®

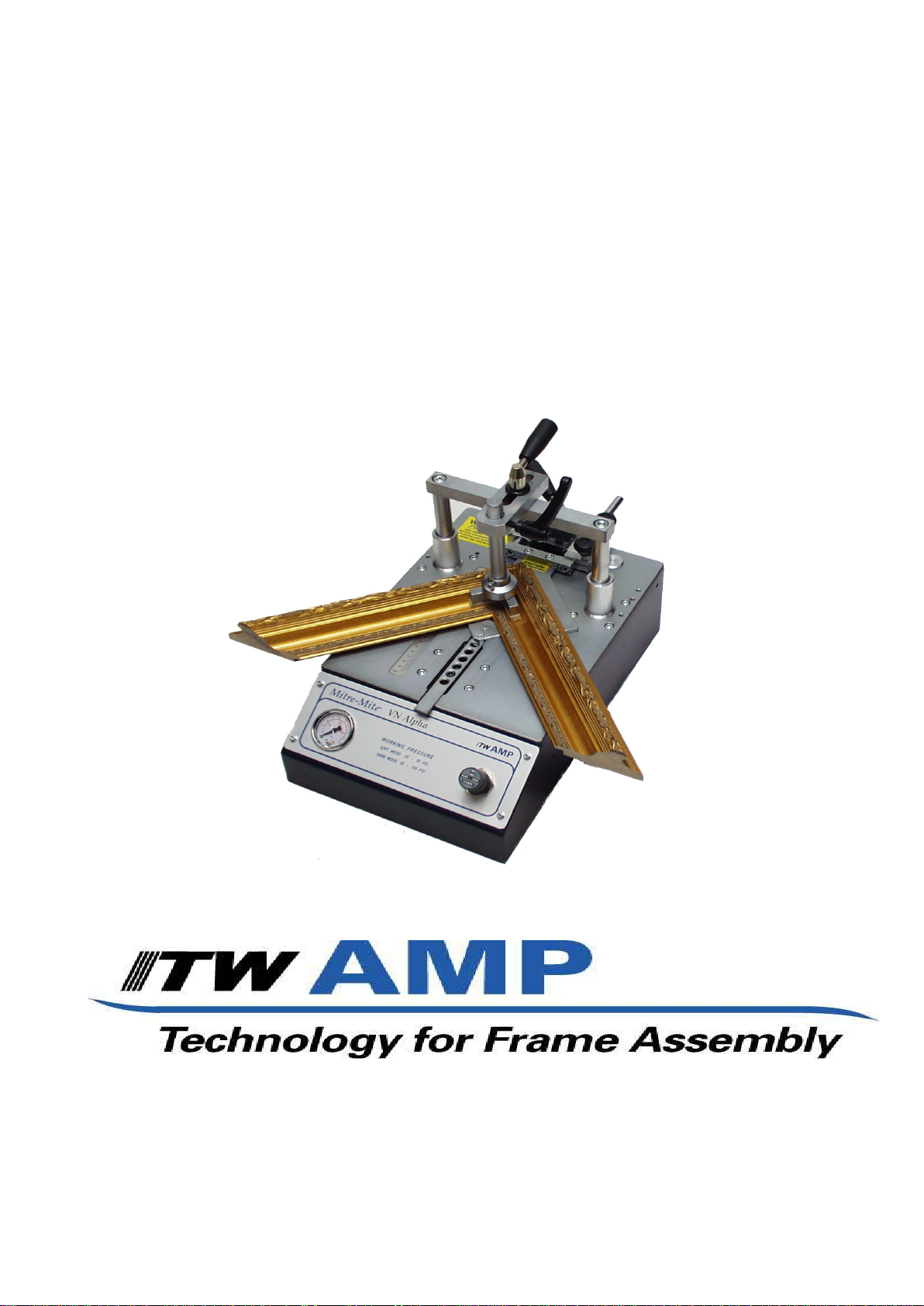

Mitre-Mite

VN Alpha

Instruction Manual

Version E

100 Fairway Drive Suite 114 Vernon Hills, IL 60061

Phone: 1-800-322-4204

Fax: 1-800-426-7019

1

Index

1. GENERAL INFORMATION 3

1.1 PRODUCER 3

1.2 ASSIST ANCE CENTERS 3

1.3 CERTIFICA TION 3

1.4 WARRANTY 3

1.5 PRE-ARRANGEMENTS CHARGED TO THE

CUSTOMER 3

1.6 HANDBOOK STRUCTURE 3

1.6.1 Object and contents 3

1.6.2 Users 3

1.6.3 Preservation 3

1.6.4 Symbols utilized 4

2. MACHINE DESCRIPTION 5

2.1 WORKING PRINCIPLE 5

2.2 MAIN COMPONENTS 5

2.3 MACHINE STRUCTURE 5

2.4 DIMENSIONS 5

2.5 SURROUNDING CONDITIONS 5

2.6 LIGHTING 5

2.7 VIBRATIONS 5

2.8 NOISE EMISSIONS 5

2.9 TECHNICAL DATA 6

2.10 STANDARD EQUIPMENT 6

2.10.1 Standard accessories 6

2.10.2 Upgrading and implementing of mechanical parts 6

2.10.3 Optional accessories 6

2.10.4 Customized optional accessories 6

2.1 1 ELECTROMAGNETIC AMBIENT 6

4.7.2 V-nail

(R)

clawhead replacement to change V-nails size10

4.8 ADJUSTMENTS 11

4.8.1 V-nails

4.8.2 Vertical clamp adjustment 12

4.8.2a Vertical clamp position adjustment 12

4.8.2b Vertical clamp height adjustment 12

4.8.3 Frontal clamp adjustment 12

4.8.4 Working pressure adjustment 13

4.8.5 Protective shield adjustment 14

(R)

inserting positions adjustment 11

4.9 CHECKING OPERATIONS TO BE EFFECTED

BEFORE WORKING ST ART 14

5. FUNCTIONING 15

5.1 OPERATORS 15

5.2 FUNCTIONING DESCRIPTION 15

5.3 TIPS FOR PERFECT JUNCTIONS 15

5.4 MACHINE STOP 16

5.5 MACHINE REINSTA TEMENT 16

5.6 PUTTING OUT OF SERVICE 16

6. MAINTENANCE 16

6.1 STATE OF MAINTENANCE 16

6.2 MACHINE ISOLATION 16

6.3 SPECIAL CAUTIONS 16

6.4 CLEANING 16

6.5 LUBRICATION 17

6.6 ORDINARY MAINTENANCE 17

6.7 EXTRAORDINARY MAINTENANCE 17

7. DIAGNOSTIC 18

7.1 SAFETY WARNINGS 18

7.2 TROUBLESHOOTING 18

7.3 REQUEST OF ASSIST ANCE 19

8. SPARE PARTS 20

3. SAFETY 7

3.1 GENERAL W ARNINGS 7

3.2 SCHEDULED USE 7

3.3 INADVISABLE USE 7

3.4 DANGEROUS AREAS 7

3.5 PROTECTION DEVICES 7

3.6 STOP FUNCTIONS 7

3.7 SAFE WORKING PROCEDURES 7

3.8 RESIDUAL RISKS 8

3.9 PLATES 8

4. INSTALLATION 8

4.1 SHIPPING AND HANDLING 8

4.2 STORAGE 8

4.3 PRELIMINARY ARRANGEMENTS 9

4.4 UNPACKING 9

4.5 CONNECTIONS 9

4.5.1 Pneumatic connection 9

4.6 PRELIMINARY CONTROLS 10

4.7 MACHINE ARRANGEMENT 10

4.7.1 V-Nails

2

(R)

magazine loading 10

8.1 SPARE PARTS LIST 20

8.2 SPARE PARTS ORDERING 20

9 DEMOLITION 20

9.1 DEMOLITION 20

10. ATTACHMENTS 20

10.1 DECLARA TIONS 20

10.2 SCHEMES 20

1. GENERAL INFORMATION

1.1 PRODUCER

The firm Alfamacchine-ITW/AMP can boast more than 10

years of experience in the construction of Woodworking

Machines. It has acquired the technological know-how,

developed during years of research in strict touch with

manufacturing departments and international

commercialization. We offer the best warranty that anyone

can grant its customers.

