Page 1

Torch Handles,

Cutting Attachments,

and Heating Nozzles

English

Français

Español

Safety and Operating

Instructions

Issue Date: May 14, 2008Revision: C Form No.: 0056-0138

Page 2

We appreciate your business!

Congratulations on your new Victor® product. We are proud to have you as our customer

and will strive to provide you with the best service and reliability in the industry. This

product is backed by our extensive warranty and worldwide service network. To

locate your nearest distributor or service agency, please contact a representative at

the address and phone number in your area listed on the inside back cover of this

manual, or visit us on the web at www.victorequip.com.

This Operating Manual has been designed to instruct you on the correct use and

operation of your Victor® product. Your satisfaction with this product and its safe

operation is our ultimate concern. Therefore, please take the time to read the entire

manual, especially the Safety Precautions. They will help you to avoid potential hazards

that may exist when working with this product.

you are in GooD coMpany!

The Brand of Choice for Contractors and Fabricators Worldwide.

Victor® is a Global Brand of gas equipment products for Thermadyne Industries, Inc.

We manufacture and supply to major welding and cutting industry sectors worldwide,

including: Manufacturing, Construction, Mining, Automotive, Aerospace, Engineering,

Rural and DIY/Hobbyist, Scrap, Demolitions and Shipyards.

We distinguish ourselves from our competition through market-leading, dependable

products that have stood the test of time. We pride ourselves on technical innovation,

competitive prices, excellent delivery, superior customer service and technical support,

together with excellence in sales and marketing expertise.

Above all, we are committed to develop technologically advanced products to achieve

a safer working environment within the welding industry.

Page 3

WARNING

Read and understand this entire manual and your employer’s safety practices

before installing, operating, or servicing the equipment. While the information

contained in this manual represents the Manufacturer’s judgment, the

Manufacturer assumes no liability for its use.

Torch Handles, Cutting Attachments, and Heating Nozzles

Safety and Operating Instructions

Part Number 0056-0138

Published by:

Thermadyne® Industries, Inc.

2800 Airport Rd.

Denton, TX. 76208

(940) 566-2000

www.victorequip.com

U.S. Customer Care: (800) 426-1888

International Customer Care: (905) 827-9777

Copyright © 2008 Thermadyne Industries, Inc. All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is

prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any

loss or damage caused by any error or omission in this Manual, whether such error

results from negligence, accident, or any other cause.

Publication Date: March 18, 2008

Record the following information for Warranty purposes:

Where Purchased: _______________________________________________

Purchase Date: _________________________________________________

Equipment Serial #: ______________________________________________

i

Page 4

Table of Contents

SECTION 1: INTRODUCTION ....................................................... 1-1

SECTION 2: GENERAL SAFETY INFORMATION ...........................2-2

2.01 Fire Prevention ..................................................2-2

2.02 Housekeeping .................................................... 2-3

2.03 Ventilation ........................................................2-3

2.04 Personal Protection ..........................................2-3

2.05 Compressed Gas Cylinders ...............................2-4

SECTION 3: TORCH HANDLES ..................................................... 3-5

3.01 Welding Preparation .......................................... 3-5

3.02 Welding Setup ...................................................3-7

3.03 Welding Operation ............................................. 3-8

3.04 Welding or Heating Completion ......................... 3-9

SECTION 4: CUTTING ATTACHMENT .........................................4-10

4.01 Cutting Preparation ......................................... 4-10

4.02 Cutting Completion .......................................... 5-13

SECTION 5: CHECK VALVES AND FLASH ARRESTORS ..............5-13

5.01 Reverse Flow Check Valves .............................5-13

5.02 Flashback Arrestors ......................................... 5-14

5.03 Leak Testing .................................................... 5-15

SECTION 6: WELDING NOZZLES ................................................6-16

SECTION 7: SPECIFICATIONS ....................................................7-17

SECTION 8: STATEMENT OF WARRANTY .................................. 8-22

ii

Page 5

SECTION 1:

INTRODUCTION

This booklet is a guide to the safe and efficient operation of apparatus

used in oxy-fuel applications. If the apparatus is not used in an oxyfuel application, the operator must still follow safety and operating

procedures that apply. Usage presents several potential hazards. Read

this booklet thoroughly and carefully before operating this equipment.

All operations should conform to applicable Federal, State, County, or

City regulations for installation, operation, ventilation, fire prevention,

and protection of personnel. ANSI Standard Z49.1, “Safety in Welding

and Cutting" contains detailed safety instructions. It is available from the

American Welding Society, P.O. Box 351040, Miami, FL 33135.

A system of notes, cautions, and warnings emphasize important safety

and operating information in this booklet:

NOTE

Conveys installation, operation, or maintenance information which

is important but not hazard-related.

CAUTION

Caution indicates a potentially hazardous situation which, if not

avoided, may result in injury.

WARNING

WARNING

avoided, could result in death or serious injury.

DO NOT

and understand all safety and operating instructions provided. For

your safety, practice the safety and operating procedures described

in this booklet every time you use the apparatus. Deviating from

these procedures may result in fire, explosion, property damage

and/or operator injury. If at any time the apparatus you are using

does not perform in its usual manner, or you have any difficulty in

the use of the apparatus, STOP using it immediately. DO NOT use

the apparatus until the problem has been corrected!

indicates a potentially hazardous situation which, if not

WARNING

attempt to use this apparatus until you thoroughly read

1-1

Page 6

WARNING

Service or repair of apparatus should be performed only by a

qualified repair technician capable of servicing gas apparatus in

strict accordance to applicable Part and Service bulletins for Victor

®

manufactured products. Improper service repair, or modification of

the product could result in damage to the product or injury to the

operator. Improper service repair, USE OF NON-GENUINE VICTOR

®

PARTS, or modification could result in damage to the product or

injury to the operator.

WARNING

This product contains chemicals, including lead, or otherwise

produces chemicals known to the State of California to cause cancer,

birth defects and other reproductive harm. Wash hands after

handling. (California Health & Safety Code § 25249.5 et seq.)

SECTION 2:

GENERAL SAFETY INFORMATION

Read and understand all safety and operating instructions provided before

using this apparatus. RETAIN THESE INSTRUCTIONS IN A READILY

AVAILABLE LOCATION FOR FUTURE REFERENCE.

2.01 FIRE PREVENTION

Welding and cutting operations use fire or combustion as a basic tool. The

process is very useful when properly controlled. However, it can be extremely

destructive if not performed correctly in the proper environment.

1. The work area must have a fireproof floor.

2. Work benches or tables used during welding or cutting operations

must have fireproof tops.

3. Use heat resistant shields or other approved material to protect

nearby walls or unprotected flooring from sparks and hot metal.

4. Keep an approved fire extinguisher of the proper size and type

in the work area. Inspect it regularly to ensure that it is in proper

working order. Know how to use the fire extinguisher.

2-2

Page 7

5. Move combustible materials away from the work site. If you can

not move them, protect them with fireproof covers.

WARNING

NEVER pe rform welding, heating, or cutting operations

on a container that has held toxic, combustible or flammable

liquids, or vapors. NEVER perform welding, heating, or cutting

operations in an area containing combustible vapors, flammable

liquids, or explosive dust.

2.02 HOUSEKEEPING

WARNING

NEVER allow oxygen to contact grease, oil, or other flammable

substances. Although oxygen by itself will not burn, these

substances become highly explosive. They can ignite and burn

violently in the presence of oxygen.

Keep ALL apparatus clean and free of grease, oil, and other flammable

substances.

2.03 VENTILATION

WARNING

Adequately ventilate welding, heating, and cutting work areas

to prevent accumulation of explosive or toxic concentrations

of gases. Certain combinations of metals, coatings, and gases

generate toxic fumes. Use respiratory protection equipment in these

circumstances. When welding/brazing, read and understand the

Material Safety Data Sheet for the welding/brazing alloy.

2.04 PERSONAL PROTECTION

Gas flames produce infrared radiation which may have a harmful effect on

the skin and especially on the eyes. Select goggles or a mask with tempered

lenses, shaded 4 or darker, to protect your eyes from injury and provide

good visibility of the work.

2-3

Page 8

Always wear protective gloves and flame-resistant clothing to protect skin and

clothing from sparks and slag. Keep collars, sleeves, and pockets buttoned. DO

NOT roll up sleeves or cuff pants.

When working in a non-welding or cutting environment, always wear

suitable eye protection or face shield. Practice the following safety and

operation precautions EVERY TIME you use pressure regulation equipment.

Deviation from the following safety and operation instructions can result in

fire, explosion, damage to equipment, or injury to the operator.

2.05 COMPRESSED GAS CYLINDERS

The Department of Transportation (DOT) approves the design and

manufacture of cylinders that contain gases used for welding or cutting

operations.

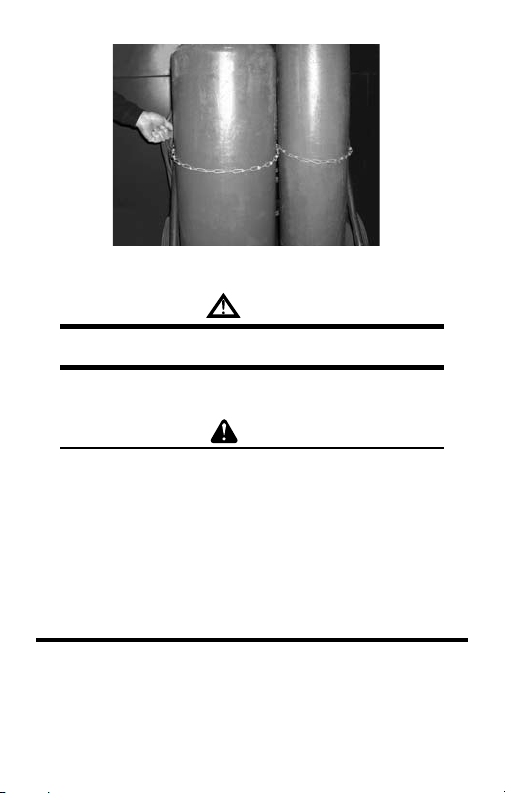

1. Place the cylinder (Figure 1) where you will use it. Keep the cylinder

in a vertical position. Secure it to a cart, wall, work bench, post, etc.

