Twin City ES-52 User Manual

Centrifugal Fans

INSTALLATION, OPERATION & MAINTENANCE MANUAL

ES-52

August 2014

Contents

Introduction .........................................................................1

Shipping and Receiving .....................................................1

Handling .............................................................................. 1

Short Term Storage ...........................................................2

Long Term Storage............................................................2

Foundations and Supporting Structures .......................... 2

Fan Installation ...................................................................2

Factory Assembled Units ............................................. 2

Disassembled Units .......................................................3

Fan Operation – Safety .....................................................4

Operation Checklist ............................................................ 5

Maintenance of Fans ......................................................... 5

General Motor Maintenance ......................................... 5

Drive Maintenance ......................................................... 5

Bearing Maintenance .....................................................5

Lubrication ...................................................................... 6

Wheel and Shaft Maintenance ..................................... 7

Structural Maintenance ................................................. 7

Troubleshooting Guidelines................................................ 7

Troubleshooting Performance Problems

Air Capacity Problems ..................................................7

Noise Problems .............................................................7

Vibration Problems ........................................................ 7

Motor Problems ............................................................. 7

Drive Problems .............................................................. 7

Bearing Problems .......................................................... 8

Limitation of Warranties and Claims ............................... 8

immediately to the carrier and the necessary damage

report filed.

Handling

Handling of all air moving equipment should be conducted by trained personnel and be consistent with safe

handling practices. Verify the lift capacity and operating condition of handling equipment. Maintain handling

equipment to avoid serious personal injury.