TEL 1-800-322-4204 FAX 1- 800-426-7019

1.2 ASSISTANCE CENTERS

ITW/AMP is represented in North and South America by a

numerous and prepared sales organization. Contact our firm

directly to get the name of your local distributor.

For every need regarding Use, Maintenance or Request of

Spare Parts, the Customer should call the local authorized

service center or directly to ITW/AMP, specifying the

machine identification data impressed on the plate.

The warranty is also void in case you use V-nails

from the original ITW/AMP ones.

To take advantage of warranty services is necessar y, at the

moment you receive your machine, to fill out the war ranty

card and send it back as soon as possible to ITW/AMP.

The warranty will be valid only after ITW/AMP receives the

warranty card & records it.

(R)

different

1.5 PRE-ARRANGEMENTS CHARGED TO THE CUSTOMER

It is the customer’s duty , on times agreed with the producer ,

to execute what is indicated in our documentation.

Things normally charged to the customer are:

• Premises predisposition, included building works and/

or canalization eventually requested

• Pneumatic supplyng of compressed air (see the

paragraph 4.5)

1.6 HANDBOOK STRUCTURE

The customer must pay extreme attention to the indications

reported on this handbook. The proper Pre-Arrangement,

Installation and Use of the Machine, constitute the basis of

a correct customer-manufacturer relationship.

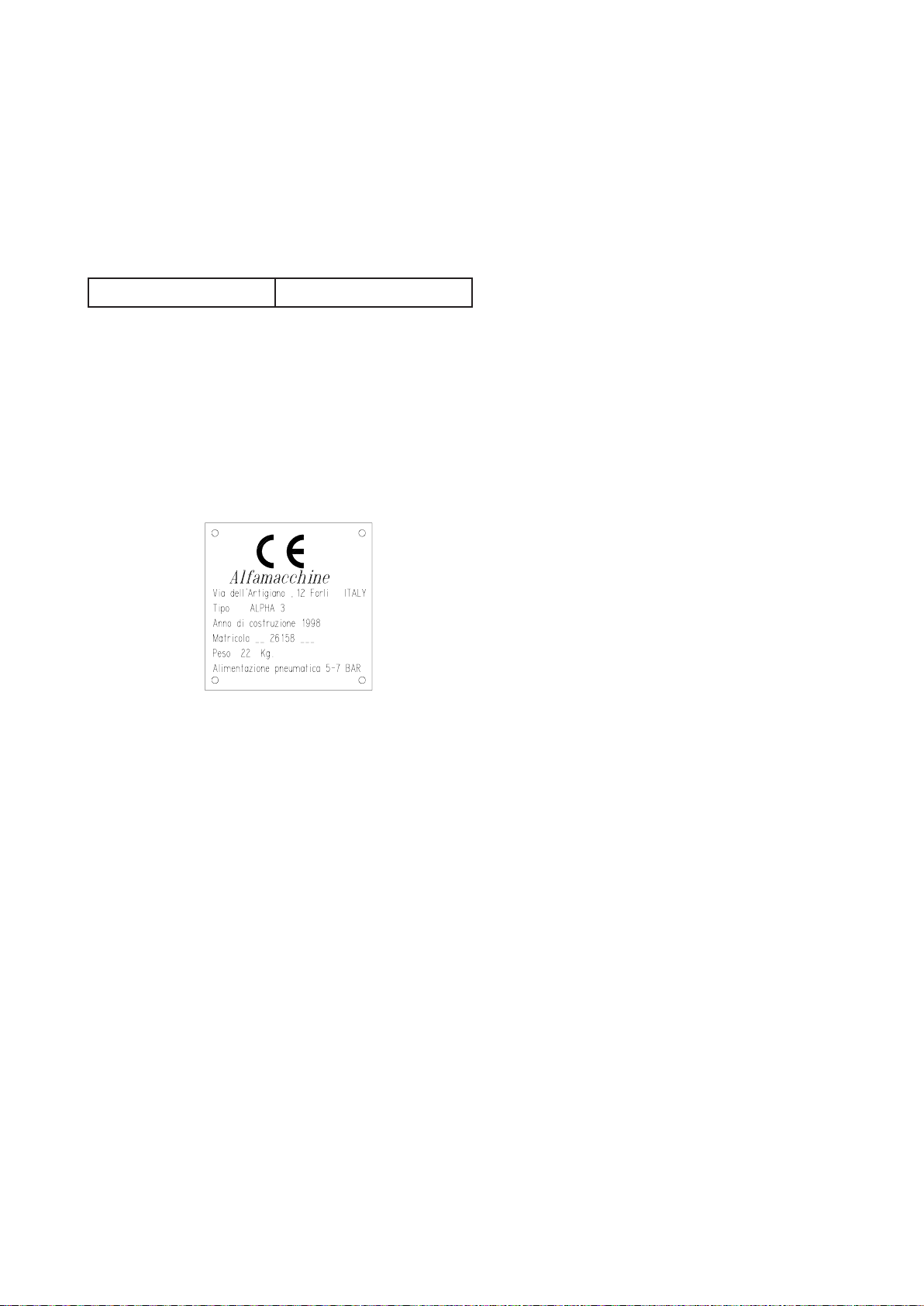

1.3 CERTIFICATION

The machine is produced in conformity to the pertinent

European Community Norms in force at the moment of its

introduction on the market.

1.4 WARRANTY

The ITW/AMP’s products are constructed to have a long life

and are tested one by one.

If, in spite of this, if any damages or malfunctioning would

occur, the replacement of defective parts is warranted

(counting from the date written on the delivery bill) for a

period of:

- 24 months for mechanical components

- 12 months for pneumatic part

The driver blade is tested for about 1.000.000 w orking cycles.

The W arranty does not include the sending of technical staff.

The repair interventions will be performed at your local

distributor or ITW/AMP’s plants. The shipping costs will be

entirely charged to the Customer.

The warranty does not cover the damages due to an

inappropriate use of the machine or not corresponding to

the instructions described in this handbook.

Warranty decays in case of unauthorized modifications or

because of accidental damages or tampering performed by

unqualif ied personnel.

1.6.1 Object and contents

This goal of this handbook is to provide to the customer all

the necessary information so that they can properly use the

machine & be able to run it in complete autonomy and safety .

The handbook contains information concerning the

technical aspects, machine working and standstill,

maintenance, spare parts and safety. Before making any

operation on the machine, the qualified technicians and

operators must read carefully this handbook. In case of doubt

about the correct interpretation of these instructions, ask

ITW/AMP or your local distributor to have the problem

explained.

1.6.2 Users

This handbook is made for the operators and technicians

authorized to perform the machine maintenance.

The operators can not execute operations reserved to the

maintaince staff or the qualified technicians.

