Tuttnauer M-Series, Mk-Series Quick maintenance manual

LEVELING THE STERILIZER

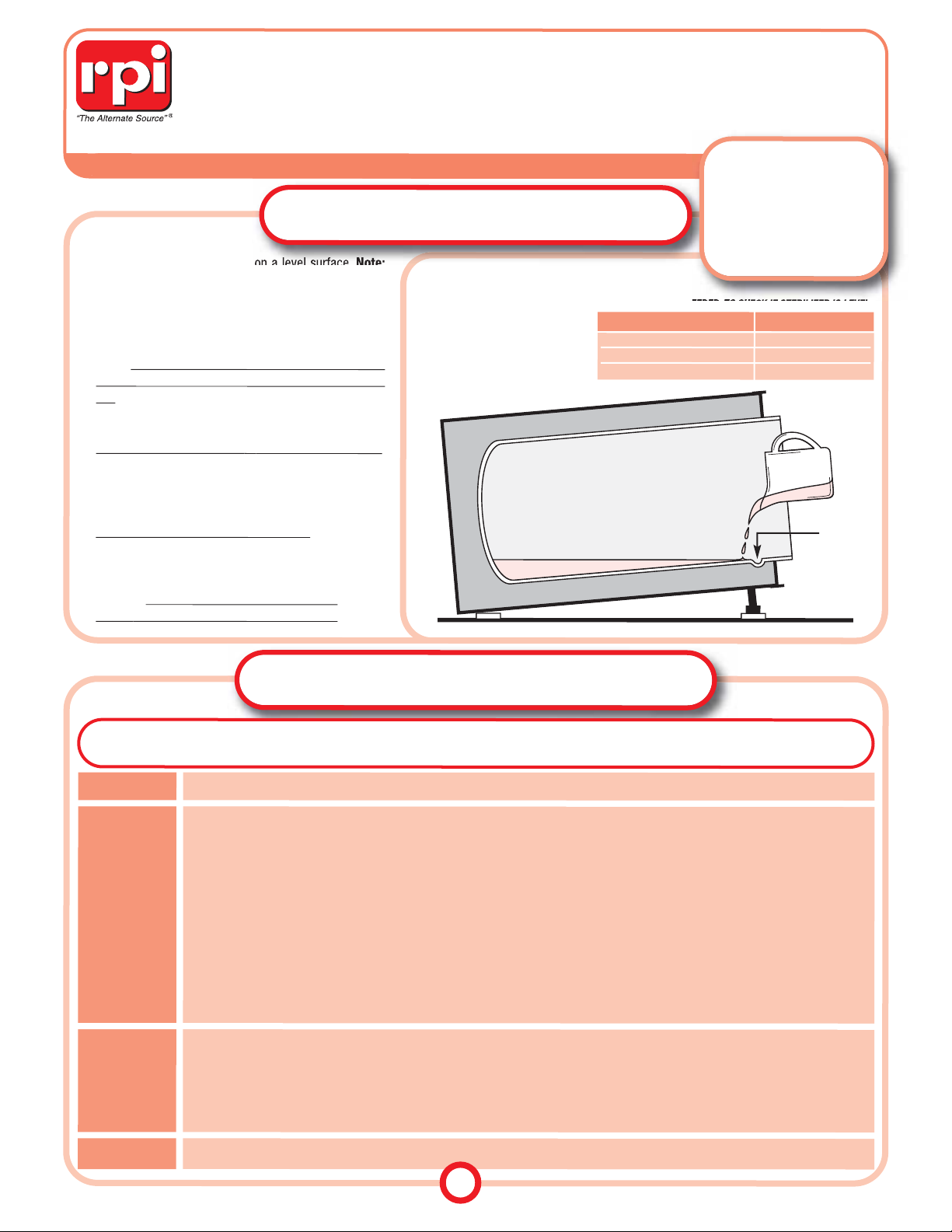

1.The sterilizer must be placed on a level surface. Note:

When positioning the sterilizer on the surface, be sure

to keep the back and right side of the sterilizer a

pproximately 1" (25mm) away from the wall to allow for

proper ventilation.

