Instruction & Operation Manual

For The

Mitre-Mite Fillet Cutter

®

Hand Operated Fillet Chopper

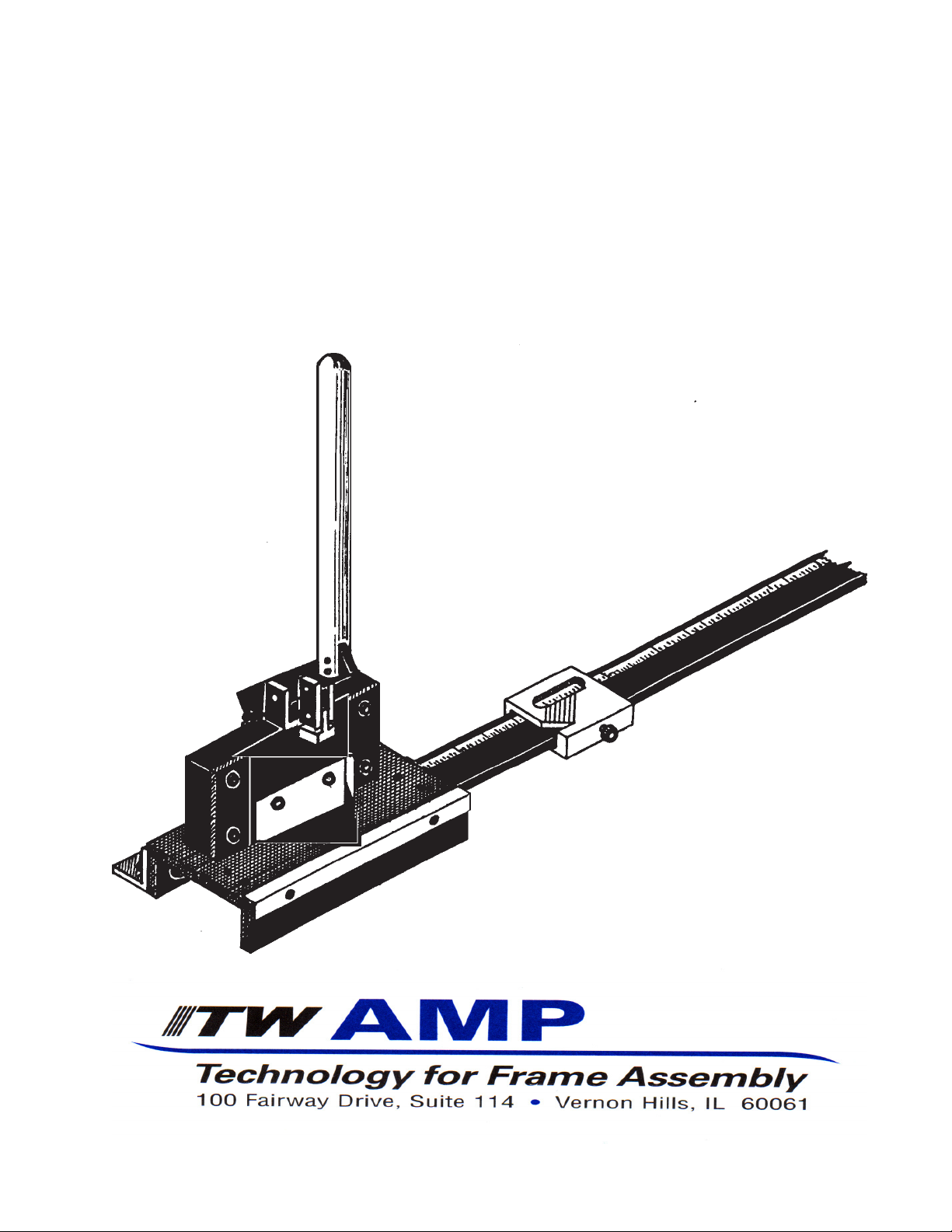

1. Install Handle & Measuring Arm:

Remove the Fillet Cutter unit & handle from the box. Unwrap the handle with the 2 screws

attached. Use the larger allen wrench to attach the handle to the top lever of the machine.

See illustration at right. Mount the measuring arm to the side bracket of the Fillet Cutter

now, before mounting the entire unit to a board or bench.

Be sure to align the measuring arm with

the front angle guide before tightening all

the screws. Use either a piece of llet at

least 36” long or a yardstick for this task

2. Mounting The Unit:

The Fillet Cutter can be mounted directly to a

work bench or attached to a small board for

portability. When mounting to a board, position

the unit to the back of the board so that most of

the wood is in front of the unit. This will eliminate

tipping. A board measuring 6” x 8” x 1/2” thick, is

large enough.You can also mount the unit to a wall

provided there are studs handy to use. It’s best to

rst mount the unit to a 1”x4” board long enough

to span at least 2 studs in your wall. Using a

longer board will allow you to build in some

support for the llet on the infeed side of the unit

as well. Small dowels work well for this.

NOTE: When mounting to a wall, rst remove the

back angle bracket. Mount through the holes in the

base channel to the board, then lag bolt the board

and unit to the studs.

