Page 1

8.0 TORCH OPERATION

Torch Parts Selection

The application will determine which torch parts must be used. Refer to the cut charts for the proper torch parts to

install for a selected application.

CAUTION

Do not interchange parts. Make sure all torch parts correspond with the plasma and shield

gases in use for the application.

Pre-Setting Power Supply Controls

Set the Power Supply controls prior to operating the system as described in the power supply Operating Manual.

Refer to the cutting charts for the proper cutting parameters for the application.

Recommended Cutting Speeds

Cutting speed depends on material and thickness. The following factors may affect system performance:

• Torch parts wear; gas quality and mass flow / pressure; operator experience; torch standoff height; proper

work cable connection; alloy content of material; cutting table capabilities & accuracy.

NOTE

This information represents realistic expectations using recommended practices and wellmaintained systems. Actual speeds may vary from those shown in the charts depending on

the alloy content of the selected material. Voltage ratings may vary depending on the CNC,

cutting table, or height controller.

For complete cutting speed chart data refer to the following pages.

Consumables Notes

Always assemble the consumable parts properly. Improper assembly may damage the parts or the torch head.

Ensure that parts are seated together correctly.

Always check the shield gas distributor for charring when changing parts. Do not use the distributor if it is charred.

Replace the shield gas distributor regularly to ensure proper performance.

Operational Notes

Always purge the torch after changing consumables or if the power supply has been shut off. The power supply's

built-in purge function may not be enough to properly purge the torch. Manually flow gas with the 'Test Cut Flow' and

'Test Pre-Flow' functions to help remove any remaining coolant from the lines.

Slightly increasing the preflow pressure may increase piercing ability on thicker materials. However, increasing the

preflow pressure too much may affect plasma starting reliability (misfiring).

Decreasing preflow pressure may improve piloting. Preflow pressure can be reduced without affecting cut performance as long as the pilot arc still transfers to the plate well. Decreasing preflow pressure too much will affect the

ability to transfer the arc to the plate and cause damage to the tip.

Notes on Chart Measurements

Pressure measurements in the charts are in psi(g), not psi(a). 0 psi(g) = 14.7 psi(a) (1 atmosphere).

Ball settings are at the center of the gauge ball.

Manual 0-4829 Rev AN 8-3 TORCH DATA for Ultra-Cut

Page 2

Ohmic Sensing

Ohmic sensing is not recommended with water shield. Water on the plate interferes electrically with the ohmic

sensing circuit.

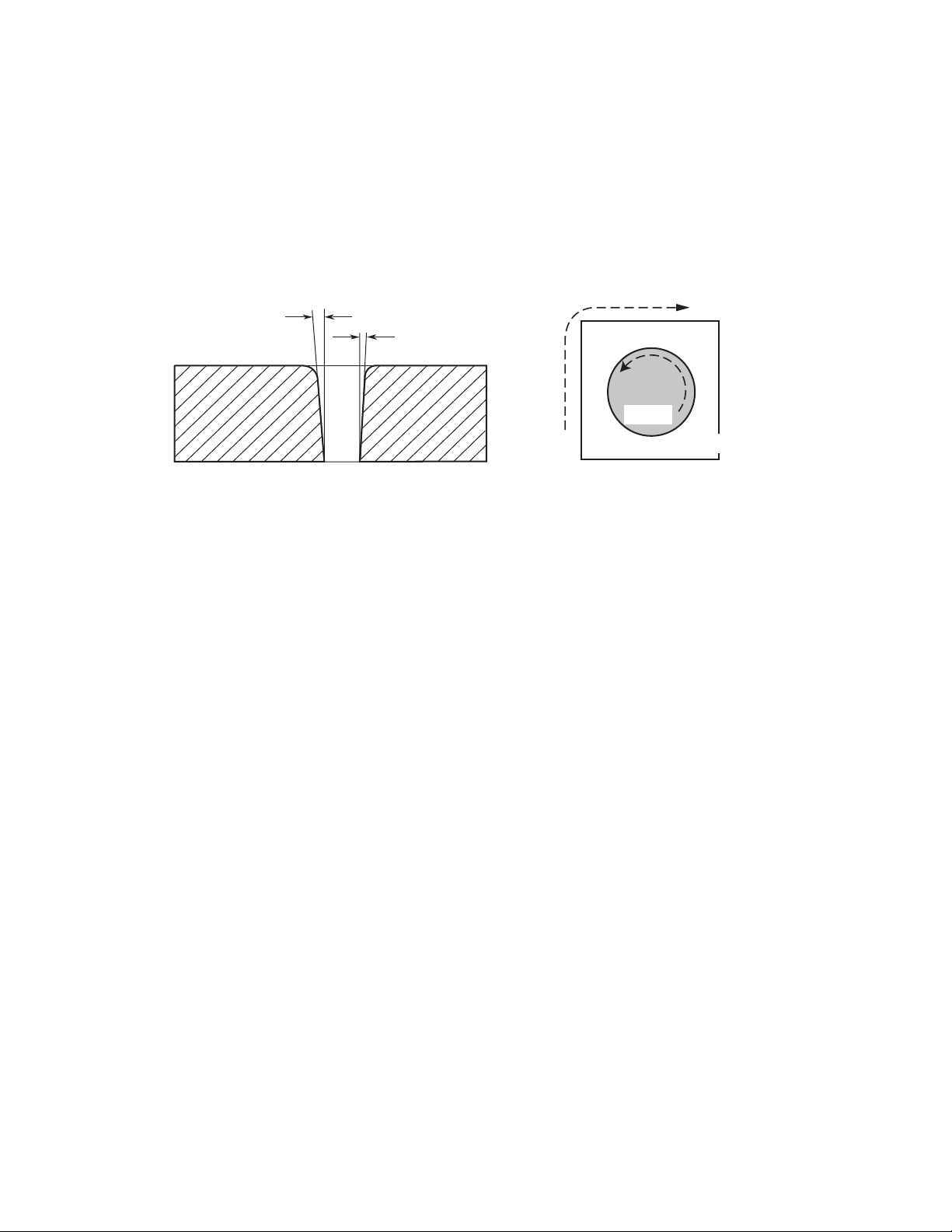

Direction of Cut

The plasma gas stream swirls as it leaves the torch to maintain a stable arc column. This swirl effect results in one

side of a cut being more square than the other. Viewed along the direction of travel, the right side of the cut is more

square than the left.

Left Side

Cut Angle

Right Side

Cut Angle

A-00512

Clockwise

Scrap

Counter-

Clockwise

Scrap

Workpiece

Art # A-04182

Side Characteristics Of Cut

To make a square - edged cut along an inside diameter of a circle, move the torch counterclockwise around the circle.

To keep the square edge along an outside diameter cut, move the torch in a clockwise direction.

Underwater Cutting

Cutting on a water table either underwater or with the water touching the plate or with a water muffler system is not

recommended. If a water table is used the water level must be a minimum of 4 inches / 100 mm from the bottom of the

plate. Failure to follow this recommendation could result in poor cut quality and short consumable parts life.

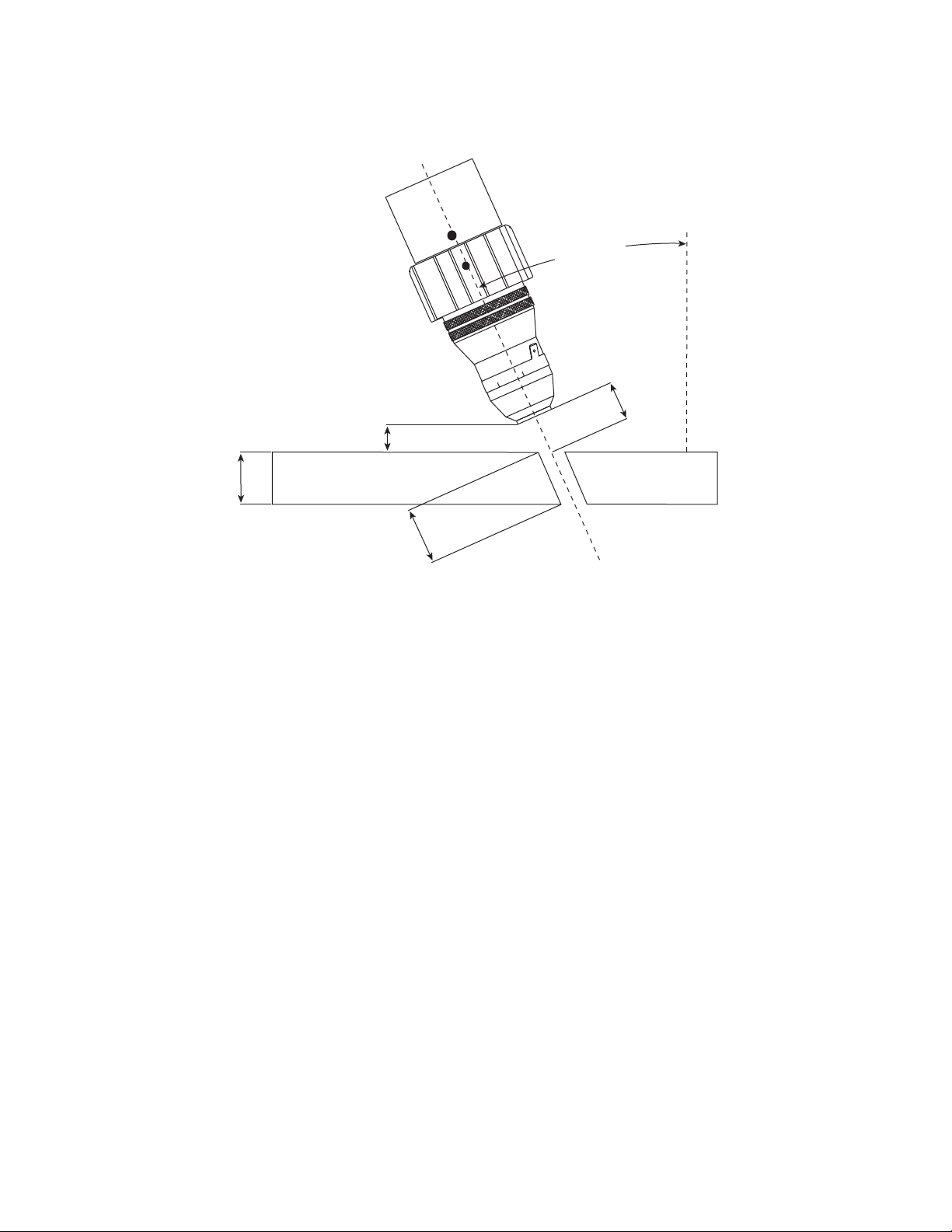

Bevel Cutting Definitions

Bevel Angle The angle between the center line of the torch and a line that is perpendicular to the workpiece.

If the torch is perpendicular to the workpiece, the Bevel Angle is zero. The maximum Bevel

Angle is 45°.

Nominal Thickness The vertical thickness of the workpiece.

Effective Thickness The length of the cut edge, or the distance the arc travels through the material while cutting.

Effective Thickness is equal to the nominal thickness divided by the cosine of the bevel

angle. Effective Thicknesses are listed in the cut chart.

Clearance The vertical distance from the lowest point of the torch to the surface of the workpiece.

Effective Cut Height The linear distance from the center of the torch outlet to the workpiece surface along the

torch center-line. A range of Effective Cut Height distances are listed in the cut chart. The

smallest number is for a straight cut (bevel angle = 0°). The largest number is for a 45° bevel

cut with a clearance of 2 mm (0.125 in).

Arc Voltage The Arc Voltage setting is dependent on the Bevel Angle and the setup of the cutting system.

The Arc Voltage setting on one system may be different from a second system even if the

workpiece is the same thickness. The arc voltages for bevel cutting are not supplied in the

bevel cut charts.

TORCH DATA for Ultra-Cut 8-4 Manual 0-4829 Rev AN

Page 3

Clearance

To rch

Center-line

0°

Bevel Angle

Effective Cut

Height

Nominal

Thickness

Work Piece

Effective

Thickness

Art # A-08568

Manual 0-4829 Rev AN 8-5 TORCH DATA for Ultra-Cut

Page 4

TORCH DATA for Ultra-Cut 8-6 Manual 0-4829 Rev AN

Page 5

Insert "Up To 100 Amp

Standard Cutting" Tab.

Discard this sheet.