WARNING

Cylinders are highly pressurized. Handle with care. Serious

accidents can result from improper handling or misuse of

compressed gas cylinders DO NOT drop the cylinder, knock it

over, or expose it to excessive heat, flames or sparks. DO NOT

strike it against other cylinders. Contact your gas supplier or refer

to CGA P-1 “Safe Handling of Compressed Gases in Containers”

publication.

NOTE

CGA P-1 publication is available by writing the Compressed Gas

Association, 4221 Walney Road, 5th Floor, Chantilly.VA 201512923

2. Place the valve protection cap on the cylinder whenever moving

it, placing it in storage, or not using it. Never drag or roll cylinders

in any way. Use a suitable hand truck to move cylinders.

3. Store empty cylinders away from full cylinders. Mark them “EMPTY”

and close the cylinder valve.

4. NEVER use compressed gas cylinders without a pressure reducing

regulator attached to the cylinder valve.

5. Inspect the cylinder valve for oil, grease, and damaged parts.

2-4

Page 9

Figure 1: Gas Cylinders

WARNING

use the cylinder if you find oil, grease or damaged parts.

DO NOT

Inform your gas supplier of this condition immediately.

6. Momentarily open and close (called “cracking”) the cylinder valve

to dislodge any dust or dirt that may be present in the valve.

CAUTION

Open the cylinder valve slightly. If you open the valve too much,

the cylinder could tip over. When cracking the cylinder valve, DO

NOT stand directly in front of the cylinder valve. Always perform

cracking in a well-ventilated area. If an acetylene cylinder sprays

a mist when cracked, let it stand for 15 minutes. Then, try to

crack the cylinder valve again. If this problem persists, contact

your gas supplier.

SECTION 3:

TORCH HANDLES

3.01 WELDING PREPARATION

1. Be certain cylinder valves and regulator connections are completely

free of dirt, dust, oil, or grease.If oil, grease, or damage is detected

on the cylinder valves, DO NOT use the cylinder. Notify the cylinder

supplier immediately.If oil, grease, or damage is detected on the

3-5

Page 10

regulator, DO NOT use the regulator. Have the regulator cleaned

or repaired by a qualified repair technician.

2. Connect the oxygen hose to the oxygen regulator. Tighten the

connection firmly with a wrench.

3. Always open the cylinder valves slowly and carefully and check for

leaks on the regulator and cylinder valve connections.

4. Momentarily open and close the cylinder valve (commonly referred

to as “cracking”). This dislodges any loose contaminants that may

be present.

CAUTION

Open the cylinder valve only slightly. If the valve is opened too

much the cylinder could tip over. When “cracking” the cylinder

valve, DO NOT stand, nor have anyone stand directly in front of

the valve opening. Stand behind or to one side. Crack the cylinder

valve in a well-ventilated area only. If an acetylene cylinder sprays

a mist when it is cracked, let it set for 30 minutes. Then try to

crack the cylinder valve again. If the problem persists, contact

your gas supplier.

WARNING

Never stand, nor have anyone stand in front or behind a regulator

when opening the cylinder valve. Always stand so that the cylinder

is between you and the regulator.

5. Adjust the oxygen regulator to allow 3 - 5 PSIG to pass through the

hose. Allow oxygen to flow for 5 - 10 seconds to clear the hose of

dust, dirt, or preservatives. Shut off the oxygen flow.

6. Attach and clear the fuel hose in the same manner.

WARNING

Clear hoses in a well-ventilated area. The escaping gases create

conditions for fires and explosions. Keep hoses clear of any falling

metal, slag, or sparks. Never allow hoses to become coated with

oil, grease, or dirt. This could conceal damaged areas on the hoses.

Examine the hoses before attaching the torch handle or regulators.

If any cuts,burns, worn areas, cracks, or damaged fittings are found,

repair or replace the hose.

3-6

Page 11

7. Inspect the torch handle head, valves, and hose connections for oil,

grease, or damaged parts. Inspect the hose connections in the same

manner. DO NOT use them if oil, grease, or damage is detected.

8. Inspect the torch handle. The tapered seating surfaces in the head

must be in good condition. If dents or burned seats are present,

the seat must be resurfaced. If the torch handle is used with poor

seating surfaces, backfire may occur.

9. Using a 3/4" open-end wrench, check the flashback arrestors

to make sure they are tight. If loose, a flashback may have

occurred.

10. Attach the hose to the torch handle and tighten securely with a

wrench.

3.02 WELDING SETUP

1. Check the thickness of the metals to be welded. Prepare the metal

as described. Refer to the welding tip selection chart to determine

the tip size that is required and the regulator pressures for the

job.

2. Open the oxygen valve on the torch handle and adjust the oxygen

regulator to the required delivery range. Then close the torch handle

oxygen control valve to purge the oxygen hose.

3. Open the fuel valve on the torch handle and adjust the fuel regulator

to the required delivery range. Then close the torch handle fuel

control valve to purge the fuel hose.

WARNING

If the torch handle and hoses are already connected to the

regulators, the system MUST still be purged after every shutdown

in a well-ventilated area. Open the oxygen valve 1/2 turn. Allow the

gas to flow ten seconds for tips up to a size three and five seconds

for sizes 4 and larger for each 25 feet of hose in the system. Close

the oxygen valve and purge the fuel system in the same manner.

4. Wear the recommended protective goggles (shaded 5 or darker)

with tempered lenses to shield your eyes from the light. Wear

protective clothing as required.

3-7

Page 12

NOTE

The following instructions cover torch adjustment procedures for

acetylene only. Contact your gas supplier for instructions on the

use of other fuel gases.

5. Hold the torch in one hand and the spark lighter in the other. Be

sure the spark lighter is away from the tip and not obstucting the

gas flow.

6. Open the torch fuel valve approximately 1/8 turn and ignite the

gas.

CAUTION

Point the flame away from people, equipment, and all flammable

materials.

7. Continue opening the fuel valve until the flame stops smoking.

8. Open the torch oxyen valve until a bright neutral flame is

established.

WARNING

If you experience a sustained backfire (a shrill hissing sound when

the flame is burning inside the nozzle), immediately turn off the

oxygen valve on the torch handle. Then, turn off the fuel valve.

Allow the torch and nozzle time to cool before attempting to reuse.

If backfire recurs, take the apparatus to a qualified repair technician

for repair before using the equipment again.

3.03 WELDING OPERATION

1. Clean the metal joints to be welded from all scale, rust, dirt, paint,

grease, and all foreign materials.

2. Some thicker metals may require additional preparation. Base

metals 1/8" or less do not require beveling.

3. Place the metal to be welded on a non-flammable work table and

determine where the tacking will be required.

4. Begin by tacking the ends of the two pieces of metal together before

welding. Longer pieces may need to be tacked every few inches

along the joint.

3-8

Page 13

5. Longer pieces may also require additional penetration gap, VICTOR®

recommends 1/16" - 1/8".

6. Hold the torch nozzle at an angle of approximately 45° to the

joint.

7. Move the torch nozzle over the starting edges of the joint. Rotate

the flame near the metal in a circular or semicircular motion until

the base metals run into a small puddle.

8. Dip the end of the filler rod in and out of the molten puddle, this

melts the rod and adds to the puddle.

9. Continue the dipping motion of the filler rod into the puddle. Then

move the torch back and forth across the joint.

10. Advance the torch nozzle at a rate of approximately 1/16" of the

filler rod as it is added to the puddle until the end of the joint is

achieved.

3.04 WELDING OR HEATING COMPLETION

1. Shut off the torch oxygen valve. Then, shut off the torch fuel valve.

Be careful not to shut off the fuel valve first; this may create a “pop”

type sound. When the “pop” happens it throws carbon soot back

into the torch and may in time partially clog gas passages and the

flashback arrestors.

2. Close both cylinder valves.

3. Open the torch handle oxygen valve. Release the pressure from

the system and then close the torch oxygen valve.

4. Turn the adjusting screw on the oxygen regulator counterclockwise

to release all spring pressure.

5. Open the torch handle fuel valve and release the pressure from the

system. Close the torch fuel valve.

6. Turn the adjusting screw on the fuel gas regulator counterclockwise

to release all spring pressure.

7. Check the inlet gauges after a few minutes to ensure the cylinder

valves are turned off completely and there is no pressure remaining

in the system.

3-9

Page 14

SECTION 4:

CUTTING ATTACHMENT

4.01 CUTTING PREPARATION

1. Inspect the cone end, coupling nut, and torch head for oil, grease, or

damaged parts. Also inspect the cone end for missing or damaged

O-rings.

WARNING

If you find oil, grease, or damage, DO NOT use the apparatus until

it has been cleaned or repaired by a qualified repair technician.

The two O-rings on the cone end must be in place and in good

condition. The absence of either of these O-rings allows pre-mixing

of oxygen and fuel gases. This can lead to a sustained backfire

within the torch handle and cutting attachment.

2. Inspect the cutting tip and cutting attachment head. All tapered

seating surfaces must be in good condition. Discard damaged

cutting tips. If you find dents, burns, or burned seats, resurface

the torch head. If you use the cutting attachment with poor seating

surfaces, a backfire or sustained backfire may occur.

WARNING

If the tapered seats on the cutting tip are damaged, DO NOT use

the tip. Poor seating surfaces may cause a backfire or sustained

backfire.

3. Inspect the preheat and cutting oxygen holes on the tip. Slag can

stick on or in these holes. If the holes are clogged or obstructed,

clean them out with the proper size tip cleaner.

4. Insert the tip into the cutting attachment head. Tighten the tip nut

securely with a wrench (15 - 20 lbs. torque).

5. Connect the cutting attachment to the torch handle and tighten

the coupling nut until it is hand tight. DO NOT use a wrench, as

damage to the O-rings may occur creating a faulty seal.

6. Refer to the Tip Flow Data Charts for correct cutting tip, regulator

pressures, and travel speed.

