Page 1

SPOOL COVER ASSEMBLY ( W4016301 ) INSTRUCTIONS

1

Manual 0-5350

Revision No.: AA

Issue Date: June 6, 2014

Spool Cover for UltraFeed VAF-4

and VAF-4HD Wirefeeders

16052 Swingley Ridge Road,

Suite 300 St, Louis, MO 63017

USA

www.victortechnologies.com

General Information

The Tweco spool cover (W4016301) is designed to be used together with UltraFeed VAF-4 and VAF-4HD Wirefeeders.

These instructions will guide you through the proper assembly procedure of the spool cover.

Supplied Parts (For UltraFeed VAF-4 and VAF-4HD Wirefeeders)

The following components are included in this kit:

Item Description Quantity

1 Bolt, M12 x 30 2

2 Star Washer, M12 2

3 Flat Washer, M12 2

Part Number: W4016301

Assembly Instructions

4 Screw, Countersunk, M5 x 12 2

5 Spool Cover Mounting Bracket 1

6 Spool Cover 1

7 Spool Cover Mounting Bracket 1

Table 1 Spool Cover Assembly

4

5

6

2

3

7

Art # A-12475

Figure 1 Spool Cover Assembly

Manual 0-5350 Rev AA 1 ©2014 Victor Technologies International, Inc

Page 2

SPOOL COVER ASSEMBLY (W4016301) INSTRUCTIONS

!

!

WARNING

Disconnect input power to the power source before installing or removing this control.

SAFETY INSTRUCTIONS AND WARNINGS

WARNING

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY.

PACEMAKER WEARERS KEEP AWAY UNTIL CONSULTING YOUR DOCTOR. DO NOT LOSE THESE INSTRUCTIONS.

READ OPERATING/INSTRUCTION MANUAL BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

Welding products and welding processes can cause serious injury or death, or damage to other equipment or

property, if the operator does not strictly observe all safety rules and take precautionary actions.

Safe practices have developed from past experience in the use of welding and cutting. These practices must be

learned through study and training before using this equipment. Some of these practices apply to equipment connected to power lines; other practices apply to engine driven equipment. Anyone not having extensive training in

welding and cutting practices should not attempt to weld.

Safe practices are outlined in the American National Standard Z49.1 entitled: SAFETY IN WELDING AND CUTTING.

This publication and other guides to what you should learn before operating this equipment are listed at the end of

these safety precautions. HAVE ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR WORK PERFORMED

ONLY BY QUALIFIED PEOPLE.

WARNING

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks or severe burns. The electrode and work circuit is

electrically live whenever the output is on. The input power circuit and machine internal circuits are also

live when power is on. In semiautomatic or automatic wire welding, the wire, wire reel, drive roll housing, and all metal parts touching the welding wire are electrically live. Incorrectly installed or improperly

grounded equipment is a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body protection.

3. Insulate yourself from work and ground using dry insulating mats or covers.

4. Disconnect input power or stop engine before installing or servicing this equipment. Lock input power disconnect switch open, or remove line fuses so power cannot be turned on accidentally.

5. Properly install and ground this equipment according to its Owner’s Manual and national, state, and local

codes.

6. Turn off all equipment when not in use. Disconnect power to equipment if it will be left unattended or out of

service.

7. Use fully insulated electrode holders. Never dip holder in water to cool it or lay it down on the ground or the

work surface. Do not touch holders connected to two welding machines at the same time or touch other people

with the holder or electrode.

8. Do not use worn, damaged, undersized, or poorly spliced cables.

©2014 Victor Technologies International, Inc 2 Manual 0-5350 Rev AA

Page 3

SPOOL COVER ASSEMBLY ( W4016301 ) INSTRUCTIONS

9. Do not wrap cables around your body.

10. Ground the workpiece to a good electrical (earth) ground.

11. Do not touch electrode while in contact with the work (ground) circuit.

12. Use only well-maintained equipment. Repair or replace damaged parts at once.

13. In confined spaces or damp locations, do not use a welder with AC output unless it is equipped with a voltage

reducer. Use equipment with DC output.

14. Wear a safety harness to prevent falling if working above floor level.

15. Keep all panels and covers securely in place.

WARNING

ARC RAYS can burn eyes and skin; NOISE can damage hearing.

Arc rays from the welding process produce intense heat and strong ultraviolet rays that can burn eyes

and skin. Noise from some processes can damage hearing.

1. Use a Welding Helmet or Welding Faceshield fitted with a proper shade of filter (see ANSI Z49.1 and AS 1674

listed in Safety Standards) to protect your face and eyes when welding or watching.

