Page 1

8. TORCH OPERATION

Torch Parts Selection

The application will determine which torch parts must be used. Refer to the cut charts for the proper torch parts to

install for a selected application.

Do not interchange parts. Make sure all torch parts correspond with the

plasma and shield gases in use for the application.

Pre-Setting Power Supply Controls

Set the Power Supply controls prior to operating the system as described in the power supply Operating Manual.

Refer to the cutting charts for the proper cutting parameters for the application.

Recommended Cutting Speeds

Cutting speed depends on material and thickness. The following factors may affect system performance:

• Torch parts wear; gas quality and mass flow / pressure; operator experience; torch standoff height; proper

work cable connection; alloying contents of material; cutting table capabilities & accuracy.

This information represents realistic expectations using recommended

practices and well-maintained systems. Actual speeds may vary from

those shown in the charts depending on the alloy content of the selected

material. Voltage ratings may vary depending on the CNC, cutting table,

or height controller.

For complete cutting speed chart data refer to the following pages.

Consumables Notes

Always assemble the consumable parts properly. Improper assembly may damage the parts or the torch head.

Ensure that parts are seated together correctly.

Always check the shield gas distributor for charring when changing parts. Do not use the distributor if it is charred.

Replace the shield gas distributor regularly to ensure proper performance.

Operational Notes

Always purge the torch after changing consumables or if the power supply has been shut off. The power supply's

built-in purge function may not be enough to properly purge the torch. Manually flow gas with the 'Test Cut Flow' and

'Test Pre-Flow' functions to help remove any remaining coolant from the lines.

Slightly increasing the preflow pressure may increase piercing ability on thicker materials. However, increasing the

preflow pressure too much may affect plasma starting reliability (misfiring).

Decreasing preflow pressure may improve piloting. Preflow pressure can be reduced without affecting cut performance as long as the pilot arc still transfers to the plate well. Decreasing preflow pressure too much will affect the

ability to transfer the arc to the plate and may cause damage to the tip.

Notes on Chart Measurements

Pressure measurements in the charts are in psi(g), not psi(a). 0 psi(g) = 14.7 psi(a) (1 atmosphere).

Ball settings are at the center of the gauge ball.

Manual 0-4825 Rev. AK 8-1 TORCH DATA for AutoCut Basic

Page 2

Ohmic Sensing

Ohmic sensing is not recommended with water shield. Water on the plate interferes electrically with the ohmic

sensing circuit.

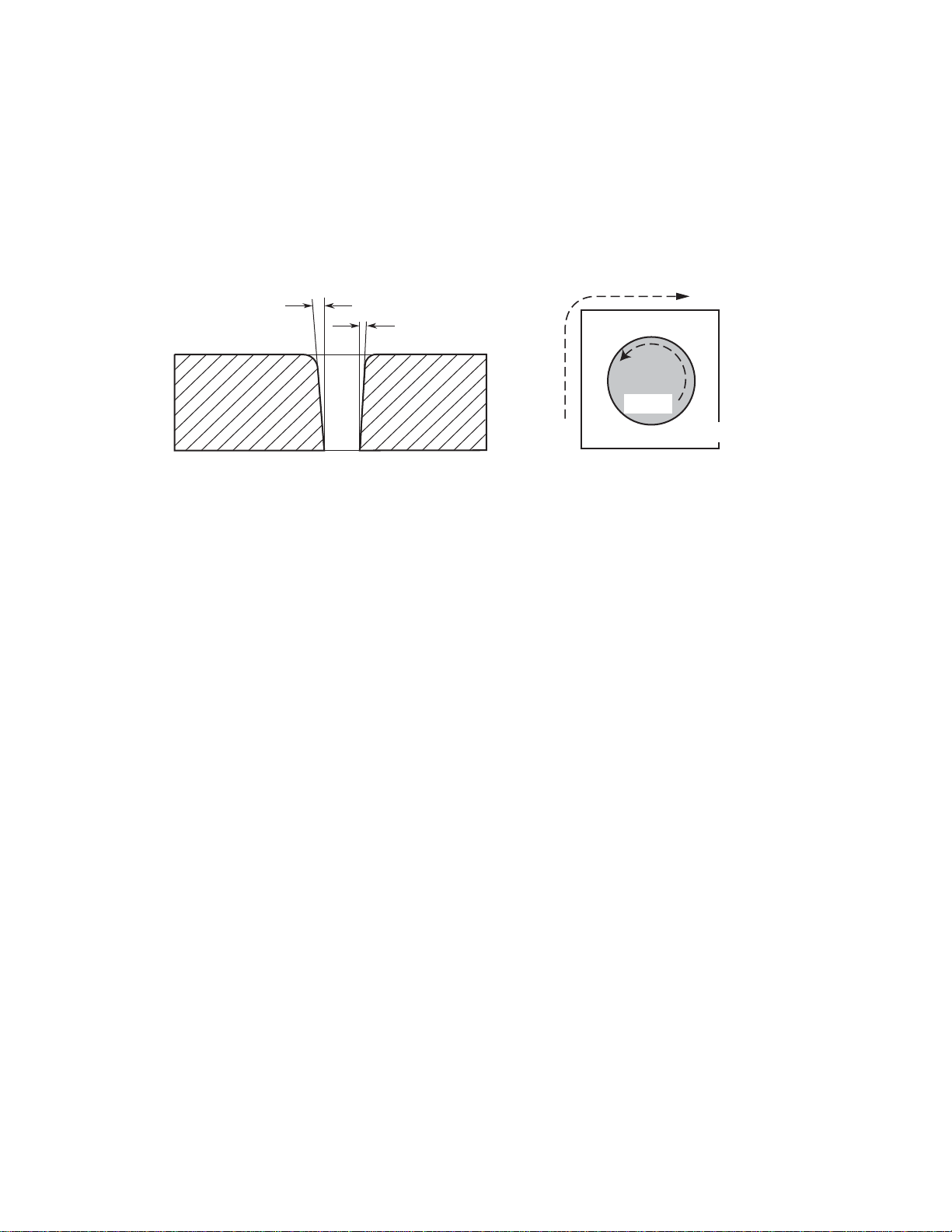

Direction of Cut

The plasma gas stream swirls as it leaves the torch to maintain a stable arc column. This swirl effect results in one

side of a cut being more square than the other. Viewed along the direction of travel, the right side of the cut is more

square than the left.

Left Side

Cut Angle

Right Side

Cut Angle

A-00512

Clockwise

Scrap

Counter-

Clockwise

Scrap

Workpiece

Art # A-04182

Side Characteristics Of Cut

To make a square - edged cut along an inside diameter of a circle, move the torch counterclockwise around the circle.

To keep the square edge along an outside diameter cut, move the torch in a clockwise direction.

Underwater Cutting

Cutting on a water table either underwater or with the water touching the plate or with a water muffler system is not

recommended. If a water table is used the water level must be a minimum of 4 inches / 100 mm from the bottom of the

plate. Failure to follow this recommendation could result in poor cut quality and short consumable parts life.

