TP11KC-DX

Two-Post Clear Floor

‘Bi-Symmetric’ Automotive Lift

11,000 lb. Capacity

(2,750 lbs. Max per Arm)

Installation & Operation Manual

Jun 2017

TABLE OF CONTENTS

1. Safety Information

1.1 Note, Caution and Warning

1.2 Important Information

1.3 Safety Instructions

2. Technical Manual

2.1 Product Description

2.2 Technical Data

3. Installation

3.1 Site Selection

3.2 Surface Condition/ Foundation & Anchoring

3.3 Tools Required

3.4 Installation Procedure

3.5 Hydraulic Scheme

4. Operation

4.1 Operation Instructions

4.1.1 Lift Preparation

4.1.2 Loading Lift

4.1.3 To Raise Lift

4.1.4 While Using Lift

4.1.5 To Lower Lift

4.1.6 Unloading Lift

4.2 Maintenance Instructions

5. Exploded View / Parts List

6. Troubleshooting Guide

7. Power Unit Priming

8. Warranty Policy

2

TP11KC-DX

Jun 2017

1. Safety Information

1.1 Note, Caution and Warning

This document uses the following terms - NOTE, CAUTION and WARNING - to alert you to special instructions,

tips, or hazards for a given procedure. Please familiarize yourself with the notations described below.

INDICATES IMPORTANT INFORMATION THAT REQUIRES SPECIAL ATTENTION, SUCH AS A

PROCEDURE FOR A SPECIFIC VEHICLE, OR TIPS ON OPERATING THE EQUIPMENT.

INDICATES THE POTENTIAL FOR DAMAGE TO EQUIPMENT, ACCESSORIES, OR THE VEHICLE

UNLESS YOU FOLLOW THE INSTRUCTIONS OR PROCEDURE EXACTLY.

INDICATES THE POTENTIAL FOR PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH DUE TO

HAZARDS ASSOCIATED WITH THE EQUIPMENT, VEHICLE, OR ENVIRONMENT. DO NO PERFORM

ANY PROCEDURE UNTIL YOU HAVE READ AND UNDERSTOOD THE WARNING INSTRUCTIONS.

1.2 Important Information

1. Read this manual thoroughly before installing, operating, or maintaining this lift.

2. This lift is designed for indoor use only, and should not be installed in a pit or depression.

3. The floor on which the lift is to be installed must be 4-1/4” minimum thickness concrete, with a

minimum compressive strength of 3,000 psi.

4. The lift has specific electrical requirements as described in the Installation Instructions section of this

manual.

5. This lift has a minimum ceiling height requirement as described in the Installation Instructions section

of this manual.

6. Failure by the owner to provide the recommended shelter, mounting surface, electrical supply, and

ceiling height could result in unsatisfactory lift performance, property damage, or personal injury.

7. The operation of the lift is permitted by authorized personnel only.

3

TP11KC-DX

Jun 2017

1.3 Safety Instructions

1. Do not raise a vehicle on the lift until the installation is completed as described in this manual.

2. Technicians should be trained to use and care for the lift by familiarizing themselves with this

instruction manual. The lift should never be operated by an untrained person.

3. Always position the arms and adapters properly out of the way before pulling the vehicle into, or out of

the bay. Failure to do so could damage the vehicle and/or the lift.

4. Do not overload the lift. The capacity of the lift is shown on cover of this document and on the lift’s

serial number tag.

5. Positioning the vehicle is very important. Only trained technicians should position the vehicle on the

lift. Never allow anyone to stand in the path of the vehicle as it is being positioned and never raise

vehicle with passengers inside.

6. Position the arms to the vehicle manufacturer’s recommended pickup points. Raise the lift until

contact is made with the vehicle. Make sure that the arms have properly engaged the vehicle before

raising the lift to a working height.

7. Keep everyone clear of the lift when the lift is moving, the locking mechanism is disengaged, or the

vehicle is in danger of falling.

8. Unauthorized personnel should never be in the shop area when the lift is in use.

9. Inspect the lift daily. The lift should never be operated if it has damaged components, or is

malfunctioning. Only qualified technicians should service the lift. Replace damaged components with

manufacturer’s parts, or equivalent.

10. Keep the area around the lift clear of obstacles.

11. Never override the self-returning lift controls.

12. Use safety stands when removing or installing heavy vehicle components.

13. Avoid excessive rocking of the vehicle when it is on the lift.

14. To reduce the risk of personal injury, keep hair, loose clothing, fingers, and all body parts away from

moving parts.

15. To reduce the risk of electric shock, do not use the lift when wet, do not expose the lift to rain.

4

TP11KC-DX

Jun 2017

16. To reduce the risk of fire, do not operate equipment in the vicinity of open containers of flammable

liquids.

17. Use the lift only as described in this manual, use only manufacturer’s recommended attachments.

18. Unusual vehicles, such as limousines, RV’s, and long wheelbase vehicles, may not be suitable for

lifting on this equipment. If necessary, consult with the manufacturer or the manufacturer’s

representative.

19. The troubleshooting and maintenance procedures described in this manual can be done by the lift’s

owner/employer. Any other procedure should only be performed by trained lift service personnel.

These restricted procedures include, but are not limited to, the following: cylinder replacement,

carriage and safety latch replacement, column replacement and overhead structure replacement.

20. Anyone who will be in the vicinity of the lift when it is in use should familiarize themselves with the

following Caution, Warning, and Safety related decals supplied with this lift, and replace them if they

are illegible or missing.

