Page 1

VA 4000S

®

ULTRAFEED

SEPARATION

SEMIAUTOMATIC

WIRE FEEDER

Operating Manual

Revision: AA Issue Date: July 13, 2009 Manual #: 0-5135

Operating Features:

50

60

Hz

875

IPM

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Thermal Arc product. We are proud

to have you as our customer and will strive to provide you with

the best service and reliability in the industry. This product is backed

by our extensive warranty and world-wide service network. To

locate your nearest distributor or service agency call

1-800-752-7621, or visit us on the web at www.Thermalarc.com.

This Operating Manual has been designed to instruct you on the

correct use and operation of your Thermal Arc product. Your

satisfaction with this product and its safe operation is our ultimate

concern. Therefore please take the time to read the entire manual,

especially the Safety Precautions. They will help you to avoid

potential hazards that may exist when working with this product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators Worldwide.

Thermal Arc is a Global Brand of Arc Welding Products for

Thermadyne Industries Inc. We manufacture and supply to major

welding industry sectors worldwide including; Manufacturing,

Construction, Mining, Automotive, Aerospace, Engineering, Rural

and DIY/Hobbyist.

We distinguish ourselves from our competition through marketleading, dependable products that have stood the test of time. We

pride ourselves on technical innovation, competitive prices,

excellent delivery, superior customer service and technical support,

together with excellence in sales and marketing expertise.

Above all, we are committed to develop technologically advanced

products to achieve a safer working environment within the welding

industry.

Page 3

!

WARNINGS

Read and understand this entire Manual and your employer’s safety practices before installing,

operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement,

the Manufacturer assumes no liability for its use.

Ultrafeed VA 4000S Separation Semiautomatic Wire Feeder

Instruction Manual Number 0-5135 for:

Ultrafeed VA 4000S Part Number W3430001

Published by:

Thermadyne Industries, Inc.

82 Benning Street

West Lebanon, New Hampshire, USA 03784

(603) 298-5711

www.thermalarc.com

Copyright 2009 by

Thermadyne Industries, Inc.

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher

is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any

loss or damage caused by any error or omission in this Manual, whether such error

results from negligence, accident, or any other cause.

Publication Date: July 13, 2009

Record the following information for Warranty purposes:

Where Purchased: ___________________________________

Purchase Date: ___________________________________

Equipment Serial #: ___________________________________

Page 4

Page 5

TABLE OF CONTENTS

SECTION 1:

SAFETY INSTRUCTIONS AND WARNINGS ....................................................... 1-1

1.01 Arc Welding Hazards ...................................................................................... 1-1

1.02 Principal Safety Standards ............................................................................. 1-4

1.03 Symbol Chart ................................................................................................. 1-5

1.04 Precautions De Securite En Soudage A L’arc.................................................. 1-6

1.05 Dangers relatifs au soudage à l’arc ................................................................. 1-6

1.06 Principales Normes De Securite ..................................................................... 1-9

1.07 Graphique de Symbole ................................................................................. 1-10

1.08 Declaration Of Conformity ............................................................................ 1-11

SECTION 2:

INTRODUCTION ...................................................................................... 2-1

2.01 How To Use This Manual ................................................................................ 2-1

2.02 Equipment Identification................................................................................. 2-1

2.03 Receipt Of Equipment ..................................................................................... 2-1

2.04 Symbol Chart ................................................................................................. 2-2

2.05 General Information ....................................................................................... 2-3

2.06 Features and Benefits ..................................................................................... 2-4

2.07 Options and Accessories ................................................................................ 2-4

SECTION 3:

INSTALLATION ....................................................................................... 2-1

3.01 Connections ................................................................................................... 2-1

3.02 Grounding ...................................................................................................... 2-1

3.03 EMI Considerations ........................................................................................ 2-1

3.04 Input And Output Wire Guide Installation ....................................................... 2-2

3.05 Selection And Installation Of Feed Rolls ......................................................... 2-3

3.06 Welding Gun Compatibility And Installation ................................................... 2-3

3.07 Threading Wire Into Feedhead ........................................................................ 2-4

Page 6

TABLE OF CONTENTS (continued)TABLE OF CONTENTS

SECTION 4:

OPERATION........................................................................................... 4-1

4.01 Front Panel ..................................................................................................... 4-1

4.02 Rear Panel Controls &Connections ................................................................ 4-2

4.03 Feedhead Components ................................................................................... 4-4

4.04 Power Source Compatibility ........................................................................... 4-5

4.05 Power Source Compatibility Details ................................................................ 4-6

4.06 Prewelding Procedure .................................................................................... 4-6

4.07 Welding - 2 Step Operation ............................................................................ 4-7

4.08 Welding - 4 Step Operation ............................................................................ 4-8

4.09 System DIP Switches ..................................................................................... 4-9

4.10 PTC Protection of A-B Circuit ....................................................................... 4-10

4.11 Ground Fault Operation ................................................................................ 4-10

4.12 Electronic Motor Protection.......................................................................... 4-10

4.13 Software Features......................................................................................... 4-10

4.14 Arc Signal Overide ........................................................................................ 4-10

SECTION 5:

SERVICE .............................................................................................. 5-1

5.01 Cleaning The Unit ........................................................................................... 5-1

5.02 Cleaning The Feed Rolls ................................................................................. 5-1

5.03 System Maintenance ...................................................................................... 5-1

5.04 Troubleshooting Guide ................................................................................... 5-1

5.05 Troubleshooting Guide ................................................................................... 5-2

SECTION 6:

PARTS LISTS ......................................................................................... 6-1

6.01 Equipment Identification................................................................................. 6-1

6.02 How To Use This Parts List ............................................................................ 6-1

6.03 Replacement Parts - VA 4000 S Controller Front............................................ 6-2

6.04 Replacement Parts - VA 4000 S Controller Rear ............................................ 6-3

6.05 Replacement Parts - VA 4000 S Separation Motor ......................................... 6-4

APPENDIX 1: FEED ROLL KITS .......................................................................... A-1

APPENDIX 2: OPTIONS AND ACCESSORIES ........................................................... A-2

APPENDIX 3: SYSTEM OUTLINE ......................................................................... A-3

Statement of Warranty ........................................................................................

2

Warranty SCHEDULE ......................................................................................... 3

GLOBAL CUSTOMER SERVICE CONTACT INFORMATION ............................................... 5

Page 7

ULTRAFEED VA 4000S

SECTION 1:

SAFETY INSTRUCTIONS AND WARNINGS

WARNING

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS KEEP

AWAY UNTIL CONSULTING YOUR DOCTOR. DO NOT LOSE THESE INSTRUCTIONS. READ OPERATING/INSTRUCTION MANUAL BEFORE

INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

Welding products and welding processes can cause serious injury or death, or damage to other equipment or property, if the operator does not

strictly observe all safety rules and take precautionary actions.

Safe practices have developed from past experience in the use of welding and cutting. These practices must be learned through study and

training before using this equipment. Some of these practices apply to equipment

connected to power lines; other practices apply to engine driven equipment. Anyone not having extensive

training in welding and cutting practices should not attempt to weld.

Safe practices are outlined in the American National Standard Z49.1 entitled: SAFETY IN WELDING AND CUTTING. This publication and other

guides to what you should learn before operating this equipment are listed at the end of these safety precautions. HAVE ALL INSTALLATION,

OPERATION, MAINTENANCE, AND REPAIR WORK PERFORMED ONLY BY QUALIFIED PEOPLE.

1.01 Arc Welding Hazards

WARNING

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks or

severe burns. The electrode and work circuit is electrically

live whenever the output is on. The input power circuit

and machine internal circuits are also live when power

is on. In semiautomatic or automatic wire welding, the

wire, wire reel, drive roll housing, and all metal parts

touching the welding wire are electrically live. Incorrectly

installed or improperly grounded equipment is a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body protection.

3. Insulate yourself from work and ground using dry insulating mats

or covers.

7. Use fully insulated electrode holders. Never dip holder in water to

cool it or lay it down on the ground or the work surface. Do not

touch holders connected to two welding machines at the same

time or touch other people with the holder or electrode.

8. Do not use worn, damaged, undersized, or poorly spliced cables.

9. Do not wrap cables around your body.

10. Ground the workpiece to a good electrical (earth) ground.

11. Do not touch electrode while in contact with the work (ground)

circuit.

12. Use only well-maintained equipment. Repair or replace damaged

parts at once.

13. In confined spaces or damp locations, do not use a welder with

AC output unless it is equipped with a voltage reducer. Use

equipment with DC output.

14. Wear a safety harness to prevent falling if working above floor

level.

15. Keep all panels and covers securely in place.

WARNING

4. Disconnect input power or stop engine before installing or

servicing this equipment. Lock input power disconnect switch

open, or remove line fuses so power cannot be turned on

accidentally.

5. Properly install and ground this equipment according to its Owner’s

Manual and national, state, and local codes.

6. Turn off all equipment when not in use. Disconnect power to

equipment if it will be left unattended or out of service.

Manual No. 0-5135 1-1 SAFETY INSTRUCTIONS

ARC RAYS can burn eyes and skin; NOISE can damage

hearing. Arc rays from the welding process produce

intense heat and strong ultraviolet rays that can burn

eyes and skin. Noise from some processes can damage

hearing.

1. Wear a welding helmet fitted with a proper shade of filter (see

ANSI Z49.1 listed in Safety Standards) to protect your face and

eyes when welding or watching.

2. Wear approved safety glasses. Side shields recommended.

Page 8

ULTRAFEED VA 4000S

3. Use protective screens or barriers to protect others from flash

and glare; warn others not to watch the arc.

4. Wear protective clothing made from durable, flame-resistant

material (wool and leather) and foot protection.

5. Use approved ear plugs or ear muffs if noise level is high.

WARNING

WARNING

WELDING can cause fire or explosion.

Sparks and spatter fly off from the welding arc. The flying

sparks and hot metal, weld spatter, hot workpiece, and

hot equipment can cause fires and burns. Accidental

contact of electrode or welding wire to metal objects

can cause sparks, overheating, or fire.

FUMES AND GASES can be hazardous to your health.

Welding produces fumes and gases. Breathing these

fumes and gases can be hazardous to your health.

1. Keep your head out of the fumes. Do not breath the fumes.

2. If inside, ventilate the area and/or use exhaust at the arc to remove

welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied respirator.

4. Read the Material Safety Data Sheets (MSDSs) and the

manufacturer’s instruction for metals, consumables, coatings, and

cleaners.

5. Work in a confined space only if it is well ventilated, or while

wearing an air-supplied respirator. Shielding gases used for

welding can displace air causing injury or death. Be sure the

breathing air is safe.

6. Do not weld in locations near degreasing, cleaning, or spraying

operations. The heat and rays of the arc can react with vapors to

form highly toxic and irritating gases.

7. Do not weld on coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from the

weld area, the area is well ventilated, and if necessary, while

wearing an air-supplied respirator. The coatings and any metals

containing these elements can give off toxic fumes if welded.

1. Protect yourself and others from flying sparks and hot metal.

2. Do not weld where flying sparks can strike flammable material.

3. Remove all flammables within 35 ft (10.7 m) of the welding arc.

If this is not possible, tightly cover them with approved covers.

4. Be alert that welding sparks and hot materials from welding can

easily go through small cracks and openings to adjacent areas.

5. Watch for fire, and keep a fire extinguisher nearby.

6. Be aware that welding on a ceiling, floor, bulkhead, or partition

can cause fire on the hidden side.

7. Do not weld on closed containers such as tanks or drums.

8. Connect work cable to the work as close to the welding area as

practical to prevent welding current from traveling long, possibly

unknown paths and causing electric shock and fire hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off welding wire at

contact tip when not in use.