TORCH DATA for AutoCut Basic 8-2 Manual 0-4825 Rev. AK

Page 3

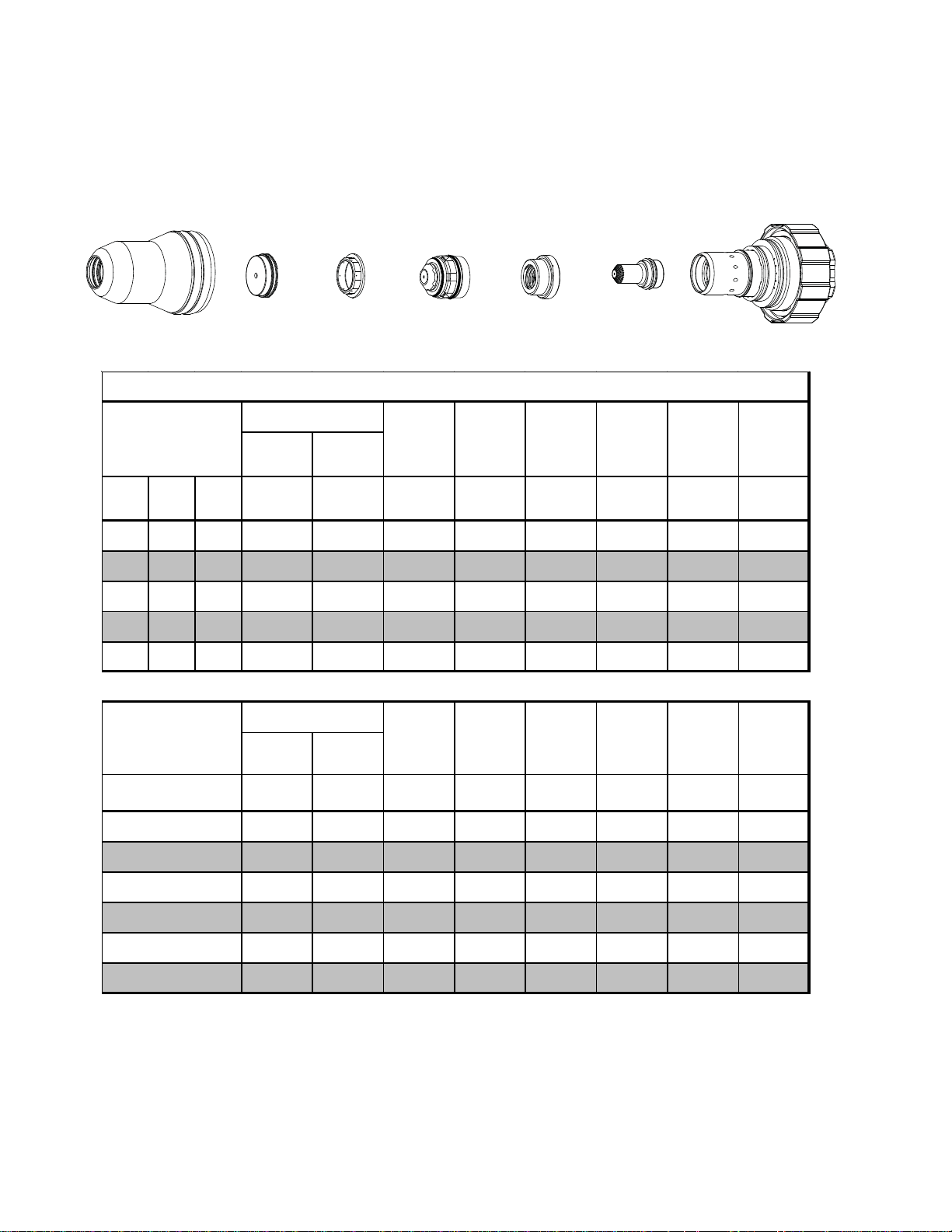

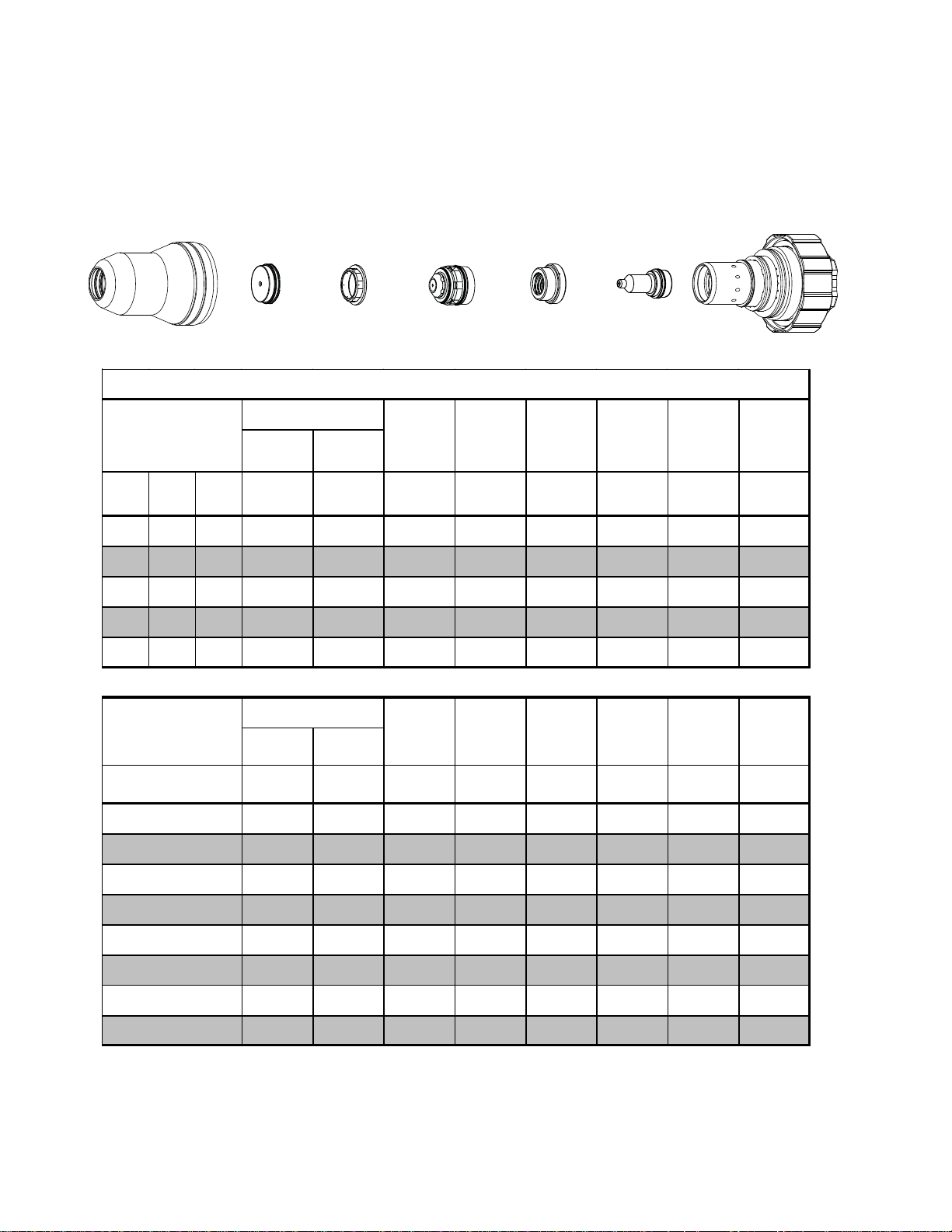

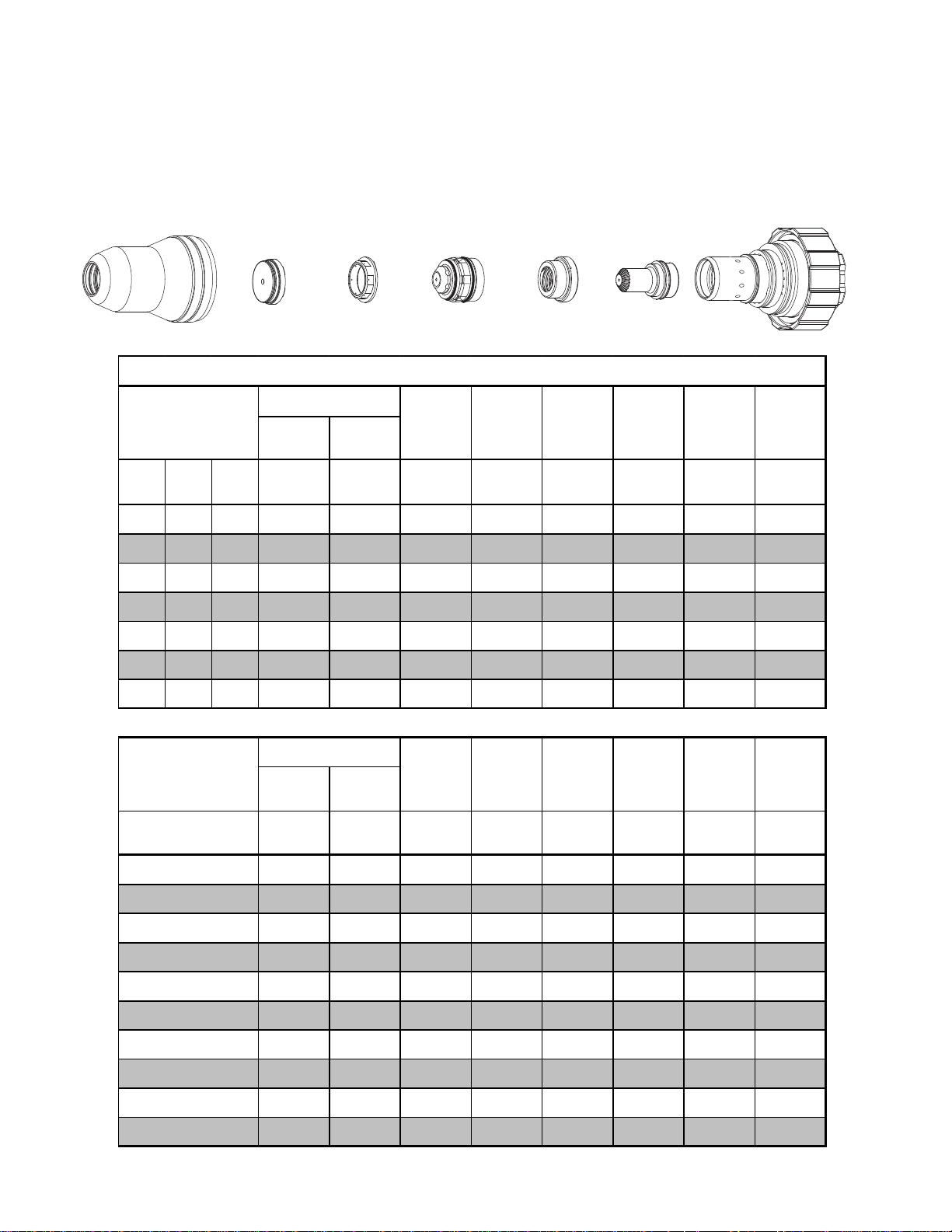

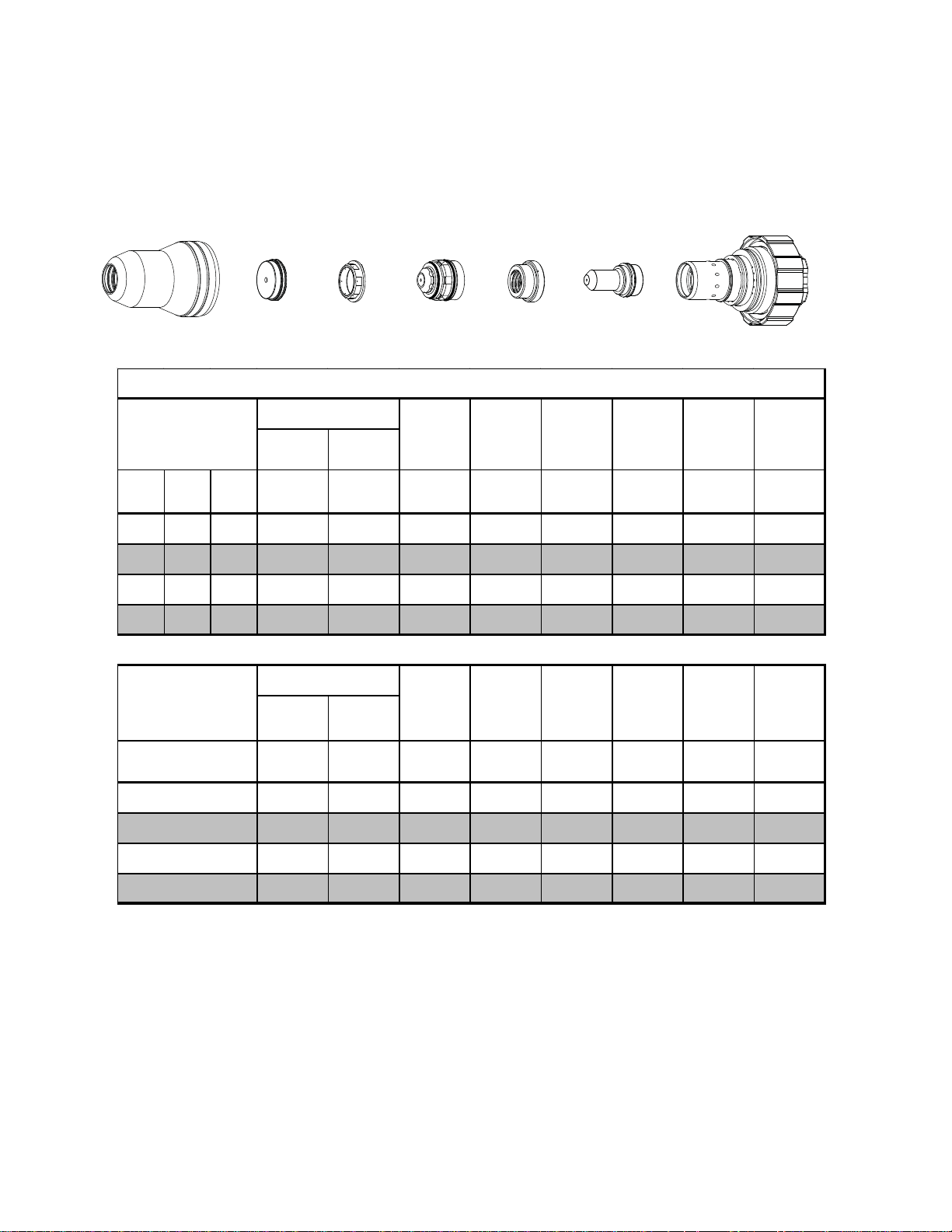

Mild Steel

55A

Air Plasma / Air Shield

Shield Cup

35-1016

Shield Cap

35-1025

Shield Gas

Distributor

35-1272

Tip

35-1051

Plasma Gas Distributor

35-1041

Electrode

35-1069

Cartridge

35-1020

Art # A-04941

55A Mild Steel (Air/Air)

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow Pr essures

Plasma

(Air)

Shield

(Air)

Arc

Voltage

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

21 0.033 70 20 152 0.188 500 0.200 0.1 0.079

16 0.060 70 20 154 0.188 300 0.200 0.1 0.086

10 0.135 92 80 166 0.188 190 0.200 0.2 0.079

3/16 0.188 92 80 166 0.188 130 0.250 0.3 0.089

1/4 0.250 92 80 170 0.188 95 0.250 0.3 0.090

Material

Thickness

(mm)

1

2

3

4

5

6

Cut Flow Pr essures

Plasma

(Air)

(Bar) (Bar) Volts

Shield

(Air)

Arc

Voltage

4.8 1.4 152 4.8 11500 5.1 0.1 2.0

4.8 1.4 157 4.8 6920 5.1 0.1 2.1

6.3 5.5 163 4.8 5460 5.1 0.2 2.0

6.3 5.5 166 4.8 4180 5.6 0.2 2.1

6.3 5.5 167 4.8 3180 6.4 0.3 2.3

6.3 5.5 169 4.8 2610 6.4 0.3 2.3

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-5 TORCH DATA for AutoCut Basic