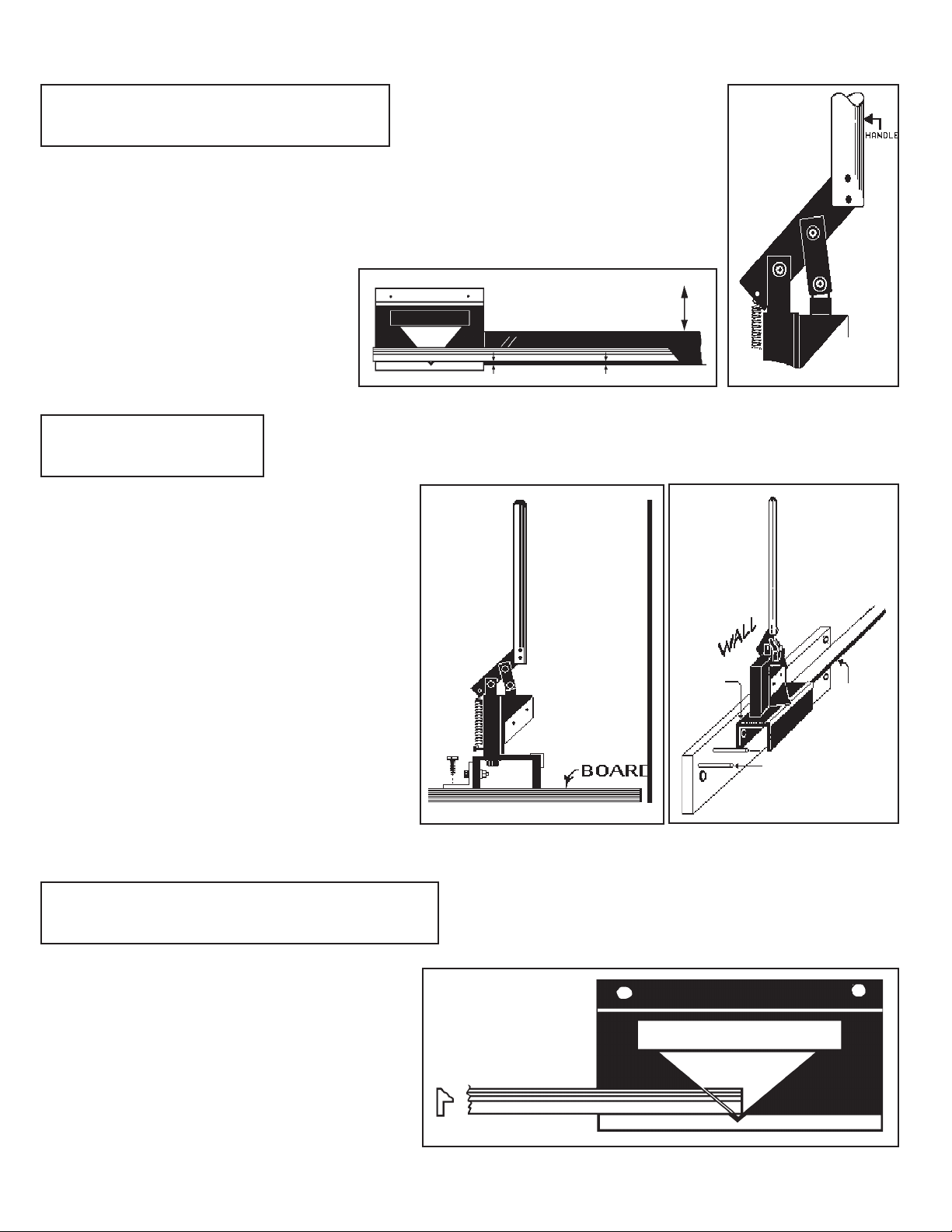

3. Measuring & Cutting Fillet To Length:

STEP 1: Place the llet on the Fillet Cutter with

the at ange portion against the front guide.

Cut off one end to create the rst 45

o

corner

STEP 2 a: If you’re using the measuring arm, after

making your rst edge cut, slide the llet over to the 45

o

ANGLED line that matches the dimension you want to

cut. (Use the vertical step in the llet to measure.)

Bring the Slide Stop over to touch the llet edge. Finger-

tighten the screw on the stop. Check the cut piece of

llet in the mat opening for trimming to exact size.

STEP 2 b: If you’re measuring by hand, place the cut llet under the mat so that the cut end will

t into one corner of the opening. Hold the llet in place with one hand and use the other hand to

mark the llet with an exacto knife or a used mat cutter blade. Make the mark straight across the

llet. Remove the llet from under the mat and continue the mark using the blade to make it easy

to see.

