Page 1

Fans with CE Mark

INSTALLATION, OPERATION & MAINTENANCE MANUAL

ES-2-06

March 2013

Contents

Introduction .........................................................................1

Personal Protection ............................................................1

Hazardous Materials........................................................... 1

Installation

Shipping and Receiving ................................................1

Handling .........................................................................2

Unit Storage ................................................................... 2

Foundations and Supporting Structures

- Industrial Fans .......................................................2

Fan Installation - Factory Assembled Units ............... 3

Fan Installation - Disassembled Units ........................4

Bearing Installation ........................................................ 5

Grouting .......................................................................... 8

Drive Mounting .............................................................. 8

Flexible Couplings ......................................................... 8

Duct Connections ..........................................................8

Guards and Enclosures ................................................8

Electrical Supply and Controls .................................... 9

Maintenance

Motor Maintenance ....................................................... 9

Drive Maintenance ....................................................... 10

Bearing Maintenance ................................................... 10

Wheel and Shaft Maintenance ...................................10

Structural Maintenance ............................................... 10

Fan Operation

Proper Use and Application....................................... 10

Sound ........................................................................... 11

Operation Checklist .....................................................12

Optional Accessories ................................................... 12

Troubleshooting Guidelines ......................................... 12

Disposal ........................................................................ 13

Appendix A - Commercial Ventilator Installation

Instructions ................................................................... 13

Appendix B - Axial Fans ................................................ 14

Introduction

This bulletin has been prepared to guide the users of

fans in the proper installation, operation and maintenance procedures to insure maximum equipment life with

trouble-free operation. Personnel operating or maintaining

this equipment shall be trained in the proper procedures

for doing so.

Since many fans of this type have custom features or

components, please refer to the attached documentation

and appendices for additional information. When manufacturers of components provide detailed installation and

operation manuals, they will be provided. Because of the

wide variety of equipment covered in this bulletin, the

instructions given here are general in nature.

For safe installation, startup and operational life of

this equipment, it is important that all involved with the

equipment be well versed in proper fan safety practices

and read this bulletin. Please review the safety section

before beginning any work. It is the user’s responsibility to make sure that all requirements of good safety

practices and any applicable safety codes are strictly

adhered to. Only properly trained personnel should operate and maintain this equipment.

©2013 Twin City Fan Companies, Ltd.

Personal Protection

For safety reasons maintenance personnel should wear

personal protection equipment when attempting to maintain fans. People with long hair are advised to tuck hair

back possibly into a cap.

Personal protection equipment should include the

following:

• Safety glasses or goggles approved by local safety

authority

• Protective shoes with steel toecaps and oil resistant soles

• Heavy gloves that can cope with sharp edges or

exposure to hazardous chemicals. This is especially

important when hazardous residues are present in

fans.

• Breathing apparatus if toxic gases or vapors are

expected to be present.

• Close fitting clothing

Do not wear:

• Rings

• Bracelets

• Necklaces

• Loose items of clothing

It is the responsibility of the maintenance personnel

to determine that the lighting is sufficient for the work

being performed. Additional portable lighting may be

required as there are no lighting fixtures supplied with

the fans.

Hazardous Materials

Twin City Fan Companies, Ltd. is not always made

aware of the materials that may be handled with a fan

and therefore can not warn the user of these hazards.

Because of this, the end user must identify the material hazards present and indicate this on the fan with

a warning label. If there is risk of residual hazardous

material being left in a fan if the gas or vapor being

handled can accumulate as a deposit, all maintenance

and operation personnel must be trained to handle such

hazards before having access to the fan.

Lubricants used on fan components could be hazardous if they contact someone’s eyes or are consumed.

For additional general safety practices for air moving

equipment, see AMCA Bulletin 410.

Installation

Shipping and Receiving

All Twin City Fan Companies, Ltd. products are carefully

constructed and inspected before shipment to insure the

highest standards of quality and performance. Compare

all components with the bill of lading or packing list to

verify that the proper unit was received. Check each unit

for any damage that may have occurred in transit. Any

damage should be reported immediately to the carrier and

the necessary damage report filed.

Page 2

Handling

Handling of all air moving equipment should be conducted by trained personnel and be consistent with safe

handling practices. Verify the lift capacity and operating condition of handling equipment. Maintain handling

equipment to avoid serious personal injury.

On most units, lifting lugs are fashioned to protect

the fan and fan housing from damage. Secure lifting

equipment to all provided lifting lugs to avoid instability

while moving the equipment. Units shipped completely

assembled may be lifted with slings and spreader bars.

(Use well-padded chains, cables or nylon straps.) Never

lift a fan by the inlet or discharge flange, shafting or

drives, wheel or impeller, motor or motor base, or in any

other manner that may bend or distort parts. Never lift

with slings or timbers passed through the fan inlets.

Figure 1. Lifting Lug Locations

Lifting Lugs

Lifting Lugs

Partial or disassembled units require special handling. All

parts should be handled in a fashion which protects the

coatings and parts from damage. Components should be

handled such that forces are not concentrated to avoid

bending or distortion.

The housing should be lifted using straps and spreaders. Do not distort housing or side plates when lifting.

Bearing pedestals should be lifted using straps or

padded chains. Under no circumstance should an

attached or separated bearing pedestal be lifted by the

shaft, bearings, drives, motor or wheel.

The shaft and wheel assembly may be lifted using

a hoist and a spreader with a sling around the shaft

at points nearest the wheel. Use the spreader bar to

ensure that the slings do not push against the sides of

the wheel as this may distort the wheel. Take care not

to scratch the shaft where the wheel or bearings will

be mounted. Never lift or support the assembly by the

wheel. Always support the assembly by the shaft when

lifting or storing. Do not support the shaft or the wheel

on the housing sides.

Wheels shipped separately can be lifted by slings running between the blades or around the hub. Never lift

the wheel by blades or flanges. Always transport wheels

by lifting. Do not roll the wheel as this can damage

coatings and change the balance of the wheel.

Bent shafting is a source of vibration and bearing

failure, so handle the shaft with care. Any scratches on

the shaft may be removed with fine emery cloth or a

stone.

For roof ventilators, also see instructions specific to

handling roof ventilators in Appendix A.

Pins to hold insulation to the housing are supplied

for some high temperature fan designs. Use caution

when handling and working around fans that have these

insulation pins as the points are sharp.

Unit Storage

If fan installation is to be delayed, store the unit in

an environmentally stable and protected area. Vibration

should not exceed 0.051 mm peak – peak displacement

at the storage site unless the fan is properly isolated

from the vibration. The unit should be reasonably protected from any accidental impacts. Cover the fan to

protect coatings and to prevent any foreign material or

moisture from entering the inlet or discharge. Take care

to protect the motor, drives and bearings. The following

precautions should be taken during extended storage to

ensure the equipment is not damaged:

• Extended storage requires monthly inspections.

Check for corrosion or damage to the unit and for

debris within the fan.

• Bearings tend to take on moisture if the atmosphere they are stored in is not at a constant

temperature. To avoid corrosion, it is necessary to

keep the bearings full of grease and to rotate them

periodically. Even when full of grease, bearings will

take on moisture, so it is necessary to purge the

bearings with new grease to expel moisture every

thirty days. It is recommended that the bearings be

purged with grease while being rotated by hand.

Do not use high-pressure greasers as they may

ruin the bearing seals.

• The drives and belts should be removed if the fan

is to be stored for a prolonged period. The drives

should be labeled for service and stored in a dry

place. Belts should be removed, coiled without

kinks, placed in a heavy carton, and stored in a

dry, well-ventilated place. To prevent belt deterioration storage conditions should not exceed 85°F

and 70% humidity. If belts show signs of deterioration, they should be replaced prior to startup.

• Motors should be stored in a clean, dry, vibrationfree location. The packaging should be opened up

enough to allow air circulation around the motor.

The winding temperature should be kept slightly

above that of the surroundings to prevent condensation. This can be accomplished by energizing

the internal heaters, if the motor is so equipped,

or by using space heaters. If it is impossible to

heat the windings, the motor should be wrapped

tightly with a waterproof material that also encloses

several bags of desiccant. Replace the desiccant

regularly to prevent moisture problems. The motor

rotor should also be rotated regularly (monthly) to

assure the bearing parts are well greased.

Foundations and Supporting Structures

— Industrial Fans

The best means of floor mounting a fan is on a welldesigned, flat, level concrete foundation. The foundation

should have a mass of at least three times that of

the supported assembly. The foundation should extend

150mm beyond the outer dimensions of the fan and

driver; however, it should be no more than twice the

area required for the equipment. If it is made larger, the

mass should be increased accordingly to resist rocking

modes of vibration. J or T type anchor bolts using one

size smaller than the nominal dimension of the base hole

shall be used. Anchor bolts should be tied into the reinforcing bar of the foundation for the foundation. A pipe

2 Twin City Fan Engineering Supplement 2-06

Page 3

sleeve with a diameter of 2 to 21⁄2 times the anchor

bolt diameter should be provided around the anchor bolt

for final adjustment (see Figure 2). The mounting surface of the foundation should be smooth for good shim

contact. When deciding the thickness of the foundation,

approximately 25 to 40mm height should be allowed for

shimming, grouting, leveling, washers, nuts, etc.

The foundation plan on the customer submittal drawing indicates the mounting hole size and locations on

the fan.

