Twin City ES-404 User Manual

Type 'E' Adjustable Pitch Propeller

INSTALLATION, OPERATION & MAINTENANCE MANUAL

ES-404

June 2004

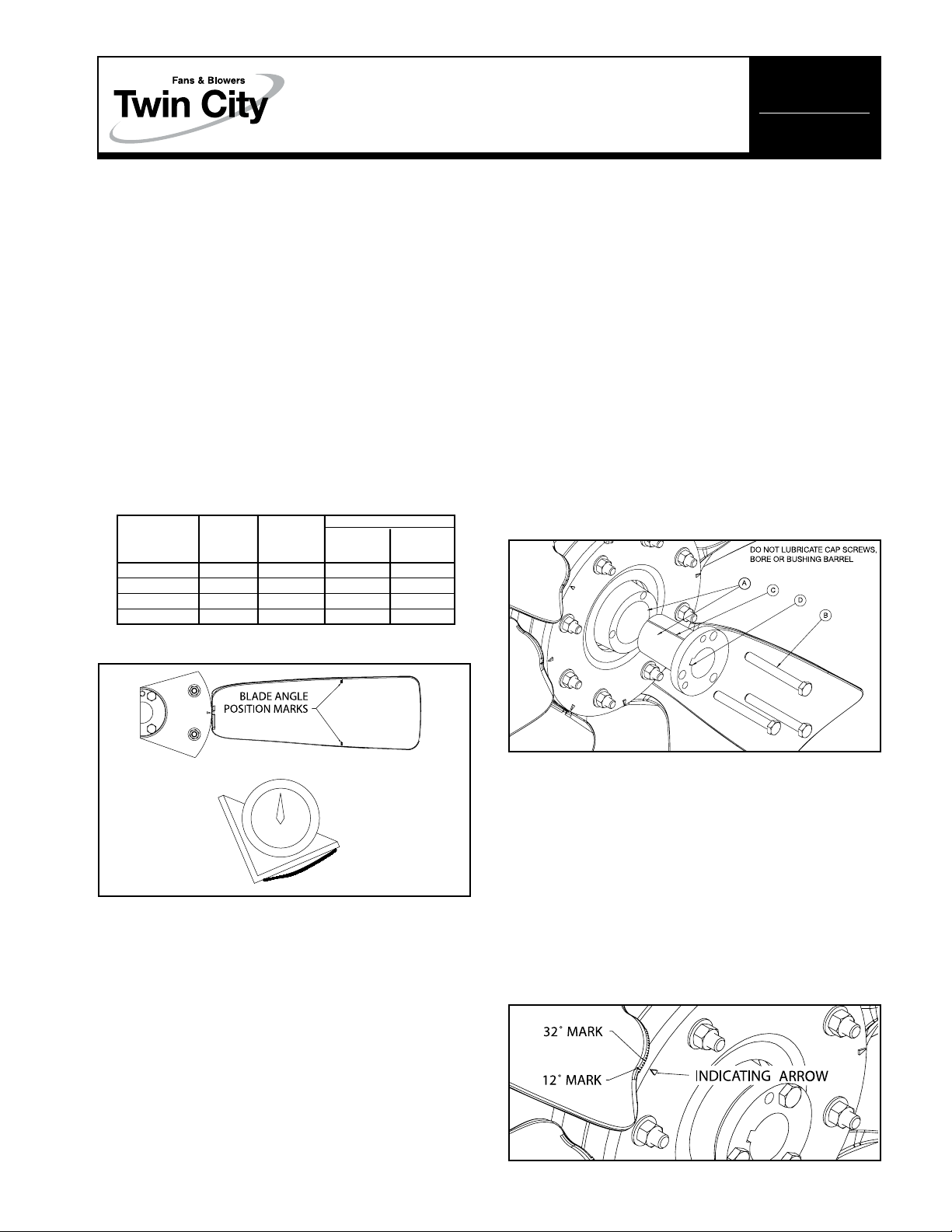

Blade Angle Adjustment

Blades are set to the specified blade angle at the factory. If adjustment in the field is required, use one of

the following two methods:

Preferred Method (more accurate)

1. Lay the hub on a horizontal surface with the concave

(air leaving) surfaces of the blades facing upwards.