5

TP11KC-DX

Jun 2017

Capacity

Height Overall

Width Overall

w/ Power Unit

Max

Lifting Height

Max Lifting Height w/ Tallest Adaptor

Width

Between Columns

Min Pad Height

Drive Thru Clearance

Front Arm Reach

–

Min / Max

Rear Arm Reach

–

Min / Max

Power

2. Technical Manual

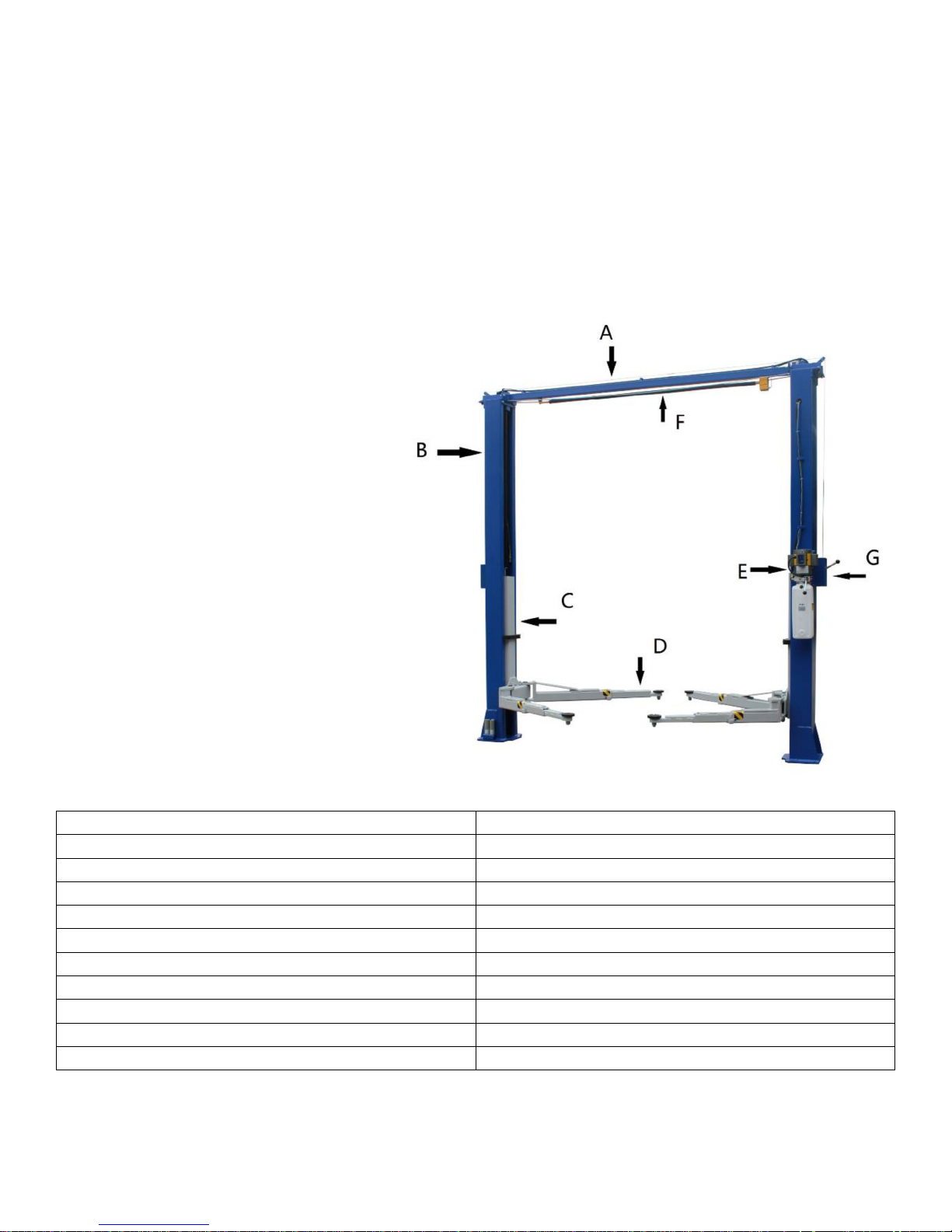

2.1 Product Description

The TP11KC-DX (165948T) 2-post hydraulic lift is a surface mounted, frame contact lift incorporating the latest safety

technologies. Designed and manufactured for a lifting capacity of 11,000 lbs. (Max 2,750 lbs. per Lifting Arm) and is fully

capable for lifting vehicles, vans and light trucks by safely holding them in an elevated position. The TP11KC-DX also

incorporates the Bi-Symmetric feature, which allows the Arms to be configured for both asymmetrical & symmetrical

lifting configurations.

The TP11KC-DX 2-post hydraulic lift consists of

a fixed structural unit (Crossbeam and

Columns), the mobile units (Carriages and Lift

Arms), and the Hydraulic Power System and

Safety devices.

A. Crossbeam

B. Column

C. Carriage

D. Lifting Arm

E. Power Unit

F. Overhead Safety Shut-Off Bar

G. Single Point Safety-Latch Release

2.2 Technical Data

11,000 lbs. (

144”

145-1/2”

71”

76-1/2”

116”

4”

104”

23” – 45”

41” – 57”

220V, 20 Amp, 1 Phase

6

TP11KC-DX

Jun 2017

Max 2,750 lbs. per Arm)