The producer does not answer to damages derived from notobserving this prohibition.

1.6.3 Preservation

The instruction handbook must be kept very closed to the

machine, into a special container protected from liquids and

whatever could compromise its legibility

3

1.6.4 Symbols utilized

P...

A...

O...

I...

C...

DANGER

WARNING

OBSERVATION

INQUIRY

EXAMINATION

ADJUSTMENT

It indicates a danger with a mortal risk for the operator

It indicates a warning or a note about key functions or useful

information. Pay the maximum attention to the paragraph

marked with this symbol.

It is requested to take a measurement data, to check a

signal,....

The user is requested to check the proper positioning of any

element of the machine, before operating a certain command

It’s necessary to consult the handbook before performing a

certain operation

In case of a strange sitituation and/or anomalies, you can be

requested to perform a certain mechanical adjustment.

R...

4

2. MACHINE DESCRIPTION

2.1 WORKING PRINCIPLE

The benchtop Frame Assembling Machine Mitre Mite VN

Alpha has been manufactured to assemble any kind of frame.

The Mitre Mite VN Alpha , being of simple construction and

extremely easy to use, makes it possible to join with absolute

precision any kind of moulding by means of special steel V-

(R)

nails

.

It uses V-Nails

(R)

with the “pulling pow er” effect in dif ferent

sizes.

2.2 MAIN COMPONENTS

The main components constituting the machine are:

- Pneumatic clamping device to allow a proper locking

of the mouldings to insert several V-nails

(R)

in different

positions

- Magnetic pressure pads of several types, at quick

replacement, to have the proper clamping of an y profile

- Dual functions foot operating pedal for separate control

of clamping and nail insertion

- Pneumatic opening of the V-nail

(R)

magazine for a very

quick reloading

- Nail heads sizes 7, 10 and 15 mm.

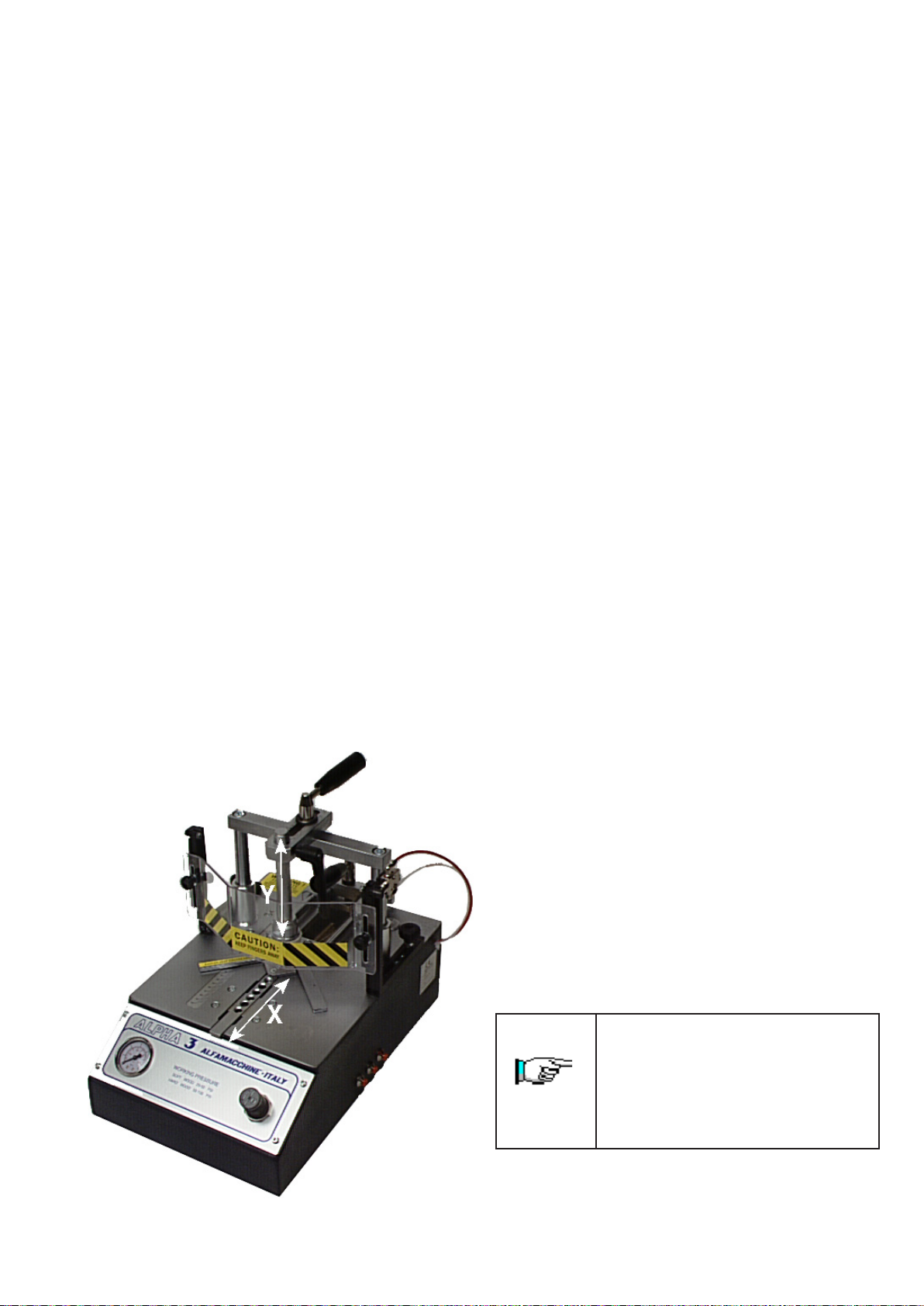

2.3 MACHINE STRUCTURE

The movement directions during the machine working are

the followings:

- X AXIS

Movement of horizontal clamp

- Y AXIS

Movement of vertical clamp

2.4 DIMENSIONS

The overall dimensions are reported on table 2.9-A

2.5 SURROUNDING CONDITIONS

The machine does not need special surrounding conditions.

It has to be installed inside an industrial building, lit, aired

and with a compact and flat floor. The permitted temperatures

go from 41° to 104° F, with a humidity level not higher than

50% at 104° F or 90% at 68° F.

2.6 LIGHTING

Premises lighting must be conformed to the norms in force

in that Country where the machine is installed and has to

guarantee a clear visibility and can not create dangerous

light reflections.

2.7 VIBRATIONS

In standard conditions conformed to the indication of

machine proper utilization the vibrations do not create

dangerous conditions. The a verage quadratic weighed level,

according to the acceleration frequency to which arms are

exposed does not exceed 2,5 m/s2.

2.8 NOISE EMISSIONS

The machine is designed and projected for reducing the noise

emission level to its source. In standard working conditions

the Machine noise power level is:

Acoustic Continuous Equivalent weighed

pression A <70dB

Acoustic Istantaneous weighed

pression <130dB

The noise levels indicated are emission levels and are not

representative of operating levels. In spite of existing a

relationship between emission levels and exposure ones,

this can not be used in a reliable way to def ine if further

precautions are necessary. The factors determining the

exposure level to which the working force is subjected,

include exposure length, working premises characteristics

and other noise sources (number of machines, closed

building, etc…). Furthermore the allowed exposure levels

could change according to the several Countries. At any

rate, the information provided, will allow the Machine

Operator to achieve a better understanding of the dangers

and risks they are submitted to.