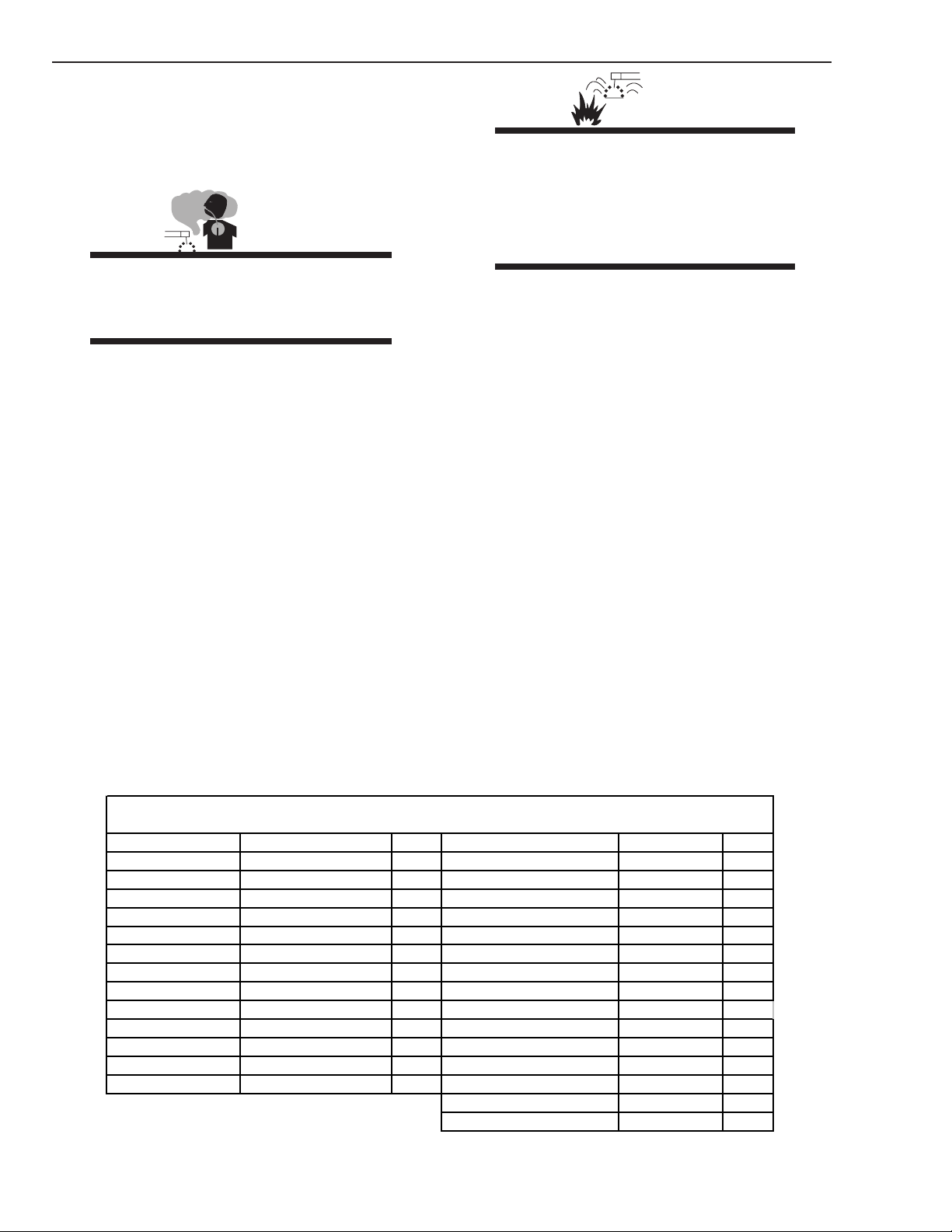

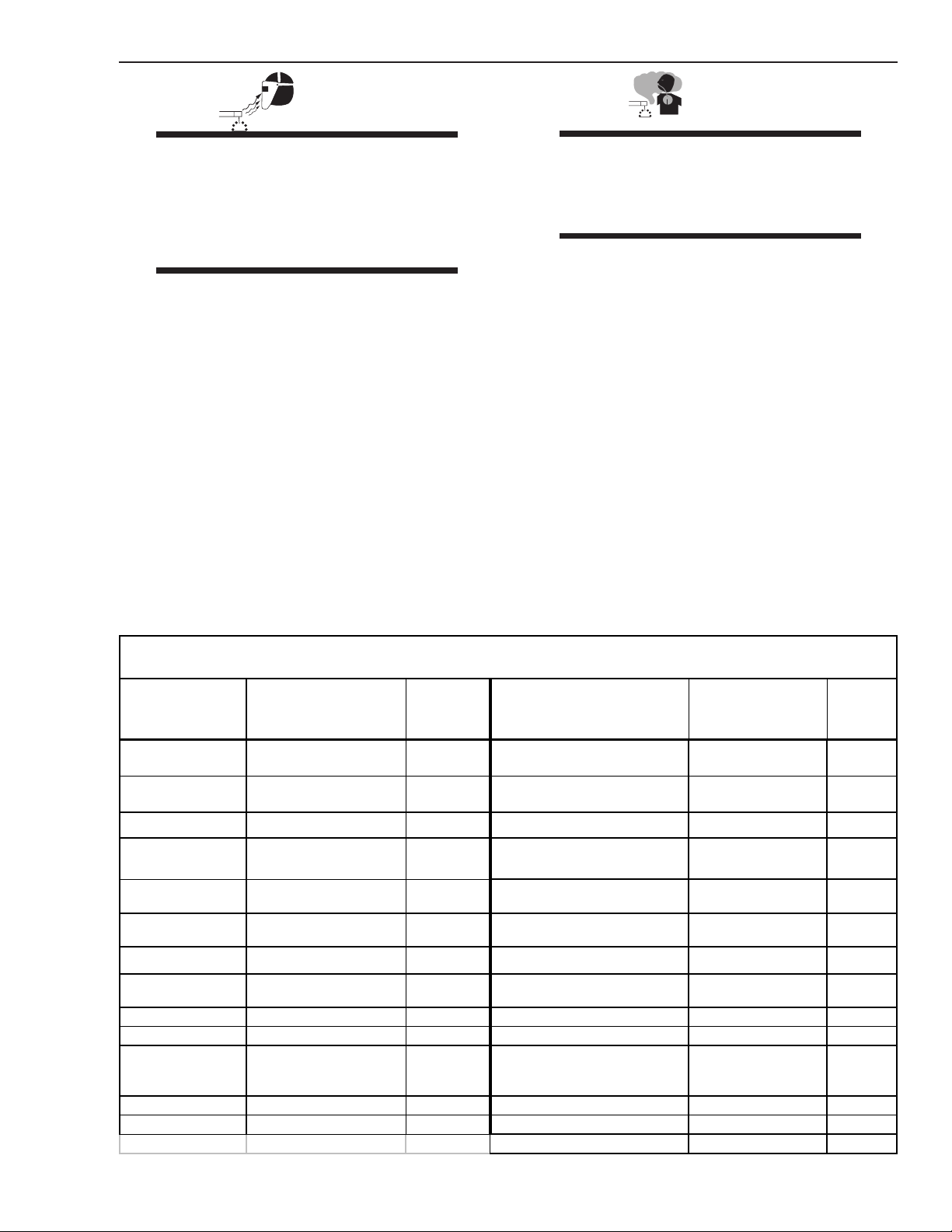

Eye protection filter shade selector for welding or cutting

(goggles or helmet), from AWS A6.2-73.

Welding or cutting Electrode Size Filter Welding or cutting Electrode Size Filter

Torch soldering 2 Gas metal-arc

Torch brazing 3 or 4 Non-ferrous base metal All 11

Oxygen C utting Ferrous base metal All 12

Light Under 1 in., 25 mm 3 or 4 Gas tungsten arc welding All 12

Medium 1 to 6 in., 25-150 mm 4 or 5 (TIG) All 12

Heavy Over 6 in., 150 mm 5 or 6 Atomic hydrogen welding All 12

Gas welding Carbon arc welding All 12

Light Under 1/8 in., 3 mm 4 or 5 Plasma arc welding

Medium 1/8 to 1/2 in., 3-12 mm 5 or 6 Carbon arc air gouging

Heavy Over 1/2 in., 12 mm 6 or 8 Light 12

Shielded metal-arc Under 5/32 in., 4 mm 10 Heavy 14

5/32 to 1/4 in., 12 Plasma arc cutting

Over 1/4 in., 6.4 mm 14 Light Under 300 Amp 9

Medium 300 to 400 Amp 12

Heavy Over 400 Amp 14

SAFETY INSTRUCTIONS 1-2 Manual No. 0-5135

Page 9

WARNING

ULTRAFEED VA 4000S

2. If used in a closed area, vent engine exhaust outside and away

from any building air intakes.

FLYING SPARKS AND HOT METAL can cause injury.

Chipping and grinding cause flying metal. As welds cool,

they can throw off slag.

1. Wear approved face shield or safety goggles. Side shields

recommended.

2. Wear proper body protection to protect skin.

WARNING

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high pressure.

If damaged, a cylinder can explode. Since gas cylinders

are normally part of the welding process, be sure to treat

them carefully.

1. Protect compressed gas cylinders from excessive heat, mechanical

shocks, and arcs.

2. Install and secure cylinders in an upright position by chaining

them to a stationary support or equipment cylinder rack to prevent

falling or tipping.

3. Keep cylinders away from any welding or other electrical circuits.

4. Never allow a welding electrode to touch any cylinder.

5. Use only correct shielding gas cylinders, regulators, hoses, and

fittings designed for the specific application; maintain them and

associated parts in good condition.

6. Turn face away from valve outlet when opening cylinder valve.

7. Keep protective cap in place over valve except when cylinder is in

use or connected for use.

8. Read and follow instructions on compressed gas cylinders,

associated equipment, and CGA publication P-1 listed in Safety

Standards.

WARNING

ENGINE FUEL can cause fire or explosion.

Engine fuel is highly flammable.

1. Stop engine before checking or adding fuel.

2. Do not add fuel while smoking or if unit is near any sparks or

open flames.

3. Allow engine to cool before fueling. If possible, check and add

fuel to cold engine before beginning job.

4. Do not overfill tank — allow room for fuel to expand.

5. Do not spill fuel. If fuel is spilled, clean up before starting engine.

WARNING

MOVING PARTS can cause injury.

Moving parts, such as fans, rotors, and belts can cut fingers and hands

and catch loose clothing.

1. Keep all doors, panels, covers, and guards closed and

securely in place.

2. Stop engine before installing or connecting unit.

3. Have only qualified people remove guards or covers for

maintenance and troubleshooting as necessary.

4. To prevent accidental starting during servicing, disconnect

negative (-) battery cable from battery.

5. Keep hands, hair, loose clothing, and tools away from moving

parts.

6. Reinstall panels or guards and close doors when servicing

is finished and before starting engine.

Engines can be dangerous.

WARNING

SPARKS can cause BATTERY GASES TO EXPLODE;

WARNING

BATTERY ACID can burn eyes and skin.

Batteries contain acid and generate explosive gases.

WARNING

1. Always wear a face shield when working on a battery.

2. Stop engine before disconnecting or connecting battery cables.

ENGINE EXHAUST GASES can kill.

3. Do not allow tools to cause sparks when working on a battery.

Engines produce harmful exhaust gases.

1. Use equipment outside in open, well-ventilated areas.

Manual No. 0-5135 1-3 SAFETY INSTRUCTIONS

4. Do not use welder to charge batteries or jump start vehicles.

5. Observe correct polarity (+ and –) on batteries.

Page 10

ULTRAFEED VA 4000S

1.02 Principal Safety Standards

WARNING

STEAM AND PRESSURIZED HOT COOLANT can burn

face, eyes, and skin.

The coolant in the radiator can be very hot and under

pressure.

1. Do not remove radiator cap when engine is hot. Allow engine to

cool.

2. Wear gloves and put a rag over cap area when removing cap.

3. Allow pressure to escape before completely removing cap.

WARNING

This product, when used for welding or cutting, produces

fumes or gases which contain chemicals know to the

State of California to cause birth defects and, in some

cases, cancer. (California Health & Safety code Sec.

25249.5 et seq.)

NOTE

Safety in Welding and Cutting, ANSI Standard Z49.1, from American

Welding Society, 550 N.W. LeJeune Rd., Miami, FL 33126.

Safety and Health Standards, OSHA 29 CFR 1910, from Superintendent

of Documents, U.S. Government Printing Office, Washington, D.C.

20402.

Recommended Safe Practices for the Preparation for Welding and

Cutting of Containers That Have Held Hazardous Substances, American

Welding Society Standard AWS F4.1, from American Welding Society,

550 N.W. LeJeune Rd., Miami, FL 33126.

National Electrical Code, NFPA Standard 70, from National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet P1, from Compressed Gas Association, 1235 Jefferson Davis Highway,

Suite 501, Arlington, VA 22202.

