Page 1

XTTM-300

LIQUID COOLED

PLASMA CUTTING TORCH

For Distributor Use With

Hypertherm

®

HD3070 System

Instruction Manual

Rev. AA.01 Date: December 20, 2006 Manual # 0-2912

Operating Features:

Coolant Flow

Minimum

0.9 gpm

Duty

Cycle

%

Page 2

Page 3

w WARNINGS

Read and understand this entire Manual and your employer’s safety practices before installing,

operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement,

the Manufacturer assumes no liability for its use.

Liquid Cooled Plasma Torch

RPT Model XT™-300 For Distributor Use With Hypertherm® HD3070 System

Instruction Manual No. 0-2912

Published by:

Thermadyne Corporation

82 Benning Street

West Lebanon, New Hampshire, USA 03784

(603) 298-5711

www.thermal-dynamics.com

© Copyright 2004, 2005, 2006 by

Thermadyne Corporation

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the

publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to any party

for any loss or damage caused by any error or omission in this Manual, whether

such error results from negligence, accident, or any other cause.

Printed in the United States of America

Publication Date: December 20, 2006

Record the following information for Warranty purposes:

Where Purchased: ___________________________________

Purchase Date: ___________________________________

Power Supply Serial #: ___________________________________

Hypertherm

Torch Serial #: ___________________________________

®

is a registered trademark of Hypertherm, Inc.

Page 4

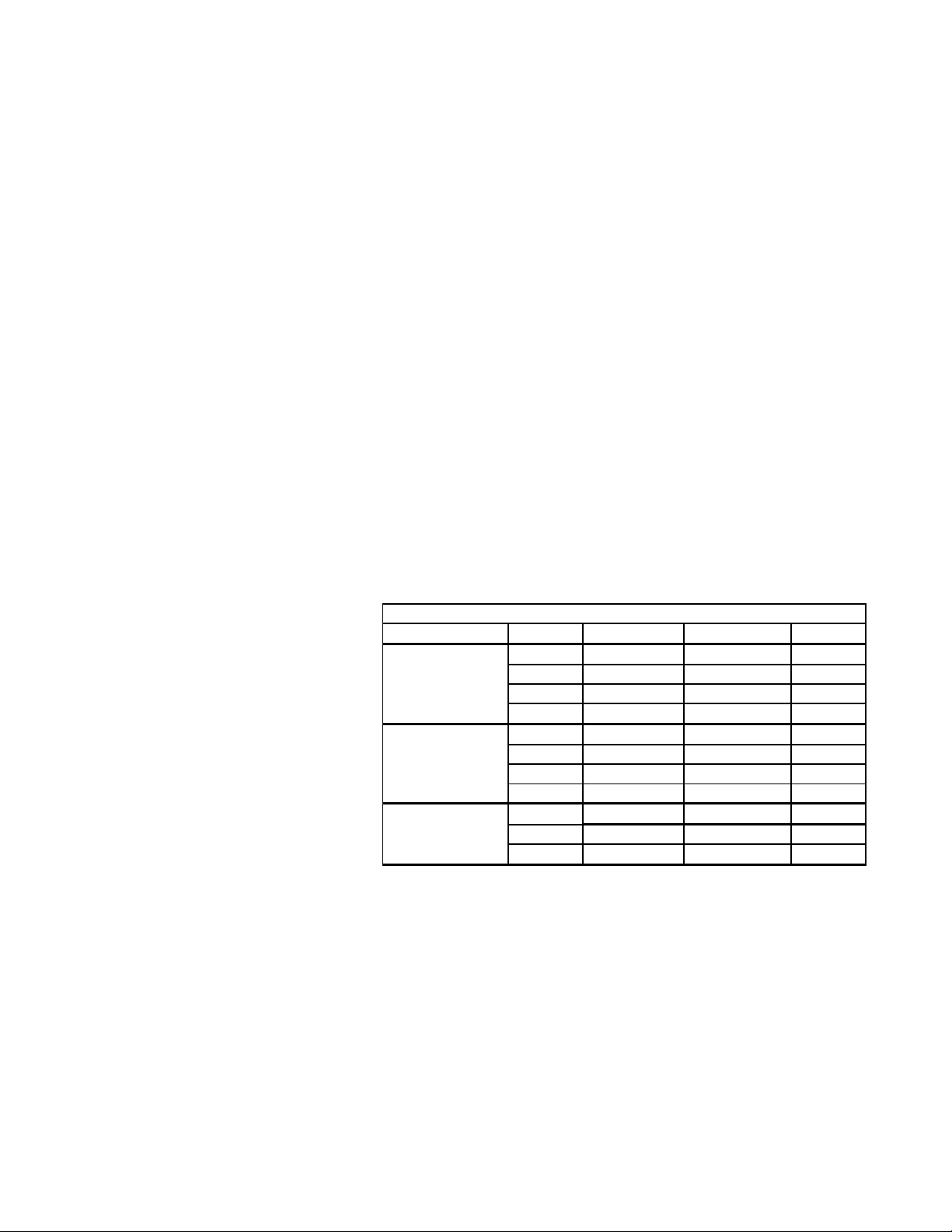

TABLE OF CONTENTS

SECTION 1:

GENERAL INFORMATION ............................................................................................... 1-1

1.01 Notes, Cautions and Warnings ..................................................................... 1-1

1.02 Important Safety Precautions ....................................................................... 1-1

1.03 Publications .................................................................................................. 1-3

Section 2: Torch Specifications ................................................................................................. 2-1

SECTION 3:

INSTALLATION ................................................................................................................. 3-1

3.01 Unpacking .................................................................................................... 3-1

3.02 Oxygen Plasma Pre-Charge Unit Installation ............................................... 3-1

3.03 Oxygen Plasma Pre-Charge Unit Switch Setting .......................................... 3-5

3.04 Connecting Torch ......................................................................................... 3-6

3.05 Consumables Selection ............................................................................... 3-8

3.06 Oxygen Plasma Pre-Charge Unit Installation Checks ................................ 3-11

3.07 Oxygen Plasma Pre-Charge Unit Operational Check ................................. 3-12

3.07 Pre-Charge Unit Checks ............................................................................ 3-12

SECTION 4-A:

OPERATION WITH MANUAL GAS CONSOLE ........................................................... 4A-1

Speed Charts for

Material Amperage Plasma Gas Shield Gas Page

30 O2 O2 - N2 4A-4

Mild Steel

Stainless Steel

Aluminum

50 O2 O2 - N2 4A-5

70 O2 O2 - N2 4A-6

100 O2 O2 - N2 4A-7

30 Air Air 4A-8

50 Air Air 4A-9

70 Air Air - CH4 4A-10

100 AR / H2 N2 4A-11

50 Air Air 4A-12

70 Air Air 4A-13

100 AR / H2 N2 4A-14

Manual

Gas Controls

Page 5

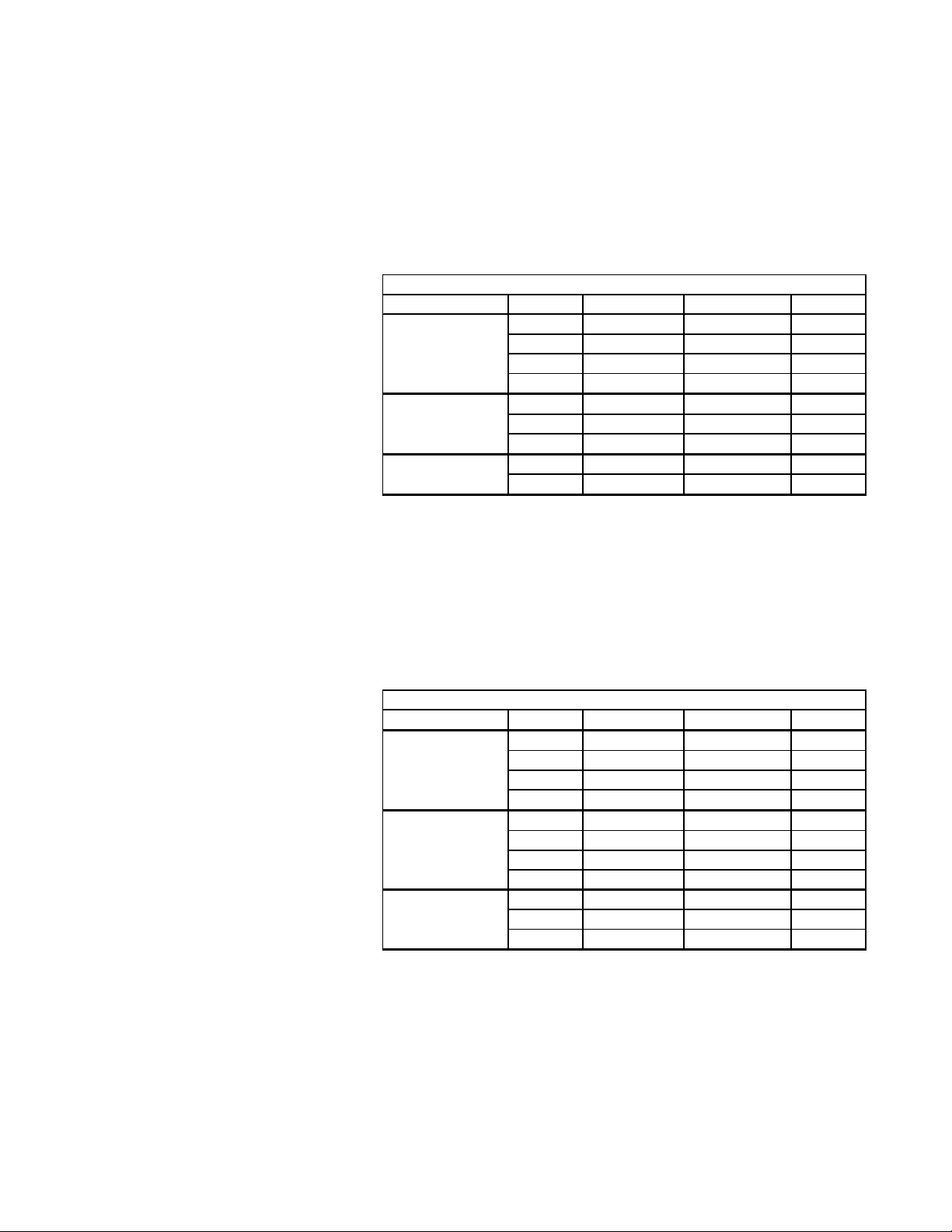

TABLE OF CONTENTS (continued)

SECTION 4B:

OPERATION WITH 5-KNOB AUTOMATIC GAS CONSOLE ......................................... 4B-1

4B.01 Torch Parts Selection .............................................................................. 4B-1

4B.02 Pre-Setting Controls ................................................................................ 4B-1

4B.03 Recommended Cutting Speeds .............................................................. 4B-2

Speed Charts for

Material Amperage Plasma Gas Shield Gas Page

30 O2 O2 - N2 4B-4

Mild Steel

Stainless Steel

Aluminum

50 O2 O2 - N2 4B-5

70 O2 O2 - N2 4B-6

100 O2 O2 - N2 4B-7

30 Air Air 4B-8

50 Air Air 4B-9

70 Air Air - CH4 4B-10

50 Air Air 4A-11

70 Air Air 4A-12

5-Knob Automatic

SECTION 4C:

OPERATION WITH 6-KNOB AUTOMATIC GAS CONSOLE .......................................4C-1

4C.01 Torch Parts Selection ..............................................................................4C-1

4C.02 Pre-Setting Controls................................................................................4C-1

4C.03 Recommended Cutting Speeds .............................................................. 4C-2

Speed Charts for

Material Amperage Plasma Gas Shield Gas Page

30 O2 O2 - N2 4C-4

Mild Steel

Stainless Steel

Aluminum

50 O2 O2 - N2 4C-5

70 O2 O2 - N2 4C-6

100 O2 O2 - N2 4C-7

30 Air Air 4C-8

50 Air Air 4C-9

70 Air Air - CH4 4C-10

100 AR / H2 N2 4C-11

50 Air Air 4C-12

70 Air Air 4C-13

100 AR / H2 N2 4C-13

6-Knob Automatic

Gas Console

Gas Console

Section 5: General Maintenance .............................................................................................. 5-1

E. Coolant Leak Trouble-Shooting .................................................................... 5-5

Page 6

TABLE OF CONTENTS

SECTION 6:

PARTS LIST ...................................................................................................................... 6-1

APPENDIX 1: ALTERNATE ARC VOLTAGE SETTINGS ........................................................... A-1

APPENDIX 2: WIRING DIAGRAM ............................................................................................ A-2

APPENDIX 3: PATENT INFORMATION .................................................................................... A-3

Page 7

SECTION 1:

GENERAL INFORMATION

1.01 Notes, Cautions and Warnings

Throughout this manual, notes, cautions, and warnings

are used to highlight important information. These highlights are categorized as follows:

NOTE

An operation, procedure, or background information which requires additional emphasis or is helpful in efficient operation of the system.

CAUTION

A procedure which, if not properly followed, may

cause damage to the equipment.

WARNING

A procedure which, if not properly followed, may

cause injury to the operator or others in the operating area.

1.02 Important Safety Precautions

WARNINGS

OPERATION AND MAINTENANCE OF

PLASMA ARC EQUIPMENT CAN BE DANGEROUS AND HAZARDOUS TO YOUR

HEALTH.

Plasma arc cutting produces intense electric and

magnetic emissions that may interfere with the

proper function of cardiac pacemakers, hearing

aids, or other electronic health equipment. Persons who work near plasma arc cutting applications should consult their medical health professional and the manufacturer of the health

equipment to determine whether a hazard exists.

GASES AND FUMES

Gases and fumes produced during the plasma cutting

process can be dangerous and hazardous to your health.

• Keep all fumes and gases from the breathing area.

Keep your head out of the welding fume plume.

• Use an air-supplied respirator if ventilation is not

adequate to remove all fumes and gases.

• The kinds of fumes and gases from the plasma arc

depend on the kind of metal being used, coatings

on the metal, and the different processes. You must

be very careful when cutting or welding any metals which may contain one or more of the following:

Antimony Chromium Mercury

Arsenic Cobalt Nickel

Barium Copper Selenium

Beryllium Lead Silver

Cadmium Manganese Vanadium

• Always read the Material Safety Data Sheets

(MSDS) that should be supplied with the material

you are using. These MSDSs will give you the information regarding the kind and amount of fumes

and gases that may be dangerous to your health.

• For information on how to test for fumes and gases

in your workplace, refer to item 1 in Subsection

1.03, Publications in this manual.

• Use special equipment, such as water or down draft

cutting tables, to capture fumes and gases.

• Do not use the plasma torch in an area where combustible or explosive gases or materials are located.

• Phosgene, a toxic gas, is generated from the vapors of chlorinated solvents and cleansers. Remove

all sources of these vapors.

• This product, when used for welding or cutting,

produces fumes or gases which contain chemicals

known to the State of California to cause birth defects and, in some cases, cancer. (California Health

& Safety Code Sec. 25249.5 et seq.)

To prevent possible injury, read, understand and

follow all warnings, safety precautions and instructions before using the equipment. Call 1-603298-5711 or your local distributor if you have any

questions.

Date: July 16, 2002 1-1 GENERAL INFORMATION

Page 8

ELECTRIC SHOCK

NOISE

Electric Shock can injure or kill. The plasma arc process

uses and produces high voltage electrical energy. This

electric energy can cause severe or fatal shock to the operator or others in the workplace.

• Never touch any parts that are electrically “live”

or “hot.”

• Wear dry gloves and clothing. Insulate yourself

from the work piece or other parts of the welding

circuit.

• Repair or replace all worn or damaged parts.

• Extra care must be taken when the workplace is

moist or damp.

• Install and maintain equipment according to NEC

code, refer to item 9 in Subsection 1.03, Publications.

• Disconnect power source before performing any

service or repairs.

• Read and follow all the instructions in the Operating Manual.

FIRE AND EXPLOSION

Fire and explosion can be caused by hot slag, sparks, or

the plasma arc.

• Be sure there is no combustible or flammable material in the workplace. Any material that cannot

be removed must be protected.

• Ventilate all flammable or explosive vapors from

the workplace.

• Do not cut or weld on containers that may have

held combustibles.

• Provide a fire watch when working in an area

where fire hazards may exist.

• Hydrogen gas may be formed and trapped under

aluminum workpieces when they are cut underwater or while using a water table. DO NOT cut

aluminum alloys underwater or on a water table

unless the hydrogen gas can be eliminated or dissipated. Trapped hydrogen gas that is ignited will

cause an explosion.

Noise can cause permanent hearing loss. Plasma arc processes can cause noise levels to exceed safe limits. You

must protect your ears from loud noise to prevent permanent loss of hearing.

• To protect your hearing from loud noise, wear protective ear plugs and/or ear muffs. Protect others

in the workplace.

• Noise levels should be measured to be sure the decibels (sound) do not exceed safe levels.

