Page 1

Protective Coatings

& Paints Guide

ES-35

February 2010

The application of special finishes for the prevention of

corrosion, abrasion, and erosion has been the subject

of study in the air handling industry for quite some time.

As might be expected, some materials or finishes are

more resistant to corrosion than others, but no finish or

coating is completely immune from corrosion in all

respects. Therefore, corrosion resistance is of degree

only, based upon the choice of material made for any

particular problem. The data published in this bulletin is

based on the recommendations and claims put forward

by the manufacturers of such paints or coatings. While

we cannot be responsible for the accuracy of this data,

it should serve as a useful guide in selecting special

paints and/or coatings for handling corrosive atmospheres. Twin City Fan & Blower does not, however,

assume any liability for the effectiveness of these coatings, since they are rated in accordance with their

manufacturers’ claims only.

The rate of corrosion on any application depends to

a large extent on the concentrations of fumes, their

temperature, and the extent of moisture associated with

them. These parameters make it extremely difficult to

define corrosion resistance of any one coating by a

single rating as shown by a letter in our guide. Plant

engineers, with their experience on specific applications,

are in a better position to suggest the best coating for

their requirements. We suggest you refer to them when

possible for such advice.

Some restrictions on fans to be coated are deserving

of mention. Naturally, bearings cannot be placed in the

airstream. The use of variable intake vanes and outlet

dampers is not recommended, since it is almost impossible to properly protect some of their component parts

such as linkages, bearings, etc. Shaft seals of a variety

of types are available and should be used. Special

types of seals may be required in some instances; refer

to factory. Drains, especially in handling moist atmospheres, are a necessity. With these points in mind, the

corrosion resisting paint or finish can be applied either

to the complete airstream of the fan, or to the entire

fan, both inside and out.

Coatings and Their Characteristics

For all special paints or coatings and their applications

with variation in fan design, construction, and metal

preparation, AMCA recommended practice No. 2601-66

is carefully followed. For special paints, fans are phosphatized and washed followed by a prime coat and one

or more finish coats depending upon the application

and its requirement. In some cases, and as indicated,

sandblasting of the parts to be coated is necessary,

followed by the necessary coats of corrosive finish to

the thickness specified in the chart.

©2010 Twin City Fan Companies, Ltd.