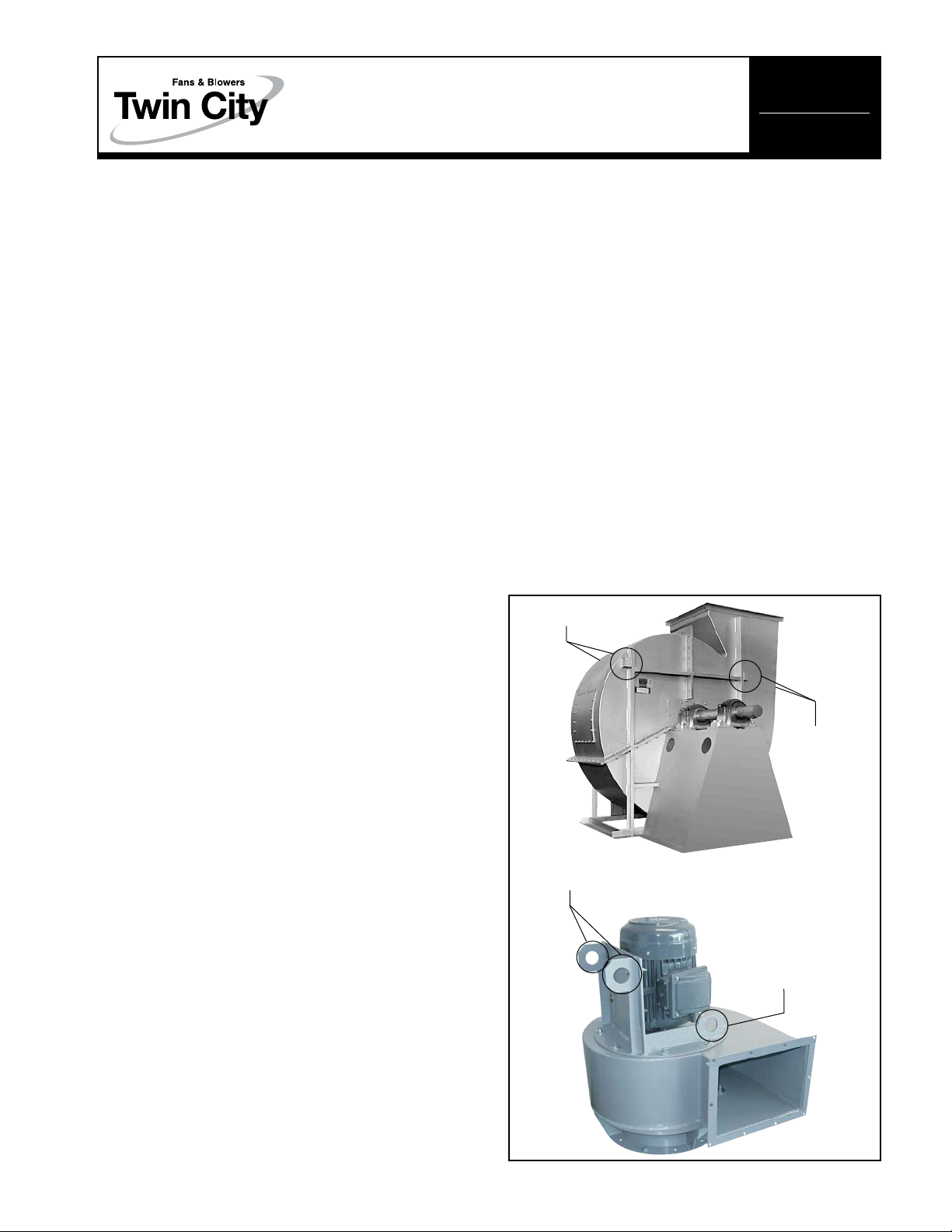

Units shipped completely assembled may be lifted with

slings and spreader bars. Use well-padded chains, cables

or nylon straps. On most units, lifting lugs are provided

for attaching chains (see Figure 1). Lift the fan in a fashion that protects the fan and fan coating from damage.

Never lift a fan by the inlet or discharge flange, shafting

or drives, wheel or impeller, motor or motor base, or in

any other manner that may bend or distort parts.

Partial or disassembled units require special handling.

All parts should be handled in a fashion which protects the coatings and parts from damage. Components

should be handled such that forces are not concentrated

and bending or distortion cannot occur.

Figure 1. Lifting Lug Locations

Lifting Lugs

Introduction

The purpose of this manual is to provide instructions

that complement good general practices when installing or operating fans manufactured by Twin City Fan &

Blower. It is the responsibility of the purchaser to provide qualified personnel experienced in the installation,

operation, and maintenance of air moving equipment.

Instructions given in the body of this manual are

general in nature and apply to a variety of models

manufactured by Twin City Fan & Blower. Most units

can be installed and maintained with the instructions

given. Additional product and engineering information is

available at www.tcf.com.

Special applications may require additional information.

These instructions are supplied in the form of attached

appendices. Use the instructions in the appendix if the directions in this manual differ from instructions in the appendix.

As always, follow good safety practices when installing, maintaining and operating your air moving equipment. A variety of safety devices are available. It is

the user’s responsibility to determine adequate safety

measures and to obtain the required safety equipment.

Shipping and Receiving

All Twin City Fan & Blower products are carefully constructed and inspected before shipment to insure the

highest standards of quality and performance.

Compare all components with the bill of lading or

packing list to verify that the proper unit was received.

Check each unit for any damage that may have

occurred in transit. Any damage should be reported

Lifting Lugs

Lifting Lugs

Lifting Lugs

©2014 Twin City Fan Companies, Ltd.

Housing should be lifted using straps and spreaders. Do

not distort housing or side plates when lifting.

Bearing pedestals should be lifted using straps or padded chains. Under no circumstances should an attached or

separated bearing pedestal be lifted by the shaft, bearings,

drives, motor or wheel.