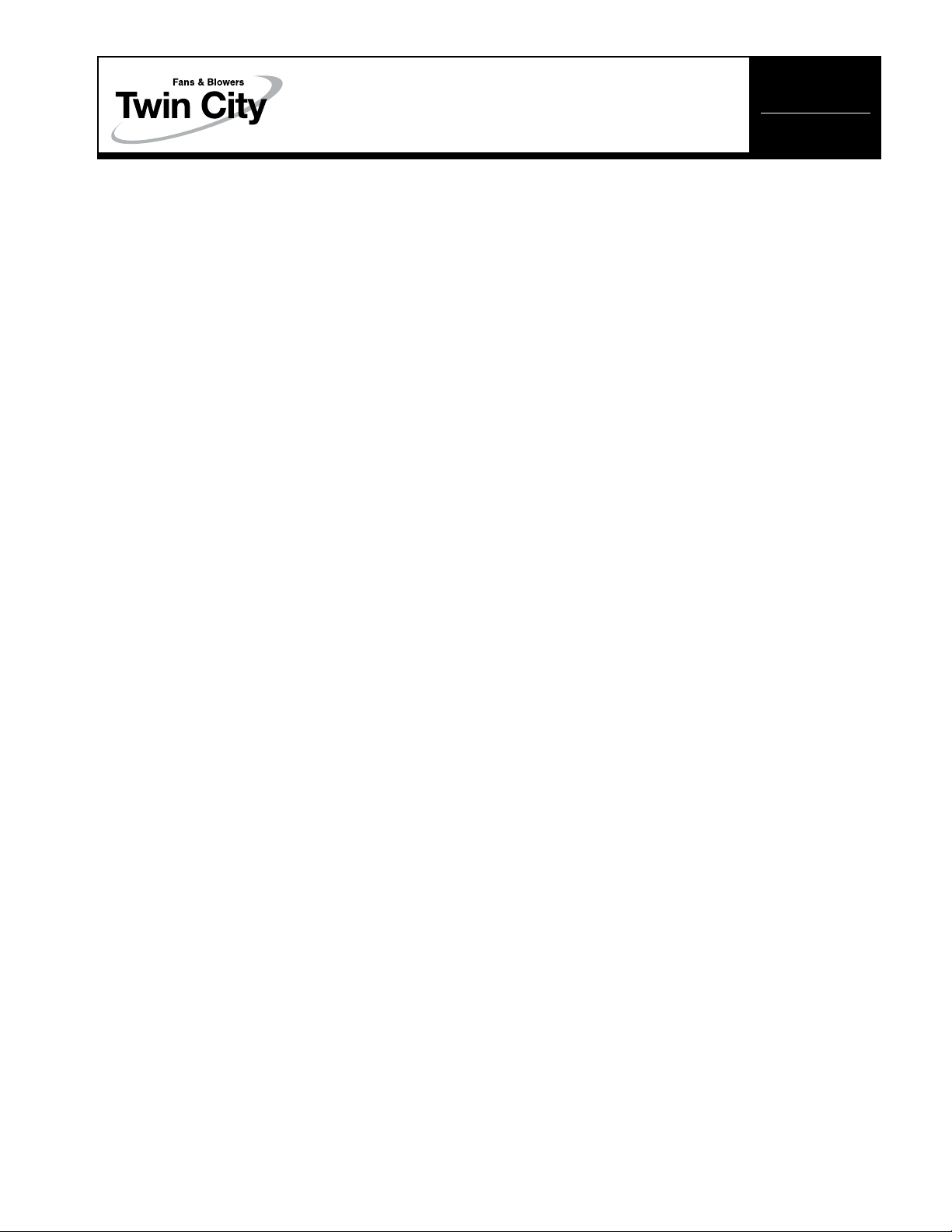

Figure 2. Typical Foundation Section

Fan Installation - Factory Assembled Units

General instructions for industrial centrifugal fans – For Axial

fans and commercial ventilators, follow steps below noting

instructions specific to those fan types in Appendix A and B.

Follow proper handling instructions as given earlier.

1. Move the fan to the final mounting position.

2. Remove skid, crates and packing materials carefully.

3. If vibration isolation is to be used, place isolation

base on mounting bolts. Line up holes in fan base

with bolts as indicated on the foundation plan of

the customer submittal drawing.

4. Consult each specific fan’s submittal drawing for

proper installation arrangement and mounting dimensions. Place the fan on mounting structure. Carefully

level the unit (checking the level on the shaft) on

the foundation and shim as necessary using stainless steel shims on both sides of each anchor bolt.

Anchor bolts are to be pre-tensioned per Table 1.

For metric grade bolts or materials not shown in

Table 1, check with bolt manufacturer for the proper

torque. (See details specific to commercial ventilators in appendix A for this step).

5. Check the alignment of the bearings. Shim or

reposition the bearings if necessary. In many split

housing roller bearings, the gap between the seal

NOTES:

1. Temporary form for grout pouring.

2. Hex nut, split ring lock washer and tapered or flat washer.

3. 1" to 1.5" grout allowance to be filled with nonshrinking machinery grout.

4. Pipe-bolt sleeve diameter 2 to 2

rection of alignment errors.

5. Care should be taken that anchor bolt sleeves are filled with

grout.

6. J-Bolt leg should be fastened to foundation rebar.

7. Shimming surface to be smooth, level, dressed if necessary.

8. Full width stainless steel shims.

9. Fan base angle or structural steel.

10. Leveling nut, if used, should be backed off after shimming for

final tightening of hex nuts.

1

/2 times bolt diameter for cor-

carrier and housing can be measured with a feeler

gage. The variation in this gap should be less than

half of the maximum gap measured. In roller bearings where this gap is not visible, alignment can

be verified by verifying the bearing is square with

the pedestal top. In ball bearings, the bearing outer

ring swivels in the housing to accommodate a small

amount of misalignment. Verify bearing set screws,

cap bolts, and collars are tightened per Tables 2a,

2b and 2c.

6. Check face alignment of sheaves on belt driven fans.

Parallel alignment should be within 5mm per meter of

center distance. Angular Misalignment should be less

than 1 degree. Check and record tension of belts

If a structural steel base or platform is to be used, the

structure must be designed for the weight of the fan,

live loads imposed by rotation of the rotor and driver,

and any external live loads. The structure should be

designed to ensure that no natural frequency will occur

within 30% of the fan speed. This is especially true if

the structure supports more than one fan.

Any ducting should have independent support. Do

not use the fan to support ducting. The fan frame

can be designed to carry some external loads. Consult

the factory if this is a concern. Isolating the fan from

ductwork with flex connections eliminates transmission

of vibration. Fans handling hot gases require expansion

joints at both the inlet and discharge to prevent excessive loads caused by thermal growth. Refer to AMCA

Publication 201 for good practices in ductwork geometry

and configuration. When possible, ductwork shall be

located where there is least risk of personnel tripping,

walking into or falling over the ductwork. If not possible,

warnings shall identify this hazard.

See Appendix A Commercial Ventilator Installation

Instructions for commercial ventilator foundation details.

Fans should not be located underneath other machinery where there might be a risk of harmful liquid falling

onto fans from above.

Fans should be installed where they are readily accessible to maintenance personnel, so that such personnel

are not required to stoop or crawl to access fans.

to see if it is sufficient. Proper belt tension is specified on the included datasheet. If belt tension needs

adjustment, instructions on belt tensioning are given

in the Drive Mounting section of this manual. Sheaves

on belt driven fans are often provided with taperlock

bushings. When tightening bushing bolts, proceed in a

progressive manner to avoid cocking the tapered surfaces between the bushing and the sheave. Bushing

bolt torque specifications are indicated in Table 3.

7. Check alignment of factory mounted couplings, as

they are subject to misalignment during shipment.

Realign if necessary in accordance with the instructions which are included with the shipment. NOTE:

Most couplings need lubrication.

8. Make sure there is no rubbing or binding and that

the wheel-inlet cone or wheel to fan housing clearances and overlap are correct. Overlap values or

other dimensions to verify proper wheel location are

given in the included documentation specific to the

fan. Wheel clearance should be verified to match

the specified value and be uniform. The measured

values should be recorded.

9. Check the tightness of the wheel on the shaft per

Table 4. The measured torque should be recorded.

10. Check the tightness of foundation bolts, motor

mounting bolts, and bearing mounting bolts per

Table 1. For metric bolts or grades not specified in

Table 1, check proper torque values per the bolt

3 Twin City Fan Engineering Supplement 2-06

manufacture.

Page 4

11. Check that bearings are fully lubricated and check

Assembled Bearing,

the oil level in the static oil lube systems (if

supplied).

12. Install any accessories shipped loose from the

factory.

Fan Installation - Disassembled Units

General instructions for industrial centrifugal fans – For Axial

fans (including mounting arrangements for inline centrifugal

fans), follow assembled fans instructions above and use

Appendix B for assembly details.

A unit is considered “disassembled” if any component

required for proper operation is shipped or supplied separately or in pieces. Reference earlier instructions concerning proper handling of fan components. Assembly shall

only be performed by trained personnel familiar with the

assembly of this type of equipment.

1. Move the lower half of the housing to its mounting

location (split housing).

2. Remove skids, crates, and packing materials carefully.

3. If vibration isolation is to be used, place the vibration isolation base on mounting bolts. Line up holes

in fan base with bolts.

4. Place the lower housing on the mounting structure.

Carefully level the lower housing on the foundation

and shim as necessary using stainless steel shims

on both sides of each anchor bolt.

5. If the bearing pedestal(s) are separated they should

be installed next.

a. Move bearing pedestal(s) to mounting location.

b. Put vibration base, if any, in place. Set pedestal(s)

on bolt(s).

c. Do not distort bearing pedestal by forcing it to

align with a non-level foundation. Shim beneath

the pedestal as necessary.

d. Check the bearing centerline height. Adjust the

height to match centerline height of the housing. High temperature units may require a lower

housing centerline when cold so that it will be

centered when hot.

e. Bring the bearing pedestal into square with the

housing using careful measurements or a large

square.

f. Bolt the pedestal into position.