2.T o check if the sterilizer is level: Refer to Table A, to the

right; measure only the amount of water indicated in

the chart for the corresponding model into a measuring

cup

; and, pour the measured water into the chamber.

The water must reach the indication groove near the

front of the chamber. Refer to Figure 1, to the right.

If the water does not reach

or

it goes past the groove

,

the sterilizer is not level and must be

adjusted. To help level the sterilizer, the front legs of the

sterilizer may be adjusted using a wrench.

FILLING THE RESERVOIR

1.Use distilled water only to fill the reservoir

. Fill the reservoir until the water level is 1" (25mm) below the base of

the Safety Valve Holder. Refer to the Min/Max lines on the

Reservoir Dip Stick.

Caution!

For proper operation of the sterilizer,

do

not fill water above the Safety Valve Holder.

YOUR GUIDE TO MAINTAINING TUTTNAUER

™

M/MK SERIES & VALUEKLAVE MKV STERILIZERS

LEVELING & FILLING PROCESS

All product names used in this document are trademarks or registered trademarks of their respective holders.

©RPI, 2012 (REV B 09/12)

The parts mentioned in this document are manufactured by Replacement Parts Industries, Inc. to fit Tuttnauer equipment.

PLANNED MAINTENANCE

FIGURE 1

LEVELING THE STERILIZER

To verify that the sterilizer is

level, the amount of water (as

indicated in Table A, to the

right) when poured into the

chamber must reach the indication groove inside the chamber.

DAILY

WEEKLY

MONTHLY

ANNUALLY

Clean the Door Gasket with a soft cloth or sponge using a soft liquid detergent and water. Rinse well and leave no residue.

Recommended parts to be replaced at this time include the Door Gasket, Chamber Filters, Door Bellows, and parts showing wear.

• During a sterilization cycle, use an insulated tool or pair of needle nose pliers to pull on the end ring of the Safety V alve , and let the

steam exhaust for a couple of seconds. This will remove debris in the lines and clean the valve's orifices. Verify its closing ability.

Caution: During this procedure, be prepared for a rush of steam to be released with a loud hissing sound. W ear appropriate

protective hand and eye gear .

•

After Every 20 Cycles -

Clean Sterilizer with Tutt-Clean™ (RPI Part #'s TUC094 &TUC095) in conjunction with the Sterilizers

Cleaning Kit (RPI Part #RPK791) to help remove water deposits, oxides and other sediments.

• 1. Remove the Trays and Tray Holder from the unit. Clean the Chamber, Tray Holder and Trays with a cloth or sponge using an

OEM recommended cleaner.

Caution: Do not use steel wool, a steel brush or chlorinated cleansers on these parts.

2. Thoroughly rinse Chamber, Tray Holder, and Trays with clean water. Flush the Chamber. Flush the Fill hole located at the back

of the Chamber by turning the Fill Knob to the FILL position for a couple of seconds.

3. Dry the Chamber, Tray Holder and Trays, and reinstall.

• Place a couple of drops of oil on the two door pins and the door tightening bolts.

•Clean the outside of the unit with a soft cloth or sponge using a non-abrasive cleaner.

• Drain and flush the Water Reservoir while using a baby bottle brush to clear any build up of debris. Refill the reservoir (see

FILLING THE RESERVOIR

, above).

• When the sterilizer is cold and not pressurized, verify the integrity of the Spring and Plunger Assembly by pulling and releasing

the end ring on the Safety Valve – it should spring back.

• Remove and clean Chamber Filters.

• Check and clean the Air Jet Valve by moving the wire back and forth several times to prevent debris buildup.

CAUTION!

Before starting any maintenance or repairs:

1) Turn the sterilizer OFF. 2) Unplug the po wer cord from the wall outlet. 3) Verify

that there is no pressure in the unit. 4) Allow to cool to room temperature. 5) Wear appropriate protective hand and eye gear.