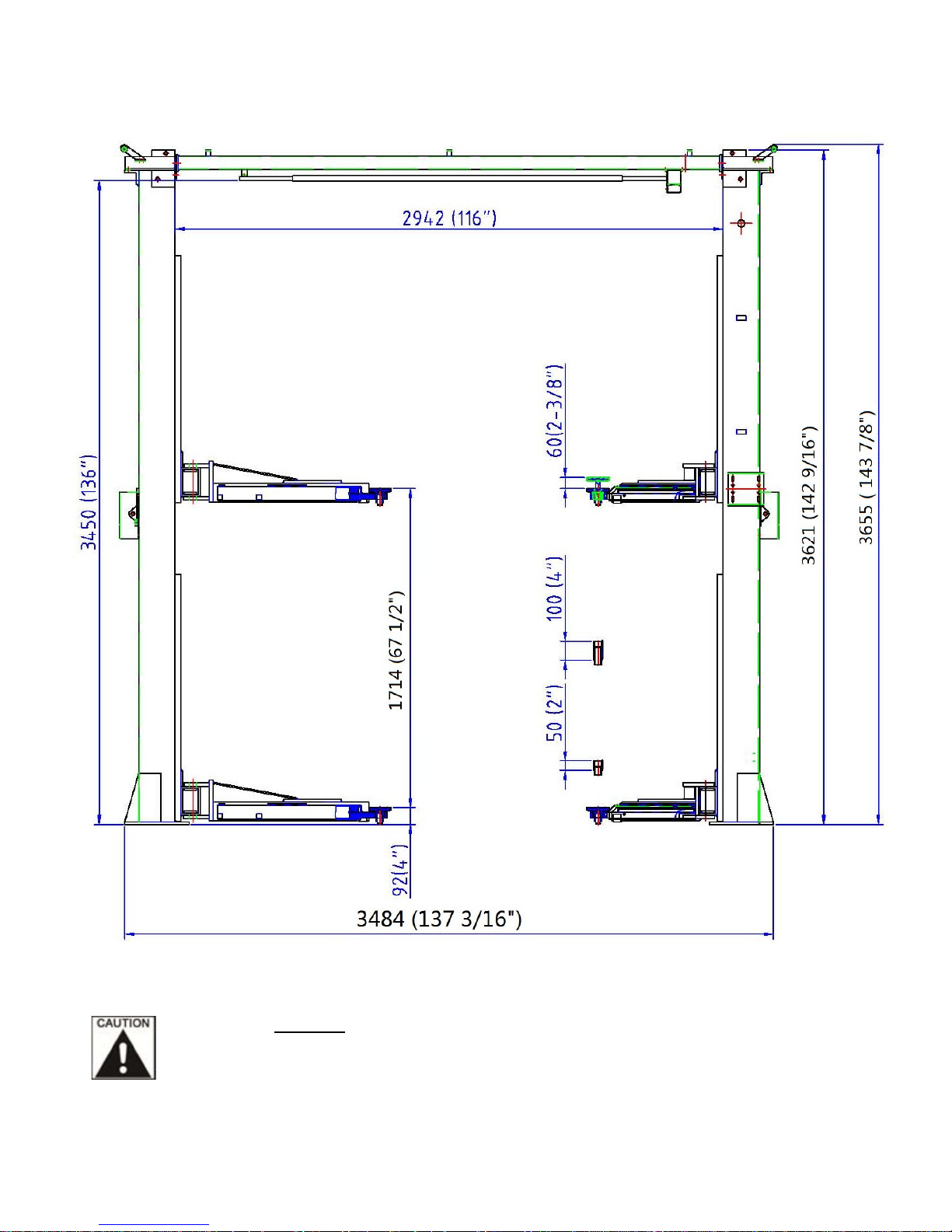

POWER UNIT MUST BE INSTALLED ON THE PASSENGER SIDE. FAILURE TO DO SO CAN RESULT

WITH INTERFERECE BETWEEN THE POWER UNIT AND SHORT SWING ARM, THUS CAUSING

DAMAGE TO POWER UNIT.

Fig. 1 – Front View Spec.

7

TP11KC-DX

Jun 2017

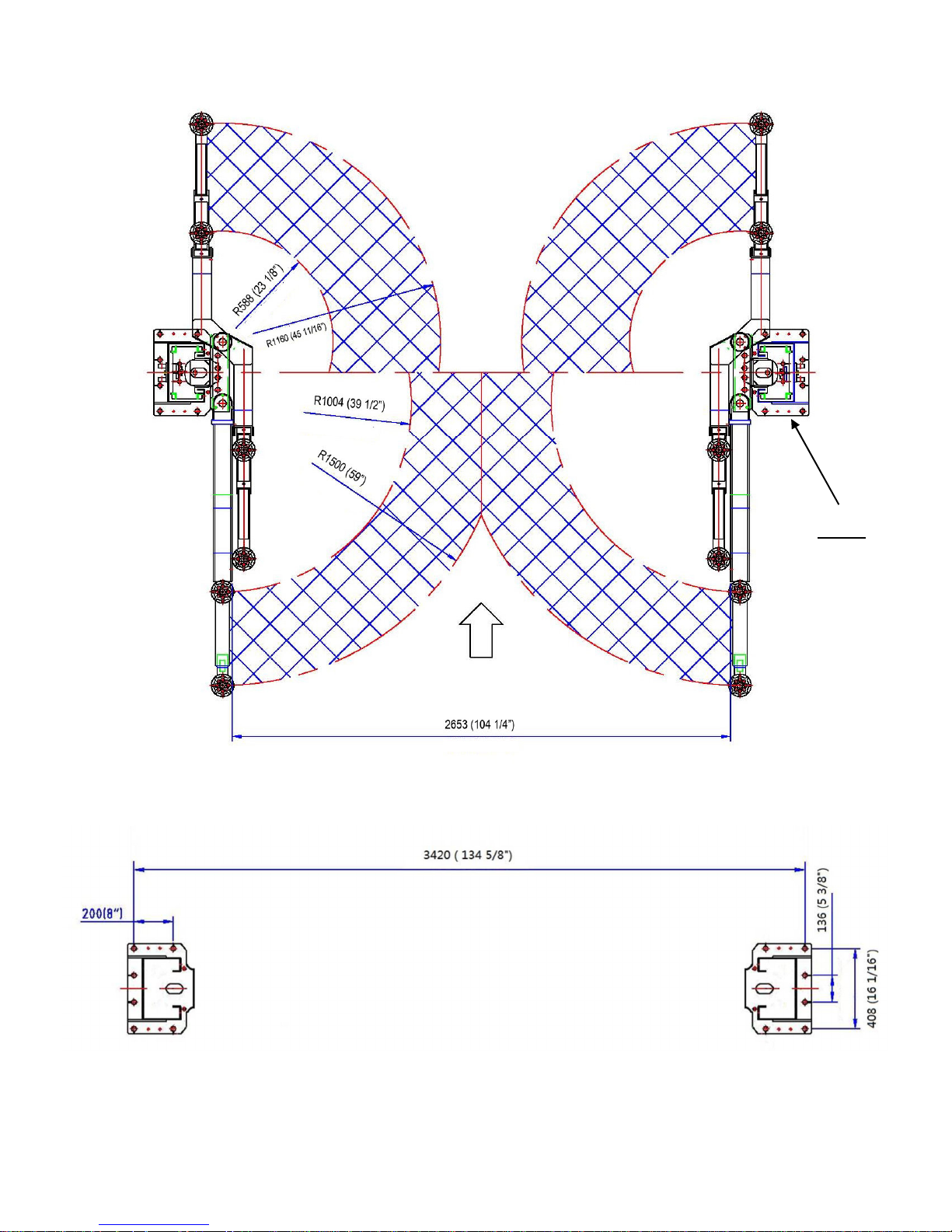

Bi-Symmetric (Asymmetric & Symmetric) Configurations

Fig.2a –Top View Spec.

NOTE:

Power Unit must be

mounted on

Passenger Side,

beside the long/rear

Swing Arm.

Fig.2b - Base Size Spec.

8

TP11KC-DX

Jun 2017

3. Installation

3.1 Site Selection

The hydraulic lift is designed only for indoor use. Application in a room with explosion hazard is not permitted. Setting

in a wet place, a car wash center for instance, is prohibited.

3.2 Surface Condition / Foundation & Anchoring

The 2-post hydraulic lift should be installed on level ground. The foundation must be 4-1/4” minimum thickness

concrete, with a minimum compressive strength of 3,000 psi. Failure to meet the foundation requirement may cause

the lift instability or personal injury. Installing on asphalt, soft clay floor or near the expansion gap is prohibited.

