Page 1

Operation and

Maintenance Manual

Electronic Table-Top Autoclaves

Models EZ9Plus & EZ11Plus

Cat. No. MAN205-0443001EN Rev U

Manufactured by:

Tuttnauer Co. Ltd., Har Tuv Industrial zone B P.O.Box 170, Beit Shemesh

99000, IsraelTel: 972 2 9904611, Fax: 972 2 9904730

Tuttnauer U.S.A. Co, Ltd. 25 Power Drive Hauppauge, NY, 11788, USA.

Tel (631) 737 4850, (800) 624 5836, Fax: (631) 737 0720

Page 2

http://www.tuttnauerusa.com/

Page 3

Page 1

TABLE OF CONTENTS

PARAGRAPH PAGE NO.

1. GENERAL...................................................................................................................................5

1.1 INCOMING INSPECTION.......................................................................................................... 5

1.2 WARRANTY................................................................................................ ............................ 5

1.3 WARRANTY STATEMENT ................................................................................................ ....... 6

2. SAFETY INSTRUCTIONS..............................................................................................................7

3. GENERAL INFORMATION ..........................................................................................................8

3.1. INTRODUCTION .......................................................................................................................... 8

3.2. OPERATING CONDITIONS ................................................................ ........................................... 10

3.3. SPECIFICATIONS........................................................................................................................ 10

3.4. ELECTRICAL DATA ................................................................ ..................................................... 14

3.5. ENVIRONMENTAL EMISSION INFORMATION ................................................................................... 14

3.6. CONSTRUCTION................................................................ ........................................................ 14

3.7. SYMBOL DESCRIPTION ............................................................................................................... 15

3.8. WATER QUALITY ...................................................................................................................... 15

3.9. DIRECTIVES AND STANDARDS ................................................................ ...................................... 16

3.9.1. Technical Directives........................................................................................................ 16

3.9.2. Technical Standards ....................................................................................................... 16

4. CONTROL PANEL .....................................................................................................................21

4.1. DESCRIPTION AND FUNCTIONS OF THE FRONT PANEL....................................................................... 22

4.1.1. Visual Information Center.............................................................................................. 22

4.1.2. The Control Center ......................................................................................................... 22

4.1.3. Data Center ....................................................................................................................23

4.2. DISPLAYED ERROR MESSAGES / SYMBOLS ................................................................ ..................... 24

4.3. DISPLAYED OPERATIONAL MESSAGES / SYMBOLS ............................................................................. 25

5. EZVIEW SCREENS ....................................................................................................................26

5.1. SCREENS SHOWING A SUCCESSFULLY COMPLETED CYCLE.................................................................... 26

