Page 1

FABRICATOR 211i & 252i ROLL CAGE ASSEMBLY INSTRUCTIONS

Manual 0-5233

Roll Cage Kit for Fabricator 211i

Part Number: W4015104

Manufacturer: Thermadyne Industries

Address: 82 Benning Street West Lebanon,

New Hampshire 03784 USA

Telephone: 1-800-426-1888 • Fax: 1-800-535-0557

Email: sales@thermalarc.com

www.thermalarc.com

General Information

This document provides a guide for the assembly and installation of the Roll Cage Kit onto the Fabricator 211i/252i

power source. The Roll Cage protects the Fabricator power source case from collision damage plus doubles as a

sturdy hand lifting frame.

NOTE

The Roll Cage Kit is designed to fit the Fabricator 211i/252i power source without any modifications.

NOTE

Only the Roll Cage Kit or Welding Equipment Cart may be fitted to the Fabricator 211i/252i power

source at any one time.

Roll Cage Kit for Fabricator 252i

Part Number: W4015101

Assembly Instructions

!

WARNING

Do Not lift the Roll Cage / power supply via a crane or similar means. The Roll Cage / power supply

should only be lifted by hand.

For an Equipment Cart specically designed for use with the Fabricator 211i or Fabricator 252i plus gas cylinder,

welding gun and various accessories, use Part No. W4015001.

Recommended Tools

12mm or 4mm Open Ended Wrench or 6” Adjustable Wrench

6mm Allen Wrench (Hex Key)

T25 Torx-Bit for power source case screw

Assembly Instructions

WARNING

Unplug the Fabricator power source unit before attaching the Roll Cage Kit.

NOTE

Use the following assembly procedure to attach the Roll Cage to the Power Source. It is difficult to

attach the Power Source to a fully assembled Roll Cage.