Replacement Parts Industries, Inc. is pleased to present this valuable work tool that can help save you and your

customers time and money. Take a look, you will find Troubleshooting Guides, diagrams, exploded views and a

complete listing of all RPI parts that fit all 1730/2340/2540/3870 M/MK and Valueklave

™

1730 MKV Tuttnauer models. It’s

all here, in one easy-to-use tool. Keep it close by–in your RPI catalog or at your workbench.

TABLE A

AMOUNT OF WATER NEEDED, TO CHECK IF STERILIZER IS LEVEL.

Model Amount of Water

1730 Series & Valueklave 1730 MKV 10 - 12 oz. (300 - 355 ML)

2340 & 2540 Series 12 - 15 oz. (355 - 444 ML)

3870 Series 24 - 27 oz. (710 - 798 ML)

INDICATION

GROOVE

1

PLEASE NOTE!

Over the years, Tuttnauer

has substituted parts from

what has been noted in their

manuals. As a precaution,

please verify parts before

replacing or servicing them.

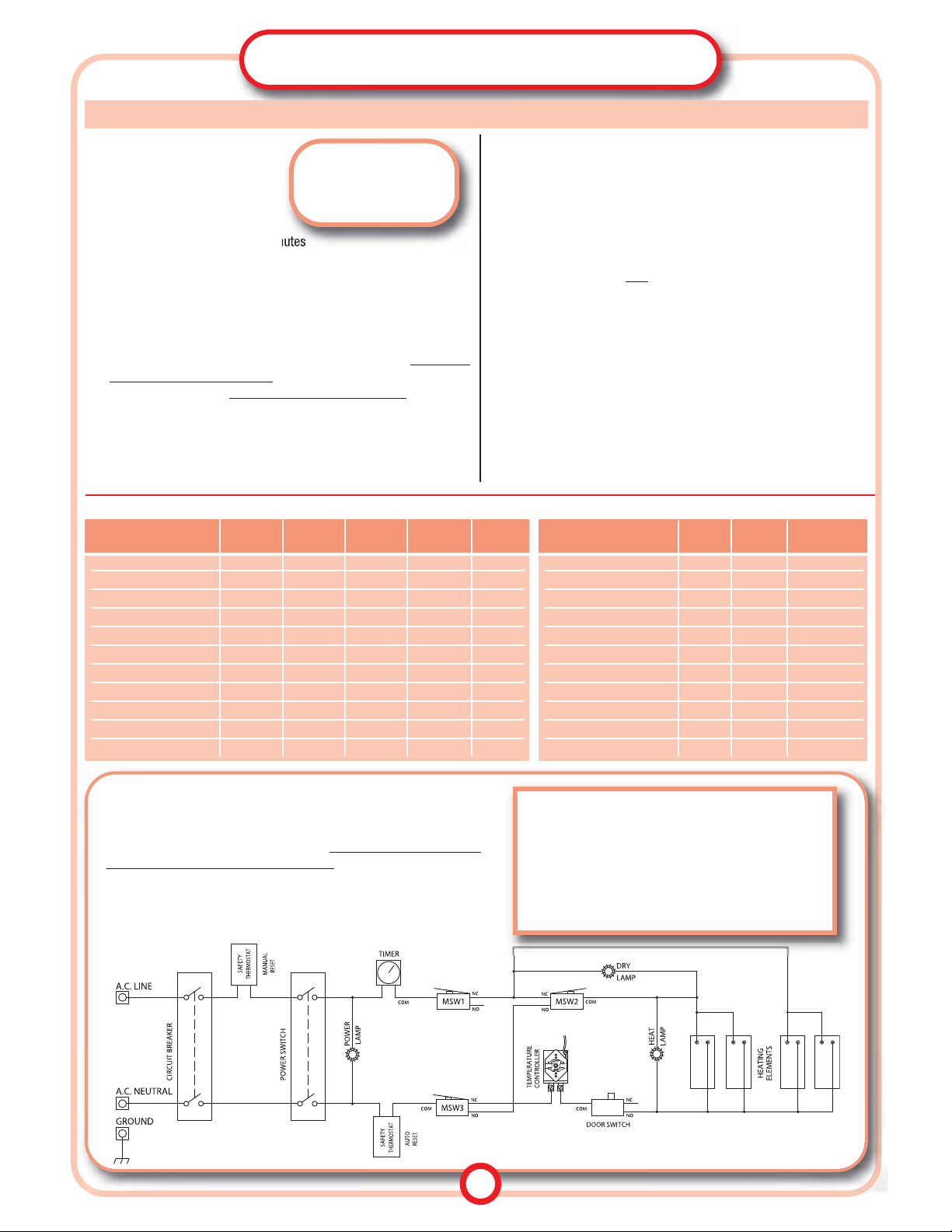

TABLE C

-

APPROXIMATE HEATER ELEMENT RESISTANCE VALUES (±10%)

ELECTRICAL TROUBLESHOOTING

& WIRING DIAGRAMS

BASIC CIRCUIT INSPECTION

1. Disconnect power to unit.

2. Set sterilizer controls to the

following settings:

• Circuit Breaker = ON

• Power Switch = ON

• Sterilizer Door = CLOSED

• Timer = Set for more than 10 minutes

• Temperature Controller = Set at 250º or higher

3. Set a multi-meter to ohm scale, then connect the line and neutral termi-

nals of the power module.

4. Rotate the Multi-Purpose Valve to each setting; starting and ending at O,

and observe the meter for the following:

• In the STE and EXH+DRY positions, the meter should read the circuit

values ( ±10%) shown in Table B, below for each model. If the meter

reads a much higher resistance than shown in Table B, it is an indication of an open circuit. If the reading is significantly lower than shown

in Table B, it is an indication of a short circuit or heater burnout.

• In the O and FILL positions, the meter should read a very high resistance – which indicates an open circuit.

5. Remove unit's covers and insulation blanket. Perform a full visual