5.2. SCREENS SHOWING ABORTED CYCLES AFTER A COMPLETED STERILIZATION STAGE ................................. 27

5.2.1. Canceled by user AFTER complete sterilization stage ................................................... 27

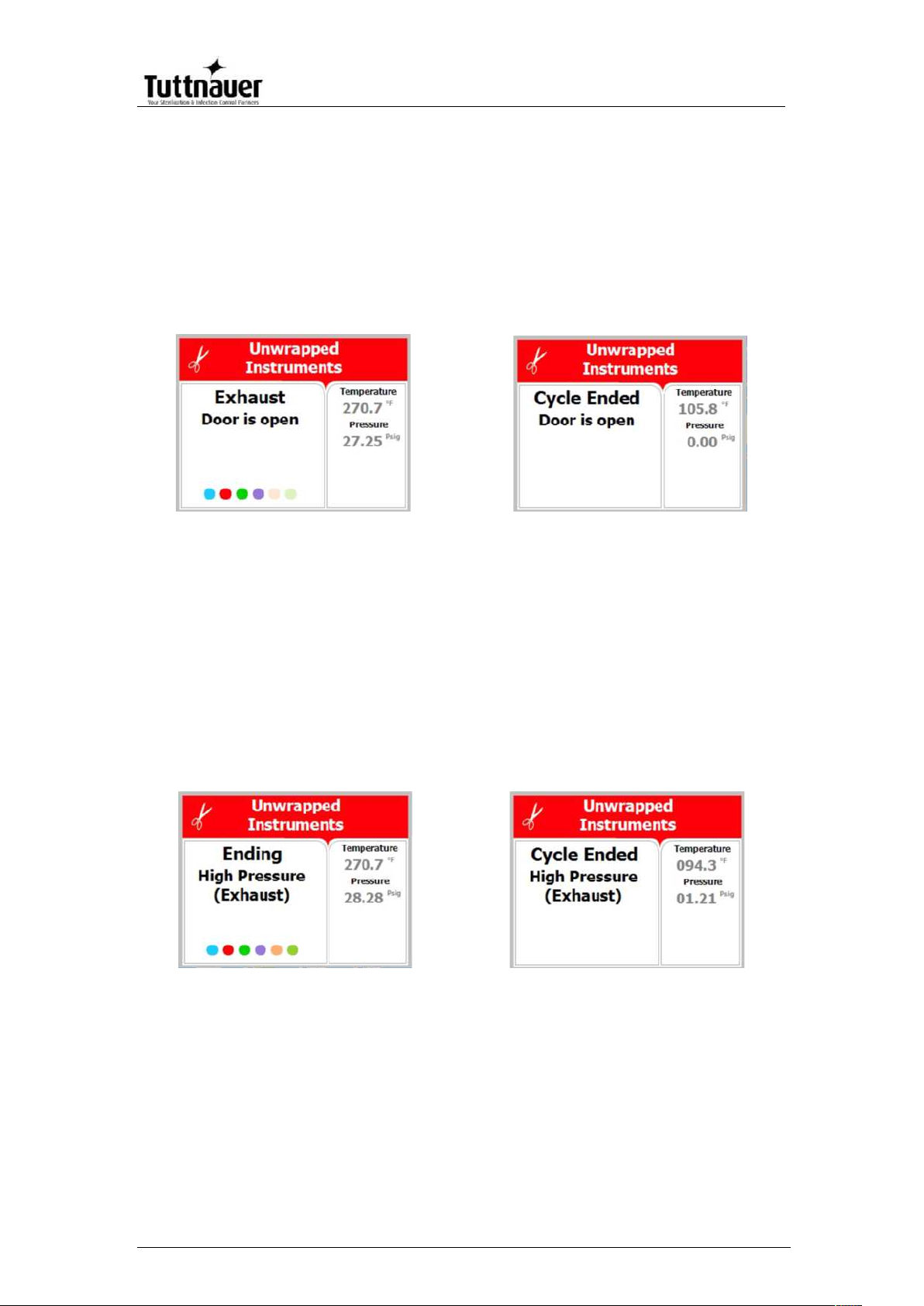

5.2.2. Door is open AFTER the sterilization stage has finished ............................................... 28

5.2.3. Screens showing a High Pressure Failure AFTER a completed sterilization stage .......28

5.3. SCREENS SHOWING A FAILED CYCLE: ............................................................................................. 29

5.3.1. Screens showing a failure because of a Heat Time Error ..............................................29

5.3.2. Failure due to Cancellation by user BEFORE completing the sterilization stage.......... 30

6. STERILIZATION PROGRAMS.....................................................................................................31

6.1. PROGRAM 1: UNWRAPPED INSTRUMENTS..................................................................................... 33

6.2. PROGRAM 2: WRAPPED INSTRUMENTS, POUCHES.......................................................................... 34

6.3. PROGRAM 3: UNWRAPPED DELICATE INSTRUMENTS................................ ....................................... 35

6.4. PROGRAM 4: HANDPIECES ................................................................ ......................................... 36

6.5. PROGRAM 5: CHAMBER BRITE CLEANING...................................................................................... 37

6.6. PROGRAM 6: CALIBRATION CYCLE ............................................................................................... 38

6.7. PROGRAM 7: EXTRA DRYING TIME .............................................................................................. 39

6.8. PROGRAM 7: CUSTOM A (MAY BE ALTERED BY THE USER)................................................................ . 40

6.9. PROGRAM 8: CUSTOM B (MAY BE ALTERED BY THE USER)................................ ................................. 41

7. CHECKING AND CHANGING PARAMETERS AND OTHER DATA .................................................42

7.1. QUICK OPTIONS DIRECTORY ................................................................................................ ....... 43

7.1.1. Add extra dry time .........................................................................................................43

7.1.2. Export to USB ................................................................................................................. 44

Page 4

Page 2

7.1.3. Print cycles...................................................................................................................... 46

7.1.4. Version information ....................................................................................................... 47

7.1.5. Start cycle by clock .........................................................................................................47

7.1.6. Set date and time ...........................................................................................................49

7.1.7. Login ............................................................................................................................... 50

