Twin City ES-409 User Manual

Aero Acoustic Diffuser

™

INSTALLATION, OPERATION & MAINTENANCE MANUAL

ES-409

June 2010

Contents

Introduction ......................................................................... 1

Shipping .............................................................................. 1

Handling .............................................................................. 1

Storage ................................................................................1

Parts List ............................................................................ 1

Aero Acoustic Diffuser™ Installation ................................ 2

Aero Acoustic Diffuser™ Operation Safety ..................... 2

Operation Checklist ............................................................ 3

Maintenance ........................................................................ 3

Troubleshooting Guidelines................................................ 3

Limitation of Warranties and Claims ............................... 3

Introduction

The purpose of this manual is to provide instructions

that complement good general practices when installing

or operating Twin City Fan & Blower’s Aero Acoustic

Diffuser™ originally provided on the E-Series Plenum

Fan or purchased as an accessory after purchasing the

E-Series plenum fan.

Instructions given in the body of this manual are

general in nature, but apply to only to the E-Series

plenum fan manufactured by Twin City Fan & Blower.

Shipping and Receiving

All Twin City Fan & Blower products are carefully constructed and inspected before shipment to insure the

highest standards of quality and performance.

Compare all the components with the bill of lading

or packing list to verify the proper unit was received.

Check each unit for any damage that may have

occurred in transit. Any damage should be reported

immediately to the carrier and the necessary damage

report filed.

Handling

Handling of all air moving equipment should be conducted by trained personnel and be consistent with safe

handling practices. Verify the lift capacity and operating

condition of handling equipment. Maintain handling

equipment to avoid serious personal injury.

Units shipped completely assembled, mounted to the

fan, require minimal handling. Use only designated lifting

lugs on fan framework for handling the fan.

Partial or disassembled units require special handling.

All parts should be handled in a fashion that protects

the parts from damage. Components should be handled

such that forces are not concentrated and bending or

distortion cannot occur.

Aero Acoustic Diffusers™ should be lifted using

straps or padded chains if necessary. Do not distort the

components when lifting. Deformed components are a

source of interference between the fan impeller and the

Aero Acoustic Diffuser™ resulting in excessive noise and

possibly fan impeller imbalance.

Storage

If the Aero Acoustic Diffuser™ installation is to be

delayed, store the unit in an indoor, protected area.

Protect the Aero Acoustic Diffuser™ from moisture and

possible incidental contact. A temperature controlled

storage facility is preferred.