• For information on how to test for noise, see item

1 in Subsection 1.03, Publications, in this manual.

PLASMA ARC RAYS

Plasma Arc Rays can injure your eyes and burn your

skin. The plasma arc process produces very bright ultra

violet and infra red light. These arc rays will damage

your eyes and burn your skin if you are not properly

protected.

• To protect your eyes, always wear a welding helmet or shield. Also always wear safety glasses with

side shields, goggles or other protective eye wear.

• Wear welding gloves and suitable clothing to protect your skin from the arc rays and sparks.

• Keep helmet and safety glasses in good condition.

Replace lenses when cracked, chipped or dirty.

• Protect others in the work area from the arc rays.

Use protective booths, screens or shields.

• Use the shade of lens as suggested in the following per ANSI/ASC Z49.1:

Minimum Protective Suggested

Arc Current Shade No. Shade No.

Less Than 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

* These values apply where the actual arc is clearly

seen. Experience has shown that lighter filters

may be used when the arc is hidden by the workpiece.

GENERAL INFORMATION 1-2 Date: July 16, 2002

Page 9

1.03 Publications

Refer to the following standards or their latest revisions

for more information:

1. OSHA, SAFETY AND HEALTH STANDARDS, 29CFR

1910, obtainable from the Superintendent of Documents,

U.S. Government Printing Office, Washington, D.C.

20402

2. ANSI Standard Z49.1, SAFETY IN WELDING AND

CUTTING, obtainable from the American Welding Society, 550 N.W. LeJeune Rd, Miami, FL 33126

3. NIOSH, SAFETY AND HEALTH IN ARC WELDING

AND GAS WELDING AND CUTTING, obtainable from

the Superintendent of Documents, U.S. Government

Printing Office, Washington, D.C. 20402

4. ANSI Standard Z87.1, SAFE PRACTICES FOR OCCUPATION AND EDUCATIONAL EYE AND FACE PROTECTION, obtainable from American National Standards Institute, 1430 Broadway, New York, NY 10018

5. ANSI Standard Z41.1, STANDARD FOR MEN’S

SAFETY-TOE FOOTWEAR, obtainable from the American National Standards Institute, 1430 Broadway, New

York, NY 10018

12. CSA Standard W117.2, CODE FOR SAFETY IN WELDING AND CUTTING, obtainable from the Canadian

Standards Association, Standards Sales, 178 Rexdale

Boulevard, Rexdale, Ontario, Canada M9W 1R3

13. NWSA booklet, WELDING SAFETY BIBLIOGRAPHY

obtainable from the National Welding Supply Association, 1900 Arch Street, Philadelphia, PA 19103

14. American Welding Society Standard AWSF4.1, RECOMMENDED SAFE PRACTICES FOR THE PREPARATION FOR WELDING AND CUTTING OF CONTAINERS AND PIPING THAT HAVE HELD HAZARDOUS

SUBSTANCES, obtainable from the American Welding

Society, 550 N.W. LeJeune Rd, Miami, FL 33126

15. ANSI Standard Z88.2, PRACTICE FOR RESPIRATORY

PROTECTION, obtainable from American National

Standards Institute, 1430 Broadway, New York, NY

10018

6. ANSI Standard Z49.2, FIRE PREVENTION IN THE USE

OF CUTTING AND WELDING PROCESSES, obtainable from American National Standards Institute, 1430

Broadway, New York, NY 10018

7. AWS Standard A6.0, WELDING AND CUTTING CONTAINERS WHICH HAVE HELD COMBUSTIBLES, obtainable from American Welding Society, 550 N.W.

LeJeune Rd, Miami, FL 33126

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS

FOR WELDING, CUTTING AND ALLIED PROCESSES, obtainable from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269

9. NFPA Standard 70, NATIONAL ELECTRICAL CODE,

obtainable from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269

10. NFPA Standard 51B, CUTTING AND WELDING PROCESSES, obtainable from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269

11. CGA Pamphlet P-1, SAFE HANDLING OF COMPRESSED GASES IN CYLINDERS, obtainable from the

Compressed Gas Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202

Date: July 16, 2002 1-3 GENERAL INFORMATION

Page 10

GENERAL INFORMATION 1-4 Date: July 16, 2002

Page 11

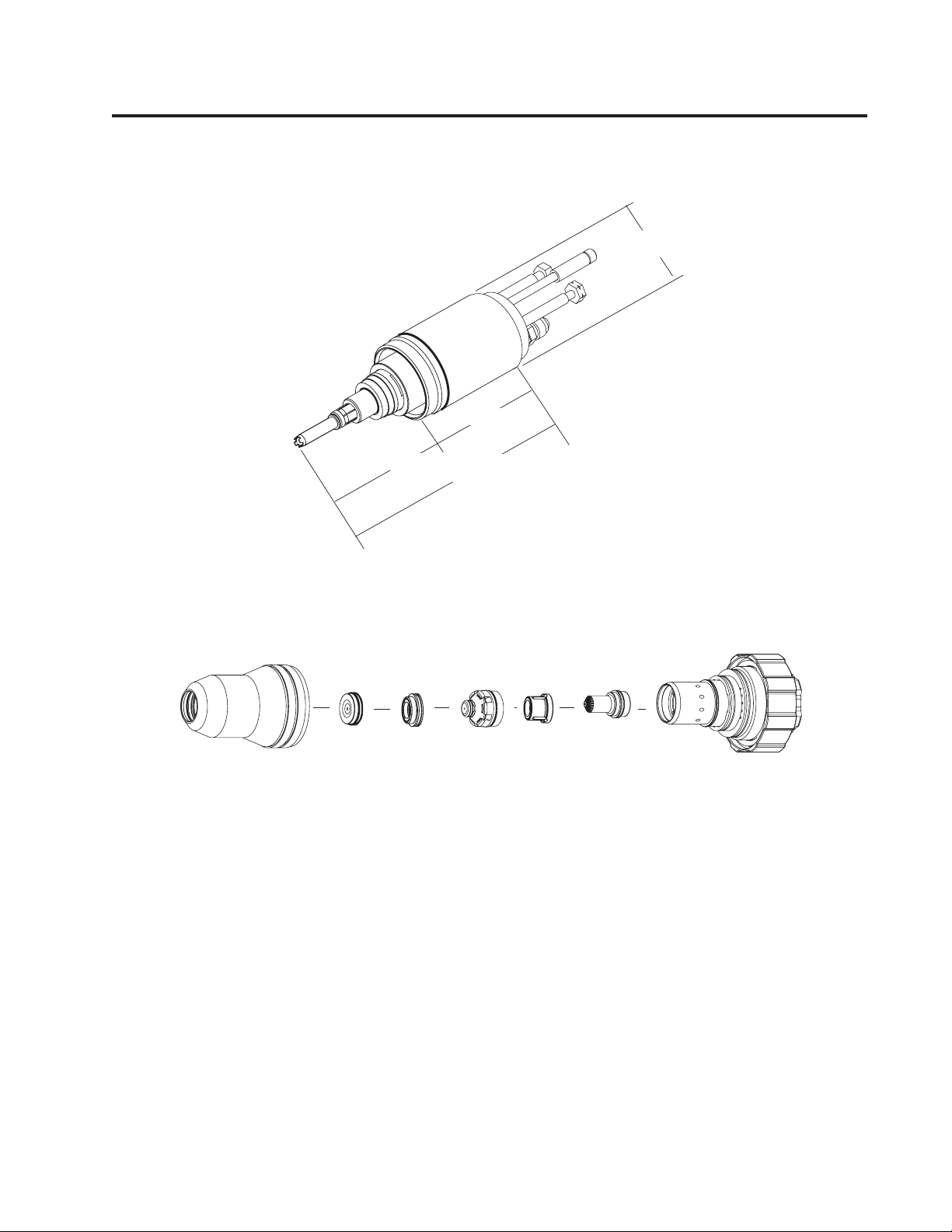

A. Torch Dimensions

Section 2: Torch Specifications

2" Diameter

3.25"

2.75"

6.00"

Art # A-04699

B. Torch Parts (Generic Parts Shown)

Art # A-04741

Shield Gas

Distributor

Shield Cap

Shield Cup

Tip

Plasma Gas

Distributor

Electrode

Cartridge

C. Parts - In - Place (PIP)

The torch is designed for use with a power supply which senses coolant return flow to confirm that torch

parts are in place. If coolant return flow to the power supply is absent or insufficient the power supply will

not provide power to the torch. Coolant leakage from the torch also indicates that torch parts are absent

or installed improperly.

D. Type of Cooling

Combination of gas stream through torch and liquid cooling.

Manual No. 0-2912 2-1 SPECIFICATIONS

Page 12

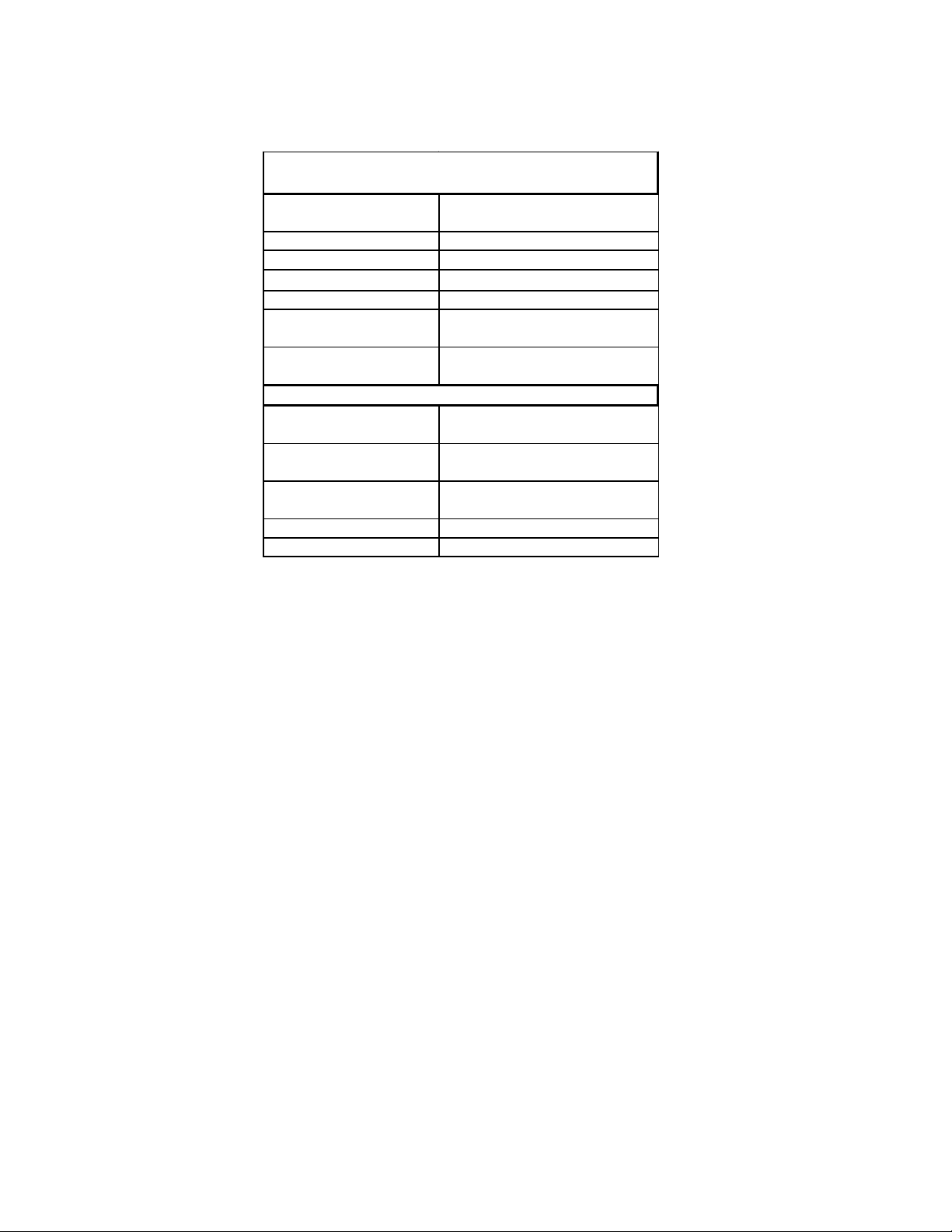

E. XTTM-300 Torch Data (with Hypertherm HD3070 Power Supply)

p

TM

XT

-300 Torch Ratings

for use with Hypertherm HD3070 Power Supply

Ambient

Temperature

Duty Cycle 100% @ 100 Amps

Maximum Current 100 Amps

Voltage (V

)500V

eak

Arc Striking Voltage 10kV

Current

Minimum Coolant

Flow Requirements

TM

XT

-300 Torch Gas Specifications

Plasma Gases:

Shield Gases:

Operating Pres sure

Maximum Input Pressure 135 psi / 9.3 bar

Gas flow 10 - 300 scfh

104° F

40° C

Up to 100 Amps, DC,

Straight Polarity

0.9 gpm (3.4 lpm)

Compressed Air, Oxygen,

Nitrogen, H35, F5

Compressed Air, Oxygen,

Nitrogen, Water

125 psi ± 10 psi

8.6 bar ± 0.7 bar

Manual No. 0-2912 2-2 SPECIFICATIONS

Page 13

SECTION 3:

INSTALLATION

3.01 Unpacking

The product is packaged and protected to prevent damage during shipping.

1. Unpack each item and remove all packing material.

2. Locate the packing list(s) and use the list to identify and account for each item.

3. Inspect each item for possible shipping damage. If damage is evident, contact your distributor and/or shipping

company before proceeding with system installation.

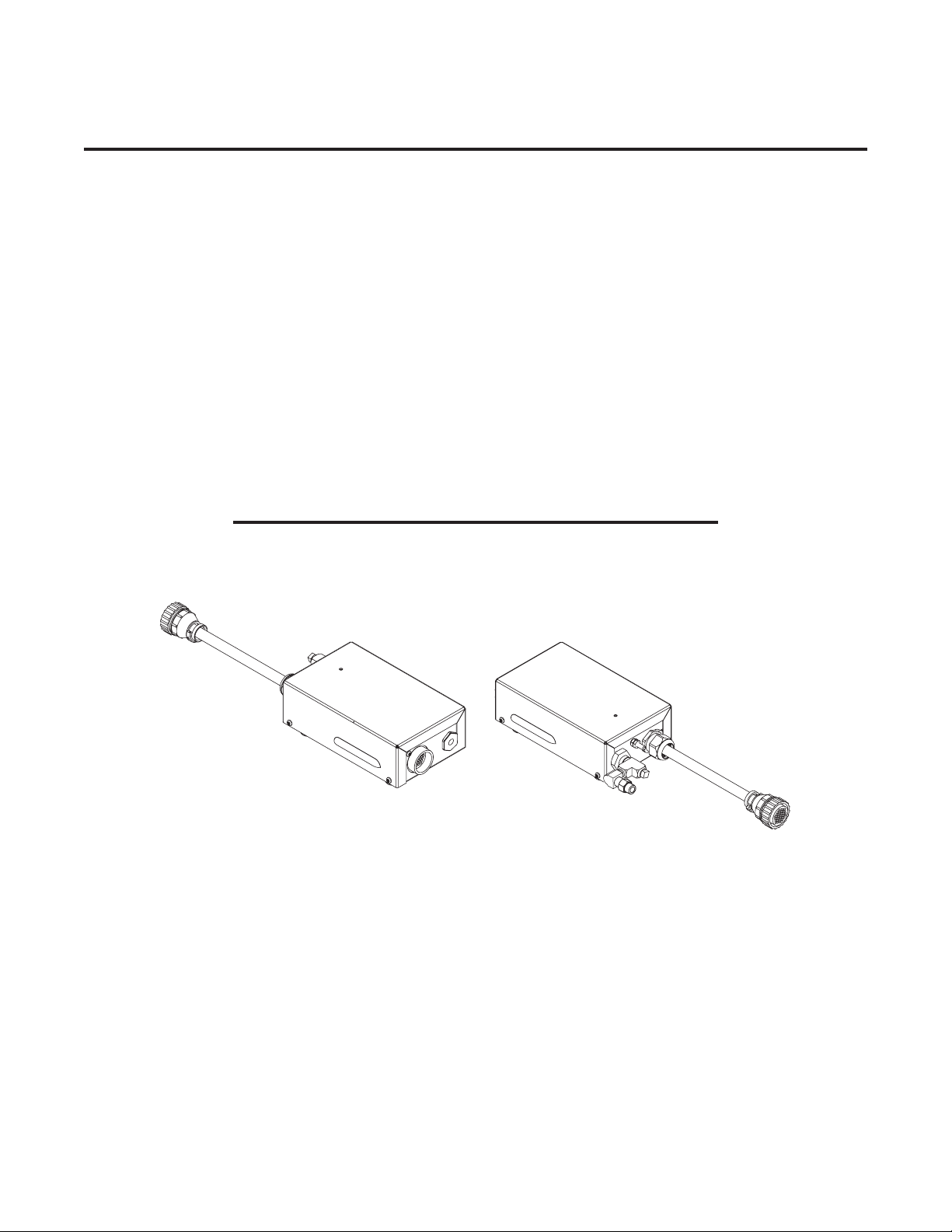

3.02 Oxygen Plasma Pre-Charge Unit Installation

The Oxygen Plasma Pre-Charge Unit is an addition to the Gas Control console on the HD-3070 Power Supply. The

pre-charge unit is used to increase the line pressure of the plasma gas (Oxygen) at the start of a cut cycle. The precharge unit is activated only during pre-flow when the gas selection switch is set to cut with Oxygen. This added

pressure provides improved consumable life during piercing. When cutting with any other plasma gas, the pre-charge

unit is not activated.