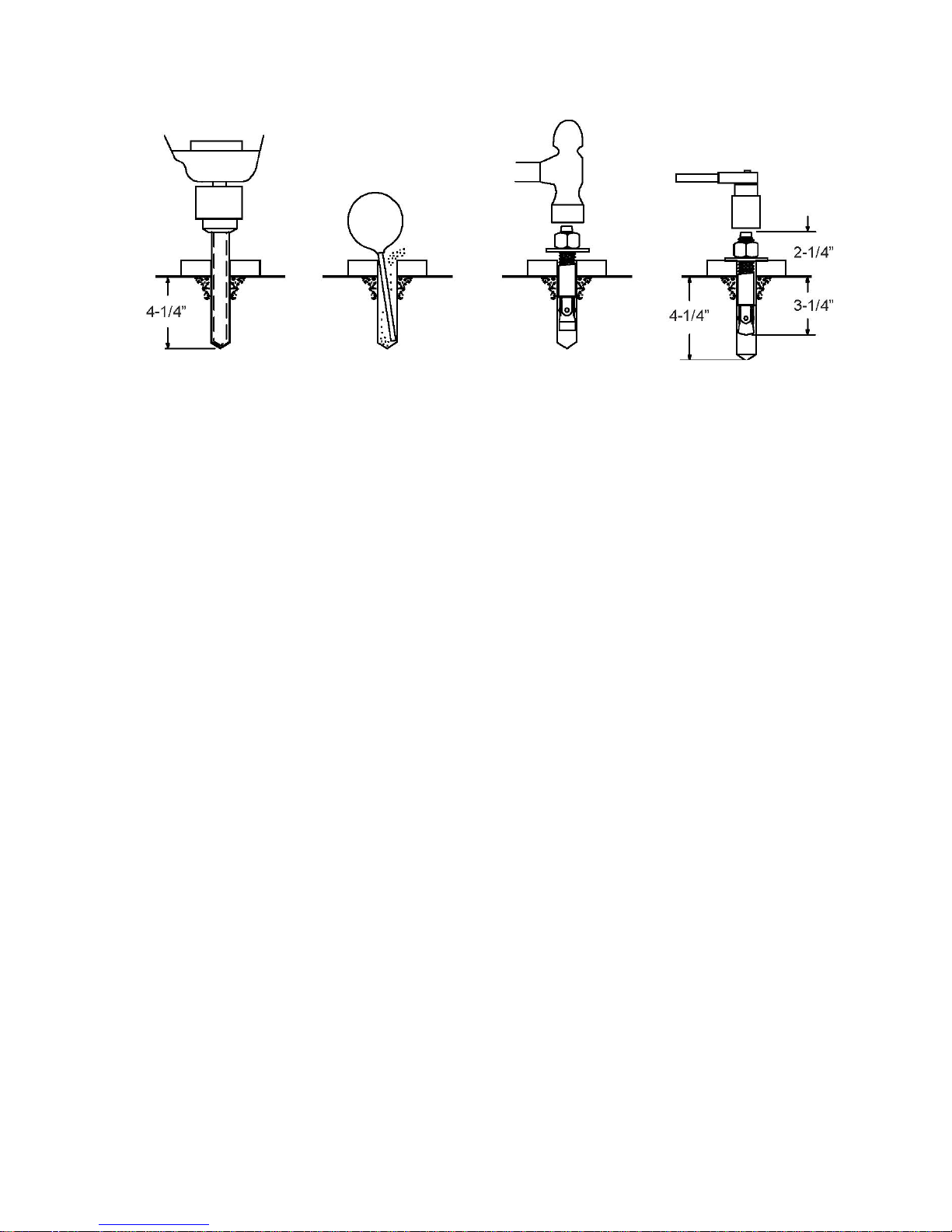

FOUNDATION and ANCHORING REQUIREMENTS

1. Concrete shall have compression strength of at least 3,000 PSI and a minimum thickness of 4-1/4” in order to

achieve a minimum anchor embedment of 3-1/4”. NOTE: When using the standard supplied 3/4” x 5-1/2” long

anchors, if the top of the anchor exceeds 2-1/4” above the floor grade, you DO NOT have enough embedment.

2. Maintain a 6” minimum distance from any slab edge or seam. Hole to hole spacing should be a minimum 6-1/2”

in any direction. Hole depth should be a minimum of 4-1/4”.

3. DO NOT install on asphalt or other similar unstable surface. Columns are supported only by anchoring to floor.

4. Using the horseshoe shims provided, shim each column base as required until each column is plumb. If one

column has to be elevated to match the plane of the other column, full size base shim plates should be used.

Torque anchors to 130 ft-lbs. Shim thickness MUST NOT exceed 1/2” when using the 5-1/2” long anchors

provided with the lift.

5. If anchors do not tighten to 130 ft-lbs. installation torque, replace the concrete under each column base with a

4’ x 4’ x 6” thick 3,000 PSI minimum concrete pad keyed under and flush with the top of existing floor. Allow

concrete to cure before installing lifts and anchors (typically 2 to 3 weeks).

ANCHORING TIPS

1. Use a concrete hammer drill with a carbide tip, solid drill bit the same diameter as the anchor, 3/4” -

(.775 to .787 inches diameter). Do not use excessively worn bits or bits which have been incorrectly sharpened.

2. Keep the drill in a perpendicular line while drilling.

3. Let the drill do the work. Do not apply excessive pressure. Lift the drill up and down occasionally to remove

residue to reduce binding.

4. Drill the hole to depth of 2” deeper than the length of anchor. NOTE: Drilling thru concrete (recommended) will

allow the anchor to be driven thru the bottom of foundation if the threads are damaged or if the lift will need to be

relocated.

5. For better holding power blow dust from the hole.

6. Place a flat washer and hex nut over threaded end of anchor, leaving the nut almost flush with the top of the

anchor bolt. Carefully tap anchor into hole. Do not damage threads. Tap anchor into the concrete until nut and

flat washer are against base plate. Do not use an impact wrench to tighten! Tighten the nut, two or three turns on

average after the concrete has cured (28-day cure). If the concrete is very hard only one or two turns may be

required.

9

TP11KC-DX

Jun 2017

FOUNDATION and ANCHORING REQUIREMENTS, Fig 3

Drill holes using 3/4” Clean hole. Run nut down just Tighten nut with

carbide tipped

masonry drill bit per

ANSI standard

B94.12.1977

below impact section Torque wrench to

of bolt. Drive anchor 130 ft.-lbs.

into hole until nut and

washer contact base.