Manual 0-4829 Rev AN 8-7 TORCH DATA for Ultra-Cut

TAB SHEET

Page 6

This Page Intentionally Blank

TORCH DATA for Ultra-Cut 8-8 Manual 0-4829 Rev AN

Page 7

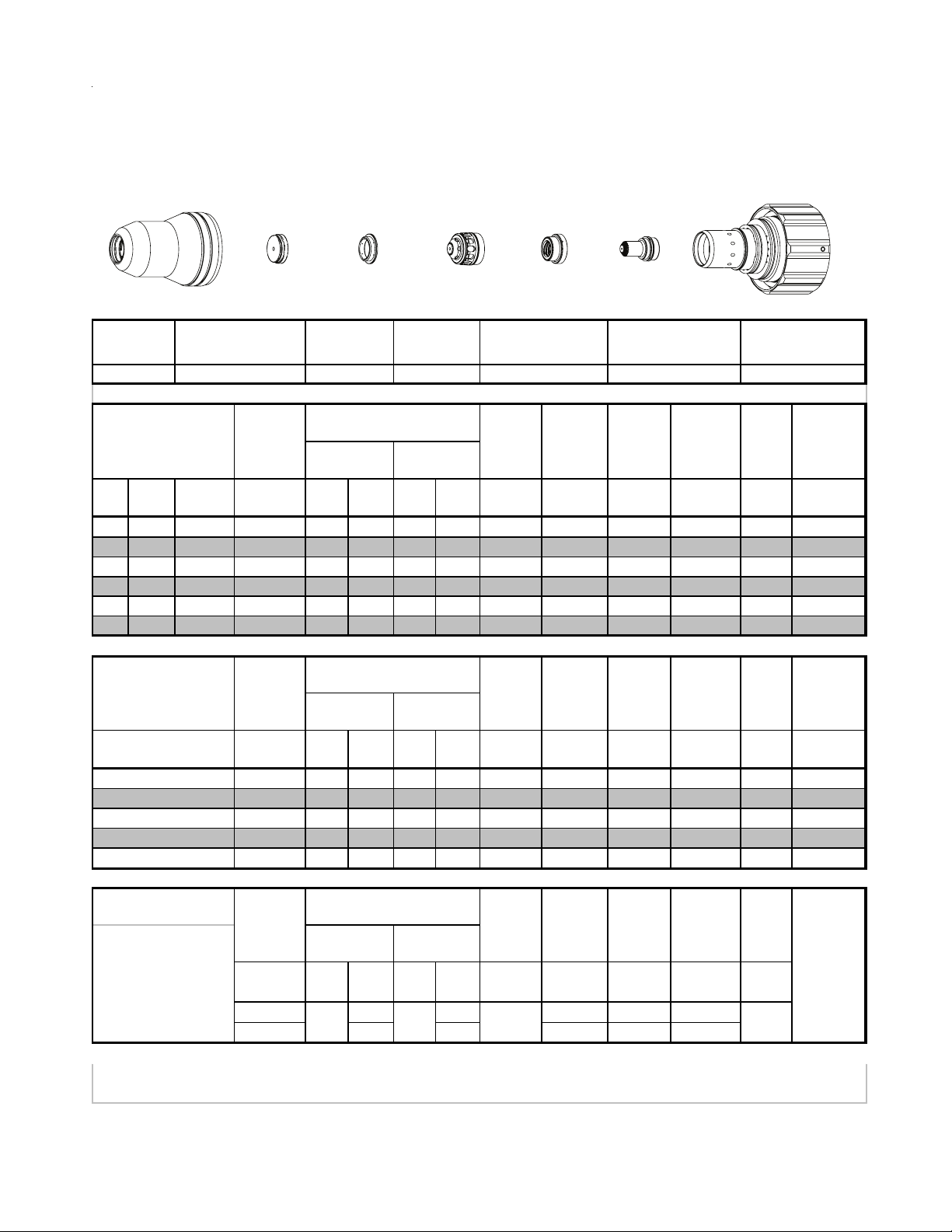

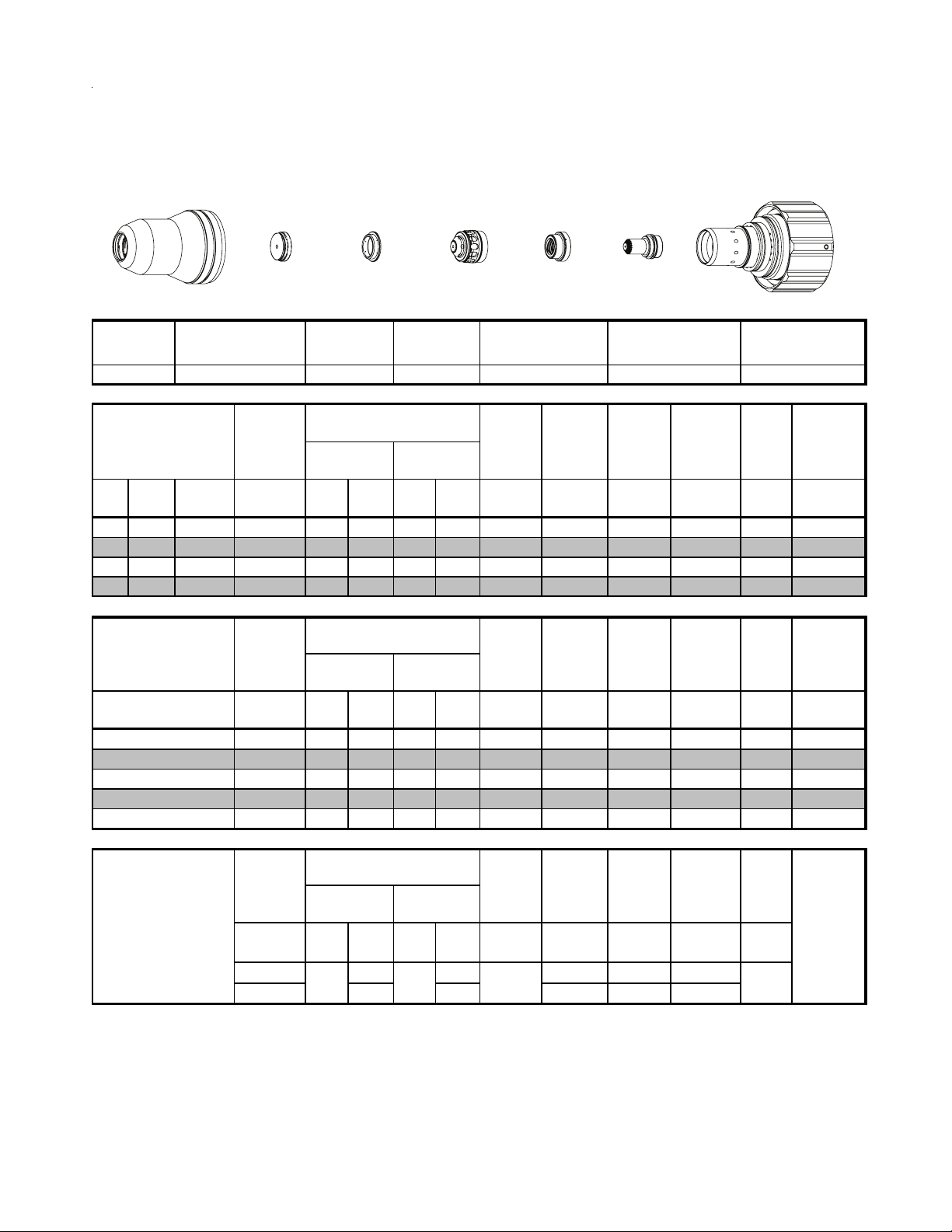

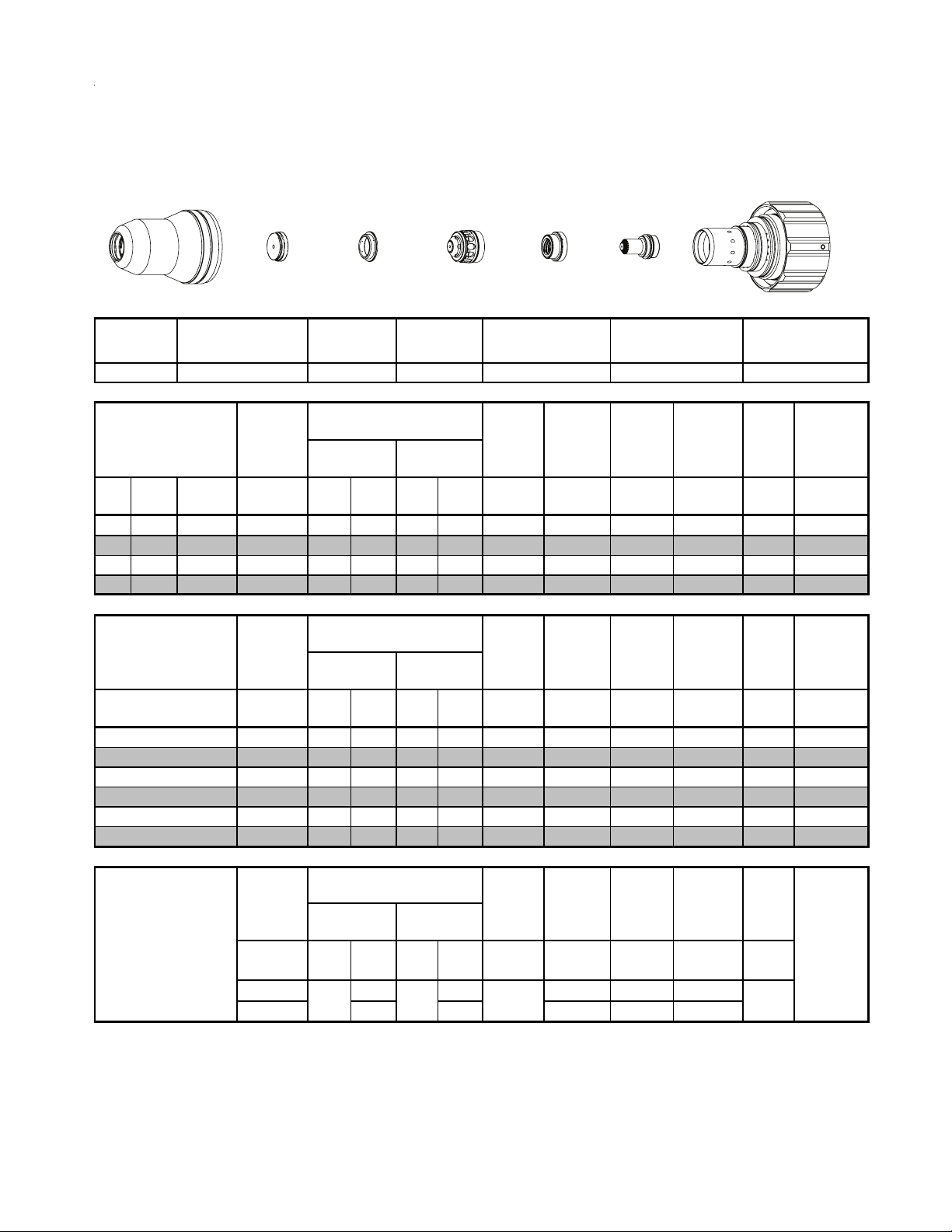

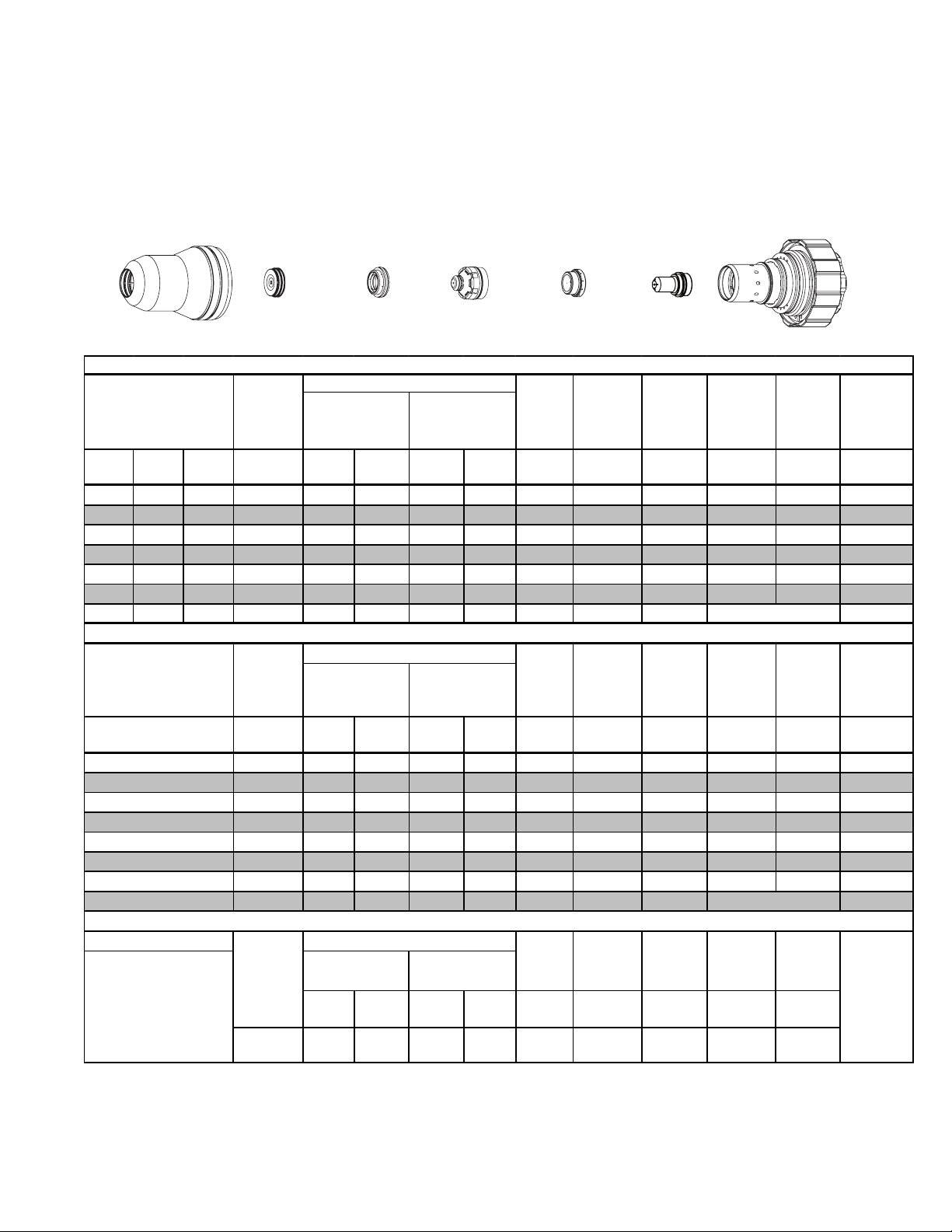

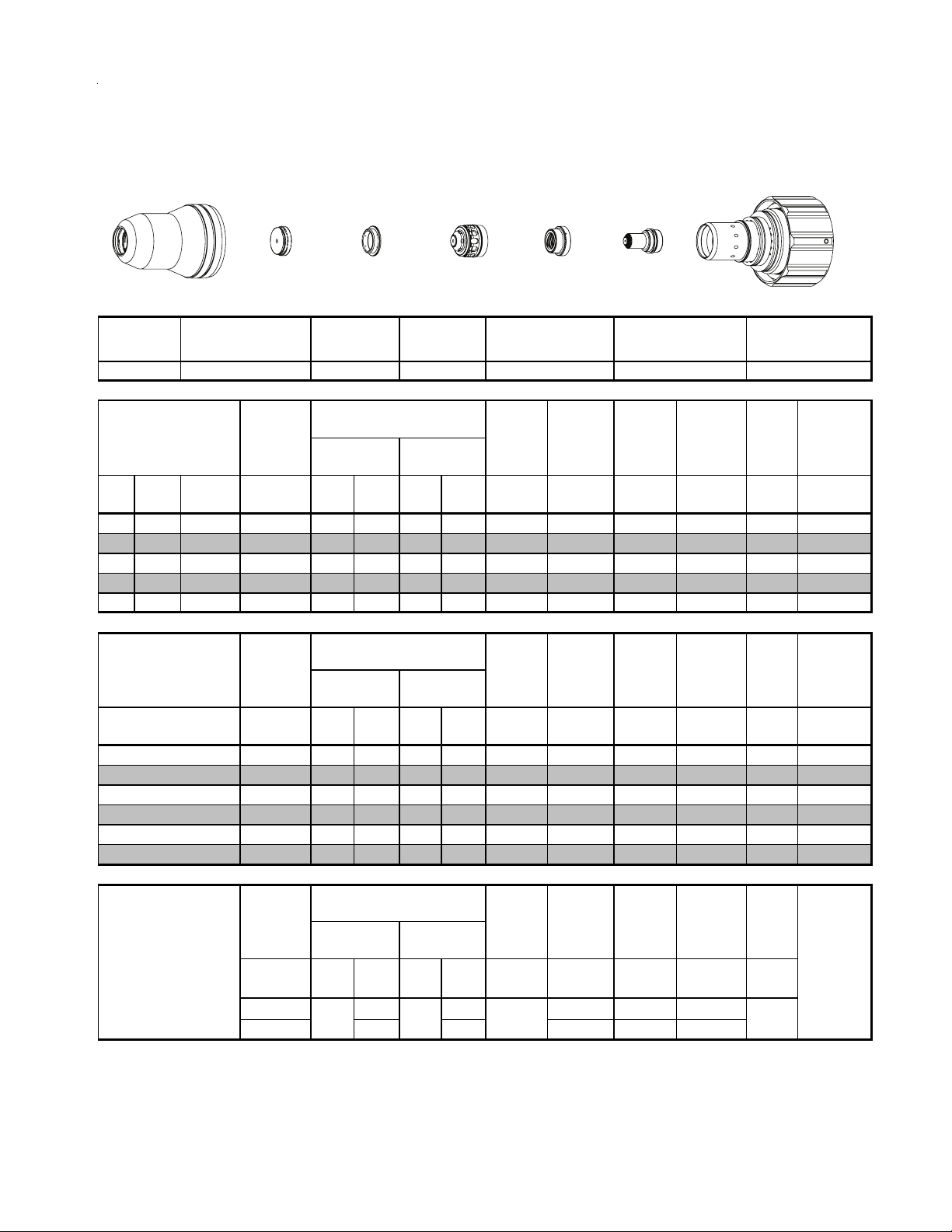

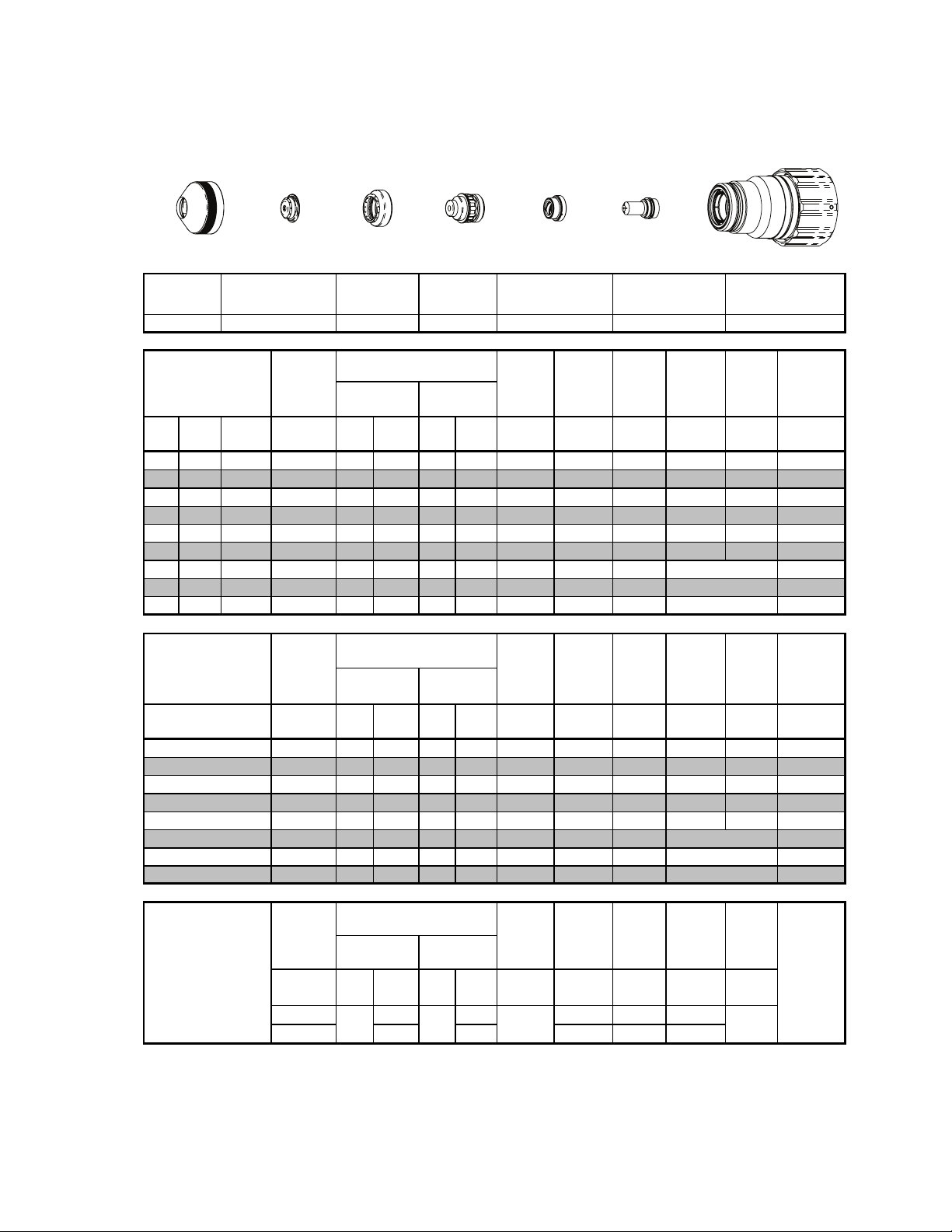

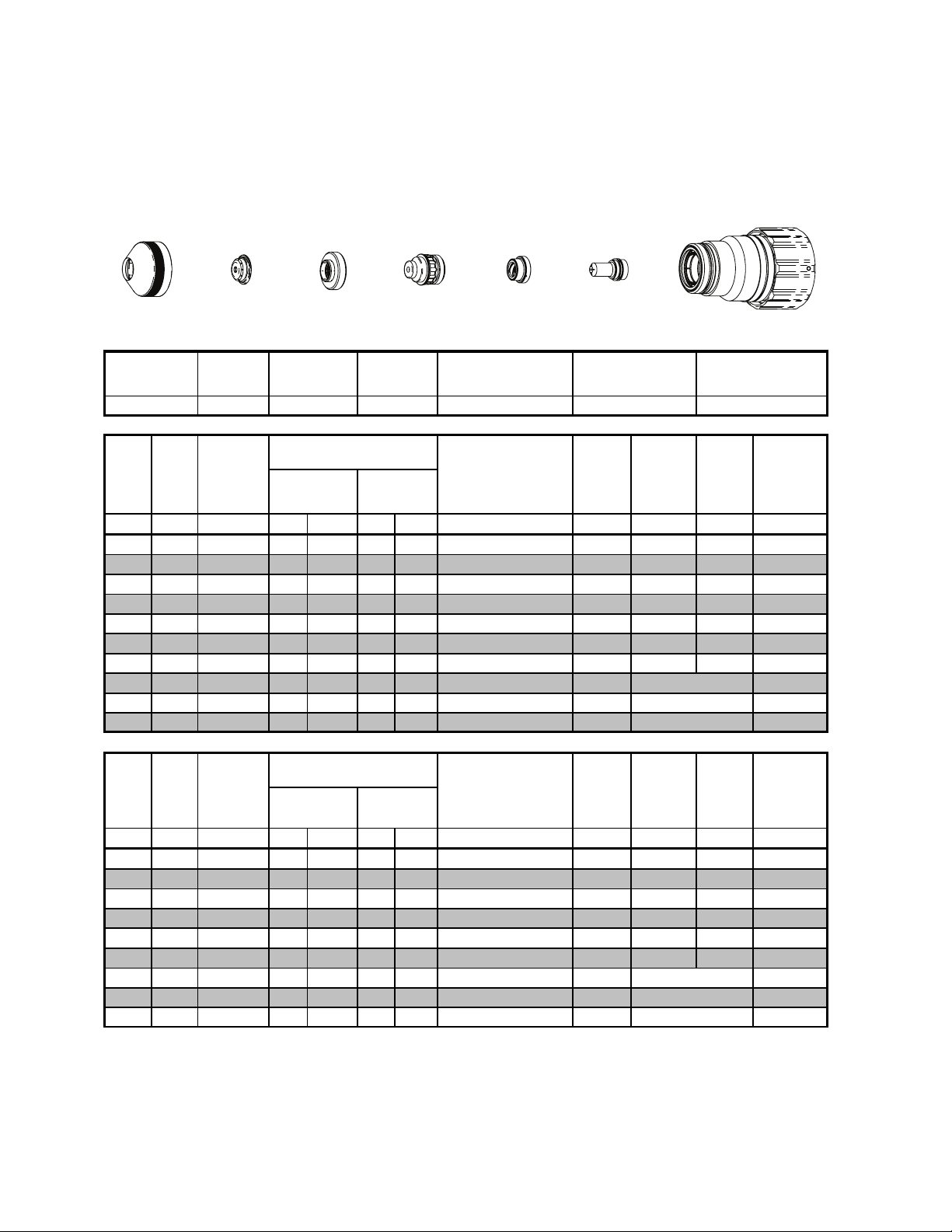

8.01 Standard Cutting Up To 100 Amp

Mild Steel

30A

Plasma / O2 Shield

O

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

20 0.036 60 22 120 21 120 128 0.050 130 0.120 0.2 0.058

16 0.060 60 22 120 21 120 143 0.050 60 0.120 0.3 0.070

14 0.075 60 22 120 21 120 145 0.070 45 0.120 0.3 0.072

12 0.105 60 22 120 21 120 148 0.110 40 0.150 0.3 0.074

10 0.135 80 22 120 21 120 154 0.130 30 0.150 0.3 0.085

3/16 0.188 80 22 120 21 120 154 0.120 25 0.150 0.4 0.075

Pre Flow

Pressure

(Air)

Shield Gas

Distributor

Cut Flow Rate s /

Pressures

2

Tip

) Shield (Air)

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1040 22-1068 22-102022-1016 22-1024 22-1082 22-1050

Arc

Vol tag e

Torch

Working

Height

(in)

±0.005

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

SpeedPlas m a (O

Mate ri al

Thickn es s

(mm)

1

2

3

4

5

16A Arc Cur r e nt

Burn-through

may occur

for th ickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

Pre Flow

Pressure

(Air)

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

4.1 22 8.3 21 8.3 130 1.3 3050 3.0 0.2 1.5

4.1 22 8.3 21 8.3 145 1.9 1130 3.1 0.3 1.8

4.1 22 8.3 21 8.3 150 3.0 910 3.8 0.3 2.0

5.5 22 8.3 21 8.3 154 3.2 710 3.8 0.3 2.1

5.5 22 8.3 21 8.3 155 3.0 640 3.8 0.4 1.9

Pre Flow

Pressure

)

(N

2

(PSI) /

(Bar)

20 40 80 0.100 300 0.100

1.4 2.8 5.5 2.5 7600 2.5

Cut Flow Rate s /

Pressures Arc

Plas m a (O

Plas m a (N

(Ball)

20 70 148

) Shield (Air)

2

Cut Flow Rate s /

Pressures Arc

) Shield (N2)

2

(PSI) /

(Bar)

(Ball)

(PSI) /

BOLD ITALIC

Vol tag e

Marking

Vol tag e

(Bar)

Torch

Working

Height

(mm)

±0.1

Torch

Working

Height

Vol ts

in ±0.005 /

mm ±0. 1

indicates edge starts only.

( mm/mi n)

Travel

Speed

Travel

Speed

ipm /

mm/min

Initial

Piercing

Height

(mm ) (sec) (m m )

Initial

Tran s fer

Height

in ±0.005 /

mm ±0.1

Pierce

Delay

Pierce

Delay

(sec)

0

Kerf Width

@ Rec.

