Twin City ES-110 User Manual

MPQN/MPQS Modular Plenum Fans

INSTALLATION, OPERATION & MAINTENANCE MANUAL

ES-110

February 2012

Contents

Introduction .........................................................................1

Shipping and Receiving .....................................................1

Handling .............................................................................. 1

Short Term Storage ...........................................................1

Long Term Storage............................................................1

Foundations and Supporting Structures .......................... 2

Fan Installation ...................................................................3

Assembly of Fans and Sealing/Isolation Strips ..............3

Fan Operation – Safety .....................................................3

Operation Checklist ............................................................ 4

Maintenance of Fans ......................................................... 4

General Motor Maintenance ......................................... 4

Wheel and Shaft Maintenance ..................................... 5

Structural Maintenance ................................................. 5

Troubleshooting Guidelines................................................ 5

Troubleshooting Performance Problems

Air Capacity Problems ..................................................5

Noise Problems .............................................................5

Vibration Problems ........................................................ 5

Motor Problems ............................................................. 5

Limitation of Warranties and Claims ............................... 6

Introduction

The purpose of this manual is to provide instructions

that complement good general practices when installing or operating fans manufactured by Twin City Fan &

Blower. It is the responsibility of the purchaser to provide qualified personnel experienced in the installation,

operation, and maintenance of air moving equipment.

Instructions given in the body of this manual are general in nature and apply to a variety of models manufactured by Twin City Fan & Blower. Most units can be

installed and maintained with the instructions given.

Special applications may require additional information.

These instructions are supplied in the form of attached

appendices. Use the instructions in the appendix if the directions in this manual differ from instructions in the appendix.

As always, follow good safety practices when installing, maintaining and operating your air moving equipment. A variety of safety devices are available. It is

the user’s responsibility to determine adequate safety

measures and to obtain the required safety equipment.

Handling

Handling of all air moving equipment should be conducted by trained personnel and be consistent with safe

handling practices. Verify the lift capacity and operating condition of handling equipment. Maintain handling

equipment to avoid serious personal injury.

Units shipped completely assembled may be lifted with

slings and spreader bars. Use well-padded chains, cables

or nylon straps. On most units, lifting lugs are provided

for attaching chains (see Figure 1). Lift the fan in a fashion that protects the fan and fan coating from damage.

Never lift a fan by the inlet or discharge flange, shafting

or drives, wheel or impeller, motor or motor base, or in

any other manner that may bend or distort parts.

Partial or disassembled units require special handling.

All parts should be handled in a fashion which protects the coatings and parts from damage. Components

should be handled such that forces are not concentrated

and bending or distortion cannot occur.

Figure 1. Lifting Lug Locations

SWIVEL

EYE HOOK

(By Customer)

A

DETAIL A

NOTE: When lifting, the straps/chains

should be at a minimum angle of 45

Housing should be lifted using straps and spreaders.

Do not distort housing or side plates when lifting.

o

Shipping and Receiving

All Twin City Fan & Blower products are carefully constructed and inspected before shipment to insure the

highest standards of quality and performance.

Compare all components with the bill of lading or

packing list to verify that the proper unit was received.

Check each unit for any damage that may have

occurred in transit. Any damage should be reported

immediately to the carrier and the necessary damage

report filed.

©2012 Twin City Fan Companies, Ltd.

Short Term Storage

If fan installation is to be delayed, store the unit in a

protected area. Protect the fan and motor bearings from

moisture and vibration (or shock loading).

Long Term Storage

Prior to Storage – Motor bearings are to be greased at

the time of going into extended storage per the motor

manufacturer’s specifications.

Storage Procedure – Fans should be stored indoors

whenever possible where control over temperature,

shock and dust is reasonably maintained. If units are to

be stored outside in the elements, they should be covered with a water-resistant material. Stored equipment

should be stored on a clean, dry floor or blocked up

off the ground on blocks to prevent unit from setting in

any water or directly on the ground. If shock or vibration

will be present during storage, the unit may need to be

placed on some type of vibration dampening material to

aid in preventing brinelling of the bearing surfaces.

Periodic Check – On a monthly interval, the equipment

should be checked to ensure that it has remained in

an acceptable stored condition. The fan wheel should

be rotated several times by hand while adding enough

grease to replenish the bearing surfaces with fresh

grease and to maintain a full bearing cavity. Grease

used must be compatible with that already supplied in

the motor and fan bearings. The fan impeller should

be left at approximately 180 degrees from that of the

previous month to prevent the shaft and impeller from

taking a set in one position. Storage records should

be maintained which indicate the above requirements

have been followed. Consult the motor manufacturer for

proper storage, space heater connection and lubrication

if the unit was supplied with one.

Start-Up – When the unit is removed from storage, all

bearing grease should be purged and replenished with

fresh grease as per the lubrication decal. The motor

should be measured to verify that the resistance is still

at a satisfactory level compared to the value recorded

prior to storage.

Foundations and Supporting Structures

Floor mounted fans should be installed on a flat, level

surface with sufficient structure support. Support shall

be suitable for static and dynamic loads and foundation

frequencies be separated at least 20% from the rotational speed/speed ranges.