4-10

Page 15

7. Follow cylinder and regulator safety and operating procedures.

8. Open the oxygen valve on the torch handle completely.

9. Open the preheat oxygen control valve on the cutting attachment

and adjust the oxygen regulator to the desired delivery pressure.

This will purge the oxygen hose.

10. Close the preheat oxygen control valve.

11. Open the fuel valve on the torch handle and adjust the fuel regulator

delivery range. This will purge the fuel hose.

12. Close the fuel control valve on the torch handle.

13. Momentarily depress the cutting oxygen lever to purge the cutting

oxygen passage in the cutting attachment.

WARNING

If the torch handle and hoses are already connected to the

regulators, the system MUST still be purged after each shutdown.

Open the oxygen valve 1/2 turn. Allow the gas to flow ten seconds

for tips up to size 3, and five seconds for sizes 4 and larger for

each 25 feet of hose in the system. Close the oxygen valve and

purge the fuel system in the same manner.

NOTE

Always wear protective clothing and proper goggles to shield your

eyes from infrared light.

14. Open the fuel valve on the torch handle approximately 1/8 turn

and ignite the gas with a spark lighter. Be sure the spark lighter is

away from the tip and not obstructing the gas flow.

15. Continue to increase the fuel supply at the torch handle until the

flame stops smoking.

16. Slowly open the preheat oxygen control valve on the cutting

attachment until the preheat flame is established with a smooth

inner cone.

17. Depress the cutting oxygen lever. If necessary, readjust the preheat

flames slightly to a neutral flame by increasing the preheat oxygen

at the cutting attachment until the preheat flames are again neutral.

If the preheat flames are not the same size and the cutting oxygen

is not straight, turn off the torch and let it cool, then clean the tip.

4-11

Page 16

WARNING

Never open and light the fuel gas torch and oxygen at the same

time.

WARNING

If you experience a sustained backfire (flame disappears and/or a

shrill hissing sound is heard caused by the flame burning inside the

cutting attachment), immediately turn off the preheat oxygen control

valve on the cutting attachment. Then turn off the torch handle fuel

valve. Allow the cutting attachment to cool before attempting to

relight. If backfire recurs, have the apparatus checked by a qualified

repair technician before using the apparatus again.

NOTE

Inspect the areas where slag and sparks will fall. Serious fires

and explosions are caused by careless torch operations. Take all

possible precautions. Have fire extinguishers available. Remove or

protect flammable substances, including oxygen and fuel hoses,

before starting to work.

18. Hold the cutting attachment and torch handle comfortably in both

hands. Stabilize the torch and position the cutting tip preheat flames

approximately 1/4" from the base metal.

19. Direct the preheat flame to the spot where the cut is to begin.

Before the cutting action can start, preheat the starting point of

the metal to a bright cherry red kindling temperature. When the red

spot appears, depress the cutting oxygen lever slowly and fully.

20. When the cut starts, move the torch in the direction you wish to

cut.

NOTE

Moving too slowly allows the cut to fuse together. Moving too fast

will not preheat the metal and the cut will be lost.

21. Continue to fully depress the cutting oxygen lever until the cutting

oxygen stream is past the base metal for a good drop cut.

4-12

Page 17

4.02 CUTTING COMPLETION

1. Shut off the oxygen preheat valve. Then, close the torch fuel valve.

Be careful not to shut off the fuel valve first, this may create a “pop"

type sound. When the “pop” happens it throws carbon soot back

into the torch and may in time partially clog gas passages and the

flashback arrestors.

2. Close both cylinder control valves on the gas source supply.

3. Open the oxygen valve and depress the cutting oxygen lever.

Release the pressure from the system and then close the oxygen

preheat and the torch handle oxygen control valve.

4. Turn the adjusting screw on the oxygen regulator counterclockwise

to release all spring pressure.

5. Open the torch fuel control valve and release the pressure from

the system. Close the fuel valve.

6. Turn the adjusting screw on the fuel gas regulator counterclockwise

to release all spring pressure.

7. Check the inlet gauges after a few minutes to ensure the cylinder

valves are turned off completely and no pressure remains in the

system.

8. Remove slag left on the cut edge with a chipping hammer or brush.

Never remove slag from the cut edge with the torch head or cutting

tip.

SECTION 5:

CHECK VALVES AND FLASH ARRESTORS

5.01 REVERSE FLOW CHECK VALVES

The body “Y” has two control valves attached to it. The valve bodies are

marked to distinguish between the two valves. The body of one valve has

left-hand threads to accept the fuel gas hose. The other valve body has

right-hand threads to accept the oxygen hose. The control valves never

require lubricating. Occasionally, the packing nuts may require a slight

adjustment.

Most VICTOR® torch handles are equipped with patented built-in reverse

flow check valves to reduce the possibility of mixing gases in the hoses

and regulators.

5-13

Page 18

CAUTION

Check valves are mechanical devices that can leak when dirty

or if abused. Check valves should be tested at least every six

months, more often if hoses are frequently disconnected. Careless

usage, dirt or abuse can shorten the service life of check valves,

thus requiring more frequent testing. Follow the manufacturer’s

instructions for testing the check valves.

NOTE

Reverse flow check valves are not the same as flashback arrestors.

Check valves are designed to help prevent reverse flow of gas

upstream of the torch. Flashback arrestors are designed to prevent

mixed gases from igniting upstream of the flashback arrestors.

5.02 FLASHBACK ARRESTORS

NOTE

VICTOR® torch handle model numbers that contain the letters

“FC” are equipped with built-in flashback arrestors and check

valves (i.e. 315FC). Model numbers with a “C” only contain built-in

check valves (i.e. 315C). Earlier versions without an “F” or “C” in

the model number contained neither (i.e. 315). For all “C” model

torch handles and earlier versions, it is recommended that add-on

flashback arrestors be installed. Most add-on flashback arrestors

also contain built-in check valves.

Most VICTOR® torch handles are equipped with built-in flashback arrestors.

Flashback arrestors are designed to prevent mixed gases from igniting

upstream of the flashback arrestors.

CAUTION

It is not recommended to use accessory flashback arrestors on

VICTOR® FC torch handles since these devices are already built-in.

Excessive flow restrictions may occur.

The flashback arrestors contained in this torch are designed to prevent a

flashback flame from entering the hose and gas supply system. A very fine

“filter-like” sintered stainless steel flame barrier stops flashback flame.

For maximum service life of the flashback arrestor, completely purge

all lines and hoses before connecting to the torch. This removes loose

5-14

Page 19

material contained in the hose or regulator that could restrict flow through

the flashback arrestor.

Flow restriction and torch overheating results if dirt or “oily” LPG residuals

are allowed to flow into the flashback arrestor and cause clogging. Make

sure not to draw liquid.

Always store and use cylinders in the upright position.

5.03 LEAK TESTING

The system MUST be tested for leaks before lighting the torch. To leak test

the system perform the following steps.

1. Be sure that both the oxygen and fuel control valves on the torch

handle are closed.

2. With the oxygen cylinder valve open, adjust the oxygen regulator

to deliver 20 PSIG.

3. With the fuel cylinder valve open, adjust the fuel regulator to deliver

10 PSIG.

4. Close both the oxygen and fuel cylinder valves.

5. Turn the adjusting screws counterclockwise 1/2 turn.

6. Observe the gauges on both regulators for five minutes. If the gauge

readings do not change, then the system is leak tight. If there is

a leak, use an approved leak detection solution to locate it. If the

inlet gauge reading decreases, there is a leak at the cylinder valve

or inlet connection. Tighten the inlet connection after the pressure

has been released from the regulator. If the inlet connection still

leaks try another cylinder. If the same leak develops, take the

regulator to a qualified repair technician. Never tighten a cylinder

valve. If the cylinder valve is leaking, remove the regulator from the

cylinder, place the cylinder outdoors and notify your gas supplier

immediately. If the delivery gauge reading decreases, there is a

leak at the regulator outlet connection, within the hose, at the

torch inlet connection or at the control valves on the torch handle.

Tighten the regulator outlet connection and the torch handle inlet

connection after the pressure has been released from the system. If

the connections are still leaking, take the regulator or torch handle

to a qualified repair technician. If the hoses are leaking, replace

them. If the high pressure gauge drops and at the same time the

5-15

Page 20

delivery gauge rises, there is a leak in the regulator seat. Take the

regulator to a qualified repair technician for repair.

7. After leak testing the system, open the cylinder valves and

proceed.

WARNING

If a leak has been detected anywhere in the system, discontinue

use and have the system repaired. DO NOT use leaking equipment.

Do not attempt to repair a leaking system while the system is under

pressure. Perform all operations in a well-ventilated area to help

prevent the concentration of flammable or toxic fumes.

SECTION 6:

WELDING NOZZLES

1. Inspect the cone end, coupling nut, O-rings, and welding nozzle

for damage, oil or grease. Do not use if damage or contaminants

are present.

WARNING

There must always be two O-rings on the cone end. The absence or

damage of either of these O-rings allows premixing of the oxygen

and fuel gases. This can lead to a sustained backfire within the

torch handle.

2. Connect the welding nozzle to the torch handle. Tighten the coupling

nut HAND TIGHT only. Using a wrench could damage the O-rings

and create a faulty seal.

MULTI-FLAME HEATING NOZZLES (ROSEBUDS)

Multi-flame heating nozzles are set up exactly as the welding nozzle.

Follow the safety and operation procedures described above for the

welding nozzle.

CAUTION

Never starve or choke a welding nozzle or multi-flame heating

nozzle. This causes overheating of the nozzle and a backfire or

sustained backfire may result. Should a sustained backfire occur

(flame pops and disappears and/or a hissing sound is heard, the

flame is burning inside the nozzle), immediately turn off the oxygen

6-16

Page 21

valve on the torch handle. Then, turn off the fuel valve. Allow the

nozzle to cool before using it. If a backfire reoccurs, have the

apparatus checked by a qualified technician before using again.