Speed

Mar ki ng

quality

degrades

as

thi ckn es s

decreases

Manual 0-4829 Rev AN 8-9 TORCH DATA for Ultra-Cut

Page 8

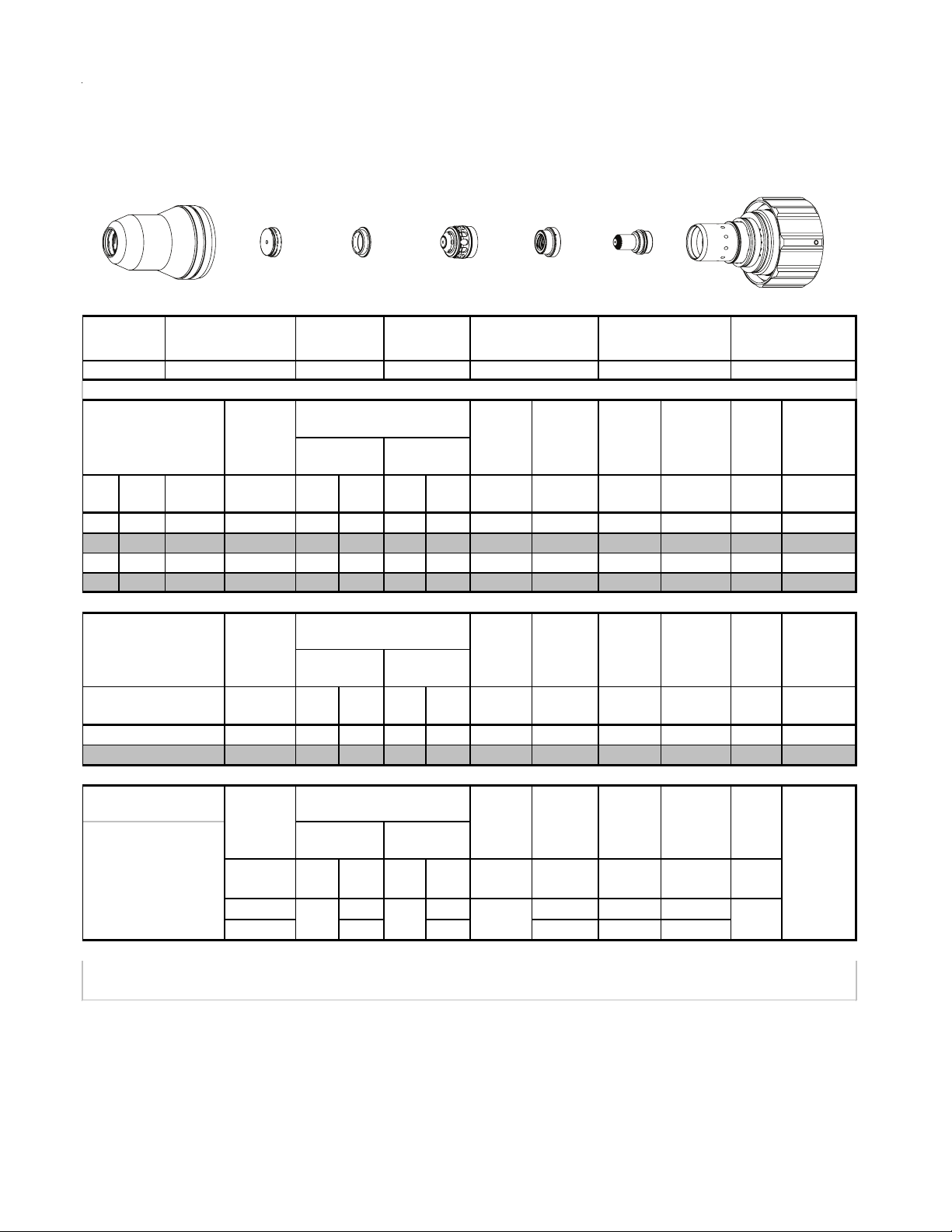

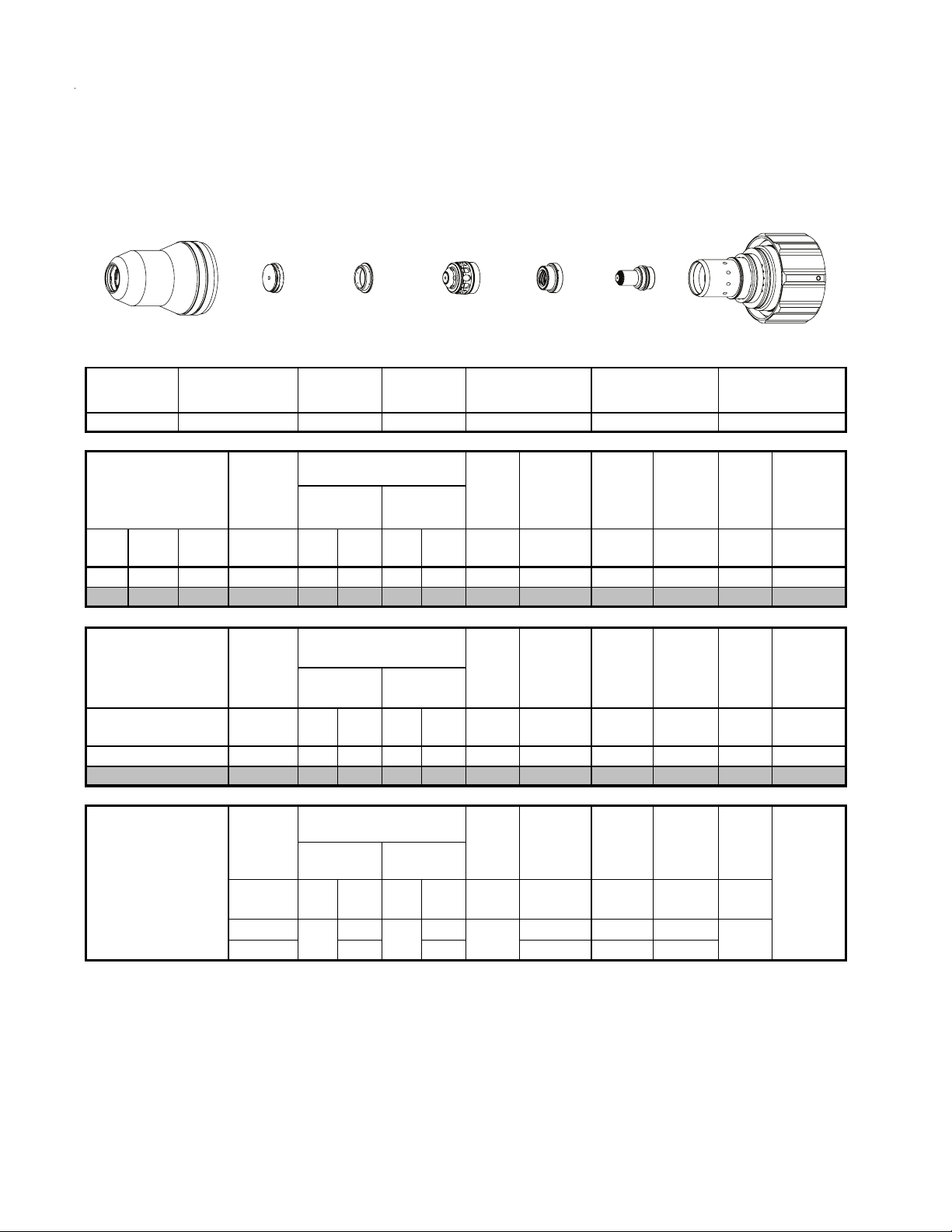

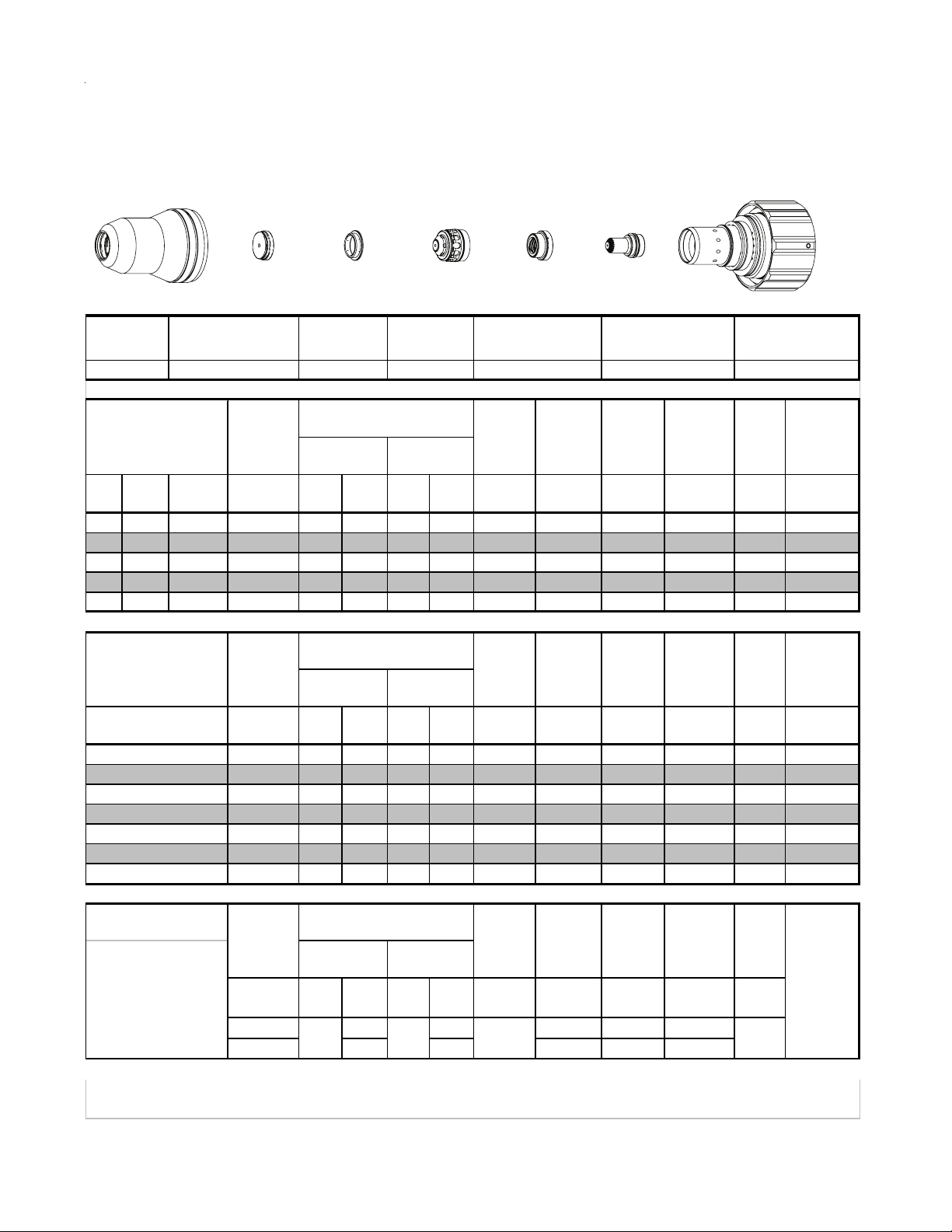

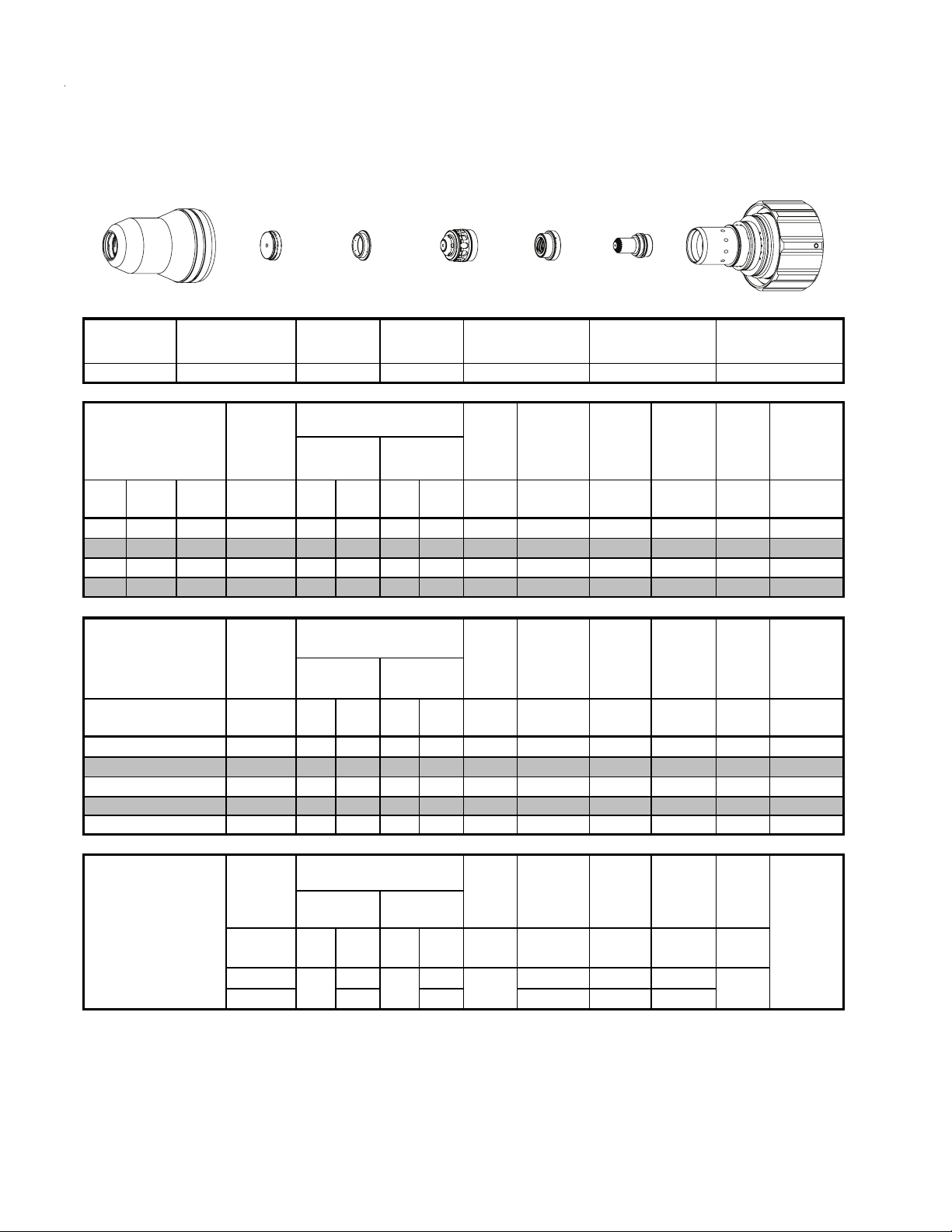

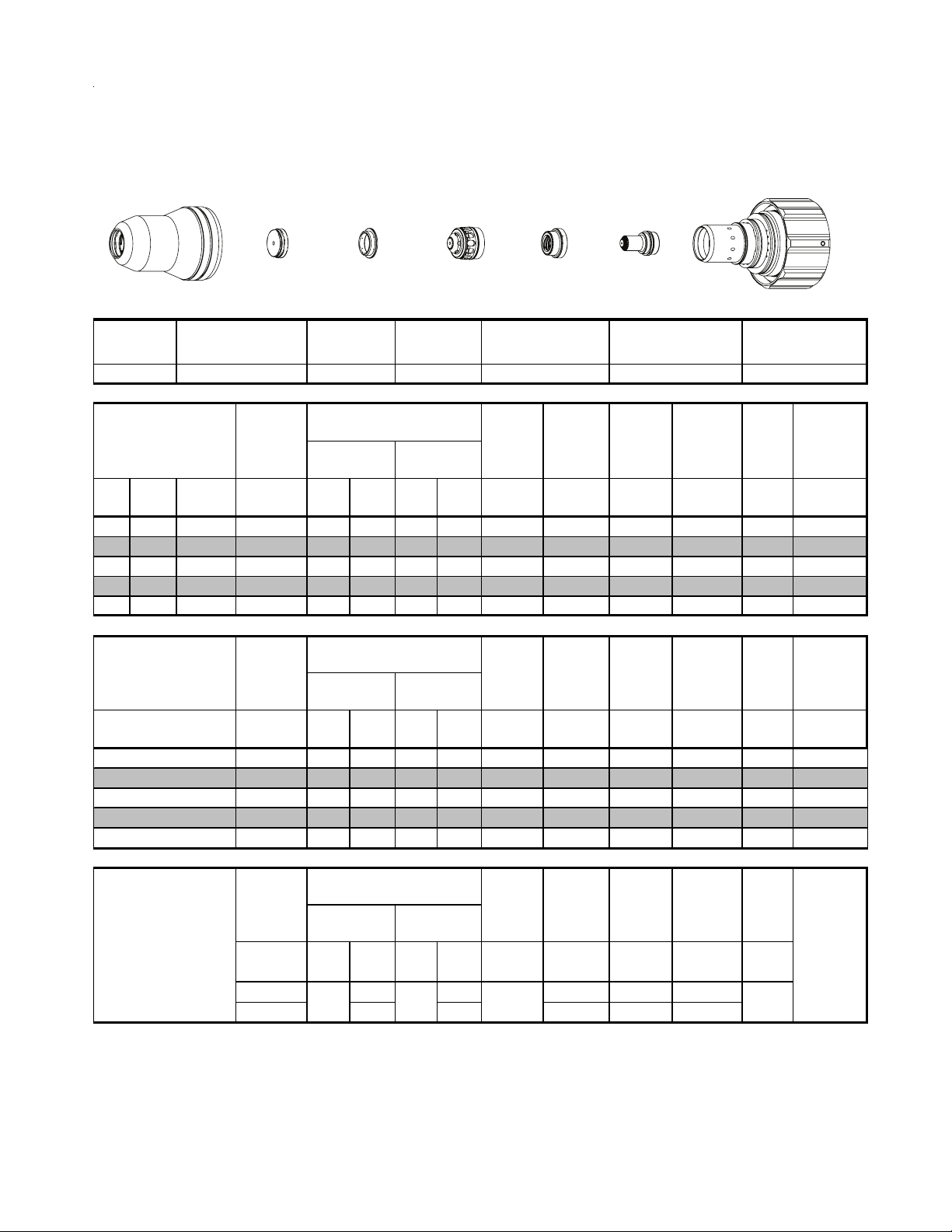

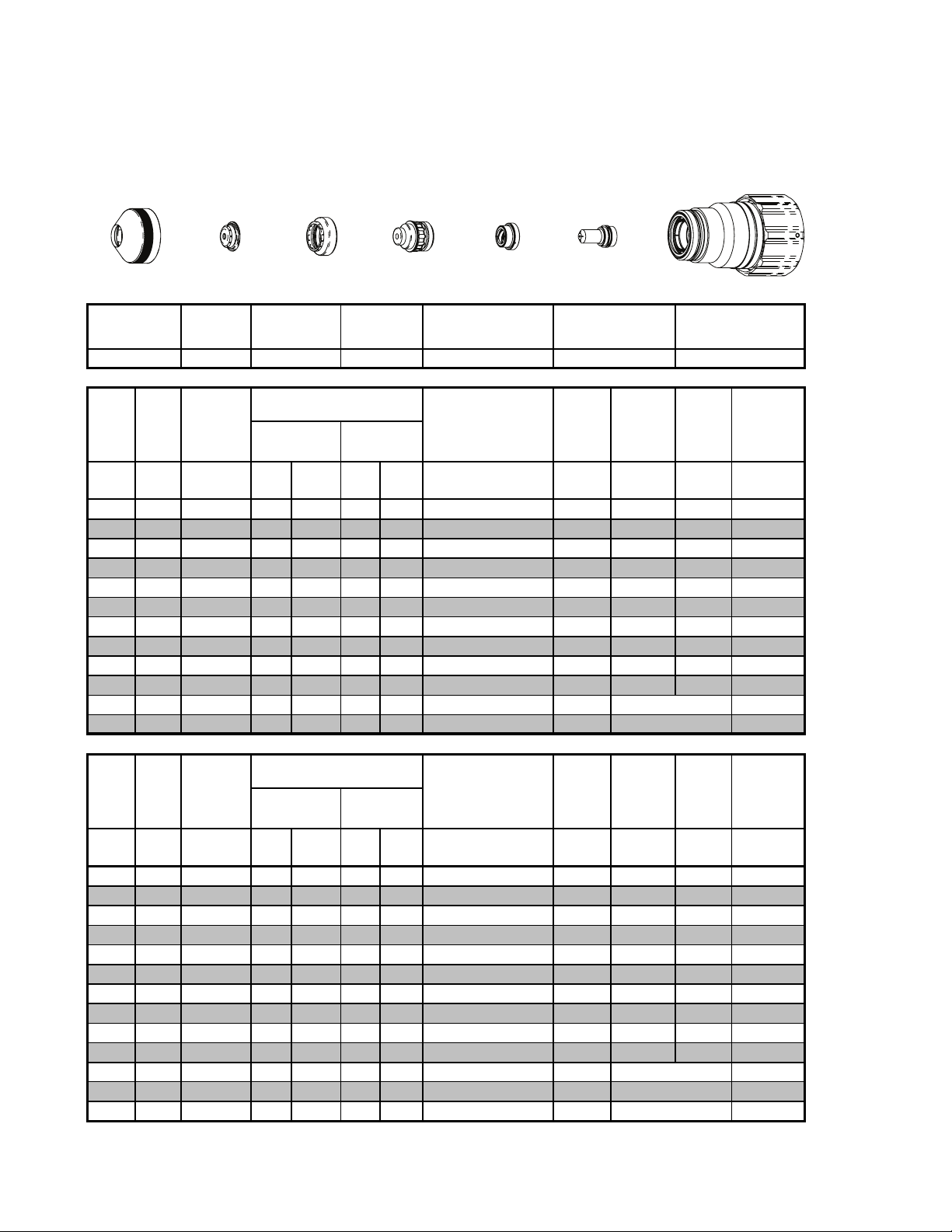

Stainless Steel

30A

Air Plasma / Air Shield

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

26 0.019 60 64 120 20 120 87 0.020 350 0.040 0.0 0.029

24 0.025 60 64 120 20 120 85 0.020 320 0.040 0.0 0.028

22 0.031 60 64 120 20 120 80 0.020 310 0.040 0.0 0.034

20 0.038 60 64 120 20 120 75 0.020 300 0.060 0.1 0.025

18 0.050 60 64 120 20 120 78 0.020 150 0.080 0.2 0.032

16 0.063 60 64 120 20 120 76 0.020 110 0.080 0.2 0.030

Pre Flow

Pressure

(Air)

Shield Gas

Distributor

Cut Flow Rate s /

Pressures

Tip

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1045 22-1077 22-102022-1016 22-1033 22-1274 22-1059

Arc

Vol tag e

Torch

Working

Height

(in)

±0.005

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

SpeedPlas m a (Air) Shield (Air)

Mate ri al

Thickn es s

(mm)

0.6

0.8

1.0

1.5

2

16A Arc Cur r e nt

Burn-through

may occur

for th ickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

Pre Flow

Pressure

(Air)

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

4.1 64.0 8.3 20.0 8.3 85.0 0.5 8300.0 1.0 0.0 0.7

4.1 64.0 8.3 20.0 8.3 80.0 0.5 7860.0 1.1 0.0 0.9

4.1 64.0 8.3 20.0 8.3 75.0 0.5 7190.0 1.6 0.1 0.7

4.1 64.0 8.3 20.0 8.3 77.0 0.5 3100.0 2.0 0.2 0.8

4.1 64.0 8.3 20.0 8.3 74.0 0.5 2600.0 2.0 0.2 0.7

Pre Flow

Pressure

)

(N

2

(PSI) /

(Bar)

20 40 80 0.100 300 0.100

1.4 2.8 5.5 2.5 7600 2.5

Cut Flow Rate s /

Pressures Arc

Marking

(Bar)

Vol tag e

Vol tag e

Vol ts

Plas m a (Air) Shield (Air)

Cut Flow Rate s /

Pressures Arc

Plas m a (N

(Ball)

20 70 93 0

) Shield (N2)

2

(PSI) /

(Bar)

(Ball)

(PSI) /

BOLD ITALIC

Torch

Working

Height

(mm)

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

indicates edge starts only.