Code for Safety in Welding and Cutting, CSA Standard W117.2, from

Canadian Standards Association, Standards Sales, 178 Rexdale

Boulevard, Rexdale, Ontario, Canada M9W 1R3.

Safe Practices for Occupation and Educational Eye and Face Protection,

ANSI Standard Z87.1, from American National Standards Institute,

1430 Broadway, New York, NY 10018.

Cutting and Welding Processes, NFPA Standard 51B, from National

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

Considerations About Welding And The Effects of Low

Frequency Electric and Magnetic Fields

The following is a quotation from the General Conclusions Section of

the U.S. Congress, Office of Technology Assessment, Biological Effects

of Power

Frequency Electric & Magnetic Fields - Background Paper, OTA-BP-E63 (Washington, DC: U.S. Government Printing Office, May 1989):

“...there is now a very large volume of scientific findings based on

experiments at the cellular level and from studies with animals and

people which clearly establish that low frequency magnetic fields and

interact with, and produce changes in, biological systems. While most

of this work is of very high quality, the results are complex. Current

scientific understanding does not yet allow us to interpret the evidence

in a single coherent framework. Even more frustrating, it does not yet

allow us to draw definite conclusions about questions of possible risk

or to offer clear science-based advice on strategies to minimize or

avoid potential risks.”

To reduce magnetic fields in the workplace, use the following

procedures.

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cable around the body.

4. Keep welding power source and cables as far away from

body as practical.

ABOUT PACEMAKERS:

The above procedures are among those also normally

recommended for pacemaker wearers. Consult your

doctor for complete information.

SAFETY INSTRUCTIONS 1-4 Manual No. 0-5135

Page 11

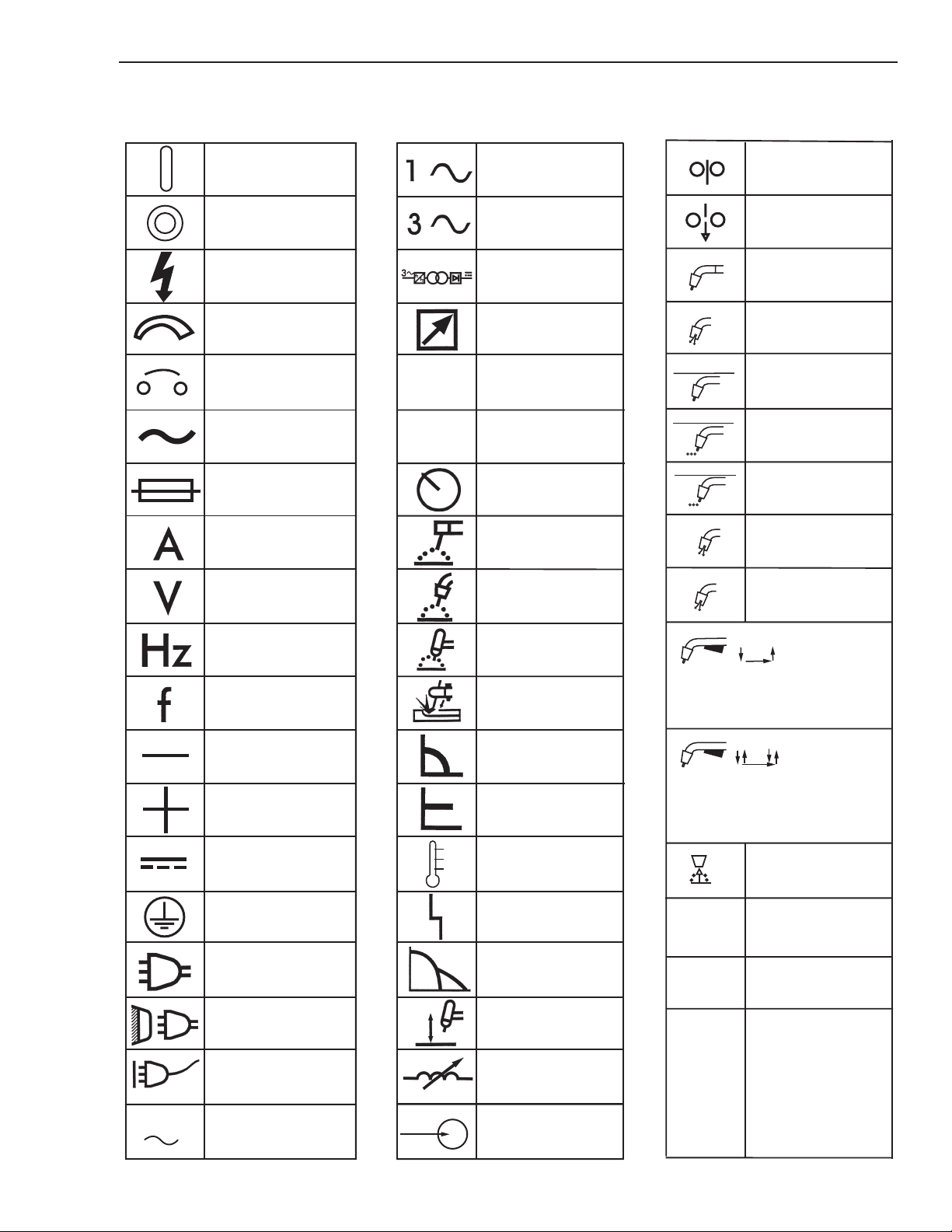

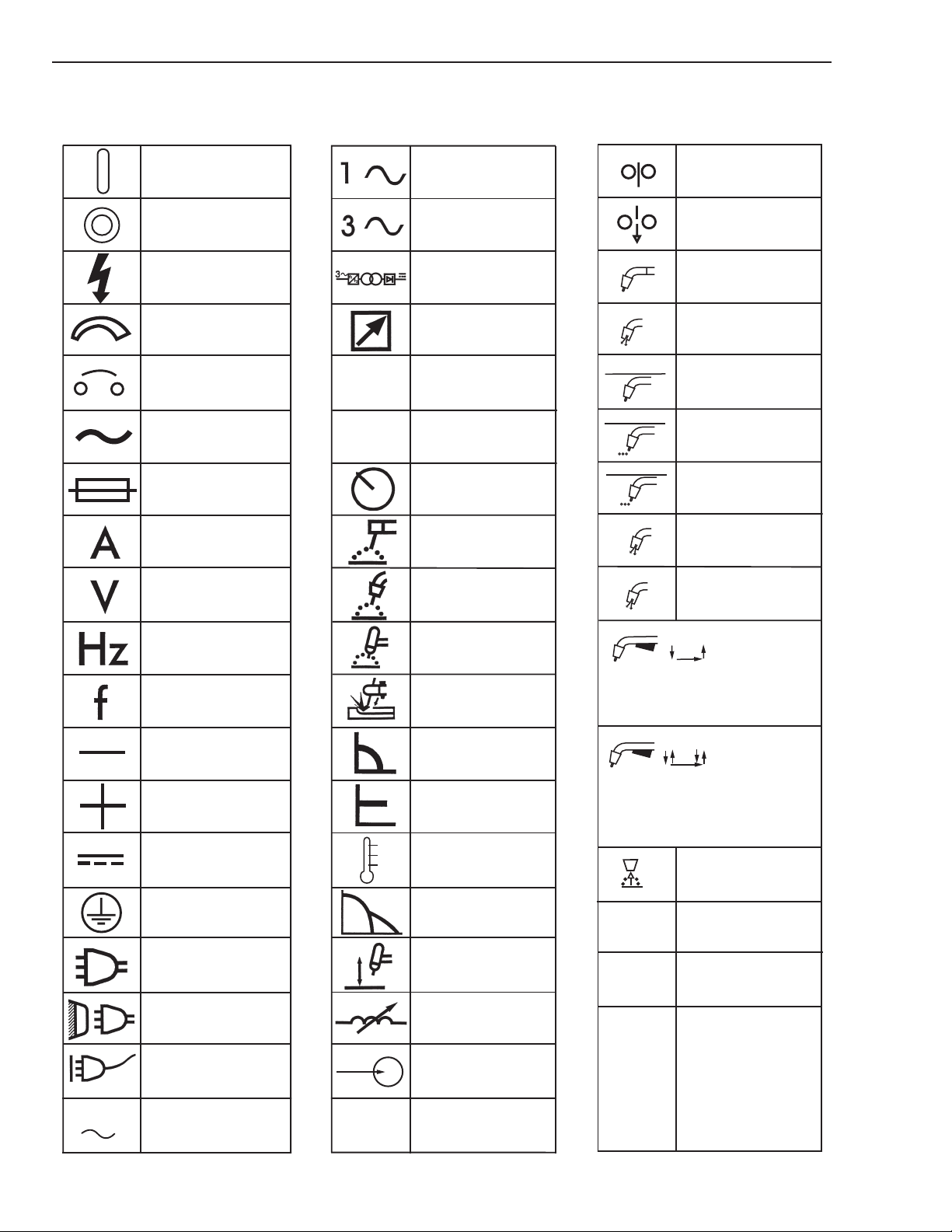

1.03 Symbol Chart

Note that only some of these symbols will appear on your model.

ULTRAFEED VA 4000S

On

Off

Dangerous Voltage

Increase/Decrease

Circuit Breaker

AC Auxiliary Power

Fuse

Amperage

Voltage

X

%

Single Phase

Three Phase

Three Phase Static

Frequency ConverterTransformer-Rectifier

Remote

Duty Cycle

Percentage

Panel/Local

Shielded Metal

Arc Welding (SMAW)

Gas Metal Arc

Welding (GMAW)

Wire Feed Function

Wire Feed Towards

Workpiece With

t1

Output Voltage Off.

Welding Gun

Purging Of Gas

Continuous Weld

Mode

Spot Weld Mode

Spot Time

t

Preflow Time

Postflow Time

t2

Hertz (cycles/sec)

Frequency

Negative

Positive

Direct Current (DC)

Protective Earth

(Ground)

Line

Line Connection

Auxiliary Power

Gas Tungsten Arc

Welding (GTAW)

Air Carbon Arc

Cutting (CAC-A)

Constant Current

Constant Voltage

Or Constant Potential

High Temperature

Fault Indication

Arc Force

Touch Start (GTAW)

Variable Inductance

2 Step Trigger

Operation

Press to initiate wirefeed and

welding, release to stop.

4 Step Trigger

Operation

Press and hold for preflow, release

to start arc. Press to stop arc, and

hold for preflow.

Burnback Time

t

IPM

MPM

Inches Per Minute

Meters Per Minute

115V 15A

Manual No. 0-5135 1-5 SAFETY INSTRUCTIONS

Receptacle RatingAuxiliary Power

Voltage Input

V

Art # A-04130

Page 12

ULTRAFEED VA 4000S

1.04 Precautions De Securite En Soudage A L’arc

MISE EN GARDE

LE SOUDAGE A L’ARC EST DANGEREUX

PROTEGEZ-VOUS, AINSI QUE LES AUTRES, CONTRE LES BLESSURES GRAVES POSSIBLES OU LA MORT. NE LAISSEZ PAS LES ENFANTS

S’APPROCHER, NI LES PORTEURS DE STIMULATEUR CARDIAQUE (A MOINS QU’ILS N’AIENT CONSULTE UN MEDECIN). CONSERVEZ CES

INSTRUCTIONS. LISEZ LE MANUEL D’OPERATION OU LES INSTRUCTIONS AVANT D’INSTALLER, UTILISER OU ENTRETENIR CET EQUIPEMENT.

Les produits et procédés de soudage peuvent sauser des blessures graves ou la mort, de même que des dommages au reste du matériel et à la

propriété, si l’utilisateur n’adhère pas strictement à toutes les règles de sécurité et ne prend pas les précautions nécessaires.

En soudage et coupage, des pratiques sécuritaires se sont développées suite à l’expérience passée. Ces pratiques doivent être apprises par

étude ou entraînement avant d’utiliser l’equipement. Toute personne n’ayant pas suivi un entraînement intensif en soudage et coupage ne devrait

pas tenter de souder. Certaines pratiques concernent les équipements raccordés aux lignes d’alimentation alors que d’autres s’adressent aux

groupes électrogènes.