NOTE

The Thermal Dynamics Pre-Charge Unit is for use only with oxygen (O2)

gas.

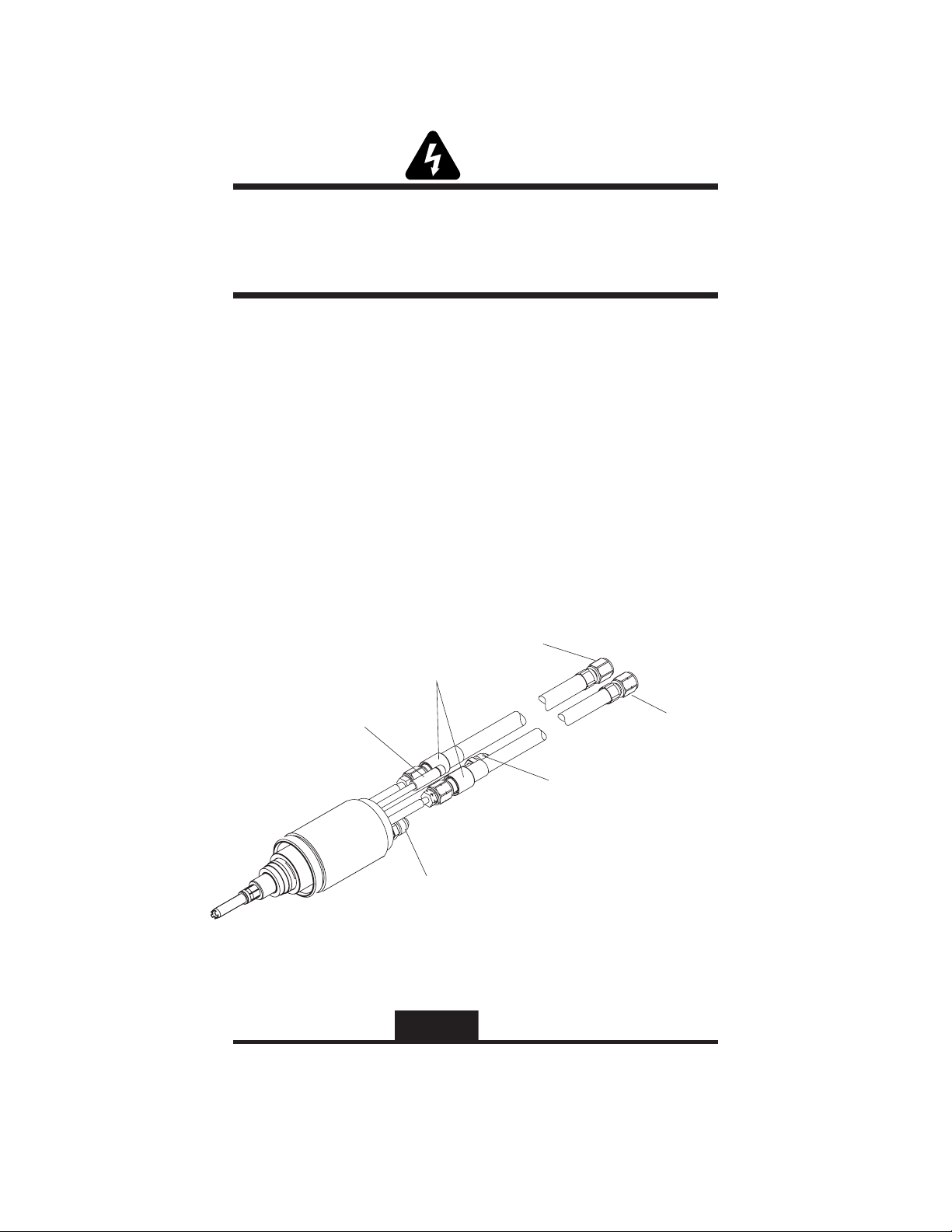

Art # A-06722

Oxygen Plasma Pre-Charge Unit

A. Parts Supplied

The Pre-Charge Unit includes:

• Oxygen Plasma Pre-Charge Unit

• Oxygen Plasma Pre-Charge Supply Hose

• Oxygen Plasma Pre-Charge Outlet Hose

• Oxygen Plasma Outlet Tee Assembly

• Flashback Arrestor

Manual 0-2912 3-1 INSTALLATION

Page 14

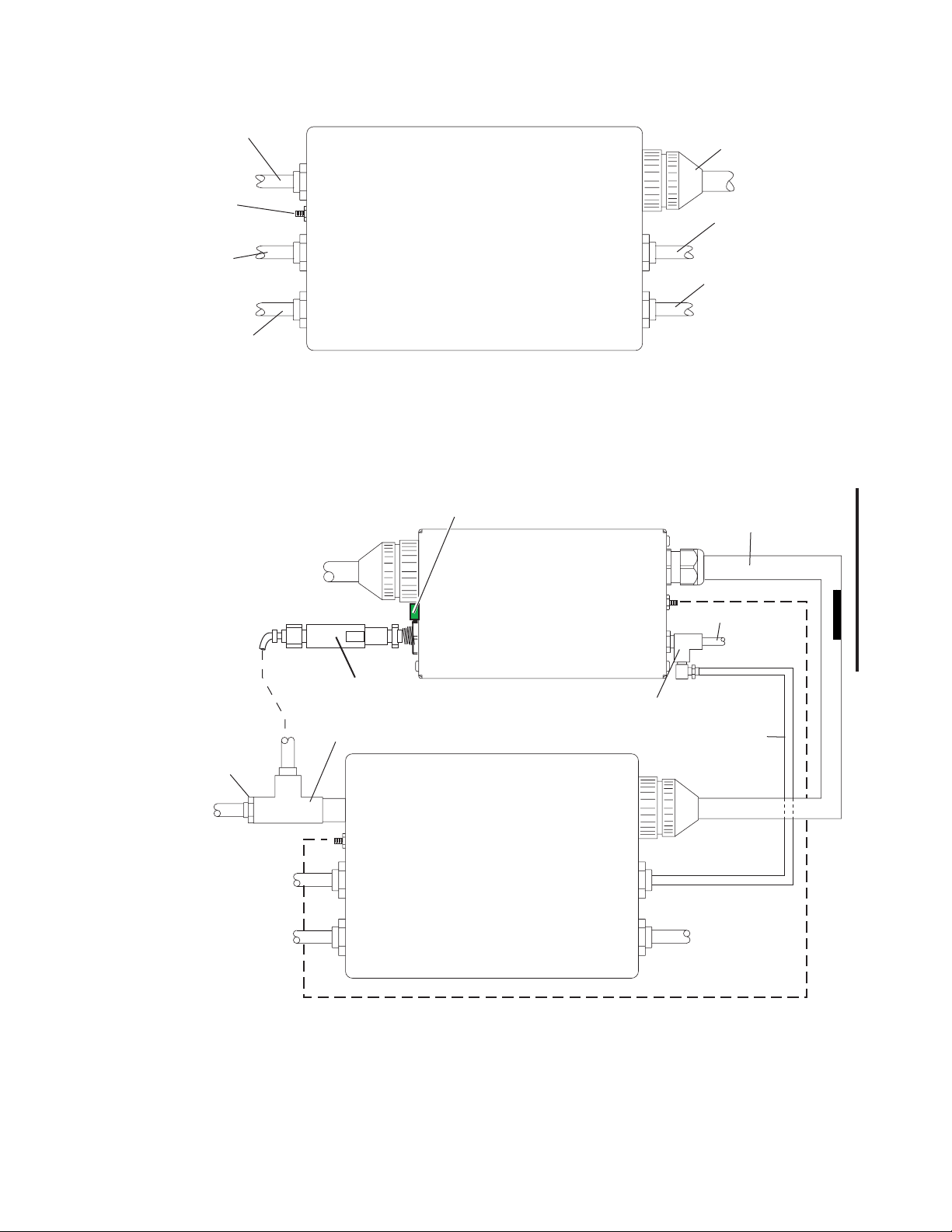

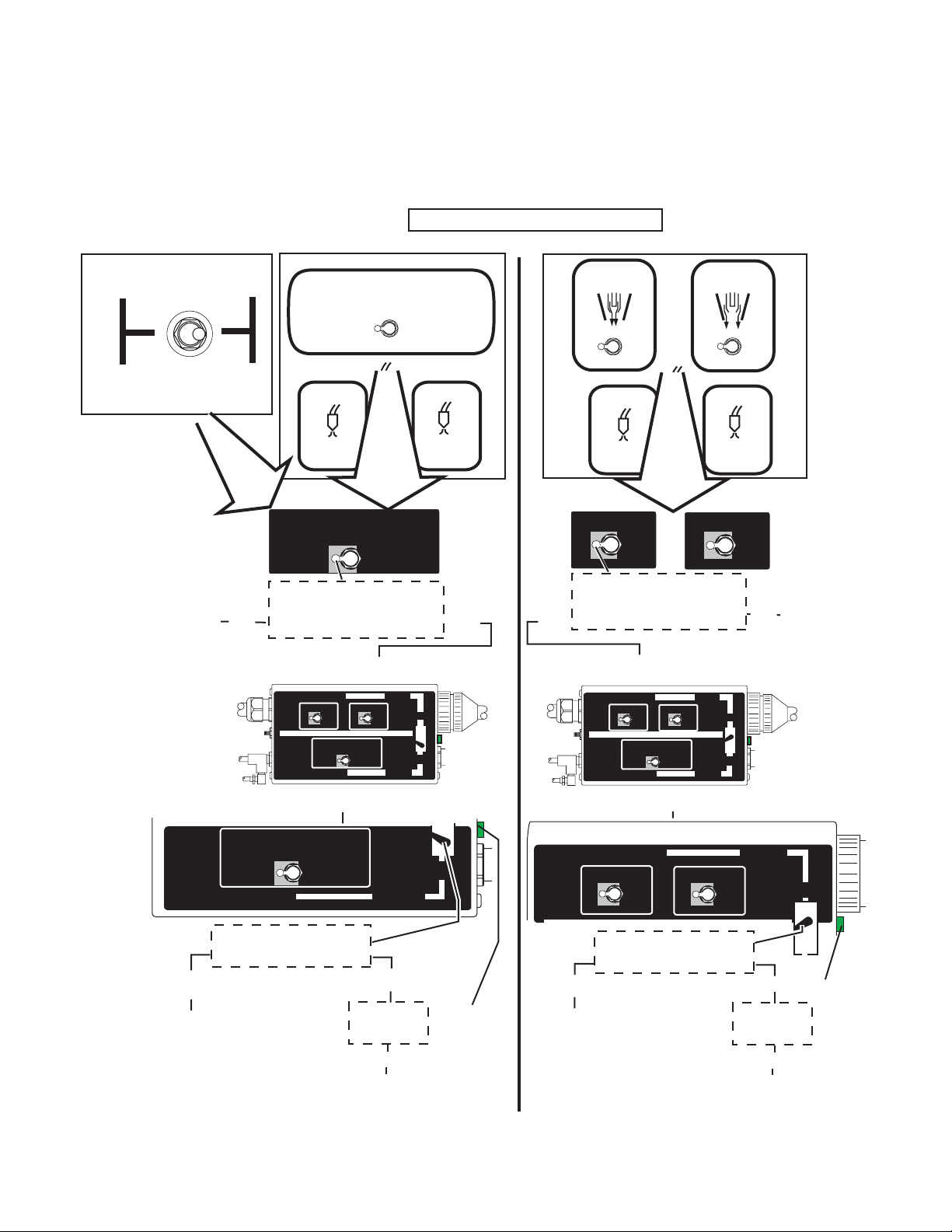

B. Connecting Oxygen Plasma Pre-Charge Unit

Refer to the connection diagrams and install the Pre-Charge Unit as follows:

1. Place the Unit on top of the existing Gas Console.

2. Disconnect the 3x1 Cable coming from the Plasma Power Supply from the existing Gas Console.

3. Connect the 3x1 Cable to the mating connector on the Oxygen Plasma Pre-Charge Unit.

4. Connect the end of the new 3x1 Cable supplied on the Pre-Charge Unit to the mating connector on the

existing Gas Console.

5. Disconnect the plasma gas line (blue) that goes to the torch from the existing Gas Console.

CAUTION

Do not use PTFE sealant with components carrying oxygen (O2). Do

not overtighten fittings or hose connections.

6. Install the Plasma Outlet Tee Assembly on the existing Gas Console. Angle the Plasma Outlet Tee Assembly

towards the Oxygen Plasma Pre-Charge Unit.

7. Connect the existing plasma gas line (blue) from the torch to the Plasma Outlet Tee Assembly.

8. Refer to the illustrations captioned 'after Pre-Charge Unit Installation'. Install the flash-back arrestor on the

pre-charge unit.

9. Connect the supplied hose between the flash-back arrestor and the Plasma Outlet Tee Assembly.

10.Connect the fitting on the hose from the Pre-Charge Unit to the O2A-1/8 NPT Straight Adapter on the Plasma

Outlet Tee Assembly.

11.Disconnect the oxygen (O2) supply line from the Gas Console.

12. Remove the existing oxygen (O2) supply line fitting from the Gas Console.

13. Connect the supplied Plasma Pre-Charge Supply Hose between the O2B fitting on the Oxygen Plasma PreCharge Unit tee and the existing Gas Console oxygen (O2) supply connection.

14. Remove the plug from the Tee Fitting of the Pre-Charge Unit.

CAUTION

Test all connections for leaks. Tighten connections as needed. Do not

overtighten.

15.Connect the oxygen (O2) supply line to the Oxygen Plasma Pre-Charge Unit tee.

16. Attach the ground wire from the ground stud on the Oxygen Plasma Pre-Charge Unit to the ground stud on

the Gas Console.

INSTALLATION 3-2 Manual 0-2912

Page 15

Plasma Gas Line

To Torch

Ground Stud

Connection

Shield Gas Line

To Torch

Pre-Flow Gas Line

To Torch

Manual Gas Console

A-03785

Connection Diagram Of Original Manual Gas Console

3X1 Cable From

Power Supply

O2 Supply Line

N2 Supply Line

3X1 Cable From Power Supply

Original Plasma

Gas Line Fitting

Plasma Gas Line

To Torch

Shield Gas Line To Torch

Pre-Flow Gas Line To Torch

Green Light (Refer to Operation

Section of Torch Manual)

Flashback Arrestor

Plasma Outlet Tee Assembly

Manual Gas Console

Pre-Charge

Unit

Connect To Mating Connector

On Gas Console

O2 Supply Line

Tee Fitting

O2 Supply Hose

To Gas Console

N2 Supply Line

CAUTION

Do not interchange parts. Make sure the parts in the torch corre-

spond with the plasma and shield gas in use for the application.

Art # A-04449

Ground Stud Connection

Connection Diagram to Manual Gas Console After Pre-Charge Unit Installation

Manual 0-2912 3-3 INSTALLATION

Page 16

Automated Gas Console

3X1 Cable From

Power Supply

Ground Stud

Connection

Art # A-03948

Plasma Gas Line

To Torch

Shield Gas Line

To Torch

Pre-Flow Gas Line

To Torch

O2 Supply Line

Connection Diagram for Original Automated Gas Console

Green Light (Refer to Operation

Section of Torch Manual)

3X1 Cable From Power Supply

Flashback Arrestor

Pre-Charge

Unit

Tee Fitting

Automated Gas Console

Shield Gas Line

To Torch

N2 Supply Line

Ground Stud Connection

O2 Supply Line

Connect To 3x1

Connector On

Gas Console

Plasma Gas Line

To Torch

Original Plasma

Gas Line Fitting

Plasma Outlet

Tee Assembly

Pre-Flow Gas Line

Connect to Plasma

Gas Line Fitting

To Torch

Connect to O

Supply Line Fitting

2

N2 Supply Line

O2 Supply Hose

To Gas Console

Connect to

Stud Connection

Art # A-04450

Connection Diagram for Automated Gas Console after pre-Charge Unit Installation.