The indicated noise levels are emission

ones measured in standard conditions of

use. In case of any machine modification,

the above mentioned levels could be

changed and should be tested on the same

machine.

5

2.9 TECHNICAL DATA

We have listed below the Machine’s data and technical

characteristics to which make reference for any eventual

contact with your distributor for Technical Assistance.

TABLE 2. 9 A

Frames thickness min.-max. .24”- 3.15”

Frames width min.-max. .24”- 2.76”

V-nails magazine capacity n. 220

V-nails size mm 7-10-15

V-nails size on request mm 3-5-12

Pneumatic Supplying 40-100 PSI

Weight about 62 LB

Height of working bench 5.1”

Overall dimensions 17.1”x13”x11.8”

2.10 STANDARD EQUIPMENT

The equipment listed below is standard.

2.10.1Standard accessories

Once you have removed the packaging, please check the

presence of the following accessories:).

- N.1 nail head mm. 7

- N.1 nail head mm.10

- N.1 nail head mm.15

- N.1 L shaped pressure pad

- N.1 Rounding pressure pad

- N.1 Allen Wrench 5 mm. for V-nails head replacement

- N.1 Brass rod magnet to remove V-nails

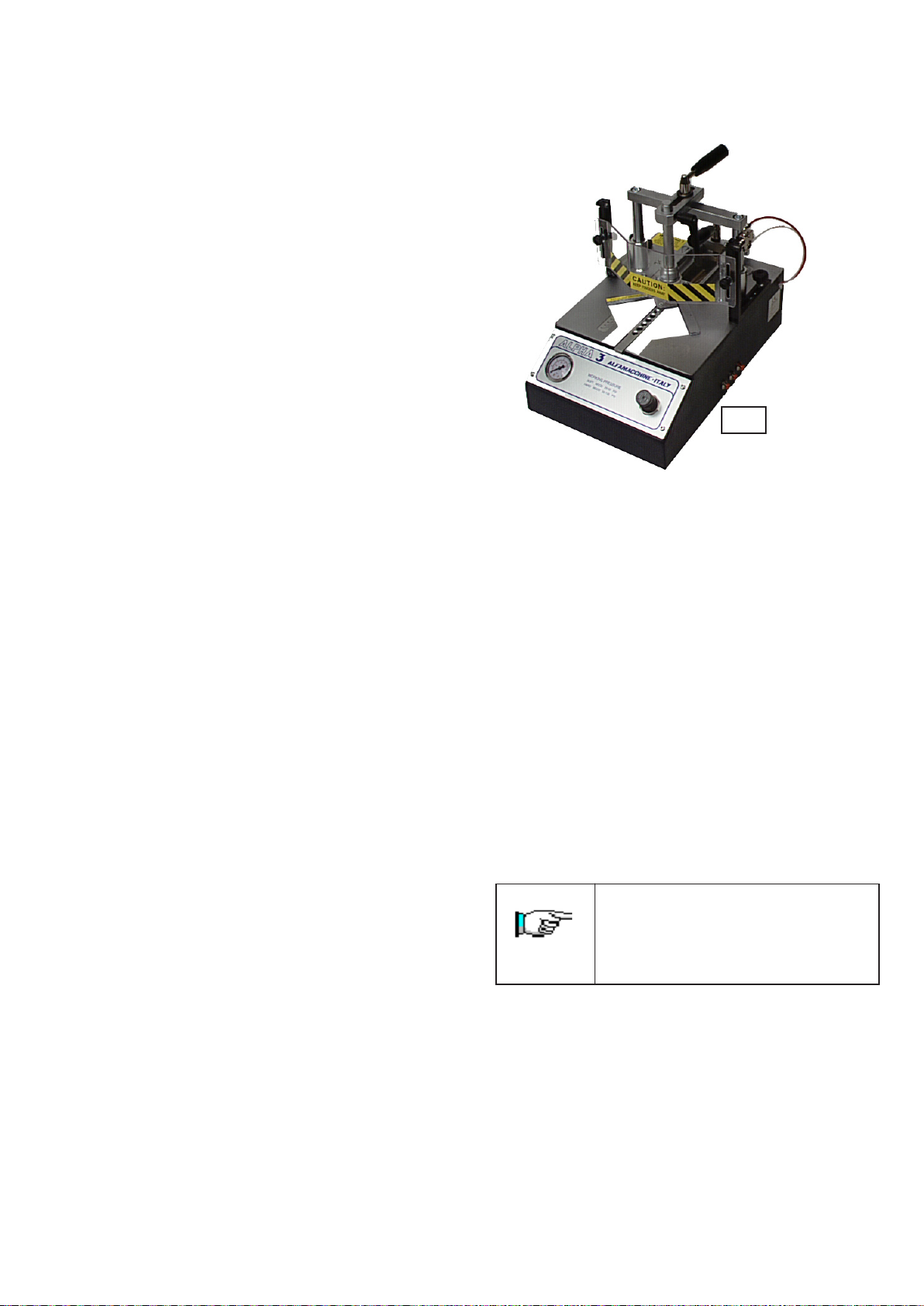

Picture 1

Picture 2

2.10.2Upgrading and implementing of mechanical parts

This machine has been manufactured following a modular

criteria, therefore the existing equipment can be further

upgraded with additional accessories that will not alter its

basic structure.

Technical upgrades on the machine model, if any, will be

such that they can be installed at any time without requiring

any substantial modifications to the machine structure.

2.10.3Optional accessories

• Soft clamping of the moulding that allows to clamp the

moulding at low pressure

• Floor stand

• Adjustable tilting fences (see fig. 3)

• Wooden working bench extension

• Metallic working bench extension

• Special fences for octagons (fig.1)

• Special fences for hexagons (fig.2)

• Round and square pressure pads in rubber

• V -nails claw heads size 3-5-12 mm.

Picture 3

2.10.4Customized optional accessories

Thanks to its versatility this machine can be ‘custom-made’

to meet our users requirements. Additional accessories can

be made by your local machine shop, that can make the

frame assembling easier: EX: special fences for peculiar

moulding shapes, special clamps to ensure the mouldings

are locked properly during V-nail firing, and so on.

2.11 ELECTROMAGNETIC AMBIENT

The Machine is designed to operate properly in an industrial

electromagnetic ambient without altering it being an

exclusively pneumatic machine.

6

3. SAFETY

3.1 GENERAL W ARNINGS

The operator must pay the maximum attention to the

information written in this Handbook, expressively about

proper precautions for Safety listed in this chapter.

It is imperative for the operator to follo w the warnings listed

below:

• Keep the machine and the working clean & ordered

• Provide appropriate containers to stock the pieces you

will be working with

• Use the Machine only in a normal psycho-physical

conditions

• Wear adequate clothing to avoid obstacles and/or

dangerous entanglements to/from the machine

• Wear the individual protection gears prescribed by the

instruction handbook, regarding the effected operations

• Do not remove or alter the warning plates and adhesive

signs

• Do not remove or elude the Machine Safety Systems

• Keep the fingers away from the working area

• Disconnect the air pressure supply during any

maintenance intervention

• Keep your foot off of the pedal during machine

maintenance

3.2 SCHEDULED USE

The Machine is designed and built to assemble mitred

corners.

The machine is projected for manual use only (under

operator’s control).

Figure 3.4.A- Working area and dangerous zones

Dangerous zone

3.5 PROTECTION DEVICES

The machine is equipped with adequate protections for

persons exposed to the risks due to the transmission mobile

elements,taking part in working (driver blade, horizontal

clamp, vertical clamp).