La norme Z49.1 de l’American National Standard, intitulée “SAFETY IN WELDING AND CUTTING” présente les pratiques sécuritaires à suivre.

Ce document ainsi que d’autres guides que vous devriez connaître avant d’utiliser cet équipement sont présentés à la fin de ces instructions de

sécurité.

SEULES DES PERSONNES QUALIFIEES DOIVENT FAIRE DES TRAVAUX D’INSTALLATION, DE REPARATION, D’ENTRETIEN ET D’ESSAI.

1.05 Dangers relatifs au soudage à l’arc

AVERTISSEMENT

L’ELECTROCUTION PEUT ETRE MORTELLE.

Une décharge électrique peut tuer ou brûler gravement.

L’électrode et le circuit de soudage sont sous tension

dès la mise en circuit. Le circuit d’alimentation et les

circuits internes de l’équipement sont aussi sous tension dès la mise en marche. En soudage automatique

ou semi-automatique avec fil, ce dernier, le rouleau ou

la bobine de fil, le logement des galets d’entrainement

et toutes les pièces métalliques en contact avec le fil de

soudage sont sous tension. Un équipement

inadéquatement installé ou inadéquatement mis à la terre

est dangereux.

1. Ne touchez pas à des pièces sous tension.

2. Portez des gants et des vêtements isolants, secs et non troués.

6. Arrêtez tout équipement après usage. Coupez l’alimentation de

l’équipement s’il est hors d’usage ou inutilisé.

7. N’utilisez que des porte-électrodes bien isolés. Ne jamais plonger

les porte-électrodes dans l’eau pour les refroidir. Ne jamais les

laisser traîner par terre ou sur les pièces à souder. Ne touchez

pas aux porte-électrodes raccordés à deux sources de courant en

même temps. Ne jamais toucher quelqu’un d’autre avec l’électrode

ou le porte-électrode.

8. N’utilisez pas de câbles électriques usés, endommagés, mal

épissés ou de section trop petite.

9. N’enroulez pas de câbles électriques autour de votre corps.

10. N’utilisez qu’une bonne prise de masse pour la mise à la terre de

la pièce à souder.

11. Ne touchez pas à l’électrode lorsqu’en contact avec le circuit de

soudage (terre).

12. N’utilisez que des équipements en bon état. Réparez ou remplacez

aussitôt les pièces endommagées.

13. Dans des espaces confinés ou mouillés, n’utilisez pas de source

de courant alternatif, à moins qu’il soit muni d’un réducteur de

tension. Utilisez plutôt une source de courant continu.

14. Portez un harnais de sécurité si vous travaillez en hauteur.

15. Fermez solidement tous les panneaux et les capots.

3 Isolez-vous de la pièce à souder et de la mise à la terre au moyen

de tapis isolants ou autres.

4. Déconnectez la prise d’alimentation de l’équipement ou arrêtez le

moteur avant de l’installer ou d’en faire l’entretien. Bloquez le

commutateur en circuit ouvert ou enlevez les fusibles de

l’alimentation afin d’éviter une mise en marche accidentelle.

5. Veuillez à installer cet équipement et à le mettre à la terre selon le

manuel d’utilisation et les codes nationaux, provinciaux et locaux

applicables.

SAFETY INSTRUCTIONS 1-6 Manual No. 0-5135

Page 13

ULTRAFEED VA 4000S

AVERTISSEMENT

LE RAYONNEMENT DE L’ARC PEUT BRÛLER LES YEUX

ET LA PEAU; LE BRUIT PEUT ENDOMMAGER L’OUIE.

L’arc de soudage produit une chaleur et des rayons

ultraviolets intenses, susceptibles de brûler les yeux et

la peau. Le bruit causé par certains procédés peut

endommager l’ouïe.

1. Portez une casque de soudeur avec filtre oculaire de nuance

appropriée (consultez la norme ANSI Z49 indiquée ci-après) pour

vous protéger le visage et les yeux lorsque vous soudez ou que

vous observez l’exécution d’une soudure.

2. Portez des lunettes de sécurité approuvées. Des écrans latéraux

sont recommandés.

3. Entourez l’aire de soudage de rideaux ou de cloisons pour protéger

les autres des coups d’arc ou de l’éblouissement; avertissez les

observateurs de ne pas regarder l’arc.

4. Portez des vêtements en matériaux ignifuges et durables (laine et

cuir) et des chaussures de sécurité.

5. Portez un casque antibruit ou des bouchons d’oreille approuvés

lorsque le niveau de bruit est élevé.

AVERTISSEMENT

LES VAPEURS ET LES FUMEES SONT DANGEREUSES

POUR LA SANTE.

Le soudage dégage des vapeurs et des fumées

dangereuses à respirer.

1. Eloignez la tête des fumées pour éviter de les respirer.

2. A l’intérieur, assurez-vous que l’aire de soudage est bien ventilée

ou que les fumées et les vapeurs sont aspirées à l’arc.

3. Si la ventilation est inadequate, portez un respirateur à adduction

d’air approuvé.

4. Lisez les fiches signalétiques et les consignes du fabricant relatives aux métaux, aux produits consummables, aux revêtements

et aux produits nettoyants.

5. Ne travaillez dans un espace confiné que s’il est bien ventilé; sinon,

portez un respirateur à adduction d’air. Les gaz protecteurs de

soudage peuvent déplacer l’oxygène de l’air et ainsi causer des

malaises ou la mort. Assurez-vous que l’air est propre à la respiration.

6. Ne soudez pas à proximité d’opérations de dégraissage, de

nettoyage ou de pulvérisation. La chaleur et les rayons de l’arc

peuvent réagir avec des vapeurs et former des gaz hautement

toxiques et irritants.

SELECTION DES NUANCES DE FILTRES OCULAIRS POUR LA PROTECTION

DES YEUX EN COUPAGE ET SOUDAGE (selon AWS á 8.2-73)

Opération de coupage

ou soudage

Brassage tendre

au chalumeau

Brassage fort

au chalumeau

Oxycoupage métaux ferreux toutes conditions 12

mince moins de 1 po. (25 mm) 2 ou 3

moyen de 1 á 6 po. (25 á 150 mm) 4 ou 5

Soudage aux gaz Soudage á l'arc Plasma (PAW) toutes dimensions 12

mince moins de 1/8 po. (3 mm) 4 ou 5

moyen de 1/8 á 1/2 po. (3 á 12 mm) 5 ou 6 mince 12

Soudage á l'arc avec

électrode enrobees

(SMAW)

Dimension d'électrode ou

Epiasseur de métal ou

Intensité de courant

toutes conditions 2

toutes conditions 3 ou 4 métaux non-ferreux toutes conditions 11

épais plus de 6 po. (150 mm) 5 ou 6

épais plus de 1/2 po. (12 mm) 6 ou 8 épais 14

moins de 5/32 po. (4 mm) 10 Coupage á l'arc Plasma (PAC)

5/32 á 1/4 po. (4 á 6.4 mm) 12 mince moins de 300 amperès 9

plus de 1/4 po. (6.4 mm) 14 moyen de 300 á 400 amperès 12

Nuance de

filtre oculaire

Opération de coupage

ou soudage

Soudage á l'arc sous gaz

avec fil plein (GMAW)

Soudage á l'arc sous gaz avec

électrode de tungstène (GTAW)

Soudage á l'hydrogène

atomique (AHW)

Soudage á l'arc avec

électrode de carbone (CAW)

Gougeage Air-Arc avec

électrode de carbone

Dimension d'électrode ou

Epiasseur de métal ou

Intensité de courant

toutes conditions 12

toutes conditions 12

toutes conditions 12

épais plus de 400 amperès 14

Nuance de

filtre oculaire

Manual No. 0-5135 1-7 SAFETY INSTRUCTIONS

Page 14

ULTRAFEED VA 4000S

7. Ne soudez des tôles galvanisées ou plaquées au plomb ou au

cadmium que si les zones à souder ont été grattées à fond, que si

l’espace est bien ventilé; si nécessaire portez un respirateur à adduction d’air. Car ces revêtements et tout métal qui contient ces

éléments peuvent dégager des fumées toxiques au moment du

soudage.

AVERTISSEMENT

AVERTISSEMENT

LES ETINCELLES ET LES PROJECTIONS BRULANTES

PEUVENT CAUSER DES BLESSURES.

Le piquage et le meulage produisent des particules

métalliques volantes. En refroidissant, la soudure peut

projeter du éclats de laitier.

LE SOUDAGE PEUT CAUSER UN INCENDIE OU UNE

EXPLOSION

L’arc produit des étincellies et des projections. Les

particules volantes, le métal chaud, les projections de

soudure et l’équipement surchauffé peuvent causer un

incendie et des brûlures. Le contact accidentel de

l’électrode ou du fil-électrode avec un objet métallique

peut provoquer des étincelles, un échauffement ou un

incendie.

1. Protégez-vous, ainsi que les autres, contre les étincelles et du

métal chaud.

2. Ne soudez pas dans un endroit où des particules volantes ou des

projections peuvent atteindre des matériaux inflammables.

3. Enlevez toutes matières inflammables dans un rayon de 10, 7

mètres autour de l’arc, ou couvrez-les soigneusement avec des

bâches approuvées.

4. Méfiez-vous des projections brulantes de soudage susceptibles

de pénétrer dans des aires adjacentes par de petites ouvertures

ou fissures.

5. Méfiez-vous des incendies et gardez un extincteur à portée de la

main.

6. N’oubliez pas qu’une soudure réalisée sur un plafond, un plancher,

une cloison ou une paroi peut enflammer l’autre côté.

7. Ne soudez pas un récipient fermé, tel un réservoir ou un baril.

8. Connectez le câble de soudage le plus près possible de la zone

de soudage pour empêcher le courant de suivre un long parcours

inconnu, et prévenir ainsi les risques d’électrocution et d’incendie.

9. Ne dégelez pas les tuyaux avec un source de courant.

10. Otez l’électrode du porte-électrode ou coupez le fil au tube-contact lorsqu’inutilisé après le soudage.

11. Portez des vêtements protecteurs non huileux, tels des gants en

cuir, une chemise épaisse, un pantalon revers, des bottines de

sécurité et un casque.

1. Portez un écran facial ou des lunettes protectrices

approuvées. Des écrans latéraux sont recommandés.

2. Portez des vêtements appropriés pour protéger la peau.

AVERTISSEMENT

LES BOUTEILLES ENDOMMAGEES PEUVENT

EXPLOSER

Les bouteilles contiennent des gaz protecteurs sous

haute pression. Des bouteilles endommagées peuvent

exploser. Comme les bouteilles font normalement partie

du procédé de soudage, traitez-les avec soin.

1. Protégez les bouteilles de gaz comprimé contre les sources de

chaleur intense, les chocs et les arcs de soudage.

2. Enchainez verticalement les bouteilles à un support ou à un cadre

fixe pour les empêcher de tomber ou d’être renversées.

3. Eloignez les bouteilles de tout circuit électrique ou de tout soudage.

4. Empêchez tout contact entre une bouteille et une électrode de

soudage.

5. N’utilisez que des bouteilles de gaz protecteur, des détendeurs,

des boyauxs et des raccords conçus pour chaque application

spécifique; ces équipements et les pièces connexes doivent être

maintenus en bon état.

6. Ne placez pas le visage face à l’ouverture du robinet de la bouteille

lors de son ouverture.

7. Laissez en place le chapeau de bouteille sauf si en utilisation ou

lorsque raccordé pour utilisation.

8. Lisez et respectez les consignes relatives aux bouteilles de gaz

comprimé et aux équipements connexes, ainsi que la publication

P-1 de la CGA, identifiée dans la liste de documents ci-dessous.

AVERTISSEMENT

LES MOTEURS PEUVENT ETRE DANGEREUX

LES GAZ D’ECHAPPEMENT DES MOTEURS PEUVENT

ETRE MORTELS.

Les moteurs produisent des gaz d’échappement nocifs.

SAFETY INSTRUCTIONS 1-8 Manual No. 0-5135

Page 15

1. Utilisez l’équipement à l’extérieur dans des aires ouvertes et bien

ventilées.

ULTRAFEED VA 4000S

Les accumulateurs contiennent de l’électrolyte acide et

dégagent des vapeurs explosives.