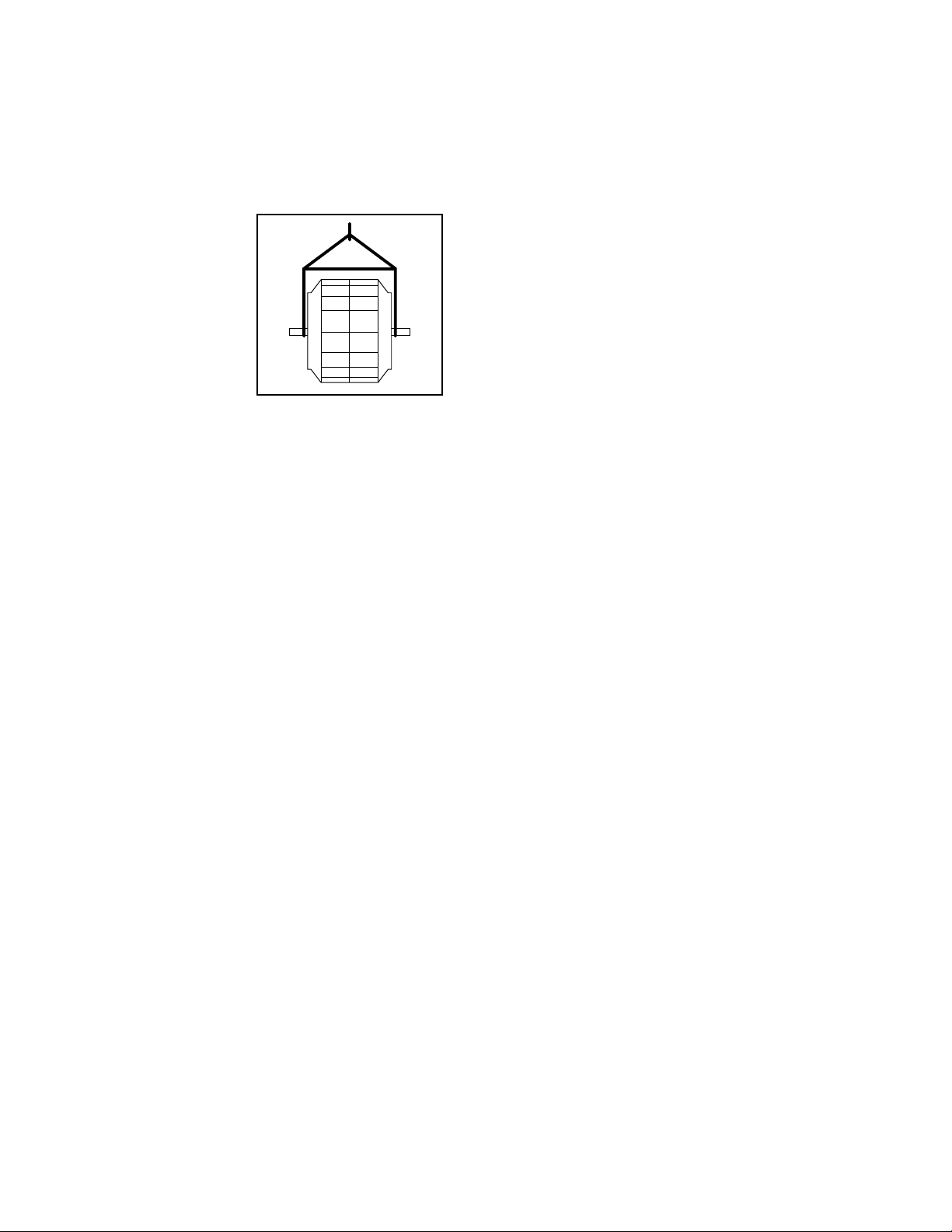

The shaft and wheel assembly may be lifted using

a hoist and a spreader

with a sling around the

shaft at points nearest the

wheel (see Figure 2). Take

care not to scratch the

shaft where the wheel or

bearings will be mounted.

Never lift or support the

assembly by the wheel.

Always support the assembly by the shaft when lifting

or storing. Do not support

the shaft or the wheel on

housing sides. Use only the

key provided with the shaft

and wheel.

Wheels shipped separately can be lifted by slings running through the blades and around the hub. Never lift the

wheel by blades or flanges. Always transport wheels by

lifting. Do not roll the wheel as this can damage coatings

and change the balance of the wheel.

Bent shafting is a source of vibration and bearing failure,

so handle the shaft with care. Any scratches on the shaft

may be removed with fine emery cloth or a stone.

Figure 2. Moving Shaft and

Wheel with Spreader Bar

Short Term Storage

If fan installation is to be delayed, store the unit in a

protected area. Protect the fan and motor bearings from

moisture and vibration (or shock loading).

Long Term Storage

Prior to Storage – Fan bearings (and motor bearings per

the motor manufacturer’s specifications) are to be greased

at the time of going into extended storage. On belt drive

units the belt tension should be reduced to less than half

the specified value for the fan’s design to prevent a sag/

set from forming in the shafts and belts.