inspection of wiring, terminals and connections. Inspect the wiring har-

STE STE EXH-DRY EXH-DRY

Model VAC Amps Ohms Amps Ohms

1730M 120 9.5 13.0 2.0 60

1730M 230 4.8 48.0 1.2 218

1730MK 230 6.0 38.0 1.3 170

1730MKV (Valueklave) 120 13.0 9.0 3.0 40

2340M 120 13.0 9.5 3.2 38

2340M 230 6.5 35.0 1.6 140

2340MK 230 11.5 21.0 2.8 90

2540M 120 13.0 9.0 3.2 38

2540M 230 6.5 35.0 1.6 140

2540MK 230 11.5 9.5 2.8 90

3870M 230 12.0 19.0 3.2 76

Resistance

Model VAC Watts (Ohms)

1730M 120 350 41

1730M 230 350 147

1730MK 230 450 117

1730MKV (Valueklave) 120 450 32

2340M 120 350 41

2340M 230 350 147

2340MK 230 550 96

2540M 120 350 41

2540M 230 350 147

2540MK 230 550 96

3870M 230 1000 112

TABLE B

-

APPROXIMATE CIRCUIT VALUES (±10%) AT STE AND EXH-DRY POSITIONS

FIGURE 2

Schematic of Current Tuttnauer Models 2340M/MK & 2540M/MK

Although the schematic below applies to the current 2340M/MK &

2540M/MK Models of Tuttnauer sterilizers, it can be used as a reference

for all of the other manual models as well. Variations to the wiring of

manual models is common among Tuttnauer sterilizers. For a list of the

variations that might be encountered when servicing these sterilizers,

see the listing to the right.

Variations Between Tuttnauer M/MK/MKV Wiring

• Single vs. Dual Circuit Breakers

• Circuit Breaker(s) or Fuse

• Single or Dual Thermostat

• Wiring of Thermostat (Manual or Automatic reset)

• Wiring of Heat Light or Dry Light

• With or without Door Switch

• Number of Heating Elements required

ness for loose leads and broken or damaged wires. Make any repairs

and retest. If no defects found, then inspect each component and conduct continuity check of the complete wiring circuit.

6. Refer to the schematic in Figure 2, below, check each circuit compo-

nent, starting with the circuit breaker. Take note of the following characteristics for each of the components:

• Safety Thermostats should be closed except at high temperature when

they open to protect the circuit.