Parts List

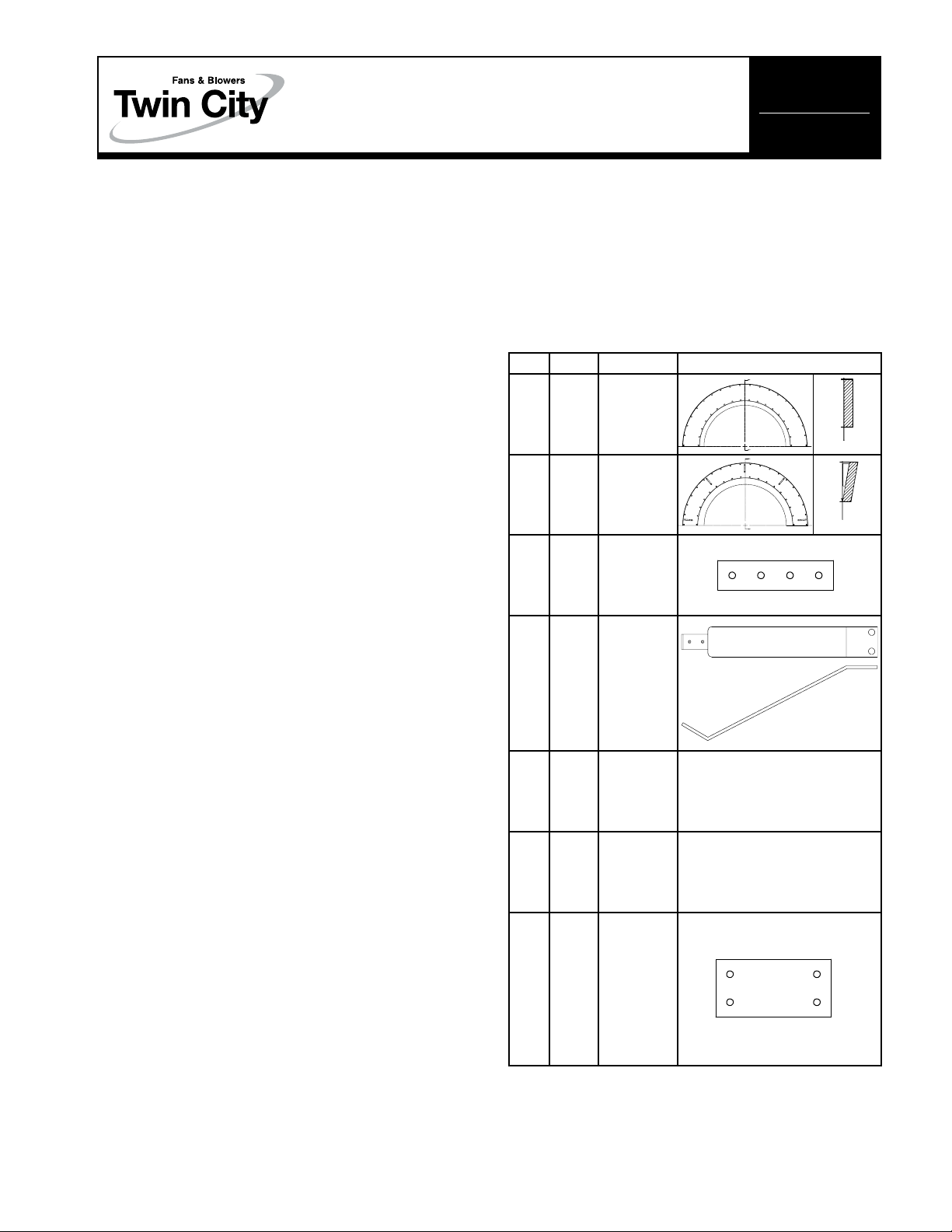

Item Qty Part Name Sketch

Backplate

4

(Only

re-

for

Sizes

807)

Diffuser

(Two (2)

Halves)

Frontplate

Diffuser

(Two (2)

Halves)

Diffuser

End

Connector

Diffuser

Mounting

Brackets

1

/4"-20

Self Tap

Screws

3

/8"-16

Bolt & Nut

Diffuser

Side

Connector

1 1

2 1

3 4

4 8

5 48

6 16

quired

7

300 to

A

A

A

A

N/A

N/A

SECTION A-A

SECTION A-A

©2010 Twin City Fan Companies, Ltd.

Aero Acoustic Diffuser™ Installation

Follow the proper handling instructions given earlier. If

mounting slots are not supplied, proceed to Step 1; if

mounting slots are supplied on fan, proceed to Step 3:

1. Using the formulas below, calculate mounting hole

locations. (See Figure 1):

“A” = Measured in the field. (Distance from inside

frame to impeller backplate)

“B” = Measured in the field. (Distance from impeller

backplate to impeller frontplate)

“C” = “A”–1.40

“D” = “A”+“B”+“F”

“E” = See Table 1

“F” = See Table 1

2. Measure, mark and drill mounting bracket holes as

shown (See Figure 1). Note: Holes are required on

both sides of fan on the top and bottom frame rails

for sixteen (16) holes. Lifting lugs may need to be

removed.

Table 1.

Size E F

122 0.89 0.03

150 0.89 0.00

165 0.89 0.00

182 0.93 0.16

200 0.93 0.13

222 1.13 0.13

245 1.13 0.19

270 1.13 0.16

300 1.13 0.16

330 1.13 0.16

Size E F

365 1.19 0.15

402 1.19 0.16

445 1.19 0.15

490 1.19 0.15

542 1.19 0.12

600 1.19 0.46

660 1.19 0.58

730 1.19 0.41

807 1.19 0.31

4. Insert each diffuser section into the fan frame. As

shown in Figure 3. The backplate diffuser mounts on

backplate side of impeller; the frontplate diffuser

mounts on the frontplate side of impeller. Note:

Perforated side of diffuser sections must be in the air

path (see Figure 3).

Figure 3.

PERF PLATE TO BE FLUSH

BACKPLATE

DIFFUSER

WITH END OF BACKPLATE

ON WHEEL

FRONTPLATE

DIFFUSER,

LOCATE AS

CLOSE TO

FRONTPLATE

TIP AS

POSSIBLE

5. With the four (4) diffuser sections located inside the

fan framework, use the screws and connector brackets removed in Step 3 to reassemble the two (2)

diffuser halves back together as shown in Figure 4.

Figure 4.

Figure 1.

D

B

1.25

TYP.

(16) 0.56 SLOTS

(8) ONE EACH SIDE

C

E

A

3. If not done so, separate backplate diffuser and frontplate diffuser into two (2) halves by removing connector brackets provided. Four (4) diffuser pieces will

result. (See Figure 2)

Figure 2.

Figure 5.

2

Twin City Engineering Supplement 409

Loading...

Loading...