© 2012 by Thermadyne Industries

February 3, 2012 1 0-5233

Page 2

FABRICATOR 211i & 252i ROLL CAGE ASSEMBLY INSTRUCTIONS

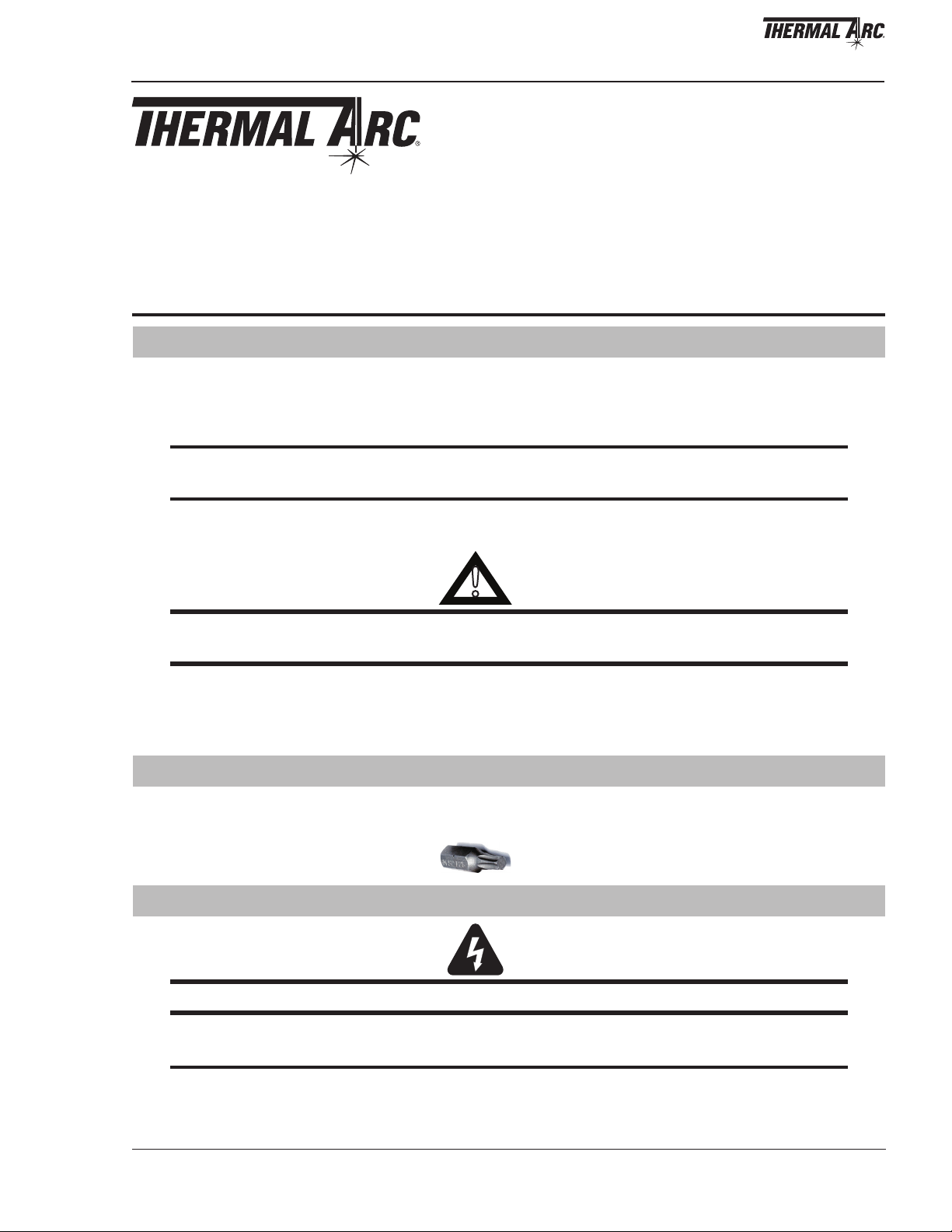

Supplied Parts

Item Description Qty

1 Rear Frame 1

2 Base Assembly 1

3 Front Frame 1

4 Top Support Plate 1

5 Handle 1

M8 x 40mm Socket Cap Screw

6

Torque force: 19 - 22 ft lb (26 - 30 N.m)

M8 x 20mm Socket Cap Screw

7

Torque force: 19 - 22 ft lb (26 - 30 N.m)

Saddle Washer (M8)

8

Nut (M6)

9

Torque force: 14 - 17 ft lb (19 - 23 N.m)