Note:

Models built after

January, 1993 have dual

Safety Thermostats, one of which has a

manual reset button and is located near the circuit breaker.

• Timer must be turned

past 10 minutes

to make contact and provide

electrical continuity.

• Control Thermostat must be set above 212˚ F to make contact and

provide electrical continuity.

• Micro-Switch positions and wiring are referenced on page 9, MULTI-

PURPOSE VALVE & MICRO-SWITCHES. (Note: Micro-Switches are

best checked with an analog ohm meter.)

• Heater element resistance values are shown in Table C, below.

7. Repair or replace all faulty circuits or components, then retest unit.

8. Replace insulation blanket and reinstall covers.

9. Run unit for several cycles and check all operations.

SERVICE TIP

When working on the

electrical system, follow

all safety requirements.

2

LEGEND (Located on Multi-Purpose Valve)

MSW1 = Micro-Switch 1 • MSW2 = Micro-Switch 2 • MSW3 = Micro-Switch 3

DOOR GASKET & DOOR BELLOWS

Check chamber Door Gasket for any steam leaks, hissing, or water

bubbles at

the Door Bellows. If steam is leaking at the door closing

device, then rotate the Gasket 180˚ to see if the leak follows it. If the

leak follows the Gasket, then replace the Gasket. If the leak does not

follow the Gasket, then replace the Door Bellows.

ISOLATING LEAKS & CORRECTIVE ACTION

HOW TO CHECK THE AIR JET VALVE

Water and steam leaks not only cause damage to the site where the unit is located but also,

will create a low water condition resulting in overheating that could cause major damage to the autoclave.

WATER/STEAM SYSTEM

TROUBLESHOOTING

AIR JET VALVE

Inspect the Air Jet Valve. It should make a slight hissing sound

throughout the STE cycle. If there is excessive hissing, steam, or

water bubbles escaping from the Air Jet Valve, refer to HOW TO

CHECK THE AIR JET VALVE, at the top right hand side of this

page.

Service Tip: Use a dental mirror to help locate the leak.

SAFETY VALVE

Remove the Water Reservoir Fill Cover and visually inspect the Safety

Valve – use a dental mirror to help locate the leak. Confirm that there

is no steam or water drops escaping from the vent holes or threads

of the Safety Valve. If a leakage is observed, replace the Safety Valve.

MULTI-PURPOSE VALVE

Inspect the Multi-Purpose Valve for leakage. Note any leaks at the

three fittings or the valve stem. If none are found, disconnect the

Condensation Coil in the water reservoir at the point where it connects inside the reservoir. Operate the sterilizer in STE mode at

273˚F for 30 minutes on M units

and 15 minutes on MK &

Valueklave 1730 MKV units, and look for any signs of leakage back

into the reservoir from the tubing fitting where the Condensation Coil

was attached. Inspect the water fill tube at the bottom of the reservoir for any signs of steam bubbling back into the reservoir. If any

leakage is noted at either position, repair or replace the MultiPurpose Valve.

Important: Reconnect Condensation Coil before

exhausting Chamber pressure.

CHAMBER & INTERNAL TUBING

Carefully inspect for steam or water bubbles at the Chamber and all

fittings. If a leak is detected at one of the fittings or tubing, tighten

or replace only after the unit has been depressurized and allowed to

cool down.

Visual and audible leaks can be

detected by operating the sterilizer in the normal STE mode with

temperature set at 273º F and the

time set for 30 minutes on M

units and 15 minutes on MK &

Valueklave 1730 MKV units.

Possible points of water/steam

leaks with corrective action, and

order in which they should be checked are noted in #1-5 below.

HOW TO UNCLOG THE MULTI-PURPOSE VALVE DURING A CYCLE

1. Refer to Table A, page 1, and pour the indicated amount of water into

the sterilizer

. Turn the power switch ON.

2. Close and lock the sterilizer door – be sure to make a tight seal and wait

for the heat light to come on.

3. Set the sterilizer to the following settings: Multi-Purpose Valve (MPV) set

to STE position; Timer Knob set to 20 minutes; and, Thermostats Knob to

273˚F (134˚C). Then press power switch to START.