Travel

Speed

( mm/mi n)

Travel

Speed

ipm /

mm/min

Initial

Piercing

Height

(mm) (sec) (mm)

Initial

Tran s fer

Height

in ±0.005 /

mm ±0.1

Pierce

Delay

Pierce

Delay

(sec)

Kerf Width

@ Rec.

Speed

Mar ki ng

quality

degrades

as

thi ckn es s

decreases

TORCH DATA for Ultra-Cut 8-10 Manual 0-4829 Rev AN

Page 9

Stainless Steel

30A

Plasma / H2O Shield

N

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

)

2

Shield Gas

Distributor

Cut Flow Rate s /

Pressures

2

Tip

) Shield (H2O)

Shield Cup Shield Cap

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

26 0.019 90 75 120 4 55 91 0.020 600 0.040 0.0 0.047

24 0.025 90 64 120 4 55 97 0.020 440 0.040 0.0 0.045

22 0.031 90 50 120 4 55 95 0.020 420 0.040 0.0 0.045

20 0.038 90 60 120 5 55 105 0.020 300 0.050 0.1 0.044

18 0.050 90 60 120 5 55 78 0.030 250 0.050 0.1 0.035

16 0.063 90 60 120 5 55 85 0.050 205 0.060 0.2 0.044

Pre Flow

Pressure

(N

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1045 22-1077 22-102022-1016 22-1033 22-1274 22-1059

Arc

Vol tag e

Torch

Working

Height

(in)

±0.005

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

SpeedPlas m a (N

Mate ri al

Thickn es s

(mm)

0.6

0.8

1.0

1.5

2.0

16A Arc Cur r e nt

Burn-through

may occur

for th ickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

Pre Flow

Pressure

(N

)

2

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

6.2 75 8.3 4 3.8 96 0.5 12110 1.0 0.0 1.2

6.2 64 8.3 4 3.8 96 0.5 10450 1.0 0.0 1.1

6.2 50 8.3 4 3.8 102 0.5 7470 1.3 0.1 1.1

6.2 60 8.3 5 3.8 83 1.0 5550 1.4 0.2 1.0

6.2 60 8.3 5 3.8 93 2.0 3820 1.8 0.3 1.4

Pre Flow

Pressure

(N

)

2

(PSI) /

(Bar)

20 40 80 0.100 300 0.100

1.4 2.8 5.5 2.5 7600 2.5

Cut Flow Rate s /

Pressures Arc

Plas m a (N

Plas m a (N

(Ball)

20 70 93

) Shield (H2O)

2

Cut Flow Rate s /

Pressures Arc

) Shield (N2)

2

(Ball)

(PSI) /

BOLD ITALIC

(PSI) /

(Bar)

Vol tag e

Marking

Vol tag e

(Bar)

Torch

Working

Height

(mm)

±0.1

Torch

Working

Height

Vol ts

in ±0.005 /

mm ±0. 1

indicates edge starts only.

Speed

( mm/mi n)

Speed

Travel

Travel

ipm /

mm/min

Initial

Piercing

Height

(mm) (sec) (mm)

Initial

Tran s fer

Height

in ±0.005 /

mm ±0.1

Pierce

Delay

Pierce

Delay

(sec)

0

Kerf Width

@ Rec.

Speed

Mar ki ng

quality

degrades

as

thi ckn es s

decreases

Manual 0-4829 Rev AN 8-11 TORCH DATA for Ultra-Cut

Page 10

Aluminium

30A

Air Plasma / Air Shield

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

)

2

Shield Gas

Distributor

Cut Flow Rate s /

Pressures

Cut Flow Rate s /

Pressures Arc

Plas m a (O

Plas m a (N

(Ball)

20 70 93 0

2

Cut Flow Rate s /

Pressures Arc

2

(PSI) /

(Bar)

Tip

) Shield (Air)

Marking

) Shield (N2)

(PSI) /

(Ball)

(Bar)

BOLD ITALIC

Shield Cup Shield Cap

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

25 0.025 60 60 120 15 120 86 0.020 500 0.040 0.0 0.029

21 0.037 60 60 120 15 120 86 0.020 240 0.060 0.1 0.046

18 0.052 60 60 120 15 120 84 0.020 230 0.100 0.2 0.034

16 0.064 60 60 120 15 120 80 0.020 220 0.100 0.2 0.036

Mate ri al

Thickn es s

(mm)

1

2

16A Arc Cur r e nt

Burn-through

may occur

for th ickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

4.1 60 8.3 15 8.3 86 0.5 6060 1.7 0.1 0.9

4.1 60 8.3 15 8.3 75 0.5 5280 2.5 0.2 0.9

Pre Flow

Pressure

(N

(PSI) /

(Bar)

20 40 80 0.100 300 0.100

1.4 2.8 5.5 2.5 7600 2.5

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1045 22-1077 22-102022-1016 22-1033 22-1274 22-1059

Arc

Vol tag e

Vol tag e

Vol tag e

Vol ts

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

(mm)

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

indicates edge starts only.

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

(sec)

Kerf Width

@ Rec.

SpeedPlas m a (Air) Shield (Air)

Kerf Width

@ Rec.

Speed

Mar ki ng

quality

degrades

thi ckn es s

decreases

Travel

Speed

(ipm ) (in) (s ec) (in)

Travel

Speed

( mm/mi n)

Travel

Speed

ipm /

mm/min

Initial

Piercing

Height

Initial

Piercing

Height

(mm) (sec) (mm)

Initial

Tran s fer

Height

in ±0.005 /

mm ±0.1

Pierce

Delay

Pierce

Delay

Pierce

Delay

as

TORCH DATA for Ultra-Cut 8-12 Manual 0-4829 Rev AN

Page 11

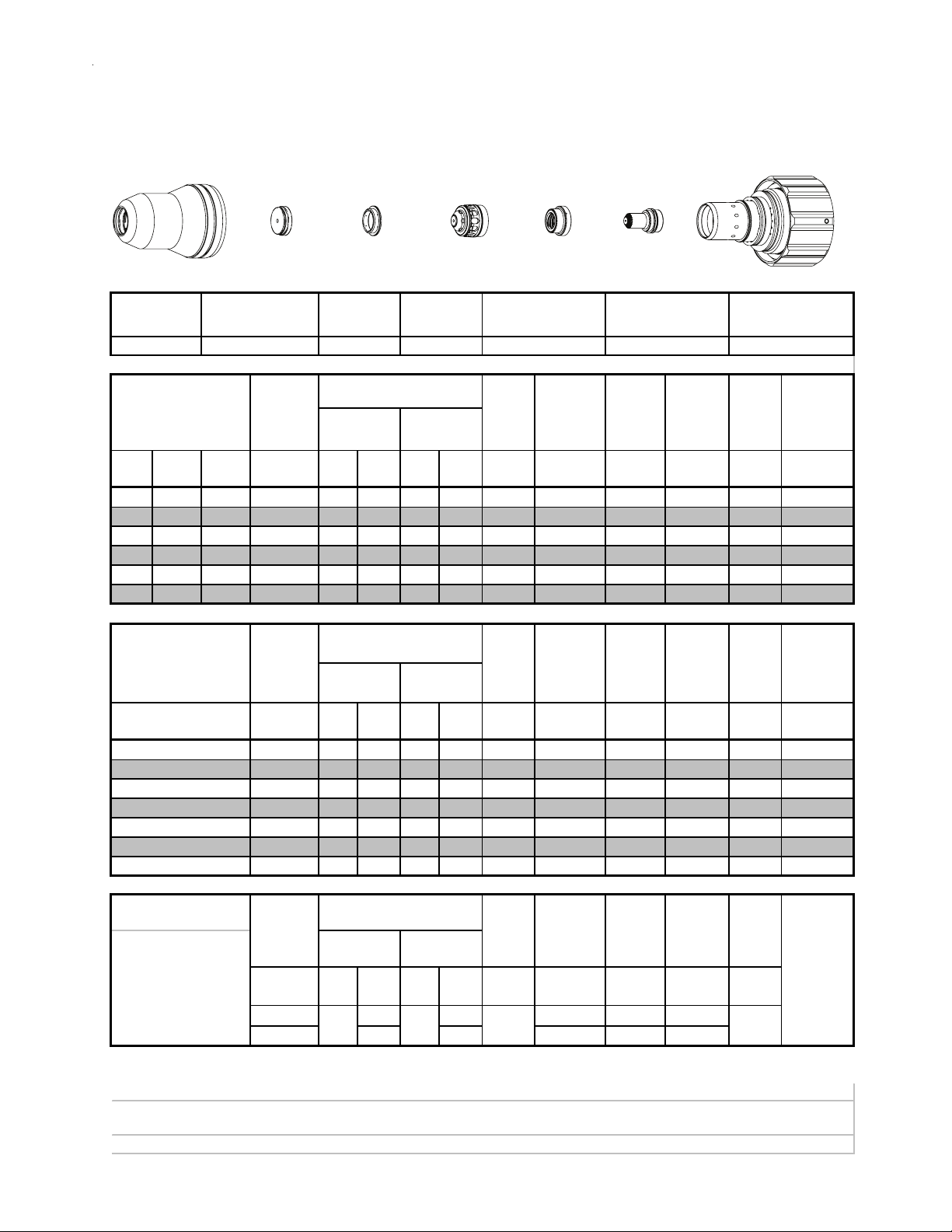

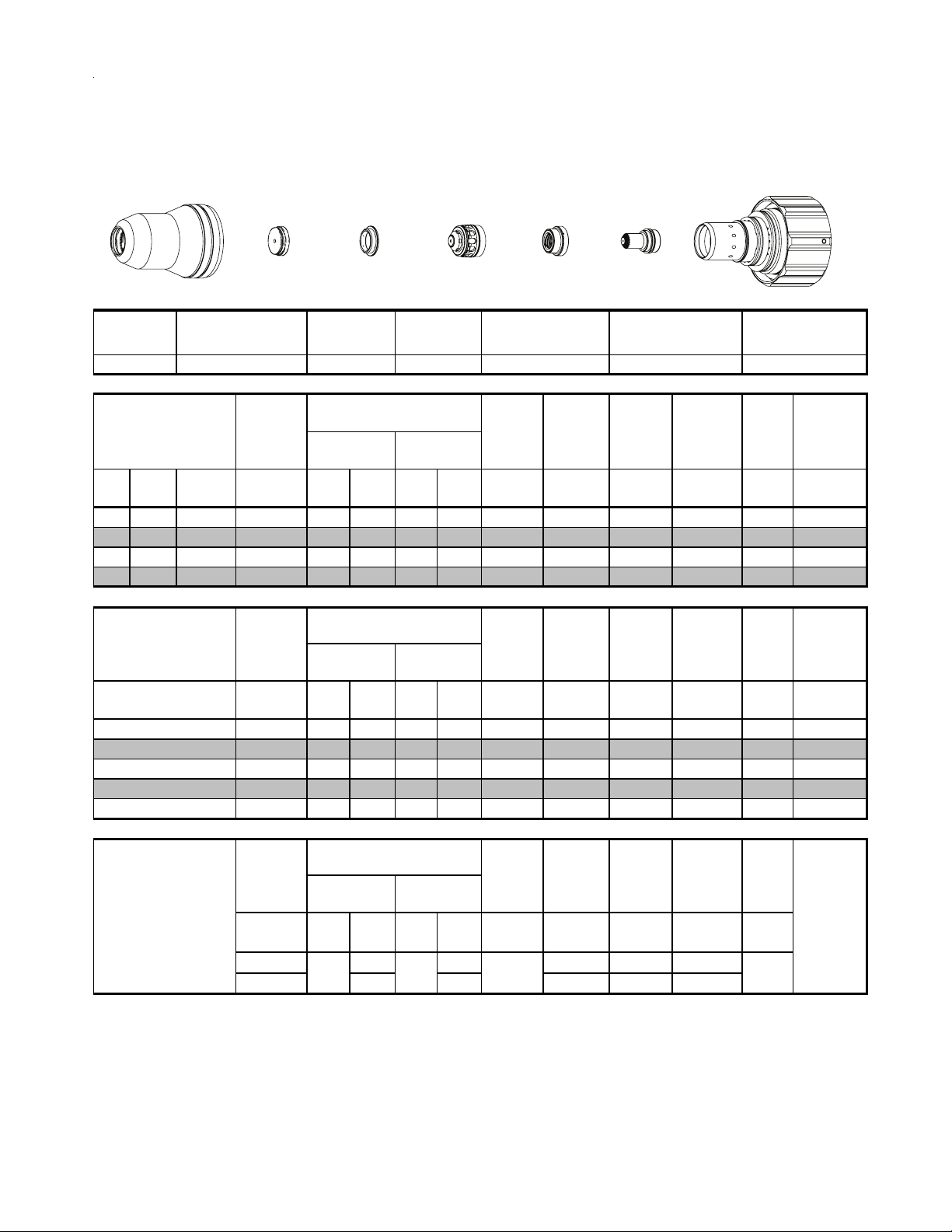

Aluminium

30A

N

Plasma / H2O Shield

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

25 0.025 96 55 120 4 55 103 0.03 230 0.08 0 0.034

21 0.037 96 55 120 4 55 103 0.03 220 0.08 0.1 0.045

18 0.052 96 55 120 4 55 103 0.03 150 0.08 0.2 0.031

16 0.064 96 55 120 4 55 103 0.03 110 0.08 0.2 0.036

Mate ri al

Thickn es s

(mm)

1

2

16A Arc Cur r e nt

Burn-through

may occur

for thickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

Pre Flow

Pressure

(N

Pre Flow

Pressure

(N

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

6.6 55 8.3 4 3.8 103 0.8 5310 2.0 0.1 1.1

6.6 55 8.3 4 3.8 103 0.8 1550 2.0 0.2 1.0

Pre Flow

Pressure

(N

(PSI) /

(Bar)

20 40 80 0.100 300 0.100

1.4 2.8 5.5 2.5 7600 2.5

Shield Gas

Distributor

Cut Flo w Rates /

Pressures

)

2

Plas m a (N

)

2

Plas m a (N

)

2

(Ball)

20 70 93

) Shield (H2O)

2

Cut Flo w Rates /

Pressures Arc

) Shield (H2O)

2

Cut Flo w Rates /

Pressures Arc

) Shield (N2)

2

(PSI) /

(Ball)

(Bar)

Tip

Marking

(PSI) /

(Bar)

BOLD ITALIC

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1045 22-1077 22-102022-1016 22-1033 22-1274 22-1059

Arc

Vol tag e

Vol tag e

Vol tag e

Vo lt s

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

(mm )

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

indicates edge starts only.

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

(sec)

0

Kerf Width

@ Rec.

SpeedPlas m a (N

Kerf Width

@ Rec.

Speed

Mar ki ng

quality

degrades

thi ckn es s

decreases

Travel

Speed

(ipm ) (in) (sec) (in)

Travel

Speed

( mm/mi n)

Travel

Speed

ipm /

mm/ min

Initial

Piercing

Height

Initial

Piercing

Height

(mm ) (sec) (m m )