6. If the wheel and shaft were shipped unassembled,

you must now install the shaft in the wheel.

a. First use solvent to clean the protective coating

off the shaft. Check all surfaces for corrosion or

nicks and clean if necessary with fine emery cloth

or a stone. After thoroughly cleaning the shaft

with solvent, do not touch it with bare hands as

perspiration can cause rust or pitting over time.

b. Remove keys from the shaft.

c. Clean the inside of the wheel bore with solvent.

Make sure the setscrews will not interfere when

inserting the shaft into the wheel bore.

7. Arrangement 1, 9 or 10: Drive Component

Assembly:

a. Insert shaft into wheel from back side of wheel

(Fig 3).

b. When shaft is flush with wheel hub, put key into

keyway and tighten wheel setscrews (for straight

bore hubs), or for bushing bore hubs, progressively tighten the bushing bolts per Table 3.

Record the measured torque value.

c. Insert shaft through opening in drive side. (If

splithoused unit, lower into position.)

d. Install bearings onto shaft. Do not tighten bear-

ing setscrews at this time. The bearing housing

should be perpendicular and the bearing base

parallel to the axis of the shaft to prevent loads

caused by misalignment.

e. Mount assembly, bolt bearings to drive stand.

Shaft must be parallel with side of bearing

pedestal.

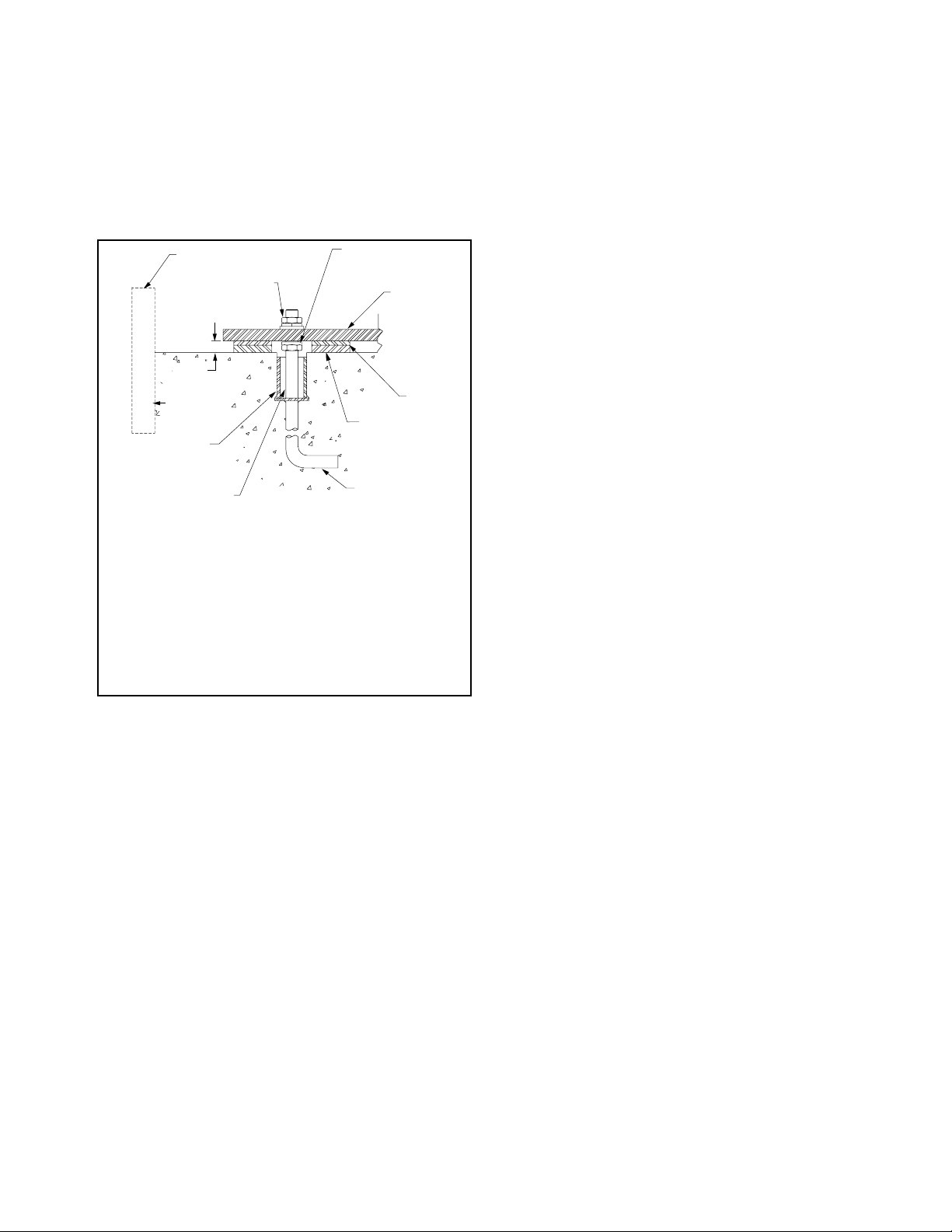

Figure 3. Drive Component Assembly

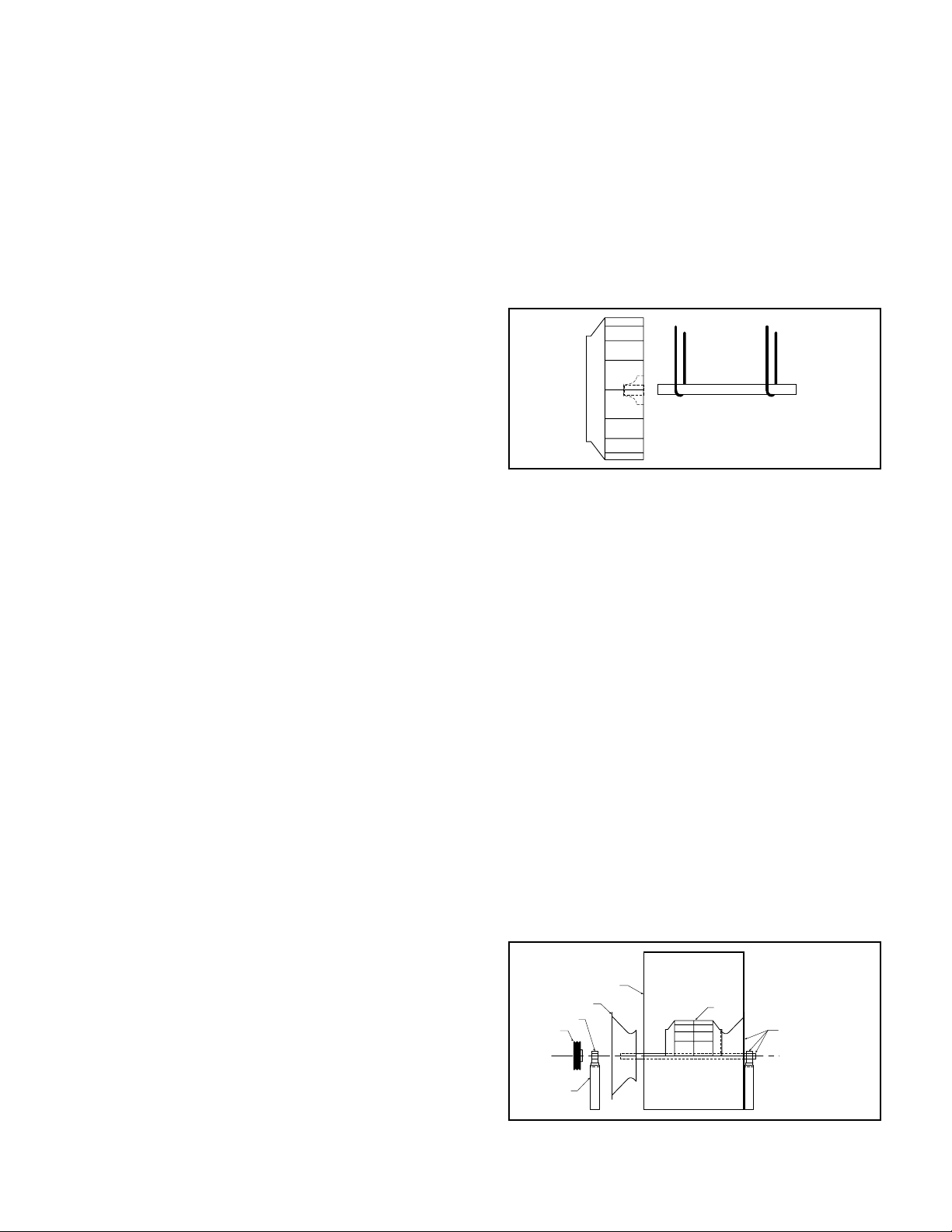

8. Arrangement 3 (Split-housed) units (See Figure 4):

a. Parts on DWDI units are assembled in the fol-

lowing order as viewed from opposite drive side:

Bearing bar assembly and opposite bearing, funnel, (housing side), wheel, (housing side), funnel,

drive side bearing bar assembly, drive bearing

and sheaves. Mount bearing bar assembly to

housing. Center wheel in funnels.

b. Parts on SWSI units are assembled in the

following order as viewed from opposite drive

side: Bearing bar assembly and opposite bearing,

funnel, (housing side), wheel, (housing side),

drive side bearing bar assembly, drive bearing

and sheaves. Mount bearing bar assembly to

housing.

c. Assemble parts in above order on shaft.

d. Move assembly into position. Lightly bolt bearings

into place.

e. Shaft should be parallel with discharge of hous-

ing. Move bearings to accommodate. Follow

bearing alignment instructions per step 5 in factory assembled units section above.

f. Level shaft; shim bearings if required. Tighten

bearing setscrews.