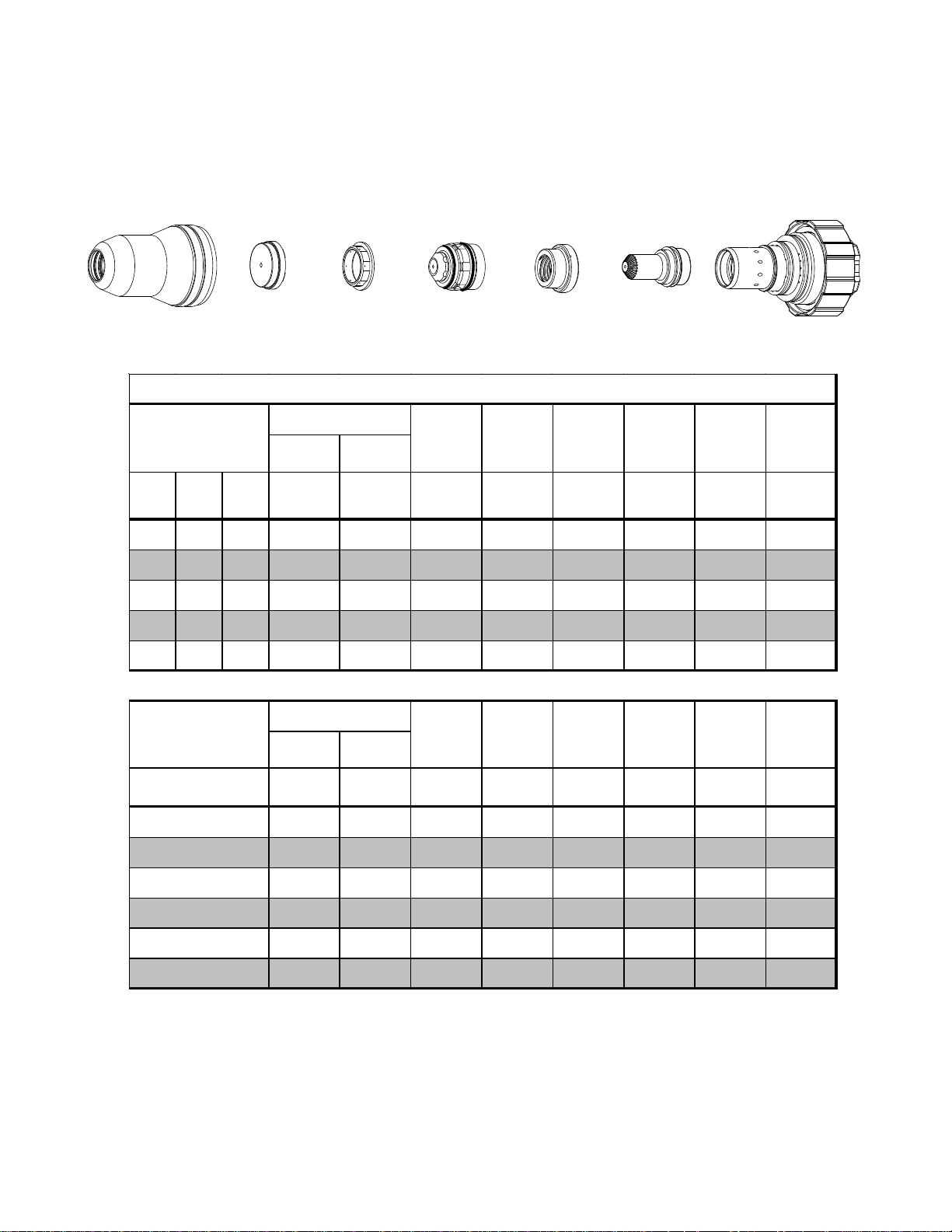

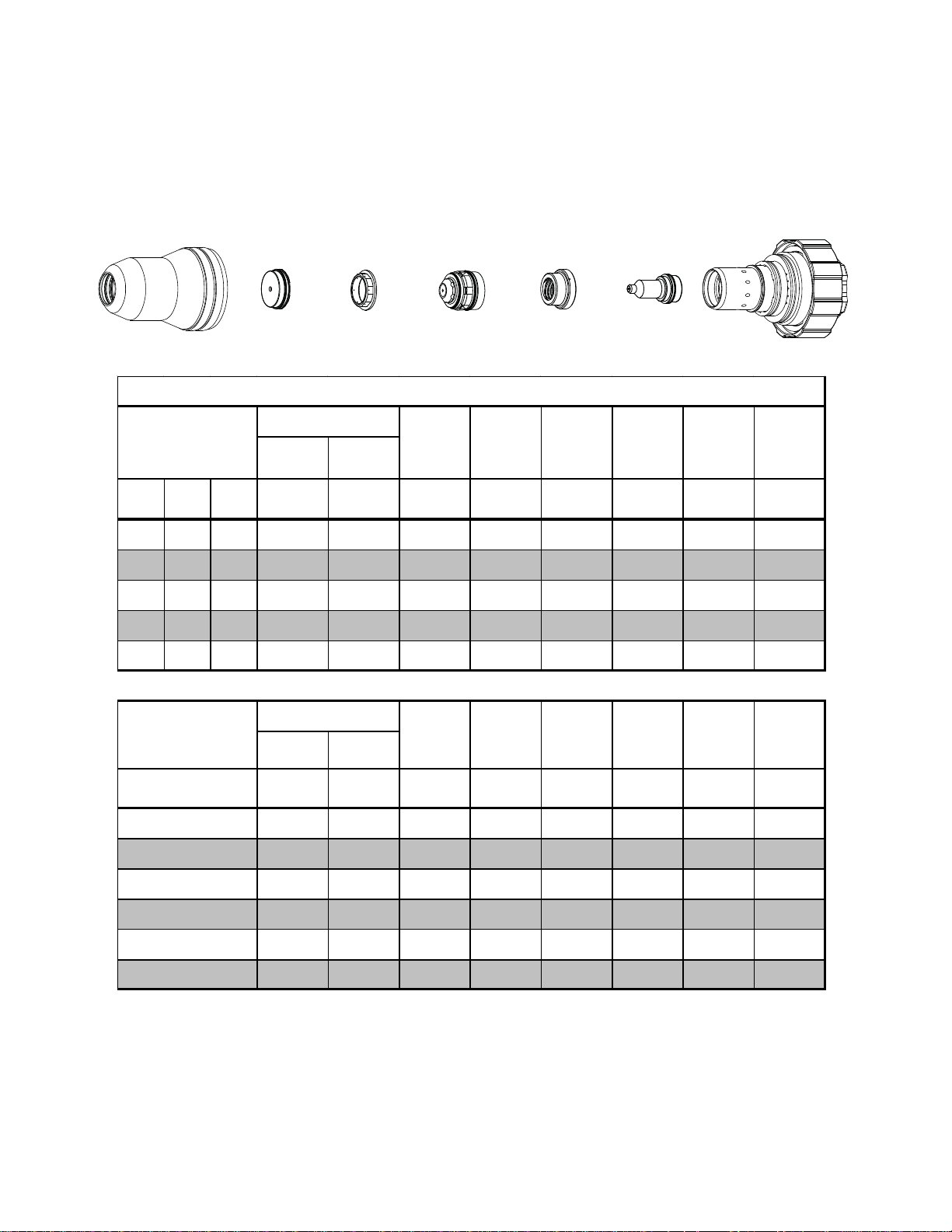

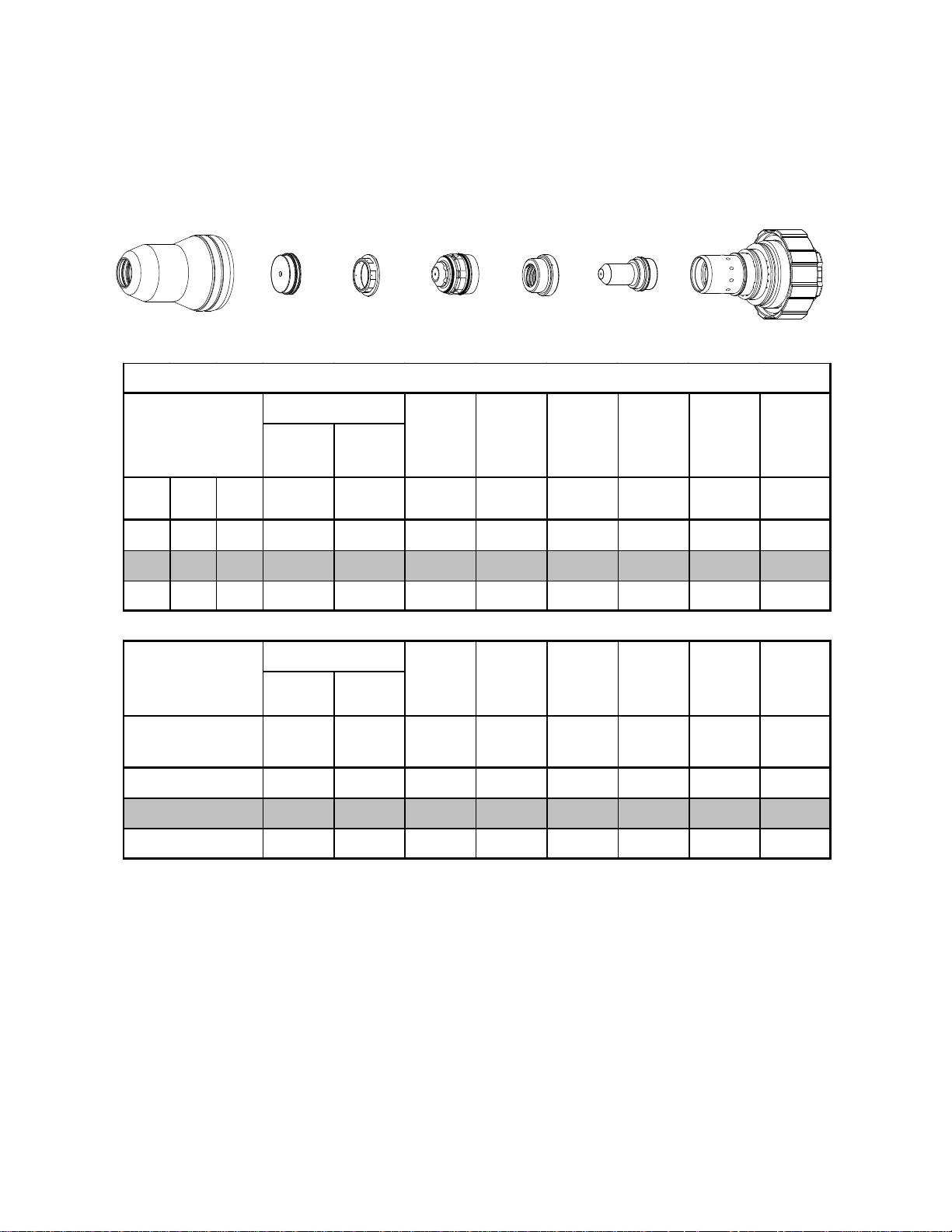

Page 4

Mild Steel,

55A

Plasma / Air Shield

O

2

Shield Cup

35-1016

Shield Cap

35-1025

Shield Gas Distributor

35-1272

Tip

35-1051

Plasma Gas Distributor

35-1041

55A Mild Steel (O2/Air)

Electrode

35-1069

Cartridge

35-1020

Art # A-04940

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow Pr essures

Plasma

(O2)

Shield

(Air)

Arc

Voltage

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

21 0.033 70 20 120 0.125 600 0.200 0.0 0.073

16 0.060 70 20 120 0.125 400 0.200 0.0 0.071

10 0.135 80 20 126 0.125 180 0.200 0.2 0.083

3/16 0.188 80 20 127 0.125 120 0.200 0.2 0.081

1/4 0.250 80 20 128 0.125 85 0.200 0.3 0.086

Material

Thickness

(mm)

1

2

Cut Flow Pr essures

Plasma

(O2)

(Bar) (Bar) Volts

Shield

(Air)

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

4.8 1.4 120 3.2 14040 5.1 0.0 1.8

4.8 1.4 121 3.2 8760 5.1 0.0 1.9

Ker f Width

@ Rec.

Speed

3

4

5

6

5.5 1.4 125 3.2 5830 5.1 0.2 2.0

5.5 1.4 126 3.2 3930 5.1 0.2 2.1

5.5 1.4 127 3.2 2920 5.1 0.2 2.1

5.5 1.4 128 3.2 2360 5.1 0.3 2.2

TORCH DATA for AutoCut Basic 8-6 Manual 0-4825 Rev. AK

Page 5

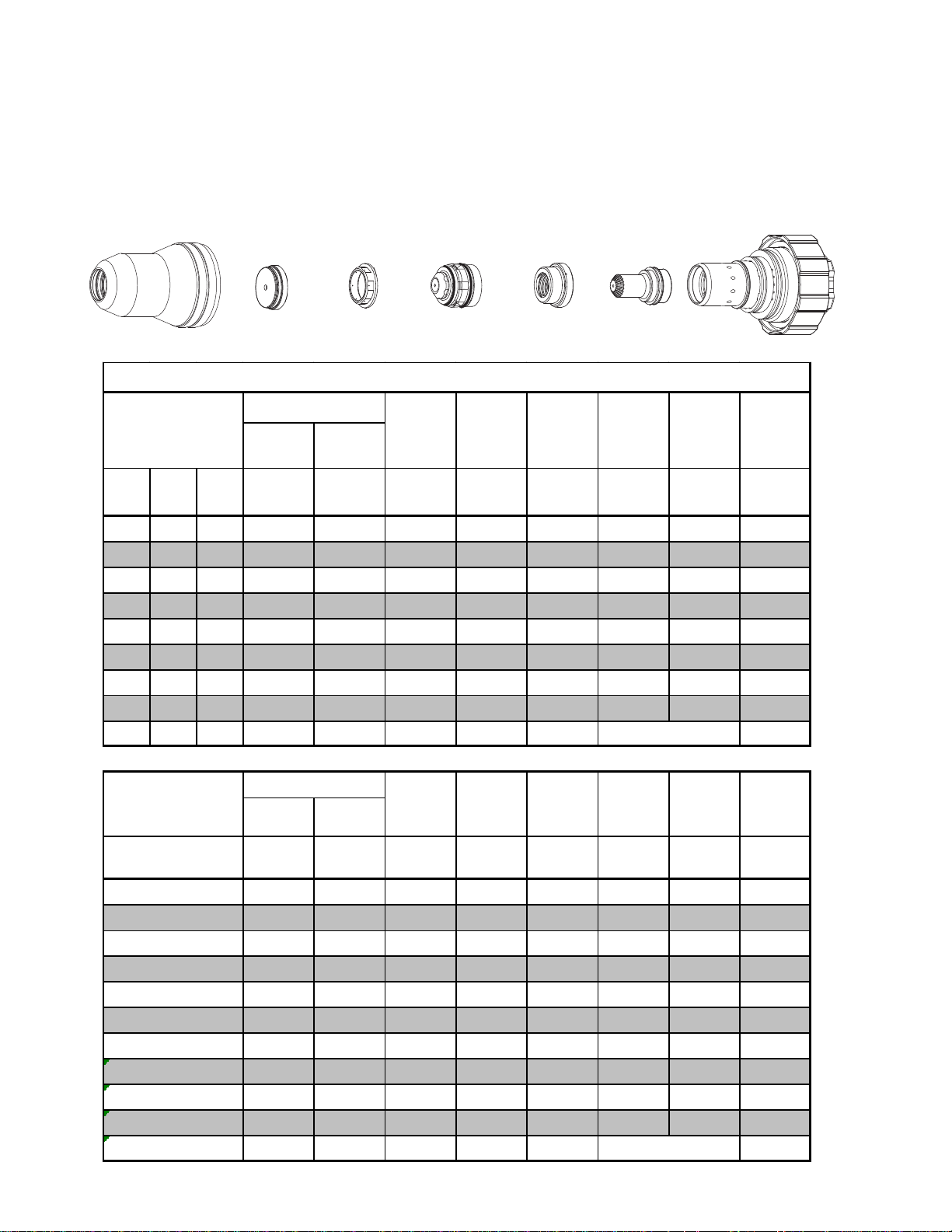

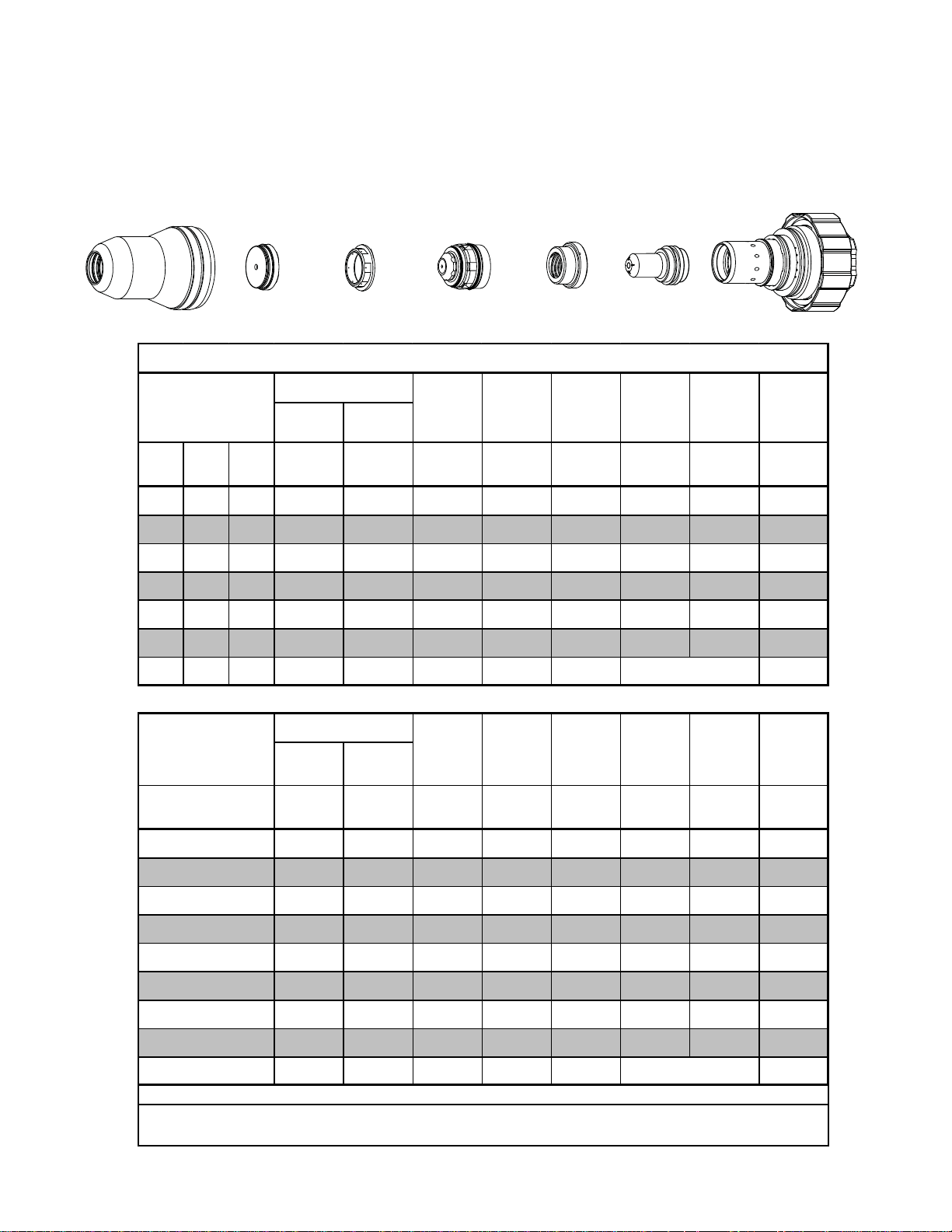

Stainless Steel

55A

Air Plasma / Air Shield

Shield Cup

35-1016

Shield Cap

35-1034

Shield Gas Distributor

35-1272

Tip

35-1060

Plasma Gas Distributor

35-1041

Electrode

35-1078

Cartridge

35-1020

Art # A-04942

55A Stainless Steel (Air/Air)

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow Pressures

Plasma

(Air)

Shield

(Air)

Arc

Voltage

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm)(in)(sec)(in)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

21 0.034 70 20 104 0.125 600 0.200 0.0 0.067

16 0.063 70 50 105 0.150 350 0.200 0.0 0.068

10 0.141 70 50 110 0.150 100 0.200 0.1 0.086

3/16 0.188 70 50 112 0.150 60 0.200 0.1 0.086

1/4 0.250 70 50 112 0.150 40 0.200 0.2 0.088

Material

Thickness

(mm)

0.8

1

1.5

2

3

4

5

6

Cut Flow Pressures

Plasma

(Air)

(Bar) (Bar) Volts

Shield

(Air)

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

4.8 1.4 104 3.2 15240 5.1 0.0 1.7

4.8 1.4 104 3.3 14060 5.1 0.0 1.7

4.8 3.4 105 3.7 9750 5.1 0.0 1.7

4.8 3.4 106 3.8 7610 5.1 0.0 1.8

4.8 3.4 109 3.8 4400 5.1 0.1 2.1

4.8 3.4 111 3.8 2180 5.1 0.1 2.2

4.8 3.4 112 3.8 1450 5.1 0.1 2.2

4.8 3.4 112 3.8 1130 5.1 0.2 2.2

Ker f Width

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-7 TORCH DATA for AutoCut Basic

