension of belts to see if it is sufficient. Sheaves

on belt driven fans are often provided with taperlock

bushings. When tightening bushing bolts, proceed in a

progressive manner to avoid cocking the tapered surfaces between the bushing and the sheave.

6. Check the tightness of the wheel on the shaft. Check

the tightness of foundation bolts, motor bolts, sheaves,

and bearings. Make sure there is no rubbing or binding

and that the wheel-inlet cone clearances and overlap

are correct.

Twin City Fan IM-1080

3

Loading...

Loading...