2

4

6

3

5

4

1

2

Art # A-10447

3

February 3, 2012 2 0-5233

Page 3

FABRICATOR 211i & 252i ROLL CAGE ASSEMBLY INSTRUCTIONS

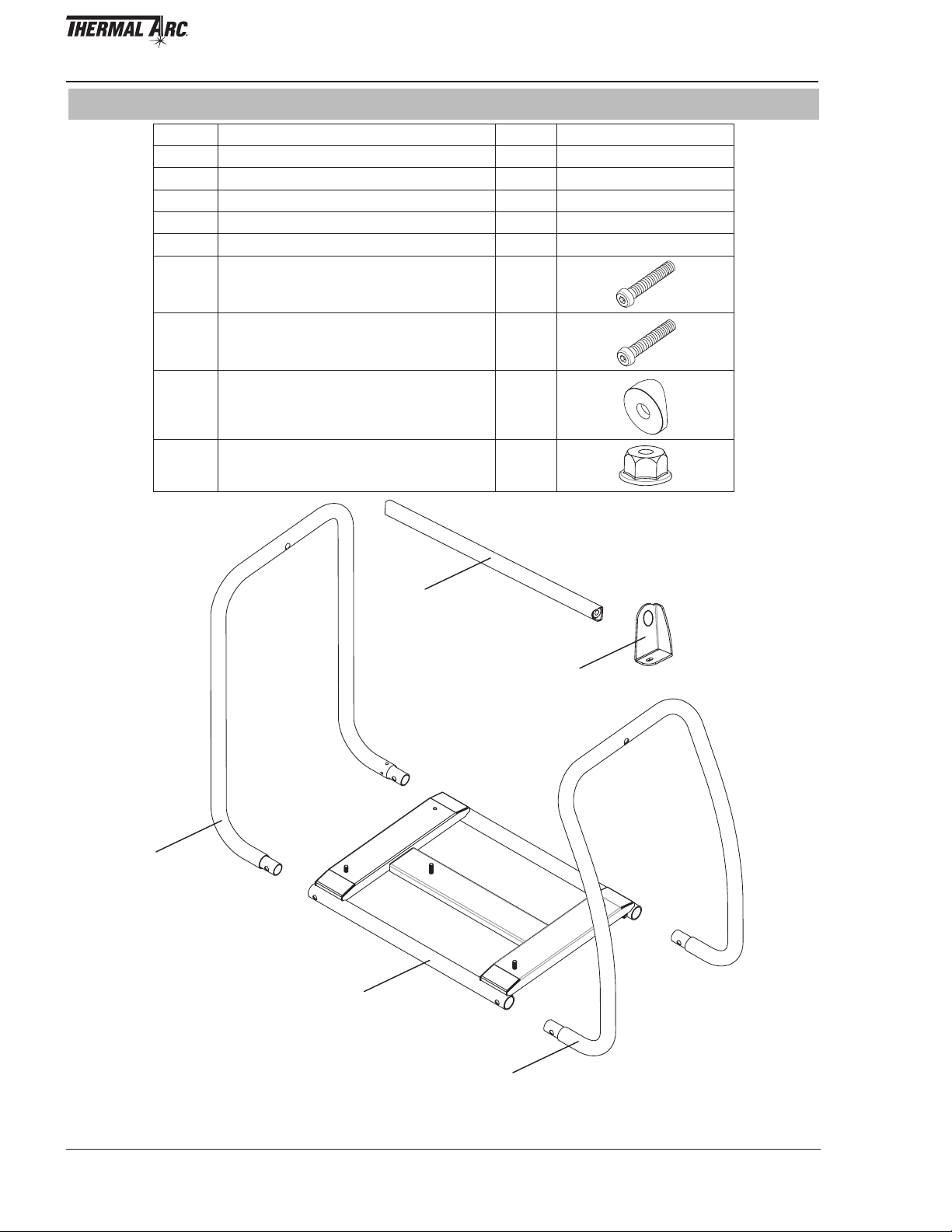

Rear Frame

A. Mount power source to Base Assembly

1. Open the wire feed compartment door and mount the power source to the Base Assembly (Item 2), carefully aligning the 3 mounting studs in the Base Assembly with the 3 holes in the power source.

2. Fasten all 3 M6 Nuts (Item 9) onto the 3 Base Assembly studs to secure the power source onto the roll

cage base.

3 Nuts

3 Holes

3 Studs

B. Install Front and Rear Frames

1. Install the Rear Frame to the Base Assembly and align Axes A with Axes B.

2. Install the Front Frame to the Base Assembly and align Axes C with Axes D.

Axes A

Base Assembly

Axes B

Axes C

Axes D

Art # A-11094

Front Frame

Art # A-11095

February 3, 2012 3 0-5233

Page 4

FABRICATOR 211i & 252i ROLL CAGE ASSEMBLY INSTRUCTIONS

3. Fasten the assembled Roll Cage together, using the following hardware:

Socket Cap Screw (Item 7)

•

• Saddle Washer (Item 8)

