TVH EL510-35PLUS Operation Instructions Manual

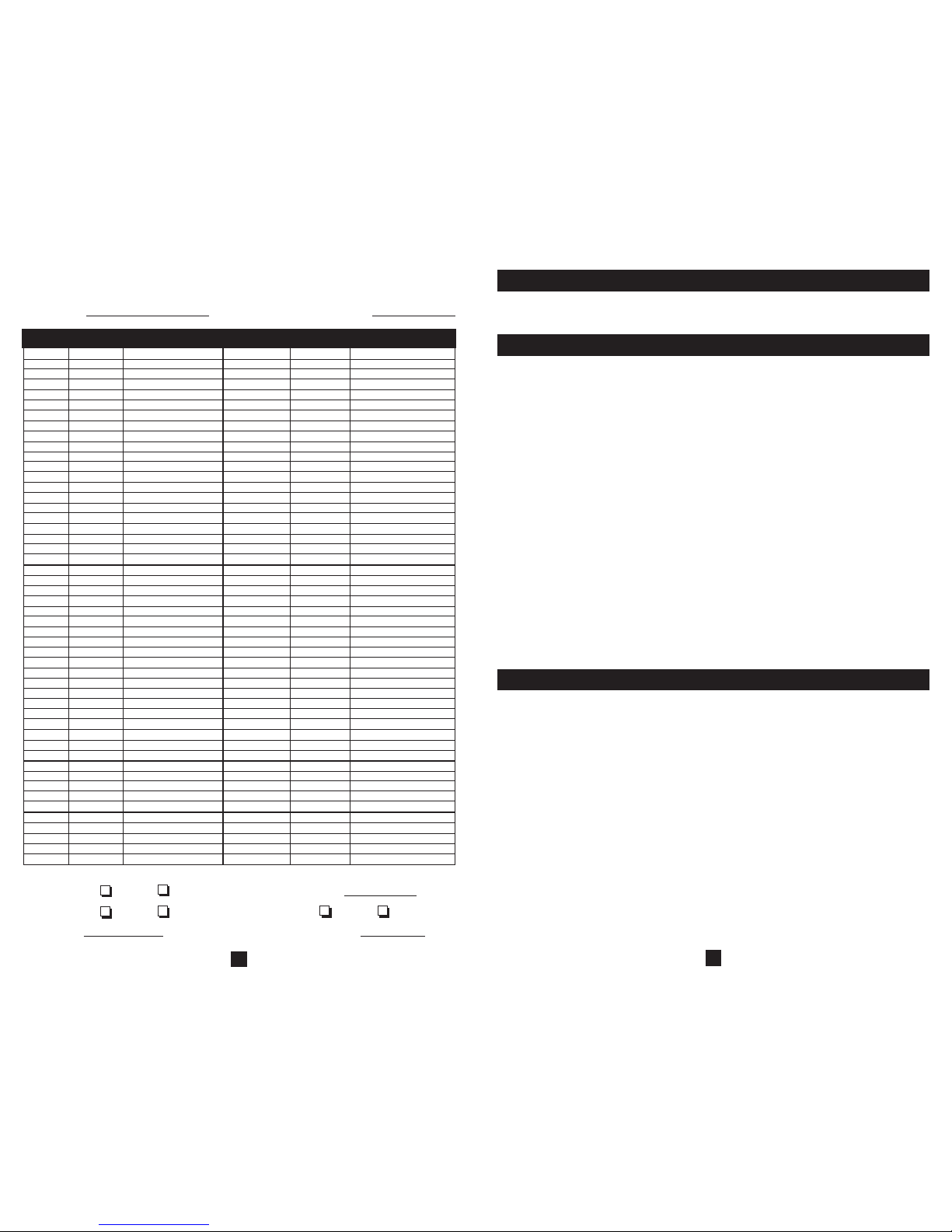

PROGRAMMABLE CODE SWITCH

OPERATION INSTRUCTIONS

Read and Save

16355 SOUTH LONE ELM ROAD

OLATHE, KANSAS 66062 • USA

PHONE: 913-829-1000 • TOLL FREE: 800-255-4109 • FAX: 913-829-9208

www.smhco.com

16355 SOUTH LONE ELM ROAD

OLATHE, KANSAS 66062 • USA

PHONE: 913-829-1000 • TOLL FREE: 800-255-4109 • FAX: 913-829-9208

www.smhco.com

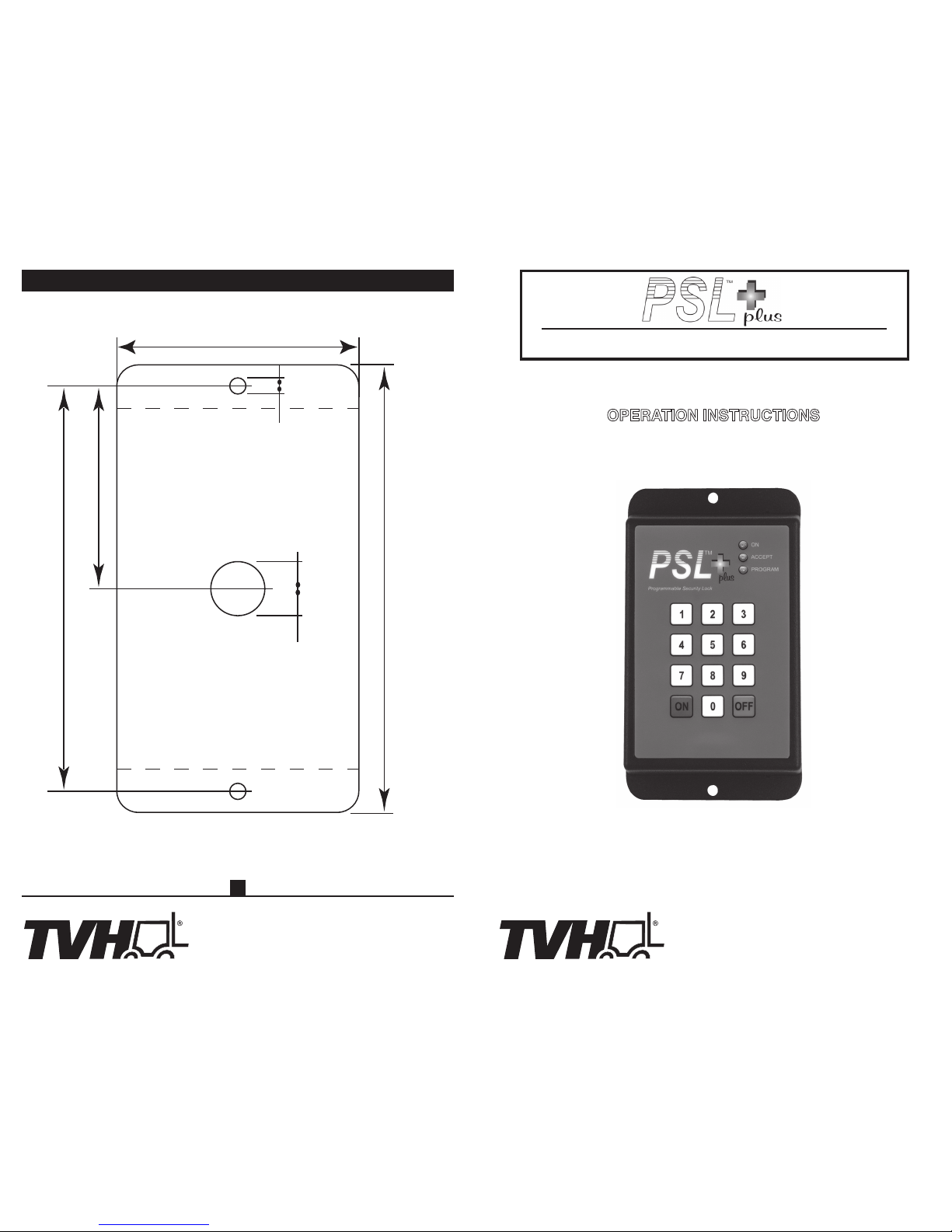

MOUNTINg TEMPlATE

4 ¹¹⁄

₁₆

"

/ 119.1mm

2 ¹¹⁄

₃₂

"

/ 59.5mm

2 ¹³⁄

₁₆

"

/ 71.4mm

5 ³⁄

₁₆

"

/ 131.8mm

³⁄

₁₆

"

/ 4.8mm

⁵

⁄

₈

"

/ 4.8mm

EL510-35PLUS

SSI0312 Printed in USA

15

PSL+™

Reset Code and Quick Reference Instruction Insert

Serial # Reset Code

User Access: Enter User # + User Code + “on”

Supervisor Access: Enter “00” + Supervisor Code

Reset Procedure: Enter “00” + “0000” + Reset Code

SUPERVISOR MENU

Key

1

2

3

4

5

6

7

8

9

ON

0

OFF

Display

Flashing Red

(none)

1 amber + 3

1 amber + 4

1 amber + 5

1 amber + 6

1 amber + 7

1 amber + 8

1 amber + 9

(none)

(none)

(none)

Function

Program User Numbers

Last User Function

Enable/Disable ASO function

Set ASO Delay Time:

Enable/Disable MC function

MC Control Internal/External:

Set Maintenance Cycle Length

Set time between MC alerts

Check various times

Turn on Output (and exit menu)

Reset Maintenance Cycle

Exit Supervisor Menu

Instruction Booklet

with Reset Code and Quick Reference

14

FEATURES:

The PSL+ ™ Programmable Security Lock is an enhanced version of the PSL ™ product with

several additional features. Like the original, this version is primarily designed for use with both

battery and I.C. engine powered vehicles to prevent unauthorized operation of the vehicle.