2. Si vous utilisez ces équipements dans un endroit confiné, les

fumées d’échappement doivent être envoyées à l’extérieur, loin

des prises d’air du bâtiment.

AVERTISSEMENT

LE CARBURANT PEUR CAUSER UN INCENDIE OU UNE

EXPLOSION.

Le carburant est hautement inflammable.

1. Arrêtez le moteur avant de vérifier le niveau e

carburant ou de faire le plein.

2. Ne faites pas le plein en fumant ou proche d’une source d’étincelles

ou d’une flamme nue.

3. Si c’est possible, laissez le moteur refroidir avant de faire le plein

de carburant ou d’en vérifier le niveau au début du soudage.

4. Ne faites pas le plein de carburant à ras bord: prévoyez de l’espace

pour son expansion.

5. Faites attention de ne pas renverser de carburant. Nettoyez tout

carburant renversé avant de faire démarrer le moteur.

AVERTISSEMENT

1. Portez toujours un écran facial en travaillant sur un accumu-lateur.

2. Arrêtez le moteur avant de connecter ou de déconnecter des câbles

d’accumulateur.

3. N’utilisez que des outils anti-étincelles pour travailler sur un

accumulateur.

4. N’utilisez pas une source de courant de soudage pour charger un

accumulateur ou survolter momentanément un véhicule.

5. Utilisez la polarité correcte (+ et –) de l’accumulateur.

AVERTISSEMENT

LA VAPEUR ET LE LIQUIDE DE REFROIDISSEMENT

BRULANT SOUS PRESSION PEUVENT BRULER LA

PEAU ET LES YEUX.

Le liquide de refroidissement d’un radiateur peut être

brûlant et sous pression.

1. N’ôtez pas le bouchon de radiateur tant que le moteur n’est pas

refroidi.

2. Mettez des gants et posez un torchon sur le bouchon pour l’ôter.

DES PIECES EN MOUVEMENT PEUVENT CAUSER DES

BLESSURES.

3. Laissez la pression s’échapper avant d’ôter complètement le

bouchon.

Des pièces en mouvement, tels des ventilateurs, des

rotors et des courroies peuvent couper doigts et mains,

ou accrocher des vêtements amples.

1. Assurez-vous que les portes, les panneaux, les capots et les

protecteurs soient bien fermés.

2. Avant d’installer ou de connecter un système, arrêtez le moteur.

3. Seules des personnes qualifiées doivent démonter des protecteurs

ou des capots pour faire l’entretien ou le dépannage nécessaire.

4. Pour empêcher un démarrage accidentel pendant l’entretien,

débranchez le câble d’accumulateur à la borne négative.

5. N’approchez pas les mains ou les cheveux de pièces en

mouvement; elles peuvent aussi accrocher des vêtements amples

et des outils.

6. Réinstallez les capots ou les protecteurs et fermez les portes après

des travaux d’entretien et avant de faire démarrer le moteur.

AVERTISSEMENT

DES ETINCELLES PEUVENT FAIRE EXPLOSER UN

1.06 Principales Normes De Securite

Safety in Welding and Cutting, norme ANSI Z49.1, American

Welding Society, 550 N.W. LeJeune Rd., Miami, FL 33128.

Safety and Health Standards, OSHA 29 CFR 1910, Superintendent

of Documents, U.S. Government Printing Office, Washington, D.C.

20402.

Recommended Safe Practices for the Preparation for Welding and

Cutting of Containers That Have Held Hazardous Substances,

norme AWS F4.1, American Welding Society, 550 N.W. LeJeune

Rd., Miami, FL 33128.

National Electrical Code, norme 70 NFPA, National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

Safe Handling of Compressed Gases in Cylinders, document P-1,

Compressed Gas Association, 1235 Jefferson Davis Highway, Suite

501, Arlington, VA 22202.

Code for Safety in Welding and Cutting, norme CSA W117.2

Association canadienne de normalisation, Standards Sales, 276

Rexdale Boulevard, Rexdale, Ontario, Canada M9W 1R3.

Safe Practices for Occupation and Educational Eye and Face

Protection, norme ANSI Z87.1, American National Standards

Institute, 1430 Broadway, New York, NY 10018.

Cutting and Welding Processes, norme 51B NFPA, National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

ACCUMULATEUR; L’ELECTROLYTE D’UN ACCUMULATEUR PEUT BRULER LA PEAU ET LES YEUX.

Manual No. 0-5135 1-9 SAFETY INSTRUCTIONS

Page 16

ULTRAFEED VA 4000S

1.07 Graphique de Symbole

Seulement certains de ces symboles apparaîtront sur votre modèle.

Sous Tension

Hors Tension

Tension dangereuse

Augmentez/Diminuer

Disjoncteur

Source AC Auxiliaire

Fusible

Intensité de Courant

Tension

Hertz (cycles/sec)

Fréquence

Négatif

Positif

X

%

Mono Phasé

Trois Phasé

Tri-Phase Statique

Fréquence Convertisseur

Transformateur-Redresseur

Distant

Facteur de Marche

Pourcentage

Panneau/Local

Soudage Arc Electrique

Avec Electrode Enrobé

(SMAW)

Soudage á L’arc Avec

Fil Electrodes Fusible

(GMAW)

Soudage á L’arc Avec

Electrode Non Fusible

(GTAW)

Decoupe Arc Carbone

(CAC-A)

Courant Constant

Tension Constante

Ou Potentiel Constant

Déroulement du Fil

Alimentation du Fil Vers

la Pièce de Fabrication

Hors Tension

Torch de

Purge Du Gaz

Soudure Par Point

Duréc du Pulse

t

t1

Appuyez pour dèruarer

l’alimentation du fils et la soudure,

le relâcher pour arrêter.

Maintenez appuyez pour pré-dèbit,

relailez pour initier l'arc. Appuyez

pour arrêter l'arc, et mainteuir pour

pré-dèbit.

Durée de Pré-Dèbit

Durée de Post-Dèbit

t2

Soudage

Mode Continu de

Soudure

Détente à 2-Temps

Détente à 4-Temps

Courant Continue (DC)

Terre de Protection

Ligne

Connexion de la Ligne

Source Auxiliaire

115V 15A

SAFETY INSTRUCTIONS 1-10 Manual No. 0-5135

Classement de PriseSource Auxiliaire

Haute Température

Force d'Arc

Amorçage de L’arc au

Contact (GTAW)

Inductance Variable

Tension

V

t

IPM

MPM

Probléme de Terre

Pouces Par Minute

Mètres Par Minute

Art # A-07639

Page 17

ULTRAFEED VA 4000S

1.08 Declaration Of Conformity

Manufacturer: Thermadyne Corporation

Address: 82 Benning Street

West Lebanon, New Hampshire 03784

USA

The equipment described in this manual conforms to all applicable aspects and regulations of the ‘Low Voltage Directive’ (2006/95 EC) and to

the National legislation for the enforcement of this Directive.

The equipment described in this manual conforms to all applicable aspects and regulations of the “EMC Directive” (European Council Directive

89/336/EEC) and to the National legislation for the enforcement of this Directive.

Serial numbers are unique with each individual piece of equipment and details description, parts used to manufacture a unit and date of

manufacture.

National Standard and Technical Specifications

The product is designed and manufactured to a number of standards and technical requirements. Among them are:

• CSA (Canadian Standards Association) standard C22.2 number 60 for Arc welding equipment.

• UL (Underwriters Laboratory) rating 94VO flammability testing for all printed-circuit boards used.

• CENELEC EN50199 EMC Product Standard for Arc Welding Equipment.

• ISO/IEC 60974-1 (BS 638-PT10) (EN 60 974-1) (EN50192) (EN50078) applicable to plasma cutting

equipment and associated accessories.

• For environments with increased hazard of electrical shock, Power Supplies bearing the S mark conform to EN50192 when used in

conjunction with hand torches with exposed cutting tips, if equipped with properly installed standoff guides.

• Extensive product design verification is conducted at the manufacturing facility as part of the routine design and manufacturing process.

This is to ensure the product is safe, when used according to instructions in this manual and related industry standards, and performs as

specified. Rigorous testing is incorporated into the manufacturing process to ensure the manufactured product meets or exceeds all

design specifications.

Thermadyne has been manufacturing products for more than 30 years, and will continue to achieve excellence in our area of manufacture.

Manufacturers responsible representative:

Steve Ward

Operations Director

Thermadyne Europe

Europa Building

Chorley N Industrial Park

Chorley, Lancashire,

England PR6 7BX

Manual No. 0-5135 1-11 SAFETY INSTRUCTIONS

Page 18

ULTRAFEED VA 4000S

This Page Intentionally Blank

SAFETY INSTRUCTIONS 1-12 Manual No. 0-5135

Page 19

ULTRAFEED VA 4000S

!

SECTION 2:

INTRODUCTION

2.01 How To Use This Manual

This Owner’s Manual applies to just specification or part

numbers listed on page 1.

To ensure safe operation, read the entire manual, including

the chapter on safety instructions and warnings.

Throughout this manual, the words WARNING,

CAUTION, and NOTE may appear. Pay particular attention

to the information provided under these headings. These

special annotations are easily recognized as

follows:

WARNING

A WARNING gives information regarding

possible personal injury.

2.02 Equipment Identification

The unit’s identification number (specification or part

number), model, and serial number usually appear on a

nameplate attached to the rear panel. In some cases, the

nameplate may be attached to the control panel.

Equipment which does not have a name plate such as

gun and cable assemblies is identified only by the

specification or part number printed on the shipping

container. Record these numbers on the bottom of page

i for future reference.

2.03 Receipt Of Equipment

When you receive the equipment, check it against the

invoice to make sure it is complete and inspect the

equipment for possible damage due to shipping. If there

is any damage, notify the carrier immediately to file a

claim. Furnish complete information concerning damage

claims or shipping errors to the location in your area

listed in the inside back cover of this manual.

Include all equipment identification numbers as described

above along with a full description of the parts in error.

CAUTION

A CAUTION refers to possible equipment

damage.

NOTE

A NOTE offers helpful information concerning

certain operating procedures.

Additional copies of this manual may be purchased by

contacting Thermal Arc at the address and phone number

in your area listed in the inside back cover of this manual.

Include the Owner’s Manual number and equipment

identification numbers.

Electronic copies of this manual can also be downloaded

at no charge in Acrobat PDF format by going to the

Thermal Arc web site listed below and clicking on the

Literature Library link:

http://www.thermalarc.com

Move the equipment to the installation site before uncrating the unit. Use care to avoid damaging the

equipment when using bars, hammers, etc., to un-crate

the unit.

Manual No. 0-5135 2-1 INTRODUCTION

Page 20

ULTRAFEED VA 4000S

2.04 Symbol Chart

Note that only some of these symbols will appear on your model.

On

Off

Dangerous Voltage

Increase/Decrease

Circuit Breaker

AC Auxiliary Power

Fuse

Amperage

Voltage

X

%

Single Phase

Three Phase

Three Phase Static

Frequency ConverterTransformer-Rectifier

Remote

Duty Cycle

Percentage

Panel/Local

Shielded Metal

Arc Welding (SMAW)

Gas Metal Arc

Welding (GMAW)

Wire Feed Function

Wire Feed Towards

Workpiece With

t1

Output Voltage Off.

Welding Gun

Purging Of Gas

Continuous Weld

Mode

Spot Weld Mode

Spot Time

t

Preflow Time

Postflow Time

t2

Hertz (cycles/sec)

Frequency

Negative

Positive

Direct Current (DC)

Protective Earth

(Ground)

Line

Line Connection

Auxiliary Power

Gas Tungsten Arc

Welding (GTAW)

Air Carbon Arc

Cutting (CAC-A)

Constant Current

Constant Voltage

Or Constant Potential

High Temperature

Fault Indication

Arc Force

Touch Start (GTAW)

Variable Inductance

2 Step Trigger

Operation

Press to initiate wirefeed and

welding, release to stop.

4 Step Trigger

Operation

Press and hold for preflow, release

to start arc. Press to stop arc, and

hold for preflow.