If the unit was supplied with a motor, the motor windings

should be measured at this time and recorded for

comparison prior to placing in service. If the fan housing

was supplied with a drain connection, this plug should

be removed to prevent any moisture from accumulating in

this portion of the unit during storage.

Storage Procedure – Fans should be stored indoors whenever possible where control over temperature, shock and

dust is reasonably maintained. If units are to be stored

outside in the elements, they should be covered with a

water-resistant material. The bearings should be shielded

individually from water and dirt; however, do not tightly

seal to avoid trapping condensation. Stored equipment

should be stored on a clean, dry floor or blocked up off

the ground on blocks to prevent unit from setting in any

water or directly on the ground. If shock or vibration will

be present during storage, the unit may need to be placed

on some type of vibration dampening material to aid in

preventing brinelling of the bearing surfaces.

Periodic Check – On a monthly interval, the equipment

should be checked to ensure that it has remained in an

acceptable stored condition. The fan (and motor if supplied) should be rotated several times by hand while adding enough grease to replenish the bearing surfaces with

fresh grease and to maintain a full bearing cavity. Grease

2

used must be compatible with that already supplied in the

motor and fan bearings. The fan impeller should be left

at approximately 180 degrees from that of the previous

month to prevent the shaft and impeller from taking a

set in one position. Storage records should be maintained

which indicate the above requirements have been followed.

Consult the motor manufacturer for proper storage, space

heater connection and lubrication if the unit was supplied

with one.

Start-Up – When the unit is removed from storage, all fan

bearing grease should be purged and replenished with fresh

grease as per the lubrication decal. The motor should be

measured to verify that the resistance is still at a satisfactory level compared to the value recorded prior to storage.

Spherical roller bearings with split pillow block housings

should be recharged with grease. The bottom half of the

housing should be 1/3 full.

Foundations and Supporting Structures

Floor mounted fans should be installed on a flat, level, rigid

concrete foundation with a mass at least three to five times

that of the assembly supported as a guide, depending on

the size and speed of the fan. Foundation shall be suitable

for static and dynamic loads and foundation frequencies

be separated at least 20% from the rotational speed/speed

ranges. The plan area should be no more than twice that

required by the equipment. Foundations with larger areas

should have correspondingly larger mass. Anchor bolts

should be “L” or “T” shaped with sufficient length for nuts,

washers, shims, and threads for draw-down. Each bolt

should be placed in a sleeve or pipe with a diameter larger

than the bolt to allow for adjustment.

If the fans are mounted on a sub-structure, an inertia

base with spring isolator system should be considered.

Fans mounted to or within a structure should be placed

as close as possible to a rigid member such as a wall or

column. The structure must be designed for rotating equipment; static design for strength is not sufficient to insure

proper operation. Supports for suspended fans must be

cross-braced to prevent side sway. Structural resonance

should be at least 20% from fan operating speed. Vibration

isolators should be used where applicable.

Any ducting should have independent support; do not

use the fan to support ducting. Isolating the fan from

ductwork with flex connections eliminates transmission of

vibration. Fans handling hot gases require expansion joints

at both the inlet and discharge to prevent excessive loads

caused by thermal growth.

For fans requiring concrete filled bases or pedestals,

please refer to Twin City Fan's installation and maintenance manual "Heavy Duty Centrifugal Fans - ES-995"

for instructions.

Fan Installation – Factory Assembled Units

Follow proper handling instructions given earlier.

1. Move the fan to the final mounting position.

2. Remove skid, crates, and packing materials carefully.

3. If supplied, place vibration pads or isolation base on

mounting bolts. Line up holes in fan base with bolts.

4. Place fan on mounting structure. Carefully level unit

using shims as required at all mounting hole locations.

Bolt down the unit. Be careful not to force the fan to

conform to the mounting structure/foundation. This may

cause the bearings to become misaligned or pinched

causing vibration and premature failure.

5. Any grout may now be used. Bolt the fan in position

before applying grout. Do not depend upon grout to

support rotating equipment.