Expanded Voltage Range

- The PSL+ is rated for nominal input voltages from 12 to 90VDC.

Expanded User Capability

The PSL+ can be programmed for up to 99 unique users. Once installed, the PSL+ requires entry of a twodigit user number and valid four-digit access code before the vehicle or equipment can be operated. All user

codes can be reprogrammed and unused user numbers can be temporarily disabled for additional security.

Last User Identification

The PSL+ can identify to the supervisor the user number of the last user of a vehicle.

Automatic Shut-Off

The PSL+ incorporates a feature that detects vehicle activity. If the vehicle has been inactive

beyond a specified period of time, the PSL+ will deactivate securing the vehicle. This feature is

optional and can be activated or deactivated as desired.

Maintenance Alert

The PSL+ can accumulate vehicle usage time and provide audible and visible signals indicating when

vehicle maintenance is due. After maintenance is performed, the cycle can be reset as desired. This

feature is optional and can be activated or deactivated by supervisor.

Accumulated Time

The PSL+ accumulates total vehicle usage time. This accumulated time can be accessed through

the Supervisor Code.

Even the supervisor’s access code can be changed using the factory programmed reset code.

Installation of the PSL+ remains simple with just 4-5 wires to connect. Diagrams showing typical

wiring schemes are included in this manual.

Case: ABS plastic

5

3

/16”h x 2 13/16”w x 1.0”d

Two (2) 3/16” mounting holes, 4 11/16” center to center

Keypad: Contacts internally sealed, moisture resistant

Voltage: Input range 12-90VDC

Current: Less than 30 mA with unit inactive; less than 90 mA with unit active.

Output: Contact rating up to 10A maximum through 48V

Maximum 1A contact rating above 48V

For loads greater than 10A use external relay

SPECIFICATIONS:

1

WARRANTy NOTE

The PSL+ is a sealed unit. There are no user serviceable parts inside. Removing or tampering with

the epoxy encapsulant will void the warranty.

Upon installation of the PSL+, the unit must first be programmed with a supervisor code. When the

unit is first powered up, or powered up for the first time after executing a reset procedure, it will

automatically go into supervisor code programming mode. This mode is indicated by alternately

displaying 3 amber flashes and 3 red flashes. When in this mode, simply enter the four digits you

would like to use as the supervisor access code. You must use all numerical digits; the “on” and

“off” keys may not be incorporated into the supervisor code. All combinations of numerical digits

are acceptable except 0000. For best security, we recommend avoiding repetitive digits like 4444

and sequential digits like 1234. You will hear a short beep to acknowledge each key entry. If an

illegal character is selected, an error beep consisting of a short beep followed by a long one will be

sounded. If this occurs, you must continue from the point prior to the illegal character being pressed

or remove power and start the code entry process over. When an acceptable 4-digit supervisor code

has been entered, the amber “accept” LED will be illuminated and the unit will stop responding. At

this point the new supervisor code has been programmed and the unit must be powered down to

allow for normal start up before proceeding. It may be a good idea to write down the supervisor

code and keep it in a safe place so you don’t forget it, but if you do the supervisor code can be reset

and reprogrammed (See page 10). Note: If an undesired key is entered during supervisor code

entry, the procedure can be aborted by removing power from the unit.

Quick Steps – Supervisor Programming

1. Enter desired 4-digit supervisor code. Unit will beep with each key depression.

2. Power down unit to save code.

Entering Supervisor Mode is necessary for configuration of programmable settings and retrieval

of data stored in the PSL+. The procedure for entering supervisor mode is a simple two step

process. Each key entry is acknowledged with a short beep and errors are indicated with the short

+ long beep pattern. Keystrokes are timed with a limit of 15 minutes between keystrokes or the

process will be aborted. The process may also be aborted manually by pressing “off”. The output

must be off before beginning this procedure:

1. Enter “00”. This identifies you as the supervisor.

2. Enter the four-digit supervisor code. Upon completion the entry is checked. If the entry is

correct, the amber “accept” LED will acknowledge the entry and then the red and amber LEDs

will begin to flash alternately to indicated the unit has entered supervisor mode. If incorrect,

the error beep is sounded and the process aborted.

Quick Steps – Entering Supervisor Mode

1. Enter “00”.

2. Enter four-digit supervisor code. The “accept” LED will acknowledge the entry and then the red

and amber LEDs will begin to flash alternately to indicate the unit has entered supervisor mode.

II. ENTERINg SUPERvISOR MOdE:

2

I. gETTINg STARTEd / PROgRAMMINg ThE SUPERvISOR COdE:

User # Code Name/Group

User # Code Name/Group

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

Automatic Shut Off: Enabled Disabled Delay Time minutes

Maintenance Cycle: Enabled Disabled Internal External

Cycle Time hours Alert Intervals minutes

Supervisor Code: Reset Code:

Optional Unit Worksheet

13

Loading...

Loading...