Burnback Time

t

IPM

MPM

Inches Per Minute

Meters Per Minute

115V 15A

Receptacle RatingAuxiliary Power

Voltage Input

V

Art # A-04130

INTRODUCTION 2-2 Manual No. 0-5135

Page 21

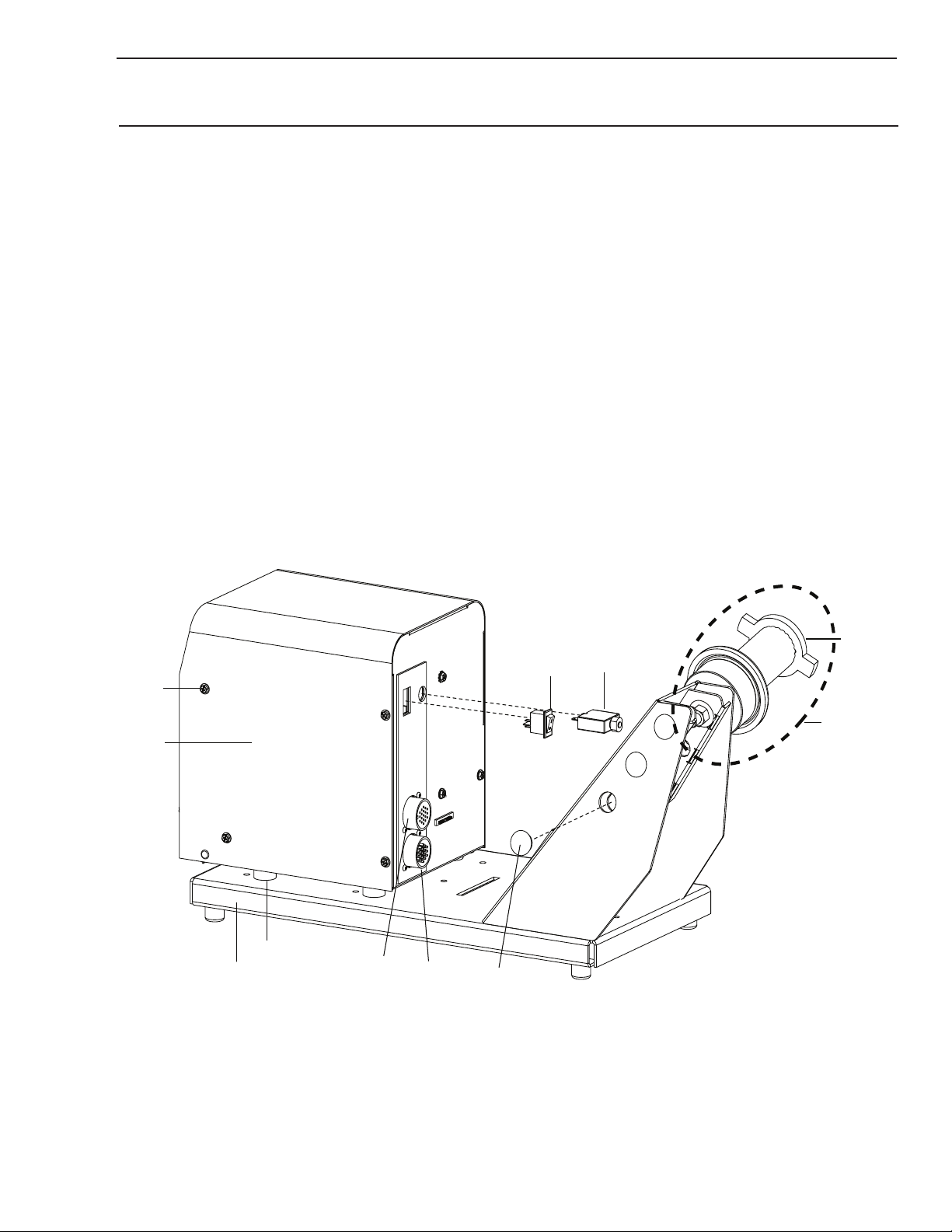

2.05 General Information

ULTRAFEED VA 4000S

The ULTRAFEED VA 4000S is a semiautomatic, solid state

controller and Separation wire feeder capable of a 100%

duty cycle. The system offers both load and line voltage

compensation helping to maintain a constant wire feed

speed, even with changes in the input voltage and/or load.

The ULTRAFEED VA 4000S sheet metal box totally

encloses the solid state control circuitry. A hinged, latched

feedhead cover allows quick and easy access to the

feedhead featuring quick change feed rolls, and tool-less

knobs and clamps for changeover of guides and guns.

The ULTRAFEED VA 4000S comes with an abundance of

standard features including:

• an on/off rocker switch

• a circuit breaker for total system protection

• a wire feed speed control

• a power source voltage control

• an inch switch

• a gas purge switch

• a 2 step / 4 step selector switch

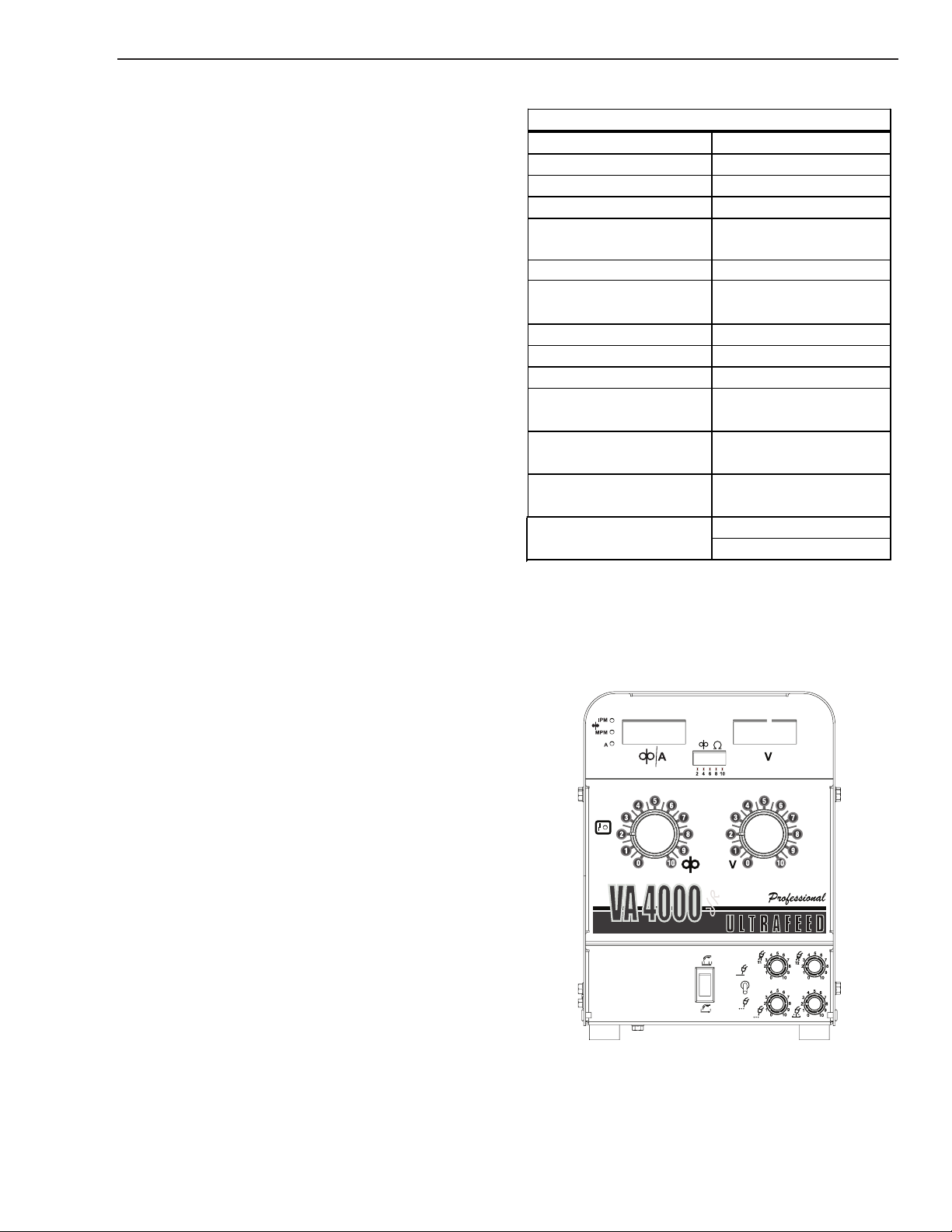

UltraFeed VA 4000S Specifications

Input Voltage:

Input Frequency: 50/60 Hz

Input Voltage Tolerance ±10%

Maximum Input Current 4.0 Amps

Wire Speed Range

for All Filler Wire Sizes

Wire Sizes

Maximum Wire

Coil/Spool Weight

Feed Rolls 4 (All Driven)

Welding Current (I) 500 A @ 100%

Welding Gun/Torch Size Tweco #4 Std

Maximum Shielding Gas

Inlet Pressure

Weight (Less Wire)

Weight (Less Wire)

Approvals NEMA EW 3

115 VAC

50 - 875 IPM

1.25 - 22.1 MPM

0.024 - 1/8" / 0.6 - 3.2

60 lb. / 27 kg

100 P.S.I. / 6.9 Bar

35 lbs. / 15.9 kg

VA4000S

28 lbs. / 12.7 kg

Separation Unit

IEC 60974-1

• PC board adjustments for enhanced runin control

• a solid state electronic brake for dynamic braking

• four quick change, gear-driven feed rolls

• a gas valve solenoid

• a low voltage gun trigger circuit for operator safety

• a variety of add-on options to configure the unit for

any wire-welding situation.

The ULTRAFEED VA 4000S has been designed to comply

with CSA NRTL/C, NEMA EW 3, and IEC 60974-1

standards.

Table 2-1: Product Specifications

S

S

S

Art # A-09220

Figure 2-1: Ultrafeed VA 4000S Front View

Manual No. 0-5135 2-3 INTRODUCTION

Page 22

ULTRAFEED VA 4000S

g

(

p

2.06 Features and Benefits

UltraFeed VA 4000S Features & Benefits

Features Benefits

A. Improved wire speed accuracy.

1. Solid State Control

2. Standard Inch/Purge

3. Standard 2 Step / 4 Step

4. Standard Remote Voltage

5. Standard 6'Control Cable A. Ready to weld.

6. Interface Cable, 32' A. Provides communication to Separation Unit

B. Line voltage compensation.

C. Load compensation.

D. Current limit to motor.

A. Allows “cold” inchin

B. Allows purging of gas without running wire.

A. Allows gun switch activated control as standard (2 Step) or

with preflow, trigger hold, and postflow

A. Allows adjustment of power source arc voltage from the wire

feeder.

B. Operator has full control of welding parameters at the wire

feeder; can remote power source.

of wire at set wire feed speed.

4 Step).

7. Run-In Parameter Adjustment

8. Ground Fault Protection

9. Input Circuit Breaker A. Provides total system protection.

10. Electronic Motor Protection

11. Small Size A. Takes up small amount of space.

12. Upgradable A. Full set of options to build feeder to your needs.

13. Quick Change Feed Rolls

14. Rotatable Feedhead

15. Gun Clamp Knob

16. Welding Gun Quick Connects A. Offers a quick and easy connection for welding guns.

17. Hinged Feedhead Cover A. Permits quick and easy access to the wire drive system.

18. Dynamic Brake

19. Replaceable Motor Brushes A. Extends motor life.

20. Needle Bearing Construction

On MotorOutput Shaft

21. Gas Valve Solenoid A. Controls the “on / off” flow of shielding gas.

22. 100% Duty Cycle A. Eliminates shutdowns due to overtemperature.

A. DIP switch located on motor control board allows operator to

tune starting characteristics to improve starting.

A. Provides protection against ground fault currents.

B. Signals operator of ground fault with STATUS LED.

A. Protects motor.

B. Eliminates need for fuse

A. Allows operator to change feed rolls without the use of tools.

B. Both feed rolls are gear-driven.

A. Allows operator to modify angle of feedhead to limit severity

of bends on the wire. Improved feedability.

A. Allows operator to secure welding gun to the feedhead

without the use of tools.

A. Solid State control of motor brake offers precise stopping of

the wire.

A. Reduces friction and extends bearing life over a sleeve

bearing.

rotection.

2.07 Options and Accessories

Refer to the Appendix section of this manual for the list of available options and accessories for this product.