Page 2

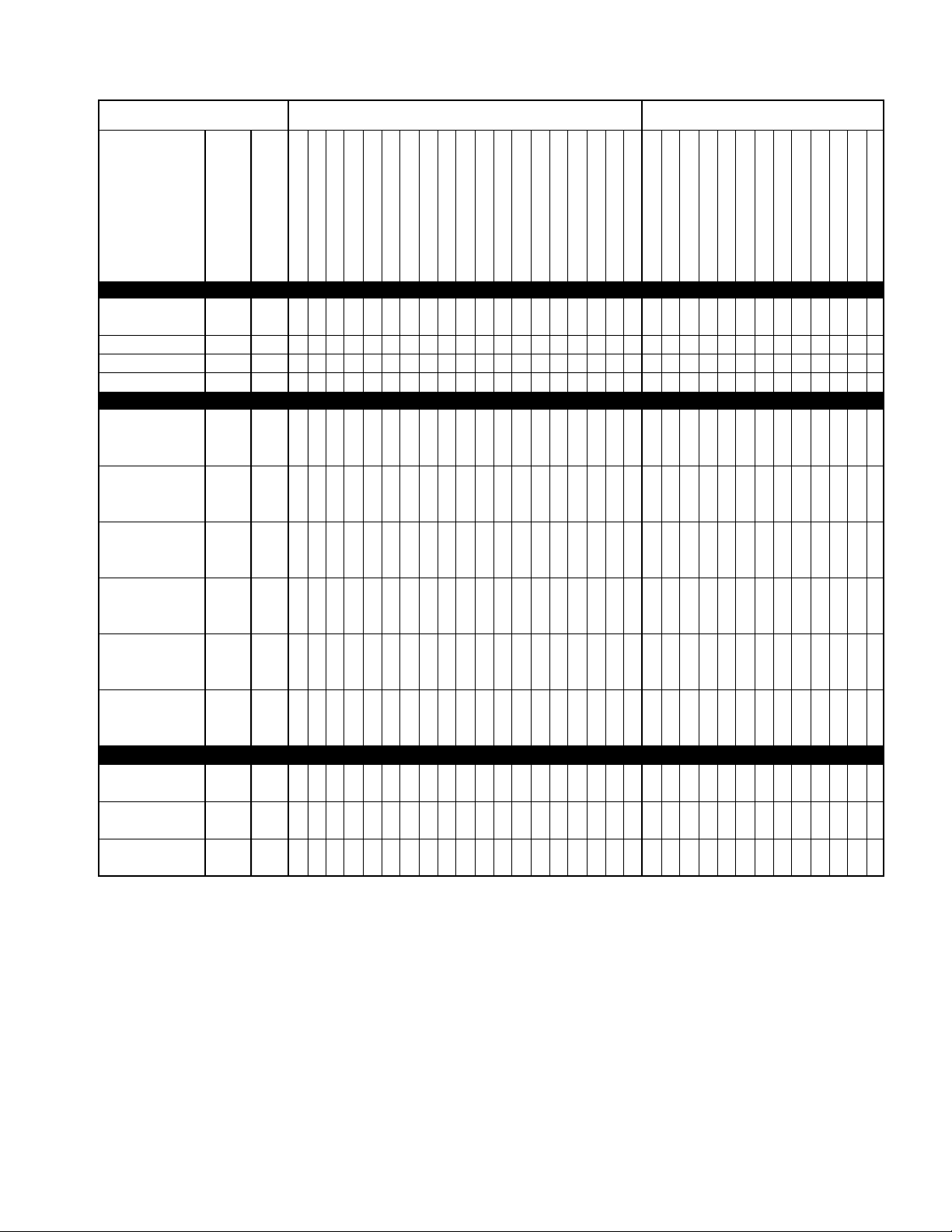

Selection Chart

CORROSIVE REAGENT ACIDS

ALKALINE SALTS, ALKALIES, ETC.

CORROSION

RESISTANT:

• METALS

• PAINTS

• COATINGS

NUMBER OF COATS MAX OPERATING TEMP.

METALS

LOW CARBON

STEEL

ALUMINUM — 250

304 S.S. — 1000

316 S.S. — 1000

PAINTS — TCF&B STANDARD SURFACE PREPARATION

ASPHALTUM

(Not Recom-

2 200

mended

For Fans)