2. Wear approved safety glasses. Side shields recommended.

3. Use protective screens or barriers to protect others from flash and glare; warn others not to watch the arc.

4. Wear protective clothing made from durable, flame-resistant material (wool and leather) and foot protection.

5. Use approved ear plugs or ear muffs if noise level is high.

6. Never wear contact lenses while welding.

WARNING

FUMES AND GASES can be hazardous to your health.

Welding produces fumes and gases. Breathing these fumes and gases can be hazardous to your health.

1. Keep your head out of the fumes. Do not breathe the fumes.

2. If inside, ventilate the area and/or use exhaust at the arc to remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied respirator.

4. Read the Material Safety Data Sheets (MSDSs) and the manufacturer’s instruction for metals, consumables,

coatings, and cleaners.

5. Work in a confined space only if it is well ventilated, or while wearing an air-supplied respirator. Shielding gases

used for welding can displace air causing injury or death. Be sure the breathing air is safe.

6. Do not weld in locations near degreasing, cleaning, or spraying operations. The heat and rays of the arc can

react with vapours to form highly toxic and irritating gases.

7. Do not weld on coated metals, such as galvanized, lead, or cadmium plated steel, unless the coating is removed

from the weld area, the area is well ventilated, and if necessary, while wearing an air-supplied respirator. The

coatings and any metals containing these elements can give off toxic fumes if welded.

Manual 0-5350 Rev AA 3 ©2014 Victor Technologies International, Inc

Page 4

SPOOL COVER ASSEMBLY (W4016301) INSTRUCTIONS

WARNING

WELDING can cause fire or explosion.

Sparks and spatter fly off from the welding arc. The flying sparks and hot metal, weld spatter, hot workpiece, and hot equipment can cause fires and burns. Accidental contact of electrode or welding wire to

metal objects can cause sparks, overheating, or fire.

1. Protect yourself and others from flying sparks and hot metal.

2. Do not weld where flying sparks can strike flammable material.

3. Remove all flammables within 35 ft (10.7 m) of the welding arc. If this is not possible, tightly cover them with

approved covers.

4. Be alert that welding sparks and hot materials from welding can easily go through small cracks and openings to

adjacent areas.

5. Watch for fire, and keep a fire extinguisher nearby.

6. Be aware that welding on a ceiling, floor, bulkhead, or partition can cause fire on the hidden side.

7. Do not weld on closed containers such as tanks or drums.

8. Connect work cable to the work as close to the welding area as practical to prevent welding current from travelling long, possibly unknown paths and causing electric shock and fire hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off welding wire at contact tip when not in use.

WARNING

FLYING SPARKS AND HOT METAL can cause injury.

Chipping and grinding cause flying metal. As welds cool, they can throw off slag.

1. Wear approved face shield or safety goggles. Side shields recommended.

2. Wear proper body protection to protect skin.

WARNING

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high pressure. If damaged, a cylinder can explode. Since gas

cylinders are normally part of the welding process, be sure to treat them carefully.

1. Protect compressed gas cylinders from excessive heat, mechanical shocks, and arcs.

2. Install and secure cylinders in an upright position by chaining them to a stationary support or equipment cylinder rack to prevent falling or tipping.

3. Keep cylinders away from any welding or other electrical circuits.

4. Never allow a welding electrode to touch any cylinder.

5. Use only correct shielding gas cylinders, regulators, hoses, and fittings designed for the specific application;

maintain them and associated parts in good condition.

6. Turn face away from valve outlet when opening cylinder valve.

©2014 Victor Technologies International, Inc 4 Manual 0-5350 Rev AA

Page 5

SPOOL COVER ASSEMBLY ( W4016301 ) INSTRUCTIONS

!

7. Keep protective cap in place over valve except when cylinder is in use or connected for use.

8. Read and follow instructions on compressed gas cylinders, associated equipment, and CGA publication P-1

listed in Safety Standards.

WARNING

MOVING PARTS can cause injury.

Moving parts, such as fans, rotors, and belts can cut fingers and hands and catch loose clothing.

1. Keep all doors, panels, covers, and guards closed and securely in place.

2. Stop engine before installing or connecting unit.

3. Have only qualified people remove guards or covers for maintenance and troubleshooting as necessary.

4. To prevent accidental starting during servicing, disconnect negative (-) battery cable from battery.

5. Keep hands, hair, loose clothing, and tools away from moving parts.

6. Reinstall panels or guards and close doors when servicing is finished and before starting engine.

This product, when used for welding or cutting, produces fumes or gases which contain chemicals

know to the State of California to cause birth defects and, in some cases, cancer. (California Health &

Safety code Sec. 25249.5 et seq.)