Initial

Transfer

Height

in ±0.005 /

mm ±0. 1

Pierce

Delay

Pierce

Delay

Pierce

Delay

as

Manual 0-4829 Rev AN 8-13 TORCH DATA for Ultra-Cut

Page 12

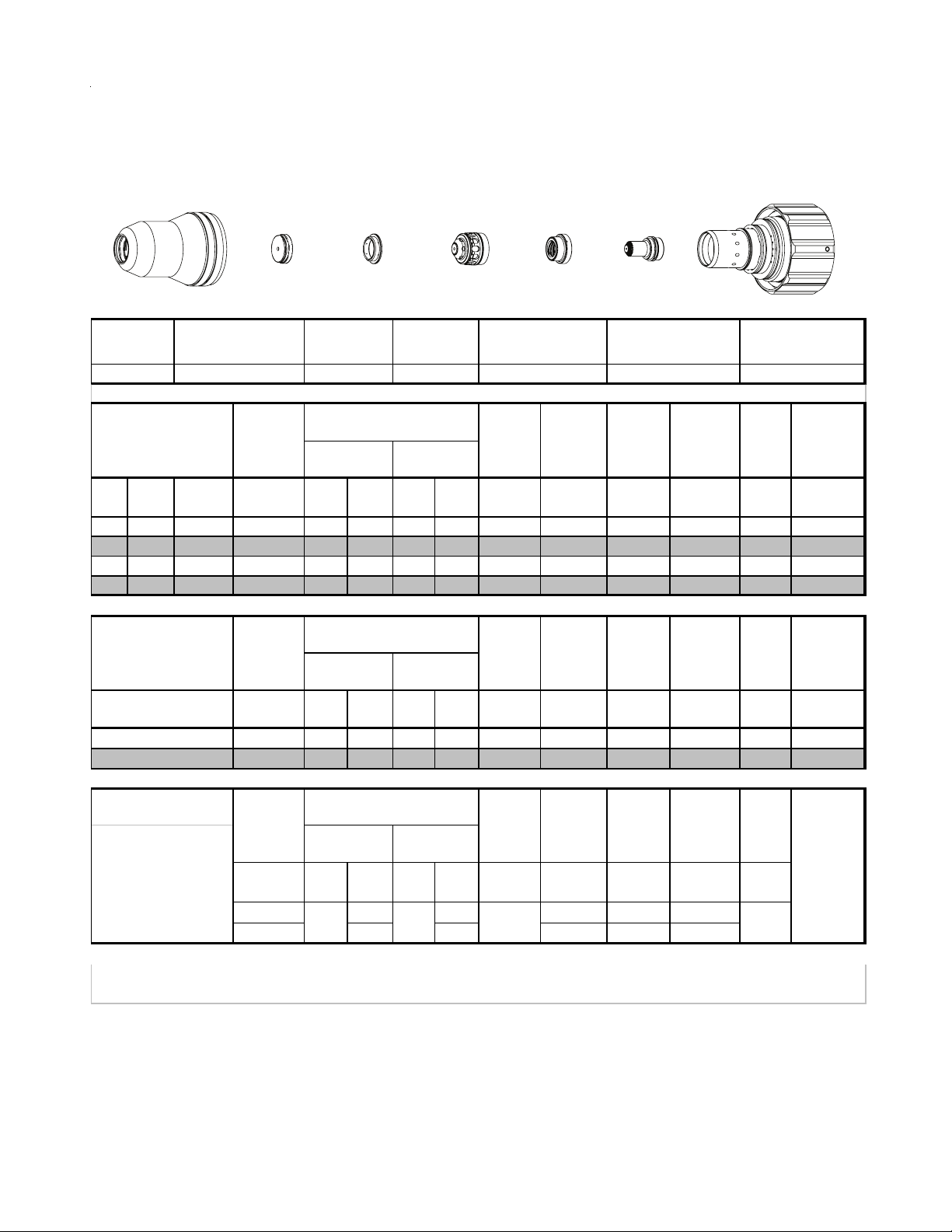

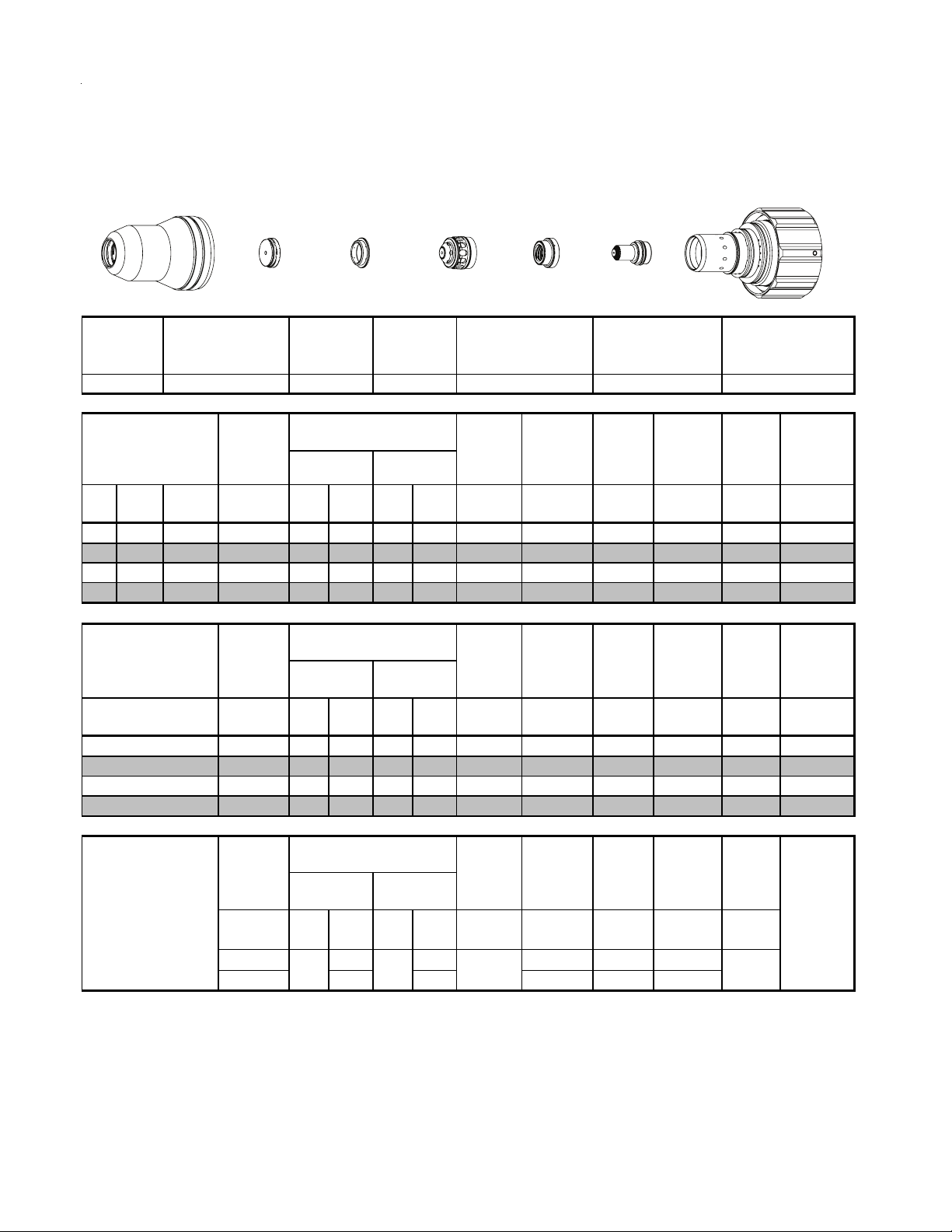

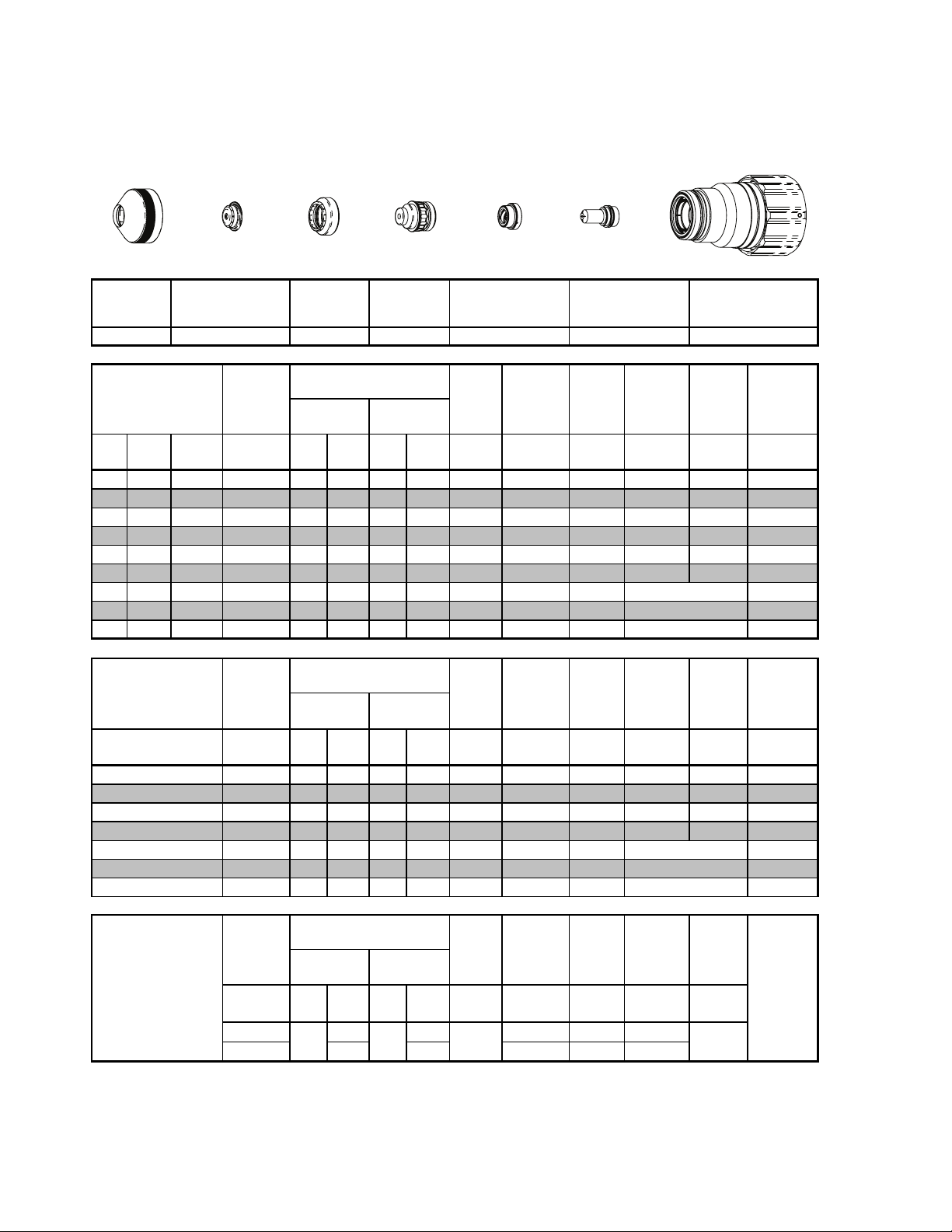

Mild Steel

50A

Plasma / Air Shield

O

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

14 0.075 70 28 120 20 120 130 0.060 280 0.100 0.0 0.040

12 0.105 70 28 120 20 120 130 0.060 270 0.100 0.0 0.052

10 0.135 70 28 120 20 120 126 0.040 160 0.100 0.4 0.044

3/16 0.188 70 28 120 40 120 130 0.060 100 0.110 0.4 0.054

1/4 0.250 70 28 120 40 120 132 0.060 90 0.110 0.4 0.062

Mate ri al

Thickn es s

(mm)

2

3

4

5

6

18A Arc Cur r e nt

Burn-through

may occur

for th ickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

4.8 28 8.3 20 8.3 130 1.5 7110 2.5 0.0 1.1

4.8 28 8.3 20 8.3 128 1.3 5640 2.5 0.2 1.2

4.8 28 8.3 20 8.3 128 1.2 3420 2.7 0.4 1.2

4.8 28 8.3 40 8.3 130 1.5 2500 2.8 0.4 1.4

4.8 28 8.3 40 8.3 132 1.5 2340 2.8 0.4 1.5

Pre Flow

Pressure

(N

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 7600 7600 3.0

Shield Gas

Distributor

Cut Flow Rate s /

Pressures

) Shield (Air)

2

Cut Flow Rate s /

Pressures Arc

Plas m a (O

Plas m a (N

)

2

(Ball)

40 75 143

) Shield (Air)

2

Cut Flow Rate s /

Pressures Arc

) Shield (N2)

2

(PSI) /

(Ball)

(Bar)

Tip

Marking

(PSI) /

(Bar)

BOLD ITALIC

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1041 22-1069 22-102022-1016 22-1025 22-1272 22-1051

Arc

Vol tag e

Vol tag e

Vol tag e

Vol ts

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

(mm)

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

indicates edge starts only.

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Travel

Speed

( mm/mi n)

Travel

Speed

ipm /

mm/min

Initial

Piercing

Height

Initial

Piercing

Height

(mm ) (sec) (m m )

Initial

Tran s fer

Height

in ±0.005 /

mm ±0.1

Pierce

Delay

Pierce

Delay

Pierce

Delay

(sec)

0

Kerf Width

@ Rec.

Kerf Width

@ Rec.

Mar ki ng

degrades

thi ckn es s

decreases

SpeedPlas m a (O

Speed

quality

as

TORCH DATA for Ultra-Cut 8-14 Manual 0-4829 Rev AN

Page 13

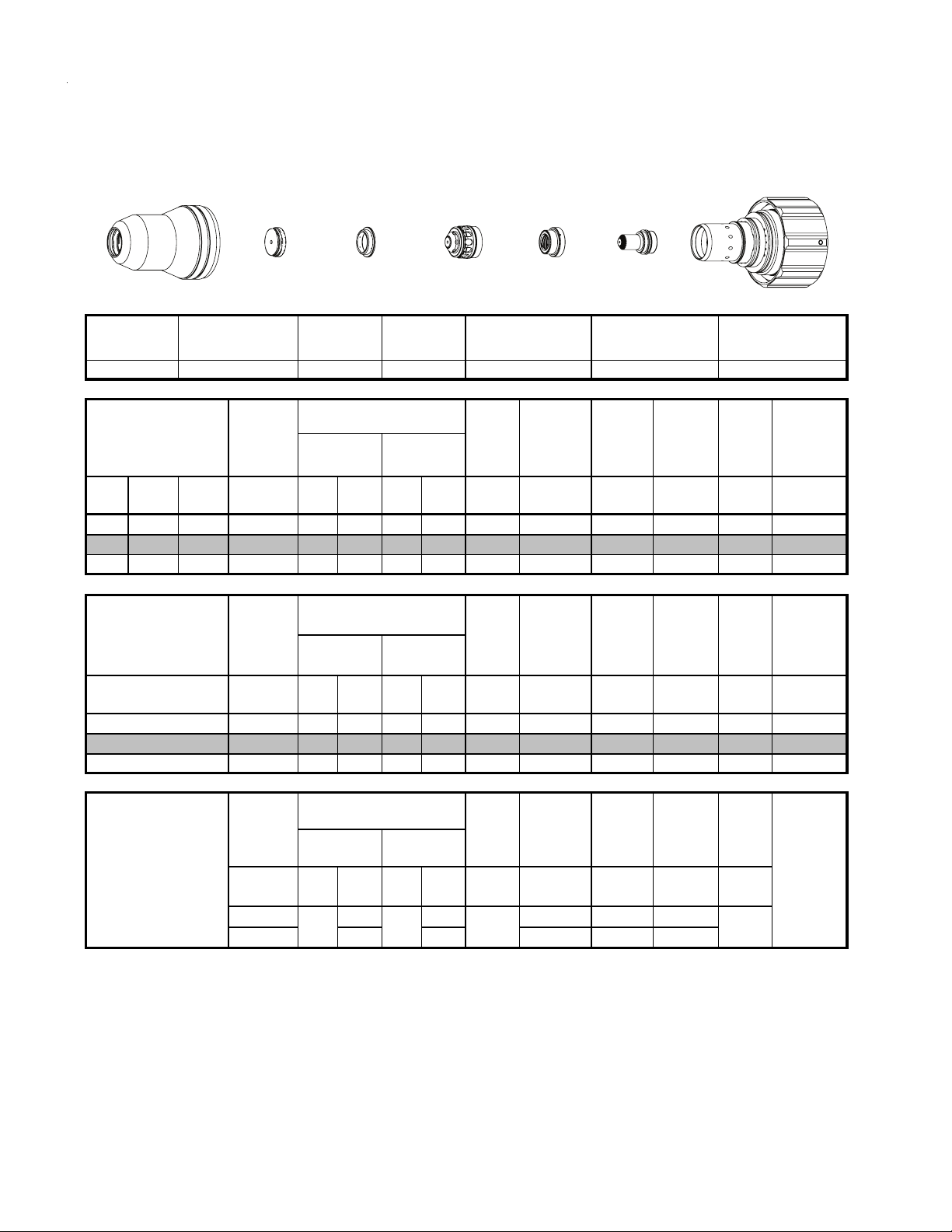

Stainless Steel

50A

Air Plasma / Air Shield

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

14 0.078 100 62 120 75 120 109 0.060 180 0.120 0.0 0.044

12 0.109 100 62 120 75 120 114 0.060 130 0.150 0.0 0.049

10 0.141 100 62 120 75 120 118 0.060 120 0.180 0.1 0.050

3/16

Mate ri al

Thickn es s

0.188 100 62 120 75 120 124 0.080 70 0.200 0.3 0.059

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

Shield Gas

Distributor

Cut Flow Rate s /

Pressures

Cut Flow Rate s /

Pressures Arc

Plas m a (Air) Shield (Air)

Tip

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1041 22-1078 22-102022-1016 22-1034 22-1274 22-1060

Arc

Vol tag e

Vol tag e

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Travel

Speed

Initial

Piercing

Height

Initial

Piercing

Height

Pierce

Delay

Pierce

Delay

Kerf Width

@ Rec.

SpeedPlas m a (Air) Shield (Air)

Kerf Width

@ Rec.

Speed

(mm)

1.5

2.0

3.0

4

5

16A Arc Cur r e nt

Burn-through

may occur

for th ickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

6.9 62.0 8.3 75.0 8.3 106.0 1.5 5350.0 2.6 0.0 1.0

6.9 62.0 8.3 75.0 8.3 109.0 1.5 4540.0 3.1 0.0 1.1

6.9 62.0 8.3 75.0 8.3 115.0 1.5 3229.7 4.0 0.0 1.3

6.9 62.0 8.3 75.0 8.3 120.0 1.7 2600.0 4.8 0.2 1.4

6.9 62.0 8.3 75.0 8.3 125.0 2.1 1520.0 5.2 0.3 1.5

Marking

Pre Flow

Pressure

)

(N

2

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

Cut Flow Rate s /

Pressures Arc

(Bar)

Vol tag e

Vol ts

Plas m a (N

(Ball)

40 75 120 0

) Shield (N2)

2

(PSI) /

(Bar)

(Ball)

(PSI) /

BOLD ITALIC

(mm)

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

indicates edge starts only.

( mm/mi n)

Travel

Speed

ipm /

mm/min

(mm ) (sec) (m m )

Initial

Tran s fer

Height

in ±0.005 /

mm ±0.1

Pierce

Delay

(sec)

Mar ki ng

quality

degrades

as

thi ckn es s

decreases

Manual 0-4829 Rev AN 8-15 TORCH DATA for Ultra-Cut

Page 14

C

g

Stainless Steel

50A

Plasma / H2O Shield

N

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap Shield Gas

Distributor

22-1016 22-1034 22-1274 22-1060

Mate ri al

Thickness

Pre Flow

Pressure

(N

)

2

(ga) (in) inch (PSI) Ball (PSI) Ball (PSI) Volts

ut Flow Rates /

Pressures

Plas m a (N

Tip Plasma Gas

Shield

)

2

(H

O)*

2

Plasma Gas

Distributor

Electrode

Cartridge

Art # A-07958_AB

Elec trode

Distributor

22-1041 22-1078 22-1020

Arc

Voltage

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm ) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Cartridge

Kerf Width

@ Rec.

Speed

14 0.078 60 62 120 4 55 117 0.110 170 0.200 0.2 0.043

12 0.109 60 62 120 4 55 119 0.110 150 0.200 0.2 0.047

Cut Flow Ra tes /

Pressures

Plas m a (N

Arc

Shield

)

2

(H

2

Voltage

O)*

Torch

Working

Height

(mm )

±0.1

Travel

Speed

( mm/mi n)

Initial

Piercing

Height

Pierce

Delay

(mm ) (s ec) (mm )

Kerf Width

@ Rec.

Speed

Mate ri al

Thickness

(mm)

2

3

Pre Flow

Pressure

(N

)

2

(Bar) Ball (Bar) Ball (Bar) Volts

4.1 62 8.3 4 3.8 117 2.8 4310 5.1 0.2 1.1

4.1 62 8.3 4 3.8 120 2.8 3660 5.1 0.2 1.2

Marking

16A Arc Cur r e nt

Burn-through

may occur

for thicknes s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

Pre Flow

Pressure

)

(N

2

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

Cut Flow Ra tes /

Pressures Arc

Plas m a (N

(PSI) /

(Ball)

(Bar)

) Shield (N2)

2

(PSI) /

(Ball)

(Bar)

Voltage

Vol ts

Torch

Working

Height

in ±0.005 /

mm ±0. 1

Travel

Speed

ipm /

mm/ mi n

Initial

Transfer

Height

in ±0.005 /

mm ±0. 1

40 75 120 0

Pierce

Delay

(sec)

Mar ki ng

quality

degrades

thi ckn es s

decreases

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later

* Pressure of the water supply line should be regulated by customer pressure regulator.

Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with the

Note1:

ohmic sensin

Water source used for shield must be demineralized.

Note2:

circuit.

as

TORCH DATA for Ultra-Cut 8-16 Manual 0-4829 Rev AN

Page 15

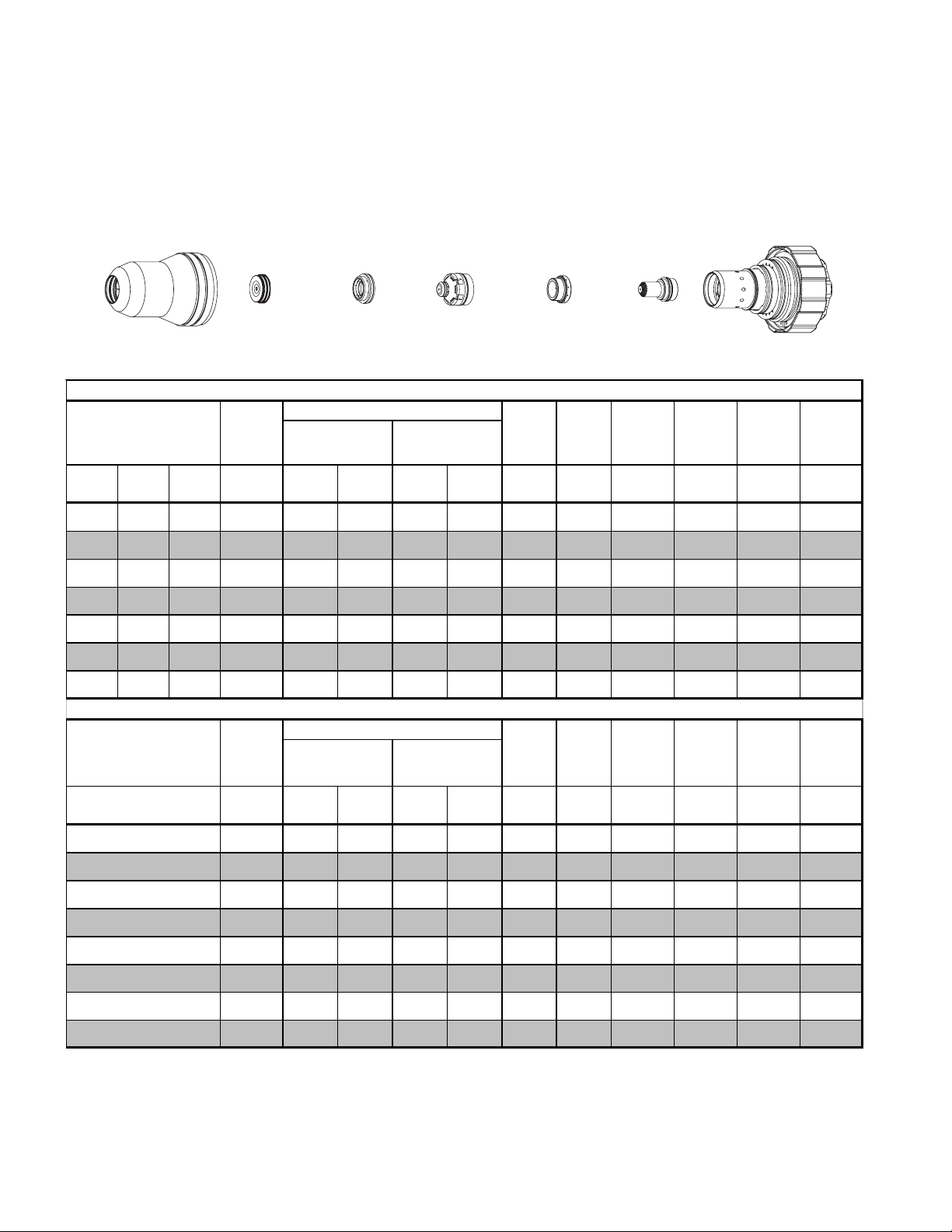

Aluminium

50A

Air Plasma / Air Shield

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

16 0.064 100 60 120 75 120 124 0.100 140 0.200 0.0 0.060

12 0.097 100 60 120 75 120 125 0.105 90 0.200 0.0 0.067

11 0.120 100 60 120 75 120 129 0.110 60 0.200 0.0 0.068

3/16 0.188 100 60 120 75 120 133 0.120 40 0.200 0.2 0.074

Mate ri al

Thickn es s

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

Shield Gas

Distributor

Cut Flo w Rates /

Pressures

Cut Flo w Rates /

Pressures Arc

Plas m a (Air) Shield (Air)

Tip

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1041 22-1078 22-102022-1016 22-1034 22-1274 22-1060

Arc

Vol tag e

Vol tag e

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

Travel

Speed

(ipm ) (in) (sec) (in)

Travel

Speed

Initial

Piercing

Height

Initial

Piercing

Height

Pierce

Delay

Pierce

Delay

Kerf Width

@ Rec.