Figure 4. Split-housed Drive Component Assembly

Housing Side

Inlet Funnel

Bearing

Sheave

Shaft

Centerline

Bearing

Pedestal

Wheel

Shaft, Funnel, and

Housing. Frame

Angles Not Shown.

9. Install motor on base. Carefully align shafts for drive

installation.

4 Twin City Fan Engineering Supplement 2-06

Page 5

10. Mount drives as follows:

a. Slip (do not pound) proper sheave onto cor-

responding shaft. CAUTION: PLACING FAN

SHEAVE ON MOTOR CAN OVERSPEED WHEEL

AND CAUSE STRUCTURAL FAILURE.

b. Align sheaves with a straight-

edge extended along the

Figure 5.

Sheave Alignment

perimeters of both sheaves,

just making contact in two

places on outside perimeters

of both sheaves (see Figure

5). Parallel alignment should

be within 5mm per meter

of center distance. Angular

Misalignment should be less

than 1 degree.

c. Tighten down sheave bolts.

d. Install a matched set of

belts. Adjust belt tension as

indicated in “Drive Mounting”

step #3.

Table 1. Bolt Tightening Torque

Size

1/4 - 20

5/16 - 18

3/8 - 16

7/16 - 14

1/2 - 13

5/8 - 11

3/4 - 10

7/8 - 9

1 - 8

1 1/4 - 7

Grade 2 Grade 5 Grade 8 Aluminum Stainless

(Ft - lbs) (N - m) (Ft - lbs) (N - m) (Ft - lbs) (N - m) (Ft - lbs) (N - m) (Ft - lbs) (N - m)

5.5 7.5 8 10.8 12 16.3 3.8 5.2 6.3 8.5

11 15 17 23 25 34 6.7 9.1 11 15

22 30 30 41 45 61 11.9 16 19 26

30 41 50 68 70 95 19 26 31 42

55 75 75 102 110 149 26 35 43 58

100 136 150 203 220 298 59 80 92 125

170 230 270 366 380 515 81 110 128 174

165 224 430 583 600 813 125 169 194 263

250 339 645 874 900 1220 184 249 287 389

500 678 1120 1518 1500 2034 336 456 523 709

e. Tighten belts to proper belt tension. Record the

belt tension used. See drive mounting section for

tensioning instructions. Proper tension is specified

in the datasheet included with the fan.

11. Fans that have motors and drives mounted at the

factory are trim balanced prior to shipment. This

is not possible on units that are shipped without

motors and drives. The addition of drive components in the field can create unbalance forces. Twin

City Companies, Ltd. recommends final balancing

of the unit after the drive components are installed.

Failure to do so voids the Twin City Fan Companies,

Ltd. warranty.

12. Repeat the installation checks indicated for factory

assembled units to assure proper tightness and

alignment of all components.

Bearing Installation

Bearings are only to be field installed when accompanied by installation instructions from the bearing manufacturer. When field installation is required, follow the

manufactures instructions carefully to install bearings.

Table 2a. Bearing Cap Bolt Torque Specifications (see page 6)

Table 2b. Metric Set Screw Torque Specifications

METRIC SHAFTS SET SCREW SIZE LOCKING COLAR SCREW SIZE

Manufacturer BRG ID Units M5 M6 M8 M10 M12 M4 M5 M6 M8

Dodge

Dodge

Dodge

SKF

Manufacturer BRG ID Units 12-35mm 40-45mm 50-65mm

SKF

Linkbelt

Table 2c. IP Set Screw Torque Specifications (see page 7)

S2000 N-m - - 17.8 35 57 - - - SCAH N-m 3.4 6.9 16 28 51 5.85 10.75 20.5 45

SCMAH N-m 3.4 6.9 16 28 51 5.85 10.75 20.5 45

SY N-m See Below 4.2 7.4

SY BEARING DIAMETER PB224 BEARING DIAMETER

70-100mm

SY N-m 4 6.5 16.5 28.5 - - - - -

PB224 N-m - - - - 21 37 52 77 153

25,30mm 35-50mm 55mm

60-80mm 90,100mm

Table 4. Set Screw Tightening Torque (other than bearing

set screws)

Table 3. Browning Split Taper Bushing Tightening Torque

Bolt

Size

1/4 - 20

5/16 - 18

3/8 - 16

1/2 - 13

Bushing

Type

H 8 11 8 11

P, B 17 23 13 18

Q, R 30 41 24 33

S 70 95 - -

Iron/Steel Hub,

Sheave

Ft - lbs N - m Ft - lbs N - m

Aluminum

Hub

Set Screw

Size

1/4 - 20

5/16 - 18

3/8 - 16

7/16 - 14

1/2 - 13

5/8 - 11

3/4 - 10

7/8 - 9

1 - 8

1 1/4 - 7

Steel Set Screws Stainless Set Screws

Ft - lbs N - m Ft - lbs N - m

5.5 7.5 5.8 7.9

11 15 11 15

22 30 19 26

30 41 28 38

55 75 42 57

100 136 82 111

170 230 115 156

165 224 - 250 339 - 500 678 - -

5 Twin City Fan Engineering Supplement 2-06

Page 6

(N-m)

TORQUE

(FT-LBS)

TORQUE

SEALMASTER

(RPB & RPB-M SERIES)

MODEL

(N-m)

TORQUE

(FT-LBS)

LINK-BELT

TORQUE

(PLB6800 SERIES)

PRPB-100M (exp) 150 203

RPB-315 (exp) 150 203

RPB-105M (fixed) 266 360

RPB-105M (exp) 150 203

RPB-110M (fixed) 266 360

RPB-110M (exp) 150 203

RPB-407 (fixed) 266 360

RPB-407 (exp) 150 203

RPB-115M (fixed) 266 360

RPB-115M (exp) 150 203

RPB-120M (fixed) 394 534

RPB-120M (exp) 266 360

RPB-125M (fixed) 394 534

RPB-125M (exp) 266 360

RPB-415 (fixed) 394 534

- - -

RPB-415 (exp) 266 360

SETSCREW

SETSCREW

TORQUE

SKF

TORQUE

(SAF SERIES)

TORQUE

TORQUE

MODEL

NUT

(N-m)

FOR LOCK

NUT

(FT-LBS)

FOR LOCK

SAE

GRADE 8

CAP BOLTS

SAE

GRADE 8

CAP BOLTS

METRIC

GRADE 8.8

CAP BOLTS

METRIC

GRADE 8.8

CAP BOLTS

PLB6863 160-180* 217-244* RPB-315 (fixed) 266 360

(N-m)

(FT-LBS)

(N-m)

(FT-LBS)

MODEL

SAE

(N-m)

TORQUE

GRADE 5

- - - - - - - - - - - - - RPB-85M 266 360

520 208-260 282-352 SAF22520 150 203 380 515 13 17 PLB6855 160-180* 217-244* RPB-307 266 360

85mm

3.438"

- - - - - - - - - - - - RPB-95M 266 360

- - - - - - - - - - PLB68M90 160-180* 217-244* RPB-90M 266 360

-

90mm

95mm

- - - - - - - - - - PLB68M100 160-180* 217-244* PRPB-100M (fixed) 266 360

522 208-260 282-352 SAF22522 150 203 380 515 13 17

3.938"

100mm

- - - - - - - - - - - - -

105mm

- - - - - - - - - - PLB68M110 160-180* 217-244*

526 320-430 433-583 SAF22526 295 399 900 1220 26 35 PLB6871 280-330* 379-447*

4.438"

110mm

- - - - - - - - - - PLB68M115 280-330* 379-447*

- - - - - - - - - - - - -

115mm

120mm

- - - - - - - - - - PLB68M125 400-430* 542-583*

528 512-640 694-867 SAF22528 295 399 900 1220 - - PLB6879 400-430* 542-583*

4.938"

125mm

- - - - - - - - - - PLB68M135 400-430* 542-583*

532 512-640 694-867 SAF22532 - 380 515 - PLB6887 400-430* 542-583* - - -

5.438"

135mm

- - - - - - - - - - PLB68M140 400-430* 542-583* - - -

- - - - - - - - - - PLB68M150 400-430* 542-583* - - -

140mm

150mm

- - - - - - - - - - PLB68M160 400-430* 542-583* - - -

534 512-640 694-867 SAF22534 - 380 515 - - - - - - -

5.938"

160mm

536 512-640 694-867 SAF22536 - 380 515 - - - - - - -

6.438"

DODGE

SAE

TORQUE

(USAF SERIES)

Table 2a. Bearing Cap Bolt Torque Specifications

SHAFT

(FT-LBS)

GRADE 5

MODEL

DIA.

- - - - - - - - - - - - - PRB-35M 31 42

509 24-30 32-40 SAF22509 45 61 70 94 6 8 PLB6823 45-50* 61-67* RPB-107 31 42

35mm

1.438"

- - - - - - - - - - PLB68M40 45-50* 61-67* RPB-40M 31 42

- - - SAF22510 45 61 70 94 6 8 PLB6827 45-50* 61-67* RPB-111 31 42

40mm

1.688"

- - - - - - - - - - PLB68M45 45-50* 61-67* RPB-45M 31 42

- - - SAF22511 60 81 110 149 13 17 PLB6831 45-50* 61-67* RPB-115 31 42

45mm

1.938"

- - - - - - - - - - PLB68M50 45-50* 61-67* RPB-50M 31 42

- - - - - - - - - - - - - RPB-55M 31 42

50mm

55mm

- - - - - - - - - - PLB68M60 45-50* 61-67* RPB-60M 75 101

513 40-50 54-67 SAF22513 60 81 110 149 13 17 PLB6835 45-50* 61-67* RPB-203 31 42

60mm

2.188"

- - - - - - - - - - PLB68M65 45-50* 61-67* RPB-65M 75 101

515 60-75 81-101 SAF22515 60 81 110 149 13 17 PLB6839 45-50* 61-67* RPB-207 75 101

65mm

2.438"

- - - - - - - - - - PLB68M70 90-100* 122-135* RPB-70M 75 101

516 120-150 162-203 SAF22516 110 149 220 298 13 17 PLB6843 90-100* 122-135* RPB-211 75 101

70mm

2.688"

- - - - - - - - - - PLB68M75 90-100* 122-135* RPB-75M 75 101

517 120-150 162-203 SAF22517 110 149 220 298 13 17 PLB6847 90-100* 122-135* RPB-215 75 101

75mm

2.938"

- - - - - - - - - - PLB68M80 90-100* 122-135* RPB-80M 266 360

80mm

6 Twin City Fan Engineering Supplement 2-06

- - - - - - - - - - PLB68M170 630-700* 854-949* - - 538 896-1120 1214-1518 SAF22538 - - 600 813 - - - - - - - -

6.938"

170mm

* Lower torque values are for oil lubricated threads.