3.6 STOP FUNCTIONS

The machine stop functions are the following:

• Fast clutch fitting stop (Category 0).

• Foot pedal Stop (Category 1).

3.3 INADVISABLE USE

The machine can not be used:

• For uses different from those listed in paragraph 3.2

• In an explosive or aggressive atmosphere, where there

is a high density of dust or oily substances suspended

in the air

• In a flammable atmosphere

• Outside in all weather severity

• For working materials not suitable with the machine’s

characteristics

3.4 DANGEROUS AREAS

The area where the frames are assembled is defined as the

“working area”

The dangerous areas of the machine, include the movable

parts and the surrounding zones

STOP CATEGORY 0

It is obtained by disconnecting the fast clutch fitting from

the air feed system (uncontrolled stop).

STOP CATEGORY 1

Controlled stop is obtained by lifting the foot from the

pneumatic pedal, which does not allow the v-nails

or the clamps to work.

(R)

to fire

3.7 SAFE WORKING PROCEDURES

The machine is projected and realized to

eliminate any risk connected with its use.

The user is requested to achieve an adequate

training to be instructed by your local

distributor or ITW/AMP’s technicians.

The other risks related with using the machine are:

- Finger crushing in the vertical clamp working area

- Finger crushing in the frontal clamp working area

It is necessary to carefully follow the follo wing instructions:

1 Keep the fingers away from frontal and vertical clamp

working areas

2 Disconnect the air pressure during any maintenance

interventions

3 Keep the foot away from the pedal during machine

maintenance

7

3.8 RESIDUAL RISKS

During the normal working cycle and while performing

maintenance, the operators are exposed to several residual

risks that, because of operations own nature, can not be

totally eliminated.

• Risk of f inger crushing in the working areas of the

vertical and frontal clamps

3.9 PLATES

The warning plates carrying out safety functions & can not

be removed, covered or damaged.

To see the location of the plates or adhesive signs , see

Fig.10.2-D

Ta ble 3.8 A- Types of plates

4. INSTALLATION

4.1 SHIPPING AND HANDLING

The shipment must be performed by a professionally

qualified staff. The machine has to be shipped in a safe way

to avoid any damage to its parts.

• All the protections and guard devices must be properly

closed and locked.

• The machine has to be shipped like positioned for

installation.

• Before the shipment, it is necessary to lubricate the parts

which are not painted

• According to the type of shipment, it is necessary to

protect the machine from any jarring impact or stress

Figure 4.1A – machine handling indications

Plate concerning machine characteristics

Adhesive sign concerning the finger danger zone

Adhesive sign concerning the behaviour to be kept during

the working cycle

Adhesive sign concerning the behaviour to be kept during

the working cycle

Machine total weight: about 62 LB

The machine lifting must be performed by 2

operators.

Any damaging of the machine caused during its shipment

or handling is not covered under wa r ranty.

Repairs or replacements of damaged parts are charged to the

customer.

4.2 STORAGE

In case of long inactivity, the machine must be stored with

precautions concerning storage place and times.

• Store the machine indoors

• Protect the machine from jarring impacts and stresses

• Protect the machine from humidity and high

temperatures

• Avoid corrosiv e materials that could touch the machine

• Lubricate the parts which are not painted

8

4.3 PRELIMINARY ARRANGEMENTS

In order to install the machine it is necessary to prepare a

working area adequate to the machines dimension & the

length of moulding you will be working with.

T o fulfill the characteristics of precision and steadiness, the

bench frame assembling machines must be positioned on a

solid and leveled plane able to sustain the weight of the

machine. The bench must be studied and prepared by the

customer and/or qualified staff.

4.4 UNPACKING

The benchtop machine is shipped packed into an

appropriate carton and protected by polystyrene parts.

Remove the external packing and save it for a future use.

Check for any casual shipping damage and report it

immediately to the carrier. Shipping damages or any other

defects must be reported to ITW AMP or your local

distributor, within 3 days from receipt of the machine.

4.5 CONNECTIONS

To avoid any problems while setting up your machine, it is

recommended that you follow the instructions below.

Picture 5

Use the supplied fast clutch fitting to connect the air

compressor system. You could use also another f itting

suitable with your pneumatic system (see fig. 6).

4.5.1 Pneumatic connection

The machine is controlled by a dual action footpedal.

The 3 pipes the pedal must inserted into the 3 fittings located

on machine’s right side in the following sequence (fi. 4-5):

Upper connection Red pipe into the red fitting

(external side)

Central connection Black pipe into the black fitting

(central fitting)

Low er connection Transparent pipe into the 3rd fitting

(user side)

Picture 6

We recommend that you install a f ilter/

lubricator on the compressed air system to

obtain clean and lubricated air.

Use only silicone lubricating oil for

pneumatic systems. The use of inadequate

oil could damage the valves.

Once you have connected the machine with the pneumatic

system, check the proper operation of the foot pedal in the

following way: Move the vertical bar to its full up position

(see paragraph 4.8.2b).

• Pressing the footpedal half way down activates the

horizontal clamp, vertical clamp and the fence locking

• The foot pedal pressed full down activates the V-nail

driver

(R)

Picture 4

Check the foot pedal operating when the

(R)

V-nail

magazine is closed. The foot

pedal control is deactivated when the V-

9

4.6 PRELIMINARY CONTROLS

The Machine preliminary operations before starting the

machine, must be executed by a technician appointed by

the customer. Before setting up the machine, it is necessary

to execute certain verifications and checks to prevent

mistakes or accidents during setup.

• Verify that the machine has not been damaged during

the assembly steps.

• Verify with extreme care, the pipes integrity

4.7 MACHINE ARRANGEMENT

4.7.1 V-Nails

To load the V-nails

• Move the clawpusher backwards by pulling backwards

on the control wire (see fig. 7).

• Insert one or more V-nail

sharpened edge of the V-nails

that they are loaded with the V of the nails pointing in

the direction indicated in the figures 8 and 9. Make sure

that you hav e the correct type of cla w head for the nails

that you are using.

• Move the claw pusher forward by gently releasing the

control wire (see fig.7)

(R)

magazine loading

(R)

magazine proceed as follows:

(R)

strips, making sure that the

(R)

(glue side) faces up and

Picture 7

Picture 8

Picture 9

4.7.2 V-nail

The V -nail

V-nails

(R)

clawhead replacement to change V-

(R)

nail

size

(R)

guide head must be changed each time you use

(R)

of different sizes.

Proceed as follows to replace it:

• Loosen the locking screw of the V-nail

(R)

guide head

using the proper 5 mm Allen wrench (the screw is on the

opposite side from the V-nail

• Remove the V-nail

(R)

guide head

(R)

magazine(See fig. 10)

• Move the clawpusher backwards by pulling backwards

on the control wire. This will permit access to the V-

(R)

nail

magazine (see fig. 8).

• Remove all the V-nails

(R)

that are still in the magazine

(using the proper brass magnet, if necessary) (see fig.11).

• Insert the new V-nail

(R)

stick(of desired height) into the

magazine

• Move the clawpusher forward by geltly releasing the

control wire. (see figure 7).

• Inser t the new size V-nail guide head to match the Vnails to be used (see fig. 12).

• Tighten the locking screw of the V-nail guide head (see

fig.10).

10

Picture 10

4.8 ADJUSTMENTS

The machine has been completely tested & checked in ITW/

AMP’s plants before its shipment. All the operator has to do

is perform the following adjustments:

4.8.1 V-nail

To properly position the mouldings to be assembled, the

Mitre Mite VN Alpha is equipped with a 90° fence.