If the fans are mounted on a sub-structure, an inertia

base with spring isolator system should be considered.

Fans mounted to or within a structure should be

placed as close as possible to a rigid member such

as a wall or column. The structure must be designed

for rotating equipment; static design for strength is

not sufficient to insure proper operation. Supports for

suspended fans must be cross-braced to prevent side

sway. Structural resonance should be at least 20% from

fan operating speed.

Any ducting and/or dampers with sleeves should have

independent support; do not use the fan for support.

Isolating the fan from ductwork with flex connections

eliminates transmission of vibration.

1. Sufficient structure must be provided to support

weight of fan assembly.

2. Sufficient restraint must be provided to resist the

pressure force against the fans. Typically fans are

assembled in an application in a modular fashion with

multiple fans working in parallel. The cumulative thrust

force must be restrained to prevent the fan assemblies

from leaning or tipping forward. The force acting on

the fan assemblies is calculated as shown below.

Thrust force (lb

27.68

H x W x N x P

f) =

s

Where

P

s = Maximum operating static pressure (in. w.g.)

W = Width of each individual fan (in.)

H = Height of each individual fan (in.)

N = Quantity of fans in system

27.68 = conversion factor for in. w.g. to PSI

Example

Parallel fan system employing nine (9) – Size 182 fans

in a 3 x 3 configuration. (3 fans high x 3 fans wide)

System pressure is 5 inches of water column.

Outside dimension of fan housing = approx. 32 in. by

32 in.

Thrust force (lb

27.68

Thrust force (lb

27.68

Note: The thrust force is distributed evenly across the front

surface of the parallel fan system.

H x W x N x P

f) =

32 x 32 x 9 x 5

f) =

s

= 1665 (lbf)

3. Recommend attachments to the sides and top of the

parallel fan system incorporating some form of spring

support, i.e. rubber snubbers/isolators or springs. Such

devices should be attached to prevent significant point

loading on an individual fan. They should be located

on the side of the parallel fan system at the top corner and along the top every 2 fans or less.

a. When the fans are rigidly mounted to the base, an

assumption can be made that half of the thrust

load will be supported at the base, and the supports added at the top of the fan need to carry a

minimum of one half of the thrust load.

b. When the fans are supported on an isolation base

or isolators, it will be necessary to add thrust

restraints around the periphery of the fan assembly

to support the entire thrust load. Flex connections are required when using isolators or isolation

base.

c. Attachments to the fan can be made utilizing the

factory mounting holes. Recommend that the gage

of the materials be checked for tear out strength

in thrust applications. If necessary utilize multiple

mounting hole locations to distribute the load.