Page 7

Table 2c. IP Set Scew Torque Specifications

INCH SHAFTS

MANU-

FACTURER

SEAL-

MASTER

SKF

SEAL-

MASTER

SEAL-

MASTER

SEAL-

MASTER

SEAL-

MASTER

SKF

LINKBELT /

REXNORD

SEAL-

MASTER

SEAL-

MASTER

DODGE

DODGE

DODGE

SKF

BROWN-

ING

BROWN-

ING

BRG

ID

RP FT-LB 2.3 5.5 5.5 10.5 10.5 19 19 19 - - - - - -

SY FT-LB 7.2 7.2 7.2 14 14 24 24 24 24 35 35 51 - -

NP FT-LB - 5.5 5.5 10.5 10.5 19 19 19 29 29 29 - - -

MP FT-LB - 5.5 10.5 10.5 19 19 19 29 29 29 42 92 - -

MPD FT-LB - 5.5 10.5 10.5 19 19 29 29 42 42 42 92 92 -

EMP FT-LB - 5.5 5.5 10.5 10.5 19 19 19 29 29 29 - - -

SYR FT-LB - - - 21 21 21 21 51 51 51 51 110 - -

PB224 FT-LB - 15.4 15.4 27 27 27 38 57 57 57 57 113 113 113

RPB FT-LB - - 9 9 9 15 15 15 34 34 34 73 120 120

ERPB FT-LB - - - - - - - 15 34 34 34 73 - 120

SCAH FT-LB 6.1 6.1 11.8 11.8 11.8 21 21 21 21 21 - - - -

SCMAH FT-LB - 6.1 11.8 11.8 21 21 21 21 21 21 21 - - -

S2000 FT-LB - - 13.8 13.8 13.8 24 24 24 52 52 52 110 110 110

SYM FT-LB - - - 13.8 24 24 24 24 - - - - - -

VPS

200

VP3

300

THRU-

UNITS

IN-LB 28 66 66 126 126 228 228 228 - - - - - -

N-m 3.1 7.5 7.5 14.2 14.2 26 26 26 - - - - - -

IN-LB 87 87 87 165 165 290 290 290 290 430 430 620 - -

N-m 9.8 9.8 9.8 19 19 33 33 33 33 47 47 69 - -

IN-LB - 66 66 126 126 228 228 228 348 348 348 - - -

N-m - 7.5 7.5 14.2 14.2 26 26 26 39 39 39 - - -

IN-LB - 66 126 126 228 228 228 348 348 348 504 1104 - -

N-m - 7.5 14.2 14.2 26 26 26 39 39 39 57 125 - -

IN-LB - 66 126 126 228 228 348 348 504 504 504 1104 1104 -

N-m - 7.5 14.2 14.2 26 26 39 39 57 57 57 125 125 -

IN-LB - 66 66 126 126 228 228 228 348 348 348 - - -

N-m - 7.5 7.5 14.2 14.2 26 26 26 39 39 39 - - -

IN-LB - - - 251 251 251 251 620 620 620 620 1325 - -

N-m - - - 28 28 28 28 69 69 69 69 149 - -

IN-LB - 185 185 325 325 325 460 680 680 680 680 1350 1350 1350

N-m - 21 21 37 37 37 52 77 77 77

IN-LB - - 108 108 108 180 180 180 408 408 408 876 1440 1440

N-m - - 12.2 12.2 12.2 20 20 20 46 46 46 99 163 163

IN-LB - - - - - - - 180 408 408 408 876 - 1440

N-m - - 20 46 46 46 99 - 163

IN-LB 73 73 141 141 141 252 252 252 252 252 - - - -

N-m 8.3 8.3 16.0 16.0 16.0 28 28 28 28 28 - - - -

IN-LB - 73 141 141 252 252 252 252 252 252 252 - - -

N-m - 8.3 16.0 16.0 28 28 28 28 28 28 28 - - -

IN-LB - - 165 165 165 290 290 290 620 620 620 1325 1325 1325

N-m - - 19 19 19 33 33 33 71 71 71 149 149 149

IN-LB - - - 165 290 290 290 290 - - - - - -

N-m - - 19 33 33 33 33 - - - - - -

IN-LB 28 66 66 126 126 228 228 228 - - - - - -

FT-LB 2.3 5.5 5.5 10.5 10.5 19 19 19 - - - - - -

N-m 3.1 7.5 7.5 14.2 14.2 26 26 26 - - - - - -

IN-LB 66 66 126 126 228 228 228 348 348 348 504 1104 - -

FT-LB 5.5 5.5 10.5 10.5 19 19 19 29 29 29 42 92 - -

N-m 7.5 7.5 14.2 14.2 26 26 26 39 39 39 57 125 - -

1 1-3/16 1-7/16 1-11/16 1-15/16 2-3/16 2-7/16 2-11/16 2-15/16 3-7/16 3-15/16 4-7/16 4-15/16

1

SHAFT DIAMETER (INCHES)

77 153 153 153

7 Twin City Fan Engineering Supplement 2-06

Page 8

Grouting

Y

X

P

P

FF

GAP

Grouting is the final installation step. Check all shims

before grouting to make sure that the fan is resting

evenly on all points with anchor bolts secured to hold

the shim. Use forms with sufficient space allowed for

working the grout. The concrete foundation should be

clean and well moistened before pouring grout. Use a

commercial grade non-shrinking grout and be especially

sure when pouring grout that the anchor bolt sleeves are

filled. Refer to Figure 2 for a detail of a proper foundation, grout allowance and anchor bolt sleeves.

Figure 6. Coupling Alignment

ANGULAR PARALLEL GAP AND

MISALIGNMENT MISALIGNMENT END FLOAT

X-Y = ANGULAR MISALIGNMENT

P = PARALLEL OFFSET (MISALIGNMENT)

F = END FLOAT

Drive Mounting

Mount drives as follows:

1. Slip (do not pound) proper sheave onto corresponding shaft. CAUTION: Placing fan sheave on motor can

overspeed wheel and cause structural failure.

2. Align sheaves with straightedge extended along

sheaves (see Fig. 5), just making contact in two

places on outside perimeters of both sheaves. This

“four-point” alignment may also be checked with a

string tied to the shaft behind one of the sheaves.

The string is then pulled taut over the faces of the

sheaves to check the alignment at the four points

at the outside perimeters. Each sheave should be

rotated about one-half revolution during this check

to look for excessive runout or a bent shaft. Parallel

alignment should be within 5mm per meter of center

distance. Angular Misalignment should be less than 1

degree.

3. Install and tighten the belts. Proper belt tension is

specified on the included documentation. Belts are

tensioned as follows:

Post type, saddle base, slide rails, and slide base

types use one or more bolts held by retaining nuts to

adjust the motor position. Loosen the retaining nuts

and adjust the bolts to push or pull the motor until

the belts reach their specified tension. Tighten the

retaining nuts per torque specifications in Table 1.

4. Run the drive for a few minutes to seat the belts.

When tightening the belts, slide the motor in to slip

the belts on. Do not use a pry bar, as this may damage the belt cords. Retighten the belts to the proper

tension if necessary. Recheck sheave alignment.

5. After initial installation of belts, recheck belt tension

and alignment as indicated in Table 7.

Flexible Couplings

These instructions are general for the installation of

several types of flexible couplings and should not be

used as a substitute for more specific manufacturer’s

instructions. The coupling manufacturer’s installation data

is included with the supplied datasheet (when applicable)

and will give specific dimensions for alignment limits,

lubricants, etc.

Before preparing to mount the coupling, make sure

that all bearings, inlet vanes, shaft seals, or other components have been installed on the shaft.

When mounting and keying the coupling halves to

the shaft, follow supplied instructions for heating and

shrink fitting. Set the coupling halves for the normal gap

specified by the manufacturer. Coupling gap is illustrated

in Figure 6.

The two types of misalignment are illustrated above.

Typically angular alignment is checked with feeler gauges between the hub faces. When angular alignment has

been adjusted to manufacturer’s specification by shimming, if necessary, parallel alignment can be checked

with a straightedge and feeler gauges on the hub halves’

O.D. When shimming has brought parallel alignment

within specification, angular alignment and gap should

again be checked, and adjustments made if necessary.

A dial indicator may be used to more accurately take

the measurements described above.

Special adjustments may need to be made for couplings used with some equipment. As an example, when

used with motors of over 300 HP, couplings may require

provisions for limiting end float. Larger drivers may grow

in operation (due to heat expansion) requiring the driver

side to be set slightly low when not operating. Specific

instruction manuals or assembly drawings will indicate

these requirements when applicable.

Thoroughly clean the coupling halves after completion

of alignment. Reassemble the coupling and tighten bolts,

washers and locknuts. Lubricate per manufacturer’s recommendations.