SECTION 7:

SPECIFICATIONS

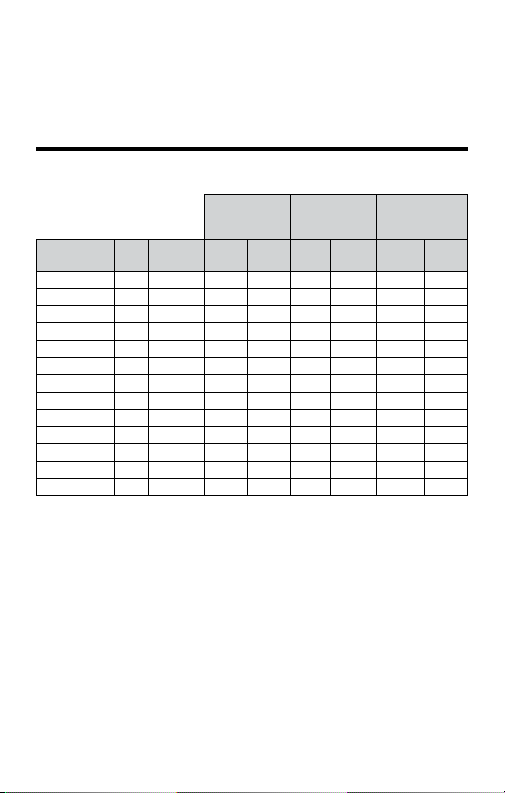

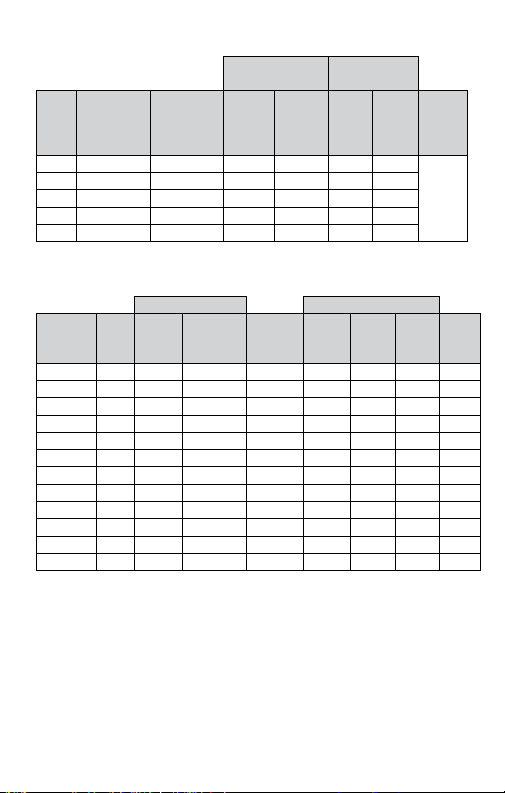

WELDING NOZZLE FLOW DATA

Oxygen

Pressure

Metal

Thickness

Up to 1/32" 000 75 (.022) 3 5 3 5 1 2

1/16" - 3/64" 00 70 (.028) 3 5 3 5 1 1/2 3

1/32" - 5/64" 0 65 (.035) 3 5 3 5 2 4

3/64" - 3/32" 1 60 (.040) 3 5 3 5 3 6

1/16" - 1/8" 2 56 (.046) 3 5 3 5 5 10

1/8" - 3/16" 3 53 (.060) 4 7 3 6 8 18

3/16" - 1/4" 4 49 (.073) 5 10 4 7 10 25

1/4" - 1/2" 5 43 (.089) 6 12 5 8 15 35

1/2" - 3/4" 6 36 (.106) 7 14 6 9 25 45

3/4" - 1 1/4" 7 30 (.128) 8 16 8 10 30 60

1 1/4" - 2" 8 29 (.136) 10 19 9 12 35 75

2 1/2" - 3" 10 27 (.144) 12 24 12 15 50 100

3 1/2" - 4" 12* 25 (.149) 18 28 12 15 80 160

Tip

Size

Drill Size

(PSIG)

Min Max Min Max Min Max

Acetylene

Pressure

(PSIG)

Acetylene

Consumption

(SCFH)

7-17

Page 22

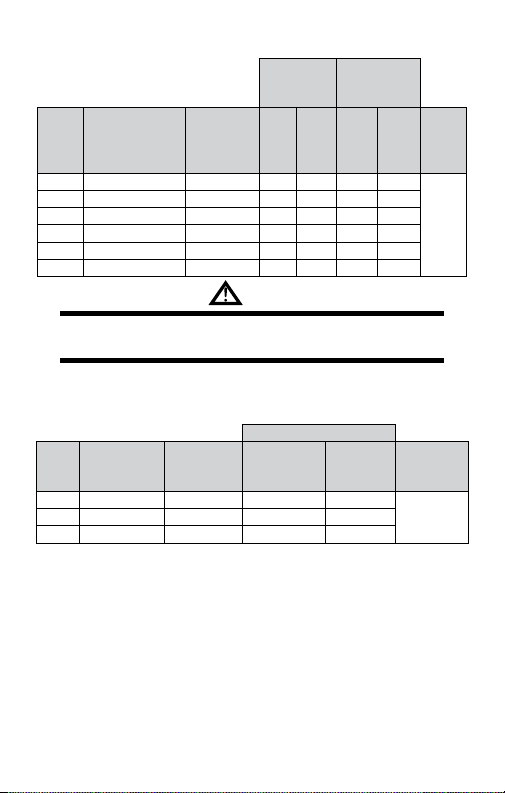

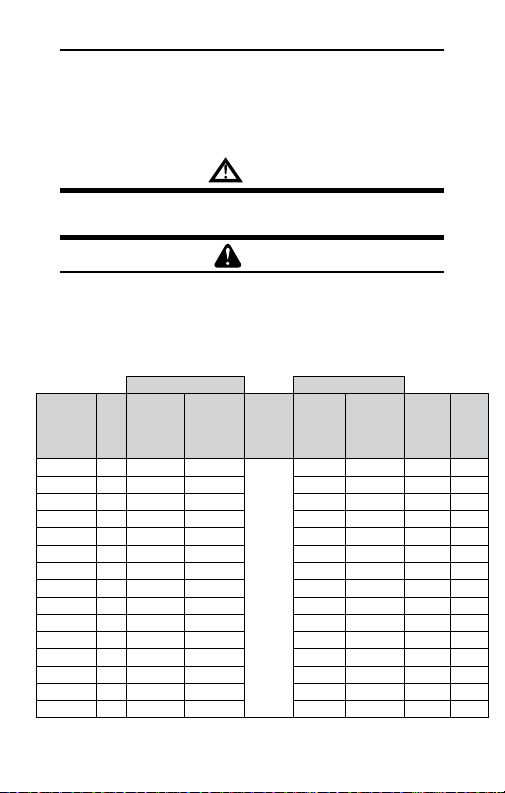

MFA HEATING NOZZLES

Acetylene

Cubic Feet

per Hour

Acetylene

Tip

Pressure Range

Size

4 6 -10 8 - 12 6 20 7 22

6 8 -12 10 - 15 14 40 15 44

8 10 - 15 20 - 30 30 80 33 88

10 12 - 15 30 - 40 40 100 44 110

12* 12 - 15 50 - 60 60 150 66 165

15* 12 - 15 50 - 60 90 220 99 244

(PSIG)

At no time should the withdrawal rate of an individual acetylene cylinder exceed

1/7 of the cylinder contents per hour. If additional flow capacity is required, use an

acetylene manifold system of sufficient size to supply the necessary volume.

Oxygen

Pressure

Range

(PSIG)

Min Max Min Max

WARNING

Oxygen

Cubic Feet per

Hour

TYPE 55 NOZZLES

Not For Use With Acetylene

Oxygen

Tip

Pressure

Size

(PSIG)

10* 70 - 100 15 - 25 350 - 460 150 - 200

15* 90 - 120 20 - 35 600 - 800 250 - 350

20* 100 - 150 30 - 50 900 - 1150 400 - 500

*Use model HD310C torch and 3/8" hose.

Fuel Gas

Pressure

(PSIG)

Consumption (SCFH)

Oxygen

Fuel Gas BTU Hour

BTU

per

Hour

See

Note,

page

23

See Note,

page 23

7-18

Page 23

MFN HEATING NOZZLES

Propane Cubic

Propane

Tip

Pressure

Range

Size

(PSIG)

8 10-15 10-20 10 35 40 140

10 12-20 10-30 20 80 80 320

12* 15 - 25 30 - 125 30 160 120 640

15* 15 - 25 30 - 125 50 200 200 800

20* 20 - 30 40 - 135 75 250 300 1000

*Use model HD310C torch and 3/8" hose.