(Note:

With the MPV in

the STE position, heaters will be

ON

, and sterilizer will begin to build pressure.

)

4. When the Chamber pressure reaches 30-31 PSI:

• Turn the Power Switch to the OFF position.

• Turn the MPV to the FILL position. Now the Chamber pressure should

force out debris from the MPV through the Fill Line into the Reservoir.

• When the pressure in the Chamber reaches 0, turn the MPV to the OFF

position, then open the door. Allow the sterilizer to cool.

• Clean out any debris from the inside of the Chamber.

• If the MPV is still clogged, rebuild or replace it.

HOW TO MANUALLY UNCLOG THE MULTI-PURPOSE VALVE

1. Disconnect power from sterilizer. Allow to cool. Remove covers.

2.

At the center port of the Multi-Purpose Valve (MPV), disconnect the fit-

ting. Set MPV to the FILL position.

Service Tip: Drain most of the water

from the Reservoir to prevent excess spillage during this process. This

will also verify that the Drain Tube and Drain Valve are clear.

• If water flows into the Chamber, then the obstruction has been c leared

from MPV and Fill Tube.

•If water does not flow into the Chamber

, check Fill Tube as follows:

Disconnect Fill Tube fitting at bottom of MPV.

- If water flows

, Fill Tube is clear, but MPV must be rebuilt or replaced.

- If water does not flow

, use forced air through Fill Tube and check for

bubbles in Reservoir. If procedure does not clear obstructions, replace

Fill T ube.

Service Tip:When disconnecting Fill Tube, straighten portion

of tube (about 1" lg.) that protrudes into the bottom of Reservoir.

Support Reservoir boss with a wrench.

3. If MPV and Fill Tube are clear, next check Chamber Tube as follows:

Disconnect and remove MPV from Chamber Tube. Use forced air or water

through tube. If procedure does not clear obstructions, replace Chamber

Tube. Also check and clear Chamber Fitting and boss of any obstructions.

4. Check exhaust lines as follows: At the top port of MPV, disconnect

Condensing Coil Tube, see MULTI-PURPOSE VALVE, page 9. Force air

through tube. If the flow is blocked, determine whether Condensing Coil

or Tube is obstructed. Clear obstruction or replace coil and/or tube.

5. If no leaks or obstructions have been found by following the previous

steps, and sterilizer is still experiencing a low water condition resulting in

overheating problems, see HOW TO CHECK THE AIR JET VALVE, above.

1

1

2

2

3

3

4

4

5

5

3

SERVICE TIP

T o help prevent

cl

ogging of the MPV,

install RPI Filters (RPI

Part #MIF062) into

the Water Fill and

Exhaust Lines.

SERVICE TIP

If the Chamber is found to be

defective, tag it as "Out of

Operation". Removal of the

power cord is recommended

until the chamber is replaced.

If a water/steam leak is not related to #1-3 above, disconnect power

from the sterilizer and remove the cover, then carefully remove the insulation blanket. Proceed to #4-5, below.Warning!

Make sure power has

been disconnected prior to removing the cover. When running the sterilizer with the cover removed, the interior of the machine will be very hot

- use extreme caution.