INTRODUCTION 2-4 Manual No. 0-5135

Page 23

ULTRAFEED VA 4000S

SECTION 3:

INSTALLATION

3.01 Connections

Refer to the System Outline drawing in the Appendix of

this manual for details.

1. Make the proper welding cable connections

between the power source and wire feeder and

between the power source and work connection.

2. Connect the control cable from the feeder to the

controller and between the controller and power

source. Control cable extensions are available;

Refer to Available Options.

NOTE

An optional 870000-001 adapter cable will be

required for connection to a power source with

only a 5 pin amphenol connection and AC

voltage outlets. An optional 870093B-001

adapter cable will be required for connection

to a power source with only a 14 pin amphenol

connection. These options are only applicable

to 19 pin plug units.

3. Make the proper gas line connection from the gas

supply to the wire feeder gas valve (if gas will be

used).

3.03 EMI Considerations

Electromagnetic interference (EMI) is common in today’s

complex industrial environment. At times, EMI levels can

become great enough to affect the operation of the

machinery. To help reduce and safeguard against EMI

levels in the welding area, follow these simple guidelines:

1. Firmly secure all sheet metal panels on the power

source and wire feeder. Repair or replace heavily

corroded or damaged panels and/or fasteners.

2. Keep the welding cables and control cables as

short as possible.

3. Route the ‘+’ and ‘-’ welding cables from a

particular power source together.

4. Keep the welding cables as straight as possible;

avoid coiling up the cables.

5. Route the control cable away from the welding

cables.

NOTE

Grounding of the workpiece may reduce

emissions in some, but not all circumstances.

To prevent the risk of injury or damage to other

electrical equipment when grounding the

workpiece, take care to follow all local laws

and regulations.

4. Attach the welding gun to the wire feeder.

5. Connect the welding gun control leads to the wire

feeder gun switch terminals located on the front

of the feeder.

3.02 Grounding

To assure operator safety in the case of a fault condition,

the frame of the power source (welding machine) must

be grounded. The wire feeder sheet metal frame is

grounded only through pin G (for 19 pin plug) of the

control cable that connects to the power source.

Therefore, if the power source frame is not grounded,

then, the wire feeder sheet metal frame is not grounded,

and a shock hazard could possibly develop. Follow the

instructions found in the power source Owner’s Manual

for correct grounding methods.

Manual No. 0-5135 3-1 INSTALLATION

Page 24

ULTRAFEED VA 4000S

3.04 Input And Output Wire Guide Installation

Refer to Figure 3-1.

Install the input wire guide (the longer one) by loosening

the input guide lockscrew and inserting the guide into

the hole in the feedhead assembly. The recessed end of

the guide should be toward the wire spool. Adjust the

guide so that it is clear of the feed rolls and tighten the

input guide lockscrew.

Input Guide Lockscrew

Install the output wire guide in the same manner, with the

conical end toward the feed rolls. The tip of the conical

end should be as close to the feed rolls as practical.

Tighten the output guide lockscrew.

NOTE

Before tightening the input and output guide

lockscrews, install the drive roll to help in the

alignment of the wire guides.

Output Wire Lockscrew

Art # A-07376

Center Wire Guide

Input Wire Guide

Figure 3-1: Wire Guide Installation

INSTALLATION 3-2 Manual No. 0-5135

Output Wire Guide

Page 25

ULTRAFEED VA 4000S

3.05 Selection And Installation Of Feed Rolls

NOTE

Refer to feed roll kit drawing (supplied in the

Appendix) to order feed roll kits. Kit includes

4 drive rolls, an input wire guide, a center

guide, and an output wire guide for a specific

wire type and size.

For selection of feed roll styles, refer to Feedroll Drive Kit

Drawing 171435 and Feedroll Chart 375980 in the

Appendix section of this manual.

Style 1: Feed rolls consist of flat smooth top rolls and

double smooth, vee grooved bottom rolls. They feed .024

- .068" hard and tubular wire.

Style 2: Feed rolls consist of flat knurled top rolls and a

double smooth, vee grooved bottom rolls. They feed .030

- .045" hard and tubular wire.

Style 3: Feed rolls consist of double smooth, vee grooved

drive rolls. This style supports 0.035 to 1/16” soft wire.

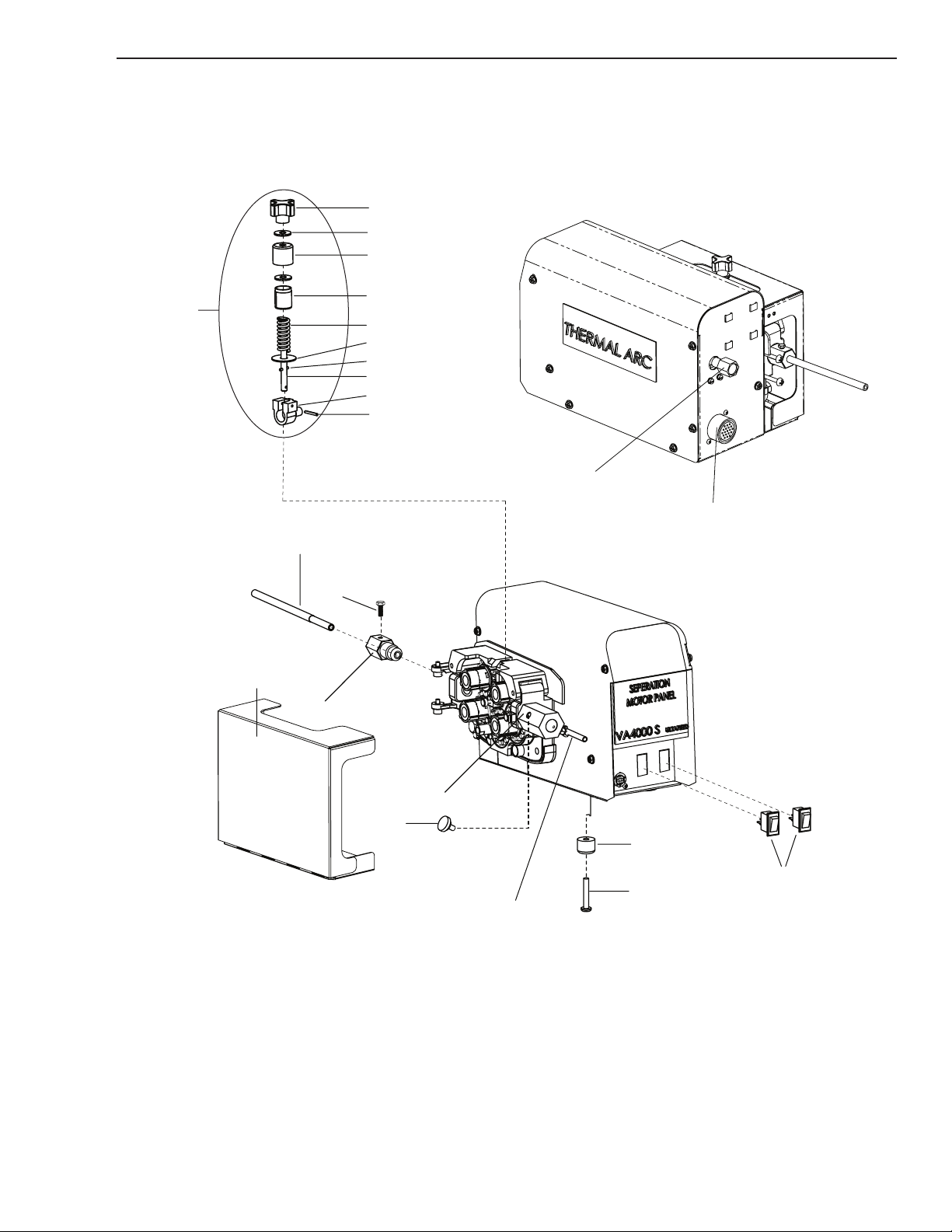

3.06 Welding Gun Compatibility And Installation

Refer to Figure 3-2.

The Ultrafeed VA 4000 S Separation Unit wire feeder is

designed to be used with most welding guns. In some

cases, a special adapter may be required.

To install the welding gun, simply loosen the gun clamp

knob and insert the welding gun into the feedhead until it

stops. Tighten the gun clamp knob and connect the

welding gun control wires to the gun switch receptacle.

NOTE

Before inserting the welding gun into the

feedhead, make sure the gun clamp does not

extend into the feedhead; otherwise, the

welding gun cannot be properly inserted.

NOTE

Check for gas leaks. If leaking gas, gun is not

all the way into the feedhead.

Style 4: Feed rolls consist of double knurled, vee grooved

grooved drive rolls. They feed .045 - 5/64" hard and tubular

wire.

Style 5: Feed rolls consist of double cog top and bottom

rolls. They feed .045 - 1/8" tubular wire.

Style 6: Feed rolls consist of double U-grooved top and

bottom feed rolls. They feed .035 - 1/16" soft wire.

NOTE

All grooved feed rolls have their wire size or

range stamped on the side of the roll. On rolls

with different size grooves, the outer (visible

when installed) stamped wire size indicates

the groove in use.

Feed rolls are removed by twisting the feed roll retainer

cap and aligning the retaining knob splines with the drive

gear splines. Feedrolls are installed by putting the feedroll

onto the drive gear splines and twisting the feedroll

retainer cap so that the splines rest against the face of

the feedroll.

Input Guide Lockscrew

Art # A-04326

Input Wire Guide

Center Wire Guide

Figure 3-2: Welding Gun Installation

Output Guide

Lockscrew

Output Wire Guide

Gun Clamp

Knob

NOTE

Installation of all styles of feed rolls for this

feeder is identical.

Manual No. 0-5135 3-3 INSTALLATION

Page 26

ULTRAFEED VA 4000S

3.07 Threading Wire Into Feedhead

Refer to Figure 3-4.

WARNING

ELECTRIC SHOCK CAN KILL! Make certain the

power source and wire feeder are turned OFF.

Do not turn the power ON until told to do so in

these instructions.

CAUTION

Use care when handling the spooled wire as

the wire tends to “unravel” when loosened

from the spool. Grasp the end of the wire

firmly, and don’t let it get away from you. Make

sure that the end of the wire is straight and

free of burrs.

1. Place end of the welding wire into the input wire guide.

Feed it through the guide and over the drive roll groove

closest to the feedhead casting.

3. Lift the pressure arm and pass the wire through the

output wire guide and into the welding gun assembly

(Refer to welding gun manual).

4. Close the pressure arm, and lock in position with the

tension lever. To adjust the amount of force the bearing

roll exerts on the welding wire, turn the spring tension

knob clockwise for increased force or

counterclockwise for decreased force.

NOTE

If the force applied to the wire is too great, the

welding wire will “bird nest” in the feedhead

and not feed properly.

5. Turn the welding machine and wire feeder ON, and

set the wire feed speed control to midrange (Refer to

Figure 4-1). Remove contact tube from welding gun.

Refer to Gun Manual. Press the gun switch or INCH

switch until wire feeds out past the gun nozzle. Thread

the contact tube over the wire and lock into place and

tighten. Cut wire off at about 1/4 inch (6 mm) from

the nozzle.

WARNING

2. Loosen the spring tension knob and pull the tension

lever forward to unlock the pressure arm.

Tension Lever

Pressure Arm

Welding Wire

The wire is electrically “HOT” if wire is fed by

depressing the gun switch. Wire contact with the

workpiece will cause an arc with gun switch

depressed. Feed motor will run feeding “HOT” wire.

Spring Tension Knob

Art # A-07276

Input Wire Guide

Center Wire Guide

Figure 3-3: Threading Wire Into Feedhead

INSTALLATION 3-4 Manual No. 0-5135

Output Wire Guide

Page 27

4.01 Front Panel

ULTRAFEED VA 4000S

SECTION 4:

OPERATION

1. FAULT INDICATOR: This LED indicates a fault condition

exists. If it is flashing, a ground fault has occurred. If

it is on continuously, the motor protection circuit has

activated.

2. WIRE FEED SPEED (WFS) CONTROL:

This knob controls wire feed speed. The wire feed

speed control knob can be adjusted during setup or

actual welding.

3. WFS/AMP METER: This meter displays the wire feed

speed or amperage.

4. WIRE SPEED FORCE METER

5. VOLT METER: Displays possible restriction in liner or

tips.