6. Continue with Operations Checklist.

Twin City Engineering Supplement ES-52

Additional instructions may be given for some fan models,

Assembled Bearing,

components and accessories in the appendix.

Fan Installation – Disassembled Units

A unit is considered “disassembled” if any component

required for proper operation is shipped or supplied separately or in pieces. Reference earlier instructions concerning

proper handling of fan components.

Instructions for Mounting and Assembly of Unit:

1. Move lower housing/framework to mounting location.

2. If vibration pads or bases are used, place on bolts first.

Place lower housing assembly onto bolts.

3. Level and shim if required. Bolt into place.

4. If separated pedestal or bearing pedestal:

a. Bring bearing pedestal to desired location.

b. Place any vibration base or pads into place. Set

bearing pedestal on bolts.

c. Never distort bearing pedestal by forcing it to align

with a non-level surface. Shim beneath the pedestal

as required.

d. Check bearing centerline height. Change centerline

height to match centerline height of housing. High

temperature units may require the housing centerline

to be lower when cold so that it will be centered

when hot.

e. Measure from housing to bearing pedestal to bring

bearing pedestal into square with housing (a large

square may also suffice).

f. Bolt into position.

5. Shaft and wheel assembly preparation:

a. Clean protective coating off shaft with solvent. Do

not touch clean areas of shaft with hands. Perspiration

can cause rust or pitting over time.

b. Remove keys from shaft.

c. Clean inside of wheel bore with solvent. Make sure

setscrews will not interfere when inserting shaft into

wheel bore.