VINYL (PVC) 2 150

ZINC 2 350

EPOXY 2 200

POLYESTER

SYNTHETIC 2 200

RESIN

AIR-DRIED

PHENOLIC

COATINGS — SURFACE PREPARATION INCLUDES STEELBLASTING

EPOXY

PHENOLIC

BAKED EPOXY

PHENOLIC

BAKED EPOXY

4 150

— 600

2 350

4 to 5

400

2 to 4

(°F)**

ASCETIC

BORIC

CARBOLIC

CARBONIC

CHROMIC

CITRIC

FLUOROBIC

FORMIC

HYDROBROMIC

HYDROCHLORIC

HYDROFLUORIC

HYDROCHLOROUS

LACTIC

NITRIC

PERCHLORIC

U F F F F U X U U U U U U U U U X U U

G G G G F G U U U U U U G U F U E U G

G E F G G G C G U U U U F E G G E U F

E E F E E E X G E U U U G E E E E F G

F E F F F G X F X G F F F F U F F F X

F G U G G G G G X G F X G G F G X F G

U E U E U U U X U U X X U U U U X U U

G G G E F G X G X G G F G G F G U G G

E E U E G G X G G E U E E E U E E G G

G G G G U G G E U G U X E G F G X G G

G E G E U G X E X G G F E F U G X U G

E E E E F E X E U E U F E F G E X E E

400

E E E E G E X E U E E G E X G E X G E

PHOSPHORIC

PICRIC

SULPHURIC ACID

ACID SALTS, NEUTRAL SALTS

SULPHUROUS ACID

ALUMINUM CHLORIDE

ALUMINUM NITRATE

ALUMINUM SULPHATE

AMMONIUM CHLORIDE

AMMONIUM HYDROXIDE

AMMONIUM NITRATE

AMMONIUM SULPHATE

BRINE

BROMINE

CALCIUM CHLORIDE

U U U U E F U X U F X F F

F G F F E E F G U G E F E

F E F F E E U E U F E E E

F E G E E E F E U F E E G

G F G F E E G X U E E E F

G F G G G E G X U E E E G

X X E G G E G X U G X G E

G X G G G E G G X F E E G

E E E G E X E E X E E E U

G F G G U G F G U G G E G

E X E G F E G G U E E E E

E G E F E G E E U E E E E

E X E E E E E E U E E E E

CALCIUM CARBONATE

CALCIUM HYDROIXIDE

CALCIUM DISULPHIDE

Please refer to page 4 for descriptions.

*

** Max. operating temperature indicates coating failure, not color change. Chalking or discoloration may below this temperature.

SELECTION INSTRUCTIONS

Coatings with E or G ratings should be selected, if possible, for best results throughout.

E = Satisfactory from 15% to 85% (depending upon coating) of concentration of fumes and for continuous operation. Also suitable for splash or

condensation.

G = Good for up to 5% to 15% of concentration of fumes. Not recommended for applications involving splash or condensation.

F = Fair. Recommended for low (maximum 5%) concentration application. Should not be specified unless detailed application is available.

U = Unsatisfactory and hence not recommended.

X = Sufficient data not available at present. User comments would be appreciated.

2

Twin City Engineering Supplement ES-35

Page 3

CORROSIVE REAGENT

CORROSION

RESISTANT:

• METALS

• PAINTS

• COATINGS

NUMBER OF COATS

METALS

LOW CARBON

STEEL

ALUMINUM — 250

304 S.S. — 1000

316 S.S. — 1000

PAINTS — TCF&B STANDARD SURFACE PREPARATION

ASPHALTUM

(Not Recom-

2 200

mended

For Fans)

VINYL (PVC) 2 150

ZINC 2 350

EPOXY 2 200

POLYESTER

SYNTHETIC 2 200

RESIN

AIR-DRIED

PHENOLIC

COATINGS — SURFACE PREPARATION INCLUDES STEELBLASTING

EPOXY

PHENOLIC

BAKED EPOXY

PHENOLIC

BAKED EPOXY

4 150

4 to 5

2 to 4

MAX OPERATING TEMP.

— 600

2 350

400

400

ACID SALTS, NEUTRAL SALTS,

ALKALINE SALTS, ALKALIES, ETC.

(°F)**

COPPER SULPHATE

FERRIC CHLORIDE

HYDROGEN PEROXIDE

POTASSIUM CYANIDE

POTASSIUM HYDROXIDE

POTASSIUM DICHROMATE

SODIUM BICARBONATE

SODIUM CHLORIDE

SODIUM DICHROMATE

U U U X G G X G G E X X F E X G E

U U E U U E E G X U G U E E E E E

E U E E E E E G X E F U E E X E E

E F E E E E E E X E G G E E X E X

G G F X E G E E E F F X G U X U G

G G F X E F E E X G F X X F X G U

E E X X U E X E E G U X U E X E G

G G G X G F G E X G F X G G X G G

E E G X E X E E X G G E E U E E U

E E U G F G E E U U U G G G G G U

E E U X U G E E X G U X E E X E E

E E U E U E E E F U U G E E E E E

E E G X G E E E X G G X E E X E G

SOIDUM HYDROXIDE

SODIUM HYPOCHLORITE

ZINC CHLORIDE

HYDRO-

CARBONS

ZINC SULPHATE

BENZENE

BUTAINE

GASES & FUMES MISCELLANEOUS

GASOLINE

XYLOL/TOLUOL

STEAM VAPOR - SAT.

AMONIA GAS - DRY

AMMONIA - WET

CHLORINE - DRY

HYDROGEN SULPHIDE

SULPHUR DIOXIDE

ABRASION

MOISTURE

SALT SPRAY

ACETONE

ALCOHOL

FORMALDEHYDE

G X X F U F F G U E E F E G X F

E E E U F G E E U E G E E E X F

E E E U F F E E F E E E E E X E

E E E F E G U E G E E E E G X G

G G X G G X U E E U F F F E X X

G F X G G X U E E U F G U E X U

X X X X U U G E E E E E E X X U

G X F G G X U E E G G G G E E G

E E X E G G G E E U E X U U X U

U U U G G G G E G G G G G F U G

E G X G E U G E E G E E U G X U

E U U E E E G E E E E E E E G E

E X X E E U G E E E E E G X X U

METHYL ETHYL KETONE

MINEARAL OILS

POLYVINYL ACETATE

TRI CHLORETHYLENE

Please refer to page 4 for descriptions.