The fence can be shifted forward or backward in order to

allow the proper positioning of the v-nails

moulding.

The fence stops (backward and forward) can be set with

precision by means of locking clamps. (see fig. 13).

The operator can easily use the machine to insert V-nails

with extreme precision into 2 different positions (fig. 14).

(R)

inserting positions adjustment

(R)

in the

Picture 11

Picture 12

Picture 13

Picture 14

11

4.8.2 Vertical clamp adjustment

The vertical clamp can be adjusted in height and position.

Proceed as follows to adjust them:

4.8.2aVertical clamp position adjustment

• Position the mouldings to be assembled on the working

bench

• Select the pressure pad suitable with the profile of the

moulding to be assembled and put it on the vertical bar

• Loosen the handle (see f ig.15) that locks the clamp,

which holds the vertical bar. This will permit its

movement forwards or backwards. You will need to

position the pressure pad directly over where the v-

(R)

nails

will be inserted.

• Tighten the handle once you have reached the proper

position

B

Picture 16

4.8.3 Frontal clamp adjustment

The Frontal Clamp (horizontal clamp) has a series of holes

in the flat bar (see fig.17).

Lift the bar upwards to take it out of its initial position. You

will now be able to move it forwards and backwards.

T o lock the bar it is suf ficient to insert it into the proper peg

located in the middle of the guide channel.

Picture 15

4.8.2bVertical clamp height adjustment

• Loosen the side handle (see f ig. 16) and adjust the

pressure pad height over the frame. It is recommended

that you set the height between 5 and 8 mm above the

moulding. This will help to a void an y accidental fingers

crushing.

• Tighten the handle once you have reached the proper

position.

• Lower the vertical clamp by pressing half w ay down on

the foot pedal. This will v erify that the mouldings to be

assembled are properly clamped.

• Press all the way down on the foot pedal to insert the V-

(R)

nail

.

Proceed as follows to position the frontal Clamp correctly:

1. Remove the bar from the peg by lifting it upwards by

about 10-15 mm. Move it forward until it touches the

moulding to be assembled (see fig.18).

2. Lower the bar into the next available hole & over the

peg.

Picture 17

12

DO NOT ADJUST the pressure

if the machine is not connected

to the air supply.

The suggested pressures are:

Soft woods (samba,........) 30-40 PSI

Medium (ramin,........) 40-60 PSI

Very hard woods (oak) 60-80 PSI

Picture 18

In case of continued use without needing

to remove the frontal clamp from its

position, it is possible to fix it into the peg

using the proper screw.

When shipping the machine, it is advisable

to fix the bar using the supplied knob.

4.8.4 Working pressure adjustment

The working pressure must be adjusted to the hardness of

the mouldings to be assembled.

The pressure regulation allows you to change the clamping

pressure.

Too high of a working pressure may cause a bad assembly

junction, & on small-size frames the moulding can be

crushed.

Too low of a working pressure may cause an incomplete

insertion of the V-nail

(R)

into the frame.

The working pressure is adjusted by means of the regulator

on the panel near the pressure gauge (see fig. 19).

Proceed as follows to adjust the working pressure:

1. Pull up on the regulator cap about 3- 4 mm to unlock it.

2. Turn it clockwise to increase the pressure and counterclockwise to decrease it.

3. Push the regulator cap back down, to lock it into position

The values listed abo ve apply to 7 and 10 mm high V-nails

Increase the pressure by 10 % for 15 mm high V -nails

When stacking 2 or more V-nails

(R)

, increase the working

(R)

pressure by 10 to 15 %.

(R)

.

.

Picture 19

13

4.8.5 Protective shield adjustment

You can order a protective shield made of transparent plastic

material (see fig. 20).

4.9 CHECKING OPERATIONS TO BE EFFECTED BEFORE WORKING START

Once the machine has been properly installed (like pre viously

described), check that:

The mouldings to be assembled are properly positioned on

the working bench.

The magazine is loaded with the type of V-nails

with the mouldings to be assembled

The adjustment of vertical and horizontal clamps are correct

(chapter 4.8.2 and 4.8.3).

The working pressure is adequate to the w ood hardness (see

chapter 4.8.4).

Pressing halfway down on the pedal both the frontal and

vertical clamps hold the frame properly.

The protective shield is properly positioned (see chapter

4.8.5)

(R)

suitable

Picture 20

Proceed as follows to adjust the protection shield:

1. Loosen the 2 knobs which hold the shield in place and

lift or lower it to a height of about 6-8 mm above the

mouldings to be assembled;

2. Tighten the knobs to lock the protection shield.

Even if the protective shield is properly adjusted, it is

necessary to follow the instructions listed below:

6 Keep the fingers aw ay from the frontal and vertical clamp

working areas.

7 Disconnect the air supply during any maintenance

intervention.

8 Keep your foot off of the pedal while adjusting the

machine.

Opening the protection shield causes the

foot pedal to be deactivated.

Press the pedal all the way down to insert the V-nail

If you want to insert 2 or more V-nails

upon the other in the same position, you must

release the pedal halfway and then press it

full down to insert the second V-nail

(R)

(R)

(R).

, one

.

14

5. FUNCTIONING

5.1 OPERATORS

The machine has been projected to be used by only one

operator.

The staff assigned to operate with the machine, must be in

possession (or acquire through adequate training) the

requirements indicated below. In addition they must have

the knowledge of this handbook and of every information

concerning safety:

• General and technical culture sufficient to comprehend

the handbook contents and properly understand the

drawings and schemes.

• Knowledge of the main sanitary, technological and antiaccidental norms.

• Overall knowledge of the production line and plant where

the machine is installed.

• Specific experience in the assembly of frames.

• To know how operate in case of emergency, where to

find the individual protection means and how to use them

properly.

The Maintenance people, in addition to the above

mentioned characteristics, must be in possession of an

adequate technical education.

5.2 FUNCTIONING DESCRIPTION

The machine has only one possible operating mode:

• Manual operation by using the pneumatic footpedal.

Press the foot pedal half way down to clamp the moulding.

Press the foot pedal full down to drive the V-nail

To assemble a corner, you must operate as follows:

1 Set the inserting positions, using the fence locking

clamps

2 Place the mouldings on the working bench. Move the

fence & the moulding to the first inser ting position.

3 Adjust the vertical clamp height and position.

4 Adjust the frontal clamp position.

5 V erify and adjust the proper working pressure according

to the mouldings to be assembled.

6. lock the fence into the first position (see fig. 5.2)

7. Press halfway down on the pneumatic pedal to verify

that the mouldings are properly clamped.

8. Press the pedal all the way down to insert the V-nail

you want to insert 2 or more V -nails one upon the other

in the same position, you must release the pedal halfway

and then press it full down to insert the second V-nail

and so on.

9. Remove your foot from the foot pedal.

10.Loosen the fence locking handle (see fig. 5.2).

11.Shift the mouldings and the fence to the next position

and repeat the steps 6,7 and 8.

(R)

.

(R)

. If

A

Fiura 5.2

5.3 TIPS FOR PERFECT JUNCTIONS

a) V-nail

In order to allow the machine to make excellent quality

junctions using different materials, it has been necessary to

manufacture different V-nail

attachment D).

V-nails

for soft woods and

soft plastic

for medium woods

for hard woods

b) Assemb ling positions

It is advisable to operate as follows in order to achieve the

best results in terms of junction is quality:

Never drive V-nails

minimum recommended distance from the external

vertex is at least 10 mm.