7.1.8. Exit..................................................................................................................................52

7.2. MAIN MENU ................................................................ ........................................................... 52

7.2.1. Cycle Parameters for Custom A and B cycles ................................................................ 53

7.2.2. Modifying a parameter for the Custom A and B cycles ................................................ 54

7.2.3. System Parameters ........................................................................................................56

7.2.4. Maintenance .................................................................................................................. 59

7.2.4.1. Export Gain and Offset to USB .................................................................................. 60

7.2.4.2. Reset atmospheric pressure ...................................................................................... 61

7.2.4.3. Printer Test (for units with an optional printer) .......................................................61

7.2.4.4. Print All Gain and Offset (for units with an optional printer) ..................................63

7.3. TABLE OF PARAMETERS ................................................................ ............................................. 64

8. PRINTER.................................................................................................................................. 70

8.1. PRINTER OUTPUT (FOR UNITS WITH OPTIONAL PRINTER)................................................................... 70

8.2. PRINTER HANDLING (FOR UNITS WITH AN OPTIONAL PRINTER)........................................................... 73

8.2.1. Maintenance .................................................................................................................. 73

8.2.2. Installing printer paper .................................................................................................. 73

8.2.3. Notes on treatment of thermal papers: ........................................................................ 75

9. INSTALLATION INSTRUCTION .................................................................................................. 77

9.1. LIFTING AND CARRYING.............................................................................................................. 77

9.2. PLACING ................................................................................................................................. 77

9.3. ELECTRICAL ................................................................ ............................................................. 77

9.4. SETUP .................................................................................................................................... 78

9.5. FILLING THE MINERAL-FREE WATER RESERVOIR. ............................................................................ 78

10. PREPARATION BEFORE STERILIZATION ...................................................................................81

11. OPERATING INSTRUCTIONS..................................................................................................... 86

11.1. TURNING ON THE AUTOCLAVE ..................................................................................................... 86

11.2. PRE-HEATING (EZ11PLUS ONLY) ................................................................................................ 86

11.3. OPENING THE DOOR.................................................................................................................. 87

11.4. ADDING ADDITIONAL DRYING TIME................................................................ ............................... 88

11.5. LOADING ................................................................................................................................ 88

11.6. UNLOADING ................................................................ ............................................................ 92

11.7. STOPPING THE PROCESS MANUALLY.............................................................................................. 92

11.8. STOPPING THE PROCESS DUE TO CYCLE FAILURE............................................................................... 93

12. MAINTENANCE INSTRUCTIONS ...............................................................................................95

12.1. PREVENTIVE AND SCHEDULED MAINTENANCE ................................................................................ 95

12.1.1. Daily........................................................................................................................... 95

12.1.2. Weekly by the operator ............................................................................................ 95

12.1.3. Periodically ................................................................................................................ 99

12.2. DRAINING THE RESERVOIR........................................................................................................ 100

12.3. REPLACING THE DOOR GASKET.................................................................................................. 101

12.4. CHECKING THE SAFETY VALVE ................................................................................................ ... 104

12.5. CLEANING THE WATER OUTLET STRAINER................................ ..................................................... 105

12.6. WATER SENSOR CLEANING....................................................................................................... 106

12.7. REPLACING THE HEPA AIR FILTER ............................................................................................. 107

12.8. EMERGENCY DOOR OPENING..................................................................................................... 108

12.8.1. Relieve pressure from inside the chamber .............................................................109

12.8.2. Opening the door .................................................................................................... 110

Page 5

Page 3

13. TROUBLESHOOTING..............................................................................................................111

14. SPARE PARTS LIST ................................................................................................................. 117

15. ACCESSORIES ........................................................................................................................117

Page 6

Page 4

TABLE OF CONTENT (Cont.)

DRAWINGS PAGE NO.

FRONT VIEW – EZ9PLUS ........................................................................................ 17

REAR VIEW – EZ9PLUS ........................................................................................... 18

FRONT VIEW – EZ11PLUS ......................................................................................19

REAR VIEW – EZ11PLUS......................................................................................... 20

POUCH RACK AR910 ...........................................................................................117

TRAY HANDLE CMT240-0097............................................................................. 117

TRAY TRY254-0003............................................................................................... 118

TRAY HOLDER FOR EZ11PLUS TRH411-0021 ..............................................118

Page 7

Page 5

1. GENERAL

Read the Operating Instructions carefully, before beginning any

operation on the autoclave!