*

** Max. operating temperature indicates coating failure, not color change. Chalking or discoloration may below this temperature.

SELECTION INSTRUCTIONS

Coatings with E or G ratings should be selected, if possible, for best results throughout.

E = Satisfactory from 15% to 85% (depending upon coating) of concentration of fumes and for continuous operation. Also suitable for splash or

condensation.

G = Good for up to 5% to 15% of concentration of fumes. Not recommended for applications involving splash or condensation.

F = Fair. Recommended for low (maximum 5%) concentration application. Should not be specified unless detailed application is available.

U = Unsatisfactory and hence not recommended.

X = Sufficient data not available at present. User comments would be appreciated.

3

Twin City Engineering Supplement ES-35

Page 4

Description of Coating Materials

Offers excellent moisture resistance. Fair protection against very mild concentrations of most organic and inorganic

acids. Exhibits poor caustic and solvent resistance. Due to poor coating and drying time characteristics, Twin City

Fan & Blower DOES NOT recommend the use of asphaltum coating for fans.

Enamel offers a quick dry time, high gloss, and good color and gloss retention. For long term corrosion protection,

a primer is recommended.

Epoxy / Epoxy Phenolic Coatings

Offers longer service life than conventional paint against mild acid of caustic solvent. Their resistant characteristics

are similar to phenolic. Four different epoxy systems are shown in the chart.

Excellent chemical resistance to splash/spillage, fumes, high humidity and moisture. Self-priming and suitable over

most existing coatings and tightly adherent to rust.

Flouropolymer Resin (PVDF) Coatings

Thermoplastic coatings used as excellent corrosion barriers. They are specified because of their unique properties:

unaffected by sunlight, most chemicals and solvents, abrasion resistance, mechanical strength and toughness.

Heat-resistant coating with good corrosion resistance and thermal stability for temperature over 500°F.

These are widely used as a fan coatings for a variety of applications. Good resistance to high concentrations of

organic or inorganic acids with the exception of strong oxidizing agents, i.e., nitric and chromic. Resistant to only

low concentrated alkalis, but excellent solvent resistance. It is not recommended for hydrofluoric acid or hypochlorite

salts. Air dried phenolic will have shorter life than baked phenolic. Heresite baked phenolic is most effective while

handling dust and explosive gases.

Asphaltum Coating

Enamel Coatings

Epoxy Mastic Coatings

High Temp Aluminum Coatings

Phenolic Coatings

TGIC powder coating offers good exterior durability, mineral acid resistance and hard films. Good humidity and salt

resistance.

Low cost and adequate resistance to severe acidic and alkaline conditions makes this coating popular. Widely used

for evaporative cooling and other air conditioning equipment.

PFA has excellent release properties, low coefficient of friction, withstands temperatures of up to 500°F, and it is a

melt flow nonporous film that offers excellent corrosion protection. PFA is an excellent choice for a wide variety of

uses, especially those involving chemical resistance.

All vinyls listed in the chart are thermoplastic material. Generally resistant to most organic and inorganic acids with

fair concentrations and low temperature.

Hot-dipped galvanizing of large fans is not physically practical. Cold zinc coating applied as a spray is said to have

better corrosion resistance than hot-dip galvanizing, and offers high impact resistance.

UPON REQUEST FROM TWIN CITY FAN & BLOWER

Color-match Enamel

Teflon (PFA)

Kynor/Dykor (PVDF)

Powder Polyester

Polyester Powder Coatings

Polyester Synthetic Resin Coatings

PFA Flouropolymer Coatings

Vinyl Coating

Zinc Coatings

OTHER COATINGS AVAILABLE

Twin ciTy fan & blower | www.Tcf.com

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601

Loading...

Loading...