Considerations About Welding And The Effects of Low Frequency Electric and Magnetic Fields

The following is a quotation from the General Conclusions Section of the U.S. Congress, Office of Technology Assessment, Biological Effects of Power

Frequency Electric & Magnetic Fields - Background Paper, OTA-BP-E-63 (Washington, DC: U.S. Government

Printing Office, May 1989): “...there is now a very large volume of scientific findings based on experiments at the

cellular level and from studies with animals and people which clearly establish that low frequency magnetic fields

and interact with, and produce changes in, biological systems. While most of this work is of very high quality, the

results are complex. Current scientific understanding does not yet allow us to interpret the evidence in a single

coherent framework. Even more frustrating, it does not yet allow us to draw definite conclusions about questions

of possible risk or to offer clear science-based advice on strategies to minimize or avoid potential risks.”

To reduce magnetic fields in the workplace, use the following procedures.

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cable around the body.

WARNING

NOTE

4. Keep welding power source and cables as far away from body as practical.

ABOUT PACEMAKERS:

The above procedures are among those also normally recommended for pacemaker wearers. Consult

your doctor for complete information.

Manual 0-5350 Rev AA 5 ©2014 Victor Technologies International, Inc

Page 6

SPOOL COVER ASSEMBLY (W4016301) INSTRUCTIONS

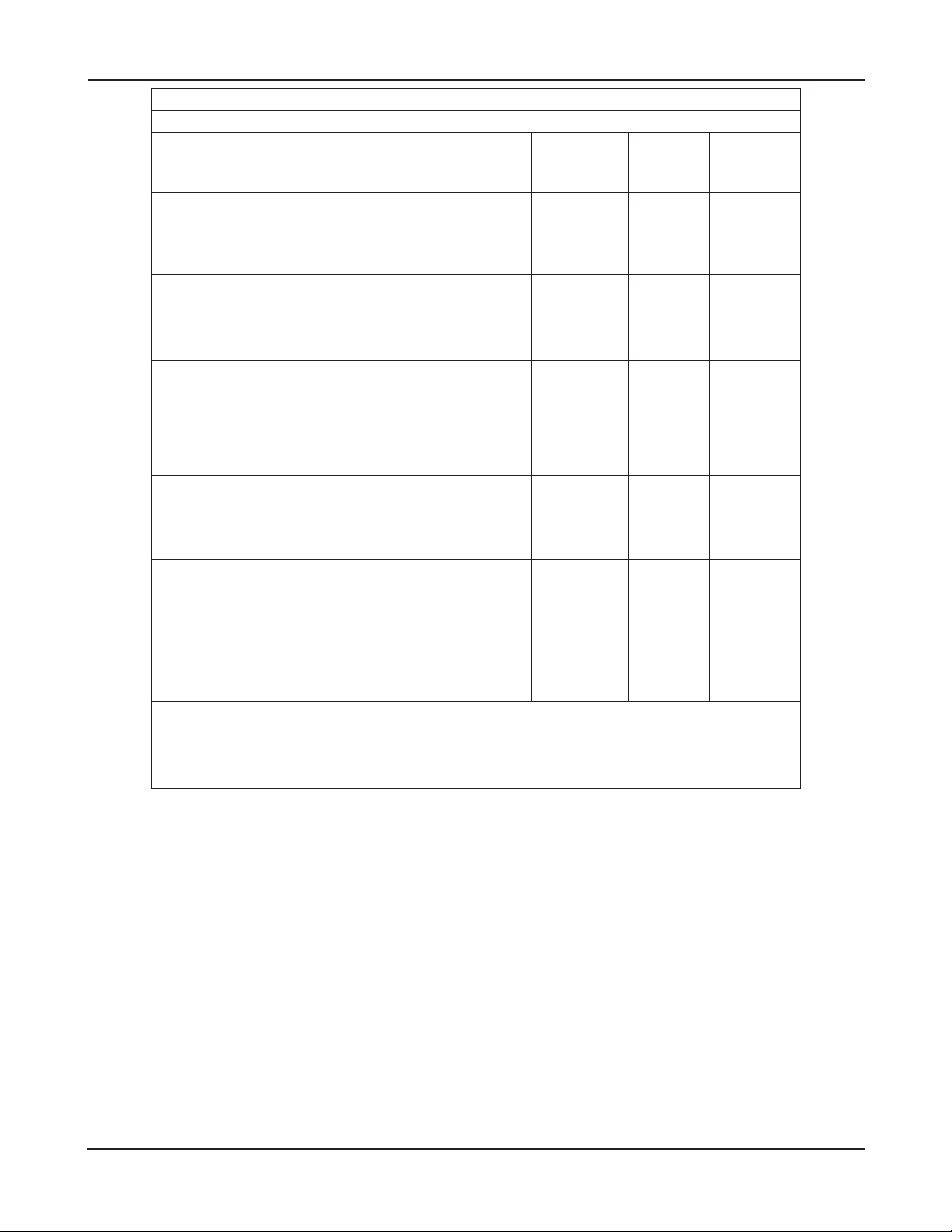

AWS F2.2:2001 (R2010), Adapted with permission of the American Welding Society (AWS), Miami, Florida

Guide for Shade Numbers

Process

Shielded Metal Arc Welding

(SMAW)

Electrode Size in.

(mm)

Less than 3/32 (2.4)

3/32-5/32 (2.4-4.0)

5/32-1/4 (4.0-6.4)

More than 1/4 (6.4)

Arc Current

(Amperes)

Less than 60

60-160

160-250

250-550

Minimum

Protective

Shade

7

8

10

11

Suggested*

Shade No.

(Comfort)

10

12

14

Gas Metal Arc Welding (GMAW)

and Flux Cored Arc Welding

(FCAW)

Gas Tungsten arc Welding

(GTAW)

Air Carbon Arc Cutting (CAC-A)

Plasma Arc Welding (PAW)

Plasma Arc Cutting (PAC)

* As a rule of thumb, start with a shade that is too dark to see the weld zone. Then go to a lighter

shade which gives sufficient view of the weld zone without going below the minimum. In oxyfuel gas