3.3 Tools & Equipment Required

• 12 quarts of Non-Detergent / Non-Foaming Hydraulic Oil - SAE-10, AW 32 or equivalent

• Chalk line and 12’ Tape Measure

• Concrete hammer drill with 3/4” bit

• 11/16” open end wrench

• 3/4” open end wrench

• Torque wrench

• 15/16” deep socket or wrench

• 1-1/8” socket

• 13/16” open end wrench

• Level (18” minimum length)

• Vise grips

• Tape measure

• Funnel

• Hoist or Forklift (optional)

• Two 12’ step ladders

• 1/4” drive ratchet with 5/16” socket

10

TP11KC-DX

Jun 2017

3.4 Installation Procedure

1. Read this manual thoroughly before installing, operating, or maintaining this lift.

2. Site Evaluation and Lift Location:

A. Always use an architect’s plan when provided. Before unpacking the lift entirely, determine if the site is

adequate for the lift model being installed see figures 1 & 2 for typical bay layout and ceiling height

requirements.

B. Snap chalk lines to identify the lift’s centerline.

C. Snap a chalk line parallel to the lift’s centerline, spaced 9.00” (230 mm) toward the rear of the bay. This line

represents the back edge of the column bases.

D. Snap chalk lines parallel to the lift’s centerline spaced 68-7/8” (1,750 mm) to the left and 68-7/8”

(1,750 mm) to the right. These lines represent the APPROXIMATE outside edges of the column bases.

DO NOT USE THESE LINES TO POSITION THE COLUMNS, FOLLOW THE INSTRUCTIONS IN THIS

MANUAL.

3. Unpack the lift. Remove the swing arms, bolt box, power unit box, and overhead beam.

A. Save all packing hardware, as these components are necessary to complete the installation.

B. Remove the 1/2” bolts from the uprights which hold the two columns together.

C. Remove the upper column. Do not stand the columns up now but lay the columns with their flat backs on

the floor.

4. Attach the cylinder mounts (uprights) using 4ea 1/2” x 1-3/4” bolts, washers and nuts provided as shown in figure

4a & 4b.

Fig. 4a Fig. 4b

11

TP11KC-DX

Jun 2017

5. Install Hydraulic Cylinders

A. Install the cylinder to the cylinder mounts (uprights) with 9/16” x 4-1/2” pins, cylinder bushings (spacer)

washers, and snap rings, as in figure 5a. The hose connecting port near the other end of the cylinder should

be positioned pointing to the column’s opening. (Fig. 5b)

B. Bolt the cylinder rods to the carriages. (Fig. 5c)NOTE: Make sure snap ring on cylinder rod is in groove.

Fig. 5a Fig. 5b Fig. 5c

DO NOT HOLD THE CYLINDER ROD IN A WAY THAT COULD DAMAGE THE FINISH. CYLINDER LEAKS CAUSED BY

DAMAGED RODS ARE NOT COVERD UNDER WARRANTY.

6. Columns Positioning & Main Side Column Anchoring

A. Carefully stand up the Main side column (w/ power unit bracket) & Off side column, position the columns

where they are to be secured. Ensure column’s openings are facing each other.

The Main side column must be positioned to be on the Passenger side or right side with the vehicle headed

forward. The distance between column back edge to wall, should be at least 2 feet for safety.

B. Using the column base as a template, drill the anchor bolt holes for the Main side column Only!

(Refer to FOUNDATION REQUIREMENTS & ANCHORING TIPS ON PAGES 9 & 10)

NOTE: DO NOT ANCHOR OFF SIDE COLUMN AT THIS TIME!

C. Install the anchor bolts, assemble washers & nuts onto the anchor bolts. Thread the nuts onto the anchors

bolts where the tops of the nuts are just above the top of the anchor bolts. Carefully tap the anchor bolts

into the concrete until the washer rests against the base plate. Ensure not to damage threads.

D. Using a level, plumb the Main side column both side to side and front to back. Shim the leg as necessary

using the Shims provided. Tighten anchor bolts to 130 ft. lbs. as noted on page 9. Re-check plumbness.

NOTE: Refer to FOUNDATION & ANCHOR REQUIREMENTS if more than 1/2” of shims are required.

E. Ensure Off side column is in the correct location. DO NOT DRILL HOLES FOR ANCHORS at this time.

7. Overhead Limit Switch & Overhead Beam (Fig. 6a, 6b & 6c)

A. Install overhead limit switch assembly to overhead beam, using 2ea 1/4”-20 Bolt & Lock Nuts as shown in

figs 6a, 6b & 6c.

B. Slide end of padded bar (without a mounting hole) through the slot in the overhead switch assembly.

Connect the padded bar to the inside hole in the overhead beam using a spacer and 1/4”-20 Bolt & Lock Nut

12

TP11KC-DX

Jun 2017

Fig. 6a Fig. 6b

Fig. 6c

8. Install overhead beam to cylinder mounts (uprights) using 2ea 1/2” x 1-3/4” bolts, washers & nuts on each end,

(Figs. 7a, 7b, 7c). NOTE: Ensure overhead Limit Switch Assembly is on the Main side column side.

Fig. 7a Fig. 7b

13

TP11KC-DX

Jun 2017

9. Anchoring Off Side Column

A. Using a level, check the alignment and plumbness of

the entire structure. Plumb the off side column both

side to side and front to back.

B. The base of the column may vary from the preliminary

layout, as it is more important that the column be

perpendicular to the floor and parallel to the other

column.

C. Install the anchor bolts and shim the base as described

in Step #6

10. Equalization Cable Routing

A. The carriages should be resting on the same column latches for proper equalization. Ensure to measure the

height above the baseplate to each carriage. The measurement should be within 3/8” of each other.

Fig. 7c

Fig. 8a Fig. 8b

14

TP11KC-DX

Jun 2017

B. Using the diagrams, rout the equalization cables according to Fig. 8a, 8b, 8c from carriage to carriage

through the cable rollers. Secure to carriages using Nylon Hex Nuts & Washers. Ensure that cables are not

crossed together. Take out slack but DO NOT TIGHTEN CABLES AT THIS TIME.

C. After equalizations cables are routed and connected to carriages, take out the slack in both cables by

turning down the nuts on top of each carriage top. Use vise grips to hold the cable end, but be very careful

not to damage the threads.

NOTE: CARRIAGES MUST REMAIN AT THE SAME COLUMN LOCK HEIGHT POSITION WHILE CABLES ARE

BEING TIGHTENED. FAILURE TO DO WILL CAUSE THE CARRIAGES SAFETY LATCHES TO BE OUT OF SYNC.

D. Alternately tighten the cable nuts at both carriages until the cables are tightened. The correct tension in

the cables are indicated by being able to pull the cables together with approximately 15 lbs. effort at

midpoint in the column. If the cables are installed correctly, both carriages will raise together.