1.1 Incoming Inspection

Upon receiving your Tuttnauer Autoclave, carefully inspect the

outside of the shipping carton for signs of damage. If any damage

to the carton is found, note the location with respect to the

autoclave and check that area of the autoclave carefully once it is

fully unpacked. Observe packing method and retain packing

materials until the unit has been inspected. Mechanical inspection

involves checking for signs of physical damage such as:

scratched panel surfaces, broken knobs, etc.

If any damage is found, contact your dealer as soon as

possible so that they can file a claim with the shipping carrier

and also notify Tuttnauer.

All Tuttnauer products are carefully inspected prior to shipment

and all reasonable precautions are taken in preparing them for

shipment to assure safe arrival at their destination.

Note: Lifting and carrying should always be done by two people.

1.2 Warranty

Tuttnauer warrantees, from the date of purchase, all new EZPlus

autoclaves for a period of two full years, covering both parts and

labor.

This two year warranty covers defects in materials and

workmanship on every part in the autoclave except door gaskets

and HEPA filters (they are considered wear items).

Tuttnauer warrantees the chamber for a period of ten (10) years

against defects in materials and workmanship.

This warranty does not include installation or operator instruction

which are covered in this manual for your convenience or which

can be provided by your dealer.

This warranty does not apply to any instrument that has

been subjected to improper use or accident, nor shall it

extend to autoclaves that have been repaired or altered

outside the factory without prior authorization from

Tuttnauer.

The warranty also does not include routine cleaning or

preventive maintenance, to be performed according to

instructions in Sec. 12.1 (Preventive and Scheduled

Maintenance).

Page 8

Page 6

Tuttnauer’s obligation is limited to the repair or replacement of

parts for the autoclave.

No other warranties or obligations are expressed or implied.

The Autoclave should only be used in a manner described in

this manual!

1.3 Warranty Statement

To activate the warranty, the registration card must be completed

and mailed or faxed to Tuttnauer within fourteen (14) days of

purchase or you may call our customer service department at the

number listed below.

Products will only be received and accepted for repair from an

authorized dealer and only with prior return authorization from

Tuttnauer. All transportation charges to and from Tuttnauer must

be paid by the owner of the autoclave. Tuttnauer will not accept

COD shipments. If repairs are needed during the first 90 days

after purchase of this autoclave and a local authorized service

dealer is not available, Tuttnauer will arrange pick up of the unit at

Tuttnauer’s expense. This will be on an individually evaluated

basis and ONLY with pre-approval.

Note: If you have any questions or there are any difficulties with this

instrument and the solution is not covered in this manual, please

contact your dealer or Tuttnauer USA Co. Do not attempt to service

this instrument yourself.

Tuttnauer USA Co., Ltd., 25 Power Drive Hauppauge, NY 11788,

USA

: (800) 624 5836, (631) 737 4850, Fax: (631) 737 0720

e-mail:info@tuttnauerUSA.com.

Page 9

Page 7

2. SAFETY INSTRUCTIONS

The autoclave has unique characteristics. Please read and understand

the operation instructions before first operation of the autoclave. This

manual includes instructions and guidance provided by the

manufacturer: how to operate the autoclave, the door safety

mechanism, and the dangers involved in circumventing safety means,

how to ensure that the door is closed, and how to select a correct

sterilization program.

Make sure that you know where the main power switch is located.

Autoclave maintenance is crucial for the correct and efficient function of

the device.

Never use the autoclave to sterilize corrosive products, such as: acids,

bases and phenols, volatile compounds or solutions such as ethanol,

methanol, chloroform or radioactive substances. Below are the

operating instructions – safety instructions:

1. All autoclave users must receive training in proper usage from an

experienced employee. Every new employee must undergo a

training period under an experienced employee.

2. When sterilizing plastic materials, refer to the item manufacture

information and make sure that the item can withstand the

sterilization temperature. Plastic that melts in the chamber is liable

to cause a great deal of damage.

3. On closing the device door, make sure it is properly locked before

activating. Verify that the DOOR OPEN symbol is replaced by

“System Ready”.

4. When withdrawing trays, use the enclosed tray handle or wear

heat resistant gloves.

5. The door is electronically locked and will not open unless the

pressure in the chamber equals the atmospheric pressure

(chamber pressure is displayed on the screen).

6. The door also remains locked if there is a cycle failure or the unit

has no power.