SpeedPlas m a (Air) Shield (Air)

Kerf Width

@ Rec.

Speed

(mm)

2

3

4

5

16A Arc Cur r e nt

Burn-through

may occur

for thickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

6.9 60 8.3 75 8.3 124 2.6 2990 5.1 0.0 1.6

6.9 60 8.3 75 8.3 129 2.8 1520 5.1 0.0 1.7

6.9 60 8.3 75 8.3 131 2.9 1240 5.1 0.1 1.8

6.9 60 8.3 75 8.3 134 3.1 950 5.1 0.2 1.9

Marking

Pre Flow

Pressure

)

(N

2

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

Cut Flo w Rates /

Pressures Arc

(Bar)

Vol tag e

Vo lt s

Plas m a (N

(Ball)

40 75 120 0

) Shield (N2)

2

(PSI) /

(Ball)

(Bar)

(PSI) /

BOLD ITALIC

(mm )

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

indicates edge starts only.

( mm/mi n)

Travel

Speed

ipm /

mm/ min

(mm ) (sec) (m m )

Initial

Transfer

Height

in ±0.005 /

mm ±0. 1

Pierce

Delay

(sec)

Mar ki ng

quality

degrades

as

thi ckn es s

decreases

Manual 0-4829 Rev AN 8-17 TORCH DATA for Ultra-Cut

Page 16

g

Aluminum

50A

N

Plasma / H2O Shield

2

Shield Cup

Shield Cap

Shield Gas

Distributor

This Art Is For Reference ONLY

Shield Cup Shield Cap Shield Gas

Distributor

Tip

Tip Plas m a Gas

Plasma Gas

Distributor

Distributor

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

22-1041 22-1078 22-102022-1016 22-1034 22-1274 22-1060

Mate ri al

Thickn es s

Pre Flow

Pres sure

)

(N

2

(ga) (in) inch (PSI) Ball (PSI) Ball (PSI) Volts

Cut Flo w Rates /

Pressures

Plas m a (N

Arc

Shield

)

2

(H

2

Vol tag e

O)*

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm ) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

16 0.064 100 60 120 4 55 120 0.11 140 0.200 0.2 0.045

12 0.097 100 60 120 4 55 120 0.11 90 0.200 0.2 0.046

11 0.120 100 60 120 4 55 123 0.11 60 0.200 0.2 0.050

3/16 0.188 100 60 120 4 55 125 0.12 40 0.200 0.2 0.051

Cut Flo w Rates /

Pressures

Plas m a (N

Arc

Shield

)

2

(H

2

Vol tag e

O)*

Torch

Working

Height

(mm)

±0.1

Travel

Speed

( mm/mi n)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

(mm) (sec) (mm)

Mate ri al

Thickn es s

(mm)

2

3

4

5

Pre Flow

Pres sure

)

(N

2

(Bar) Ball (Bar) Ball (Bar) Volts

6.9 60 8.3 4 3.8 120 2.8 2990 5.1 0.2 1.2

6.9 60 8.3 4 3.8 123 2.8 1520 5.1 0.2 1.3

6.9 60 8.3 4 3.8 124 2.9 1240 5.1 0.2 1.3

6.9 60 8.3 4 3.8 125 3.1 950 5.1 0.2 1.3

Marking

16 A Arc Curre nt

Burn-through

may occur

for thickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

Pre Flow

Pres sure

)

(N

2

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

Cut Flo w Rates /

Pressures Arc

Plas m a (N

(Ball)

) Shield (N2)

2

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

Vol tag e

Vol ts

Torch

Working

Height

in ±0.005 /

mm ±0. 1

Travel

Speed

ipm /

mm/min

Initial

Transfer

Height

in ±0.005 /

mm ±0. 1

40 75 120 0

Pierce

Delay

(sec)

Mark in g

quality

degrades

thickness

decreases

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later

* Pressure of the water supply line should be regulated by customer pressure regulator.

Ohmic height sensing is not recomm ended with water shield. Water on the plate interferes electrically with the

Note1:

ohmic sensin

Water source used for shield mus t be demineralized.

Note2:

circuit.

as

TORCH DATA for Ultra-Cut 8-18 Manual 0-4829 Rev AN

Page 17

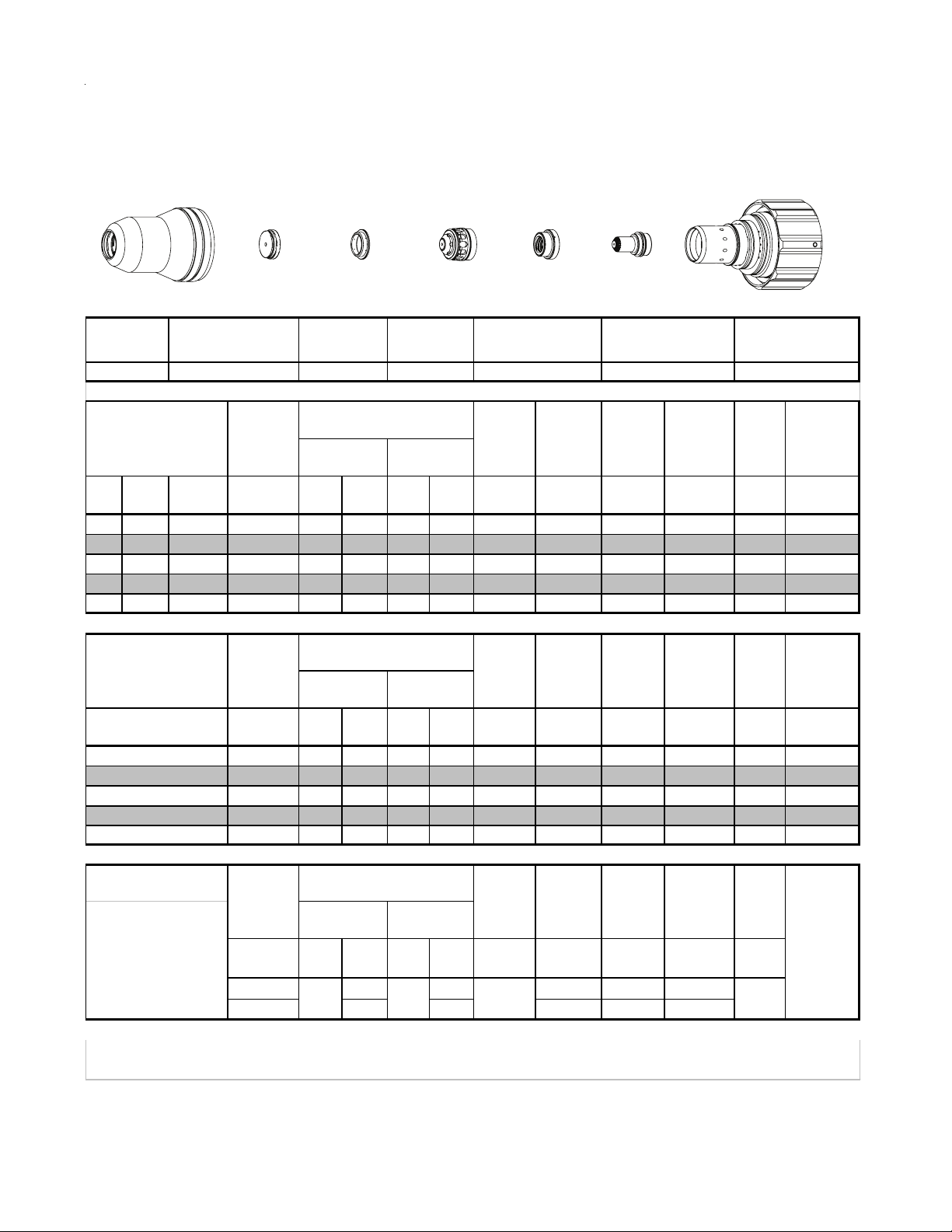

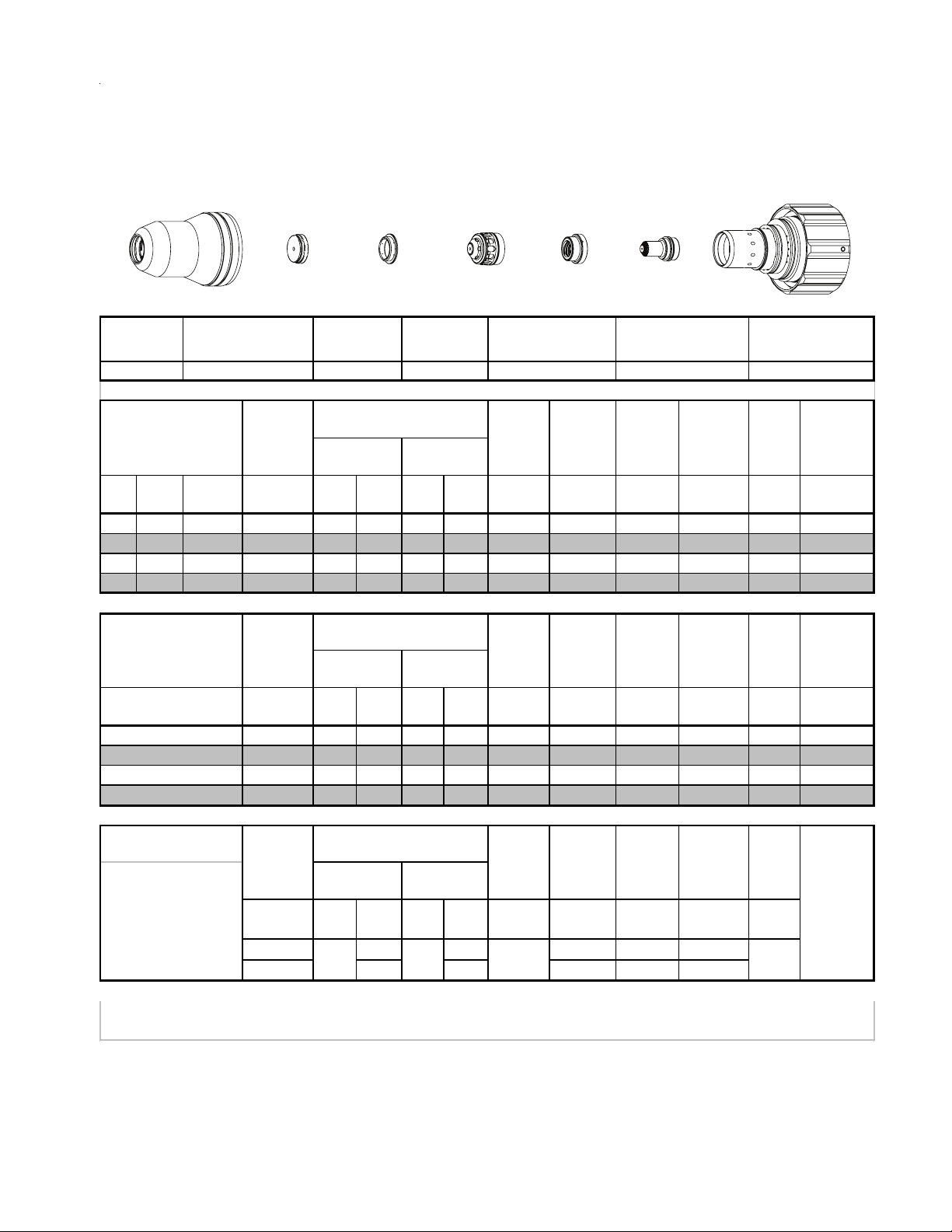

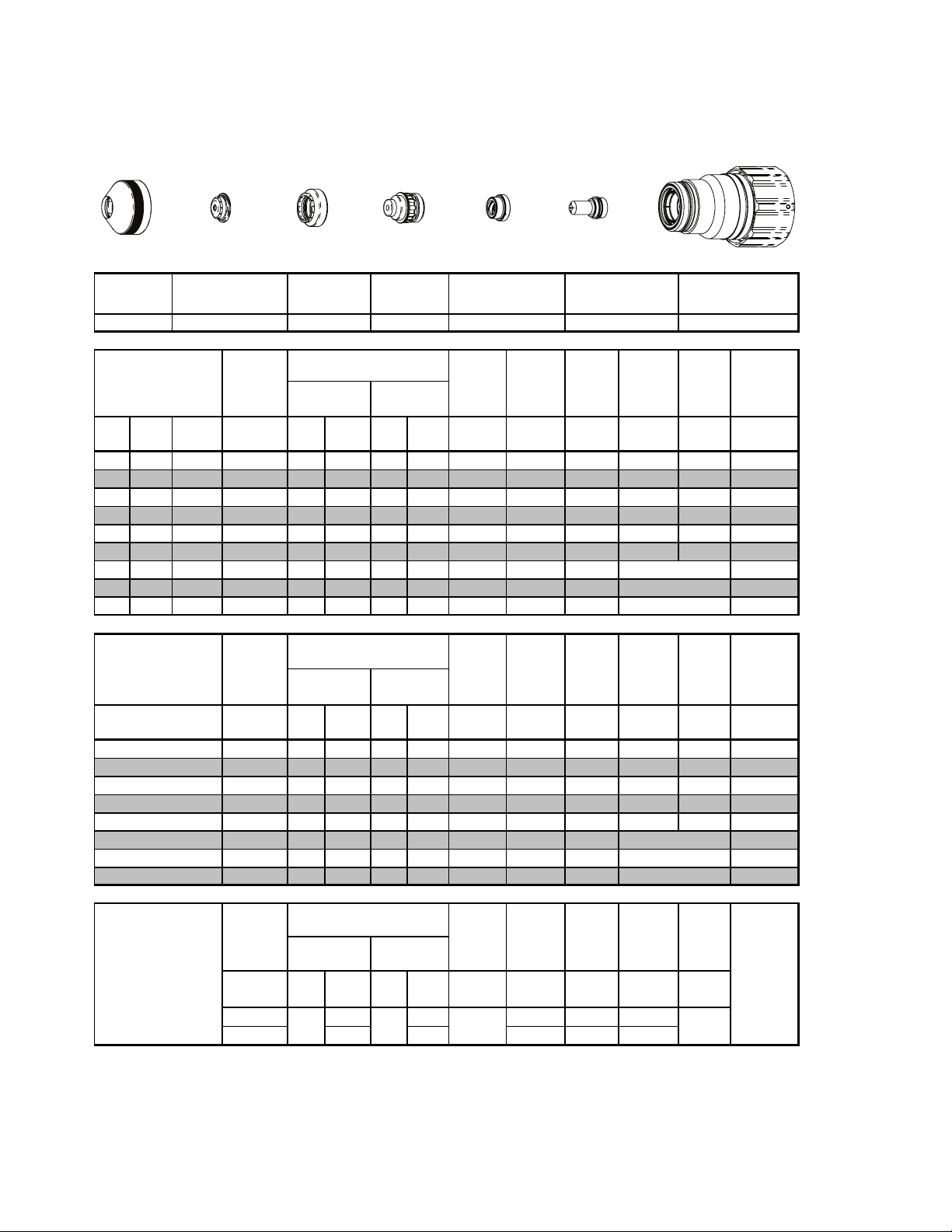

Mild Steel

70A

O

Plasma / Air Shield

2

Shield Cup

22-1016

Shield Cap

22-1026

Shield

Gas Distributor

22-1272

Tip

22-1152

Plasma

Gas Distributor

22-1041

Cartridge

22-1020Electrode

22-1170

Art # A-07663

70A Mild Steel XTL (O2/Air)

Mate ri al

Thickn es s

(ga) (in) inch (PSI) Ball (PSI) Ball (PSI) Volts

Pre Flow

Pressure

(Air)

Cut Flow Rate s / Pres s ures

Plas m a (O2) 5Shield (Air)

Arc

Vol tag e

Torch

Workin g

Height

(in)

±0.005

Travel

Speed

(ipm ) (in) (sec) (in)

Initial

Piercing

Height

Pierce

Delay

Kerf

Width

@ Rec.

Speed

16 0.060 46 35 120 41 120 138 0.070 300 0.100 0.1 0.073

14 0.075 46 35 120 41 120 138 0.070 300 0.100 0.1 0.072

12 0.105 46 55 120 60 120 142 0.080 270 0.120 0.2 0.078

10 0.135 46 55 120 60 120 142 0.080 180 0.150 0.2 0.071

3/16 0.188 46 55 120 60 120 148 0.100 130 0.200 0.4 0.077

1/4 0.250 46 55 120 60 120 148 0.100 100 0.200 0.5 0.083

Mate ri al

Thickn es s

(mm)

1.5

2

3

4

6

16A Arc Current

Burn-through

may occur

on thickness es

< 1/16" (0.063") /

1.6 mm.

Pre Flow

Pressure

(Air)

(Bar) Ball (Bar) Ball (Bar) Volts

Cut Flow Rate s / Pres s ures

Plas m a (O2)

Shield (Air)

Arc

Vol tag e

Torch

Workin g

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

3.2 35 8.3 41 8.3 138 1.8 7620 2.5 0.1 1.9

3.2 35 8.3 41 8.3 138 1.8 7530 2.6 0.1 1.9

3.2 55 8.3 60 8.3 142 2.0 5860 3.4 0.2 1.9

3.2 55 8.3 60 8.3 145 2.3 4030 4.4 0.3 1.9

3.2 55 8.3 60 8.3 148 2.5 3190 5.1 0.4 2.0

3.2 55 8.3 60 8.3 148 2.5 2710 5.1 0.5

Marking (with 70A Mild Steel Parts)

Pre Flow

Pr e s s u r e

(

)

N

2

20 psi

1.4 bar

Cut Flow Rate s / Pres s ures

)

Pressure (

Shield

Plasma

Pressure (

N

2

Ball Press Ball Press

50

40 psi

2.8 bar

80

80 psi

5.5 bar

Arc

Vol tag e

)

N

2

Vol ts

155

Tor ch

Working

Height

in ±0.005 /

mm ±0.1

0.12

3

Travel

Speed

ipm /

mm/min

300

7600

Initial

Piercing

Height

in ±0.0 05 /

mm ±0.1

0.12

3

Pierce

Delay

sec

0

Kerf

Width

@ Rec.

Speed

2.1

Marking

quality

degrades

as

thic knes s

decreas es.

Manual 0-4829 Rev AN 8-19 TORCH DATA for Ultra-Cut

Page 18

Stainless Steel

70A

Air Plasma / Air Shield

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap

22-1016

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

10 0.141 84 41 120 94 120 138 0.080 120 0.140 0.3 0.075

3/16 0.188 84 41 120 87 120 144 0.080 100 0.140 0.4 0.082

1/4 0.250 84 41 120 72 120 148 0.130 55 0.180 0.5 0.085

3/8 0.375 84 41 120 72 120 152 0.140 40 0.200 0.6 0.083

1/2 0.500 84 53 120 60 120 160 0.140 25 0.280 0.8 0.080

Mate ri al

Thickn es s

22-1035 22-1274 22-1061 22-1041 22-1079 22-1020

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

Shield Gas

Distributor

Cut Flow Rate s /

Pressures

Cut Flow Rate s /

Pressures Arc

Plas m a (Air) Shield (Air)

Tip

Plasma Gas

Distributor

Plasma Gas

Distributor

Arc

Vol tag e

Vol tag e

Torch

Working

HeightPlas m a (Air) Shield (Air)

(in)

±0.005

Torch

Working

Height

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Travel

Speed

Initial

Piercing

Height

Initial

Piercing

Height

Pierce

Delay

Pierce

Delay

Kerf Width

Kerf Width

@ Rec.

Speed

@ Rec.