Fig. 8c - Cable Routing

15

TP11KC-DX

Jun 2017

11. Install the Hydraulic Fittings, Hoses and Return Lines

A. Fitting & Hose Connecting:

1. First screw on the hose fitting connectors on the cylinder’s lower end ports. (Fig. 9a)

2. Connect the longest hose from the cylinder in Off side column to the top of Main side column.

Remember to route the hose through the hook on cross beam. (Fig. 9b & 9c)

3. Then from the T-fitting inside column, connect the shortest length hose directly down to the main

inside cylinder connector. (Fig. 9d)

4. Another middle length hose from the T-fitting goes to the motor pump through a hole on the side of

the column. (Fig. 9d)

Fig. 9a Fig. 9b

B. Return Line Connection (blue air-line)

Fig. 9c Fig 9d

1. Screw in an elbow air-line fitting on the top end of the off side cylinder (Fig. 9b).

2. Screw in another T air-line fitting on the top end of main side cylinder also. (Fig. 9c)

3. Connect the return line from off side cylinder to main side cylinder through fittings.

16

TP11KC-DX

Jun 2017

12. Mounting of the Power Unit

A. Mount on the motor pump using 5/16” x 1-1/4” bolts and

nylon nuts provided in the bolt box to Main side column.

B. Connect the hose and the ‘blue’ Return Line to the pump

valve block as shown in ( Fig 10)

13. Latch-release cable wiring and accessories mounting.

A. Mount the safety latch device on each column as shown in

( Fig. 11a & 11b)

Fig. 10

Fig. 11a Fig. 11b

17

TP11KC-DX

Jun 2017

B. Mount the Cable Pulley and support bracket on the top of the columns. (Fig. 11c)

C. Route and adjust the cable tension so that when the handle is pressed down, both latch will be released.

D. Put on the covers of the latch device. (Fig 12a & 12b)

Fig. 11c

Fig. 12a Fig. 12b

18

TP11KC-DX

Jun 2017

14. Install Lifting Arms

Lifting Pad

A. Position the gears with pin against the bottom of the arms in the orientation shown in Fig.13a. Attach the

gears to the arms with bolts. Do not tighten at this time.

Fig. 13a Fig. 13b

B. Position the restraint pawls on the carriage to mate with the gears on the arms.

C. Install the swing arms and pins.

Suggestion:

The longer arms go to the rear or drive in side of the lift, and the short arms go to the front.

DON’T FORCE THE GEARS, IT MAY BE NECESSARY TO PULL UP ON THE RESTRAINT ACTUATOR PIN

IN ORDER TO INSTALL THE SWING ARM PIN.

D. Tighten the gear bolts to 30 – 34 ft. lbs.

E. Assemble the arm extensions and lifting pads. Limit arm extensions with bolts & nuts. ( Figs. 14a & 14b)

Fig. 14a - Front Arm

19

TP11KC-DX

Jun 2017

Fig. 14b - Rear Arm

15. Fill the Tank

Remove the vent plug from the power unit and fill the reservoir with hydraulic oil. Make sure the funnel used to fill

the power unit is clean. Fill with Non-Detergent / Non-Foaming Hydraulic Oil - SAE-10, AW 32 or equivalent.

Replace the vent plug. The unit holds approximately ten quarts of fluid.

16. Lubricate the four inside corners of both columns with heavy duty grease.

17. Electrical Connection to POWER UNIT & OVERHEAD LIMIT SWITCH

A. Have a certified electrician make the electrical connection to the power unit. Use separate circuit for each

IMPORTANT! The wiring must comply with local code. Protect each circuit with time delay fuse or circuit breaker.

.

power unit, as shown below in the Wiring Diagram.

For 208V-230V single phase, use 20 amp fuse.

WARNING!! Never operate the motor in line voltage less than 208VAC as motor damage may occur.

B. Have a certified electrician make the electrical connection for the K2 overhead limit switch to power unit’s

switch box, as shown below.

20

TP11KC-DX

Jun 2017

18. Testing

(1) In this step A, there is no load on the lift.

(2) Cycle up and down must be with interval rest of 2 min.

A. Without a load, raise the lift empty to the top of its travel and lower it to the floor three (3) times to remove

B. The latches should click close together as the lift is being raised. If not, adjust the equalization cable by turn

C. When the carriages are lowered onto the locks, the Latch Release Handle should NOT be capable of being

D. The first time a vehicle is placed on the lift, raise it no higher than three feet. Lower the vehicle onto the

E. Raise the vehicle to full height and lower the carriages onto the safety latches. Lower the vehicle to the

F. After cycling the lift ten times with a vehicle on it, recheck the tightness of the anchors to at least 110 ft-lbs.

the remaining air from the hydraulic system.

(IF POWER UNIT RUNS FINE BUT WILL NOT PUMP, SEE PAGE 32 FOR PRIMING PROCEDURE)

the nuts.

pulled down. Prior to lowering down carriages, always raise up enough to free the latches, then pull down

the latch release handle to unlock the carriages to lower.

safety latches. Raise the lift a few inches and pull latch release lever then lower the vehicle to the floor.

floor.

Now the lift is ready for operation.

21

TP11KC-DX

Jun 2017

3.5 Hydraulic Scheme

1. Reservoir Tank 2. Mesh Filter 3. Gear Pump

4. Motor 5. Relief Valve 6. Check Valve

7. Hydraulic Cylinder(s) 8. Manual Release Valve 9. Pressure Gauge (not supplied)

Motor Power 3 HP @ 2,850 RPM

Hydraulic Pressure Setting 2,900 PSI

22

TP11KC-DX

Jun 2017

4. Operation

BE SURE TO READ AND FAMILIARIZE YOURSELF WITH THE SAFETY INSTRUCTIONS AT THE BEGINNING OF

THIS MANUAL. FAILURE TO FOLLOW SAFETY INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

4.1 Operating Instructions

BE SURE TO READ AND FAMILIARIZE YOURSELF WITH THE SAFETY INSTRUCTIONS AT THE

BEGINNING OF THIS MANUAL. FAILURE TO FOLLOW SAFETY INSTRUCTIONS MAY RESULT IN

PROPER DAMAGE, PERSONAL INJURY OR DEATH.

TO AVOID PERSONAL INJURY AND/OR PROPERTY DAMAGE, PERMIT ONLY TRAINED PERSONNEL

TO OPERATE LIFT. AFTER REVIEWING THESE INSTRUCTIONS, GET FAMILIAR WITH LIFT CONTROLS

BY RUNNING THE LIFT THROUGH A FEW CYCLES BEFORE LOADING VEHICLE ON THE LIFT

ALWAYS LIFT THE VEHICLE USING ALL FOUR ADAPTERS. NEVER RAISE JUST ONE END, ONE

CORNER, OR ONE SIDE OF VEHICLE.

.