7. Open the door slowly to allow steam to escape.

8. Once a month, ensure that the safety valve is operating, and once

every 5 years a certified inspector must perform a chamber

pressure safety test.

9. Make sure there are no leaks, breaks, blockages, whistles or

strange noises.

10. Perform maintenance operations as instructed. The owner of the

autoclave is responsible to perform the maintenance operations.

11. Notify the person in charge immediately of any deviation from the

proper function of the device.

12. Protective equipment and clothes and other safety instructions

should be implemented in accordance with local and national

regulations and/or rules!

Page 10

Page 8

3. GENERAL INFORMATION

3.1. Introduction

The EZPlus tabletop autoclave is designed for sterilization of

wrapped and unwrapped instruments, and related items found in

dental, medical, and veterinary clinics, first aid rooms, hospitals,

laboratories etc.

This autoclave is an electrically – heated sterilizer using steam

as the sterilizing agent. This unit uses steam flush pressure

pulse technology for removing air from the chamber. A

computerized control unit ensures a fully automatic sterilization

cycle, control and monitoring of physical parameters and a clear

documentation of the sterilization cycle.

The autoclave offers a choice of four automatic programs and

two custom programs designed to match the material to be

sterilized. In addition there is a dedicated cleaning program. The

autoclave is equipped with an Air Assisted Drying system. This

includes an air pump that during the drying stage draws air

through a HEPA filter (0.2µm) and circulates that air through the

heated chamber to remove moisture and facilitate the drying

operation. Drying is performed with the door closed.

On all models, a water pump is installed between the water

reservoir and the chamber. This pump guarantees fast and

accurate filling of the chamber every time. Entry of water may be

accompanied by a noise for approximately 30 seconds. This is

normal noise generated by the regular operation of the pump.

The EZPlus series features a digital absolute pressure display

for monitoring and control purposes. The pressure display

indicates if there is pressure in the chamber. The device is

capable of displaying the pressure in psia, psig, or in kPa

according to the operator’s requirements. When the pressure is

displayed in psig, the atmospheric pressure is shown (at sea

level) as 0 psig. If the pressure is defined in psia or kPa the

absolute zero is displayed as “0” and the atmospheric pressure

is shown (at sea level) as 14.7 psia or 100 kPa respectively.

Note: This unit comes from the factory with the pressure

parameter set to display in psig.

The EZPlus can display temperature in ºF or ºC.

Note: The unit comes from the factory set to display

temperature in ºF.

Page 11

Page 9

The control system is designed to meet the most current

sterilization standards to ensure efficacy, safety of personnel

and reliable operation. See sec. 3.9

A printer is an optional addition to the autoclave. The printer

prints the preset and actual parameters of the cycle

(temperature, time and pressure).

The EZPlus features built in memory to record up to 100

sterilization cycles. These can be reprinted on the optional

printer or exported to a USB device to be transferred to a PC.

The EZPlus has a built in Network Port for use with Tuttnauer’s

R.PC.R software when connected to your local network.

The R.PC.R software has been developed especially for the

Tuttnauer autoclaves.

This application will allow you to:

Monitor up to 8 autoclaves

Monitor the real time activity of any autoclave connected via

the network port.

Manage the history files of the cycles run on your autoclave.

The history files can be downloaded either directly through a

physical connection to the network port or transferred

manually using a USB device.

Store all the history of the processes that have been run on

your autoclave

Track the parameter setting that have been used in each of

the cycles and stages run.

Choose the style of the report to view; either graph, table, or a

print out

All reports can be saved as a PDF.

The graph style report offers the user an option to customize

the inputs and outputs used in the presentation.

For more information on the R.PC.R refer to the R.PC.R user

guide.

This manual is intended for the user and gives the user a

general understanding of the instrument and the best ways to

operate and take care of it in order to obtain effective results.

Before operating this autoclave read carefully this operation

manual. After reading this manual, operating the autoclave will

be easy. However since this instrument is built with high

technology sensitive components, no attempt should be made

by the user or any other unauthorized person to repair or

recalibrate it.

Page 12

Page 10

Only technical personnel, of an authorized Tuttnauer dealer,

having proper qualifications and holding technical

documentation (including a technician manual) and

adequate information are authorized to service the

apparatus.

3.2. Operating Conditions

This device is for indoor use only!

The minimum counter depth for the EZ9Plus and EZ11Plus is 22

inches.