Page 6

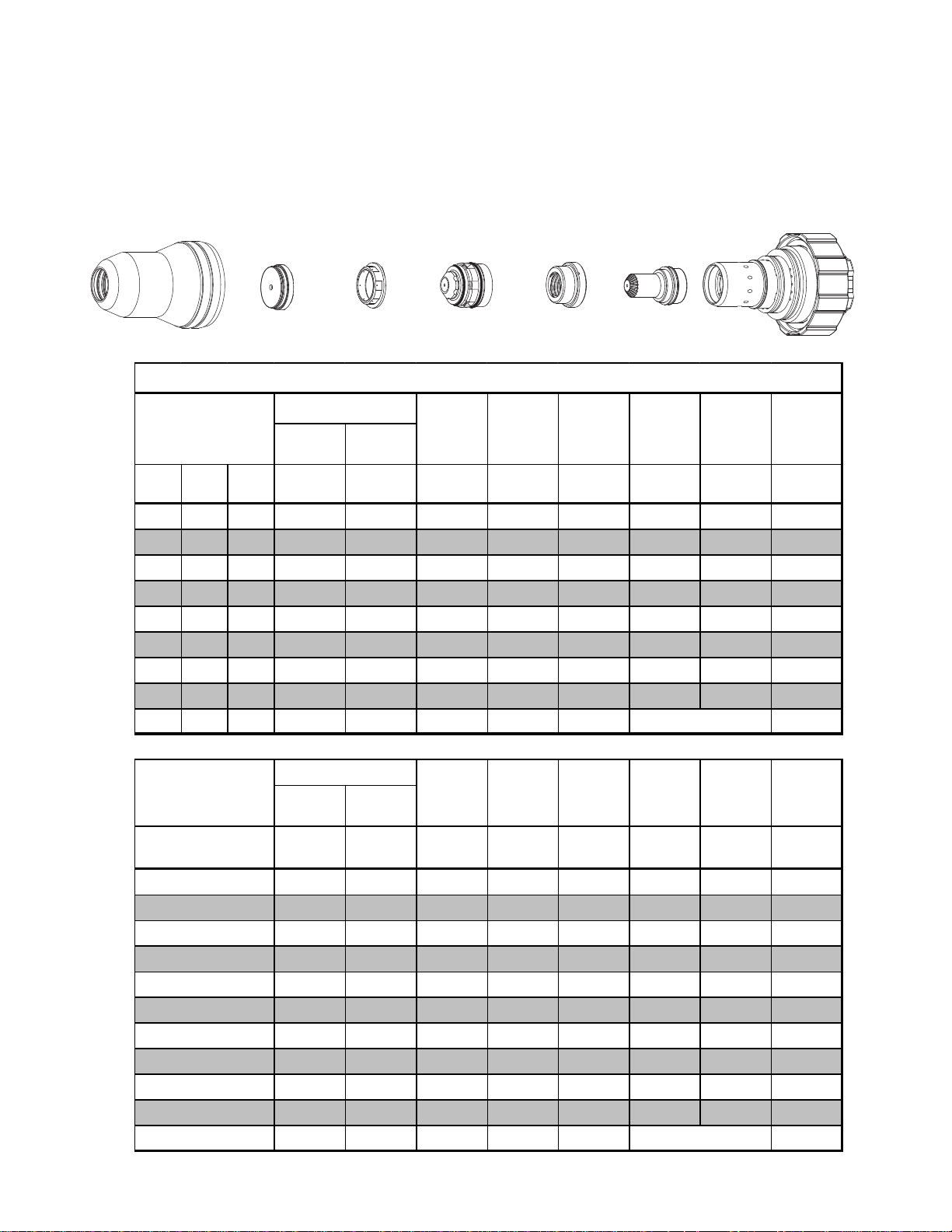

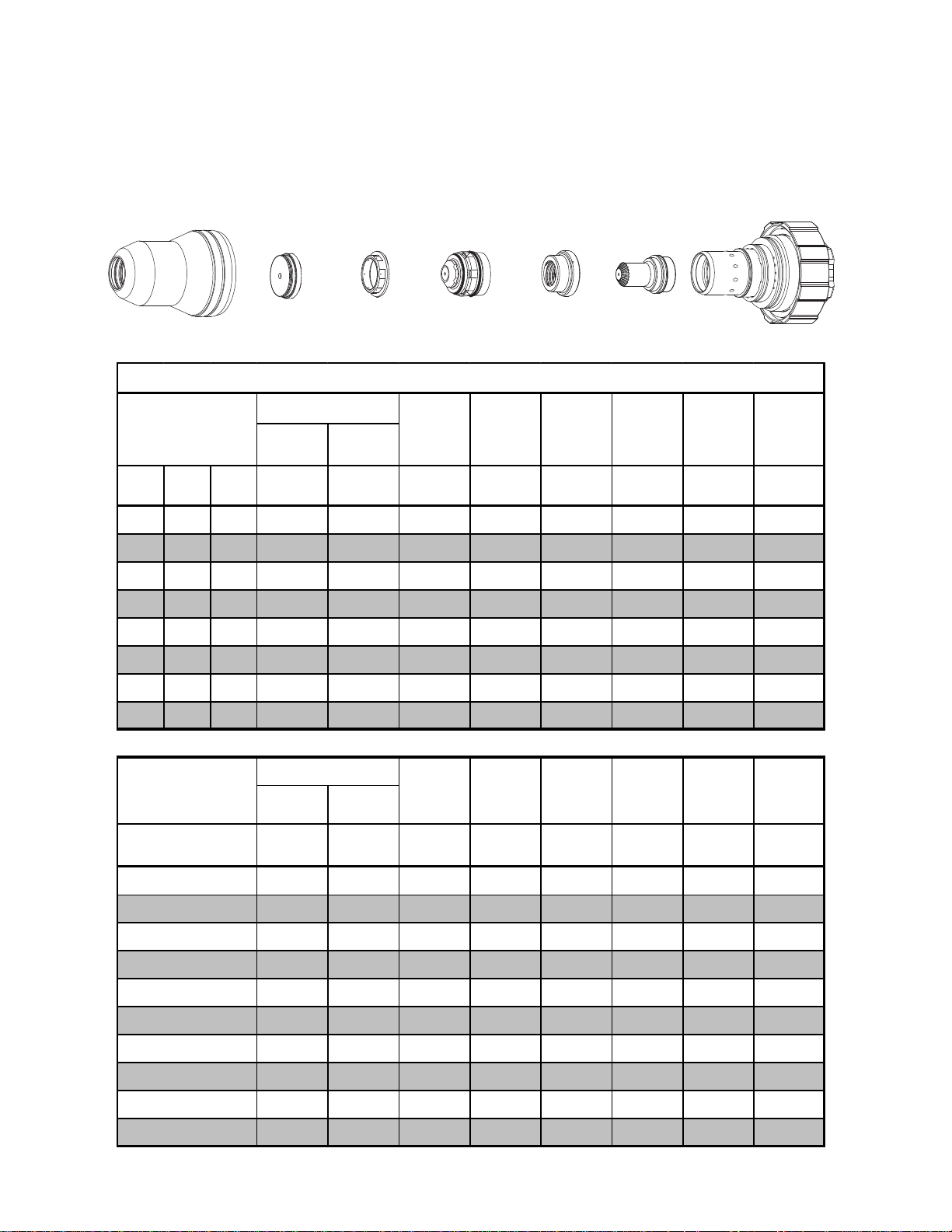

Aluminum

55A

Air Plasma / Air Shield

Shield Cup

35-1016

Shield Cap

35-1034

Shield Gas Distributor

35-1272

Tip

35-1060

Plasma Gas Distributor

35-1041

Electrode

35-1078

Cartridge

35-1020

Art # A-04942

55A Aluminum (Air/Air)

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow Pr essures

Plasma

(Air)

Shield

(Air)

Arc

Voltage

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm) (in) (s ec) (in)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

23 0.031 70 50 100 0.100 600 0.150 0.0 0.066

16 0.064 70 50 105 0.100 400 0.200 0.0 0.070

10 0.135 70 50 115 0.150 140 0.200 0.0 0.084

3/16 0.188 70 50 120 0.150 100 0.200 0.0 0.084

1/4 0.250 70 50 122 0.150 50 0.200 0.1 0.089

Material

Thickness

(mm)

1

2

3

4

5

6

Cut Flow Pr essures

Plasma

(Air)

(Bar) (Bar) Volts

Shield

(Air)

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

4.8 3.4 101 2.5 13950 4.1 0.0 1.7

4.8 3.4 107 2.8 8790 5.1 0.0 1.9

4.8 3.4 113 3.5 5130 5.1 0.0 2.0

4.8 3.4 117 3.8 3130 5.1 0.0 2.1

4.8 3.4 120 3.8 2360 5.1 0.0 2.2

4.8 3.4 122 3.8 1550 5.1 0.1 2.2

Ker f Width

@ Rec.

Speed

TORCH DATA for AutoCut Basic 8-8 Manual 0-4825 Rev. AK

Page 7

Mild Steel

100A

Air Plasma / Air Shield

Shield Cup

35-1016

Shield Cap

35-1027

Shield

Gas Distributor

35-1272

Tip

35-1053

Plasma

Gas Distributor

35-1041

Electrode

35-1071

Cartridge

35-1020

Art # A-04863

100A Mild Ste e l (Air/Air)

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow Pressures

Plasma

(Air)

Shield

(Air)

Arc

Voltage

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm)(in)(sec)(in)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

16 0.060 90 45 149 0.110 600 0.250 0.1 0.072

10 0.135 90 45 145 0.110 300 0.250 0.2 0.065

3/16 0.188 90 45 149 0.110 210 0.250 0.3 0.073

1/4 0.250 90 45 152 0.120 150 0.300 0.3 0.078

3/8 0.375 90 45 152 0.130 85 0.300 0.3 0.091

1/2 0.500 90 45 159 0.140 75 0.300 0.3 0.095

5/8 0.625 90 45 153 0.140 55 0.350 0.5 0.099

3/4 0.750 90 45 163 0.150 30 0.350 0.6 0.120

1 1.00 90 45 180 0.200 20 0.112

Edge Start

Material

Thickness

(mm)

2

3

4

5

6

8

10

12

15

20

25

Cut Flow Pressures

Plasma

(Air)

(Bar) (Bar) Volts

Shield

(Air)

Arc

Voltage

6.2 3.1 148 2.8 13340 6.4 0.1 1.8

6.2 3.1 146 2.8 9340 6.4 0.2 1.7

6.2 3.1 147 2.8 6650 6.4 0.2 1.7

6.2 3.1 149 2.8 5120 6.5 0.3 1.9

6.2 3.1 151 3.0 4150 7.3 0.3 2.0

6.2 3.1 152 3.2 2950 7.6 0.3 2.2

6.2 3.1 153 3.3 2120 7.6 0.3 2.3

6.2 3.1 157 3.5 1960 7.6 0.3 2.4

6.2 3.1 155 3.6 1540 8.5 0.4 2.5

6.2 3.1 166 4.0 720 9.5 0.6 3.0

6.2 3.1 179 5.0 520 2.9

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

Edge Start

Manual 0-4825 Rev. AK 8-9 TORCH DATA for AutoCut Basic

Page 8

Mild Steel

100A

Plasma / Air Shield

O

2

Gas Distributor

Torch

(in)

Plasma

Electrode

35-1041

/Air)

2

Travel

Speed

(ipm)(in)(sec)(in)

35-1071

Initial

Piercing

Height

Cartridge

35-1020

Art # A-04863

Pierce

Delay

Ker f Width

@ Rec.

Speed

Shield Cup

35-1016

Shield Cap

35-1027

Shield

Gas Distributor

35-1272

35-1053

100A Mild Ste e l (O

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut FlowPressures

Plasma

(O

Shield

)

2

(Air)

Arc

Voltage

Tip

Working

Height

±0.005

16 0.060 94 49 127 0.110 500 0.250 0.1 0.071

10 0.135 94 49 134 0.110 240 0.250 0.2 0.081

3/16 0.188 94 49 128 0.120 185 0.250 0.3 0.073

1/4 0.250 94 49 130 0.120 130 0.300 0.3 0.095

3/8 0.375 94 49 138 0.130 80 0.300 0.3 0.113

1/2 0.500 94 49 138 0.140 57 0.300 0.3 0.113

5/8 0.625 94 49 144 0.140 45 0.350 0.5 0.111

3/4 0.750 94 49 150 0.150 25 0.350 0.6 0.138

1 1.000 94 49 164 0.200 10 0.140

Edge Start

Material

Thickness

(mm)

2

3

4

5

6

8

10

12

15

20

25

Cut Flow Pressures

Plasma

(O

(Bar) (Bar) Volts

Shield

)

2

(Air)

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

6.5 3.4 129 2.8 11050 6.4 0.1 1.9

6.5 3.4 132 2.8 7580 6.4 0.2 2.0

6.5 3.4 131 2.9 5500 6.4 0.2 2.0

6.5 3.4 128 3.1 4500 6.5 0.3 1.9

6.5 3.4 130 3.1 3610 7.3 0.3 2.3

6.5 3.4 134 3.2 2640 7.6 0.3 2.7

6.5 3.4 138 3.3 1950 7.6 0.3 2.9

6.5 3.4 138 3.5 1580 7.6 0.3 2.9

6.5 3.4 142 3.6 1230 8.5 0.4 2.8

6.5 3.4 152 4.0 580 9.5 0.6 3.5

6.5 3.4 163 5.0 280 3.6

Edge Start

Ker f Width

@ Rec.