THE HEAVY END OF THE VEHICLE MUST PUT ON THE SHORT / FRONT / CURVED ARMS.

4.1.1 Lift Preparation

Lift arms must be fully lowered and service bay clear of all personnel before the vehicle be brought into the bay.

Swing arms out to full drive-thru position

4.1.2 Loading Lift

Swing arms under vehicle and position adapters at vehicle manufacturer’s recommended lift points. Use intermediate,

high step, or optional adapters for under body clearance when required.

Typical Lifting Points. Some Vehicle may have the manufacturer’s Service Garage Lift Point

locations identified by triangle shape marks on its undercarriage. Also, there may be a label

located on the right front door lock face showing specific vehicle lift points. If the specific vehicle

lift points are not identified, refer to the vehicle operation manual or consult the vehicle agent.

ALWAYS follow the operating instructions supplied with the lift.

4.1.3 To Raise Lift

a. Push START button of the motor pump.

b. Stop before arms making contact with vehicle. Check arm restraint pins for engagement. If required,

slightly move arm to allow restraint gear and pawl to match. DO NOT hammer pin down, as this will

damage the restraint gear teeth.

c. Raise vehicle until the wheels slightly clear the floor, then release the START button.

23

TP11KC-DX

Jun 2017

d. Check support adapters for secure contact at vehicle manufacturer recommended lift points.

e. Continue to raise to desired height only if vehicle is secure on lift. Then release the START button.

f. DO NOT go under vehicle if all four adapters are not in secure contact at vehicle manufacture

recommended lift point.

g. Repeat complete spotting, loading and raising procedures if required.

h. Press down the hydraulic pressure release lever on the motor pump to lower the vehicle into the locking

position. The locking latches are engaged.

DO NOT GO UNDER VEHICLE IF LOCKING LATCHES ARE NOT ENGAGED.

BEFORE ATTEMPTING TO LIFT PICKUP TRUCKS OR OTHER TRUCK FRAME VEHICLES,

BE SURE THAT:

• Vehicle frame is strong enough to support its weight and has not been weakened by modification or

corrosion.

• Vehicle individual axle weight does not exceed one-half lift capacity.

• Adapters are in secure contact with frame at vehicle manufacturers recommended lift point.

• Vehicle is stable on lift

• The overhead switch bar will contact the highest point on the vehicle

4.1.4 While Using Lift

a. Avoid excessive rocking of vehicle while on lift.

b. Always use safety stands as needed or when removing or installing heavy components.

4.1.5 To Lower Lift

a. Remove all tools or other objects from lift area

b. Press START button a few seconds to raise up a little. Then pull down the latch-release handle by left hand

and at the same time press down the pressure-release lever.

REMAIN CLEAR OF LIFT WHEN LOWERING VEHICLE. OBSERVE PINCH POINT WARNING DECALS.

4.1.6 Unloading Lift

After the lift is lowered down onto the ground, remove adapters from under vehicle and swing arms to full drive-thru

position before moving vehicle out.

IF LIFT IS NOT OPERATING PROPERLY, DO NOT USE UNTIL ADJUSTMENT OR REPAIRS ARE MADE BY

QUALIFIED LIFT SERVICE PERSONNEL.

24

TP11KC-DX

Jun 2017

4.2 Maintenance Instructions

Contact your service provider for instruction before starting up if you are not completely familiar with

automotive lift maintenance procedures. Only qualified personnel can perform maintenance on this

equipment. Any failure in operation may cause personal injury or death.

Daily

Always keep bolts tight. Check periodically.

Always keep lift components clean.

Always if oil leakage is observed, contact your service provider.

Check cables and sheaves for wear every day. Replace worn or broken parts with lift manufacturer’s

parts, or their equivalent.

Monthly

Check equalizer cable tension.

Lubricate locking latch shafts. Push latch handle several times for oil to penetrate joints.

Lubricate the four inside corners of the columns with heavy duty bearing grease.

With lift lowered, check the hydraulic fluid level. If necessary add oil as described in the Installation

Instruction section of this manual

Check carriage latch synching: Latches should click at the same time. If necessary adjust equalization

cables.

Check tightness of all bolts.

Check the nuts for tightness every week for the first month, and every month afterwards.

Every 3 Months

Check anchor bolts for tightness. Anchors should be torqued to 130 ft.-lbs.

Check and clean the oil filter

Every 6 Months

Check fluid level of lift power unit and refill if required.

If Lift stops short of full rise or chatters, contact your service provider.

Replace all caution, warning or safety related decals on the lift if unable to read or missing. Reorder

labels from service provider.