Counter tops or slide-outs need to have a minimum capacity of

175 pounds for the EZ9Plus and 190 pounds for the EZ11Plus.

The sterilizer should be loaded only with autoclavable material!

Minimum room ventilation shall be 10 cycles per hour.

The environment shall not exceed an ambient temperature range

of from 41ºF (5ºC) to 104ºF (40ºC) and a relative humidity of

85%.

The operational altitude shall not be over 6562 feet (2000

meters) (ambient pressure shall not be lower than 11.6 psia (80

kPa)).

Operate the autoclave only in the manner specified in the

manual. If the equipment is used in a manner not specified by

the manufacturer, the protection provided by the equipment may

be impaired.

CAUTION!

Waste water should be brought into the public net in

accordance with the local rules or requirements

ONLY NON-HAZARDOUS LIQUIDS SHALL BE DISPOSED IN

PUBLIC SEWAGE!

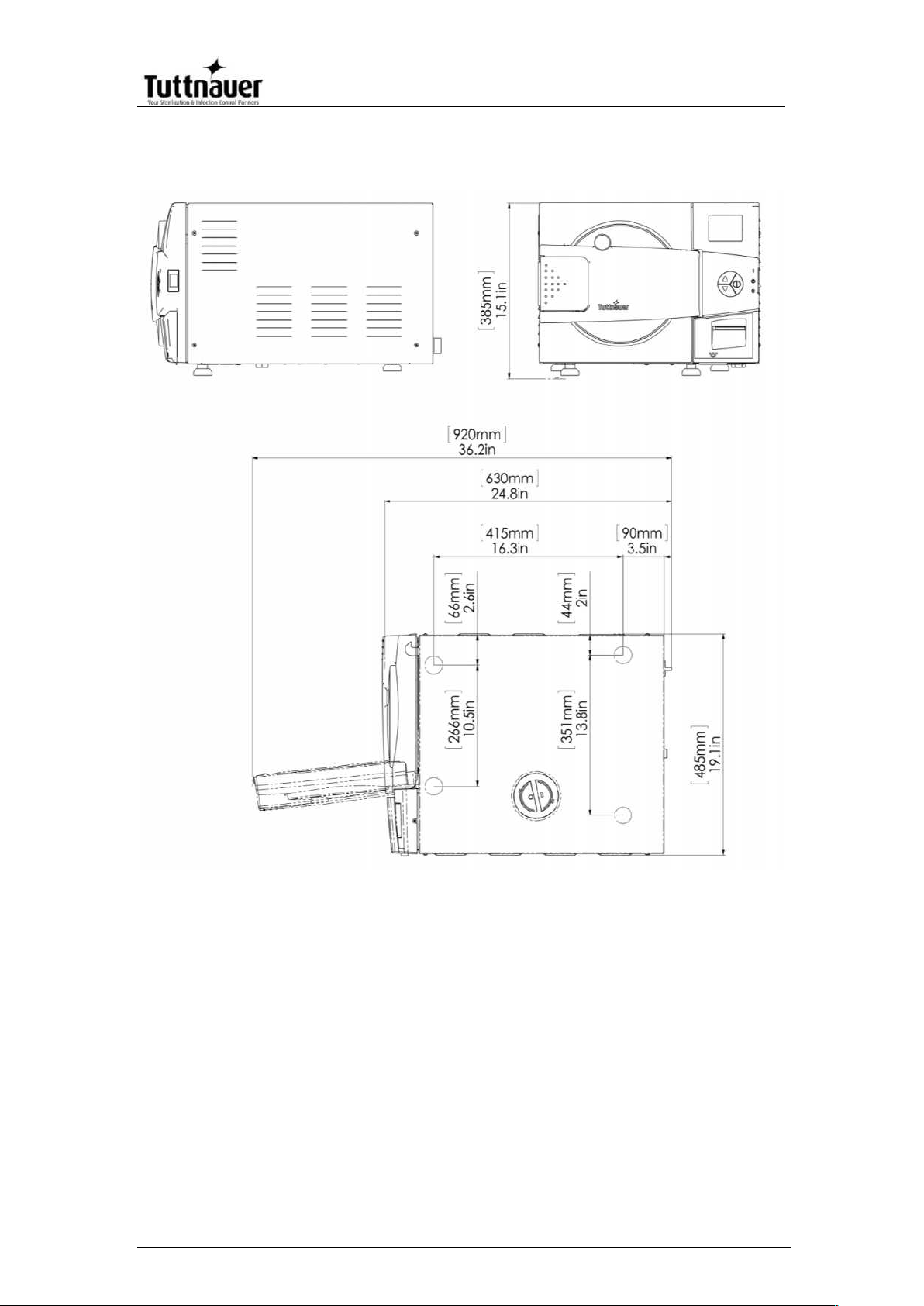

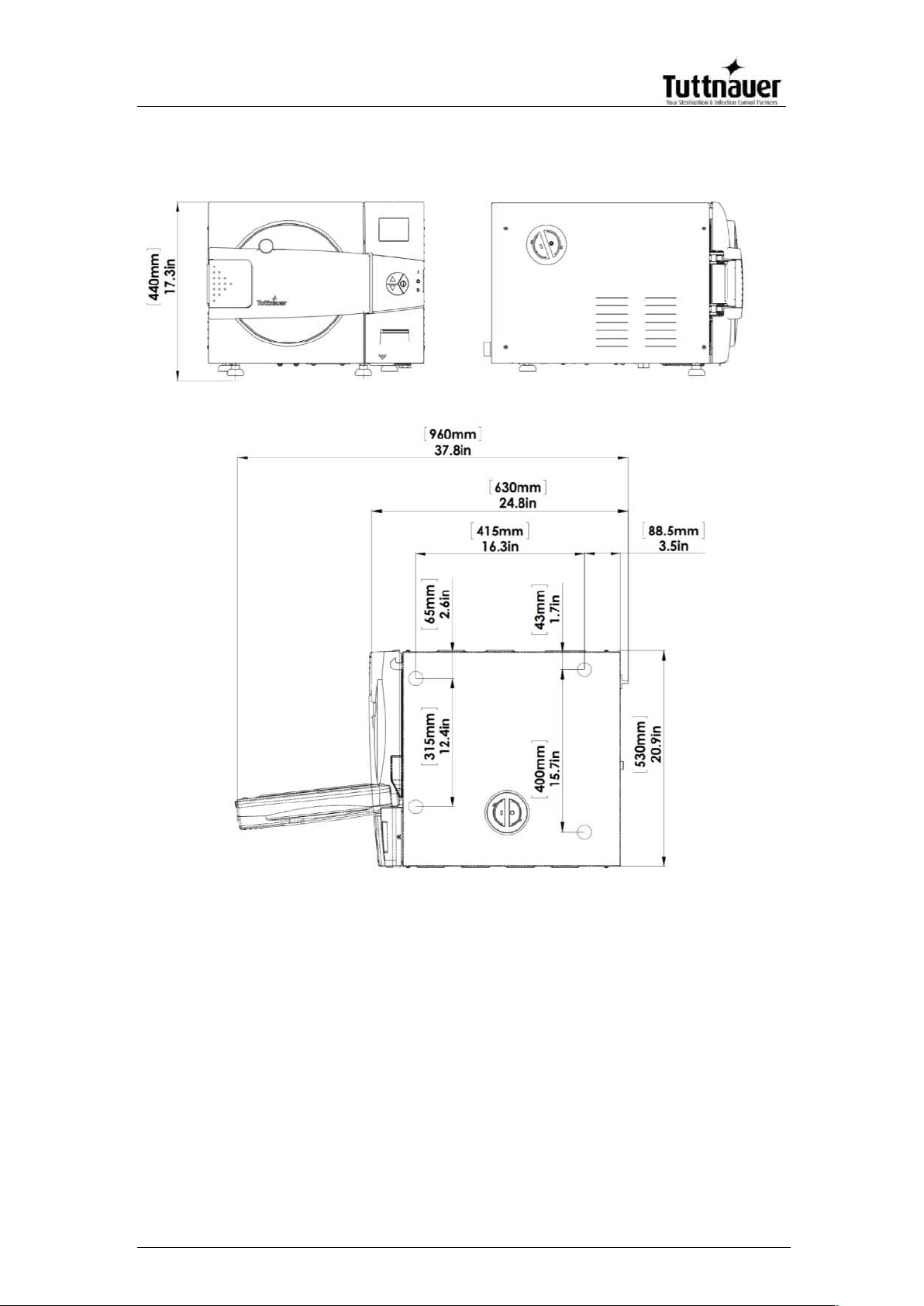

3.3. Specifications

Property

Value

9"

11"

Chamber

Dia.