Speed

(mm)

3

4

5

6

8

10

12

16A Arc Cur r e nt

Burn-through

may occur

for th ickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

5.8 41 8.3 94 8.3 135 2.0 3300 3.6 0.3 1.8

5.8 41 8.3 94 8.3 140 2.0 2870 3.6 0.3 2.0

5.8 41 8.3 87 8.3 145 2.2 2380 3.7 0.4 2.1

5.8 41 8.3 72 8.3 148 2.3 1440 4.5 0.5 2.1

5.8 41 8.3 72 8.3 150 2.4 1200 4.8 0.6 2.1

5.8 41 8.3 72 8.3 153 3.6 960 5.4 0.6 2.1

5.8 53 8.3 60 8.3 158 3.6 720 6.7 0.8 2.1

Marking

Pre Flow

Pressure

(N

)

2

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

Cut Flow Rate s /

Pressures Arc

Plas m a (N

(Ball)

50 75

) Shield (N2)

2

(PSI) /

(Bar)

(Ball)

(PSI) /

(Bar)

Vol tag e

Vol ts

135 0

(mm)

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

( mm/mi n)

Travel

Speed

ipm /

mm/min

(mm ) (sec) (m m )

Initial

Tran s fer

Height

in ±0.005 /

mm ±0.1

Pierce

Delay

(sec)

Mar ki ng

quality

degrades

as

thi ckn es s

decreases

TORCH DATA for Ultra-Cut 8-20 Manual 0-4829 Rev AN

Page 19

2

Stainless Steel

70A

Plasma / H2O Shield

N

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

)

2

Shield Gas

Distributor

Plas m a (N

Plas m a (N

(Ball)

Tip

Cut Flo w Rates /

Pressures

Shield

)

2

(H

2

Cut Flo w Rates /

Pressures Arc

Shield

)

2

(H

Cut Flo w Rates /

Pressures Arc

) Shield (N2)

2

(PSI) /

50 75

(Bar)

(Ball)

O)*

O)*

Marking

(PSI) /

(Bar)

Shield Cup Shield Cap

22-1016 22-1084 22-1020

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

10 0.141 45 55 90 5 55 146 0.100 120 0.250 0.3 0.075

3/16 0.188 45 55 90 5 55 150 0.100 90 0.250 0.4 0.086

1/4 0.250 45 55 90 5 55 159 0.150 50 0.250 0.5 0.095

3/8 0.375 45 55 90 5 55 168 0.150 35 0.250 0.7 0.103

Mate ri al

Thickn es s

(mm)

3

4

5

6

8

10

18A Arc Cur r e nt

Burn-through

may occur

for thickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

22-1047 22-1274 22-1064

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

3.1 55 6.2 5 3.8 142 2.5 3040 6.3 0.3 1.8

3.1 55 6.2 5 3.8 143 2.5 2780 6.3 0.3 2.0

3.1 55 6.2 5 3.8 151 2.5 2140 6.3 0.4 2.2

3.1 55 6.2 5 3.8 157 3.8 1495 6.3 0.5 2.3

3.1 55 6.2 5 3.8 164 3.8 1070 6.3 0.6 2.5

3.1 55 6.2 5 3.8 170 3.8 980 6.3 0.7 2.6

Pre Flow

Pressure

(N

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

indicates maximum piercing parameters.

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1041

Arc

Vol tag e

Vol tag e

Vol tag e

Vo lt s

150 0

Torch

Working

HeightPlasma (N

±0.005

Torch

Working

Height

(mm )

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

(in)

Electrode

Electrode Cartridge

Travel

Speed

(ipm ) (in) (sec) (in)

Travel

Speed

( mm/mi n)

Travel

Speed

ipm /

mm/ min

Cartridge

Art # A-07958_AB

Initial

Piercing

Height

Initial

Piercing

Height

(mm ) (sec) (m m )

Initial

Transfer

Height

in ±0.005 /

mm ±0. 1

Pierce

Delay

Pierce

Delay

Pierce

Delay

(sec)

Kerf Width

@ Rec.

Speed

Kerf Width

@ Rec.

Speed

Mar ki ng

quality

degrades

thi ckn es s

decreases

as

Manual 0-4829 Rev AN 8-21 TORCH DATA for Ultra-Cut

Page 20

Aluminium

70A

Air Plasma / Air Shield

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

14 0.079 84 42 120 70 120 153 0.060 300 0.140 0.0 0.058

12 0.097 84 42 120 70 120 160 0.080 200 0.140 0.1 0.062

3/16 0.188 84 42 120 70 120 162 0.120 100 0.140 0.1 0.072

1/4 0.250 84 42 120 70 120 166 0.140 70 0.180 0.2 0.073

3/8 0.375 84 42 120 70 120 168 0.140 60 0.180 0.3 0.078

Mate ri al

Thickn es s

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

Shield Gas

Distributor

Cut Flow Rate s /

Pressures

Cut Flow Rate s /

Pressures Arc

Plas m a (Air) Shield (Air)

Tip

Plasma Gas

Distributor

Plasma Gas

Distributor

22-1041 22-1079 22-102022-1016 22-1035 22-1274 22-1061

Arc

Vol tag e

Vol tag e

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Travel

Speed

Initial

Piercing

Height

Initial

Piercing

Height

Pierce

Delay

Pierce

Delay

Kerf Width

@ Rec.

SpeedPlas m a (Air) Shield (Air)

Kerf Width

@ Rec.

Speed

(mm)

2

3

4

5

6

8

10

16A Arc Cur r e nt

Burn-through

may occur

for th ickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates maximum piercing parameters.

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

5.8 42 8.3 70 8.3 153 1.5 7620 3.6 0.0 1.5

5.8 42 8.3 70 8.3 160 2.3 4490 3.6 0.1 1.6

5.8 42 8.3 70 8.3 161 2.7 3390 3.6 0.1 1.7

5.8 42 8.3 70 8.3 163 3.1 2430 3.7 0.1 1.8

5.8 42 8.3 70 8.3 165 3.4 1950 4.4 0.2 1.9

5.8 42 8.3 70 8.3 167 3.6 1650 4.6 0.3 2.0

5.8 42 8.3 70 8.3 168 3.6 1490 4.6 0.3 2.0

Marking

Pre Flow

Pressure

)

(N

2

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

Cut Flow Rate s /

Pressures Arc

Plas m a (N

(Ball)

50 75

) Shield (N2)

2

(PSI) /

(Bar)

(Ball)

Vol tag e

(PSI) /

(Bar)

BOLD ITALIC

Vol ts

135 0

(mm)

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

indicates edge starts only.

( mm/mi n)

Travel

Speed

ipm /

mm/min

Tran s fer

Height

in ±0.005 /

mm ±0.1

(mm ) (sec) (m m )

Initial

Pierce

Delay

(sec)

Mar ki ng

quality

degrades

as

thi ckn es s

decreases

TORCH DATA for Ultra-Cut 8-22 Manual 0-4829 Rev AN

Page 21

Aluminum

g

70A

N

Plasma / H2O Shield

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Electrode

Cartridge

This Art Is For Reference ONLY

Shield Cup Shield Cap Shield Gas

Distribut or

Tip P l as m a Gas

Distributor

Electrode Cartridge

Art # A-07958_AB

22-1041 22-1084 22-102022-1016 22-1047 22-1274 22-1064

Mate ri al

Thicknes s

Pre Flow

Pressure

)

(N

2

(ga) (in) inch (PSI) Ball (PSI) Ball (PSI) Volts

Cut Flow Rates /

Pressures

Plasma (N

Arc

Shield

)

2

(H

2

Voltage

O)*

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm ) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

16 0.064 45 55 90 5 55 155 0.100 300 0.250 0 0.057

14 0.079 45 55 90 5 55 148 0.100 240 0.250 0 0.068

12 0.097 45 55 90 5 55 150 0.150 200 0.250 0.1 0.095

3/16 0.188 45 55 90 5 55 150 0.150 120 0.250 0.3 0.095

1/4 0.250 45 55 90 5 55 158 0.150 70 0.250 0.3 0.097

3/8 0.375 45 55 90 5 55 162 0.150 35 0.250 0.5 0.100

Cut Flow Rates /

Pressures

Plasma (N

Arc

Shield

)

2

(H

2

Voltage

O)*

Torch

Working

Height

(mm)

±0.1

Travel

Speed

( mm/mi n)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

(mm) (s ec) (mm )

Mate ri al

Thicknes s

(mm)

2

3

4

5

6

7

8

Pre Flow

Pressure

)

(N

2

(Bar) Ball (Bar) Ball (Bar) Volts

3.1 55 6.2 5 3.8 148 2.5 6100 6.3 0 1.7

3.1 55 6.2 5 3.8 150 3.8 4610 6.3 0.2 2.4

3.1 55 6.2 5 3.8 150 3.8 3730 6.3 0.3 2.4

3.1 55 6.2 5 3.8 151 3.8 2870 6.3 0.3 2.4

3.1 55 6.2 5 3.8 156 3.8 2060.3 6.3 0.3 2.5

3.1 55 6.2 5 3.8 160 3.8 1315 6.3 0.4 2.6

3.1 55 6.2 5 3.8 163 3.8 880 6.3 0.5 2.7

Marking

18A Arc Current

Burn-through

may occur

for thi cknes s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

indicates m aximum piercing parameters.

Pre Flow

Pressure

(N

)

2

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

Cut Flow Rates /

Pressures Arc

Plasma (N

(Ball)

) Shield (N2)

2

(PSI) /

(Bar)

(Ball)

50 75

(PSI) /

(Bar)

Voltage

Vol ts

Torch

Working

Height

in ±0.005 /

mm ±0.1

Travel

Speed

ipm /

mm/ min

Initial

Transfer

Height

in ±0.005 /

mm ±0.1

150 0

Pierce

Delay

(sec)

Marki ng

quality

degrades

thicknes s

decreases

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later

* Pressure of the water supply line should be regulated by customer pressure regulator.

Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with the

Note1 :

ohmic sensin

Water source used for shield must be demineralized.

Note2 :

circui t.

as

Manual 0-4829 Rev AN 8-23 TORCH DATA for Ultra-Cut

Page 22

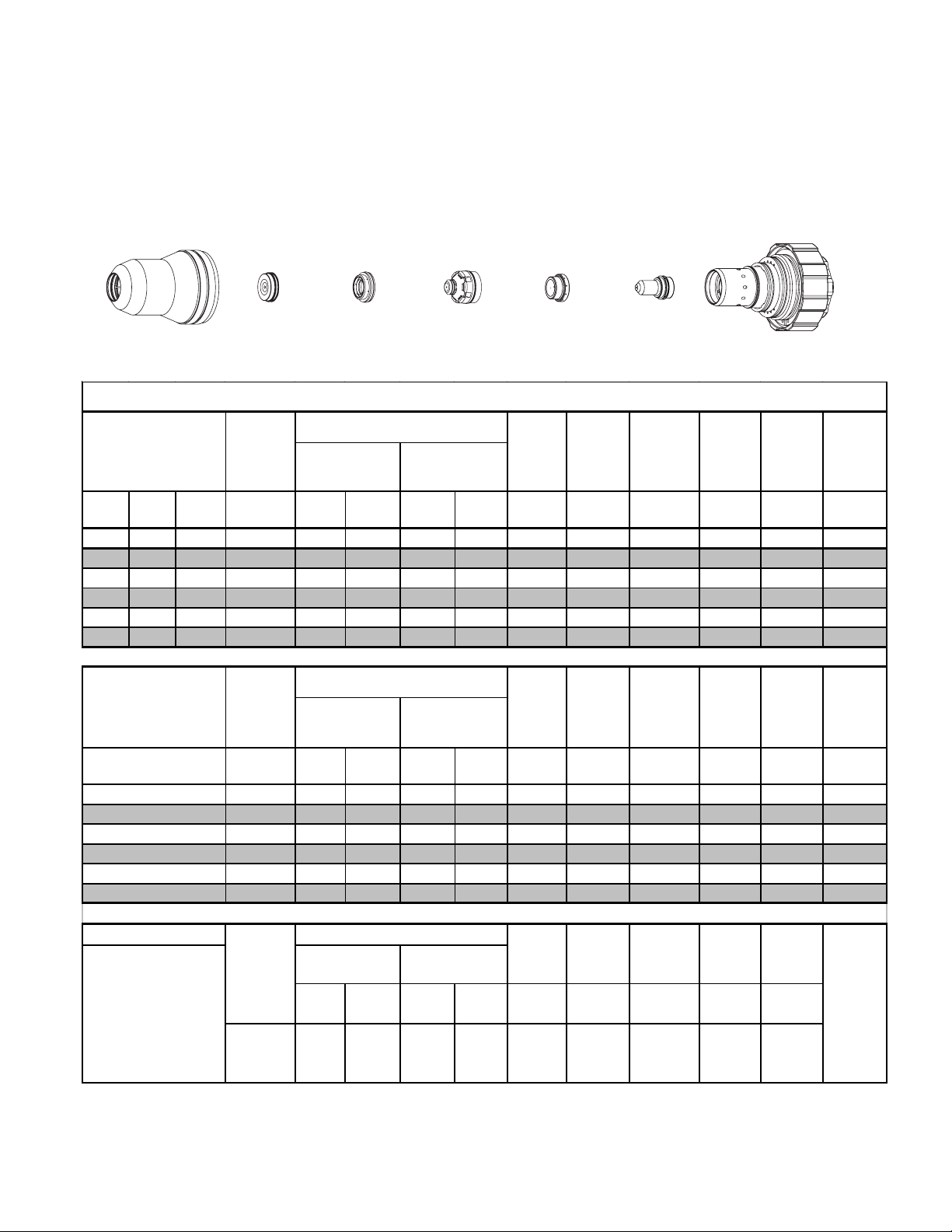

Mild Steel

Kerf

p

85A

Air Plasma / Air Shield

Shield Cup

22-1016

Shield Cap

22-1027

Shield

Gas Distributor

22-1272

Tip

22-1153

Plasma

Gas Distributor

22-1041

Electrode

22-1071

Cartridge

22-1020

Art # A-06040

85A Mild Steel Air/Air

Mate ri al

Thickn es s

(ga) (in) inch (psi) Ball (psi) Ball (ps i) Volts

Pre Flow

Pr e s s u r e

(Air)

Cut Flo w Rates / Pres sures

Plas m a (Air) Shield (Air)

Arc

Vo lt ag e

Tor ch

Working

Height

(in)

±0.005

Travel

Speed

(ipm ) (in) (sec) (in)

Initial

Piercing

Height

Pierce

Delay

Width

@ Rec.

S

eed

10 0.135 74 55 120 80 120 160 0.070 240 0.200 0.0 0.062

3/16 0.188 74 55 120 80 120 161 0.090 174 0.200 0.1 0.065

1/4 0.250 74 55 120 80 120 164 0.090 140 0.200 0.2 0.065

3/8 0.375 74 55 120 80 120 175 0.170 75 0.250 0.3 0.085

1/2 0.500 74 55 120 80 120 169 0.120 64 0.300 0.3 0.081

5/8 0.625 74 55 120 80 120 178 0.140 30 0.350 0.8 0.095

3/4 0.750 74 55 120 80 120 186 0.150 25 NR NR 0.098

Mate ri al

Thickn es s

(mm)

4

5

6

8

10

12

15

20

Pre Flow

Pr e s s u r e

(Air)

(bar) Ball (bar) Ball (bar) Volts

Cut Flo w Rates / Pres sures

Plas m a (Air) Shield (Air)

Vo lt ag e

Arc

Tor ch

Working

Height

(mm)

±0.1

Travel

Speed

( mm/mi n)

5.1 55 8.3 80 8.3 160 2.0 5310 5.1 0.0 1.6

5.1 55 8.3 80 8.3 162 2.3 4240 5.1 0.1 1.7

5.1 55 8.3 80 8.3 163 2.3 3730 5.1 0.2 0.2

5.1 55 8.3 80 8.3 170 3.3 2700 5.7 0.3 1.9

5.1 55 8.3 80 8.3 174 4.1 1860 6.5 0.3 2.2

5.1 55 8.3 80 8.3 170 3.3 1690 7.3 0.3 2.1

5.1 55 8.3 80 8.3 176 3.4 1000 8.5 0.7 2.3

5.1 55 8.3 80 8.3 188 3.9 600 NR NR 2.5

Initial

Piercing

Height

(mm) (sec) (mm)

Pierce

Delay

Kerf

Width

@ Rec.

Speed

TORCH DATA for Ultra-Cut 8-24 Manual 0-4829 Rev AN

Page 23

Mild Steel

100A

O

Plasma / Air Shield

2

Shield Cup

22-1016

Shield Cap

22-1027

Mat er ia l

Thic kn ess

(ga) (in) inch (PSI) Ball (PSI) Ball (PSI) Volts

10 0.135 40 55 120 80 120 138 0.070 280 0.200 0.2 0.065

3/16 0.188 40 55 120 80 120 140 0.090 190 0.200 0.2 0.070

1/4 0.250 40 55 120 80 120 141 0.100 150 0.200 0.3 0.078

3/8 0.375 40 55 120 80 120 143 0.110 95 0.250 0.4 0.085

1/2 0.500 40 55 120 80 120 147 0.120 64 0.300 0.6 0.097

5/8 0.625 40 55 120 80 120 148 0.120 50 0.350 0.8 0.100

3/4 0.750 40 55 120 80 120 157 0.150 25 0.125

Mat er ia l

Thic kn ess

Pr e Flo w

Pr e s s u r e

(Air)

Pr e Flo w

Pr e s s u r e

(Air)

Shield

Gas Distributor

22-1272

Cut Fl ow Rate s / Pre s s u r e s

) Shield (Air)

2

Cut Fl ow Rate s / Pre s s u r e s

Pla s ma (O

) Shield (Air)

2

22-1153

100A Mild Ste e l XTL O

Tip

Plasma

Gas Distributor

22-1041

/Air

2

Arc

Voltage

Arc

Voltage

Tor ch

Working

Height

±0.005

Tor ch

Working

Height

(in)

Electrode

22-1171

Travel

SpeedPla s ma (O

(ipm) (in) (sec) (in)

Travel

Speed

Pie r c i n g

Pie r c i n g

Cartridge

22-1020

Art # A-07666

Initial

Heig ht

Edge s tart Only

Initial

Heig ht

Pie r c e

Dela y

Pie r c e

Dela y

Kerf Width

@ Rec.

Speed

Kerf Width

@ Rec.

Speed

( mm)

4

5

6

8

10

12

15

20

15A Arc Curr e nt

Burn-through

may occur

for thicknesses

< 1/16" (0.063") / 1.6 mm.

(Bar) Ball (Bar) Ball (Bar) Volts

2.8 55 8.3 80 8.3 139 2.0 6120 5.1 0.2 1.7

2.8 55 8.3 80 8.3 140 2.3 4670 5.1 0.2 1.8

2.8 55 8.3 80 8.3 141 2.5 4030 5.1 0.3 1.9

2.8 55 8.3 80 8.3 142 2.7 3080 5.7 0.4 2.1

2.8 55 8.3 80 8.3 144 2.8 2300 6.5 0.4 2.2

2.8 55 8.3 80 8.3 146 3.0 1800 7.3 0.6 2.4

2.8 55 8.3 80 8.3 148 3.1 1370 8.5 0.7 2.5

2.8 55 8.3 80 8.3 157 3.8 640 3.2

Mark ing (w ith 100A M ild Ste e l Parts)

Pr e Flo w

Pr e s s u r e

)

(

N

2

20 psi

1.4 bar

Cut Fl ow Rate s / Pre s s u r e s

Pla s ma

Pr e s s u r e (

Ball Press Ball Press Volts

50

N

2

40 psi

2.8 bar

)

Shield

Pr e s s u r e (

100

N

80 psi

5.5 bar

2

)

Arc

Voltage

190

( mm)

±0.1

Tor ch

Working

Height

in ±0.005 /

mm ±0.1

0.12

3

( mm/mi n) ( mm) ( s ec ) ( mm)

Edge Start Only

Travel

Speed

ipm /

mm/ min

300

7600

Initial

Pie r c i n g

Heig ht

in ±0.005 /

mm ±0. 1

0.12

3

Pie r c e

Dela y

(sec)

0

Mar ki ng

quality

degrades

as

thickness

decreases

Manual 0-4829 Rev AN 8-25 TORCH DATA for Ultra-Cut

Page 24

Stainless Steel

100A

H35 Plasma / N

Shield Cup

Shield

2

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap Shield Gas

Distributor

Mate ri a l

Thi cknes s

(ga) (in) inch (PSI) Ball (PSI) Ball (PSI) Volts

1/4 0.250 40 50 120 97 120 148 0.145 72 0.250 0.3 0.093

3/8 0.375 40 55 120 97 120 152 0.130 55 0.300 0.3 0.090

1/2 0.500 40 55 120 97 120 155 0.130 42 0.350 0.5 0.095

5/8 0.625 40 62 120 97 120 157 0.130 25 0.350 0.6 0.100

Pre Flow

Pressure

)

(N

2

Cut Flow Rate s /

Pressures

Plas m a

(H35)

Tip Plasma Gas

Arc

Shield (N

)

2

Vo lt ag e

Plasma Gas

Distributor

Distributor

22-1041 22-1080 22-102022-1016 22-1036 22-1274 22-1062

Torch

Working

Height

(in)

±0.005

Electrode

Cartridge

Art # A-07958_AB

Elec trode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

Mate ri a l

Thi cknes s

(mm)

6

8

10

12

15

18 A Arc Curre nt

Burn-through

may occur

for thickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later

indicates m aximum piercing parameters.