INSTALLATION 3-4 Manual 0-2912

Page 17

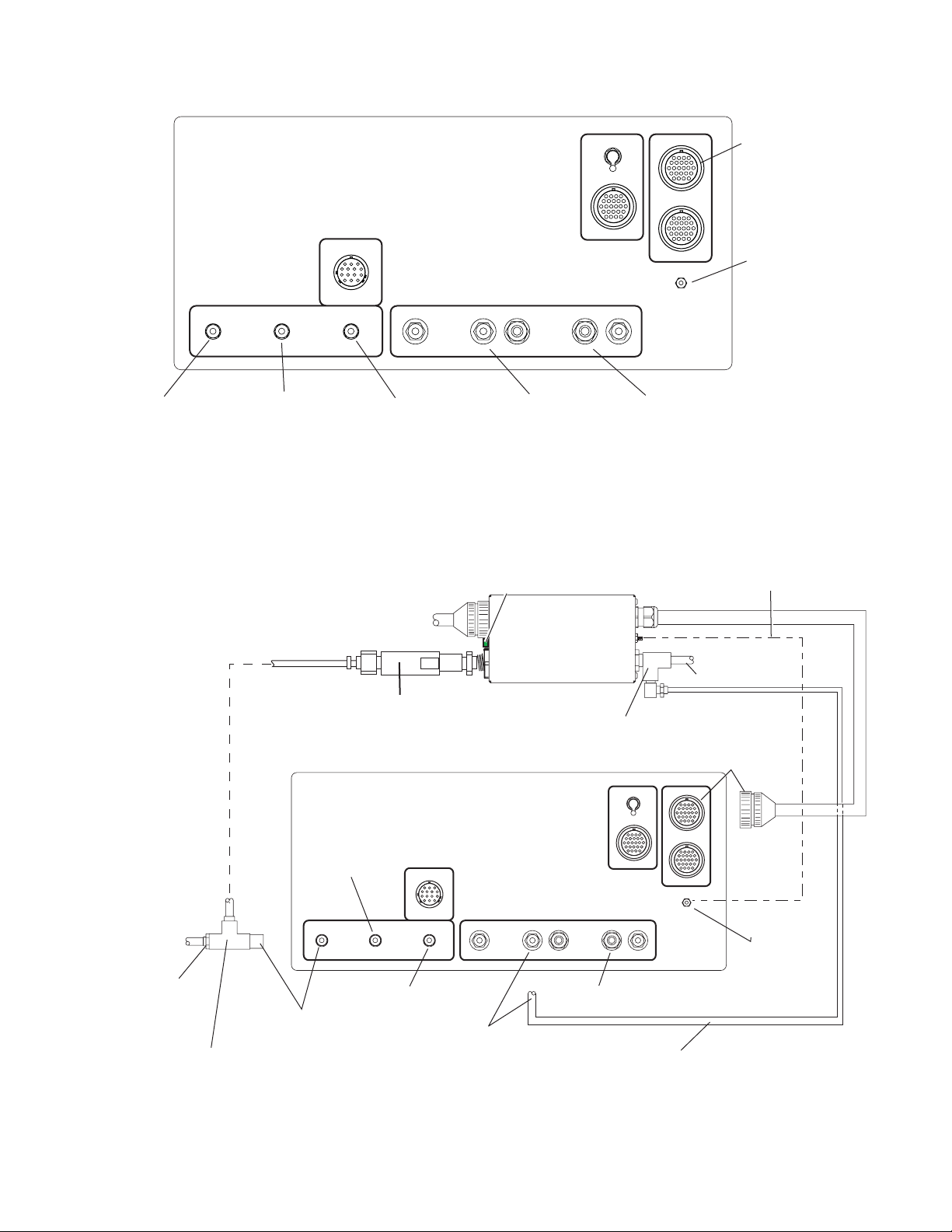

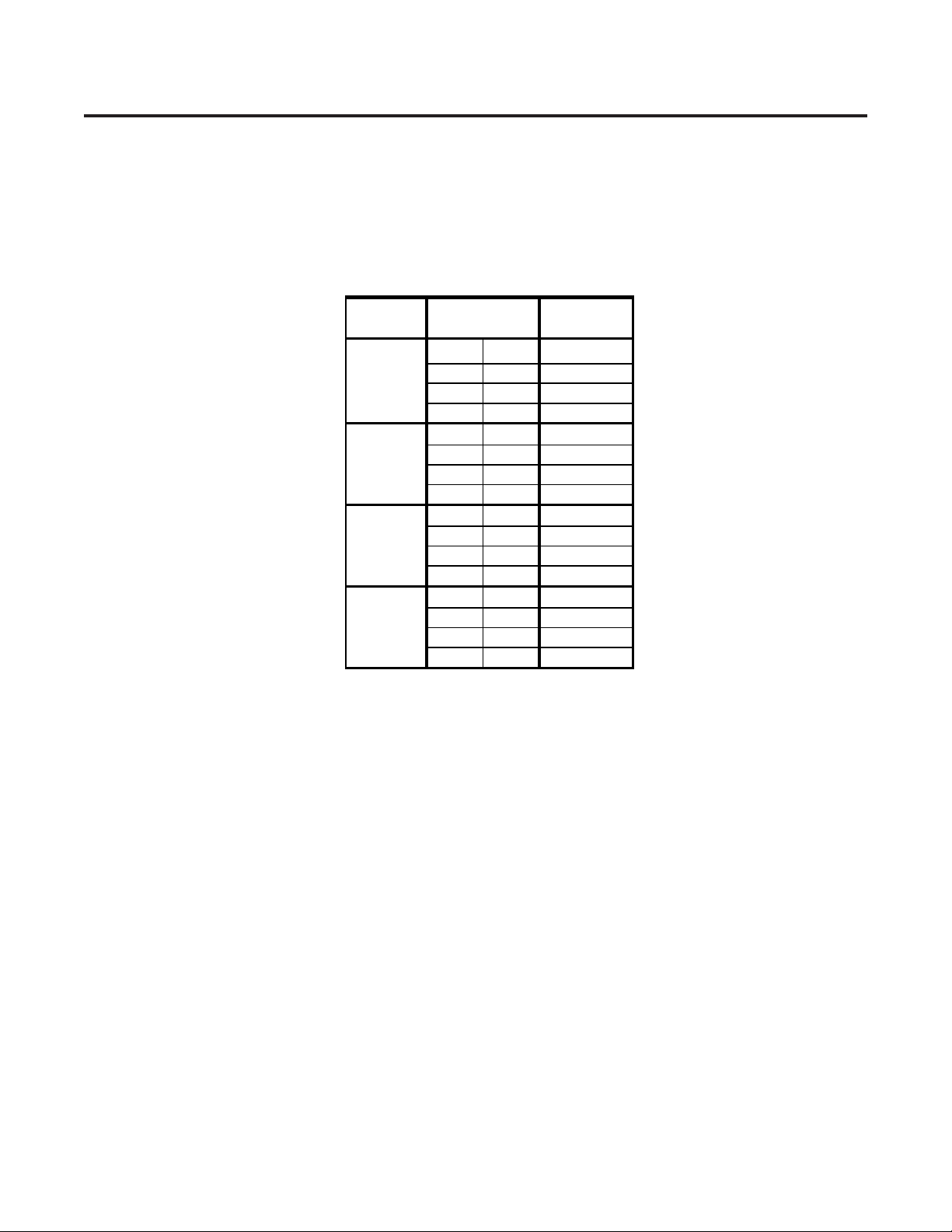

3.03 Oxygen Plasma Pre-Charge Unit Switch Setting

1. Turn the Oxygen Plasma Pre-Charge Unit upside down. The bottom of the assembly includes a label and a

cut-out. There is a toggle switch inside the cut-out.

2. Compare the label on the bottom of the Oxygen Plasma Pre-Charge Unit to the switches on the Gas Console.

For installations with Gas Consoles with switches as shown on the lower half of the label, set the toggle switch

on the Oxygen Plasma Pre-Charge Unit to position 'A'. For installations with Gas Consoles with switches as

shown on the upper half of the label, set the toggle switch on the Pre-Charge Unit to position 'B'. Use a pencil

or similar tool to set the switch. Do not open the Oxygen Plasma Pre-Charge Unit.

Cut-out

Art # A-04447

AUTO GAS BOX VERSION

PLASMA

AUX

2 N2

O

ALL MANUAL GAS BOXES

AUTO GAS BOX VERSION

A

PLASMA GAS SELECTOR

O

2 H35&N2

SHIELD

AIR

AUX

B

INCLUDES

B

A

INCLUDES

Toggle Switch (in 'A' Position)

View of Bottom of Pre-Charge Unit

3. Turn the Oxygen Plasma Pre-Charge Unit right side up. Set the unit securely on the Gas Control.

4. Turn on the oxygen (O2) gas supply and check all connections for leaks.

5. This completes the installation of the Oxygen Plasma Pre-Charge Unit.

Manual 0-2912 3-5 INSTALLATION

Page 18

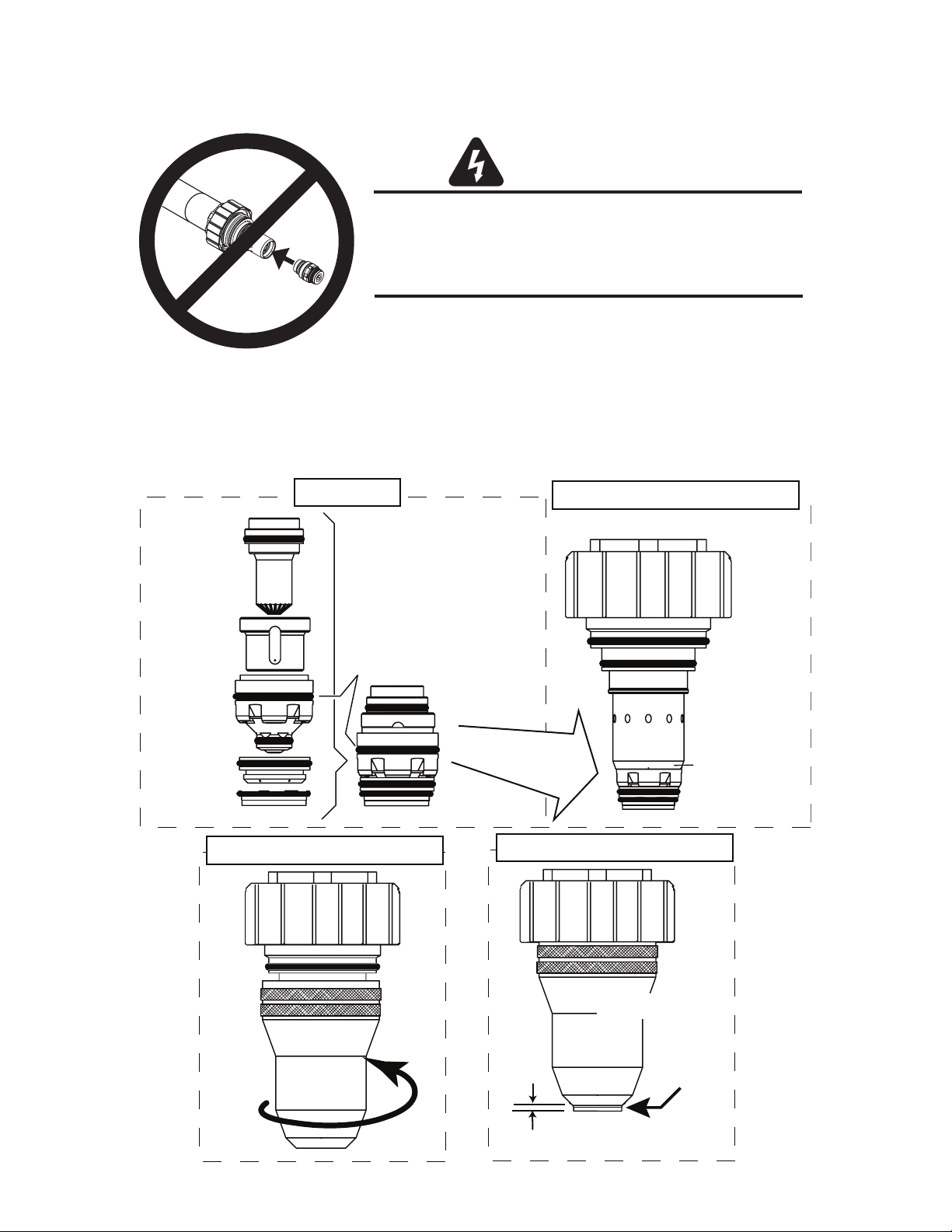

3.04 Connecting Torch

WARNINGS

Disconnect primary power at the source before disassembling the torch

or torch leads.

Use caution when removing the Pilot Return Lead from the existing Torch

as damage to the connection can result.

The Torch Head is a direct replacement for the Hypertherm Torch Head on the HD3070 System. Connect the Torch

Leads as follows:

1. Remove and set aside any consumables installed in the original torch. Release the torch positioning tube

from its support. Do not rotate the torch head or leads. Support the Torch Head and positioning tube manually.

2. Rotate the positioning tube to disconnect the Hypertherm Torch Head from the tube. Slide the tube back on

the leads to expose the torch leads connections to the torch head.

3. Disconnect the torch head from the leads. Set the torch head aside.

4. Connect the gas and coolant leads to the Torch Head.

a. Coolant supply and return connections to the Torch Head are of different lengths.

b. Plasma and secondary gas connections to the Torch Head are threaded differently; the plasma gas con-

nection is left-hand thread, the shield gas connection is right-hand thread.

Shield Gas

Heat Shrink

Pilot Lead (+)

Coolant Supply

Power Lead (-)

Coolant Return

Plasma Gas

(Left Hand Thread)

&

Art # A-04518

c. Hold the Torch Head leads connectors stationary; turn the leads fittings with a wrench to secure the leads

to the Torch Head. Do not overtighten.

CAUTION

The gas and coolant leads include compression fittings. Do not use sealant on these connections.

Slowly apply pressure to the gas lines. Check for leaks at all connections

before continuing. If there are no leaks, shut off the gas supplies and

continue with installation.

INSTALLATION 3-6 Manual 0-2912

Page 19

5. Connect the pilot lead to the Torch Head. Press the two ends of the connector firmly together. Thread the

plastic lead cover/connector onto the mating Torch Head connector.

6. Press the Torch Head Assembly upward to connect to the Mounting Tube. Pull the leads back as needed to

ensure a proper fit to the Mounting Tube. Hold the Torch Head Assembly stationary; rotate the Mounting Tube

to thread it onto the Torch Head.

CAUTION

Ensure that the leads do not twist within the mounting tube. Leads must

lie as shown in the installation sketch.