Measure Point Is At Mat Corner

Matboard

Fillet under

the matboard

Hold blade against this side

of mat & rock the blade to

make a mark straight across

the llet. The remainder of marked

llet will be cut off & discarded

STEP 3 b: Place the marked llet onto the Fillet Cutter so the ange is against the front guide. Slide the llet

over, so that the mark is under the blade. Sight down onto the blade to align the mark with the blade edge. Cut

through the llet with a smooth motion. Check the cut rail in the mat opening for t. It should be cut so there is a

small amount of play in the opening. 1/64” to 1/32” is about right, since the other pieces will eventually tighten

the t in the opening. The Fillet Cutter is designed to shave very small amounts from the cut edge so you can get

a perfect t. A little practice will make you an expert in a short time.

Mat opening

Fillet

Flange

Blade edge aligns with cut mark

at the point where the ange starts

4. Sharpening or Replacing Blades:

The two cutter blades are made from tool steel and can be sharpened easily

with an oil stone. (The kind used for sharpening jack knives, etc. and

available at K-Mart or similar stores.) It’s best to use a stone that is 1-1/4” to

1-1/2” wide x 3” to 4” in length. Both blades can be removed using the

small allen wrench supplied with the unit. Please be extremely careful when

handling the blades. The sharp edges can cut easily. Hold the blade with

the bevel against the stone and push forward as shown in the drawing.

Lift the blade slightly on the backstroke and bear down on the forward stroke.

After 10-15 passes on the stone, you can lay the at side against the stone

and gently stroke it forward several times to remove the burr that forms.

DO NOT tip the at side of the blade UP on the stone. This surface must

remain at for an accurate cut. When you’re nished, it’s good practice

to strop the blade edge backwards against a piece of leather, heavy cloth, or

matboard, several times to remove the rolled edge that forms when

sharpening. Remount the blades using the original screws. If your blades

become nicked or damaged beyond repair, replacement sets are available

from your supplier.

5. Adjustments

Although the Fillet Cutter unit comes from the factory fully adjusted, wear on some parts could require that adjust

ments be made in the future. If the vee-block, which moves in the dovetail slide, becomes loose, simply loosen the

screws on one side just a little and tap the guide bar towards the vee-block. Snug the two screws and check for

binding through the entire movement. If it is too tight, tap the vee-block in the opposite direction slightly, and

recheck. If replacement blades do not t exactly the same as the original blades, the vertical block (item #2 in

parts drawing) can be moved by loosening the two bolts under the base channel. Retighten after the correct

alignment is achieved. NOTE: All nuts and bolts are metric.

6. Precautions

The aluminum handle provides for a 10 to 1 mechanical advantage. DO NOT try to increase the length of the

handle with a piece of pipe or other device. Damage to the unit could result from overstressing components in this

way, and will VOID THE WARRANTY! Do NOT cut small wood or aluminum mouldings with this cutter.

Aluminum wrapped wood llets or aluminum core plastic llets can be cut, but will require a second clean-up cut

to get the 45

LIMITED WARRANTY

The manufacturer warrants this equipment to the original Purchaser to be free from defects in material or workmanship for a period of one (1) year from the date of

purchase on the complete machine. This Limited Warranty shall be limited to the repair or replacement, at the sole discretion of the Manufacturer, of any defective

part or parts. In the event of a defect in material or workmanship within the period of this Limited Warranty, Purchaser shall return to Manufacturer’s Warranty Service

Center, TRANSPORTATION PREPAID, the defective equipment.

PROOF AND DATE OF PURCHASE WILL BE REQUIRED ON ANY PRODUCT SO ASSOCIATED WITH ANY WARRANTY CLAIM. Failure of this equipment

caused by accident, corrosion, misuse or abuse of the equipment including but not limited to, damages or defects resulting from improper packaging of returned

equipment or improper repairs made by others, is not covered by this Limited Warranty. Manufacturer reserves the right to determine whether the defect is covered by

this Limited Warranty. If Manufacturer determines that the returned equipment is not covered by this Limited Warranty, then at Purchaser’s option, such equipment

shall be either: 1) returned to Purchaser, TRANSPORTATION COLLECT, or 2) repaired or replaced on the basis of Manufacturer’s regular repair, replacement, or

reconditioning charges, which charges shall be payable by Purchaser, C.O.D.

This Limited Warranty extends only to the initial Purchaser and may not be transferred to subsequent owners.

o

angle correct.

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED INCLUDING ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR USE AND PURPOSE. PURCHASER AGREES THAT THE SOLE AND EXCLUSIVE REMEDY

AGAINST MANUFACTURER SHALL BE LIMITED TO THE REPAIR OR REPLACEMENT OF

DEFECTIVE PARTS. PURCHASER FURTHER AGREES THAT NO OTHER REMEDY, INCLUDING BUT NOT LIMITED TO INCIDENTAL OR

CONSEQUENTIAL DAMAGES FOR LOST PROFITS, LOST SALES, INJURY TO PERSON OR PROPERTY, OR ANY OTHER INCIDENTAL OR

CONSEQUENTIAL LOSS, SHALL BE AVAILABLE TO IT, AND, IN ANY EVENT, THE LIABILITY OF MANUFACTURER FOR ANY DAMAGES SHALL BE

LIMITED TO THE PURCHASE PRICE OF THE EQUIPMENT.

Loading...

Loading...