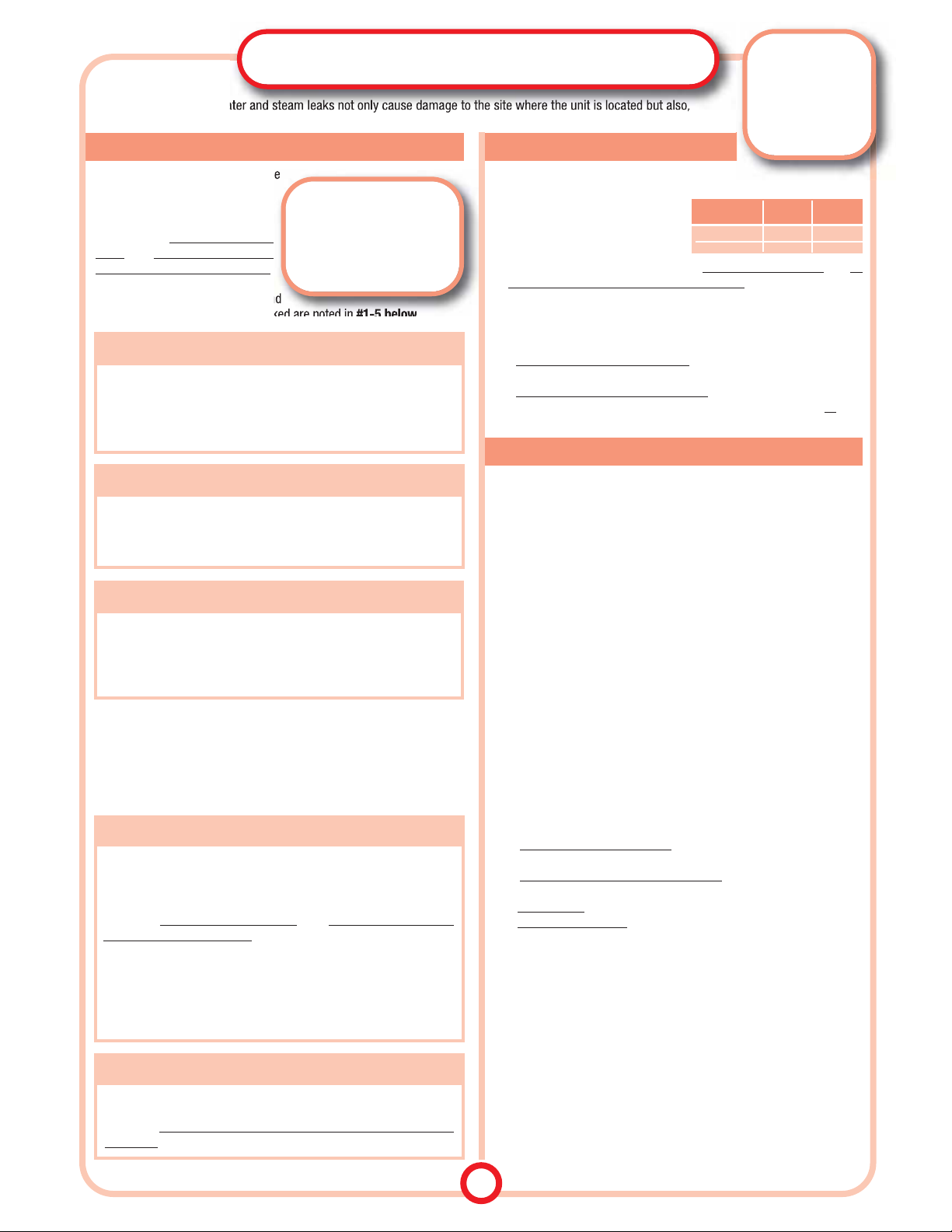

1. Refer to Table A, page 1, and in a

measuring cup, fill it with the amount

of water indicated in the chart for the

corresponding model, then pour the

measured water into the Chamber.

2. Bypass the FILL setting to manually

run sterilizer in STE mode at 273˚F for 30 minutes for M units

and 15

minutes for MK & Valueklave 1730 MKV units. After 30 minutes (or 15

minutes), shut off power , but leave MPV in STE mode until chamber pressure is reduced to 0 PSI and chamber has cooled (approx. 15 minutes).

3. Open Chamber Door, siphon water back into the measuring cup, and

measure the amount of water remaining in the chamber.

- If remaining water is less than 50%

of the original volume and no other

leaks were detected, replace Air Jet Valve.

- If remaining water is greater than 50%

and the pressure did not reach

28 psi within the nominal times (see TABLE D, above), and no

fault

was found within the heating system, then replace the Air Jet Valve.

REMOVING OBSTRUCTIONS

TABLE D

NOMINAL TIMES FOR REACHING 28 PSI

Time from Time from

Model Hot Start Cold Start

M Series 19 min. 24 min.

MK Series & MKV 6 min. 9 min.

Loading...

Loading...