Manual 0-2912 3-7 INSTALLATION

Page 20

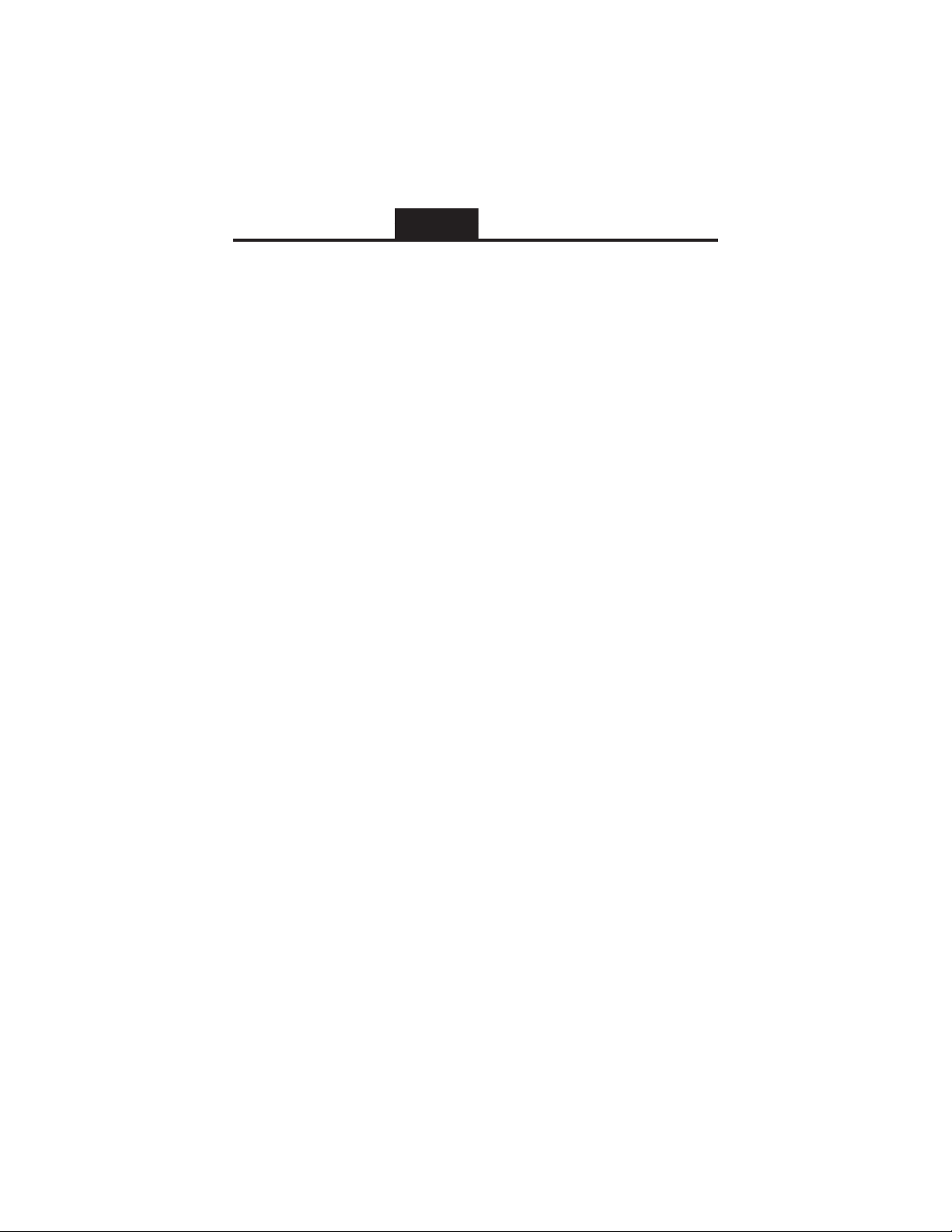

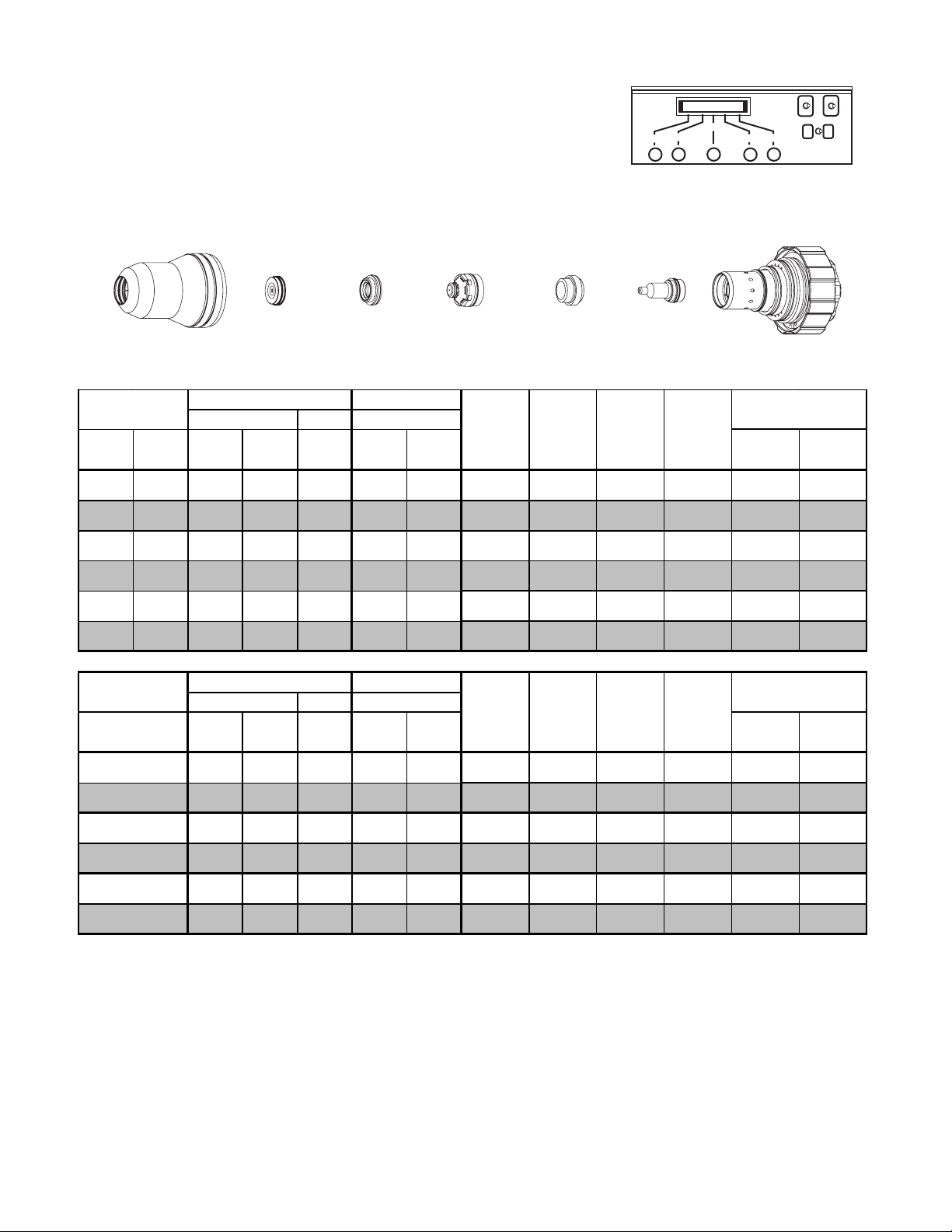

3.05 Consumables Selection

21-1020

Cartridge

Art # A-04031

30A Mild Steel, Precision

Electrode, 30A MS

Plasma

Tip, 30A MS

Shield

50A Mild Steel, Precision

21-1068

30A MS

21-1040

Gas Distributor,

21-1050

30A MS

21-1082

Gas Distributor,

21-1069

Electrode, 50A MS

21-1051

Tip, 50A MS

70A Mild Steel, Precision

21-1070

Electrode, 70A MS

Plasma

Gas Distributor

21-1052

Tip, 70A MS

Shield

Gas Distributor

100A Mild Steel, Precision

Electrode, 100A MS

21-1041

Tip, 100A MS

Swirl

21-1272

21-1071

21-1053

30A Stainless Steel, Precision

Electrode, 30A SS

Plasma

Tip, 30A SS

Shield

50A Stainless Steel / Aluminum, Precision

21-1077

Electrode, 50A SS/AL

21-1045

Gas Distributor

21-1059

No Swirl

Gas Distributor

Tip, 50A SS/AL

21-1274

70A Stainless Steel , Precision

21-1078

21-1060

100A Stainless Steel / Aluminum, Precision

21-1079

Electrode, 70A SS

Plasma

21-1041

Gas Distributor

21-1061

Tip, 70A SS

Shield

No Swirl

Gas Distributor

Electrode, 100A SS/AL

Tip, 100A SS/AL

21-1274

21-1080

21-1062

21-1024

Shield Cap, 30A MS

21-1025

Shield Cap, 50A MS

21-1026

Shield Cap, 70A MS

21-1027

Shield Cap, 100A MS

21-1033

Shield Cap, 30A SS

21-1016

Shield Cup

21-1034

Shield Cap, 50A SS/AL

21-1035

Shield Cap, 70A SS

21-1036

Shield Cap, 100A SS/AL

INSTALLATION 3-8 Manual 0-2912

Page 21

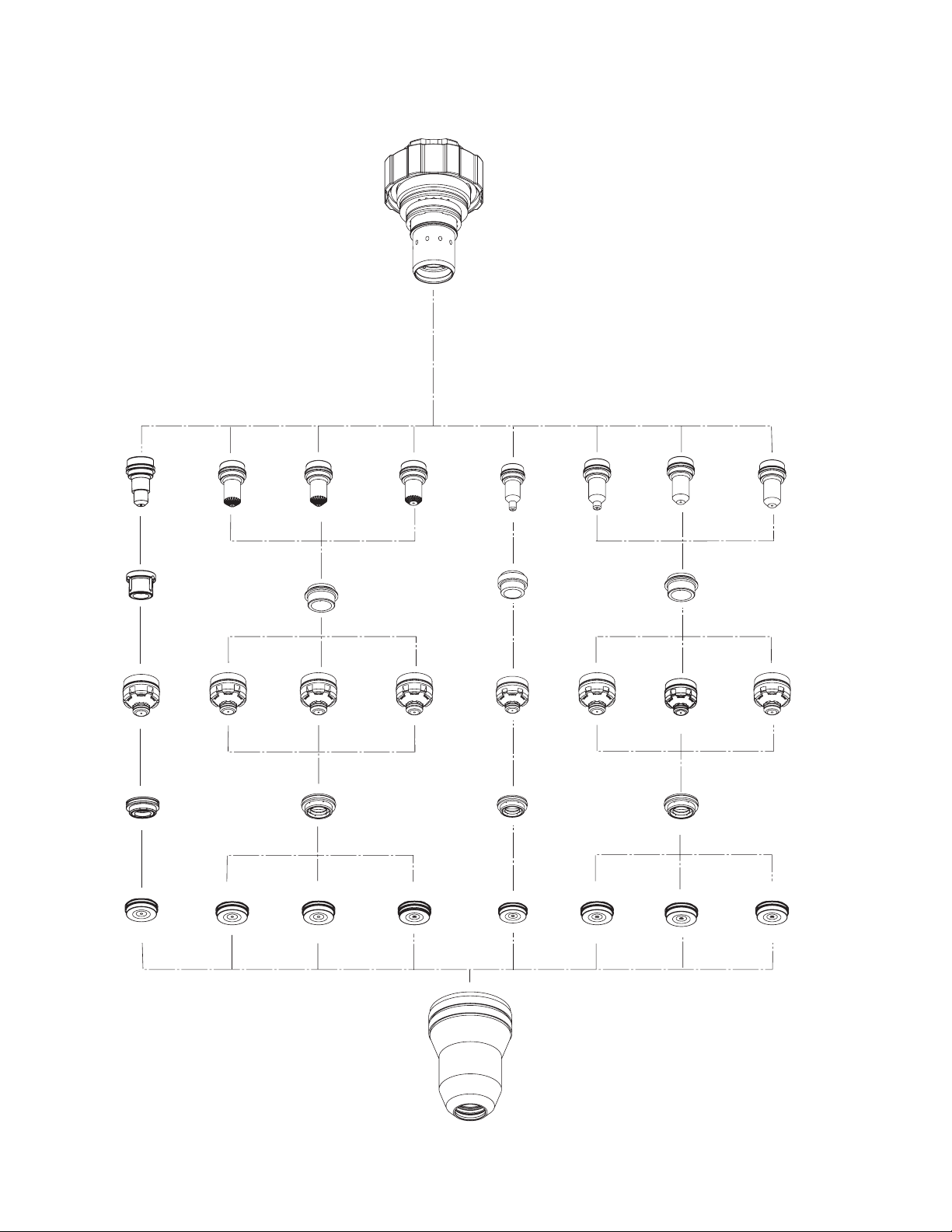

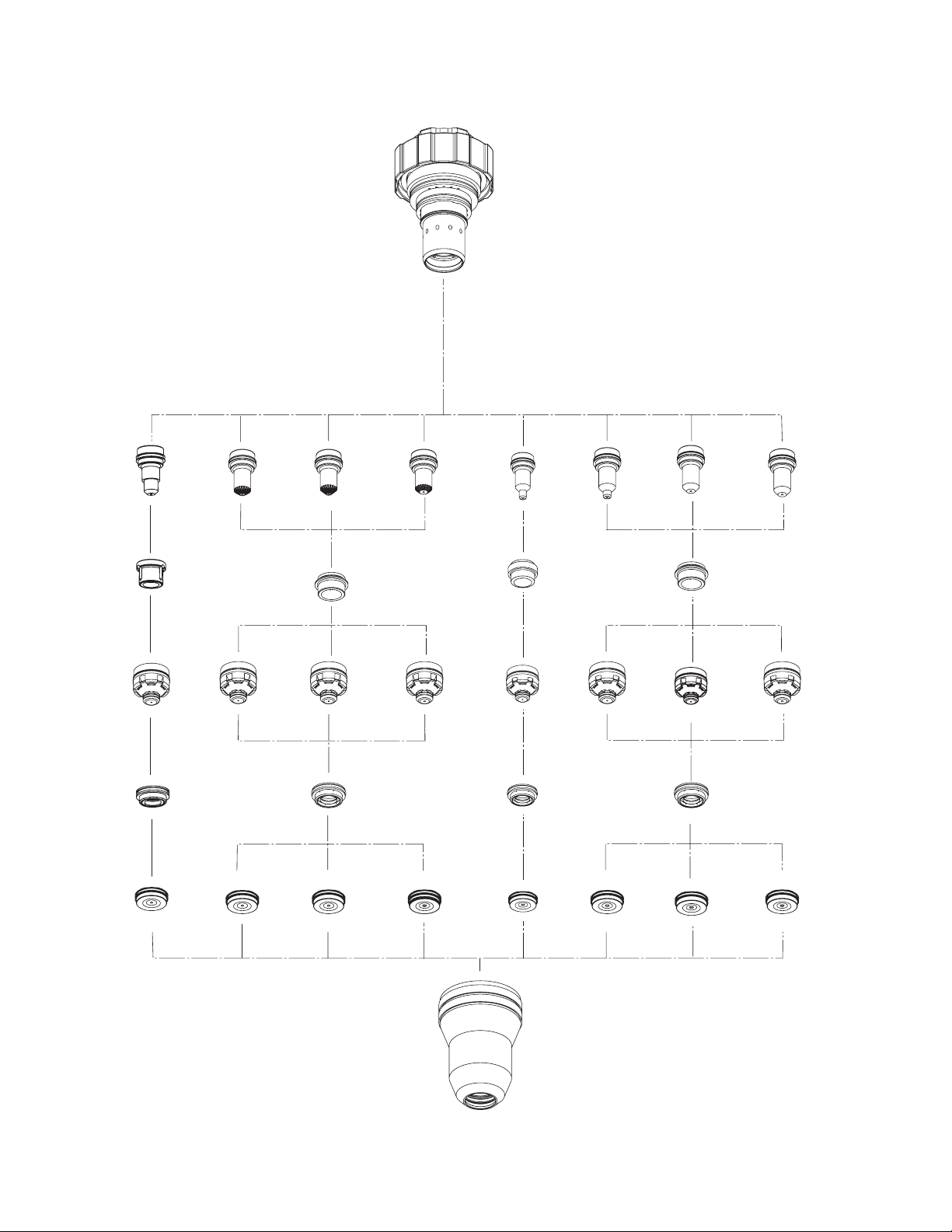

Install Consumable Torch Parts

WARNINGS

Do not install consumables into the Cartridge

while the Cartridge is attached to the Torch Head.

Keep foreign materials out of the consumables and Cartridge.

Handle all parts carefully to avoid damage,

which may affect torch performance.

Art # A-03887

1. Check the appropriate cut chart for the right combination of parts for the cutting application.

2. Install the consumable parts as follows to ensure proper operation. These steps will help ensure that parts are

seated correctly.

Electrode

Plasma Gas

Distributor

Tip

Shield Gas

Distributor

Shield Cap

3: Thread Shield Cup onto Cartridge

1: Stack Parts

Upper O-Ring

on Tip

2: Press Cartridge onto Stacked Parts

No Gaps

Between Parts

Cartridge Covers

Upper O-Ring

on Torch Tip

4: Check Shield Cap Protrusion

Shield Cup

Shield Cap

Shield Cap Protrudes

0.063-0.083" (1.6 - 2.1 mm)

Art # A-04716

Manual 0-2912 3-9 INSTALLATION

Page 22

3. Use the removal tool to hold the cartridge assembly, while turning the shield cup onto the cartridge

assembly. When this group is fully assembled, the shield should protrude from the front of the shield cup

0.063" to 0.083" (1.6 - 2.1 mm). Without this protrusion the shield cup is not properly tightened onto the

cartridge assembly.

4. Take the removal tool off the cartridge. Fit the cartridge assembly onto the torch head. The cartridge should

seal to the large O-ring on the torch body as shown. If the cartridge does not seal on the O-ring, the cartridge

is not fully tightened.

CAUTION

Do not force the cartridge if it will not fully tighten. Remove the cartridge

and gently clean the threads on the torch head body with a wire brush.

Apply oxygen-compatible lubricant (supplied with the torch) to the threads.

Torch Head

0.063 - 0.083"

(1.6 - 2.1 mm)

Protrusion

Installing Assembled Cartridge Onto Torch Head

5. Slide the ohmic clip over the shield cup if using ohmic torch height sensing.

Torch Head O-Ring

Art # A-07202

Ohmic Clip

A-03393

6. Connect the wire lead from the height finder to the ohmic clip if using ohmic torch height sensing.

7. Connect the wire lead from the height finder to the ohmic clip.

INSTALLATION 3-10 Manual 0-2912

Page 23

3.06 Oxygen Plasma Pre-Charge Unit Installation Checks

ALWAYS verify proper function of the plasma pre-charge unit. Follow the steps below to verify the unit is installed

properly.

The pre-charge unit is used to increase the line pressure of the plasma gas (Oxygen) at the start of a cut cycle. The

pre-charge unit is activated only during pre-flow when the gas selection switch is set to cut with Oxygen. This added

pressure provides improved consumable life during piercing. When cutting with any other plasma gas, the pre-charge

unit is not activated.

To verify that the Oxygen Plasma Pre-Charge Unit is installed properly, check it as follows:

1. Be sure that O2 is being supplied to the pre-charge unit and to the gas box.

2. Be sure the gas outlet of the plasma pre-charge box is teed into the plasma lead.

3. Check the switch on the bottom of the pre-charge box to see if it is in the proper position (switch is changed

according to the type of gas box used.