Speed

TORCH DATA for AutoCut Basic 8-10 Manual 0-4825 Rev. AK

Page 9

Stainless Steel

100A

Air Plasma / Air Shield

Shield Cup

35-1016

Shield Cap

35-1027

Shield

Gas Distributor

35-1272

Tip

35-1053

Plasma

Gas Distributor

35-1041

Electrode

35-1071

Cartridge

35-1020

Art # A-04863

100A Stainless Ste e l (Air/Air)

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow Pressures

Plasma

(Air)

Shield

(Air)

Arc

Voltage

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm)(in)(sec)(in)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

16 0.063 85 42 144 0.080 500 0.200 0.0 0.099

10 0.141 85 42 150 0.100 225 0.325 0.0 0.102

3/16 0.188 85 42 153 0.140 175 0.325 0.1 0.105

1/4 0.250 85 42 155 0.140 100 0.325 0.1 0.105

3/8 0.375 85 42 160 0.140 65 0.325 0.2 0.110

1/2 0.500 85 42 166 0.160 45 0.325 0.4 0.112

5/8 0.625 85 42 165 0.160 35 0.350 1.0 0.114

Material

Thickness

(mm)

1.5

2

3

4

5

6

8

10

12

Cut Flow Pressures

Plasma

(Air)

(Bar) (Bar) Volts

Shield

(Air)

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

5.7 2.9 144 2.0 12700 5.1 0.0 2.4

5.7 2.9 145 2.1 11290 5.7 0.0 2.5

5.7 2.9 149 2.0 6330 8.3 0.0 2.6

5.7 2.9 150 3.6 7030 8.3 0.1 2.7

5.7 2.9 153 3.6 4170 8.3 0.1 2.7

5.7 2.9 155 3.6 2960 8.3 0.1 2.7

5.7 2.9 158 3.6 2080 8.3 0.2 2.7

5.7 2.9 161 3.6 1580 8.3 0.2 2.8

5.7 2.9 165 4.0 1260 8.3 0.4 2.8

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

15

5.7 2.9 165 4.1 960 8.7 0.8 2.9

Manual 0-4825 Rev. AK 8-11 TORCH DATA for AutoCut Basic

Page 10

Stainless Steel

100A

H35 Plasma / N

Shield Cup

35-1016

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

3/8 0.375 100 80 145 0.130 50 0.250 0.3 0.090

1/2 0.500 100 80 148 0.130 37 0.250 0.5 0.100

5/8 0.625 100 80 155 0.140 26 0.250 0.6 0.115

Shield

2

Shield Cap

35-1034

Cut Flow Pressures

Plasma

(H35)

Shield

Gas Distributor

35-1272

Tip

35-1062

100A Stainless Steel (H35/N

Shield

)

(N

2

Arc

Voltage

Working

Height

±0.005

Plasma

Gas Distributor

35-1041

Torch

(in)

Electrode

35-1080

)

2

Travel

Speed

(ipm)(in)(sec)(in)

Initial

Piercing

Height

Cartridge

35-1020

Art # A-04938

Pierce

Delay

Ker f Width

@ Rec.

Speed

Material

Thickness

(mm)

10

12

15

Cut Flow Pressures

Plasma

(H35)

(Bar) (Bar) Volts

Shield

)

(N

2

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

6.9 5.5 145 3.3 1220 6.4 0.3 2.3

6.9 5.5 147 3.3 1010 6.4 0.5 2.5

6.9 5.5 151 3.5 740 6.4 0.6 2.8

Ker f Width

@ Rec.

Speed

TORCH DATA for AutoCut Basic 8-12 Manual 0-4825 Rev. AK

Page 11

Stainless Steel

100A

Plasma / H2O Shield

N

2

Shield Cup

35-1016

Material

Thickness

(ga) (in) inch (PSI ) Ball * Volts

Shield Cap

35-1034

Shield Gas Distributor

35-1272

Cut Flow Pressures

Plasma

(N

2

Shield

)

10 0.141 100 5 160 0.125 160 0.200 0.000 0.074

3/16 0.188 100 5 157 0.125 100 0.250 0.300 0.080

1/4 0.250 100 5 155 0.125 60 0.250 0.300 0.086

3/8 0.375 100 5 159 0.125 50 0.250 0.300 0.087

1/2 0.500 100 5 169 0.130 35 0.300 0.500 0.100

5/8 0.625 100 5 175 0.140 30 0.300 0.600 0.110

Tip

35-1053

100A Stainless Steel (N

Arc

Voltage

(H2O)

Torch

Working

Height

±0.005

Plasma Gas Distributor*

35-1041

O)

2/H2

Travel

Speed

(in)

(ipm)(in)(sec)(in)

Electrode

35-1089

Initial

Piercing

Height

Cartridge

35-1020

Art # A-04939

Pierce

Delay

Ker f Width

@ Rec.

Speed

3/4 0.750 100 5 177 0.150 25 **0.125

Edge St art

** Note m easur ed, ext rap olat ed value.

Material

Thickness

(mm)

3

4

5

6

8

10

12

15

20

Cut Flow Pressures

Plasma

(N

2

(Bar ) Ba ll * V olts

Shield

)

(H2O)

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

6.9 5 161 3.2 4810 4.5 0 1.8

6.9 5 159 3.2 3530 5.5 0.1 1.9

6.9 5 157 3.2 2400 6.4 0.3 2.1

6.9 5 155 3.2 1750 6.4 0.3 2.2

6.9 5 157 3.2 1390 6.4 0.3 2.2

6.9 5 160 3.2 1210 6.5 0.3 2.3

6.9 5 167 3.3 970 7.3 0.5 2.5

6.9 5 173 3.5 800 7.6 0.6 2.7

6.9 5 178 3.9 600 3.3

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

Edge St art

* Ball setting for shi eld wat er i s s et using a l i ne pres s ure of 55 PS I / 3. 8 Bar

NOTE: Ohmic height sens i ng is not rec om m ended wit h wat er s hi el d.

W at er on t he plate int erferes electri call y wit h the ohmic s ensing sy stem .

Ker f Width

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-13 TORCH DATA for AutoCut Basic

Page 12

Aluminum

100A

Air Plasma / Air Shield

Shield Cup

35-1016

Shield Cap

35-1027

Shield

Gas Distributor

35-1272

Tip

35-1053

Plasma

Gas Distributor

35-1041

Electrode

35-1071

Cartridge

35-1020

Art # A-04863

100A Aluminum (Air/Air)

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow Pressures

Plasma

(Air)

Shield

(Air)

Arc

Voltage

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm)(in)(sec)(in)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

16 0.064 85 42 154 0.130 500 0.200 0.0 0.103

10 0.135 85 42 157 0.130 260 0.200 0.0 0.106

3/16 0.188 85 42 156 0.130 120 0.325 0.1 0.100

1/4 0.250 85 42 158 0.140 100 0.325 0.2 0.104

3/8 0.375 85 42 162 0.140 75 0.325 0.2 0.107

1/2 0.500 85 42 168 0.140 45 0.325 0.3 0.109

5/8 0.625 85 42 175 0.140 35 0.325 0.4 0.112

3/4 0.750 85 42 180 0.180 35 0.350 1.0 0.121

Material

Thickness

(mm)

2

3

4

5

6

8

10

12

15

Cut Flow Pressures

Plasma

(Air)

(Bar) (Bar) Volts

Shield

(Air)

Arc

Voltage

5.9 2.9 155 3.3 11430 5.1 0.0 2.6

5.9 2.9 156 3.3 8050 5.1 0.0 2.7

5.9 2.9 157 3.3 5100 6.4 0.0 2.6

5.9 2.9 156 3.3 2980 8.3 0.1 2.6

5.9 2.9 158 3.5 2650 8.3 0.2 2.6

5.9 2.9 160 3.6 2210 8.3 0.2 2.7

5.9 2.9 163 3.6 1790 8.3 0.2 2.7

5.9 2.9 167 3.6 1310 8.3 0.3 2.8

5.9 2.9 173 3.6 960 8.3 0.4 2.8

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

20

5.9 2.9 181 4.9 890 9.9 1.0 3.1

TORCH DATA for AutoCut Basic 8-14 Manual 0-4825 Rev. AK

Page 13

Aluminum

100A

H35 Plasma / N

Shield Cup

35-1016

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Shield

2

Shield Cap

35-1034

Cut Flow Pressures

Plasma

Gas Distributor

(H35)

Shield

35-1272

Shield

3/8 0.375 120 50 150 0.188 60 0.350 0.1 0.100

1/2 0.500 120 50 156 0.188 40 0.350 0.4 0.110

5/8 0.625 120 50 160 0.188 30 0.350 0.5 0.113

3/4 0.750 120 50 171 0.250 20 0.350 0.6 0.130

Tip

35-1062

100A Aluminum (H35/N

(N

Arc

Voltage

)

2

Working

Plasma

Gas Distributor

35-1041

Torch

Height

(in)

±0.005

Electrode

35-1080

)

2

Travel

Speed

(ipm)(in)(sec)(in)

Initial

Piercing

Height

Cartridge

35-1020

Art # A-04938

Pierce

Delay

Ker f Width

@ Rec.

Speed

Material

Thickness

(mm)

10

12

15

20

Cut Flow Pressures

Plasma

(H35)

(PSI) (PSI) Volts

Shield

)

(N

2

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

8.3 3.4 151 4.8 1450 8.9 0.1 2.6

8.3 3.4 155 4.8 1130 8.9 0.3 2.7

8.3 3.4 159 4.8 830 8.9 0.5 2.8

8.3 3.4 174 6.8 430 8.9 0.6 3.4

Ker f Width

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-15 TORCH DATA for AutoCut Basic

Page 14

Aluminum

100A

Plasma / H2O Shield

N

2

Shield Cup

35-1016

Shield Cap

35-1034

Shield

Gas Distributor

35-1272

Tip

35-1053

Plasma

Gas Distributor

35-1041

Electrode

35-1089

Cartridge

35-1020

Art # A-06788

100A Aluminum (N2/H2O)

Material

Thickness

(ga) (in) inch (PS I) Ball * Volt s

Cut Flow Pressures

Plasma

(N

2

Shield

)

(H2O)

Arc

Voltage

Torch

Working

Height

(in)

±0.005

Travel

Speed

(ipm)(in)(sec)(in)

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

10 0.135 100 5 148 0.125 170 0.200 0.0 0.072

3/16 0.188 100 5 158 0.125 80 0.250 0.3 0.080

1/4 0.250 100 5 158 0.125 60 0.250 0.3 0.085

3/8 0.375 100 5 161 0.125 50 0.250 0.3 0.086

1/2 0.500 100 5 170 0.130 35 0.300 0.6 0.091

5/8 0.625 100 5 180 0.140 20 0.300 0.8 0.120

Material

Thickness

(mm)

4

5

6

8

10

12

15

Cut Flow Pressures

Plasma

(N

2

(Bar) Ball * Volt s

Shield

)

(H2O)

Arc

Voltage

6.9 5 152 3.2 3350 5.6 0.1 1.9

6.9 5 158 3.2 1960 6.4 0.3 2.1

6.9 5 158 3.2 1640 6.4 0.3 2.1

6.9 5 160 3.2 1390 6.4 0.3 2.2

6.9 5 162 3.2 1210 6.5 0.3 2.2

6.9 5 168 3.3 970 7.3 0.5 2.3

6.9 5 177 3.5 610 7.6 0.7 2.8

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

* Bal l set t i ng for shiel d wat er is set us i ng a l ine pres sure of 55 PSI / 3. 8 B ar

NOTE: Ohmic height sensing is not recommended with water shield.

Water on the plate int erferes elect rically wit h t he ohm ic sens ing sy st em.

Ker f Width

@ Rec.

Speed

TORCH DATA for AutoCut Basic 8-16 Manual 0-4825 Rev. AK

Page 15

This Chart for Custom e r S e ttings

Make Copies as Desired

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow Pressures

Plasma

(H35)

Shield

)

(N

2

Arc

Voltage

3/8 0.375

1/2 0.500

5/8 0.625

3/4 0.750

Material

Thickness

(mm)

Cut Flow Pressures

Plasma

(H35)

(PSI) (PSI) Volts

Shield

(N

)

2

Voltage

Arc

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(ipm)(in)(sec)(in)

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Initial

Piercing

Height

Pierce

Delay

Pierce

Delay

Ker f Width

@ Rec.

Speed

Ker f Width

@ Rec.

Speed

10

12

15

20

Manual 0-4825 Rev. AK 8-17 TORCH DATA for AutoCut Basic

Page 16

This Page Intentionally Blank

TORCH DATA for AutoCut Basic 8-18 Manual 0-4825 Rev. AK

Page 17

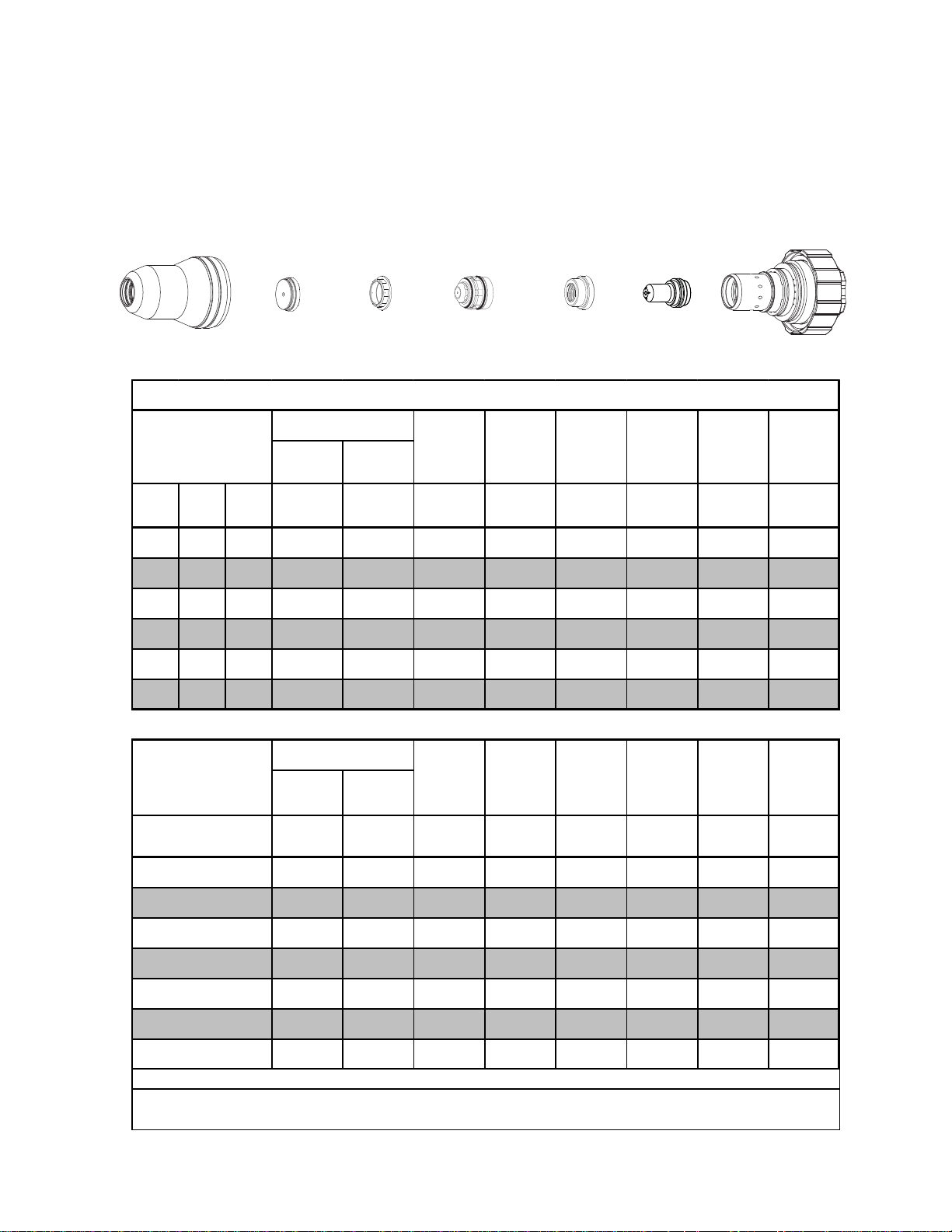

Material

Gases

Used

Consumable

Description

100A 55A

Electrode

35-1071 35-1069

Plasma Gas Distributor

35-1041 35-1041

Tip

35-1053 35-1051

O2/Air 35-1272 35-1272

Air/Air

Shield Retainer

Shield Cup

35-1016 35-1016

Cartridge Assy

35-1020 35-1020

35-1080

H35/N2

35-1078

35-1089

N2/H2O

35-1071

Air/Air

35-1041 35-1041

35-1062

H35/N2

35-1060

H35/N2 35-1053

N2/H2O

Air/Air 35-1272 35-1272

35-1034 35-1034

35-1027

Air/Air

Shield Retainer

Shield Cup

35-1016 35-1016

Cartridge Assy

35-1020 35-1020

Stainless

Steel/

Aluminum

Electrode

Plasma Gas Distributor

Tip

Shield Gas Distributor

Shield Cap

Auto-Cut Basic

Mild Steel

Shield Gas Distributor

Shield Cap

35-1027

35-1025

Art # A-08447

Manual 0-4825 Rev. AK 8-19 TORCH DATA for AutoCut Basic

Page 18

This Page Intentionally Blank

TORCH DATA for AutoCut Basic 8-20 Manual 0-4825 Rev. AK

Page 19

Mild Steel

200A

Air Plasma / Air Shield

Shield

Retainer

35-1019

Shield Cup

35-1018

Shield

Cap

35-1028

Shield Gas

Distributor

35-1280

Tip

35-1055

Plasma Gas

Distributor

35-1041

Electrode

35-1085

Cartridge

35-1020

Art # A-06988

200A Mild Ste e l (Air/Air)