3

6. ARC VOLTAGE CONTROL: This knob controls arc

voltage or pulse frequency from the power source.

The arc voltage (or pulse reference) control can be

adjusted during setup or actual welding.

7. FUNCTION TIMERS: These knobs provide timed

control over preflow/postflow gas, wire burnback

distance and spot weld time.

8. 2 STEP / 4 STEP SWITCH: This switch selects 2 Step

or 4 Step mode of operation.

.

4

5

2

1

S

S

S

Art # A-09218

Figure 4-1: Front Panel Controls and Connections

8

6

7

Manual No. 0-5135 4-1 OPERATION

Page 28

ULTRAFEED VA 4000S

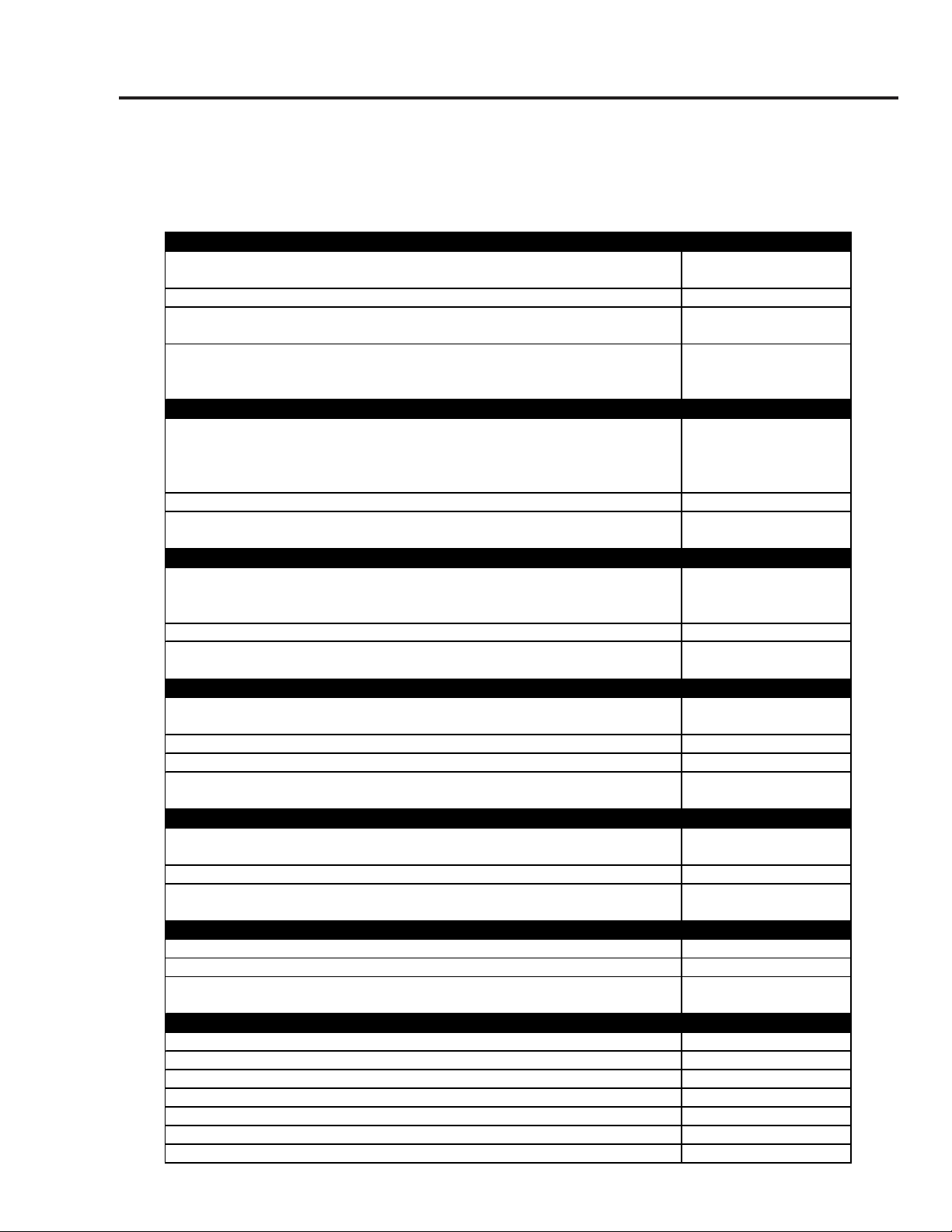

4.02 Rear Panel Controls &Connections

11.6' CONTROL CABLE PLUG: The control cable connects

to the power source at the bottom 19-pin amphenol

connector (of which 14 pins are used). It contains the

signals required to allow the welding power source

and the Separation unit to work together as a system.

Refer to figure 4-2 and 4-4.

WARNING

CAUTION

The relay contacts between pins A and B have

a maximum rating of 1/3 Horsepower (HP),

115 VAC or 10A, 230 VAC.

If the power source only has a 5 pin amphenol and AC

voltage outlets, a 870000-001 adapter cable will be

required for proper hookup with the Ultrafeed VA 4000 S

wire feeder.

The protective earth ground (pin G) of the

control cable is established

only when the

power source is properly grounded. See the

power source owner’s manual for proper

grounding methods.

Control Cable

Pin

A

B

C

D Not Used

E 115 VAC Hot

F 115 VAC Neutral

G Protec tive Earth Ground

H Remote Control Maximum

J Remote Control Signal

K Remote Control Minimum

L Control Circuit Common

M Arc Established (= +15 VDC)

N Power Source Select Line

P Not Used

R Not Used

S Not Used

T Not Used

U

V ‘-’ Power Source Terminal

Contactor + (Short ed to B to

turn on Power Source)

Contactor - (Shorted to A to

turn on Power Source)

Voltage Feedback ( 1 Volt is

10 Arc Volts), or ‘+’ Power

Source Terminal

Current Feedback (1 Volt is

100 Arc Amps)

Function

If the power source only has a 14 pin amphenol, a

870093B-001 adapter cable will be required for proper

hookup with the Ultrafeed VA 4000S wire feeder. Refer to

section 2.07 Options and Accessories.

Keyway

L

KUNB

H S RD

A

M

CPVTJ

EFG

Figure 4-2: Pin Identification Male Plug

Table 4-1: 19-Pin Control Cable Descriptions

OPERATION 4-2 Manual No. 0-5135

Page 29

ULTRAFEED VA 4000S

12.32' CONTROL CABLE SOCKET: The 32' control cable connects to the VA 4000 S controller at the upper 19-pin

amphenol connector socket (of which 14 pins are used). It contains the signals required to allow the welding

power source, controller and the wire feeder to work together as a system. Refer to figure 4-3 and 4-4

WARNING

The protective earth ground (pin G) of the control cable is established

only when the power source is

properly grounded. See the power source owner’s manual for proper grounding methods.

19 PIN CONNECTOR FOR VA4000S

PIN LETTER DESCRIPTION WIRE COLOR WIRE NUMBER

A Motor Plus RED 17

B Motor Negative BLACK 16

CGas Valve BLUE 14

DGas Valve WHITE 15

E Board Pin 4 BLACK N/A

F Dual Schedule Receptacle-not used N/A N/A

G Inch/Purge Common RED 11

H Purge BROWN 10

J Inch YELLOW 9

K Gun Switch ORANGE 7

L NOT USED N/A N/A

M Board Pin 3 RED N/A

N Board Pin 2 YELLOW N/A

P Board Pin 1 WHITE N/A

R Board Pin 5 BROWN N/A

S Dual Schedule Receptacle-not used N/A N/A

T Gun Switch BLUE 8

U Ground GREEN/YELLOW FRAME GROUND

V Board Pin 6 ORANGE N/A

Keyway

AML

KUNB

CPVTJ

HSRD

EFG

Figure 4-3: Pin Identification Female Receptacle

Manual No. 0-5135 4-3 OPERATION

Page 30

ULTRAFEED VA 4000S

13.CAN INTERFACE PORT (J2): This connection allows

the ULTRAFEED VA 4000 S to communicate with other

select Thermal Arc power sources. This is available

with the advanced interface kit.

14.SERIAL PORT (J1): This connection allows the

ULTRAFEED VA 4000 S to communicate with a

personal computer. This feature is available with the

advanced interface kit.

15.POWER ON/OFF SWITCH: This switch controls only

the wire feeder and not the power source.

16.CIRCUIT BREAKER: This breaker protects the unit

from electrical faults.

NOTE

If the circuit breaker trips, it turns the power

switch to the OFF position. A short cooling

period must be allowed before an attempt is

made to reset the unit by pressing the circuit

breaker reset switch.

18.GAS VALVE INLET: This is where the shielding gas

hose is connected to the wire feeder. The gas valve

inlet controls the “on/off” flow of shielding gas through

the welding gun.

19.32' CONTROL CABLE PLUG: The 32' control cable

connects to the VA 4000 S Separation wire feeder/

motor to this 19-pin amphenol connector plug(of

which 14 pins are used). It contains the signals

required to allow the welding power source, controller

and the wire feeder to work together as a system. Refer

to Previous Chart and figure 4-2 and 4-5.

20.WELD CABLE CONNECTION: This is where the power

source welding cable is connected to the feeder. Make

sure this connection is tight or arcing could occur.

18

15

14

13

12

11

AML

CPVTJ

EFG

AML

KUNB

H S RD

EFG

16

19

Art # A-09225

20

Figure 4-5: Separation Motor Connections

4.03 Feedhead Components

KUNB

HSRD

CPVTJ

Art # A-09223

21.INPUT GUIDE LOCKSCREW: Tighten this lockscrew

to secure the input wire guide.

22.SPRING TENSION KNOB: Use the spring tension knob

to adjust the amount of force the feed rolls exert on

the welding wire.

23.FEEDROLL GEAR / KNOB : This knob is used to secure

the feedroll to the pressure arm. Rotate the knob to

change the feedroll.

24.PRESSURE ARM: This arm pivots off the front of the

Figure 4-4: Rear Panel Controls and Connections

feedhead to allow access to the wire guides and wire

path.

25.CENTER GUIDE LOCKSCREW: Tighten this lockscrew

to secure the center wire guide.

26.OUTPUT GUIDE LOCKSCREW: Tighten this lockscrew

to secure the output wire guide.

OPERATION 4-4 Manual No. 0-5135

Page 31

ULTRAFEED VA 4000S

27.GUN CLAMP KNOB: This knob is used to tighten the welding gun into the feedhead.

28.GUN ADAPTER: This adapter accepts the welding gun plug. It can optionally be replaced with different adapters

for a variety of different guns.

29.FEEDHEAD POSITIONING SCREW (3x): These screws are tightened to position the rotation angle of the feedhead.

To change the angle of the feedhead, LOOSEN these 3 screws and turn the feedhead to the desired angle. Then

tighten the 3 screws to secure.

30.INPUT WIRE GUIDE: This guide is required to direct the welding wire from the drive roll to the welding gun cable.

31.WELD CABLE CONNECTION: This is where the power source welding cable is connected to the feeder. Make sure

this connection is tight or arcing could occur.

21

24

23

Figure 4-6: Separation Feedhead Components

4.04 Power Source Compatibility

25

22

3031

29

24

26

27

28

Art # A-09224

If the Thermal Arc power source only offers a 14 pin amphenol connector, a 870093B-001 adapter cable will be

required to connect between the 19 pin control cable of the VA 4000 S contoller and the 14 pin amphenol connector

of the power source.

The Ultrafeed VA 4000 S will also work with most competitive power sources that provide 115 VAC and require a relay

closure to become energized.

Manual No. 0-5135 4-5 OPERATION

Page 32

ULTRAFEED VA 4000S

4.05 Power Source Compatibility Details

Power Source Compatibility Details

Machine Details

PowerMaster 500 Fully Compatible

PowerMaster 500P For GMAW - Set Motor Control S1 Switches for:

Runin Speed 25%, Motor Ramp Rate 0.3 S, Arc Established ON.

For Pulse GMAW - Set Motor Control S1 Switches for:

Runin Speed - 75%, Motor Ramp Rate - 0.2 S, Arc Established - ON

ExcelArc 6045 Fully Compatible

ExcelArc 8065 For GMAW - Set Motor Control S1 Switches for:

Runin Speed 50%, Motor Ramp Rate 0.2 S, Arc Established ON.