Duct Connections

The fan support structure is normally not designed to

carry loads imposed by the weight of ducts, silencers,

stacks, etc. Supporting these loads on the fan can

cause housing distortion and may cause performance

problems due to the relation of fan housing to wheel.

Use of flexible connections is recommended.

Where hazardous materials will be conveyed in the

fan, all connections made by the user shall be completely sealed with material suitable for the gas or vapor

to be handled.

Guards and Enclosures

When advised of the need for guards fully complying

with the machinery directive, Twin City Fan Companies,

Ltd. will supply the guarding identified as being required.

In most cases, Twin City Fan Companies, Ltd. is not

aware of the end use and installation of the fan, which

typically eliminates the need for more restrictive guarding to be compliant with EN 294 and EN 811. For this

reason, the user is must verify that the final installation

is compliant with EN 953, EN 294, and EN 811. This is

especially true of plug and plenum fans. Specific items

that should be considered include but are not limited

to the following:

• Outlet ducting / enclosure. The ducting or enclosure

must be compliant to the requirements of EN 953

and EN 294 and EN 811. This is not assured by

Twin City Fan Companies, Ltd. unless specifically

notified by the end user at the time of the order.

• Inlet guards. Inlet guarding relies on the additional

safety distance provided by inlet ducting or other

enclosure increasing the safety distance to 850 mm

or greater. This is because the installation usually

eliminates the need for excessive guarding on the

inlet of the fan. In addition, excessive guarding on

the inlet of the fan would significantly deteriorate

performance and is therefore not desirable.

8 Twin City Fan Engineering Supplement 2-06

Page 9

• Plug and Plenum fans. These fans are intended for

installation in a user supplied enclosure. Twin City

Fan Companies, Ltd. rarely knows the details of

the enclosure and therefore can not provide guarding based on the needs of the final installation for

these types of fans. The user must verify that the

enclosure a plug or plenum fan is located in is

compliant with EN 953 and EN 294 and EN 811.

Guards shall not be removed during fan operation as

this could cause severe injury. Guards shall not be stood

on or used to support any additional load.

Electrical Supply and Controls

Twin City Fan Companies, Ltd. does not supply electrical controls. Items identified below are intended to

guide the user in supplying controls in conformance to

Annex I of the Machinery Directive and EN 14461:2005

– Industrial Fans – Safety requirements. Furthermore,

electrical installations shall fulfill the requirements of EN

60204-1 and shall be selected for compliance with the

low voltage directive. Those involved with the design

of the electrical supply and control systems should

be familiar with the above mentioned standards and

directives. Control systems including relays, contactors,

Variable Frequency Drive Units, isolating transformers,

over-current and short circuit protection devices may be

required. Relays, contactors, Variable Frequency Drive

Units, isolating transformers, over-current and short

circuit protection devices should all be in compliance

with the Low Voltage Directive. The following is a list

of some of the more common European standards that

are observed when considering compliance with the Low

Voltage Directive.

EN60742 - Isolating Transformers

EN50178 - Electronic Equipment for use in

Power Installations.

EN60730-2-10 - Motor Starting Relays.

EN60947-2-1 - Overload trips.

EN60947-3-1 - Switches, Disconnectors, Switch

Disconnectors and Fuse Combination

Units.

EN60947-4-1 - Electro-mechanical Contactors and

Motor control circuits.

EN60947-5-1 - Electromechanical control circuit

devices.

EN60947-5-5 - Low voltage switchgear and control

gear - Part 5: Control circuit devices

and switching elements - Electrical

emergency stop devices with mechan

ical latching function.

EN61810-1 - Electromechanical elementary relays Part 1: General and requirements.

EN60255-23 - Electrical relays - Part 23: Contact

performance.

EN60439-1 - Low Voltage Switchgear and

Switchgear Assemblies, Part 1.

EN 60034 - Rotating Electrical machines Parts 1

and 5.

Variable Frequency Drive Units come under the Low

Voltage and EMC Directives. Standards that shall be

considered for compliance with the EMC Directive are

listed below:

EN 61000-6-4: 2001 Generic Industrial Emission

Standard.

EN 55011: 1998 + A1 Conducted Emissions

Industrial (Group 1 Class A)

In addition, controls shall meet the requirements for

category 2 safety critical control systems as detailed

in EN 954-1. When a VFD is used, controls shall be

implemented to guard against the VFD causing the fan

to run above the maximum safe speed of the fan.

Wiring diagrams provided by the electrical equipment

manufacture shall be followed.

General Considerations for Controls

Intended automatic or remote restart after short term

power failure shall only be permitted if no risk exists

and if there are no other fault conditions.

Warning signs that automatic or remote start may

take place shall be provided when applicable.

After a stop caused by the safety devices indicating

hazardous conditions, restart shall only be possible by

an intentional operation of manual control.

When possible, electrical power cables connected to

fans should be routed where there is least risk of personnel tripping, walking into or falling over such items

because they have been routed in areas where personnel are expected to move.

If it is necessary for periodical inspection and repairs

to override the monitoring and control systems during

operation, then consideration shall be given to the provision of stand-by fans, motors or other features. This is

allowed provided that:

• The alarm system remains in operation during the

override and an alarm signal is given when the

safety limits are reached.

• Override is indicated by a clearly visible signal.

• Override is affected by auxiliaries specially installed

for that purpose, e.g. key operated switches.

Maintenance

Any maintenance requiring the guards to be removed

shall be performed while the fan is not operating.

When restarting fan after maintenance, follow operation

checklist for start up of fan.

Lockouts shall be used whenever unexpected energizing of the fan could cause a mechanical or electrical

hazard.

Motor Maintenance

The three basic rules of motor maintenance are:

1. Keep the motor clean.

2. Keep the motor dry.

3. Keep the motor properly lubricated.

Blow dust off periodically (with low pressure air) to prevent motor from overheating.

If the motor is to be started after sitting for more

than a week, the resistance of the motor windings to

earth should be measured (at 500 V DC). If the resistance is less than 10 megohms, the motor should be

dried until a resistance over 10 megohms is measured.

Some smaller motors are lubricated for life.

Lubrication requirements are normally attached to the

motor. Use the motor manufacturer’s recommendations

for re-lubrication. If this information is not available, the

following schedule may be used. Motors less than 10

HP running about eight hours a day in a clean environment should be lubricated once every five years; motors

15 to 40 HP, every three years. For motors in dusty or

dirty environments or running 24 hours a day: divide the

service interval by 4. Do not over lubricate. Note that

motors typically use a different type of lubricant than

fan shaft bearings.

9 Twin City Fan Engineering Supplement 2-06

Page 10

Drive Maintenance

V-belt drives need periodic inspection, re-tensioning, and

occasional belt replacement. Follow Table 5 on page 11

for drive inspections and maintenance. Proper belt tension can be found on the included datasheet specific to

each fan. A log should be kept with belt tension and

replacement information.

Bearing Maintenance

Proper lubrication of the fan drive bearings helps assure

maximum bearing life. All fans are equipped with decals

indicating re-lubrication intervals for normal operating

conditions. Bearings should be inspected after the first

24 hours of operation and then inspected each time they

are lubricated. Lubrication schedules for the included

type of bearings are attached to the fan. Note that all

speeds shown do not apply to all shaft sizes in that

group. Consult the factory if in doubt of maximum speed

for a particular bearing. Note that every installation is

different and the frequency of re-lubrication should be

adjusted accordingly.

On high moisture applications the lubrication frequency may need to be doubled or tripled to adequately

protect the bearings. Double the relubrication frequency

on fans with vertical shafts.

Observation of the conditions of the grease expelled

from the bearings at the time of relubrication is the best

guide as to whether regreasing intervals and amount of

grease added should be altered.

Greases are made with different bases. There are

synthetic base greases, lithium base, sodium base, etc.

Avoid mixing greases with different bases. They could be

incompatible and result in rapid deterioration or breakdown of the grease. The lubrication sticker identifies a

list of acceptable lubricants. All fan shaft bearings are

filled with a lithium-based grease before leaving the factory unless otherwise specified. When the fans are started, the bearings may discharge excess grease through

the seals for a short period of time. Do not replace the

initial discharge because leakage will cease when the

excess grease has worked out. Sometimes the bearings

have a tendency to run hotter during this period. This

is no reason for alarm unless it lasts over 48 hours or

gets very hot (over 200°F, 93°C).

If bearings are exhibiting excessive vibration at any

time or are running hotter than 200°F, 93°C, the bearings should be inspected for proper lubrication, alignment, tightness of set screws, cap bolts, and collars,

and inspected for signs of contamination in the lubricant.

The bearings or damaged bearing components shall be

replaced if found faulty or showing signs of wear. When

relubricating, use a sufficient amount of grease to purge

the seals. Rotate bearings by hand during relubrication.

Wheel and Shaft Maintenance

Inspect the shaft and wheel for dirt buildup, corrosion,

and signs of excess stress or fatigue after one month

of service. Future inspection interval shall be based on

findings in this initial inspection. Clean the components.

If any signs of damage, stress, or fatigue are present

(deformation, cracks, excessively worn surfaces) the

part shall be replaced. Any material buildup on rotating

parts or parts that could contact rotating parts shall be

cleaned. If the wheel is removed for any reason, make

sure that it is securely attached to the shaft before

restarting the fan. The wheel and shaft shall also be

inspected any time excessive vibration is observed (filter

in readings should be 7.2 mm/s RMS or less). Reference

ISO 14694:2003, “Industrial Fans – Specifications for

Balance Quality and Vibration Levels” for more details

on acceptable fan vibration levels.