4. Set the gas selection switch on the gas box to “O2/N2” cutting.

5. Turn on “Test Cut Flow” and observe the plasma outlet pressure of the gas box. This pressure will vary with

the consumables in the torch, but should generally be less than 60 psi. This is called the

pressure

6. Now turn the switch to “Test Pre-Flow”, and observe the outlet pressure of the plasma gas. It should climb to

120 PSI and the Green Light should be illuminated. This indicates that the plasma line (Oxygen) is correctly

being “pre-charged” to 120 PSI during pre-flow.

.

plasma cold flow

7. Now turn the switch back to “Test Cut-Flow”, and observe the outlet pressure of the plasma gas. It should drop

down to the plasma cold flow pressure.

Now verify that the plasma pre-charge unit is not energizing under the following conditions:

1. Set the Plasma Gas Selection switch off of Oxygen cutting (to H35 or Aux).

2. Turn on “Test Cut Flow” and observe the

3. Now turn the switch to “Test Pre-Flow”, and observe the outlet pressure of the plasma gas. It should remain at

the plasma cold flow pressure and the Green light should not be illuminated. This indicates that the plasma

pre-charge unit is not activating.

plasma cold flow pressure

.

Manual 0-2912 3-11 INSTALLATION

Page 24

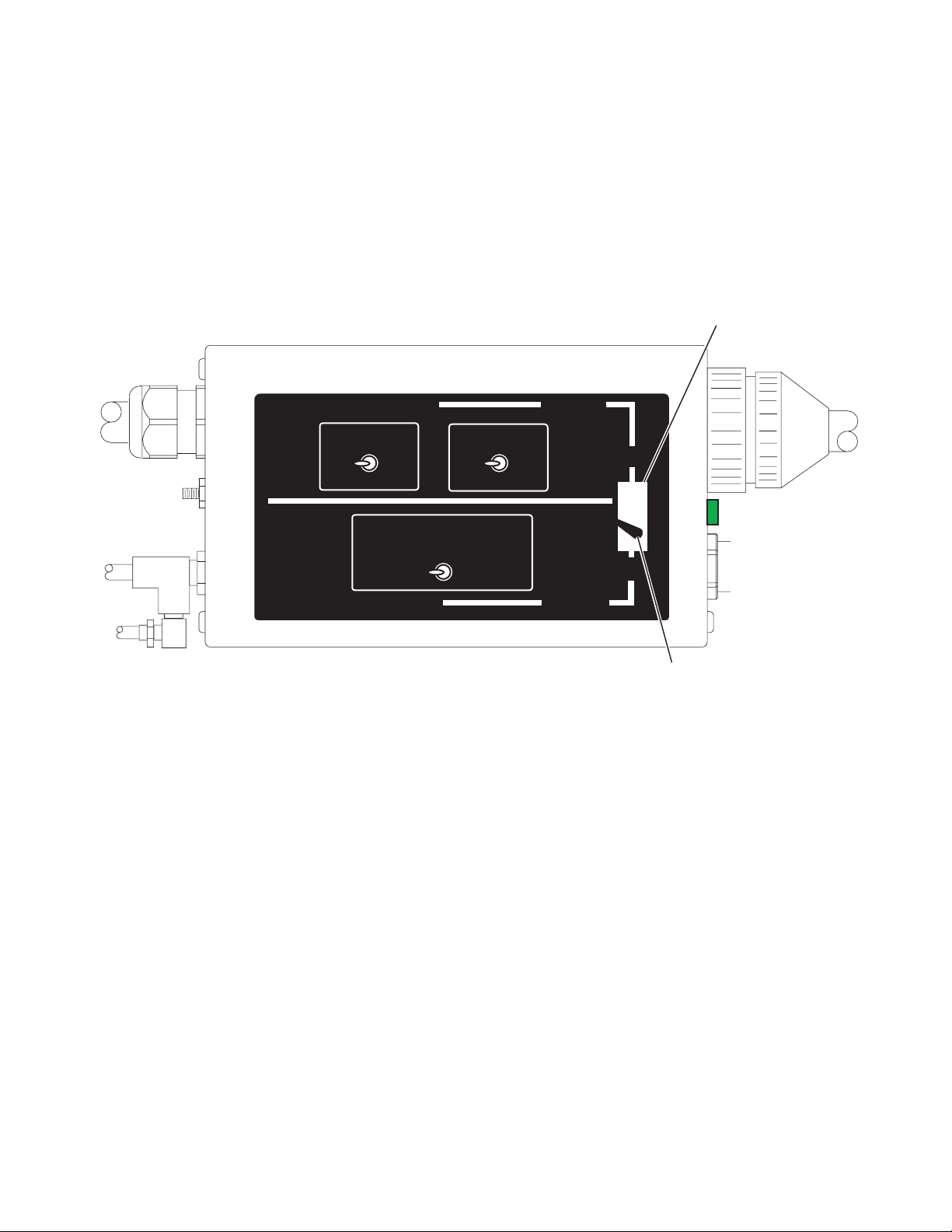

3.07 Oxygen Plasma Pre-Charge Unit Operational Check

THE PRE-CHARGE UNIT INCLUDES A GREEN LIGHT TO INDICATE THAT THE SYSTEM IS PRE-CHARGING

THE TORCH LEADS WITH OXYGEN. Follow the steps shown to confirm that switches on the gas console and on

the pre-charge unit are set properly. DO NOT OPERATE the system unless all gas control switches are set properly.

Compare to Gas Control Console Switches

HD3070 3-KNOB MANUAL BOX

PLASMA

(AUX A)

HD3070 6-KNOB AUTO BOX SWITCH SETTINGS

O

PLASMA GAS SELECTION

2

AIR

O

2

H35 & N2

HD3070 5-KNOB AUTO BOX SWITCH SETTINGS

PLASMA

O

2

AUX

A

SHIELD

N2

AUX

B

(AUX B)

Change Switch

to O2 position.

SHIELD

N

2

TEST

RUN

PREFLOW

PLASMA GAS SELECTION

AIR

2

H35&N

O

In Version A installations:

Is the Plasma Gas Selector switch

No

in the O2 position?

Check underside of Plasma Pre-Charge Unit

AUTO GAS BOX VERSION

PLASMA

AUX

O

2

PLASMA GAS SELECTOR

O

ALL MANUAL GAS BOXES

AUTO GAS BOX VERSION

A

2

H35&N

INCLUDES

SHIELD

AUX

N2

B

AIR

2

INCLUDES

Underside of Pre-Charge Unit

TEST

CUTFLOW

2

B

A

Version A

Yes

TEST

PREFLOW

(4, 5)

RUN

TEST

CUTFLOW

(1, 2, 3)

Version B

PLASMA

O

2

AUX

A

SHIELD

N2

AUX

B

In Version B installations:

Is the Plasma Gas Selector switch

Yes

in the O2 position?

No

Check underside of Plasma Pre-Charge Unit

AUTO GAS BOX VERSION

PLASMA

AUX

O

2

PLASMA GAS SELECTOR

O

ALL MANUAL GAS BOXES

AUTO GAS BOX VERSION

A

2

H35&N

INCLUDES

SHIELD

N2

AIR

B

AUX

B

A

2

INCLUDES

Underside of Pre-Charge Unit

Change Switch

to O2 position.

PLASMA GAS SELECTION

Change Switch

Art # A-06409

ALL MANUAL GAS BOXES

AUTO GAS BOX VERSION

Is the Pre-Charge Unit switch

No

to A position.

AIR

O

2

H35&N

in the A position?

2

INCLUDES

Yes

Is the green

light ON?

Yes

All switches are

set properly.

A

Green Light

AUTO GAS BOX VERSION

PLASMA

AUX

O

2

Is the Pre-Charge Unit switch

No

Change Switch

to B position.

SHIELD

N2

A

in the B position?

INCLUDES

AUX

B

Yes

Is the green

light ON?

Yes

All switches are

set properly.

B

Green Light

INSTALLATION 3-12 Manual 0-2912

Page 25

SECTION 4-A:

OPERATION WITH MANUAL GAS CONSOLE

4A.01 Torch Parts Selection

The application will determine which torch parts must be used. Refer to the speed charts in Section 4.02, Recommended Cutting Speeds, for the proper torch parts to install for a selected application.

CAUTION

Do not interchange parts. Make sure all parts in the torch correspond with the plasma and shield gas in use for the

application.

4A.02 Pre-Setting Controls

A. Power Supply Setting

Set the Power Supply controls as follows before operating the system.

1. Set the proper cutting current at the AMPS thumbwheel.

2. Use data from the Speed Charts in Section 4.03 for each combination of material and amperage:

a. Set the initial torch height.

b. Set arc voltage on the torch height control.

c. Set the PIERCE DELAY potentiometer.

3. On the gas console select the plasma gas to be used with the PROCESS SELECTION switch.

4. All gas supplies are connected and set at 120 psi (8.3 bar) at the inlet pressure gauges.

B. Pre-Charge Box Setting

Before operating the system:

1. Set the gas supply pressure at the oxygen cylinder to 120 psi (8.3 bar).

2. On the front of the gas console set the RUN TEST switch to the TEST PREFLOW position. This will enable

gas to flow by opening the solenoid in the Pre-Charge Box.

3. If system plasma pressure gauge indicates more than 120 psi (8.3 bar) the system is over pressurized. Stop

and do the following:

a. On the front of the gas console set the RUN TEST switch to the TEST CUT FLOW position.

b. Let gas flow for 20 seconds. This will allow the system pressure to bleed off.

c. Repeat steps 2 and 3 above.

Manual 0-2912 4A-1 Operation with Manual Gas Control

Page 26

4A.03 Recommended Cutting Speeds

!

Cutting speed depends on material and thickness. The following factors may affect system performance:

• Torch parts wear

• Speed

• Gas quality

• Operator experience

• Torch standoff height

• Proper work cable connection

• Alloy content of material

NOTE

This information represents realistic expectations using recommended practices and well-maintained systems. Actual speeds may vary from those shown in the charts depending on the alloy content of the selected material.

For complete cutting speed chart data refer to the following pages.

WARNING

Information in this section is for torch operation with the HD3070 System with a manual gas console.

Refer to Section 3B or 3C for information on torch operation with the HD3070 System with an automatic gas console.

Art # A-04492

Art # A-04491

Preflow Controls

Shield Controls

Plasma Control

Plasma Controls

Preflow Controls

Shield Controls

Operation with Manual Gas Control 4A-2 Manual 0-2912

Page 27

OPERATING INFORMATION

** - Arc voltage is based on 50 ft (15.2 m) torch lead length. For other lead lengths the operator may need to adjust

the Arc Voltage setting. Refer to Appendix 1 for Alternate Arc Voltage Settings.

NOTE: The preflow rates shown generate increased dross at the start of a cut. Increasing the amount of oxygen and

reducing the amount of nitrogen will reduce dross at the start of a cut, but will also reduce electrode life.

Oxygen (O2) gas inlet pressures must be 120 psi (8.3 bar) for all material thicknesses.

Slightly increasing the preflow flow rates may increase piercing capability on the thicker materials listed above.

However, increasing the preflow flow rates too much may affect plasma starting reliability (misfiring).

Torch Working Height tolerances are ±0.005 inch (±0.125 mm).

Thermal Dynamics Pre-Charge Unit must be installed before cutting.

ChartS give set-up parameters for use with a Hypertherm HD 3070 System. For technical and legal reasons the

settings in the chartS may not be appropriate for use with other systems.

Manual 0-2912 4A-3 Operation with Manual Gas Control

Page 28

Mild Steel

30A

O

Plasma / O2 - N2 Shield

2

Manual

Gas Control

Or

Art # A-06838

Shield Cup

21-1016

Material

Thickness

(ga) (in)

Shield

Shield Cap

21-1024

Cut Flow Rates (%)

Gas Distributor

21-1082

Preflow Flow

Tip

21-1050

Rates

Plasma (%) Shield (%) Preflow (%)

O

2

-O2N2 O

N2

2

Plasma

Gas Distributor

21-1040

Tor c h

** Arc

Voltage

Working

Height

(volts )

(in)

Electrode

21-1068

Travel

Speed

(ipm)

Cartridge

21-1020

Initial

Piercing

Height

(in)

Art # A-04338

Pierce

Delay

(sec )

20 0.036 13 - 13 0 5 55 129 0.050 140 0.120 0.2

16 0.060 13 - 13 0 5 55 137 0.050 80 0.120 0.2

14 0.075 13 - 13 0 5 55 139 0.070 50 0.120 0.2

11 0.120 13 - 17 3 5 55 140 0.070 40 0.120 0.2

10 0.135 13 - 17 3 5 55 142 0.070 35 0.120 0.2

9 0.150 13 - 17 3 5 55 143 0.070 33 0.120 0.3

7 0.179 13 - 17 3 5 55 144 0.070 30 0.120 0.3

Preflow Flow

Rates

Tor c h

** Arc

Voltage

N2

2

(volts )

Working

Height

(mm)

Travel

Speed

(m/min)

indicates maximum piercing parameters.

Initial

Piercing

Height

(mm)

Pierce

Delay

(sec )

Material

Thickness

(mm)

0.6

0.8

1

1.2

1.5

2

3

4

5

Cut Flow Rates (%)

Plasma (%) Shield (%) Preflow (%)

O

2

-O2N2 O

13 - 13 0 5 55 125 1.3 4.8 3.0 0.1

13 - 13 0 5 55 125 1.3 4.1 3.0 0.1

13 - 13 0 5 55 129 1.3 3.6 3.0 0.1

13 - 13 0 5 55 129 1.3 2.9 3.0 0.1

13 - 13 0 5 55 136 1.3 2.2 3.0 0.2

13 - 13 0 5 55 139 1.8 1.3 3.0 0.2

13 - 17 3 5 55 140 1.8 1.1 3.0 0.2

13 - 17 3 5 55 142 1.8 0.9 3.0 0.2

13 - 17 3 5 55 145 1.8 0.7 3.0 0.3

Bold type

Operation with Manual Gas Control 4A-4 Manual 0-2912

Page 29

Mild Steel

50A

O

Plasma / O2 - N2 Shield

2

Manual

Gas Control

Or

Art # A-06838

Shield Cup

21-1016

Material

Thickness

(ga) (in)

Shield

Shield Cap

21-1025

Gas Distributor

Cut Flow Rates (%)

21-1272

Tip

21-1051

Preflow Flow

Rates

Plasma % Shield % Preflow %

O

2

- O

2

N2 O

N2

2

Plasma

Gas Distributor

21-1041

Tor c h

** Arc

Voltage

Working

Height

(volts )

(in)

Electrode

21-1069

Travel

Speed

(ipm)

Cartridge

21-1020

Initial

Piercing

Height

(in)

Art # A-04026

Pierce

Delay

(sec )

20 0.036 20 - 5 25 10 40 122 0.060 500 0.100 0.3 *

16 0.060 20 - 5 25 10 40 126 0.060 300 0.100 0.3 *

10 0.135 20 - 5 25 10 40 130 0.060 150 0.200 0.1

7 0.179 20 - 5 25 5 65 134 0.080 100 0.200 0.1

1/4 20 - 5 25 5 65 135 0.080 80 0.200 0.1

3/8 20 - 5 15 5 65 148 0.110 25 0.350 0.3

Material

Thickness

(mm)

0.8

1.0

1.2

1.5

2.0

3.0

4.0

5.0

6.0

8.0

10.0

Bold type

Cut Flow Rates (%)

Plasma % Shield % Preflow %

2

- O

O

2

N2 O

20 - 5 25 10 40 122 1.5 12.7 2.5 0.3 *

20 - 5 25 10 40 123 1.5 12.0 2.5 0.3 *

20 - 5 25 10 40 124 1.5 9. 5 2.5 0.3 *

20 - 5 25 10 40 126 1.5 7. 6 2.5 0.3 *

20 - 5 25 10 40 127 1.5 6. 5 3.3 0.2 *

20 - 5 25 10 40 130 1.5 3. 8 4.8 0.1

20 - 5 25 10 40 132 2.0 3. 1 5.0 0.1

20 - 5 25 5 65 134 2.0 2.5 5.1 0.1

20 - 5 25 5 65 135 2.0 2.1 5.1 0.1

20 - 5 15 5 65 146 2.5 0.8 6.4 0.2

20 - 5 15 5 65 148 2.8 0.6 8.9 0.3

indicates maximum piercing parameters.