When you want to make the junction using only one Vnail

moulding (see fig. 21)

In case you want to insert 2 or more V-nails

junction, we recommend you to insert the most external

one 1/3 from the external vertex and the most internal

one 1/4 from the internal vertex.

(R)

types

(R)

types for different uses (see

(R)

can be classif ied into three different groups:

Suggested V-

(R)

nail

code

Suggested V-

(R)

nail

code

Suggested V-

(R)

nails

code

(R)

near the junction vertex. The

(R)

, the most suitable position is in the middle of the

SW

MW

HW

(R)

into each

15

Picture 21

5.4 MACHINE STOP

The machine can only work b y pressing the pneumatic foot

pedal. To stop the machine remove y our foot from the pedal.

It is possible also to disconnect the fast clutch fitting from

the compressed air.

6. MAINTENANCE

6.1 ST ATE OF MAINTENANCE

The maintenance operations must be performed with the

machine in the conditions described at the “state of the

machine” table (tab 6.6.A and 6.7.A)

6.2 MACHINE ISOLATION

Before performing any type of maintenance or repair , it is

necessary to isolate the machine from it’ s suppl ying sources,

by making the following operations:

1) Disconnect the fast clutch fitting from the pneumatic

system.

Once the maintenance is finished the & before you reconnect

the pneumatic supply, ascertain that all components and

any pneumatic connections are properly reinstalled.

6.3 SPECIAL CAUTIONS

During the maintenance or repair operations is suggested to

proceed as follows:

• Before starting any operation place a sign “machine

under maintenance” in a highly visible position.

• Do not use solvents or flammable materials.

• Do not step on the machine parts, because they have

not been projected to sustain the weight of persons.

• Once all the operations are finished, restore and properly

place the protections and shields that were removed or

opened.

5.5 MACHINE REINST ATEMENT

The machine reinstatement is effected by pressing the

pneumatic foot pedal.

5.6 PUTTING OUT OF SERVICE

In case on long inactivity periods it is necessary to disconnect

the fast clutch f itting from pneumatic system.

6.4 CLEANING

The machine structure is simple and robust therefore the

mechanical parts do not require any special maintenance.

It is advisable to follow the rules listed below:

• Regularly remove glue or other residues from the V-nail

head and from the upper part of the driver blade;

• Always keep the V-nail

(R)

magazine clean & without

residues.

• Remove any residue from the V-nails

(R)

guide “L” shaped

support.

Do not use water to clean the machine, otherwise metallic

parts may rust.

Before performing any cleaning intervention,

the operator must disconnect the pneumatic

system.

(R)

16

6.5 LUBRICATION

Use preferably CASTR OL MA GN A GC 32 or equiv alent oil( ITW/AMP part number T-064).

Furthermore, we recommend to lubricate the driver blade every 200 working hours.

Unsuitable lubricants may cause to the valves seal problems (seals may become too large) and consequent

jamming of them.

6.6 ORDINARY MAINTENANCE

The following operations must be performed at the times indicated below. Not observing the following instructions exonerate

the Producer from any responsibility regarding the warranty.

The operations described below, even if simple, must be executed by qualified personnel.

The scheduled ordinary maintenance includes overhauls, checks and interventions that, to prevent stops and breakdowns,

keep the system working properly.

• Lubrication state of the machine

• Wear and tear parts state

TAB 6.6 A

Maintenance

(R)

V-nail

driver blade

Description

Replacement every 1.000.000 V-nails

Machine state

(R)

Isolation for maintenance

shot

Movable parts lubrication

Lubricate the driver blade every 200

Isolation for maintenance

working hours

V-nails

(R)

claw heads

Replacement every 5.000.000 V-nails

(R)

Isolation for maintenance

shot

“L” shaped supports (V-nails

guide)

(R)

Replacement every 5.000.000 V-nails

shot

(R)

Isolation for maintenance

6.7 EXTRAORDINARY MAINTENANCE

Listed below are the operations that need the intervention of ITW/AMP or your local distributor’s T echnical Assistance (see the

paragraph 1.2). You can also use qualified staff authorized by the Producer

The extraordinary maintenance includes interventions to be performed in exceptional cases:

• Breakage

• Revisions

TAB. 6.7 A

MAINTENANCE

Valves and Reducers

Frontal and vertical clamping

gaskets

DESCRIPTION

Suggested replacement every 6/8 million

of V-nails

Replacement in case of leak of air

(R)++

shot

MACHINE ST ATE

Isolation for maintenance

Isolation for maintenance

17

7. DIAGNOSTIC

7.1 SAFETY W ARNINGS

The interventions must be executed by personnel properly trained and they must take all precautions in order to avoid

accidental starts.

7.2 TROUBLESHOOTING

TABLE 7. 2 - A

TROUBLE

Pressing the foot pedal the V-nails

ejection is irregular

Pressing the foot pedal the V-nails

ejection is irregular

Pressing the foot pedal the V-nails

ejection is irregular

Pressing the foot pedal the V-nails

ejection is irregular

Pressing the foot pedal the V-nails

ejection is irregular

Pressing the foot pedal the V-nails

ejection is irregular

POSSIBLE CAUSE

(R)

Insufficient working pressure

(R)

V-nails

into the magazine

(R)

Guide channels damaged or

jammed

(R)

Claw pusher has insufficient

thrust

(R)

Claw head not suitable with Vnails

(R)

Faulty V-nails

(R)

wrongly positioned

(R)

size

(R)

REMEDY

Check that the minimum value indicated

from main pressure gauge is higher than

3 Bar

- Check that the V-nails

(glue side) faces up

- Check that V-nails

toward machine’s external side

- Check that the guide channels are not

dirty or jammed

Check to see if the feed springs are

broken, if so replace them

Check that the number engraved on the

(R)

v-nail

claw head match up the V-nails

size

- Replace the V-nails

- Use shorter sticks of V-nails

(R)

sharpened side

(R)

V vertex is pointing

(R)

(R)

(R)

Pressing the foot pedal the V-nails

(R)

ejection is irregular

Pressing the foot pedal the V-nails

(R)

ejection is irregular

Pressing the foot pedal the V-nails

(R)

ejection is irregular

Pressing the foot pedal for several times

the machine’s working that was correct

at the beginning becomes irregular later

Pressing the foot pedal the working

pressure indicated on the pressure gauge

deeply decreases

Pressing the foot pedal the working

pressure indicated on the pressure gauge

deeply decreases

Insufficient working pressure

Opened V-nails

(R)

magazine

Faulty valves

Jammed valves because of

surplus of oil or condensation

Faulty pressure regulator

Feeding pipe too long or of

inadequate diameter

Check that the air pressure coming out

from the compressor is at least 3 Bars.