25

TP11KC-DX

Jun 2017

5. Exploded View / Parts List

26

TP11KC-DX

Jun 2017

Parts List

ITEM CODE DESCRIPTION QTY

1 165948T*01-001 column (offside) 1

2 165948T*01-002 socket screw 8

3 165948T*01-003 pad adapter (low) 4

4 165948T*01-004 pad adapter (high) 4

5 165948T*01-005 screw 26

6 165948T*01-006 roller 3

7 165948T*01-007 pin 1# 3

8 165948T*01-008 split pin 3

9 165948T*01-009 cover 2# 1

10 165948T*01-010 flat washer 8

11 165948T*01-011 small frame 1

12 165948T*01-012 bolt 2

13 165948T*01-013 nut 2

14 165948T*01-014 bolt 2

15 165948T*01-015 nut 2

16 165948T*01-016 threaded pin 4

17 165948T*01-017 turning board 1

18 165948T*01-018 spring 2# 2

19 165948T*01-019 latch 2

20 165948T*01-020 spring 1# 2

21 165948T*01-021 shaft 2

22 165948T*01-022 nut 12

23 165948T*01-023 washer 28

24 165948T*01-024 flat washer 6

25 165948T*01-025 bearing 6

26 165948T*01-026 shaft 2

27 165948T*01-027 split pin 6

28 165948T*01-028 roller 6

29 165948T*01-029 shaft 2

30 165948T*01-030 cross beam 1

31 165948T*01-031 bolt 12

32 165948T*01-032 lock nut 5

33 165948T*01-033 ceiling limit bat 1

34 165948T*01-034 T-type air connector 1

35 165948T*01-035 cylinder base 2

36 165948T*01-036 large frame 2

27

TP11KC-DX

Jun 2017

ITEM CODE DESCRIPTION QTY

37 165948T*01-037 air hose (2#) 1

38 165948T*01-038 column (main) 1

39 165948T*01-039 protect ring 1

40 165948T*01-040 cover 1# 1

41 165948T*01-041 handle ball 1

42 165948T*01-042 steel cable 2

43 165948T*01-043 handle 1

44 165948T*01-044 bearing 2# 2

45 165948T*01-045 oil hose 3# 1

46 165948T*01-046 T-type oil connector 1

47 165948T*01-047 oil hose 1# 1

48 165948T*01-048 oil hose 2# 1

49 165948T*01-049 carriage 2

50 165948T*01-050 nylon block 16

51 165948T*01-051 circlips 4

52 165948T*01-052 spring 4

53 165948T*01-053 gear shaft 4

54 165948T*01-054 small gear 4

55 165948T*01-055 cotter pin 4

56 165948T*01-056 anchor 12

57 165948T*01-057 angle connector 1

58 165948T*01-058 O-ring 1

59 165948T*01-059 bolt 4

60 165948T*01-060 motor pump 1

61 165948T*01-061 turning board 1

62 165948T*01-062 bearing 1# 2

63 165948T*01-063 washer 9

64 165948T*01-064 fitting adaptor 1

65 165948T*01-065 angle air fitting 2

66 165948T*01-066 shim 16

67 165948T*01-067 adaptor frame 2

68 165948T*01-068 switch board 1

69 165948T*01-069 cable nut 1

70 165948T*01-070 switch cover 1

71 165948T*01-071 switch 1

72 165948T*01-072 threaded pin 4

28

TP11KC-DX

Jun 2017

ITEM CODE DESCRIPTION QTY

73 165948T*01-073 rubber bar 2

74 165948T*01-074 straight arm 2

75 165948T*01-075 thin nut 2

76 165948T*01-076 nut 2

77 165948T*01-077 cylinder 2

77-1 165948T*01-077-1 piston rod 2

77-2 165948T*01-077-2 oil seal 2

77-3 165948T*01-077-3 O-ring 2

77-4 165948T*01-077-4 guide ring 2

77-5 165948T*01-077-5 steel ring 2

77-6 165948T*01-077-6 duct ring 2

77-7 165948T*01-077-7 circlips 2

77-8 165948T*01-077-8 O-ring 2

77-9 165948T*01-077-9 piston 2

77-10 165948T*01-077-10 oil seal 4

77-11 165948T*01-077-11 guide belt ring 2

77-12 165948T*01-077-12 nut 2

77-13 165948T*01-077-13 base plate 2

77-14 165948T*01-077-14 spring 2

77-15 165948T*01-077-15 throttle valve 2

77-16 165948T*01-077-16 washer 2

77-17 165948T*01-077-17 fitting adaptor 2

77-18 165948T*01-077-18 fitting adaptor 2

77-19 165948T*01-077-19 cylinder body 2

80 165948T*01-080 bolt 8

81 165948T*01-081 large gear 4

82 165948T*01-082 curved arm left 1

83 165948T*01-083 pad rubber 4

84 165948T*01-084 lifting pad 4

85 165948T*01-085 short screw slot 4

86 165948T*01-086 straight arm extension 2

87 165948T*01-087 nut 4

88 165948T*01-088 steel cable 2

89 165948T*01-089 washer 4

90 165948T*01-090 nut 8

91 165948T*01-091 curved arm extension 2# 2

29

TP11KC-DX

Jun 2017

ITEM CODE DESCRIPTION QTY

92 165948T*01-092 curved arm right 1

93 165948T*01-093 curved arm extension 1# 2

94 165948T*01-094 arm pin 4

95 165948T*01-095 circlips 4

96 165948T*01-096 slot 4

97 165948T*01-097 air hose (1#) 1

98 165948T*01-098 sponge bush 1

101 165948T*01-101 bolt 1

102 165948T*01-102 long screw slot 4

103 165948T*01-103 screw 4

104 165948T*01-104 fixing plate 2

105 165948T*01-105 Steel ring 4

106 165948T*01-106 Ripe grip 2

107 165948T*01-107 turnbuckle 1

30

TP11KC-DX

Jun 2017

A. Problem

Motor does not run.

Problem

Motor

runs but lift will not raise.

Problem

Lift will raise up only without load.

Problem

Lift slowly settles down.

Problem

Slow lifting speed or oil blowing out breather cap

Problem

Lift going up unleveled.

Problem

Anchors will not stay tight.

Problem

Locking latches do not engage.

6. Troubleshooting Guide

Possible cause: Solution:

B.

1. Open lowering valve.

C

1. Motor running on low voltage.

D

1. Debris in check valve seat.

E

1. Air mixed with oil.

F

1. Equalizer cables out of adjustment.

G

1. Holes drilled oversize.

H

1. Latch shafts rusted.

1. Blown fuse or circuit breaker.

2. Incorrect voltage to motor.

3. Bad wiring connections.

4. Motor up switch burned out.

5. Overhead limit switch burned out.

6. Motor windings burned out.

Possible cause: Solution:

2. Pump sucking air.

3. Suction stub off pump.

4. Low oil level.

Possible cause: Solution:

2. Debris in lowering valve.

3. Improper relief valve adjustment.

4. Overloading.

Possible cause: Solution:

2. Debris in lowering valve seat.

3. External oil leaks.

Possible cause: Solution:

2. Air mixed with oil suction.

3. Oil over filled.

Possible cause: Solution:

2. Lift installed on unleveled floor.

Possible cause: Solution:

2. Concrete floor thickness or holding

strength not sufficient.

Possible cause: Solution:

2. Latch spring broken.

3. Latch cable needs adjustment.

1. Replace fuse or reset circuit breaker.

2. Supply correct voltage to motor.

3. Repair and insulate all connections.

4. Replace switch.

5. Replace switch.

6. Replace motor.

1. Repair or replace lowering valve.

2. Tighten all suction line fittings.

3. Replace suction stub.

4. Fill tank with SAE-10, AW 32 or equivalent.

1. Supply correct voltage to motor.

2. Clean lowering valve.

3. Replace relief valve cartridge.

4. Check or balance the vehicle weight on lift.

1. Clean check valve.

2. Clean lowering valve.

3. Repair external leaks.

1. Change oil to ‘non-foaming’ SAE-10, AW 32 or equivalent.

2. Tighten all suction line fittings.

3. Only fill or add oil to tank when lift is fully lowered.

1. Adjust the length of the cables again.

2. Level the floor or level the column base by shims.

1. Relocate lift using a new bit to drill holes.

2. Break out old concrete and pour new pads, as required for

1. Oil latch mechanism. Grease the shaft.

2. Replace broken spring.

3. Adjust clamps at cable end.

each lift column.

31

TP11KC-DX

Jun 2017

7. Power Unit Priming

32

TP11KC-DX

Jun 2017

8. Warranty

33

TP11KC-DX

Jun 2017

Loading...

Loading...