Pre Flow

Pressure

)

(N

2

(Bar) Ball (Bar) Ball (Bar) Volts

2.8 50 8.3 97 8.3 148 3.7 1880 6.2 0.3 2.0

2.8 55 8.3 97 8.3 150 3.5 1600 7.0 0.3 2.0

2.8 55 8.3 97 8.3 152 3.3 1350 7.8 0.3 1.9

2.8 62 8.3 97 8.3 154 3.3 1140 8.6 0.5 1.9

2.8 62 8.3 97 8.3 156 3.3 750 8.9 0.7 1.9

Pre Flow

Pressure

)

(N

2

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

Cut Flow Rate s /

Pressures

Plas m a

(H35)

Cut Flow Rate s /

Plas m a (N

(PSI) /

(Ball)

50

Shield (N

Pressures Arc

) Shield (N2)

2

(Ball)

(Bar)

75

)

2

Marking

(PSI) /

(Bar)

Arc

Vo lt ag e

Vo lt ag e

Vol ts

125 0

Torch

Working

Height

(mm)

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

Travel

Speed

( mm/mi n)

Travel

Speed

ipm /

mm/ min

Initial

Piercing

Height

(mm) (sec) (mm)

Initial

Tran s fer

Height

in ±0.005 /

mm ±0.1

Pierce

Delay

Pierce

Delay

(sec)

Kerf Width

@ Rec.

Speed

Mar ki ng

quality

degrades

thi ckn es s

decreases

as

TORCH DATA for Ultra-Cut 8-26 Manual 0-4829 Rev AN

Page 25

2

Stainless Steel

100A

Plasma / H2O Shield

N

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap

22-1016

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

3/16 0.188 45 60 90 7 55 148 0.100 140 0.300 0.1 0.091

1/4 0.250 45 60 90 7 55 158 0.100 95 0.300 0.1 0.091

3/8 0.375 45 60 90 7 55 168 0.150 65 0.350 0.2 0.100

1/2 0.500 45 60 90 7 55 168 0.150 50 0.350 0.4 0.102

Mate ri al

Thickn es s

(mm)

5

6

8

10

12

18A Arc Cur r e nt

Burn-through

may occur

for th ickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

22-1036 22-1274 22-1053 22-1041 22-1089 22-1020

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

3.1 60 6.2 7 3.8 149 2.5 3390 7.6 0.1 2.3

3.1 60 6.2 7 3.8 156 2.5 2665 7.6 0.1 2.3

3.1 60 6.2 7 3.8 163 3.8 2015 8.9 0.2 2.5

3.1 60 6.2 7 3.8 168 3.8 1595 8.9 0.3 2.6

3.1 60 6.2 7 3.8 168 3.8 1355 8.9 0.4 2.6

Pre Flow

Pressure

(N

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

indicates maximum piercing parameters.

Shield Gas

Distributor

Plas m a (N

Plas m a (N

)

2

(Ball)

50 75

Tip

Cut Flow Rate s /

Pressures

Shield

)

2

Cut Flow Rate s /

Pressures Arc

)

2

Cut Flow Rate s /

Pressures Arc

) Shield (N2)

2

(PSI) /

(Bar)

(H

Shield

(H

(Ball)

O)*

2

O)*

Marking

(PSI) /

(Bar)

Plasma Gas

Distributor

Plasma Gas

Distributor

Arc

Vol tag e

Vol tag e

Vol tag e

Vol ts

150 0

Torch

Working

HeightPlas m a (N

(in)

±0.005

Torch

Working

Height

(mm)

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

Electrode

Electrode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Travel

Speed

( mm/mi n)

Travel

Speed

ipm /

mm/min

Cartridge

Art # A-07958_AB

Initial

Piercing

Height

Initial

Piercing

Height

(mm) (sec) (mm)

Initial

Tran s fer

Height

in ±0.005 /

mm ±0.1

Pierce

Delay

Pierce

Delay

Pierce

Delay

(sec)

Kerf Width

@ Rec.

Speed

Kerf Width

@ Rec.

Speed

Mar ki ng

quality

degrades

as

thi ckn es s

decreases

Manual 0-4829 Rev AN 8-27 TORCH DATA for Ultra-Cut

Page 26

Aluminum

100A

H35 Plasma / N

Shield Cup

Shield

2

Shield Cap

Shield Gas

Distributor

Plasma Gas

Tip

This Art Is For Reference ONLY

Shield Cup Shield Cap Shield Gas

Distributor

Mate ri al

Thickn es s

(ga) (in) inch (PSI) Ball (PSI) Ball (PSI) Volts

3/8 0.375 40 67 120 62 120 152 0.154 60 0.350 0.2 0.105

1/2 0.500 40 67 120 62 120 158 0.150 50 0.350 0.2 0.110

5/8 0.625 40 67 120 62 120 160 0.150 35 0.350 0.5 0.110

Mate ri al

Thickn es s

(mm)

10

12

15

18 A Arc Curre nt

Burn-through

may occur

for thickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later

indicates maximum piercing parameters.

Pre Flow

Pres sure

)

(N

2

Pre Flow

Pres sure

)

(N

2

(Bar) Ball (Bar) Ball (Bar) Volts

2.8 67 8.3 62 8.3 153 3.9 1490 8.9 0.2 2.7

2.8 67 8.3 62 8.3 157 3.8 1330 8.9 0.2 2.8

2.8 67 8.3 62 8.3 159 3.8 990 8.9 0.5 2.8

Pre Flow

Pres sure

(N

)

2

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

Cut Flo w Rates /

Pressures

Plas m a

(H35)

Cut Flo w Rates /

Pressures

Plas m a

(H35)

Cut Flo w Rates /

Pressures

Plas m a (N

(PSI) /

(Ball)

(Bar)

50

Tip Plas m a Gas

Distributor

22-1041 22-1080 22-102022-1016 22-1036 22-1274 22-1062

Arc

Vol tag e

Shield (N

Shield (N

) Shield (N2)

2

(Ball)

75 125 0

)

2

)

2

Marking

(PSI) /

(Bar)

Arc

Vol tag e

Arc

Vol tag e

Vol ts

Distributor

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

(mm)

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

Electrode

Cartridge

Art # A-07958_AB

Electrode Cartridge

Travel

Speed

(ipm ) (in) (s ec) (in)

Travel

Speed

( mm/mi n)

Travel

Speed

ipm /

mm/min

Initial

Piercing

Height

Initial

Piercing

Height

(mm) (sec) (mm)

Initial

Transfer

Height

in ±0.005 /

mm ±0. 1

Pierce

Delay

Pierce

Delay

Pierce

Delay

(sec)

Kerf Width

@ Rec.

Speed

Kerf Width

@ Rec.

Speed

Mark in g

quality

degrades

thickness

decreases

as

TORCH DATA for Ultra-Cut 8-28 Manual 0-4829 Rev AN

Page 27

Aluminum

100A

Plasma / H2O Shield

N

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Electrode

Cartridge

This Art Is For Reference ONLY

Shield Cup Shield Cap

22-1016 22-1089 22-1020

Mate ri al

Thickn es s

(ga) (in) inch (PSI) (Ball) (PSI) (Ball) (PSI) Volts

3/16 0.188 45 60 90 7 55 158 0.150 130 0.300 0.1 0.095

1/4 0.250 45 60 90 7 55 160 0.150 90 0.300 0.1 0.100

3/8 0.375 45 60 90 7 55 161 0.150 70 0.300 0.2 0.100

1/2 0.500 45 60 90 7 55 171 0.150 40 0.300 0.4 0.100

5/8 0.625 45 60 90 7 55 175 0.180 35 0.350 0.5 0.105

Mate ri al

Thickn es s

(mm)

5

6

8

10

12

15

18A Arc Cur r e nt

Burn-through

may occur

for thickn es s es

< 1/16" (0.063") / 1.6

mm.

BOLD TYPE

22-1036 22-1274 22-1053 22-1041

Pre Flow

Pressure

(Air)

Pre Flow

Pressure

(Air)

(Bar) (Ball) (Bar) (Ball) (Bar) Volts

3.1 60 6.2 7 3.8 158 3.8 3150 7.6 0.1 2.4

3.1 60 6.2 7 3.8 160 3.8 2510 7.6 0.1 2.5

3.1 60 6.2 7 3.8 161 3.8 2025 7.6 0.2 2.5

3.1 60 6.2 7 3.8 162 3.8 1665 7.6 0.3 2.5

3.1 60 6.2 7 3.8 169 3.8 1190 7.6 0.4 2.5

3.1 60 6.2 7 3.8 174 4.6 925 8.9 0.5 2.7

Pre Flow

Pressure

(N

(PSI) /

(Bar)

20 40 80 0.120 300 0.120

1.4 2.8 5.5 3.0 7600 3.0

indicates maximum piercing parameters.

Shield Gas

Distributor

Cut Flo w Rates /

Pressures

)

2

Cut Flo w Rates /

Pressures Arc

Plas m a (Air) Shield (Air)

Cut Flo w Rates /

Pressures Arc

)

2

Plas m a (N

(Ball)

50 75

) Shield (N2)

2

(PSI) /

(Bar)

Shield

(H

(Ball)

Tip

O)*

2

(PSI) /

(Bar)

Marking

Plasma Gas

Distributor

Arc

Vol tag e

Vol tag e

Vol tag e

Vo lt s

150 0

Torch

Working

HeightPlasma (N

(in)

±0.005

Torch

Working

Height

(mm )

±0.1

Torch

Working

Height

in ±0.005 /

mm ±0. 1

Travel

Speed

(ipm ) (in) (sec) (in)

Travel

Speed

( mm/mi n)

Travel

Speed

ipm /

mm/ min

Art # A-07958_AB

Electrode Cartridge

Initial

Piercing

Height

Initial

Piercing

Height

(mm ) (sec) (m m )

Initial

Transfer

Height

in ±0.005 /

mm ±0. 1

Pierce

Delay

Pierce

Delay

Pierce

Delay

Kerf Width

Kerf Width

(sec)

decreases

@ Rec.

Speed

@ Rec.

Speed

Mar ki ng

quality

degrades

as

thi ckn es s

Manual 0-4829 Rev AN 8-29 TORCH DATA for Ultra-Cut

Page 28

This Page Intentionally Blank

TORCH DATA for Ultra-Cut 8-30 Manual 0-4829 Rev AN

Page 29

Insert "Up to 100 Amp

Bevel Cutting" Tab.

Discard this sheet.

Manual 0-4829 Rev AN 8-31 TORCH DATA for Ultra-Cut

TAB SHEET

Page 30

TORCH DATA for Ultra-Cut 8-32 Manual 0-4829 Rev AN

Page 31

8.02 Bevel Cutting Up To 100 Amp

Mild Steel

100A Bevel Cut

Plasma / Air Shield

O

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield Cup

22-1016

Effective cut

Thickness

ga in in psi Ball psi Ball psi (ipm) (in) (sec) (in)

10

3/16

1/4

Shield

Cap

22-1127

Minimum

0.07

0.07

0.07

3/8

1/2

5/8

3/4 0.07 40 55 120 40 120 25 0.125

0.07

0.07

0.07

Shield Gas

Distributor

22-1278

Pre Flow

Pressure

(Air)

Clearance

40 55 120 35 120 280 0.200 0.2 0.065

40 55 120 35 120 190 0.200 0.2 0.070

40 55 120 35 120 150 0.200 0.3 0.078

40 55 120 35 120 95 0.250 0.4 0.085

40 55 120 40 120 68 0.300 0.6 0.097

40 55 120 40 120 55 0.350 0.8 0.100

Tip

22-1154 22-1041

Cut Flow Ra tes /

Pressures

)

2

Plasma Gas

Distributor

Shield

(Air)

Plasma Gas

Distributor

Electrode

Torch Working

Height

(in)

.070-.250

.090-.250

.100-.250

.110-.250

.120-.250

.120-.250

.150-.250

Electrode

22-1172

Travel

Speed

Cartridge

Art # A-07958_AB

Cartridge

22-1020

Initial

Piercing

Height

Edge Start Only

Pierce

Delay

Kerf Width

@ Rec.

SpeedPlas m a (O

Cut Flow Ra tes /

Pressures Travel

Plas m a (O

2

)

Shield

(Air)

8.3 640 3.2

40

Torch Working

Height

(mm)

2.0-6.35

2.3-6.35

2.5-6.35

2.7-6.35

2.8-6.35

3.0-6.35

3.1-6.35

3.8-6.35

BOLD ITALIC

Initial

Speed

( mm/mi n)

indicates edge starts only.

Piercing

Height

(mm ) (sec) (m m )

Edge Start

Pierce

Delay

Kerf Width

@ Rec.

Speed

Effective cut

Thickness

mm

4

5

6

8

10

12

15

20

BOLD TYPE

Pre Flow

Pressure

(Air

)

Minimum

Clearance

mm bar Ball bar Ball bar

1.8 2.8 55 8.3 35 8.3 6120 5.1 0.2 1.7

1.8 2.8 55 8.3 35 8.3 4670 5.1 0.2 1.8

1.8 2.8 55 8.3 35 8.3 4030 5.1 0.3 1.9

1.8 2.8 55 8.3 35 8.3 3080 5.7 0.4 2.1

1.8 2.8 55 8.3 35 8.3 2300 6.5 0.4 2.2

1.8 2.8 55 8.3 40 8.3 1800 7.3 0.6 2.4

1.8 2.8 55 8.3 40 8.3 1370 8.5 0.7 2.5

1.8

indicates maximum piercing parameters.

2

2.8 55 8.3

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later.

Manual 0-4829 Rev AN 8-33 TORCH DATA for Ultra-Cut

Page 32

This Page Intentionally Blank

TORCH DATA for Ultra-Cut 8-34 Manual 0-4829 Rev AN

Page 33

Chart is for Customer Settings

Make Copies as Desired

Mate ri al

Thickn es s

(in) inch (PSI) Ball (PSI) Ball (PSI) * Volts

Pre Flow

Pressure

(N

Cut Flo w Rates / Pres sures

)

2

Plas m a (N

) Shield (H2O)

2

Arc

Voltage

3/16 0.188

1/4 0.250

3/8 0.375

1/2 0.500

5/8 0.625

Mate ri al

Thickn es s

(mm)

Pre Flow

Pressure

(N

(Bar) Ball (Bar) Ball (Bar) * Volts

Cut Flo w Rates / Pres sures

Plas m a (N

)

2

) Shield (H2O)

2

Arc

Voltage

5

6

8

10

12

15

Torch

Worki n g

Height

(in)

±0.005

Torch

Worki n g

Height

(mm)

±0.1

Travel

Speed

(ipm ) (in) (s ec) (in)

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Initial

Piercing

Height

Pierce

Delay

Pierce

Delay

Kerf

Width

@ Rec.

Speed

Kerf

Width

@ Rec.

Speed

Manual 0-4829 Rev AN 8-35 TORCH DATA for Ultra-Cut

Page 34

This Page Intentionallly Blank

TORCH DATA for Ultra-Cut 8-36 Manual 0-4829 Rev AN

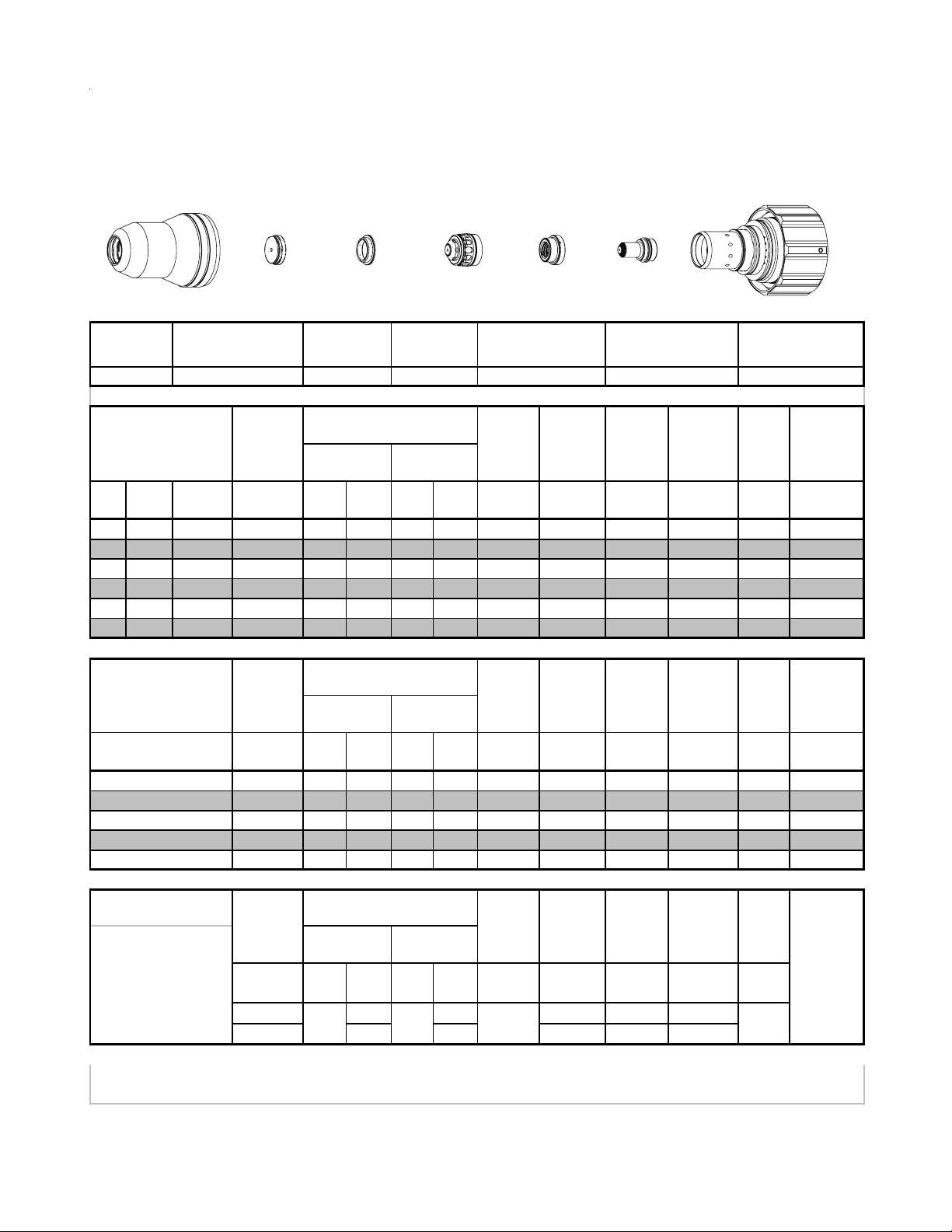

Page 35

Material

Gases

Used

Consumable

Description

100A 70A 50A 30A

Plasma Gas Distributor

22-1041 22-1041 22-1041

22-1040

O2/O2

O2/O2

O2/Air

Shield Retainer

Shield Cup

22-1016 22-1016 22-1016 22-1016

Cartridge Assy

22-1020 22-1020 22-1020 22-1020

H35/N2

N2/H2O

Shield Gas Distributor

22-1274 22-1274 22-1274 22-1274

Air/Air

Shield Retainer

Shield Cup

22-1016 22-1016 22-1016 22-1016

Cartridge Assy

22-1020 22-1020 22-1020 22-1020

22-1036

22-1035

Air/Air

22-1047

N2/H2O

22-1034

22-1033

Shield Cap

22-1062

H35/N2

22-1053

N2/H2O

22-1061

Air/Air

22-1064

N2/H2O

22-1060

22-1059

22-1041

22-1041

22-1041

22-1045

Tip

22-1069

22-1068 O2/O2

Electrode

Mild Steel

Electrode

Tip

Stainless

Steel/

Aluminum

Plasma Gas Distributor

22-1051

22-1152

22-1082

O2/O2

22-1050

O2/O2

22-1171

22-1170

22-1153

Shield Cap

22-1027

22-1077

22-1079

22-1064

N2/H2O

22-1078

22-1080

H35/N2

22-1089

N2/H2O

22-1026

22-1025

22-1024

O2/O2

Ultra Cut 100

22-1272

22-1272

Shield Gas Distributor

22-1272

Manual 0-4829 Rev AN 8-37 TORCH DATA for Ultra-Cut

Art # A-08444

Page 36

This Page Intentionallly Blank

TORCH DATA for Ultra-Cut 8-38 Manual 0-4829 Rev AN

Page 37

Insert "150-200 Amp

Standard Cutting" Tab.

Discard this sheet.

Manual 0-4829 Rev AN 8-39 TORCH DATA for Ultra-Cut

TAB SHEET

Page 38

This Page Intentionallly Blank

TORCH DATA for Ultra-Cut 8-40 Manual 0-4829 Rev AN

Page 39

(

)

(

)

8.03 Standard Cutting 150 - 200 Amp

Mild Steel

150A

O

Plasma / Air Shield

2

Shield Cup

22-1016

Shield Cap

22-1028

<

3/4” (20mm)

=

Shield

Gas Distributor

22-1273

22-1054

Tip

Plasma

Gas Distributor

22-1042

Cartridge

22-1020Electrode

22-1072

22-1275

> 3/4” (20mm)

Arc

Voltage

Arc

Voltage

Arc

Voltage

145

/Air)

2

Tor c h

Working

Height

(in)

±0.005

Tor c h

Working

Height

( mm)

±0.1

Tor c h

Working

Height

in ±0.005 /

mm ±0. 1

0.12

3

Travel

Speed

(ipm)(in)(sec)(in)

Travel

Speed

( mm/mi n) ( mm) ( s ec ) ( mm)

Travel

Speed

ipm /

mm/ min

300

7600

Initial

Pie r c in g

Height