Saddle Washer

Socket Cap Screw

Art # A-11096

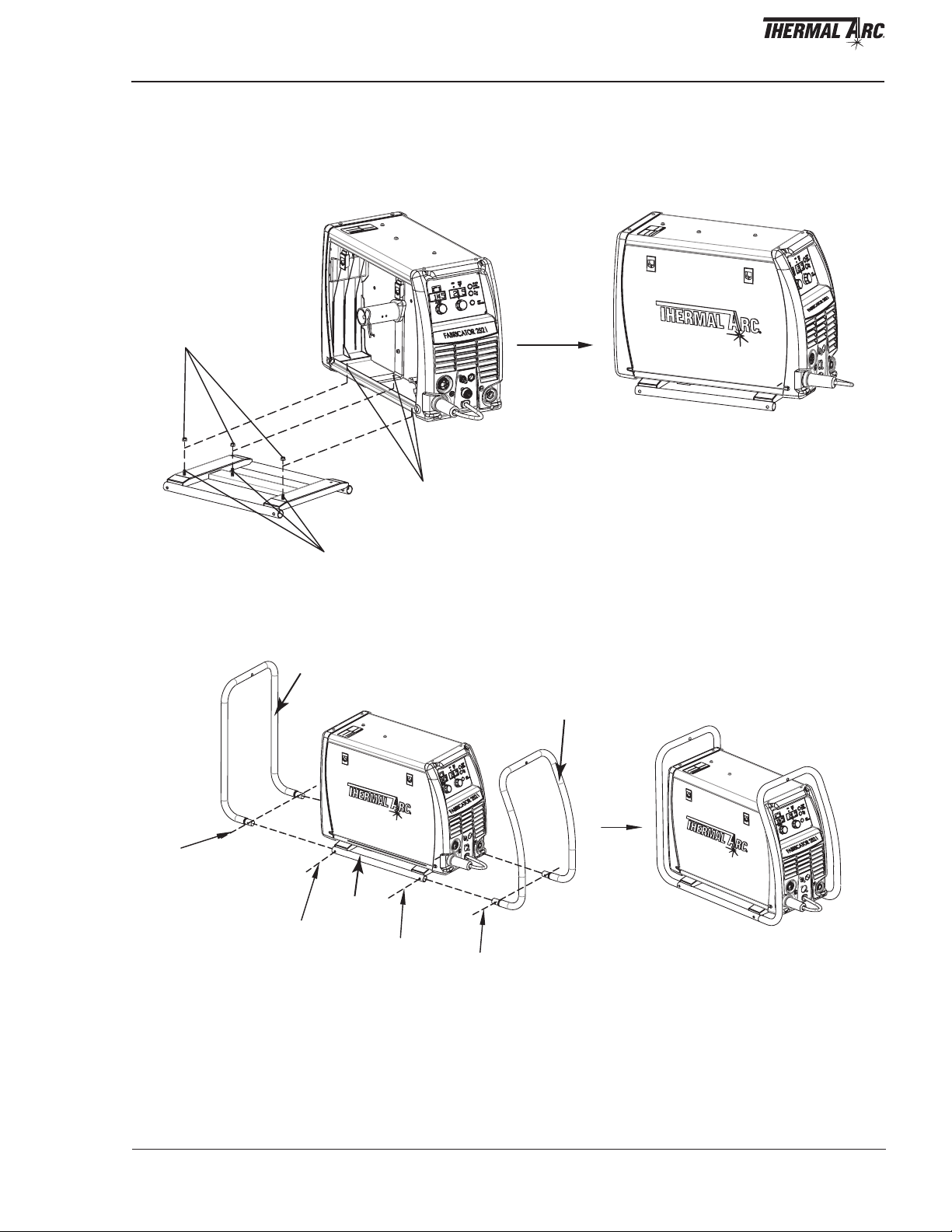

C. Install Handle to the Roll Cage

1. Remove the Screw from the top cover using the Torx-Bit T25. Keep this screw as it will be reinstalled later

in Step 5.

Specication of the Screw is M6 x 12mm.

Screw

Art # A-10604

February 3, 2012 4 0-5233

Page 5

FABRICATOR 211i & 252i ROLL CAGE ASSEMBLY INSTRUCTIONS

Top Support Plate

2. Insert Handle (Item 5) through hole in Top Support Plate (Item 4).

3. Place the Handle against the Front and Rear Frame with holes on the ends of the Handle aligned with holes

on the Frames.

4. Use fasteners to fasten the Handle and the Frames together.

Fasteners are as follows:

• Socket Cap Screw (Item 6)

• Saddle Washer (Item 8)

Rear Frame

Handle

Saddle Washer

Socket Cap Screw

Front Frame

Art # A-10605_AB

5. Reinstall the Screw (taken out in Step 1) to the Fabricator 211i/252i. Fasten the Screw to secure the power

source to the Roll Cage.

February 3, 2012 5 0-5233

Page 6

FABRICATOR 211i & 252i ROLL CAGE ASSEMBLY INSTRUCTIONS

D. When all the procedures are done, it should look like Figure below:

!

WARNING

Fully tighten all the fasteners (refer to torque force data in Supplied Parts section).

Art # A-10606

February 3, 2012 6 0-5233

Page 7

FABRICATOR 211i & 252i ROLL CAGE ASSEMBLY INSTRUCTIONS

This page left blank intentionally

February 3, 2012 7 0-5233

Page 8

Printed in: China

U.S. Customer Care: 800-426-1888 / FAX 800-535-0557 • Canada Customer Care: 905-827-4515 / FAX 800-588-1714

International Customer Care: 940-381-1212 /

FAX 940-483-8178

•

www.thermalarc.com

W ORLD HEADQUARTERS : 16052 Swingley Ridge Road, Suite 300 • St. Louis, Missouri 63017 U.S.A.

A Global Cutting & Welding Market Leader

THE AMERICAS EUROPE ASIA/PACIFIC

Denton, TX USA

U.S. Customer Care

Ph: 1-800-426-1888 (tollfree)

Fax: 1-800-535-0557 (tollfree)

International Customer Care

Ph: 1-940-381-1212

Fax: 1-940-483-8178

© 2010 Thermadyne Industries, Inc. www.thermadyne.com

Miami, FL USA

Sales Office, Latin America

Ph: 1-954-727-8371

Fax: 1-954-727-8376

Oakville, Ontario, Canada

Canada Customer Care

Ph: 1-905-827-4515

Fax: 1-800-588-1714 (tollfree)

Chorley, United Kingdom

Customer Care

Ph: +44 1257-261755

Fax: +44 1257-224800

Milan, Italy

Customer Care

Ph: +39 0236546801

Fax: +39 0236546840

Cikarang, Indonesia

Customer Care

Ph: 6221-8990-6095

Fax: 6221-8990-6096

Rawang, Malaysia

Customer Care

Ph: +603 6092-2988

Fax: +603 6092-1085

Melbourne, Australia

Australia Customer Care

Ph: 1300-654-674 (tollfree)

Ph: 61-3-9474-7400

Fax: 61-3-9474-7391

International

Ph: 61-3-9474-7508

Fax: 61-3-9474-7488

Shanghai, China

Sales Office

Ph: +86 21-64072626

Fax: +86 21-64483032

Singapore

Sales Office

Ph: +65 6832-8066

Fax: +65 6763-5812

™

Loading...

Loading...