2

Twin City Engineering Supplement ES-110

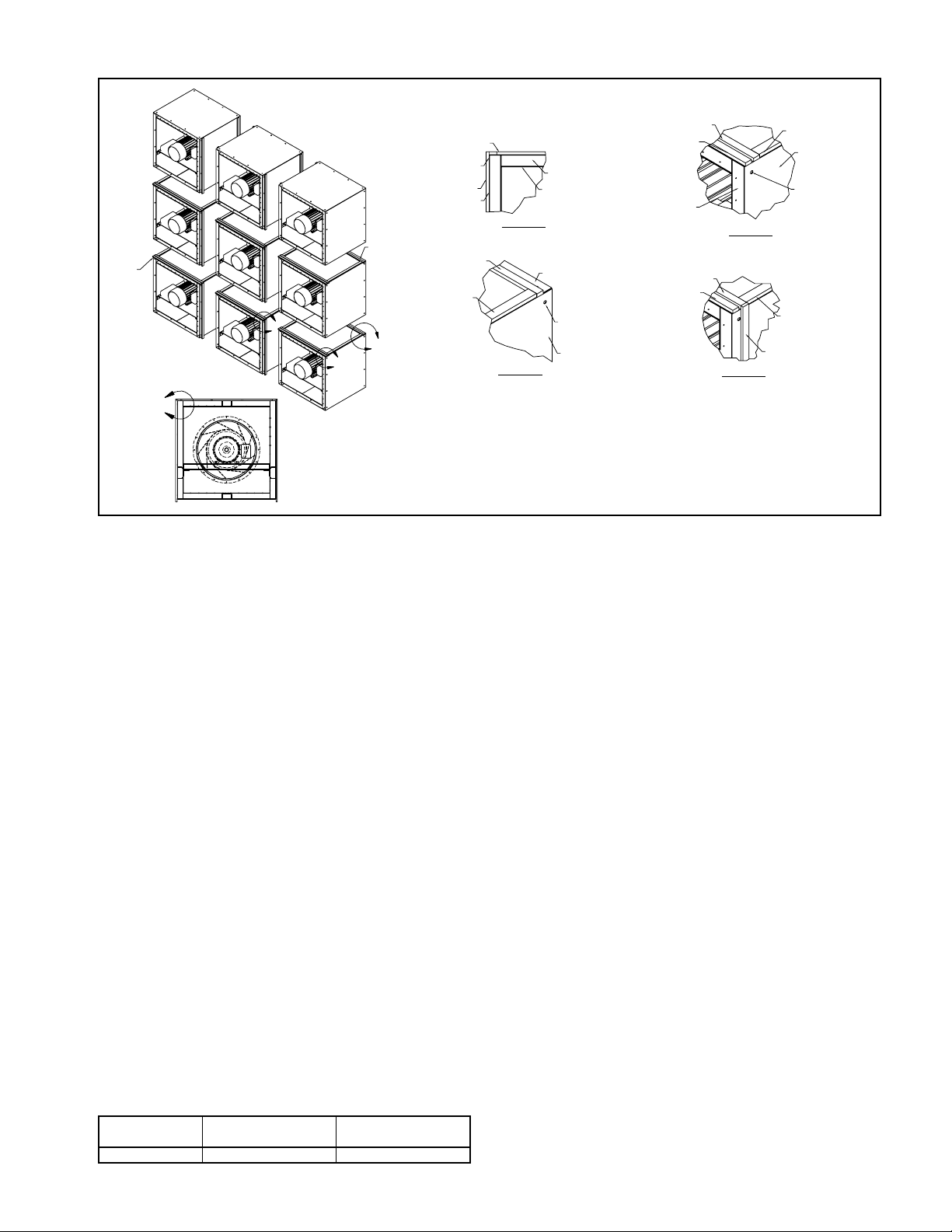

Figure 2.

RUBBER GASKET

NOTE 5

RUBBER GASKET

OUTER SHELL

RUBBER GASKET

NOTES

D

B

A

RUBBER GASKET

RUBBER GASKET

C

NOTES:

1. On the horizontal between fans, one strip of gasket material is needed on inlet side & two

on drive end on 222 & above, 200 and below get one strip on each end.

2. Gaskets need to connect in all corners to ensure proper sealing.

3. Rubber gasket is to be placed directly next to the mounting holes on the inlet and drive side.

4. Rubber gasket is 1/2 in. x 2 in. x cut-to-fit.

5. Rubber gasket is to be held in place be double-stick foam tape during assembly.

Fan Installation – Factory Assembled Units

Follow proper handling instructions given earlier.

1. Move the fan to the final mounting position.

2. Remove skid, crates, and packing materials carefully.

3. If supplied, place vibration pads or isolation base on

mounting bolts. Line up holes in fan base with bolts.

4. Place fan on mounting structure. Carefully level unit

using shims as required at all mounting hole locations. Bolt down the unit.

Assembly of Fans and Sealing/Isolation

Strips

1. Fans must be securely bolted to a base either directly

through the factory mounting holes or with a properly

designed clip. Final bolting of layer of fans to the

support structure or base should be done after the

individual fans are bolted together as a row.

2. During installation rubber strips need to be installed

between each fan. Use double-sided foam tape to

hold strips in place during installation. Two (2) to

three (3) pieces of tape can be used as needed for

this purpose (each end and middle of rubber strip).

Location of these strips is documented in Figure 2.

3. The first fan on the bottom row will have the 2 vertical strips placed next to the mounting holes. Note:

Strips should be cut to ensure an airtight seal between

fans.

4. The bolts to be snugged up on vertical sections for the

first row. Once all strips are in place, the bolts shall

be tightened to torque values in table. See Table 1.

Table 1. Torque Values MPQN/MPQS Fasteners

Size

3/8 – 16 UNC

Net Type

Nylock 16 – 17

Torque Values

(ft lbs)

DETAIL A

DETAIL C

FRAME

PERF. PLATE

OUTER SHELL

MOUNTING HOLE

OUTER SHELL

RUBBER GASKET

RUBBER GASKET

OUTLET ONLY

222 & ABOVE

FRAME

RUBBER GASKET

RUBBER GASKET

DETAIL B

DETAIL D

RUBBER GASKET

OUTER SHELL

MOUNTING HOLE

RUBBER GASKET

RUBBER GASKET

5. The bolts holding the fan to the supporting structure

can now be torqued.

6. Rubber strips are then placed on the top of the fan

to support the fan above it according to the pattern

shown. Note: On larger fan assemblies 2 strips are

used in the back to support the weight of the motor.

7. The second row and succeeding rows can be installed

using the same assembly steps as the first row.

8. Rubber strips are not normally needed on the outside

or top of the parralel fan system.

9. Sealing around the perimeter should be accomplished

using a flexible material.

Fan Operation - Safety

For general safety practices for air moving equipment,

see AMCA Bulletin 410.

Twin City Fan & Blower has many safety accessories available. These safety devices include (but are not

limited to) inlet and discharge screens. The use, abuse,

or non-use of safety devices is the responsibility of the

purchaser.

Facility-related safety conditions include fan accessibility and location. How easily can non-service personnel access the unit? Is the fan in a hazardous duty

environment? Was the unit ordered for this duty? Other

concerns must also be addressed. All fans should be

powered through switches which are easily accessible to

service personnel from the fan. Every switch should have

the ability to be “locked-off” by the service person and

the key to be retained by this person to prevent accidental power of the fan while service is in process.

3

Twin City Engineering Supplement ES-110

Loading...

Loading...