Preflow Flow

Rates

N2

2

** Arc

Voltage

(volts )

Tor c h

Working

Height

(mm)

Travel

Speed

(m/min)

Initial

Piercing

Height

(mm)

Pierce

Delay

(sec )

Manual 0-2912 4A-5 Operation with Manual Gas Control

Page 30

Mild Steel

70A

O

Plasma / O2 - N2 Shield

2

Manual

Gas Control

Or

Art # A-06838

Shield Cup

21-1016

Material

Thickness

(ga) (in)

Shield

Shield Cap

21-1026

Gas Distributor

21-1272

Cut Flow Rates (%)

Tip

21-1052

Preflow Flow

Rates (% )

Gas Distributor

Plasma % Shield % Preflow %

O2 - O2N2O2N2

Plasma

21-1041

** Arc

Voltage

(volts )

21-1070

Tor c h

Working

Height

(in)

Travel

Speed

(ipm)

Cartridge

21-1020Electrode

Art # A-04027

Initial

Piercing

Height

(in)

Pierce

Delay

(sec )

16 0.060 25 - 25 0 5 65 138 0.060 300 0.100 0.0

14 0.075 25 - 25 0 5 65 138 0.060 250 0.100 0.0

12 0.105 65 - 10 45 5 65 140 0.060 225 0.120 0.0

10 0.135 65 - 10 45 5 65 142 0.060 200 0.150 0.0

7 0.179 65 - 10 45 5 65 143 0.070 120 0.200 0.1

- 1/4 65 - 10 45 5 65 146 0.080 110 0.200 0.2

- 3/8 65 - 10 45 5 65 150 0.120 70 0.300 0.2

Preflow Flow

Rates (% )

** Arc

Voltage

(volts )

Tor c h

Working

Height

(mm)

Travel

Speed

(m/min)

Initial

Piercing

Height

(mm)

Material

Thickness

(mm)

1.5

2

3

4

5

6

8

Bold type

Cut Flow Rates (%)

Plasma % Shield % Preflow %

O2 - O2 N2 O2 N2

25 - 25 0 5 65 138 1.5 7.6 2.5 0.0

25 - 25 0 5 65 138 1.5 6.8 2.5 0.0

65 - 10 45 5 65 141 1.5 5.3 3.7 0.0

65 - 10 45 5 65 141 1.5 4.1 3.7 0.0

65 - 10 45 5 65 144 1.9 3.0 5.2 0.0

65 - 10 45 5 65 146 1.9 2.5 5.2 0.0

65 - 10 45 5 65 148 2.5 2.3 6.4 0.1

indicates maximum piercing parameters.

Pierce

Delay

(sec )

Operation with Manual Gas Control 4A-6 Manual 0-2912

Page 31

Mild Steel

100A

O

Plasma / O2 - N2 Shield

2

Manual

Gas Control

Or

Art # A-06838

Shield Cup

21-1016

Material

Thickness

(ga) (in)

Cut Flow Rates (%)

Plasma % Shield % Preflow %

O

2

10 0.135 62

7 0.179 62

-1/462

-3/862

-1/262

-5/862

Shield Cap

21-1027

Shield

Gas Distributor

21-1272

Tip

21-1053

Plasma

Gas Distributor

21-1041

Electrode

21-1071

Preflow Flow

Rates (%)

Tor c h

** Arc

-O2N2 O

- 15 70 15 80 141 0.070 280 0.200 0.0

- 15 70 15 80 145 0.090 235 0.200 0.0

-

- 15 70 15 80 156 0.110 100 0.250 0.2

- 15 86 15 80 158 0.120 70 0.300 0.3

- 15 86 15 80 163 0.120 50 0.350 0.5

15 70 15 80 153 0.100 150 0.200 0.0

2

N2

Voltage

(volts )

Working

Height

(in)

Travel

Speed

(ipm)

Initial

Piercing

Height

(in)

Cartridge

21-1020

Art # A-04028

Pierce

Delay

(sec )

-3/462

Material

Thickness

Plasma % Shield % Preflow %

(mm)

O

3

4

5

6

8

10

12

15

20

Bold type

indicates maximum piercing parameters.

62

62

62

62

62

62

62 - 15 86 15 80 158 3.0 1.9 7.1 0.3

62 - 15 86 15 80 162 3.0 1.2 8.4 0.4

62 - 15 86 15 80 176 3.8 0.6 10.2 0. 4

-

15 86 15 80 176 0.150 25 0.400 0.6

Cut Flow Rates (%)

2

-O2N2 O

- 15 70 15 80 142 2.3 6.2 4.5 0.0

- 15 70 15 80 145 2.3 5.7 4.8 0.0

- 15 70 15 80 148 2.3 5.3 5.1 0.0

-

- 15 70 15 80 155 2.8 3.2 5.8 0.1

- 15 70 15 80 156 3.0 2.1 6.6 0.2

15 70 15 80 152 2.3 4.6 5.1 0.0

Preflow Flow

Rates (%)

N2

2

** Arc

Voltage

(volts )

Tor c h

Working

Height

(mm)

Travel

Speed

(m/min)

Initial

Piercing

Height

(mm)

Pierce

Delay

(sec )

Manual 0-2912 4A-7 Operation with Manual Gas Control

Page 32

Stainless Steel

30A

Air Plasma / Air Shield

Manual

Gas Control

Or

Art # A-06838

Shield Cup

21-1016

Material

Thickness

(ga) (in) Air - Air - Air -

Shield Cap

21-1033

Cut Flow Rates (%)

Plasma % Shield % Preflow %

Shield

Gas Distributor

21-1274

Tip

21-1059

Preflow Flow

Gas Distributor

Plasma

21-1045

** Arc

Voltage

(volts )

Tor c h

Working

Height

(in)

21-1077

Travel

Speed

(ipm)

Cartridge

21-1020Electrode

Initial

Piercing

Height

(in)

Art # A-04498

Pierce

Delay

(sec )

26 0.019 60 - 10 - 75 - 75 0.020 250 0.200 0.0

24 0.025 60 - 10 - 75 - 75 0.020 220 0.200 0.0

22 0.031 60 - 10 - 75 - 75 0.020 200 0.200 0.0

20 0.038 60 - 10 - 75 - 75 0.020 180 0.200 0.0

18 0.050 60 - 10 - 75 - 79 0.020 150 0.200 0.0

16 0.063 60 - 10 - 75 - 79 0.020 120 0.200 0.0

Material

Thickness

(mm)

0.6

0.8

1.0

1.2

1.5

2.0

Bold type

Cut Flow Rates (%)

Plasma % Shield % Preflow %

Air - Air - Air -

60 - 10 - 75 - 75 0.5 5.8 5.0 0.0

60 - 10 - 75 - 75 0.5 5.1 5.0 0.0

60 - 10 - 75 - 75 0.5 4.6 5.0 0.0

60 - 10 - 75 - 79 0.5 3.9 5.0 0.0

60 - 10 - 75 - 79 0.5 3.3 5.0 0.0

60 - 10 - 75 - 79 0.5 2.0 5.0 0.1

indicates maximum piercing parameters.

Preflow Flow

** Arc

Voltage

(volts )

Tor c h

Working

Height

(mm)

Travel

Speed

(m/min)

Initial

Piercing

Height

(mm)

Pierce

Delay

(sec )

Operation with Manual Gas Control 4A-8 Manual 0-2912

Page 33

Stainless Steel

50A

Air Plasma / Air Shield

Manual

Gas Control

Or

Art # A-06838

Shield Cup

21-1016

Material

Thickness

(ga) (in) Air - Air - Air -

Shield Cap

21-1034

Cut Flow Rates (%)

Plasma % Shield %

Shield

Gas Distributor

21-1274

Tip

21-1060

Preflow Flow

Preflow %

Gas Distributor

Plasma

21-1041

** Arc

Voltage

(volts )

21-1078

Tor c h

Working

Height

(in)

Travel

Speed

(ipm)

Cartridge

21-1020Electrode

Art # A-04029

Initial

Piercing

Height

(in)

14 0.075 65 - 80 - 65 - 113 0.060 120 0.120 0.0

12 0.105 65 - 80 - 65 - 117 0.060 80 0.150 0.0

10 0.135 65 - 80 - 65 - 121 0.060 55 0.180 0.1

- 3/16 65 - 80 - 65 - 123 0.080 40 0.250 0.3

Material

Thickness

(mm)

1.2

1.5

2

3

4

5

Bold type

Cut Flow Rates (%)

Plasma % Shield % Preflow %

Air - Air - Air -

65 80 - 65 -

65 80 - 65 -

65 80 - 65 -

65 80 - 65 -

65 80 - 65 -

65 80 - 65 -

indicates maximum piercing parameters.

Preflow Flow

** Arc

Voltage

(volts )

Tor c h

Working

Height

(mm)

Travel

Speed

(m/min)

Initial

Piercing

Height

(mm)

109 1.5 4.0 2.3 0.0

111 1.5 3.6 2.6 0.0

113 1.5 2.9 3.1 0.0

119 1.5 1.8 4.1 0.1

122 1.5 1.2 5.3 0.2

123 2.0 0.9 6.7 0.3

Pierce

Delay

(sec )

Pierce

Delay

(sec )

Manual 0-2912 4A-9 Operation with Manual Gas Control

Page 34

Stainless Steel

70A

Air Plasma / Air - CH

Shield

4

Manual

Gas Control

Or

Art # A-06838

Shield Cup

21-1016

Material

Thickness

(ga) (in) Air - Air CH

Shield Cap

21-1035

Cut Flow Rates (%)

Plasma (%) Shield (%) Preflow (%)

Shield

Gas Distributor

21-1274

Preflow Flow

Air C H

4

Tip

21-1061

Plasma

Gas Distributor

21-1041

** Arc

Voltage

(volts )

4

Electrode

Working

Height

(in)

21-1079

Travel

Speed

(ipm)

Cartridge

21-1020

Art # A-04341

Piercing

Height

(in)

Pierce

Delay

(sec )

10 0.135 35 - 60 30 75 0 141 0.080 100 0.140 0.3

-3/1635

-1/435

-3/835

-1/253

Material

Thickness

(mm)

1.5

Plasma (%) Shield (%) Preflow (%)

Ai r

35 - 20 10 75 0 140 2.0 3.2 3.0 0.2

- 60 20 75 0 151 0.080 60 0.140 0.4

-

- 20 10 75 0 154 0.140 40 0.200 0.5

-

Cut Flow Rates (%)

-

20 10 75 0 146 0.140 55 0.180 0.5

45 15 75 0 168 0.130 25 0.280 0.7

Air C H

Preflow Flow

Air C H

4

4

** Arc

Voltage

(volts )

Working

Height

(mm)

Travel

Speed

(m/min)

Piercing

Height

(mm)

Pierce

Delay

(sec )

2

3

4

5

6

8

10

12

Bold type

35

35

- 20 10 75 0 141 2.0 3.0 3.5 0.2

-

20 10 75 0 143 2.0 2.5 4.0 0.2

35 - 20 10 75 0 145 2.0 2.0 4.5 0.2

35 - 20 10 75 0 146 2.0 1.6 5.0 0.2

35 - 20 10 75 0 146 4.0 1.4 5.0 0.2

35 - 20 10 75 0 146 4.0 1.2 5.0 0.2

35 - 20 10 75 0 154 4.0 1.0 5.0 0.5

53 - 45 15 75 0 168 3.9 0.9 7.0 0.7

indicates maximum piercing parameters.

Operation with Manual Gas Control 4A-10 Manual 0-2912

Page 35

Stainless Steel

!

100A

Ar/H2 Plasma / N2 Shield

Manual

Gas Control

Art # A-06839

Shield Cup

21-1016

Material

Thickness

(ga)(in)H35N2N2N2N2N2

- 1/8 0 35 35 35 35 35 148 0.125 80 0.200 0.1

- 1/4 35 35 35 35 35 35 161 0.125 65 0.250 0.3

- 3/8 35 35 35 35 35 35 161 0.125 60 0.300 0.3

- 1/2 35 35 35 35 35 35 161 0.130 50 0.350 0.5

- 5/8 35 35 35 35 35 35 169 0.140 30 0.350 0.8

Material

Thickness

(mm)

3

Shield Cap

21-1036

Cut Flow Rates (%)

Plasma % Shield % Preflow %

Cut Flow Rates (%)

Plasma % Shield % Preflow %

H35N2N2N2N2N2

0 3535353535 148 3.2 2.0 5.1 0.1

Shield

Gas Distributor

21-1274

Plasma

Tip

21-1062

Preflow Flow ** Arc

Preflow Flow ** Arc

Gas Distributor

21-1041

Voltage

(volts )

Voltage

(volts )

Electrode

21-1080

Tor c h

Working

Height

Tor c h

Working

Height

Travel

Speed

(ipm)

Travel

Speed

(m/min)

Cartridge

21-1020

Art # A-04030

Initial

Piercing

Height

Initial

Piercing

Height

Pierce

Delay

(sec )

Pierce

Delay

(sec )

4

5

6

8

10

12

15

Bold type

indicates maximum piercing parameters.

35 35 35 35 35 35 155 3.2 1.9 6.0 0.3

35 35 35 35 35 35 161 3.2 1.8 6.4 0.3

35 35 35 35 35 35 161 3.2 1.7 6.4 0.3

35 35 35 35 35 35 161 3.2 1.6 6.4 0.3

35 35 35 35 35 35 161 3.2 1.5 7.6 0.4

35 35 35 35 35 35 161 3.3 1.3 8.9 0.5

35 35 35 35 35 35 167 3.6 0.9 8.9 0.7

CAUTION

Manual gas consoles with 3 flow meters cannot be used for 100A cutting with stainless steel.

Manual 0-2912 4A-11 Operation with Manual Gas Control

Page 36

Aluminum

50A

Air Plasma / Air Shield

Manual

Gas Control

Or

Art # A-06838

Shield Cup

21-1016

Material

Thickness

(ga) (in) - Air Air - Air -

14 0.075

12 0.105

10 0.135

-3/16

Material

Thickness

(mm)

0.6

Shield Cap

21-1034

Cut Flow Rates (%) Preflow Flow

Plasma % Shield % Preflow %

-

- 65 80 - 65 - 139 0.105 90 0.200 0.0

- 65 80 - 65 - 142 0.110 60 0.200 0.0

-

65 80

65 80

Cut Flow Rates (%)

Plasma % Shield % Preflow %

-AirAir -Air -

-

65 80 - 65 - 130 2.5 4.6 3.5 0. 0

Shield

Gas Distributor

21-1274

-

-

Tip

21-1060

65

65

Preflow Flow

Gas Distributor

21-1041

** Arc

Voltage

(volts )

-

-

** Arc

Voltage

(volts )

Plasma

21-1078

Tor c h

Working

Height

Travel

Speed

(ipm)

Cartridge

21-1020Electrode

Art # A-04029

Initial

Piercing

Height

Pierce

Delay

(sec )

135 0.100 135 0.150 0.0

145 0.120 40 0.250 0.2

Tor c h

Working

Height

Travel

Speed

(m/min)

Initial

Piercing

Height

Pierce

Delay

(sec )

0.8

1

1.2

1.5

2.0

3.0

4.0

5.0

Bold type

- 65 80 - 65 - 130 2.5 4.5 3.5 0.0

- 65 80 - 65 - 130 2.5 4.3 3.5 0.0

- 65 80 - 65 - 133 2.8 4.0 3.7 0.0

- 65 80 - 65 - 133 2.8 3.8 3.7 0.0

- 65 80 - 65 - 135 2.8 3.2 4.0 0.0

- 65 80 - 65 - 142 2.8 1.5 5.1 0.0

- 65 80 - 65 - 123 3.0 1.2 6.5 0.2

- 65 80 - 65 - 145 3.0 1.0 6.5 0.2

indicates maximum piercing parameters.

Operation with Manual Gas Control 4A-12 Manual 0-2912

Page 37

Aluminum

70A

Air Plasma / Air Shield

Manual

Gas Control

Or

Art # A-06838

Shield Cup

21-1016

Material

Thickness

(ga) (in) Air - Air CH

Shield Cap

21-1035

Cut Flow Rates (%)

Plasma (%) Shield (%) Preflow (%)

Shield

Gas Distributor

21-1274

21-1061

Preflow Flow

Rates (%)

Air C H

4

Tip

Plasma

Gas Distributor

21-1041

** Arc

Voltage

(volts)

4

Electrode

21-1079

Torch

Working

Height

(in)

Travel

Speed

(ipm)

Cartridge

21-1020

Art # A-04341

Initial

Piercing

Height

(in)

Pierce

Delay

(sec)

12 0.097 35 - 65 0 63 0 132 0.080 200 0.140 0.1

-1/835

-3/1635

-1/435

-3/835

Material

Plasma (%) Shield (%) Preflow (%)

Thickness

(mm)

2

Ai r

35

- 65 0 63 0 140 0.100 110 0.140 0.1

- 65 0 63 0 144 0.120 100 0.140 0.1

-

-

Cut Flow Rates (%)

-

-

65 0 63 0 148 0.140 70 0.180 0.2

65 0 63 0 152 0.140 40 0.180 0.3

Preflow Flow

Air C H

4

Rates

Air C H

4

** Arc

Voltage

(volts)

Torch

Working

Height

(mm)

Travel

Speed

(m/min)

Initial

Piercing

Height

(mm)

65 0 63 0 130 1.5 7.6 3.6 0.1

Pierce

Delay

(sec)

3

4

5

6

8

10

Bold type

indicates maximum piercing parameters.