Material

Thickness

Cut Flow Pressures

Plasma

(Air)

Shield

(Air)

Arc

Voltage

(ga) (in) inch (PSI) (PSI) Volts

Torch

Working

Height

(in)

±0.005

Tr avel

Speed

Initial

Piercing

Height

Pierce

Delay

(ipm) (in) (sec) (in)

1/4 0.250 90 60 163 0.140 185 0.300 0 0.096

3/8 0.375 90 60 160 0.140 130 0.300 0.1 0.131

1/2 0.500 90 60 162 0.140 100 0.300 0.3 0.150

5/8 0.625 90 60 164 0.140 75 0.300 0.4 0.158

3/4 0.750 90 60 168 0.180 60 0.350 0.5 0.176

1 1.000 90 60 177 0.200 35 0.500 1.5 0.189

1-1/4 1.250 90 60 185 0.250 20 0.209

1-1/2 1.500 90 60 189 0.250 15 0.225

2 2.000 90 60 204 0.300 10 0.270

Edge Start

Edge Start

Edge Start

Ker f Width

@ Rec.

Speed

Material

Thickness

(mm)

6

8

10

12

15

20

25

32

38

44

50

Cut Flow Pressures

Plasma

(Air)

Shield

(Air)

Voltage

(Bar) (Bar) Volts

Arc

Torch

Working

Height

(mm)

±0.1

6.2 4.1 163 3.6 4700 7.6 0 2.4

6.2 4.1 161 3.6 3970 7.6 0.1 2.9

6.2 4.1 160 3.6 3190 7.6 0.1 3.4

6.2 4.1 162 3.6 2710 7.6 0.3 3.7

6.2 4.1 163 3.6 2080 7.6 0.4 4.0

6.2 4.1 169 4.6 1430 9.5 0.6 4.5

6.2 4.1 176 5.0 920 12.5 1.4 4.8

6.2 4.1 185 6.4 500 5.3

6.2 4.1 189 6.4 380 5.7

6.2 4.1 196 6.9 320 6.2

6.2 4.1 203 7.5 260 6.8

Tr avel

Speed

Initial

Piercing

Height

Pierce

Delay

Ker f Width

@ Rec.

Speed

(mm/min) (mm) (sec) (mm)

Edge Start

Edge Start

Edge Start

Edge Start

Manual 0-4825 Rev. AK 8-23 TORCH DATA for AutoCut Basic

Page 20

Mild Steel

200A

Plasma / Air Shield

O

2

Shield Retainer

35-1019

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

1/4 0.250 90 58 154 0.140 190 0.300 0.1 0.153

3/8 0.375 90 58 156 0.140 140 0.300 0.3 0.159

1/2 0.500 90 58 158 0.140 100 0.350 0.4 0.168

5/8 0.625 90 58 161 0.140 70 0.350 0.5 0.183

3/4 0.750 90 58 168 0.160 60 0.400 0.6 0.192

1 1.000 90 58 170 0.180 40 0.500 0.9 0.207

1 1/4 1.250

1 1/ 2 1.500

22.000

Shield Cup

35-1018

Shield Cap

35-1029

Cut Flow

Plasma

(O

90 58 175 0.200 30 0.500 2 0.216

90 58 178 0.200 20 0.237

90 58 203 0.250 10 0.268

Shield

)

2

Shield Gas

Distributor

35-1281

200A Mild S t e el O

Arc

(Air)

Voltage

Tip

35-1056

/Air

2

Torch

Working

Height

(in)

±0.005

Art # A-07612

Pierce

Delay

Cartridge

35-1020

Kerf Width

@ Rec.

Speed

Plasma Gas

Distributor

35-1041

Travel

Speed

(ipm) (in) (sec) (in)

Electrode

35-1085

Initial

Piercing

Height

Edge Start

Edge Start

200A Mild Steel O2/Air

Material

Thickness

(mm)

6

8

10

12

15

20

25

32

38 Edge Start

44 Edge Start

50 Edge Start

Bold type

indicates maximum piercing parameters.

Cut Flow

Plasma

(O

(Bar) (Bar) Volts

6.2 4.0 154 3.6 4830 7.6 0.1 3.9

6.2 4.0 155 3.6 4170 7.6 0.2 4.0

6.2 4.0 156 3.6 3400 7.8 0.3 4.1

6.2 4.0 158 3.6 2760 8.6 0.4 4.2

6.2 4.0 160 3.6 1990 8.9 0.5 4.5

6.2 4.0 168 4.1 1450 12.7 0.6 4.9

6.2 4.0 170 4.5 1050 12.7 0.9 5.2

6.2 4.0 175 5.1 750 12.7 2.1 5.5

6.2 4.0 178 5.1 510 6.0

6.2 4.0 190 5.7 390 6.4

6.2 4.0 201 6.3 270 6.8

Shield

)

(Air)

2

Arc

Voltage

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Bold italic

indicates edge star ts only .

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

TORCH DATA for AutoCut Basic 8-24 Manual 0-4825 Rev. AK

Page 21

Stainless Steel

200A

Air Plasma / Air Shield

Shield

Retainer

35-1019

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

3/16

Shield Cup

35-1018

Cut Flow Pr essures

Plasma

0.1875

Shield

Cap

35-1030

(Air)

90

Shield Gas

Distributor

35-1282

200A Stainl ess Steel Air/Air

Shield

(Air)

Arc

Voltage

70 168 0.140 300 0.300 0 0.169

Tip

35-1055

Plasma Gas

Distributor

Torch

Working

Height

(in)

±0.005

Electrode

35-1041

Travel

Speed

(ipm) (in) (sec) (in)

35-1085

Initial

Piercing

Height

Art # A-07594

Pierce

Delay

1/4 0.250 90 70 165 0.140 275 0.300 0.1 0.162

3/8 0.375 90 70 167 0.140 200 0.300 0.2 0.169

1/2 0.500 90 70 170 0.140 145 0.350 0.3 0.169

5/8 0.625 90 70 170 0.140 110 0.400 0.4 0.174

3/4 0.750 90 70 171 0.160 75 0.450 0.5 0.176

7/8 0.875 90 70 172 0.170 55 0.450 0.7 0.181

1 1.000 90 70 175 0.180 40 0.500 1.3 0.181

1 1/4 1. 250

1 1/2 1. 500

2 2.000 90 70 198 0.200 8 0.230

90 70 185 0.200 20 0.500 3 0.207

90 70 191 0.200 13 0.220

Edge Start

Edge Start

Cartridge

35-1020

Kerf Width

@ Rec.

Speed

200A Stainl ess Steel Air/Air

Material

Thickness

(mm)

5

6

8

10

12

15

20

25

32

38

50

Cut Flow Pr essures

Plasma

(Air)

Shield

(Air)

Voltage

(Bar) (Bar) Volts

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

(mm/min) (mm) (sec) (mm)

6.2 4.8 168 3.6 7530 7.6 0 4.1

6.2 4.8 166 3.6 7130 7.6 0.1 4.1

6.2 4.8 166 3.6 6000 7.6 0.2 4.2

6.2 4.8 166 3.6 4870 7.8 0.2 4.3

6.2 4.8 169 3.6 3990 8.6 0.3 4.3

6.2 4.8 170 3.6 3040 9.8 0.4 4.4

6.2 4.8 171 4.1 1750 11.4 0.6 4.5

6.2 4.8 175 4.5 1060 12.5 1.2 4.6

6.2 4.8 185 5.1 500 12.7 3.0 5.3

6.2 4.8 191 5.1 330 5.6

6.2 4.8 198 5.1 210 5.8

Edge Start

Edge Start

Kerf Width

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-25 TORCH DATA for AutoCut Basic

Page 22

Stainless Steel

200A

H35 Plasma / N

Shield Cup

35-1016

Shield **

2

Shield Cap

< 1” (25mm)

35-1031

>

1” + (25mm)

35-1032

Shield Gas

Distributor

35-1273

200A Stainless Steel (H35/N

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow

Plasma

(H35)

Shield

3/8 0.375 70 120 157 0.240 90 0.300 0.5 0.158

1/2 0.5 70 120 160 0.260 65 0.300 0.6 0.171

5/8 0.625 70 120 165 0.280 50 0.350 0.7 0.178

3/4 0.75 70 120 168 0.300 40 0.450 0.8 0.180

7/8 0.875 70 120 172 0.300 30 0.450 0.9 0.178

1 1 70 120 175 0.325 25 0.450 1.3 0.185

1 1/4 1.25 70 120 180 0. 300 20 0.175

1 1/2 1.5 70 120 182 0.300 15 0.180

2 2 70 120 185 0.325 10 0.195

(N

2

)

Tip

35-1058

Arc

Voltage

Plasma Gas

Distributor

35-1043

Torch

Working

Height

(in)

±0.005

Cartridge

Electrode

35-1087

)

2

Travel

Speed

(ipm) (in) (sec) (in)

Initial

Piercing

Height*

35-1020

Art # A-07610

Pierce

Delay

Ker f Width

@ Rec.

Speed

Edge Start

Edge Start

Edge Start

Material

Thickness

(mm)

10

12

15

20

25

32

38

50

Cut Flow

Plasma

(H35)

(Bar) (Bar) Volts

Shield

(N

2

)

Arc

Voltage

4.8 8.3 157 6.2 2190 7.6 0.5 4.1

4.8 8.3 159 6.5 1790 7.6 0.6 4.3

4.8 8.3 164 7.3 1380 8.5 0.7 4.5

4.8 8.3 169 7.8 940 11.4 0.8 4.6

4.8 8.3 175 8.3 650 11.4 1.2 4.7

4.8 8.3 180 8.3 500 4.5

4.8 8.3 182 8.3 380 4.6

4.8 8.3 185 8.3 260 4.9

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/mi

n)

Initial

Piercing

Height*

(m m) (sec) (mm)

Pierce

Delay

Edge Start

Edge Start

Edge Start

* Lock pierc e hei ght bet ween 0.5" to 1" to avoid torch hi t ting t he pierce met al puddle.

**Requires Fi rm ware versi on 3. 2 or higher.

Ker f Width

@ Rec.

Speed

TORCH DATA for AutoCut Basic 8-26 Manual 0-4825 Rev. AK

Page 23

(

2

Stainless Steel

200A

N

Plasma / H2O Shield

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Electrode

Cartridge

This Art Is For Reference ONLY

Shield Cup

Material

Thickness

(ga) (in) inch (PSI) (Ball) Volts

7/8 0.875 110 5 180 0.250 50 0.300 0.7 0.141

1 1.000 110 5 185 0.300 40 0.350 1.0 0.151

Material

Thickness

BOLD TYPE

Requires CCM version 3.4 or l ater. Requires G CM ve r sion 3. 2 o r later.

* Pre ssure of the water supply lin e should be re gulated at 55 PSI / 3.4 Bar by customer pr essure regulator.

Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with the

Note1:

ohmic sensing circ ui t.

Water source used f or shield must be demineralized.

Note2:

Shield

35-1039 35-1273 35-1064

1/2 0.500 90 5 170 0.160 90 0.300 0.4 0.117

5/8 0.625 90 5 173 0.200 75 0.300 0.5 0.128

3/4 0.750 110 5 175 0.250 60 0.300 0.6 0.132

1.25 1.250 110 5 189 0.350 30 0.163

1.5 1.500 110 5 202 0.350 20 0.175

1.75 1.750 110 5 205 0.400 15 0.180

(mm)

12

15

20

25

32

38

44

indicates maximum piercing parameters.

Cap

Shield Gas

Distributor

Cut Flo ws / P ressures

Plasma (N2)

Cut Flo ws / P ressures

Plasma (N

2

(Bar) (Ball) Volts

6.2 5 169 4.1 2300 7.6 0.4 2.9

6.2 5 173 5.0 1950 7.6 0.5 3.2

7.6 5 178 6.4 1450 7.6 0.6 3.4

7.6 5 185 7.6 1000 8.9 1.0 3.8

7.6 5 190 8.9 750 4.1

7.6 5 202 8.9 500 4.4

7.6 5 205 10.2 380 4.6

Tip

Shield

H

O)*

Shield

)

(H

O)*

Plasma Gas

Distributor

35-1046 35-1089 35-102035-1016

Arc

Voltage

Arc

Voltage

BOLD ITALIC

Electrode Cartridge

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(ipm) (in) (sec) (in)

Travel

Speed

(mm/min) (mm) (sec) (mm)

indicates edge star ts only .

Art # A-07958_AB

Initial

Piercing

Height

Edge Start

Edge Start

Edge Start

Initial

Piercing

Height

Edge Start

Edge Start

Edge Start

Pierce

Delay

Pierce

Delay

Kerf Width

Kerf Width

@ Rec.