Oxygen

Pressure

Range

(PSIG)

Feet per Hour

Min Max Min Max

Oxygen Cubic

Feet per Hour

BTU per

Hour

See

Note,

page

23

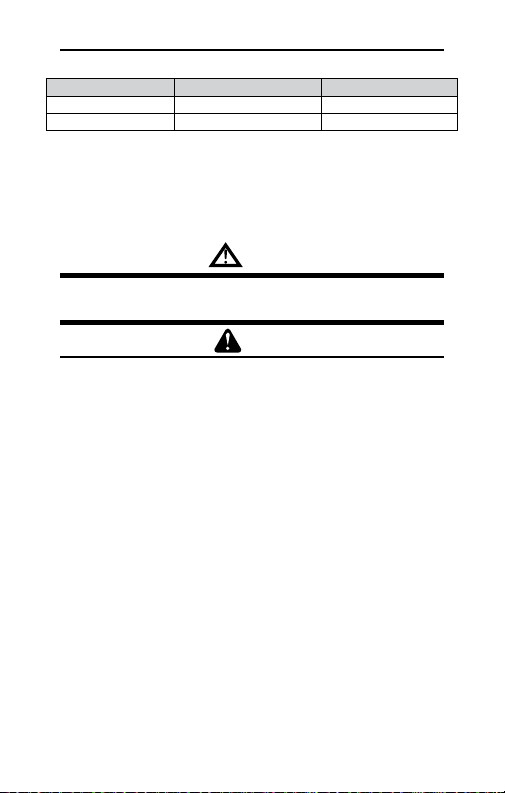

TYPES 1-101, 3-101 (OXY-ACETYLENE)

Cutting Oxygen Acetylene

-

Tip

Size

Pres

sure***

(PSIG)

Flow***

(SCFH)

Metal

Thickness

1/8" 000 20 - 25 20 - 25 3 - 5 3 - 5 6 - 11 20 - 30 .04

1/4" 00 20 - 25 30 - 35 3 - 5 3 - 5 6 - 11 20 - 28 .05

3/8" 0 25 - 30 55 - 60 3 - 5 3 - 5 6 - 11 18 - 26 .06

1/2" 0 30 - 35 60 - 65 3 - 6 3 - 5 9 - 16 16 - 22 .06

3/4" 1 30 - 35 80 - 85 4 - 7 3 - 5 8 - 13 15 - 20 .07

1" 2 35 - 40 140 - 160 4 - 8 3 - 6 10 - 18 13 - 18 .09

2" 3 40 - 45 210 - 240 5 - 10 4 - 8 14 -24 10 - 12 .11

3" 4 40 - 50 280 - 320 5 - 10 5 - 11 18 - 28 10 - 12 .12

4" 5 45 - 55 390 - 450 6 - 12 6 - 13 22 - 30 6 - 9 .15

6" 6** 45 - 55 500 - 600 6 - 15 8 - 14 25 - 35 4 - 7 .15

10" 7** 45 - 55 700 - 850 6 - 20 10 - 15 25 - 35 3 - 5 .34

12" 8** 45 - 55 900 - 1050 7 - 25 10 - 15 25 - 35 3 - 4 .41

* Applicable for three-hose machine cutting torches only. With a two-hose cuting torch,

preheat pressure is set by the cuttting oxygen.

** For best results use HC1200C series torches and 3/8" hose using a size 6 tip or

larger.

*** All pressures are measured at the regulator using 25' x 1/4" hose through tip size 5,

and 25' x 3/8" hose for tip size 6 and larger.

Pre-heat

Oxygen*

(PSIG)

Pres-

sure

(PSIG)

Flow

(SCFH)

Speed

(IPM)

Kerf

Width

7-19

Page 24

Approximate gross BTU contents per cubic foot:

Acetylene - 1470

•

Butane - 3374

•

Natural Gas - 1000

•

Propane - 2458

•

At no time should the withdrawal rate of an individual acetylene cylinder exceed

1/7 of the cylinder contents per hour. If additional flow capacity is required, use an

acetylene manifold system of sufficient size to supply the necessary volume.

NOTE

•

•

•

WARNING

Mapp - 2406

Methane - 1000

Propylene - 2371

Always make sure your equipment is rated for the size tip you have selected. A tip

with too much capacity for the equipment can starve or choke the tip. This causes

overheating of the head and a backfire may result. Use only genuine VICTOR®,

Cutskill®, or Firepower® cutting tips, welding nozzles and multi-flame nozzles to

ensure leak-free connections and balanced equipment.

CAUTION

TYPES 303M, GPM, GPN, GPP

Cutting Oxygen Pre-Heat Fuel Gas

Metal

Tip

Thickness

1/8" 000 20 - 25 12 - 14

1/4" 00 20 - 25 22 - 26 3 - 5 5 - 7 20 - 28 .05

3/8" 0 25 - 30 45 - 55 3 - 5 8 - 10 18 - 26 .06

1/2" 0 30 - 35 50 - 55 3 - 5 8 - 10 16 - 22 .06

3/4" 1 30 - 35 70 - 80 4 - 6 10 - 12 15 - 20 .08

1" 2 35 - 40 115 - 125 4 - 8 12 - 15 13 - 20 .09

1 1/2" 2 40 - 45 125 - 135 4 - 8 12 - 15 13 - 18 .09

2" 3 40 - 45 150 - 175 5 - 9 14 - 18 11 - 13 .10

2 1/2" 3 45 - 50 175 - 200 5 - 9 14 - 18 10 - 12 .10

3" 4 40 - 50 210 - 250 6 - 10 16 - 20 8 - 10 .12

4" 5 45 - 55 300 - 360 8 - 12 20 - 30 6 - 9 .14

5" 5 50 - 55 330 - 360 8 - 12 20 - 30 4 - 7 .14

6" 6 45 - 55 400 - 500 10 - 15 25 - 35 3 - 5 .17

8" 6 55 - 65 450 - 500 10 - 15 25 - 35 3 - 4 .18

12" 8** 60 - 70 750 - 850 10 - 14 25 - 120 3 - 4 .41

Size

Pressure

*** PSIG

Flow

SCFH

Pre-

Heat

Oxygen

PSIG

Note,

page

Pressure

PSIG

3 - 5 5 - 6 20 - 30 .04

See

23

Flow

SCFH

Speed

IPM

7-20

Kerf

Width

Page 25

The above data applies to all torches with the following exceptions:

Torch Series Pre-heat Oxygen Pre-heat Fuel

MT 200 Series N/A 8 oz. - Up

MT 300 Series 10-50 PSIG 8 oz. - Up

* Applicable for 3-hose machine cutting torches only. With a two hose cutting torch,

preheat pressure is set by the cuttting oxygen.

** For best results use HC1200C and HC1100C series torches and 3/8" hose when using

a size 6 tip or larger.

*** All pressures are measured at the regulator using 25' x 3/8" hose for tip size 6 and

larger.

High gas withdrawal rates require use of a manifold system of sufficient size to

supply the necessary volume. High gas withdrawal rates may also require use

of a vaporizer.

NOTE:

WARNING

Always make sure your equipment is rated for the size tip you have selected. A tip

with too much capacity for the equipment can starve or choke the tip. This causes

overheating of the head and a backfire may result. Use only genuine VICTOR®,

Cutskill® or Firepower® cutting tips, welding nozzles and multi-flame nozzles to

ensure leak-free connections and balanced equipment.

CAUTION

7-21

Page 26

SECTION 8:

STATEMENT OF WARRANTY

LIMITED WARRANTY: THERMADYNE® warrants that its products will

be free of defects in workmanship or material. Should any failure to

conform to this warranty appear within the time period applicable to the

THERMADYNE products as stated below, THERMADYNE shall, upon

notification thereof and substantiation that the product has been stored,

installed, operated, and maintained in accordance with THERMADYNE’s

specifications, instructions, recommendations and recognized standard

industry practice, and not subject to misuse, repair, neglect, alteration,

or accident, correct such defects by suitable repair or replacement, at

THERMADYNE’s sole option, of any components or parts of the product

determined by THERMADYNE to be defective.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: THERMADYNE shall not under any

circumstances be liable for special or consequential damages, such as,

but not limited to, damage or loss of purchased or replacement goods,

or claims of customers of distributor (hereinafter the “Purchaser") for

service interruption. The remedies of the Purchaser set forth herein are

exclusive and the liability of THERMADYNE with respect to any contract,

or anything done in connection therewith such as the performance

or breach thereof, or from the manufacture, sale, delivery, resale, or

use of any goods covered by or furnished by THERMADYNE whether

arising out of contract, negligence, strict tort, or under any warranty,

or otherwise, shall not, except as expressly provided herein, exceed

the price of the goods upon which such liability is based.

THIS WARRANTY BECOMES INVALID IF REPLACEMENT PARTS OR

ACCESSORIES ARE USED WHICH MAY IMPAIR THE SAFETY OR

PERFORMANCE OF ANY THERMADYNE PRODUCT.

THIS WARRANTY IS INVALID IF THE PRODUCT IS SOLD BY NONAUTHORIZED PERSONS.

This warranty is effective for the time stated in the Warranty Schedule

beginning on the date that the authorized distributor delivers the

products to the Purchaser.

8-22

Page 27

Warranty repairs or replacement claims under this limited warranty

must be submitted by an authorized THERMADYNE repair facility within

thirty (30) days of the repair. No transportation costs of any kind will

be paid under this warranty. Transportation charges to send products

to an authorized warranty repair facility shall be the responsibility of

the Purchaser. All returned goods shall be at the Purchaser’s risk

and expense. This warranty supersedes all previous THERMADYNE

warranties.

8-23

Page 28

Les Chalumeaux, Les

Attachements Coupeurs

et Buses de Chauffage

English

Français

Español

Guide d’installation et

d’utilisation

Date d’émission: 14 Mai 2008Révision: C Nº de document: 0056-0138

Page 29

VOTRE ACTIVITÉ NOUS INTÉRESSE!

Félicitations pour votre nouveau produit Victor®. Nous sommes fiers de vous avoir

comme client et nous tâcherons de vous fournir les meilleurs services et fiabilité

dans l’industrie. Ce produit est soutenu par une vaste garantie et un réseau mondial

de service. Pour localiser votre distributeur ou agence de service le plus proche,

veuillez communiquer avec un représentant à l’adresse ou au numéro de téléphone

correspondant à votre région, indiqué au verso de la couverture du manuel, ou visitez

notre site web www.victorequip.com.

Ce Manuel d’utilisation a été conçu pour vous permettre d’utiliser et de faire fonctionner

correctement votre produit Victor®. Votre satisfaction et le fonctionnement en toute

sécurité de votre produit sont nos principaux soucis. Par conséquent, veuillez prendre

le temps de lire tout le manuel, spécialement en ce qui concerne les Précautions de

Sécurité. Ceci vous aidera à éviter déventuels accidents qui pourraient survenir en

travaillant avec ce produit.

VOUS ÊTES EN BONNE COMPAGNIE!

La Marque de Choix pour les Entrepreneurs et les Fabricants

dans le Monde.

Victor® est une marque mondialement reconnue pour ses produits d’équipement de

gaz pour Thermadyne Industries, Inc. Nous fabriquons et fournissons dans le monde

entier aux secteurs industriels majeurs de soudage et coupage, incluant fabrication,

construction, exploitation minière, automobile, aérospatiale, ingénierie, rural et

bricolage/hobby, reyclage, démolition et construction navale.