Structural Maintenance

All structural components or devices used to support

or attach the fan to a structure should be checked at

regular intervals. Vibration isolators, bolts, foundations,

etc., are all subject to failure from corrosion, erosion,

and other causes. Improper mounting can lead to poor

operation characteristics or fan fatigue and failure. Check

metallic components for corrosion, cracks, or other

signs of stress. Replace any components showing any

of these signs. Concrete should be checked to insure

the structural integrity of the foundation and repaired or

replaced if any signs of damage are found.

Where the fan is used to handle toxic gasses or

vapors, the housing, and welds shall be inspected for

signs of corrosion or cracking at regular intervals to

assure no toxic gasses can escape. The condition of

the coating shall be inspected as well to verify that

bare parts of the fan are not exposed. All gaskets and

ducting shall be inspected for signs of erosion as well.

An initial inspection after one month of service shall be

used to determine an appropriate inspection interval.

Fan Operation

Proper Use and Application

It is critical that fans are operated only as their design

intended. Standard construction is designed for standard

applications as defined below:

• Clean air – no solids, particles, or corrosive or abrasive gasses.

• Air stream temperatures between 120°F (49°C) and

-20°F (-29°C) with a maximum temperature fluctuation of 15°F (8°C) per minute.

• Ambient temperatures shall not exceed 104°F (40°C)

for standard design fans.

• Constant speed operation.

Operating a fan in any of the following conditions could

cause a safety hazard:

• Do not operate a fan in an environment that it was

not designed for. This includes operating the fan in

temperatures or with abrasive or corrosive vapors

or chemicals or solid material (including fly ash)

other than the fan was designed for. Operating at

elevated temperatures or with abrasive or corrosive

vapors requires special considerations that must be

incorporated in the design, material selection, coating, and maintenance of the fan.

• Do not operate a fan at a higher speed than the

fan, drives, seals, bearings, or other components

were designed for.

• Do not use variable rotational speed service without

first consulting Twin City Fan Companies, Ltd.

• Do not operate a fan without the bearings and couplings properly lubricated. Lubrication intervals are

explained in corresponding maintenance sections of

this manual.

• Do not operate a fan exhibiting increased vibration

levels. Filter in readings should be 7.2 mm/s RMS

or less.

• Do not operate the fan in stall.

• Do not operate the fan with replacement or added

components that are not recommended by Twin

City Fan Companies, Ltd. The use of insufficient

components could cause premature wear and

failure.

10 Twin City Fan Engineering Supplement 2-06

Page 11

Table 5. Drive Maintenance and Inspection

TYPE OF MAINTENANCE WHEN TO DO WHAT TO DO

Check for sheave groove wear Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.*

Check for sheave runout. Initial inspection: 8 hours. Second in-

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.*

Inspect for heat build-up and

proper ventilation

Clean belts and sheave grooves Initial inspection: 8 hours. Second in-

Check belt tension Initial inspection: 8 hours. Second in-

Check sheave alignment Initial inspection: 8 hours. Second in-

Mismatched belt check Initial inspection: 8 hours. Second in-

Check for worn belts Initial inspection: 8 hours. Second in-

Check sheave setscrews and/or

busing capscrews

Initial inspection: 8 hours. Second inspection: 24 hours. Third inspection:

100 hours. Periodically thereafter.*

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.*

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.*

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.*

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.*

spection: 24 hours. Third inspection:

100 hours. Periodically thereafter.*

Initial inspection: 8 hours. Second inspection: 24 hours. Third inspection:

100 hours. Periodically thereafter.*

Check for belt ride in the groove. In multiple groove

drives, belt ride should be uniform, not more than

1/16" above or below top of sheave groove. Check

groove wear area for wear. Side wall of groove

should be straight, not dished out. Bottom of groove

should show no signs of belt contact.

Check sheave by eye for runout. If runout is excessive, it can easily be seen by visual inspection. If

runout is noticeable, check sheave for source of

problem and correct.

Check bolts for heat. Ambient temperature should

not exceed 140°F. Contact temperatures should not

exceed 180°F. Make sure drives are properly ventilated.

Inspect belts for contaminates, such as oil or grease.

Wipe belts clean with detergent and water. Inspect

sheave grooves for build-up of such material and

remove, if necessary.

Check belt tension using BROWNING belt tension

checker. Tension to recommendations shown in current catalogs.

Check alignment with straight edge, string or machinist level. Correct alignment to as near perfect

as possible.

Check belt sag on slack side of drive. All belts

should have a slight bow. If this bow is not uniform

with all belts, replace entire set with a matched

set.

Check wear surfaces for belt for excessive wear.

if belts have a slick, glazed look, belts ares lipping. Check drive capacity and belt tension. Never

replace only one belt in a used set, as used belts

will elongate. Replace entire set if replacement is

necessary.

Check all setscrews and/or bushing capscrews for

looseness. Retighten to recommended torque, if necessary.

* Inspections listed as “Periodically” must be performed at least monthly for ATEX fans.

All of the above conditions could lead to mechanical failure causing safety hazards including exposure to ejected

The following EN standards can be referred to as a

guide when making noise measurements:

objects and toxic material or vapors.

For high temperature applications, it is recommended

that an auxiliary device be provided (such as a turning gear available from Twin City Fan Companies, Ltd.)

to slowly rotate the fan when it is not operating while

exposed to high temperatures. Exposure to high temperatures while not operating could be due to a power failure

or standard operation of a process.

When multiple fans are installed for redundancy, the

fan used shall be switched at least weekly to avoid the

need for storage considerations.

EN 809 EN ISO 5136:2003 - Acoustics - Determination

of sound power radiated

into a duct by fans and

other air-moving devices

- In-duct method.

EN ISO 11200/A1 1997 - Noise emitted by

machinery and equipment - Guidelines for

the use of basic standards for the determination of sound pressure

Sound

Sound power levels are supplied with each fan. These

levels are based on AMCA 300 reverberant room test

methods. This method is similar to ISO 3741. Field

installation and conditions can affect sound greatly.

Because of this, the user shall verify if the sound pressure levels in the installed condition are below 70 dBA.

If sound pressure levels are above 70 dBA, actions shall

be taken to reduce sound pressure levels to acceptable

levels.

EN ISO 11202/A1 1997 - Noise emitted by

levels at a workstation

and at other specified

positions.

machinery and equipment - Measurement of

emission sound pressure

levels at a workstation

and at other specified positions – Survey

method in situ.

11 Twin City Fan Engineering Supplement 2-06

Page 12

Operation Checklist

RIGHT

WRONG

□ Verify that proper safety precautions have been followed.

□ Electrical power must be locked off.

Check fan mechanism components:

□ Nuts, bolts, setscrews are tight per Tables 1 - 4.

□ Mounting connections are properly made and tightened.

□ Bearings are properly lubricated.

□ Wheel, drives and fan surfaces are clean and tightened.

□ Rotating assembly turns freely and does not rub.

□ Drives on correct shafts, properly aligned, and prop-

erly tensioned.

□ Check that no foreign objects are in the fan or

ductwork.

Check fan electrical components:

which case the manufacturer’s installation and operating manuals will be provided.

4. Inlet Box and Inlet Box Dampers — Inlet boxes may

be provided to allow transition from a duct to the

fan inlet. Inlet box dampers may also be provided for

volumetric regulation similar to inlet vanes. Dampers

are usually provided as a complete assembly and are

installed with the damper axles parallel to the fan

shaft. They should be installed to pre-spin the air in

the direction of fan rotation. See Figure 7.

Figure 7.Orientation of Damper Blades As Related to Fan Rotation

□ Motor is wired for proper supply voltage.

□ Motor was properly sized for power of rotating assembly.

□ Motor is properly grounded.

□ All leads are properly insulated.

□ Resistance between motor windings and earth is over

10 megohms (see motor maintenance section).

□ Control equipment is functioning properly.

Trial “bump”:

□ Turn on power just long enough to start assembly

rotating.

□ Check rotation for agreement with rotation arrow

□ Listen for any unusual noise.

Run unit up to speed:

□ Bearing temperatures are acceptable (<200°F, 93°C)

after one to two hours of operation.

□ Check for excess levels of vibration. Filter in readings

should be 7.2 mm/s RMS or less.

□ Check that motor current draw is not above the

nameplate value.

After one week of operation:

□ Check all nuts, bolts and setscrews and tighten if

necessary.

□ Readjust drive tension if necessary. (See Table 5 for

drive maintenance schedule.)

Optional Accessories

1. Turning Gear — A turning gear is sometimes used

in high temperature applications where the fan is

exposed to high temperature gases while not operating. The wheel and shaft can expand unevenly due

to the temperature when sitting idle, which can cause

vibration at startup and/or a permanent set to the

rotor. The turning gear slowly turns the fan from the

outboard side while it is not operating, providing for

even thermal expansion. It starts automatically when

the fan shuts down and disengages automatically

when the fan starts up again. More specific information will be provided for each application.

2. Shaft Seals — The standard shaft seal is a ceramic

fiber element retained with an aluminum retaining

plate and clips. Other configurations of shaft seals

are available for special applications, such as when it

is necessary to keep the shaft seal as gas tight as

possible. Shaft seal application manuals are provided

in Engineering Supplement ES-595.

3. Variable Inlet Vanes — Variable inlet vanes are provided as assemblies internally in the inlet cone or

externally in a flanged cylinder. The vanes are used to

control volume and save power in installations where

different volumetric operating conditions are used.

Installation manuals are provided in other engineering supplements for specific fan types. Variable inlet

vanes may be provided with powered operators in

12 Twin City Fan Engineering Supplement 2-06

5. Outlet Dampers — Outlet dampers are usually provided

completely assembled like the inlet dampers. The damper is bolted to the fan discharge for volume control.

6. Shaft Cooler — Also referred to as “heat slingers”

or “cooling wheels,” these are small, radially bladed

aluminum wheels that are split and bolted for installation between the inboard bearing and fan housing.