Speed

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-27 TORCH DATA for AutoCut Basic

Page 24

Aluminum

200A

Air Plasma / Air Shield

Shield

Retainer

35-1019

Shield Cup

35-1018

Shield

Cap

35-1030

Shield Gas

Distributor

35-1282

35-1055

200A Aluminum Air/Air

Cut F l ow

Material

Thickness

Pressures

Plasma

(Air)

Shield

(Air)

Arc

Voltage

(ga) (in) inch (PSI) (PSI) Volts

3/16 0.1875 90 70 170 0.14 225 0.300 0.0 0.173

1/4

0.250

90 70 174 0.140 195 0.300 0.1 0.177

3/8 0.375 90 70 179 0.140 150 0.300 0.2 0.173

1/2 0.500 90 70 181 0.140 115 0.350 0.3 0.166

5/8 0.625 90 70 182 0.140 90 0.400 0.4 0.164

3/4 0.750 90 70 185 0.160 70 0.400 0.5 0.171

7/8 0.875 90 70 189 0.170 55 0.450 0.7 0.175

1 1.000 90 70 196 0.180 40 0.500 1.3 0.197

1 1/4 1. 250 90 70 205 0. 200 25 0. 500 3. 0 0.185

1 1/2 1. 500 90 70 210 0. 200 15 0.198

2 2.000

90 70 213 0.200 8 0.220

Tip

Plasma Gas

Distributor

35-1041

Torch

Working

Height

(in)

±0.005

Cartridge

35-1020

Art # A-07594

Pierce

Delay

Kerf

Width

@ Rec.

Speed

Travel

Speed

Electrode

35-1085

Initial

Piercing

Height

(ipm) (in) (sec) (in)

Edge Start

Edge Start

Material

Thickness

(mm)

5

6

8

10

12

15

20

25

32

38

50

Cut F l ow

Pressures

Plasma

(Air)

Shield

(Air)

Voltage

(Bar) (Bar) Volts

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

(mm/min) (mm) (sec) (mm)

6.2 4.8 171 3.6 5600 7.6 0 4.4

6.2 4.8 173 3.6 5120 7.6 0.1 4.5

6.2 4.8 177 3.6 4360 7.6 0.2 4.4

6.2 4.8 179 3.6 3680 7.8 0.2 4.4

6.2 4.8 181 3.6 3120 8.6 0.3 4.3

6.2 4.8 182 4.1 2460 9.8 0.4 4.2

6.2 4.8 186 4.5 1660 10.5 0.6 4.4

6.2 4.8 195 5.1 1060 12.5 1.2 4.6

6.2 4.8 205 5.1 630 12.7 2.9 4.7

6.2 4.8 210 5.1 390 5.0

6.2 4.8 213 5.1 210 5.6

Edge Start

Edge Start

Kerf

Width

@ Rec.

Speed

TORCH DATA for AutoCut Basic 8-28 Manual 0-4825 Rev. AK

Page 25

Aluminum

200A

H35 Plasma / N

Shield Cup

35-1016

Shield **

2

Shield Cap

< 1” (25mm)

35-1031

>

1” + (25mm)

35-1032

Shield Gas

Distributor

35-1273

200A Aluminu m (H35/N

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

Cut Flow

Plasma

(H35)

Shield

(N

)

2

1/2 0.5 70 100 155 0.300 150 0.350 0.2 0.163

5/8 0.625 70 100 160 0.300 110 0.350 0.3 0.169

3/4 0.75 70 100 166 0.300 70 0.400 0.4 0.177

7/8 0.875 70 100 171 0.350 55 0.450 0.5 0.192

1 1 70 100 177 0.350 40 0.196

1 1/4 1.25 70 100 181 0.350 32 0. 180

1 1/ 2 1. 5 7 0 100 188 0 .350 25 0 .190

2 2 70 100 190 0.350 15 0.195

Tip

35-1058

Arc

Voltage

Plasma Gas

Distributor

35-1043

Torch

Working

Height

(in)

±0.005

Cartridge

Electrode

35-1087

)

2

Travel

Speed

(ipm) (in) (sec) (in)

Initial

Piercing

Height*

35-1020

Art # A-07610

Pierce

Delay

Edge Start

Edge Start

Edge Start

Edge Start

Kerf Width

@ Rec.

Speed

Material

Thickness

(m m)

12

15

20

25

32

38

50

Cut Flow

Plasma

(H35)

(Bar) (Bar) Volts

Shield

(N

)

2

Arc

Voltage

4.8 6.9 155 7.6 3810 7.6 0.2 4.3

4.8 6.9 159 7.6 3070 8.9 0.3 4.3

4.8 6.9 167 8.0 1660 10.5 0.4 4.6

4.8 6.9 176 8.9 1060 5.0

4.8 6.9 181 8.9 810 4.6

4.8 6.9 188 8.9 640 4.8

4.8 6.9 190 8.9 400 4.9

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min)

Initial

Piercing

Height*

(m m) (sec) (mm)

Pierce

Delay

Kerf Width

Edge Start

Edge Start

Edge Start

Edge Start

* Lock pierce height for first 0.5" to 1" of c utting to avoid torch hitting the pierce metal puddle.

Sli ght l y decreas ing t he shiel d gas pres sure mini m i z es dross on alum inum cut t i ng

**Requires Fi rm ware versi on 3. 2 or higher.

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-29 TORCH DATA for AutoCut Basic

Page 26

(

2

Aluminum

200A

Plasma / H2O Shield

N

2

Shield Cup

Shield Cap

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Electrode

Cartridge

Initial

Piercing

Height

Edge Start

Edge Start

Edge Start

Initial

Piercing

Height

Edge Start

Edge Start44

Edge Start

Art # A-07958_AB

Pierce

Delay

Pierce

Delay

Kerf Width

Kerf Width

This Art Is For Reference ONLY

Shield Cup

Material

Thickness

(ga) (in) inch (PSI) (Ball) Volts

7/8 0.875 110 5 178 0.300 60 0.350 0.8 0.152

1 1.000 110 5 188 0.350 40 0.400 0.9 0.165

Material

Thickness

BOLD TYPE

Requires CCM version 3.4 or later . Requires GC M version 3. 2 or later .

* Pre ssure of the water supply li ne should be r egulated at 55 PSI / 3.4 B ar by customer pressure regulat o r .

Ohmic height sensing is not re c ommended with water shield. Water on the plate int er feres elect rically wit h the

Note1:

ohmic sensing circuit.

Water source used f or shield must be demineralized.

Note2:

Shield

35-1039 35-1273 35-1064

1/2 0.500 70 5 156 0.250 110 0.300 0.3 0.133

5/8 0.625 70 5 165 0.250 100 0.300 0.4 0.140

3/4 0.750 110 5 170 0.250 70 0.300 0.6 0.138

1 1/ 4 1.250 110 5 197 0.350 30 0.400 1.9 0.175

1 1/2 1.5 00 110 5 198 0.350 20 0.181

1 3/4 1.7 50 110 5 198 0.350 18 0.188

2 2.000 110 5 198 0.350 15 0.196

(mm)

12

15

20

25

32

38

50

indicates maximum piercing parameters.

Cap

Shield Gas

Distributor

Cut Flows / Pressures

Plasma (N2)

Cut Flows / Pressures

Plasma (N

2

(Bar) (Ball) Volts

4.9 5 155 6.4 2 80 0 7.6 0.3 3 .3

4.9 5 163 6.4 2 50 0 7.6 0.4 3 .5

7.6 5 171 6.4 1 70 0 7.6 0.6 4 .0

7.6 5 187 8.0 1000 10.2 0.9 4.2

7.6 5 197 8.9 750 10.2 1.9 4.4

7.6 5 198 8.9 500 4.6

7.6 5 198 8.9 450 4.8

7.6 5 198 8.9 380 5.0

Tip

Shield

H

O)*

Shield

)

(H

O)*

Plasma Gas

Distributor

35-1046 35-1089 35-102035-1016

Arc

Voltage

Arc

Voltage

BOLD ITALIC

Electrode Cartridge

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(ipm) (in) (sec) (in)

Travel

Speed

(mm/min) (mm) (sec) (mm)

indicates edge star ts only .

@ Rec.

Speed

@ Rec.

Speed

TORCH DATA for AutoCut Basic 8-30 Manual 0-4825 Rev. AK

Page 27

(

This Chart for Customer Settings

Make Copies as Desired

Shield C up

Material

Thickness

(ga) (in) inch (P S I) (Ball) Volts

7/8 0.875

11.000

Shield

1/2 0.500

5/8 0.625

3/4 0.750

1.25 1.250

1.5 1.500

1.75 1.000

Cap

S hield Gas

Distributor

Cut F lows / Pressures

Plasma (N2)

Tip

Shield

H

O)*

Plasma Gas

Arc

Voltage

Distributor

Torch

Working

Height

±0.005

(in)

Electrode Cartridge

T rav el

Speed

(ipm) (in) (sec) (in)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

Material

Thickness

(mm)

12

15

20

25

32

38

44

Cut F lows / Pressures

Plasma (N

(Bar) (Ball) V olts

Shield

)

2

(H

O)*

2

Arc

Voltage

Torch

Working

Height

(mm)

±0.1

T rav el

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Pierce

Delay

Kerf Width

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-31 TORCH DATA for AutoCut Basic

Page 28

This Page Intentionally Blank

TORCH DATA for AutoCut Basic 8-32 Manual 0-4825 Rev. AK

Page 29

Material

Gases

Used

Consumable

Description

200A 100A 55A

Electrode

35-1085 35-1071 35-1069

Plasma Gas Distributor

35-1041 35-1041 35-1041

Tip

35-1055

Air/Air

35-1056

O2/Air

35-1053 35-1051

O2/Air

35-1280

Air/Air

35-1272 35-1272

Air/Air

35-1281

O2/Air

35-1028

Air/Air

35-1029

O2/Air

Shield Retainer

35-1019

Shield Cup

35-1018 35-1016 35-1016

Cartridge Assy

35-1020 35-1020 35-1020

35-1087

H35/N2

35-1080

H35/N2

35-1078

35-1089

N2/H2O

35-1089

N2/H2O

35-1085

Air/Air

35-1071

Air/Air

35-1043

H35/N2

35-1041 35-1041

35-1041

Air/Air

35-1058

H35/N2

35-1062

H35/N2

35-1060

H35/N2

35-1064

N2/H2O

35-1053

N2/H2O

35-1055

Air/Air

Air/Air 35-1273 35-1272 35-1272

35-1282

Air/Air

35-1031

H35/N2 < 25mm

35-1034 35-1034

35-1032

H35/N2 > 25mm

35-1027

Air/Air

35-1039

N2/H2O

35-1030

Air/Air

Shield Retainer

35-1019

Air/Air

Shield Cup

35-1018

Air/Air

35-1016

Ar/H2,N2/H2O

35-1016 35-1016

Cartridge Assy

35-1020 35-1020 35-1020

Stainless

Steel/

Aluminum

Electrode

Plasma Gas Distributor

Tip

Shield Gas Distributor

Shield Cap

Auto-Cut Basic

Mild Steel

Shield Gas Distributor

Shield Cap

35-1027

35-1025

Art # A-08448

Manual 0-4825 Rev. AK 8-33 TORCH DATA for AutoCut Basic

Page 30

This Page Intentionally Blank

TORCH DATA for AutoCut Basic 8-34 Manual 0-4825 Rev. AK

Page 31

Mild Steel

300A

Air Plasma / Air Shield

Shield Retainer

Shield

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield

Retainer

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

7/8 0.875 90 80 172 0.150 65 0.400 0.6 0.220

1 1.000 90 80 175 0.150 55 0.400 1.0 0.230

Shield

Cap

35-1037 35-1283 35-1050

3/4 0.750 90 80 166 0.150 75 0.350 0.4 0.210

1.25 1.250 90 80 184 0.250 40 0.500 1.8 0.260

1.5 1.500 90 80 193 0.250 20 0.500 3.0 0.300

1.75 1.750 90 80 203 0.350 15 0.325

2 2.000 90 80 210 0.350 10 0.355

2 1/4 2.250 90 80 215 0. 350 6 0.360

2 3/4 2.750 120 90 252 0.35 0 4 NA

Shield Gas

Distributor

Cut Flow Rates /

Plasma (Air) Shield (Air)

Tip

Plasma Gas

Distributor

Arc

Voltage

35-1044 35-1088 35-102235-1021

Plasma Gas

Distributor

Torch

Working

Height

(in)

±0.005

Electrode

Cartridge

Art # A-07917_AC

Electrode Cartridge

Travel

Speed

(ipm) (in) (sec) (in)

Initial

Piercing

Height

Edge Start

Edge Start

Edge Start

Edge Start

Pierce

Delay

Kerf Width

@ Rec.

Speed

Material

Thickness

(mm)

20

25

30

40

50

60 Edge Start

70

BOLD TYPE

BOLD ITALIC

Cut Flow Rates /

Plasma (Air) Shield (Air)

(Bar) (Bar) Volts

6.2 5.5 168 3.8 1830 9.3 0.5 5.4

6.2 5.5 175 3.8 1430 10.2 0.9 5.8

6.2 5.5 184 6.4 1020 12.7 1.8 6.6

6.2 5.5 196 7.1 470 7.8

6.2 5.5 209 8.7 270 8.9

6.2 5.5 222 8.7 130 9.0

8.2 6.2 253 8.7 100 6.0

indicates maximum piercing parameters.

indicates edge star ts only .

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Edge Start

Edge Start

Edge Start

Pierce

Delay

Kerf Width

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-37 TORCH DATA for AutoCut Basic

Page 32

Stainless Steel

300A

Air Plasma / Air Shield

Shield Retainer

Shield

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield

Retainer

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

7/8 0.875 90 80 182 0.300 75 0.400 0.7 0.133

1 1.000 90 80 190 0.300 60 0.400 0.8 0.166

Shield

35-1037 35-1283 35-1050

3/4 0.750 90 80 179 0.300 100 0.400 0.5 0.125

1.25 1.250 90 80 193 0.300 40 0.500 3.0 0.200

1.5 1.500 90 80 196 0.300 15 0.500 10.0 0.220

1.75 1.750 90 80 206 0.300 8 0.265

Shield Gas

Cap

Distributor

Cut Flow Rates /

Plasma (Air) Shield (Air)

Tip

Arc

Voltage

Plasma Gas

Distributor

Plasma Gas

Distributor

35-1044 35-1088 35-102235-1021

Torch

Working

Height

(in)

±0.005

Electrode

Cartridge

Art # A-07917_AC

Electrode Cartridge

Travel

Speed

(ipm) (in) (sec) (in)

Initial

Piercing

Height

Edge Start

Pierce

Delay

Kerf Width

@ Rec.