Nous nous distinguons de notre concurrence grâce à nos produits en tête du marché,

fiables, ayant résisté à l’épreuve du temps. Nous sommes fiers de notre innovation

technique, nos prix compétitifs, notre excellente livraison, notre service clientèle et

notre support technique de qualité supérieure, ainsi que de l’excellence dans les

ventes et l’expertise en marketing.

Surtout, nous nous engageons à développer des produits utilisant des technologies

de pointe pour obtenir un environnement de travail plus sécurisé dans l’industrie

de la soudure.

Page 30

AVERTISSEMENT

Lisez et comprenez tout le Manuel et les pratiques de sécurité de l’utilisateur

avant l’installation, le fonctionnement ou l’entretien de l’équipement. Même si

les informations contenues dans ce Manuel représentent le meilleur jugement

du Fabricant, celui-ci n’assume aucune responsabilité pour son usage.

Les Chalumeaux, Les Attachements Coupeurs et Buses de Chauffage

Guide d’installation et d’utilisation

Numéro du Manuel d’Instructions pour 0056-0138

Publié par:

Thermadyne® Products Inc.

2800 Airport Road

Denton, TX 76208

(940) 566-2000

www.victorequip.com

Copyright © 2008 par Thermadyne Industries Inc.

® Tous droits réservés.

La reproduction, de tout ou partie de ce manuel, sans l’autorisation écrite de l’éditeur,

est interdite.

L’éditeur n’assume pas et dément toute responsabilité pour perte ou dommage causés

à une partie par erreur ou omission dans ce manuel, si une telle erreur résulte d’une

négligence, d’un accident, ou de toute autre cause.

Date de Parution: 19 Marche 2008

Complétez les informations suivantes à des fins de garantie:

Lieu D’achat: ___________________________________________________

Date D’achat: ___________________________________________________

Numéro de: ____________________________________________________

i

Page 31

Table of Contents

SECTION 1: INTRODUCTION ........................................................ 1-1

SECTION 2: INFORMATIONS GÉNÉRALES DE SÉCURITÉ ............. 2-2

2.01 Prévention D’incendie ........................................ 2-2

2.02 Entretien des Locaux ......................................... 2-3

2.03 Aération ............................................................. 2-3

2.04 Protection Personnelle ......................................2-4

2.05 Bouteilles de Gaz Comprimé .............................. 2-4

SECTION 3: LES CHALUMEAUX ...................................................3-6

3.01 Préparation de Soudure ..................................... 3-6

3.02 Installation de Soudure ......................................3-8

3.03 Opération de Soudure ......................................3-10

3.04 Accomplissement de Soudure et

de Chauffage ................................................... 3-10

SECTION 4: LES ATTACHEMENTS COUPEURS ...........................4-11

4.01 Préparation de Découpage............................... 4-11

4.02 Accomplissement de Découpage ..................... 4-15

SECTION 5: CLAPETS ANTI-RETOUR ET LES

5.01 Clapets Anti-Retour .........................................5-16

5.02 Les Intercepteurs de Retour de Flamme .......... 5-16

5.03 Recherche de Fuites ........................................5-17

SECTION 6: BUSE DE BRASAGE ................................................6-19

SECTION 7: CARACTÉRISTIQUES .............................................. 7-20

SECTION 8: GARANTIE .............................................................. 8-26

INTERCEPTEURS DE RETOUR DE FLAMME .........5-16

ii

Page 32

SECTION 1:

INTRODUCTION

Ce fascicule est un guide pour une utilisation sécurisée et efficace l’appareil

utilisés dans les applications à gaz oxygène carburant. Si l’appareil n’est

pas utilisé dans cet environnement, l’opérateur doit malgré tout appliquer

les procédures d’emploi qui s’appliquent à son application particulière.

Il y a plusieurs dangers potentiels à j’utilisation. Lisez complètement et

soigneusement ce fascicule avant de faire fonctionner cet équipement.

Toutes les opérations doivent être en conformité avec les règlements

fédéraux, d’état, de province ou ville applicables, pour l’installation, le

fonctionnement, la ventilation, la prévention d’incendie et la protection

des personnes. La norme ANSI Z49.1, “Sécurité en soudage et découpe”,

contient des instructions de sécurité détaillées. Elle peut s’obtenir auprès de

l’American Welding Society, P.O. Box 351040, Miami, FL 33135, U.S.A.

Un ensemble de conseils attirant l’attention et avertissant met en avant

des informations importantes sur la sécurité et le fonctionnement dans ce

document. Il s’agit de:

AVIS

Lavis donne de conseils d’installationou des informations

d’entretien qui sontimportants mais n’impliquent pas derisques.

MISE EN GARDE

La mention d’mise en garde indique une situation potentiellement

dangereuse qui, sans précautions, peut entraîner des dom.

AVERTISSEMENT

L’avertissement indique une situation potentiellement dan gereuse

qui, sans précautions, peut entraîner des dommages graves voire

mortels.

AVERTISSEMENT

N’essayez pas d’utiliser cet appareil sauf si vous êtes formé à sa

bonne utilisation ou bénéficiez d’une supervision qualifiée. Pour

votre sécurité, mettez en pratique les procédures de sécurité et

de mode opératoire décrites dans ce fascicule à chaque fois que

vous utilisez cet appareil. Si vous déviez de ces procédures, cela

peut entraîner incendie, explosion, dégâts matériels et/ou blessures

1-1

Page 33

corporelles. Si à un moment quelconque l’appareil que vous utilisez

ne se comporte pas de la façon habituelle, ou si vous éprouvez

des difficultés à le faire fonctionner, arrêtez immédiatement de

l’utiliser. Ne vous en servez plus jusqu’à ce que le problème ait

été corrigé!

AVERTISSEMENT

L’entretien ou la réparation de l’appareil ne doit être effectué que

par un technicien de support qualifié à même de s’occuper d’un

appareillage à gaz en stricte conformité avec les notes techniques

de pièces et réparation applicables pour les produits construits

par VICTOR®. Une mauvaise exécution de réparation, ou une

modification du produit, peut entraîner des dommages au produit

ou/blesser son opérateur. La réparation inexacte de service,

L’UTILISATION DES PIÈCES NON-VÉRITABLES DE VICTOR®, ou

la modification ont pu avoir comme conséquence les dommages

au produit ou les dommages à l’opérateur.

AVERTISSEMENT

Ce produit contient des produits chimiques, comme le plomb, ou

engendre des produits chimiques, reconnus par l’état de Californie

comme pouvant être à l’origine de cancer, de malformations fœtales

ou d’autres problèmes de reproduction. Il faut se laver les mains

après toute manipulation. (Code de Californie de la sécurité et

santé, paragraphe 25249.5 et suivants)

SECTION 2:

INFORMATIONS GÉNÉRALES DE SÉCURITÉ

Lisez et assimilez toutes les instructions de sécurité et de fonctionnement

fournies avant d’utiliser cet appareil. Gardez toutes ces instructions à un

emplacement facilement accessible comme référence ultérieure.

2.01 PRÉVENTION D’INCENDIE

Les opérations de soudage utilisent le feu ou la combustion comme outil de

base. Ce processus est très utile quand il est correctement contrôlé.

1. La zone doit comporter un sol ignifugé.

2-2

Page 34

2. Les établis ou tables utilisés pendant les opérations de

soudage doivent avoir un revêtement ignifuge.

3. Utilisez des écrans résistants à la chaleur ou en matériau approuvé

pour protéger les cloisons proches ou le sol vulnérable des

étincelles et du métal chaud.

4. Gardez un extincteur approuvé du bon type et de la bonne taille dans

la zone de travail. Inspectez-le régulièrement pour vous assurer

qu’il est en état de fonctionner. Apprenez à vous en servir.

5. Enlevez tous les matériaux combustibles de la zone de travail.

Si vous ne pouvez pas les enlever, protégez-les avec une couvre

ignifuge.

AVERTISSEMENT

N’effectuez JAMAIS d’opérations de soudage sur un récipient

qui a contenu des liquides ou vapeurs toxiques, combustibles

ou inflammables. N’effectuez JAMAIS d’opérations de soudage

dans une zone contenant des vapeurs combustibles, des liquides

inflammables ou des poussières explosives.

2.02 ENTRETIEN DES LOCAUX

AVERTISSEMENT

Ne laissez jamais l’oxygène en contact avec la graisse, l’huile ou

d’autres substances inflammables. Bien que l’oxygène ellemême

ne brûle pas, ces substances peuvent devenir extrêmement

explosives. Elles peuvent prendre feu et brûler violemment en

présence d’oxygène.

Gardez TOUS les appareils propres et exempts de graisse, huile ou autres

substances inflammables.

2.03 AÉRATION

AVERTISSEMENT

Ventilez les zones de soudage, chauffage et découpage de façon

adéquate pour éviter l’accumulation de gaz explosifs ou toxiques.

Certaines combinaisons de métaux, revêtements et gaz génèrent

des fumées toxiques: Utilisez un équipement de protection

2-3

Page 35

respiratoire dans ces circonstances. Si vous soudez ou brasez, lisez

et assimilez la fiche technique de sécurité de matériau relative à

l’alliage de soudage/brasage.

2.04 PROTECTION PERSONNELLE

Les flammes de gaz produisent une radiation infrarouge qui peut avoir un

effet néfaste sur la peau, et particulièrement sur les yeux. Choisissez des

lunettes ou un masque avec des verres trempés assombris au niveau 4 ou

plus sombre, pour protéger vos yeux des dommages et garder une bonne

visibilité sur le travail.

Portez en permanence des gants de protection et des vêtements ignifuges

pour la protection de la peau et des vêtements contre les étincelles et le

laitier. Gardez col, manches et poches boutonnés. Il ne faut pas remonter

vos manches ou les pantalons à revers.

Quand vous travaillez dans un environnement non dédié au soudage ou

découpage, portez toujours une protection des yeux appropriées ou un

masque facial.