The backplate usually is closest to the fan housing

and the blades face the bearing. Specific instructions

will be provided by application.

7. Oil Circulating Systems — Usually the following modi-

fications will have to be made to the bearing if an

oil circulating system is used. When an oil circulating system is included, a manual for its installation,

operation, and maintenance will accompany it.

a. Four drain holes will be drilled in the bearing, two

on each side of the bearing. Because of this, the

bearing may be drained from either side. (Drain

from both holes on one side of the bearing.)

b. It is not necessary to drain the bearing.

c. The bearing will be packed with grease to prevent

corrosion until installed and started up. The drain

holes will be plugged with plastic covers to make sure

they are open. The customer MUST REMOVE most

of the grease using solvent and remove the plastic

covers prior to starting the oil circulating system.

d. A wet sump will be added in case of circulating

oil pump failure. Seals will be provided to accommodate the resultant splashing.

e. The zerk on top of the bearing will be removed

for that hole to be used as the oil inlet.

Troubleshooting Guidelines

Use current safety practices when investigating fan or

system performance problems. General safe practices

and performance troubleshooting guidelines can be

found in AMCA Publications 410 and 202, respectively.

Fan application and field measurement procedures can

be found in AMCA Publications 201 and 203.

Below is a list of possible areas to check when air

or sound values do not match expectations. Most fan

problems can be pinpointed to one of these common

causes.

Page 13

Air Capacity Problems

1. Resistance of the system is not at design rating. If

resistance is lower than expected, both airflow and

horsepower may be up. If resistance is higher than

anticipated, air volume will be down.

2. Fan speed is not at design speed.

3. Air density is not at the design value. Also check air

performance measurement techniques/procedures.

4. Devices for air modulation are closed or plugged.

Also check filters.

5. Wheel mounted improperly or is rotating in reverse.

6. Parts of the system or fan have been damaged or

need cleaning.

Noise Problems

1. Air performance is incorrect and the fan is not at

design point of operation. Fan is being forced to

operate in an unstable flow region.

2. Bearing failure. Check bearings (lubrication).

3. Supply voltage high or inconsistent supply frequency.

Adjustable frequency controllers can generate motor

noise.

4. Objects that are installed in a high velocity airstream

can generate noise. This includes flow sensors, turning vanes, etc.

5. Poor fan inlet conditions.

6. Acoustics or sound measurement procedure incorrect.

4. Damaged rotating components (bearings, shaft, fan,

wheel, sheaves).

5. Broken, loose or missing setscrews.

6. Loose bolts.

7. Vibration transmitted by another source.

8. Water accumulating in airfoil blades.

9. Fan is operating in stall or unstable flow region.

Motor Problems

1. Incorrect wiring.

2. Speed of fan too high.

3. Parts improperly installed; binding.

4. Bearings improperly lubricated.

2

5. WR

6. Protection devices may be improperly sized.

Drive Problems

1. Belts improperly tensioned.

2. Drive alignment is poor.

capability of motor too low for application.

Disposal

All metal and other recyclable materials should be

separated and properly recycled. Paint, insulation, plastic,

packaging materials, lubricants, electrical components

and other items should be disposed of per local

regulations.

Vibration Problems

1. Misalignment of drive components.

2. Poor foundation or mounting structure (resonances).

3. Foreign material attached to rotating components.

Appendix A – Commercial Ventilator Installation instructions

Handling

Roof ventilators should be lifted by using straps around

the fan housing or base only. Spreader bars should also

be used to avoid damage to stack caps or hoods. DO

NOT LIFT ROOF VENTILATORS BY THE STACK CAP

OR HOOD. On hooded units, disassemble the stack

from hood when lifting. Upblast models may be lifted

assembled.

Installation Instructions – Follow the above section

titled “Fan Installation, Factory Assembled Units” with

the exception of the instructions below for commercial

ventilators.

Roof ventilators should always be mounted to a flat,

level, solid and rigid structure. Particular caution should

be exercised when installing fans on metal buildings. Be

sure wall or roof is capable of supporting the fan(s). Fans

mounted on walls or roofs and not supported correctly

will cause vibration that could cause damage or injury.

Fans mounted off ground level should be rigidly

mounted to a structural platform and be placed over or

as near as possible to a solid wall or column.

Support for suspended fans must be cross-braced for

live load support to prevent side sway. Use guy wires

to help secure roof units if excessively windy conditions

prevail.

When the roof ventilator is designed to be mounted

on a curb, the curb should be securely installed prior to

the fan installation.

A damper, if used, should be securely mounted within

the curb or wall in a manner which allows free and

unobstructed operation.

On roof units, anchor the fan securely to the curb.

Anchoring through the vertical portion of the curb cap

flange is recommended. Use a minimum of four lag bolts

or other suitable fasteners. See Fig 8 below.

Figure 8. Mounting Roof Ventilator to Curb Cap

13 Twin City Fan Engineering Supplement 2-06

Page 14

Appendix A – Commercial Ventilator Installation instructions (cont'd)

Hooded Ventilators

Hooded units sizes 12 to 42 use a one-piece hinged

hood. To lift the hood, remove the two bolts located

under the mushroom cap and prop the hood up with the

supplied safety rods. Push and lock into place. A screw

is installed at the end of the pin side of the hinge in the

hood angle to prevent accidental removal of the hood. To

close the hood, replace the bolts to lock in place. For

size 48, a one-piece bolted hood connects directly to the

fan stack. To lift the hood off the unit, remove the bolts

located under the mushroom cap. For sizes 54–72, a twopiece bolted hood connects directly to the fan stack. To

lift the hood off the unit, remove the sheet metal bolts

than connect the right and left sides of the hood and

then remove the bolts located under the mushroom cap.

See Figure 9 below.

Appendix B – Axial Fans

Axial Fans - Securing the Wheel to the Shaft

If the propeller is removed for any reason, make sure that

it is securely attached to the shaft before restarting the

fan. If the propeller is attached to the shaft by means of

a Trantorque bushing, use the tightening torque values

shown in Table 6 below. For other bushings, see table 3

for proper torque values.

Table 6. Trantorque Bushing Torque Values

Trantorque

Size

7/8 7/8 1-1/2 71 96

1-1/8 1-1/8 1-3/4 130 176

1-3/8 1-3/8 2 141 191

1-5/8 1-5/8 2-1/4 233 316

1-7/8 1-7/8 2-1/2 325 441

2-1/8 2-1/8 2-3/4 440 597

2-3/8 2-3/8 3 470 637

2-7/8 2-7/8 3-1/2 550 746

Note: These torque values are to be obtained with a calibrated

torque wrench. DO NOT apply any lubricant to any part of the

Trantorque® hub. DO NOT use an anaerobic thread adhesive

such as Loctite® on the threads.

Shaft

Diameter

Socket

Size

Axial Fans with Adjustable Blade Angles

The blades are set at the factory to the blade angle that

gives the performance specified on the order. This angle

should be checked prior to start-up. The blade angle

should not be changed from that stated for the order

without assuring that a change in blade angle will not

overload the motor, any controls, or other items. Vibration

levels shall also be checked in accordance with ISO

14694:2003, “Industrial Fans – Specifications for Balance

Quality and Vibration Levels” if any change is made to

blade angles.

Torque

Ft-Lb N-m

Figure 9. Typical Hooded Roof Ventilator Installations

HINGED HOOD

SIZE 12" – 42" ACCESS

DOOR FOR INSPECTION

SAFETY SCREEN STANDARD.

OPTIONAL DAMPER NOT SHOWN.

BOLTED HOOD

SIZE 48" – 60"

ACCESS DOOR FOR DAMPER

REMOVAL

OPTIONAL DAMPER

Blade Adjustment on Adjustable Pitch Vaneaxial

Type TCVX, VJ

The patented wheel construction uses friction and centrifugal force to hold the blades in place. No disassembly

of the wheel is required to change the blade angles. If

it is necessary to change the blade angle, the following

procedure should be used:

1. Work safely. Make sure that proper safety precautions

have been followed. Electrical power must be locked

off.

2. The adjustment can be made through the inlet on open

inlet fans. On fans with ducted inlets, open the wheel

area access door.

3. Place adjustment tool around end of blade (see Figure

10). If necessary, apply “cheater bar” around the 11/4"

(31.75mm) diameter end for additional leverage. The

blades can be turned by hand on open inlet fans. If

additional leverage is needed, place a wrench on the

leading edge of the blade near the hub. Take care not

to mar the surface of the blade.

Blade Adjustment on Type "E" Adjustable Pitch

Propeller

Preferred Method (more Accurate)

1. Lay the hub on a horizontal surface with the concave

(air leaving) surfaces of the blades facing upwards.

2. Loosen the blade retaining bolts until they are fingertight. At this point, the blades should rotate in their

sockets when grasped firmly and twisted, but not turn

on their own.

3. Place an angle meter across the two blade angle position marks on a blade. See Figure 11.

4. Twist the blade to the desired blade angle.

5. Repeat steps 3 and 4 for the remaining blades.

14 Twin City Fan Engineering Supplement 2-06

Page 15

Figure 10. TCVX Blade Angle Adjustment

Detail "X"

5

4

3

Blade

Leading Edge

Hub

25.0"

3. Twist each blade to the desired blade angle.

4. Re-tighten the blade retaining bolts to the torque

shown in Table 7. Work in a star pattern, working your

5

5.0"

4

3

Blade

2.5"

way up to the desired torque in steps. Tightening one

bolt to the full torque before moving on to the next

can crack the hub.

Figure 12. "E" Prop Blade Angle Indicating Marks

Hub

Detail “X”

Vernier Index Line

(Blade As Shown

Is Adjusted To 35°

Blade Tip

)

Tool AS-14093

Blade

Trailing Edge

Cheater Bar