2. Loosen the blade retaining bolts until they are fingertight. At this point, the blades should rotate in their

sockets when grasped firmly and twisted, but not turn

on their own.

3. Place an angle meter across the two blade angle

position marks on a blade. See Figure 1.

4. Twist the blade to the desired blade angle.

5. Repeat steps 3 and 4 for the remaining blades.

6. Re-tighten the blade retaining bolts to the torque

shown in Table 1. Work in a star pattern, working

your way up to the desired torque in steps. Tightening

one bolt to the full torque before moving on to the

next can crack the hub.

Table 1.

TORQUE (ft. lbs.)

FAN HUB

SIZE DIA.

14 - 24 6" H 17 7.5

30 - 36 9" P 30 13

42 - 48 12" P 75 13

42 - 48 12" Q 75 24

BUSHING BLADE BUSHING

BOLT BOLT

Mounting the Propeller Assembly

on the Shaft

Type ‘E’ propellers are furnished with hubs that have a

tapered bore. A split-tapered bushing is used for mounting the propeller assembly to the shaft. When properly

assembled, the bushing grips the hub and the shaft with

a positive clamping action. See Figure 3 below.

A. The bushing barrel and the bore of the propeller hub

are tapered. This assures concentric mounting and a

true running propeller.

B. The cap screws, when tightened, lock the bushing in

the propeller.

C. The bushing is split so that when the locking cap

screws force the bushing into the tapered bore, the

bushing grips the shaft with a positive clamping fit.

This will withstand vibration and punishing loads

without loosening.

D. The propeller and bushing assembly is keyed to the

shaft and held in place by compression. This gives

added driving strength.

Figure 3.

Figure 1.

Alternate Method

1. Loosen the blade retaining bolts until they are fingertight. At this point, the blades should rotate in their

sockets when grasped firmly and twisted, but not turn

on their own.

2. Angle setting marks on the blade line up with an

indicating arrow on the hub. There are two long marks

on the blade, one for 12° blade angle and another

for 32°. Shorter indicating marks at 5° increments are

in between the two longer marks. See Figure 2 to the

right.

3. Twist each blade to the desired blade angle.

4. Re-tighten the blade retaining bolts to the torque

shown in Table 1. Work in a star pattern, working

your way up to the desired torque in steps. Tightening

one bolt to the full torque before moving on to the

next can crack the hub.

©2004 Twin City Fan Companies, Ltd.

Put the bushing loosely into the propeller. Do not press

or drive. Start the cap screws by hand, turning them

just enough to engage the threads in the tapped holes

on the propeller. Do not use a wrench at this time. The

bushing should be loose enough in the propeller to

move slightly. Be sure the shaft and keyway are clean

and smooth. Check the key size with both the shaft and

bushing keyways. Slide the propeller and bushing

assembly onto the shaft, making allowance for endplay

in the shaft to prevent rubbing. Do not force the propeller and bushing onto the shaft. If it does not go on

easily, check the shaft, bushing, and key sizes.

Figure 2.

Tighten the caps screws progressively with a wrench.

Do this evenly as in mounting an automobile wheel.

Take a part turn on each cap screw successively until

all are tightened to the torque shown in Table 1.

These cap screws force the tapered bushing into the

hub, which in turn compresses the bushing on to the

shaft.

WARNING: Do not attempt to pull the bushing flange

flush with the hub end. There should be 1/8" to 1/4"

clearance when tightened.

Removing the Propeller Assembly

from the Shaft

The propeller is easily removed from the shaft by inserting and tightening two of the cap screws into the

tapped holes in the bushing flange. This forces the

bushing loose from the propeller and releases the compression so that the entire assembly will slide off the

shaft.

1. Remove all the cap screws from the propeller and

hub assembly.

2. Start the cap screws into the threaded holes in the

bushing flange.

3. Tighten each bolt part of a turn successively to force

the propeller off the bushing.

4. Pull the bushing off the shaft. If the assembly has

been in place for some time, it may be necessary to

use a wheel puller to remove the bushing. Never use

a wheel puller on the propeller.

Twin ciTy fan & blower | www.Tcf.com

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601

5MPP06/04

Loading...

Loading...