AVERTISSEMENT

Mettez en pratique les procédures de sécurité et de mode opératoire

suivantes à chaque fois que vous utilisez cet appareil de régulation

de pression. Si vous déviez de ces procédures, cela peut entraîner

incendie, explosion, dégâts matériels et/ou blessures corporelles

pour l’opérateur. *

AVIS

Ce document CGA p. t peut être obtenu en écrivant à “Compressed

Gas Association”, 4221 Walney Roed, 5th Floor. Chantilly, VA

20151.2923, USA.

2.05 BOUTEILLES DE GAZ COMPRIMÉ

Le Département des Transports américain (DOT) approuve la conception

et la fabrication des bouteilles qui contiennent les gaz utilisés pour les

opérations de soudage ou de découpage.

1. Placez la bouteille (Le schéma 1) là où elle sera utilisée. Gardez-la

en position verticale. Fixez-la sur un chariot une cloison, un établi, etc.

2-4

Page 36

Le schéma 1: Cylindres de gaz

AVERTISSEMENT

Les bouteilles sont sous haute pression. Manipulez-les avec

précautions. Des accidents sérieux peuvent résulter d’une

mauvaise manutention ou d’un mauvais emploi des bouteilles

de gaz comprimé. NE faites PAS tomber la bouteille, ne la cognez

pas, ne l’exposez pas à une chaleur excessive, aux flammes ou

étincelles. NE la cognez PAS contre d’autres bouteilles. Contactez

votre fournisseur de gaz ou reportezvous à la publication CGA

P-1 “Manipulation sécurisée des gaz comprimés en conteneur”

pour plus d’informations sur l’utilisation et la manutention des

bouteilles.

2. Placez le bouchon de protection de vanne sur la bouteille à chaque

fois que vous la déplacez ou ne l’utilisez pas. Ne faites jamais

glisser ou rouler d’aucune manière les bouteilles. Utilisez un diable

approprié pour les déplacer.

3. Entreposez les bouteilles vides à l’écart des bouteilles pleines.

Marquez-les “VIDE” et refermez leur vanne.

4. N’utilisez JAMAIS des bouteilles de gaz comprimé sans un

régulateur de pression en série sur la vanne de bouteille.

5. Inspectez la vanne de bouteille pour y détecter de l’huile ou de la

graisse, ou dès pièces endommagées.

2-5

Page 37

AVERTISSEMENT

N’UTILISEZ PAS la bouteille si vous trouvez de l’huile, de la graisse

ou des pièces endommagées. Informez immédiatement votre

fournisseur de’ gaz de cet état.

6. Ouvrez et fermez momentanément la vanne de la bouteille,

délogeant ainsi d’éventu lIes poussières ou saletés. qui pourraient

être présentes dans la vanne.

MISE EN GARDE

Ouvrez la vanne de bouteille légèrement. Si vous l’ouvrez trop en grand,

la bouteille pourrait se renverser. Quand vous ouvrez/fermez rapidement

la vanne de bouteille, ne vous tenez pas directement devant. Opérez

toujours cette opération dans une zone bien ventilée. Si une bouteille

d’acétylène crache un brouillard, laissez reposer pendant 15 minutes.

Essayez de nouveau la vanne. Si le problème persiste, contactez votre

fournisseur de gaz.

SECTION 3:

LES CHALUMEAUX

3.01 PRÉPARATION DE SOUDURE

1. Assurez-vous que les robinets de la bouteille et les branchements

du détendeur sont dépourvus de poussières, saletés ou graisse.Si

vous détectez de l’huile, de la graisse ou des dommages sur les

robinets de la bouteille, ne l’utilisez PAS. Avisez le fournisseur de

bouteilles immédiatement.Si vous détectez de l’huile, de la graisse

ou des dommages sur le détendeur, ne l’utilisez PAS. Faites nettoyer

ou réparer le détendeur par un technicien de réparation qualifié.

2. Branchez le tuyau d’oxygène au détendeur d’oxygène. Serrez le

branchement solidement à l’aide d’une clé.

3. Ouvrez toujours les robinets de la bouteille très lentement et

avec précaution.Vérifiez toujours la présence de fuites sur les

branchements du détendeur et du robinet de la bouteille.

4. Ouvrez lentement et soigneusement le robinet de la bouteille

d’oxygène jusqu’à ce que la pression maximum apparaisse sur

3-6

Page 38

le manomètre haute pression. Ouvrez maintenant le robinet de la

bouteille entièrement afin de sceller sa garniture d’étanchéité.

MISE EN GARDE

Ouvrez le robinet de la bouteille d’acétylène environ trois quarts

de tour mais pas plus d’un tour et demi. Pour tous les autres gaz

combustibles, ouvrez la bouteille entièrement. Gardez la clé, si

une est nécessaire, sur le robinet de la bouteille afin de pouvoir

rapidement fermer le robinet en cas de présence d’une situation

d’urgence.

AVERTISSEMENT

Ne vous placez, ni ne laissez une personne se tenir debout

directement devant ou derrière un détendeur lors de l’ouverture

du robinet de la bouteille. Tenez-vous debout de façon à ce que le

robinet de la bouteille soit entre vous et le détendeur.

5. Ajustez le détendeur d’oxygène afin de permettre à 21 à 34 kPa de

circuler dans le tuyau. Laissez l’oxygène circuler 5 à 10 secondes

afin de retirer les poussières, saletés ou agents conservateurs du

tuyau. Fermez le débit d’oxygène.

6. Fixez et nettoyez le tuyau de gaz combustible de la même façon.

AVERTISSEMENT

Assurez-vous de nettoyer les tuyaux dans un endroit bien ventilé.

Les fuites de gaz créent un risque d’explosion ou d’incendies.

Gardez les tuyaux de soudage éloignés de toutes chutes de métal,

scories ou étincelles. Ne laissez jamais les tuyaux se recouvrir

d’huile, de graisse ou de saleté. Cela risquerait de cacher des zones

endommagées dans les tuyaux. Examinez les tuyaux avant de les

brancher sur la lance du chalumeau ou sur les détendeurs. Si vous

remarquez des coupures, des brûlures, des zones usées ou des

raccords endommagés, réparez ou remplacez le tuyau.

7. Inspectez la tête de la lance du chalumeau, les branchements des

robinets et tuyaux pour la présence d’huile, de graisse ou de pièces

endommagées.Inspectez les branchements du tuyau de la même

3-7

Page 39

façon. Si vous détectez de l’huile, de la graisse ou des dommages,

NE les utilisez PAS.

8. Inspectez la lance du chalumeau. Les surfaces de siège conique

de la tête doivent être en bon état. En cas d’encoches ou de sièges

brûlés, faites réusiner le siège. Si vous utilisez un chalumeau

avec de mauvaises surfaces de siège, vous risquez un retour de

flamme.

9. Au moyen de clé plate de 3/4", assurez-vous que les intercepteurs

de retours sont bien serrés. Dans le cas contraire, un retour de

flamme a pu se produire.

10. Fixez le tuyau de soudage sur la lance du chalumeau et serrez

fermement à l’aide d’une clé.

3.02 INSTALLATION DE SOUDURE

1. Vérifiez l’épaisseur des métaux à souder. . Reportez-vous au tableau

de sélection des buses de soudage des pages 62 afin de déterminer

la bonne dimension de buse ainsi que la pression du détendeur

necessaires à ce type de travail.

2. Ouvrez le robinet d’oxygène de la lance du chalumeau et réglez

le détendeur d’oxygène sur la pression necessaire. Puis fermez

le robinet d’oxygène de la lance du chalumeau ; cela permet de

purger le tuyau d’oxygène.

3. Ouvrez le robinet de gaz de la lance du chalumeau et réglez le

détendeur de gaz sur la pression necessaire. Puis fermez le robinet

de gaz de la lance du chalumeau ; cela permet de purger le tuyau

de gaz.

AVERTISSEMENT

Si la lance du chalumeau et les tuyaux sont déjà branchés sur le

détendeur, vous DEVEZ quand même purger le système après

chaque arrêt dans un endroit bien ventilé. Ouvrez le robinet

d’oxygène d’un demi-tour. Laissez le gaz circuler pendant dix

secondes pour les buses de taille trois ou inférieurs et 5 secondes

pour celles de taille 4 ou plus pour chaque longueur de 7 mètres et

demi de tuyaux du système. Fermez le robinet d’oxygène et purgez

le système de gaz de la même façon.

3-8

Page 40

4. Portez des lunettes de sécurité recommandées (teintées de

catégorie 5 ou plus) avec des verres teintés afin de protéger vos

yeux contre la lumière. Portez des vêtements de protection selon

les exigences.

MISE EN GARDE

Les instructions suivantes concernent les procédures de réglage

du chalumeau pour l’acétylène uniquement. Contactez votre

fournisseur en gaz pour les instructions d’utilisation des autres

gaz combustibles.

MISE EN GARDE

Ne dirigez pas la flamme vers les personnes, les équipements ou

tous matériaux inflammables.

5. Tenez le chalumeau dans une main et l’allume-gaz à étincelle dans

l’autre. Assurez-vous que l’allume-gaz à étincelle est éloigné de la

buse et n’obstrue pas le débit du gaz.

6. Ouvrez le robinet de gaz du chalumeau d’environ un huitième de

tour et allumez le gaz.

7. Continuez d’ouvrir le robinet de gaz jusqu’à ce que la flamme ne fume

plus.

8. Ouvrez le robinet d’oxygène du chalumeau jusqu’à l’apparition

d’une flamme neutre vive.

AVERTISSEMENT

Si la flamme produit trop de chaleur pour le métal à souder, Ne

diminuez PAS les pressions, ne fermez pas les robinets, UTILISEZ

UNE BUSE PLUS PETITE.

AVERTISSEMENT

S’il devait se produire un retour de flamme soutenu (un bruit aïgu

lorsque la flamme brûle à l’intérieur de la buse de soudage), fermez

immédiatement le robinet d’oxygène de la lance du chalumeau.

Puis, fermez le robinet de gaz. Laissez le chalumeau et la buse se

refroidir avant de tenter de les essayer de nouveau. Si un retour de

flamme se renouvelle, faites réparer l’appareil par un technicien

qualifié avant de l’utiliser de nouveau.