35

- 65 0 63 0 139 2.3 3.0 3.6 0.1

35 - 65 0 63 0 142 2.7 2.6 3.6 0.1

35 - 65 0 63 0 145 3.1 2.4 3.7 0.1

35 - 65 0 63 0 147 3.4 2.0 4.4 0.2

35 - 65 0 63 0 150 3.6 1.5 4.6 0.3

35 - 65 0 63 0 154 3.6 0.8 4.6 0.4

Manual 0-2912 4A-13 Operation with Manual Gas Control

Page 38

Aluminum

!

100A

Ar/H2 Plasma / N2 Shield

Manual

Gas Control

Art # A-06839

Shield Cup

21-1016

Material

Thickness

(ga)(in)H35N2N2N2N2N2

- 1/4 35 35 35 35 35 35 161 0.150 100 0.350 0.2

- 3/8 35 35 35 35 35 35 163 0.150 60 0.350 0.2

- 1/2 35 35 35 35 35 35 166 0.150 50 0.350 0.3

- 5/8 60 30 35 35 35 35 173 0.150 40 0.400 0.5

Material

Thickness

(mm)

3

Shield Cap

21-1036

Cut Flow Rates (%)

Plasma % Shield % Preflow %

Cut Flow Rates (%)

Plasma % Shield % Preflow %

H35N2N2N2N2N2

35 35 35 35 35 35 155 3.8 3.3 8.0 0.2

Shield

Gas Distributor

21-1274

Tip

21-1062

Preflow Flow

Preflow Flow

Plasma

Gas Distributor

21-1041

** Arc

Voltage

(volts )

** Arc

Voltage

(volts )

Working

Working

Tor c h

Height

(in)

Tor c h

Height

(mm)

Electrode

21-1080

Travel

Speed

(ipm)

Travel

Speed

(m/min)

Cartridge

21-1020

Art # A-04030

Initial

Piercing

Height

(in)

Initial

Piercing

Height

(mm)

Pierce

Delay

(sec )

Pierce

Delay

(sec )

4

5

6

8

10

12

15

Bold type

indicates maximum piercing parameters.

35 35 35 35 35 35 158 3.8 3.0 8.0 0.2

35 35 35 35 35 35 160 3.8 2.8 8.9 0.2

35 35 35 35 35 35 160 3.8 2.5 8.9 0.2

35 35 35 35 35 35 162 3.8 2.0 8.9 0.2

35 35 35 35 35 35 163 3.8 1.5 8.9 0.2

35 35 35 35 35 35 165 3.8 1.3 8.9 0.3

60 30 35 35 35 35 172 3.8 1.1 10.2 0.5

CAUTION

Manual gas consoles with 3 flow meters cannot be used for 100A cutting with stainless steel.

Operation with Manual Gas Control 4A-14 Manual 0-2912

Page 39

SECTION 4B:

OPERATION WITH 5-KNOB AUTOMATIC GAS CONSOLE

4B.01 Torch Parts Selection

The application will determine which torch parts must be used. Refer to the speed charts in Section 4B.03, Recommended Cutting Speeds, for the proper torch parts to install for a selected application.

CAUTION

Do not interchange parts. Make sure all parts in the torch correspond with the plasma and shield gas in use for the

application.

4B.02 Pre-Setting Controls

A. Power Supply Setting

Set the Power Supply controls as follows before operating the system.

1. Set the proper cutting current at the AMPS thumbwheel.

2. Use data from the Speed Charts in Section 4.03 for each combination of material and amperage:

a. Set the initial torch height.

b. Set arc voltage on the torch height control.

c. Set the PIERCE DELAY potentiometer.

3. On the gas console select the plasma gas to be used with the PROCESS SELECTION switch.

4. All gas supplies are connected and set at 120 psi (8.3 bar) at the inlet pressure gauges.

B. Pre-Charge Box Setting

Before operating the system:

1. Set the gas supply pressure at the oxygen cylinder to 120 psi (8.3 bar).

2. On the front of the gas console set the RUN TEST switch to the TEST PREFLOW position. This will enable

gas to flow by opening the solenoid in the Pre-Charge Box.

3. If system plasma pressure gauge indicates more than 120 psi (8.3 bar) the system is over pressurized. Stop

and do the following:

a. On the front of the gas console set the RUN TEST switch to the TEST CUT FLOW position.

b. Let gas flow for 20 seconds. This will allow the system pressure to bleed off.

c. Repeat steps 2 and 3 above.

Manual 0-2912 4B-1 Operation with 5-Knob Automatic Gas Console

Page 40

4B.03 Recommended Cutting Speeds

!

Cutting speed depends on material and thickness. The following factors may affect system performance:

• Torch parts wear

• Speed

• Gas quality

• Operator experience

• Torch standoff height

• Proper work cable connection

• Alloy content of material

NOTE

This information represents realistic expectations using recommended practices and well-maintained systems. Actual speeds may vary from those shown in the charts depending on the alloy content of the selected material.

For complete cutting speed chart data refer to the following pages.

CAUTION

Information in this section is for the HD3070 System with an automatic gas control with 5 control knobs.

1

Shield Controls

2

Plasma Control

3

4

5

Art # A-04493

Preflow Controls

Operation with 5-Knob Automatic Gas Console 4B-2 Manual 0-2912

Page 41

NOTE

This information represents realistic expectations using recommended practices and well-maintained systems. Actual speeds may vary from those shown in the charts depending on the alloy content of the selected material.

Refer to Section 3C for information for the HD3070 System with an automatic gas control with 6 control knobs.

** - Arc voltage is based on 50 ft (15.2 m) torch lead length. For other lead lengths the operator may need to adjust

the Arc Voltage setting. Refer to Appendix 1 for Alternate Arc Voltage Settings.

NOTE: The preflow rates shown generate increased dross at the start of a cut. Increasing the amount of oxygen and

reducing the amount of nitrogen will reduce dross at the start of a cut, but will also reduce electrode life.

Oxygen (O2) gas inlet pressures must be 120 psi (8.3 bar) for all material thicknesses.

Slightly increasing the preflow flow rates may increase piercing capability on the thicker materials listed above.

However, increasing the preflow flow rates too much may affect plasma starting reliability (misfiring).

Torch Working Height tolerances are ±0.005 inch (±0.125 mm).

Thermal Dynamics Pre-Charge Unit must be installed before cutting.

Chart gives set-up parameters for use with a Hypertherm HD 3070 System. For technical and legal reasons the

settings in the chart may not be appropriate for use with other systems.

Manual 0-2912 4B-3 Operation with 5-Knob Automatic Gas Console

Page 42

Mild Steel

30A

O

Plasma / O2 - N2 Shield

2

3

2

1

4

5

Art # A-06840

Shield Cup

21-1016

Material

Thickness

(ga) (in)

Shield

Shield Cap

21-1024

Cut Flow Rates

Shield Preflow

O

(1*)

N2

2

(2*)

Plasma

O

2

(3*)

Gas Distributor

21-1082

Preflow Flow

O

2

(4*)

Rates

N2

(5*)

Tip

21-1050

** Arc

Voltage

(volts)

Plasma

Gas Distributor

21-1040

Tor c h

Working

Height

(in)

Electrode

Travel

Speed

(ipm)

21-1068

Piercing

Height

Initial

(in)

Cartridge

21-1020

Art # A-04338

Pierce Delay

(Dial) (Sec)

20 0.036 13 0 13 5 55 129 0.050 140 0.120 0.5 0.2

16 0.060 13 0 13 5 55 137 0.050 80 0.120 0.5 0.2

14 0.075 13 0 13 5 55 139 0.070 50 0.120 0.5 0.2

11 0.120 17 3 13 5 55 140 0.070 40 0.120 0.5 0.2

10 0.135 17 3 13 5 55 142 0.070 35 0.120 0.5 0.2

9 0.150 17 3 13 5 55 143 0.070 33 0.120 1.0 0.3

7 0.179 17 3 13 5 55 144 0.070 30 0.120 1.0 0.3

2

Preflow Flow

Rates

O

(4*)

N2

2

(5*)

Bold type

** Arc

Voltage

(volts)

indicates maximum piercing parameters.* Refers to Control Knob Number

Tor c h

Working

Height

(mm)

Travel

Speed

(m/min)

Initial

Piercing

Height

(mm)

Pierce Delay

(Dial) (Sec)

Material

Thickness

(mm)

0.6

0.8

1

1.2

1.5

2

3

4

5

Cut Flow Rates

Shield Preflow

O

2

(1*)

N2

(2*)

Plasma

O

(3*)

13 0 13 5 55 125 1.3 4.8 3.0 0.0 0.1

13 0 13 5 55 125 1.3 4.1 3.0 0.0 0.1

13 0 13 5 55 129 1.3 3.6 3.0 0.0 0.1

13 0 13 5 55 129 1.3 2.9 3.0 0.0 0.1

13 0 13 5 55 136 1.3 2.2 3.0 0.5 0.2

13 0 13 5 55 139 1.8 1.3 3.0 0.5 0.2

17 3 13 5 55 140 1.8 1.1 3.0 0.5 0.2

17 3 13 5 55 142 1.8 0.9 3.0 0.5 0.2

17 3 13 5 55 145 1.8 0.7 3.0 1.0 0.3

Operation with 5-Knob Automatic Gas Console 4B-4 Manual 0-2912

Page 43

Mild Steel

r

50A

O

Plasma / O2 - N2 Shield

2

3

2

1

4

5

Art # A-06840

Shield Cup

21-1016

Material

Thickness

(ga) (in)

Shield

Shield Cap

21-1025

Cut Flow Rates

Shield Preflow

O

(1*)

N2

2

(2*)

Gas Distributor

21-1272

Plasma

O

2

(3*)

Preflow Flow

O

2

(4*)N2(5*)

Rates

Tip

21-1051

** Arc

Voltage

(volts)

Plasma

Gas Distributor

21-1041

Tor c h

Working

Height

(in)

Electrode

21-1069

Travel

Speed

(ipm)

Initial

Piercing

Height

(in)

Cartridge

21-1020

Art # A-04026

Pierce Delay

(Dial) (s ec)

20 0.036 5 25 20 10 40 122 0.060 500 0.100 1.0 0.3 *

16 0.060 5 25 20 10 40 126 0.060 300 0.100 1.0 0.3 *

10 0.135 5 25 20 10 40 130 0.060 150 0.200 0.0 0.1

7 0.179 5 25 20 5 65 134 0.080 100 0.200 0.0 0.1

0.250 5 25 20 5 65 135 0.100 80 0.200 0.5 0.2

0.375 5 15 20 5 65 148 0.110 25 0.350 1.0 0.3

Material

Thickness

(mm)

0.8

1.0

1.2

1.5

2.0

3.0

4.0

5.0

6.0

8.0

10.0

Cut Flow Rates

Shield Preflow

O

2

(1*)

N2

(2*)

Plasma

O

2

(3*)

5 25 20 10 40 122 1.5 12.7 2.5 1.0 0.3 *

5 25 20 10 40 123 1.5 12.0 2.5 1.0 0.3 *

5 25 20 10 40 124 1.5 9.5 2.5 1.0 0.3 *

5 25 20 10 40 126 1.5 7.6 2.5 1.0 0.3 *

5 25 20 10 40 127 1.5 6.5 3.3 1.0 0.3 *

5 25 20 10 40 130 1.5 3.8 4.8 0.0 0.1

5 25 20 10 40 132 2.0 3.1 5.0 0.0 0.1

5 25 20 5 65 134 2.0 2.5 5.1 0.0 0.1

5 25 20 5 65 135 2.0 2.1 5.1 0.0 0.1

5 15 20 5 65 146 2.5 0.8 6.4 0.5 0.2

5 15 20 5 65 148 2.8 0.6 8.9 1.0 0.3

* Refers to Control Knob Numbe

Preflow Flow

Rates

O

2

(4*)N2(5*)

** Arc

Voltage

(volts)

Bold type

Tor c h

Working

Height

(mm)

Travel

Speed

(m/min)

Initial

Piercing

Height

(mm)

Pierce Delay

(Dial) (s ec)

indicates maximum piercing parameters.

Manual 0-2912 4B-5 Operation with 5-Knob Automatic Gas Console

Page 44

Mild Steel

70A

O

Plasma / O2 - N2 Shield

2

Shield Cup

21-1016

Material

Thickness

(ga) (in)

Shield Cap

21-1026

Cut Flow Rates

Shield Preflow

O

(1*)

N2

2

(2*)

Gas Distributor

21-1272

Plasma

O

2

(3*)

Shield

Preflow Flow

Rates

O

2

(4*)

N2

(5*)

Tip

21-1052

** Arc

Voltage

(volts)

Plasma

Gas Distributor

21-1041

Torch

Working

Height

(in)

1

21-1070

Travel

Speed

(ipm)

3

2

Initial

Piercing

Height

(in)

4

5

Cartridge

21-1020Electrode

Art # A-04027

Pierce Delay

(Dial) (s ec)

16 0.060 25 0 25 5 65 138 0.060 300 0.100 0.0 0.0

14 0.075 25 0 25 5 65 138 0.060 250 0.100 0.0 0.0

Art # A-06840

12 0.105 10 45 65 5 65 140 0.060 225 0.120 0.0 0.0

10 0.135 10 45 65 5 65 142 0.060 200 0.150 0.0 0.0

7 0.179 10 45 65 5 65 143 0.070 120 0.200 0.0 0.1

- 1/4 10 45 65 5 65 146 0.080 110 0.200 0.5 0.2

- 3/8 10 45 65 5 65 150 0.120 70 0.300 0.5 0.2

Cut Flow Rates

Preflow Flow

Rates

Material

Thickness

(mm)

1.5

2.0

3.0

4.0

5.0

Shield Preflow

O

2

(1*)

25 0 25 5 65 138 1.5 7.6 2.5 0.0 0.0

25 0 25 5 65 138 1.5 6.8 2.5 0.0 0.0

10 45 65 5 65 141 1.5 5.3 3.7 0.0 0.0

10 45 65 5 65 141 1.5 4.1 3.7 0.0 0.0

10 45 65 5 65 144 1.9 3.0 5.2 0.0 0.0

N2

(2*)

Plasma

O

2

(3*)

O

(4*)

Torch

N2

** Arc

2

(5*)

Voltage

(volts)

Working

Height

(mm)

Travel

Speed

(m/ min)

Initial

Piercing

Height

(mm)

Pierce Delay

(Dial) (s ec)

6.0

8.0

* Refers to control knob number.

10 45 65 5 65 146 1.9 2.5 5.2 0.0 0.0

10 45 65 5 65 148 2.5 2.3 6.4 0.0 0.1

Bold type

indicates maximum piercing parameters.

Operation with 5-Knob Automatic Gas Console 4B-6 Manual 0-2912

Page 45

Mild Steel

100A

O

Plasma / O2 - N2 Shield

2

Shield Cup

21-1016

Material

Thi c k ness

(ga) (in)

Shield Cap

21-1027

Cut Flow Rates

Shield Preflow

O

(1*)

N2

2

(2*)

Shield

Gas Distributor

21-1272

Plasma

O

2

(3*)

21-1053

Preflow Flow

Rates

O

(4*)

N2

2

(5*)

Tip

** Arc

Voltage

(volts )

Plasma

Gas Distributor

21-1041

Tor c h

Working

Height

(in)

1

Electrode

21-1071

Travel

Speed

(ipm)

3

2

Initial

Piercing

Height

(in)

4

5

Cartridge

21-1020

Art # A-04028

Pierce Delay

(Dial) (sec)

10 0.135 15 70 62 15 80 141 0.070 280 0.200 0.0 0.0

7 0.179 15 70 62 15 80 145 0.090 235 0.200 0.0 0.0

- 0.25 15 70 62 15 80 153 0.100 150 0.200 0.0 0.0

Art # A-06840

- 0.375 15 70 62 15 80 156 0.110 100 0.250 0.5 0.2

- 0.5 15 86 62 15 80 158 0.120 70 0.300 1.0 0.3

- 0.625 15 86 62 15 80 163 0.120 50 0.350 2.0 0.5

-0.7515866215801760.150250.4002.5 0.6

Cut Flow Rates

Preflow Flow

Rates

Material

Thi c k ness

(mm)

3

4

5

6

8

10

12

Shield Preflow

O

2

(1*)

15 70 62 15 80 142 2.3 6.2 4.5 0.0 0.0

15 70 62 15 80 145 2.3 5.7 4.8 0.0 0.0

15 70 62 15 80 148 2.3 5.3 5.1 0.0 0.0

15 70 62 15 80 152 2.3 4.6 5.1 0.0 0.0

15 70 62 15 80 155 2.8 3.2 5.8 0.0 0.1

15 70 62 15 80 156 3.0 2.1 6.6 0.5 0.2

15 86 62 15 80 158 3.0 1.9 7.1 1.0 0.3

N2

(2*)

Plasma

O

2

(3*)

O

(4*)

Tor c h

N2

** Arc

2