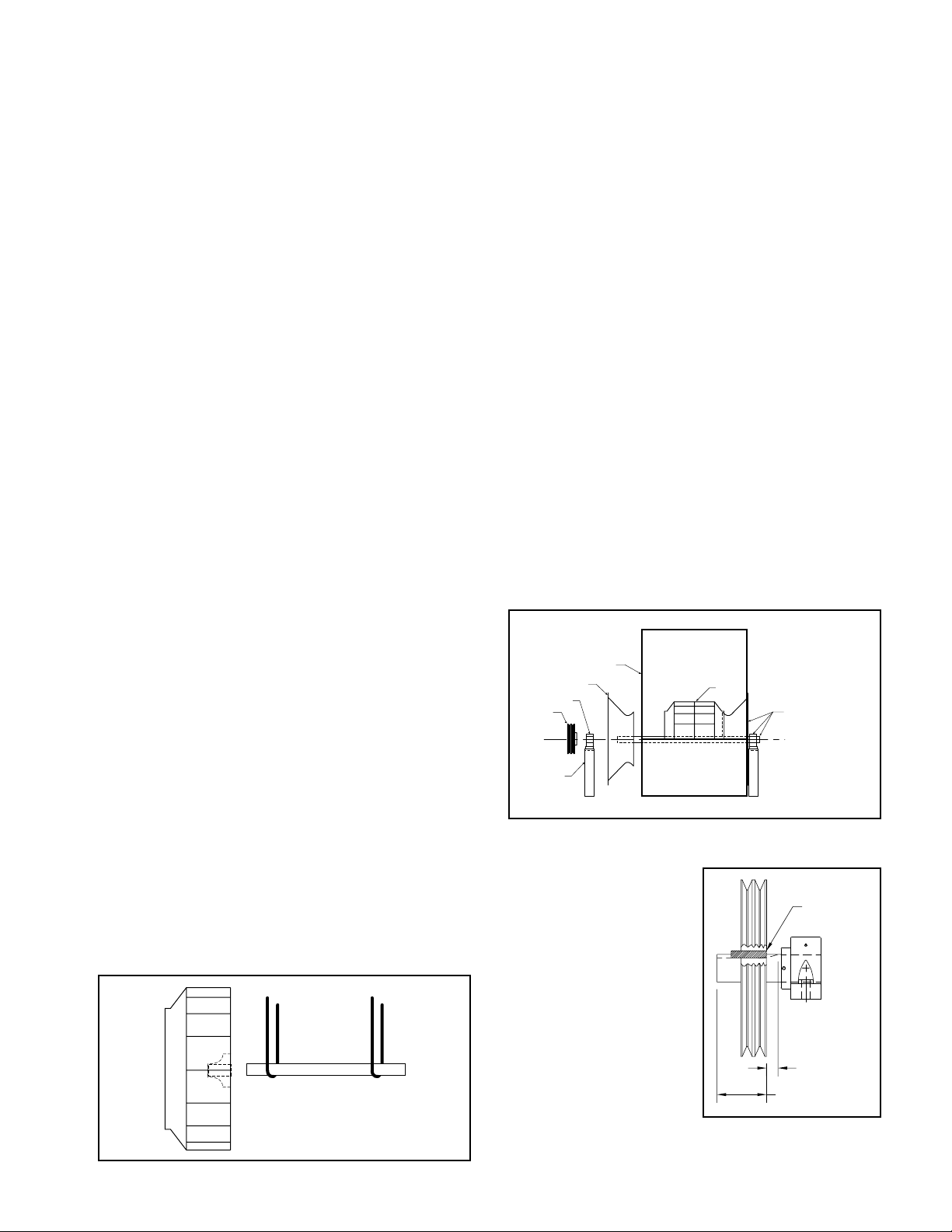

6. Arrangement 1, 9 or 10: Drive Component Assembly

(See Figure 3):

a. Insert shaft into wheel from back side of wheel.

b. When shaft is flush with wheel hub, put key into

keyway and tighten wheel setscrews.

c. Insert shaft through opening in drive side. (If split

housed unit, lower into position.)

d. Install bearings onto shaft. Do not tighten bearing

setscrews at this time. The bearing housing should

be perpendicular and the bearing base parallel to the

axis of the shaft to prevent loads caused by misalignment.

e. Mount assembly, bolt bearings to drive stand. Shaft

Figure 3. Drive Component Assembly

must be parallel with side of bearing pedestal.

Precision shim bearings as required. After aligning

and bolting bearings to pedestal, lock bearings. Be

sure expansion bearing (if supplied) is set to allow

for growth. Continue with step 8.

7. Arrangement 3 (Split-housed) units (See Figure 4):

a. Parts on DWDI units are assembled in the following

order as viewed from opposite drive side: Bearing

bar assembly and opposite bearing, funnel, (housing side), wheel, (housing side), funnel, drive side

bearing bar assembly, drive bearing and sheaves.

Mount bearing bar assembly to housing. Center

wheel in funnels.

b. Parts on SWSI units are assembled in the following

order as viewed from opposite drive side: Bearing

bar assembly and opposite bearing, funnel, (housing

side), wheel, (housing side), drive side bearing bar

assembly, drive bearing and sheaves. Mount bearing

bar assembly to housing. (See Figure 7 for wheel-

funnel overlap.)

c. Assemble parts in above order on shaft.

d. Move assembly into position. Lightly bolt bearings

into place.

e. Shaft should be parallel with discharge of housing.

Move bearings to accommodate.

f. Level shaft; shim bearings if required. Lock bearings.

Be sure expansion bearing (if supplied) is set to allow

for shaft growth.

8. Install motor on base. Carefully align shafts for drive

installation.

Figure 4. Split-housed Drive Component Assembly

Housing Side

Inlet Funnel

Bearing

Sheave

Shaft

Centerline

Bearing

Pedestal

9. Mount drives as follows:

Wheel

Shaft, Funnel, and

Housing. Frame

Angles Not Shown.

Figure 5. Sheave Position

a. Slip (do not pound)

proper sheave

onto corresponding shaft. CAUTION:

SHEAVE LINED

UP WITH END

OF KEYWAY

RUN OUT

PLACING FAN

SHEAVE ON MOTOR

CAN OVERSPEED

WHEEL AND CAUSE

STRUCTURAL

FAILURE.

b. Position sheaves

so they are placed

on motor shaft and

fan shaft as close

as possible to the

RUN OUT OF

KEYWAY

KEYWAY LENGTH

motor and/or bearing. Sheave must be

placed so that it does not rub on the bearing,

motor guard or other structures. On keyed shafts,

Twin City Engineering Supplement ES-52 3

Loading...

Loading...