welding, cutting, or brazing where the torch and/or the flux produces a high yellow light, it is desirable

to use a filter lens that absorbs the yellow or sodium line of the visible light spectrum.

(Light)

(Heavy)

Less than 60

60-160

160-250

250-550

Less than 50

50-150

150-500

Less than

500

500-1000

Less than 20

20-100

100-400

400-800

Less than 20

20-40

40-60

60-80

80-300

300-400

400-800

7

10

10

10

8

8

10

10

11

6

8

10

11

4

5

6

8

8

9

10

11

12

14

10

12

14

12

14

6 to 8

10

12

14

4

5

6

8

9

12

14

©2014 Victor Technologies International, Inc 6 Manual 0-5350 Rev AA

Page 7

SPOOL COVER ASSEMBLY ( W4016301 ) INSTRUCTIONS

Spring Washer

M12 x 30 Bolts;

Assembly Procedure

Spool cover is assembled in the following steps:

1. Remove the spool hub assembly.

a. Remove the clip from the spool hub.

b. Unscrew the 3-lobe screw.

c. Remove the spool hub parts and the spacer in the following sequence. Note that the spacer is not required

when fitting the spool cover.

Flat Washer,large hole

Spacer

Friction Washer

Keyed Washer

Flat Washer, small hole

Shaft

Hub Wire Reel

Compression Spring

3-lobe Screw

Retaining Clip

Hexagon Nut

Art # A-12476

Figure 2 Removing Spool Hub Assembly

2. Assemble the Spool Cover Mounting Brackets, one inside and one outside the spool cover, with the two countersunk screws M5 x 12.

3. Secure the spool cover assembly to the spool support arm with M12 x 30 Bolts, Star Washers, M12, and Flat

Washers, M12 as shown in the diagram below.

Star Washers, M12;

Flat Washers, M12

Countersunk Screws,

M5×12

Spool Cover Mounting Brackets

Art # A-12477

Keyed Washer

Flat Washer, small hole

3-lobe Screw

Retaining Clip

Compression Spring

Spool Cover

Friction Washer

Hub Wire Reel

Figure 3 Installing Spool Cover

Manual 0-5350 Rev AA 7 ©2014 Victor Technologies International, Inc

Page 8

SPOOL COVER ASSEMBLY (W4016301) INSTRUCTIONS

4. Install the spool hub component parts over the spool hub shaft in the following sequence.

Spool Hub

Spring

3-lobe Screw

Retaining Clip

Flat Washer

Keyed Washer

Friction Washer

Figure 4 Spool Hub Assembly

WARNING

Fully tighten all fasteners.

Refer to the figures below for the assembled spool cover:

Art # A-12478

Art # A-12479

Figure 5a Assembled Spool Cover (door opened)

Art # A-12480

Figure 5b Assembled Spool Cover

©2014 Victor Technologies International, Inc 8 Manual 0-5350 Rev AA

Loading...

Loading...