Close the magazine by means of the

control wire

- Replace the foot pedal valve

- Replace the control valves

-Remove the surplus of oil and

condensation from the valves by

disconnecting one by one the control

pipes to remove the contamination

-Replace the regulator

Replace the piping with a new one of

bigger diameter

18

TROUBLE

POSSIBLE CAUSE

REMEDY

Pressing the foot pedal the machine

works properly, but once the pedal is

released you can note a certain delay in

re-positioning of driver blade and/or

vertical clamp cylinders

Wishing to insert several V-nails

(R)

one

upon the other in the same point, they

do not stack properly or tilt during their

insertion

Wishing to insert several V-nails

(R)

one

upon the other in the same point, they

do not stack properly or tilt during their

insertion

Wishing to insert several V-nails

(R)

one

upon the other in the same point, they

do not stack properly or tilt during their

insertion

Wishing to insert several V-nails

(R)

one

upon the other in the same point, they

do not stack properly or tilt during their

insertion

Faulty or jammed valves

Unsuitable V-nails

(R)

Poor frames clamping (the frame

moves during the V-nail

(R)

insertion)

Wore and torn driver blade

Jammed driver blade

- Remove the surplus of oil and/or

condensation

- Replace the foot pedal valve

- Replace the faulty control valves

Replace the V-nails

(R)

with suitable ones

- Check and in case replace the vertical

and frontal clamping positions

- Increase the clamp pressure

- Replace the pressure pad with a suitable

one

Replace the driver blade

Clean the driver blade upper part

removing any material jamming the upper

profile

7.3 REQUEST OF ASSISTANCE

For an y information regarding Use, Maintenance, Installation, etc.. w e remain at your disposal. The Customer has to formulate

the questions clearly, by sending us a fax with a detailed description of the troubles met. For e ventual e xplanations y ou should

use this handbook and the instructions listed in the paragraph 1.2.

Web Site: http://www.itwamp.com

E- Mail: itwamp@paslode.com

Phone: 1-800-322-4204

FAX: 1-800-426-7019

19

8. SPARE PARTS

8.1 SP ARE PARTS LIST

Even though the machine has been submitted to several tests and functional checks, we listed below the components that we

suggest you keep a minimum and sufficient set of. This will help gaurantee the shortest possible downtime.

T ABLE 8.1 - A

COMPONENT

• V-NAILS DRIVER BLADE

• V-NAILS CLAW HEADS “L”

• SHAPED SUPPORT (V-NAILS GUIDE)

• VALVES-REDUCERS-REGULATORS

• VERTICAL AND HORIZONT AL CLAMPING

GASKETS

8.2 SP ARE PARTS ORDERING

We remind you that only a qualified technician can repair the machine.

Therefore we suggest the intervention of your local distributor or ITW/AMP’s center of technical assistance, which has access

to qualified staff, proper equipment and tools, and who uses original spare parts.

To order the spare parts listed above, send by fax/letter/Email the following data:

• Model of the Machine

• Code of mechanical exploded drawing

• Reference & code number of spare part or group indicated on the mechanical drawing

• Code number of single or group spare part

9 DEMOLITION

9.1 DEMOLITION

At the act of demolition it is necessary to separate the parts in plastic material from electric components, that must be send to

differentiate gatherings respecting the current Norms.

Concerning the machine metallic mass, it is enough the subdivision between the steel parts and those of other metals or alloys,

for a proper recycling by smelting.

10. A TTACHMENTS

10.1 DECLARATIONS

You can find here attached the following declarations

• Declaration of conformity to the Norm 89/392/CEE

10.2 SCHEMES

You can find here attached the following schemes:

• (A) Mechanical Schemes

• (B) Pneumatic Scheme

• (C) Plates location

• (D) Sharpening Table

20

SCHEMES A - Mechanic Schemes (code: DWG n° 006.3.100)

40 **

** Supplied only on CE market

21

22

Ref. Code Number Description

Ref Code Number Description

1 244660010 Handle

2 336100030 Washer

3 714300041 Headless screw

4 710100151 Screw

5 243170010 Handle

6 376400010 Support

7 383600040 Support

8 753320002 Knob

9 336100020 Spacer

10 393150010 Clamp

11 334000020 Slide

12 383900010 Support

13 718100002 Washer

14 710100045 Screw

15 710100072 Screw

16 383900020 Support

17 375200010 Fence

18 710100112 Screw

19 211250040 Casing

20 701000115 Screw

21 718100004 Washer

22 294200010 Support

23 735630002 Pressure regulator

24 365210320 Plate

25 718100001 Washer

26 710100003 Screw

27 734230004 Pressure gauge

28 366710050 Inch rule

29 710100076 Screw

30 718100003 Washer

31 392750010 Support

32 710100074 Screw

33 366210030 Special screw

34 242170010 Horizontal clamp

35 753320001 Knob

36 242230020 Square pressure plate

37 242230010 Round pressure plate

38 244120110 Rod

39 383600030 Support

40 248950020 Protection unit

41 241300020 Support

42 732540003 Valve

43 398950020 Protection

44 241300010 Support

45 753320005 Knob

46 710100086 Screw

47 381600100 Spacer

48 381300080 Support

49 371200010 Slide

50 225120010 Complete cylinder

51 384400010 Support

52 710600002 Screw

53 710200081 Screw

54 352200030 Head

55 298390050 Gasket kit

56 331000030 Piston

57 352200020 Head

58 333500020 Cylinder

59 710100087 Screw

60 384200020 Bracket

61 765000018 Spring

62 393850010 Spring support

63 337500220 Spacer

64 337000070 Pulley

65 718100003 Washer

66 710100075 Screw

67 395450040 Nail pusher

68 398350050 Nail magazine

69 710100093 Screw

70 224240150 Complete driver assy.

71 394950020 7mm nailhead

71 394950030 10mm nailhead

71 394950050 15mm nailhead

72 383600020 Block

73 710100070 Screw

74 352200060 Head

75 710100079 Screw

76 384200050 L block

77 298390040 Gasket kit

78 298420040 Piston and driver blade

79 352200050 Cylinder

80 225220010 Complete cylinder

81 352400020 Head

82 298390070 Gasket kit

83 331000020 Piston

84 333500030 Cylinder

85 352200040 Bottom

86 710100088 Screw

87 391650511 Extension

88 391650501 Extension

89 710100073 Screw

90 243160020 Complete tilt fence

91 336300040 Knob

92 337500040 Washer

93 386200040 Left tilt fence

94 386200030 Right tilt fence

23

SCHEMES B - Pneumatic Scheme

Ref. Description

1 Pressure Regulator

2 Pressure Gauge

3A Valve 228.52.1 1.1

3B Valve 228.52.1 1.1

24

SCHEMES C - plates location

25

SCHEMES D - SHARPENING TABLE

SOFT WOOD HARD WOOD

ABC DEF

Height

mm

H 3* mm

H 5* mm

H 7 mm

H 10 mm

H 12 mm

H 15 mm

SP T Suitable for soft wood such as: Thailand and Asian South-East w ood, Cedar, Pine, Bass,

Banak, Obeche, Poplar

Other materials: Cellular, P ol ystyrene, Vertical Grain MDF

HPT Suitable for soft wood such as: Thailand and Asian South-East wood, Cedar , Pine, Bass,

Banak, Obeche, Poplar , polystyrene, pvc

V ery soft

wood

HPT

HPT

SPT

SPT

SPT

SPT

Soft wood

HPT

HPT

SPT

SPT

SPT

SPT

Averaged

soft wood

HPT

HPT

HPT

HPT

HPT

HPT

Averaged hard

wood

HPT

HPT

HPT

HPT

HPT

HPT

Hard wood

HPT

HPT

HPT

HPT

HPT

HPT

Very hard

wood

HPT

HPT

HPT

HPT

HPT

HPT

HP T Suitable for soft wood such as: Oak, Ash, Hickory, P ecan, Maple, Cherry, Ramin

Other materials: Horizontal grain MDF

HDF Suitable for horizontal Grain MDF & HDF

In order to stack 2 or more V-nails per junction, use V-nails coded HPT OR HDF

26

Loading...

Loading...