Speed

Material

Thickness

(mm)

20

25

30

40

50

BOLD TYPE

BOLD ITALIC

Cut Flow Rates /

Plasma (Air) Shield (Air)

(Bar) (Bar) Volts

6.2 5.5 178 7.6 2330 10.2 0.5 3.2

6.2 5.5 190 7.6 1520 10.2 0.8 4.2

6.2 5.5 192 7.6 1010 12.7 3.0 5.1

6.2 5.5 197 7.6 810 12.7 10.0 5.6

6.2 5.5 210 7.6 100 7.0

indicates maximum piercing parameters.

indicates edge star ts only .

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Edge Start

Pierce

Delay

Kerf Width

@ Rec.

Speed

TORCH DATA for AutoCut Basic 8-38 Manual 0-4825 Rev. AK

Page 33

Aluminum

300A

Air Plasma / Air Shield

Shield Retainer

Shield

Shield Gas

Distributor

Tip

This Art Is For Reference ONLY

Shield

Retainer

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

7/8 0.875 90 80 179 0.200 75 0.400 0.5 0.230

1 1.000 90 80 180 0.200 70 0.400 0.7 0.240

Shield

Cap

35-1037 35-1283 35-1050

3/4 0.750 90 80 179 0.200 90 0.350 0.4 0.220

1.25 1.250 90 80 194 0.250 45 0.450 1.5 0.270

1.5 1.500 90 80 200 0.250 20 0.450 2.2 0.300

1.75 1.750 90 80 210 0.250 19 0.300

2 2.000 90 80 220 0.250 18 0.300

Shield Gas

Distributor

Cut Flow Rates /

Plasma (Air) Shield (Air)

Tip

Plasma Gas

Arc

Voltage

Plasma Gas

Distributor

Distributor

35-1044 35-1088 35-102235-1021

Torch

Working

Height

±0.005

(in)

Electrode

Cartridge

Art # A-07917_AC

Electrode Cartridge

Travel

Speed

(ipm) (in) (sec) (in)

Initial

Piercing

Height

Edge Start

Edge Start

Pierce

Delay

Kerf Width

@ Rec.

Speed

Material

Thickness

(mm)

20

25

30

40

50

BOLD TYPE

BOLD ITALIC

Cut Flow Rates /

Plasma (Air) Shield (Air)

(Bar) (Bar) Volts

6.2 5.5 179 5.1 2290 8.9 0.4 5.6

6.2 5.5 180 5.1 1780 10.2 0.7 6.1

6.2 5.5 192 6.4 1140 11.4 1.5 7.0

6.2 5.5 201 6.4 510 11.4 2.2 7.6

6.2 5.5 219 6.4 460 7.6

indicates maximum piercing parameters.

indicates edge star ts only .

Voltage

Arc

Torch

Working

Height

(mm)

±0.1

Travel

Speed

(mm/min) (mm) (sec) (mm)

Initial

Piercing

Height

Edge Start

Pierce

Delay

Kerf Width

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-39 TORCH DATA for AutoCut Basic

Page 34

This Page Intentionally Blank

TORCH DATA for AutoCut Basic 8-40 Manual 0-4825 Rev. AK

Page 35

This Chart for Customer Settings

Make Copies as Desired

Shield

Retainer

Material

Thickness

(ga) (in) inch (PSI) (PSI) Volts

7/8 0.875

11.000

Material

Thickness

Shield

Cap

35-1037 35-1283 35-1050

3/4 0.750

1.25 1.250

1.5 1.500

1.75 1.750

22.000

(m m)

20

25

30

40

50

Shield Gas

Distributor

Cut Flow Rates /

Plasma (A ir) Shield (Air)

Cut Flow Rates /

Plasma (A ir) Shield (Air)

(Bar) (Bar) Volts

Tip

Plasma Gas

Distributor

Arc

Voltage

Arc

Voltage

Electrode Cartridge

35-1044 35-1088

Torch

Working

Height

(in)

±0.005

Torch

Working

Height

(m m)

±0.1

Travel

Speed

(ipm) (in) (sec) (in)

Travel

Speed

(mm/min) (mm) (sec) (mm)

Piercing

Piercing

Initial

Height

Initial

Height

Pierce

Delay

Pierce

Delay

35-102235-1021

Kerf Width

@ Rec.

Speed

Kerf Width

@ Rec.

Speed

Manual 0-4825 Rev. AK 8-41 TORCH DATA for AutoCut Basic

Page 36

This Page Intentionally Blank

TORCH DATA for AutoCut Basic 8-42 Manual 0-4825 Rev. AK

Page 37

Material

Gases

Used

Consumable

Description

300A 200A 100A 55A

Electrode

35-1088

Air/Air

35-1085 35-1071 35-1069

Plasma Gas Distributor

35-1044

Air/Air

35-1041 35-1041 35-1041

Tip

35-1050

Air/Air

35-1055

Air/Air

35-1056

O2/Air

35-1053 35-1051

Shield Gas Distributor

35-1283

Air/Air

35-1280

Air/Air

35-1281

O2/Air

35-1272 35-1272

Shield Cap

35-1037

Air/Air

35-1028

Air/Air

35-1029

O2/Air

35-1027 35-1025

Shield Retainer

35-1021 35-1019

Shield Cup

35-1017 35-1018 35-1016 35-1016

Cartridge Assy

35-1022 35-1020 35-1020 35-1020

Plasma Gas Distributor

35-1044

Air/Air

35-1043

H35/N2

35-1041

Air/Air

35-1041 35-1041

Tip

35-1050

Air/Air

35-1058

H35/N2

35-1064

N2/H2O

35-1055

Air/Air

35-1062

H35/N2

35-1053

35-1060

Shield Gas Distributor

35-1283

Air/Air

35-1273

35-1282 Air/Air

35-1272 35-1272

Shield Cap

35-1037

Air/Air

35-1031

H35/N2 < 25mm

35-1032

H35/N2 > 25mm

35-1039

N2/H2O

35-1030

Air/Air

35-1034

35-1027

Air/Air

35-1034

Shield Retainer

35-1021

Air/Air

35-1019

Air/Air

Shield Cup

35-1017

35-1018

Air/Air

35-1016

Ar/H2,N2/H2O

35-1016 35-1016

Cartridge Assy

35-1022 35-1020 35-1020 35-1020

Auto-Cut 300

Mild Steel

Electrode

H35/N2

N2/H2O

Air/Air

O2/Air

Air/Air

Stainless

Steel/

Aluminum

35-1088

Air/Air

35-1087

H35/N2

35-1089

N2/H2O

35-1085

Air/Air

35-1080

H35/N2

35-1089

N2/H2O

35-1071

Air/Air

35-1078

Manual 0-4825 Rev. AK 8-43 TORCH DATA for AutoCut Basic

Art # A-08449

Page 38

This Page Intentionally Blank

TORCH DATA for AutoCut Basic 8-44 Manual 0-4825 Rev. AK

Page 39

TORCH REPLACEMENT PARTS

Returns

If a product must be returned for service, contact your authorized distributor. Materials returned without proper authorization will not be accepted.

Ordering Information

Order replacement parts by catalog number and complete description of the part or assembly. Also include the

model and serial number of the machine or torch.

Refer to parts diagrams within the body of the manual for consumable parts and replacement O-Ring catalog numbers.

Qty. Description Catalog Number

1 XT-301 Torch w/ 25' / 7.6 m Leads, w/ 100-Amp Mild Steel Consumables 2-7000

1 XT-301 Torch w/ 35' / 10.6 m Leads, w/ 100-Amp Mild Steel Consumables 2-7001

1 XT-301 Torch w/ 50' / 15.2 m Leads, w/ 100-Amp Mild Steel Consumables 2-7002

1 XT-301 Torch w/ 75' / 22.9 m Leads, w/ 100-Amp Mild Steel Consumables 2-7003

1 XT-301 Torch w/ 100' / 30.5 m Leads, w/ 100-Amp Mild Steel Consumables 2-7004

1 O-Ring Lubricant (Christo-Lube MCG-129) 9-4893

1 Water Shield Regulator 8-6118

1 Consumables Tool 9-9431

1 Torch Cartridge (includes Consumables Tool) 35-1020

1 Shield Cup (all applications except 200-A Mild Steel) 35-1016

Inner O-Ring (Cat. No. 9-3030)

Location (Under Locking Ring)

300 Amp and Less

Cartridge Retaining

Ring (Cat. No. 9-9489)

Snap Ring

O-Ring, Cat. No. 9-3029

O-Ring, Cat. No. 9-3028

Cartridge Assembly

Art # A-07087_AD

O-Rings

Cat. No. 9-9041

Cat. No. 9-3027

Cat. No. 9-3026

Cat. No. 9-3025

Torch Head

Coolant Tube Kit

9-9429

Art # A-07088_AB

Manual 0-4825 Rev. AK 8-47 TORCH DATA for AutoCut Basic

Page 40

Cartridge Assembly (35-1022) Consumables

Cartridge Assembly

35-1022

Art # A-09242

35-1007

Shield Cup

2x-1005

Baffle

35-1023

Cartridge Body

TORCH DATA for AutoCut Basic 8-48 Manual 0-4825 Rev. AK

Page 41

Qty . Description Catalog Number

1 XT-301 Torch Head Kit 35-1002

1Torch Positioning Tube 9-4700

1Torch Clamp Assembly 9-9336

1 Coolant Tube Kit 9-9429

1 Coolant Check Valve Kit 9-4846

1Mounting Tube Hardware Kit (includes Mounting Tube O-ring) 9-4847

1 Ohmic Clip Kit 9-9414

Torch Head

Coolant Tube Assembly

Torch Clamp

Coolant Return

Check Valve

and Connector

End Cap

O-Ring (included

in Hardware Kit)

R

G

Positioning Tube

Torch Leads

Leads Clamp

Art # A-06980

To GCM-1000

Manual 0-4825 Rev. AK 8-49 TORCH DATA for AutoCut Basic

Page 42

Electrodes

Art # A-07250

35-1088

35-1087

O-Ring 9-9035

35-1080

35-1089

O-Ring 9-9035

35-1085

35-1069

35-1071

O-Ring 9-9035

B

A

Tips

B

A

Consumables O-Ring Locations and Catalog Numbers

35-1086

35-1055

35-1051

O-Ring 9-9035

A - O-Ring 8-5525

B - O-Ring 9-9060

B - O-Ring 9-9060

A - O-Ring 9-9038

35-1080

35-1056

B - O-Ring 9-9060

A - O-Ring 8-5525

35-1053

B - O-Ring 9-9060

A - O-Ring 9-9038

O-Ring 9-9035

35-1058

35-1060

B - O-Ring 9-9060

A - O-Ring 9-9038

B - O-Ring 9-9060

A - O-Ring 9-9038

35-1078

35-1062

B - O-Ring 9-9060

A - O-Ring 9-9038

Shield Cap

O-Ring 9-9039

TORCH DATA for AutoCut Basic 8-50 Manual 0-4825 Rev. AK

35-1034

Page 43

PA TENT INFORMATION

TMTM

TM

TMTM

XTXT

-301 Plasma Cutting -301 Plasma Cutting

XT

-301 Plasma Cutting

XTXT

-301 Plasma Cutting -301 Plasma Cutting

The following parts are covered under U.S. and Foreign Patents as follows:

Catalog # Description Patent(s)

35-1020 Cartridge US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1022 Cartridge US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1068 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566; D517577 Other Pat(s) Pending

35-1069 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566; D517576 Other Pat(s) Pending

35-1070 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566; D517576 Other Pat(s) Pending

35-1071 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566; D517576 Other Pat(s) Pending

35-1072 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566; D517576 Other Pat(s) Pending

35-1077 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566 Other Pat(s) Pending

35-1078 Electrode US Pat No(s) 6946616; 6919526; D505963; 6989505; 6998566 Other Pat(s) Pending

35-1079 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566 Other Pat(s) Pending

35-1080 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566; D517577 Other Pat(s) Pending

35-1085 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566 Other Pat(s) Pending

35-1086 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566; D517576 Other Pat(s) Pending

35-1087 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566; D517577 Other Pat(s) Pending

35-1088 Electrode US Pat No(s) 6946616; 6919526; 6989505; 6998566; D517576 Other Pat(s) Pending

35-1040 Plasma Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1041 Plasma Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1043 Plasma Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1044 Plasma Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1046 Plasma Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1024 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1025 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1026 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1027 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1034 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1028 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1029 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1030 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1031 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1032 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1033 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1035 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1036 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1037 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1039 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1275 Shield Cap US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1016 Shield CupUS Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1018 Shield CupUS Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1082 Shield Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1272 Shield Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1273 Shield Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1274 Shield Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1280 Shield Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1281 Shield Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1282 Shield Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1283 Shield Gas Distributor US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1019 Shield Retainer US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1021 Shield Retainer US Pat No(s) 6946616; 6919526; 6989505 Other Pat(s) Pending

35-1050 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600; D519135; D524,336 Other

Pat(s) Pending

35-1051 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600; D519135; D524,336 Other

Pat(s)Pending

35-1052 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600; D519135; D524,336 Ot her

Pat(s) Pending

TT

oror

cc

h Ph P

aa

h P

h Ph P

tentstents

a

tents

aa

tentstents

T

or

c

TT

oror

cc

Manual 0-4825 Rev. AK 8-51 TORCH DATA for AutoCut Basic

Page 44

TMTM

TM

TMTM

-301 Plasma Cutting -301 Plasma Cutting

XTXT

-301 Plasma Cutting

XT

-301 Plasma Cutting -301 Plasma Cutting

XTXT

TT

oror

cc

h Ph P

aa

c

cc

h P

h Ph P

tentstents

a

tents

aa

tentstents

T

or

TT

oror

The following parts are covered under U.S. and Foreign Patents as follows:

Catalog # Description Patent(s)

35-1053 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600; D519135; D524,336 Other

Pat(s)Pending

35-1054 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600; D519135; D524,336 Other

Pat(s) Pending

35-1055 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600 Other Pat(s) Pending

35-1056 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600 Other Pat(s) Pending

35-1057 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600 Other Pat(s) Pending

35-1058 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600; D519135; D524,336 Other

Pat(s)Pending

35-1060 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600; Other

Pat(s) Pending

35-1061 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600; D519135; D524,336 Other

Pat(s) Pending

35-1062 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600; D519135; D524,336 Other

Pat(s)Pending

35-1064 Tip US Pat No(s) 6946616; 6919526; 6989505; 7005600 Other Pat(s) Pending

35-1001 Torch Head US Pat No(s) 6946616; 6919526; 6852944; 6989505; 7071443 Other Pat(s) Pending

The following parts are licensed under U.S. Patent No. 5,120,930 and 5,132,512:

Catalog # Description

35-1027 Shield Cap

35-1028 Shield Cap

35-1029 Shield Cap

35-1030 Shield Cap

35-1032 Shield Cap

This manual may refer to some or all of the parts listed.

TORCH DATA for AutoCut Basic 8-52 Manual 0-4825 Rev. AK

Loading...

Loading...