3-9

Page 41

3.03 OPÉRATION DE SOUDURE

1. Nettoyez les surfaces des métaux à souder. Il est nécessaire de

retirer tout dépôt calcaire, rouille, saleté, peinture, graisse et autre

matériau étranger.

2. Certains métaux plus épais peuvent nécessiter une préparation

supplémentaire. Les métaux de base d’épaisseur inférieure ou

égale à 3,18 mm n’ont pas besoin de chanfrein.

3. Placez le métal à souder sur une table de travail inflammable et

déterminez où le pointage sera nécessaire.

4. Commencez par souder par point ensemble les extrémités des

deux morceaux de métal avant de souder. Pour les plus longues

pièces de métal vous devez soudez par point tous les quelques

centimètres le long du joint.

5. Les pièces plus longues peuvent également nécessiter un espace

de pénétration supplémentaire, VICTOR® recommande 1,59 à 3,18

mm.

6. Maintenez la buse de soudage à un angle d’environ 45° par rapport

au joint.

7. Déplacez la buse du chalumeau au-dessus des arêtes au début

du joint. Faites tourner la flamme à proximité du métal avec un

mouvement circulaire ou semi-circulaire jusqu’à ce que le métal

de base forme un petit bain de fusion en surface.

8. Faites tremper et ressortir l’extrémité de l’apport de métal dans le

bain de fusion, cela permet de fondre l’apport de métal et augmente

le volume du bain de fusion.

9. Continuez le mouvement de trempage de l’apport de métal dans

le bain. Puis déplacez le chalumeau d’avant en arrière au travers

du joint.

10. Avancez la buse du chalumeau à une vitesse d’environ un seizième

de l’apport de métal qui s’ajoute au bain jusqu’à la fin de la

réalisation du joint.

3.04 ACCOMPLISSEMENT DE SOUDURE ET DE CHAUFFAGE

1. Fermez le robinet d’oxygène du chalumeau. Puis, fermez le robinet

de gaz du chalumeau. Assurez-vous de ne pas fermer en premier

le robinet de gaz, cela risquerait de créer un bruit de claquement.

3-10

Page 42

Ce bruit de claquement renvoie de la suie de carbone dans le

chalumeau. Celle-ci peut partiellement boucher les passages de

gaz et les intercepteurs de retour de flamme.

2. Fermez les deux robinets de la bouteille.

3. Ouvrez le robinet d’oxygène de la lance du chalumeau. Relâchez

la pression du système et puis, fermez le robinet d’oxygène du

chalumeau.

4. Tournez la vis de réglage de pression du détendeur d’oxygène dans

le sens inverse des aiguilles d’une montre jusqu’à ce que le ressort

de la vis n’exerce plus de pression.

5. Ouvrez le robinet de gaz du chalumeau et relâchez la pression du

système. Fermez le robinet de gaz du chalumeau.

5. Tournez la vis de réglage de pression du détendeur de gaz

combustible dans le sens inverse des aiguilles d’une montre jusqu’à

ce que le ressort de la vis n’exerce plus de pression.

6. Vérifiez les manomètres d’entrée après quelques minutes afin

de vous assurer que les robinets de la bouteille sont entièrement

fermés et qu’il ne reste aucune pression dans le système.

SECTION 4:

LES ATTACHEMENTS COUPEURS

4.01 PRÉPARATION DE DÉCOUPAGE

1. Inspectez l’extrémité conique, l’écrou d’accouplement, et la tête du

chalumeau pour la présence de dommages, d’huile ou de graisse.

Inspectez également l’extrémité conique pour vérifier si des joints

toriques sont endommagés ou manquants.

AVERTISSEMENT

Si vous constatez de l’huile, de la graisse et des dommages,

N’utilisez PAS le chalumeau tant qu’il n’a pas été nettoyé ou

réparé par un technicien qualifié. Les joints toriques de l’extrémité

conique permettent la séparation continue de l’oxygène et des gaz

combustibles. Si l’un ou les deux joints toriques sont manquants, il

y a risque de pré-mélange de l’oxygène et des gaz combustibles.

Cela peut entraîner un retour de flamme soutenu dans la lance du

chalumeau et de l’accessoire de coupe.

4-11

Page 43

2. Inspectez la buse de coupe et la tête de l’accessoire de coupe.

Toutes les surfaces de siège conique de la tête doivent être

en bon état. Jetez les buses de coupe endommagées. En cas

d’encoches, de brûlures ou de sièges brûlés, faites réusiner la tête

du chalumeau. Si vous utilisez un accessoire de coupe avec de

mauvaises surfaces de siège, vous risquez un retour de flamme

ou un retour de flamme soutenu.

AVERTISSEMENT

Si les surfaces de siège conique de la buse de coupe sont

endommagées, Ne l’utilisez PAS. Des surfaces de siège en

mauvais état peuvent causer un retour de flamme ou un retour

de flamme soutenu.

3. Inspectez les orifices d’oxygène de coupe et de préchauffe de la

buse. Des scories peuvent se coller sur ou dans ces orifices. Si

ces trous sont bouchés ou obstrués, nettoyez-les à l’aide d’un

cure-buse approprié.

4. Insérez la buse dans la tête de l’accessoire de coupe. Serrez l’écrou

de la buse solidement à l’aide d’une clé (torque de 20 à 27 N.m).

5. Branchez l’accessoire de coupe à la lance du chalumeau et serrez

suffisamment l’écrou d’accouplement manuellement. N’utilisez PAS

de clé car cela risquerait d’endommager les joints toriques et donc

de créer une mauvaise étanchéité.

6. Reportez-vous aux tableaux de débits des buses pour les bonnes

dimensions des buses de coupe, les pressions des détendeurs et

les vitesses de déplacement.

7. Observez les procédures de réglage et instructions de sécurité de

la bouteille et du détendeur.

8. Ouvre z entiè rement le ro binet d’oxyg ène de la lance du

chalumeau.

9. Ouvrez le robinet d’oxygène de préchauffe de l’accessoire de

coupe et ajustez le détendeur d’oxygène sur la pression désirée.

Cela permet de purger le tuyau d’oxygène.

10. Fermez le robinet d’oxygène de préchauffe.

4-12

Page 44

11. Ouvrez le robinet de gaz de la lance du chalumeau et ajustez le

détendeur de gaz sur la pression nécessaire. Cela permet de purger

le tuyau de gaz.

12. Fermez le robinet de gaz de la lance du chalumeau.

13. Appuyez momentanément sur le levier d’oxygène de coupe afin de

purger le passage d’oxygène de coupe de l’accessoire de coupe.

AVERTISSEMENT

Si la lance du chalumeau et les tuyaux sont déjà branchés sur

le détendeur, vous DEVEZ quand même purger le système après

chaque arrêt. Ouvrez le robinet d’oxygène d’un demi-tour. Laissez

le gaz circuler pendant dix secondes pour les buses de taille 3

et inférieure et 5 secondes pour celles de taille 4 ou plus pour

chaque longueur de 7 mètres et demi de tuyaux du système.

Ouvrez le robinet d’oxygène et purgez le système de gaz de la

même façon.

AVERTISSEMENT

Portez toujours des vêtements de protection et une protection

occulaire adaptée afin de protéger vos yeux de la lumière infrarouge.

14. Ouvrez le robinet de gaz de la lance du chalumeau environ un

huitième de tour et enflammez le gaz à l’aide d’un allume-gaz à

étincelle. Assurez-vous que l’allume-gaz à étincelle est éloigné de

la buse et n’obstrue pas le débit du gaz.

15. Continuez d’augmenter l’alimentation en gaz de la lance du

chalumeau jusqu’à ce que la flamme s’arrête de fumer.

16. Ouvrez doucement le robinet d’oxygène de préchauffe de

l’accessoire de coupe jusqu’à obtention d’une flamme de

préchauffe avec un cône intérieur bien défini.

17. Appuyez sur le levier d’oxygène de coupe. Si nécessaire, réajustez

légèrement les flammes de préchauffe sur une flamme neutre en

augmentant l’oxygène de préchauffe de l’accessoire de coupe

jusqu’à ce que les flammes de préchauffe soient de nouveau

neutres. Si les flammes de préchauffe ne sont pas de la même taille

4-13

Page 45

et si l’oxygène n’est pas droit, éteignez le chalumeau et laissez-le

refroidir, puis nettoyez la buse.

AVERTISSEMENT

S’il devait se produire un retour de flamme soutenu (la flamme

disparaît et/ou il se produit un bruit aïgu car la flamme brûle

à l’intérieur de l’accessoire de coupe), fermez immédiatement

le robinet d’oxygène de préchauffe de l’accessoire de coupe.

Puis, fermez le robinet de gaz de la lance du chalumeau. Laissez

l’accessoire de coupe se refroidir avant d’essayer de l’enflammer

de nouveau. Si un retour de flamme se renouvelle, faites vérifier

votre chalumeau par un technicien qualifié en réparation avant de

l’utiliser de nouveau.

AVIS

Inspectez les zones où les scories et étincelles peuvent tomber. Des

incendies et des explosions graves sont causés par une mauvaise

utilisation du chalumeau. Prenez toutes les précautions possibles.

Ayez des extincteurs à portée de main. Retirez ou protégez les

substances inflammables, y compris les tuyaux d’oxygène et de

gaz avant de démarrer votre travail.

18. Tenez comfortablement avec les deux mains l’accessoire de

coupe et la lance du chalumeau. Stabilisez le chalumeau et placez

l’extrémité des flammes de préchauffe à environ 6 mm du métal

de base.

19. Dirigez la flamme de préchauffe à l’endroit où la coupe doit

commencer. Avant que la coupe ne puisse commencer, préchauffez

le point de départ du métal jusqu’à obtention de la température

de combustion rouge vif. Lorsque le point rouge apparaît, appuyez

doucement et complètement sur le levier d’oxygène de coupe.

20. Lorsque la coupe débute, déplacez le chalumeau dans la direction

désirée de la coupe.

AVIS

Si vous vous déplacez trop doucement, vous risquez de fusionner

ensemble les arêtes de la coupe. Si vous vous déplacez trop vite,