9” (230 mm)

11” (280 mm)

Depth

19.8” (504

mm)

19.8” (504 mm)

Chamber volume

5.2 gal (19.8 lit)

7.5 gal. (28.5 lit)

External

dimensions

Width

19.1”(485 mm )

20.9” (530 mm)

Height

15.1” (384 mm)

17.3” (440 mm)

Depth

24.8” (630 mm)

24.8”(630 mm)

Maximum

dimensions (door

open)

36.2”(920 mm)

37.8”(960 mm)

Page 13

Page 11

Property

Value

9"

11"

Distance

between

supporting legs

Between

front and

rear legs

16.3” (415 mm)

16.3” (415 mm)

Front legs

10.5” (266 mm)

12.4” (315 mm)

Rear legs

13.8” (351 mm)

15.7” (400 mm)

Weight

94 lbs. (43 kg)

110 lbs. (50 kg)

Weight w/max solid load and full

reservoir

114.6 lbs. (52 kg)

136 lbs. (62 kg)

Shipping weight

106 lbs. (48 kg)

126lbs. (57 kg)

Weight per support area (max.

load)

Counter tops or slide-outs need to have a

minimum capacity of 175 pounds for the

EZ9Plus and 190 pounds for the EZ11Plus.

Minimum counter depth

22 inches

22 inches

Shipping

dimensions

Width

25” (63.5cm)

25.5” (64.7 cm)

Height

19” (48cm)

22” (55cm)

Depth

29” (75 cm)

29” (75 cm)

Volume

7.97 ft3 (0.23 m3)

9.4 ft3 (0.267 m3)

Mineral-free

water reservoir

Max. water

volume

1.375 US gal (5.2 lit.)

Min. water

volume

0.4 US gal (1.5 lit.)

Maximum solid load per item

1.1 lbs. (0.5 kg)

1.1 lbs. (0.5 kg)

Maximum solid load per tray

3.0 lbs (1.4 kg)

3.0 lbs (1.4 kg)

Maximum solid load

9.0 lbs (4.1 kg)

15 lbs (6.8 kg)

Maximum textile load

1.5lbs (0.7kg)

1.7lbs (0.8)

Tray dimensions

W

6.7” (169 mm)

6.7” (169 mm)

H

0.6” (16 mm)

0.6” (16 mm)

D

16.3” (413 mm)

16.3” (413mm)

Max. Allowable Working

pressure (MAWP)

40 psi (2.8 bar)

No. of trays

3

5

Cassette capacity based on

8”x11” and 8”x 5.5”

Miltex Thompson cassettes

2 full & 2 half

Loaded horizontally

4 full & 4 half

Loaded vertically

Page 14

Page 12

Overall Dimensions – EZ9Plus

Page 15

Page 13

Overall Dimensions – EZ11Plus

Page 16

Page 14

3.4. Electrical Data

Model

Specifications

9"

11"

EZ

EZ

Total Power

1400W

1400W

Voltage

120VAC ±5%, 60Hz / 1

ph*

120VAC ±5%,

60Hz / 1 ph*

Amperage

12A

12A

Recommended circuit breaker

15A

15A

Protection against electrical shock

Class I (IEC 60601-1) (GFCI)

Mains supply fluctuation

+/- 5%

Degree of protection by enclosure

IP31

Electrical Circuit

Dedicated electrical circuit

* According to the local network.

Note:

In order to avoid any injury by electrical hazard, it is mandatory

that a ground fault protection device (GFCI) be installed in the

electrical panel feeding the autoclave (local codes may make

this mandatory).

Attention:

The electrical net must be protected with a current leakage

safety relay (GFCI).

The electrical network must comply with local rules or

regulations.

Verify that there is an easy access to the main power switch

and to the current leakage safety relay (GFCI).

Surge protection is recommended in areas that experience

large voltage or ground fluctuations.

It is recommended that the autoclave be installed on a

dedicated line.

3.5. Environmental Emission Information

1. The peak sound level generated by the autoclave is 65dBa

with background noise of 48 dBa.

2. The total heat per hour transmitted by the autoclave is

<200Wh.

3.6. Construction

The main parts of the autoclave are made of materials as

indicated below:

Chamber is built of stainless steel 316 L.

Door is made of stainless steel 304.

Trays are made of stainless steel 304.

Page 17

Page 15

Water reservoir is made of polyethylene.

Door handle and door cover are made of hard plastic

material, which is safe to touch and thermo-insulated.

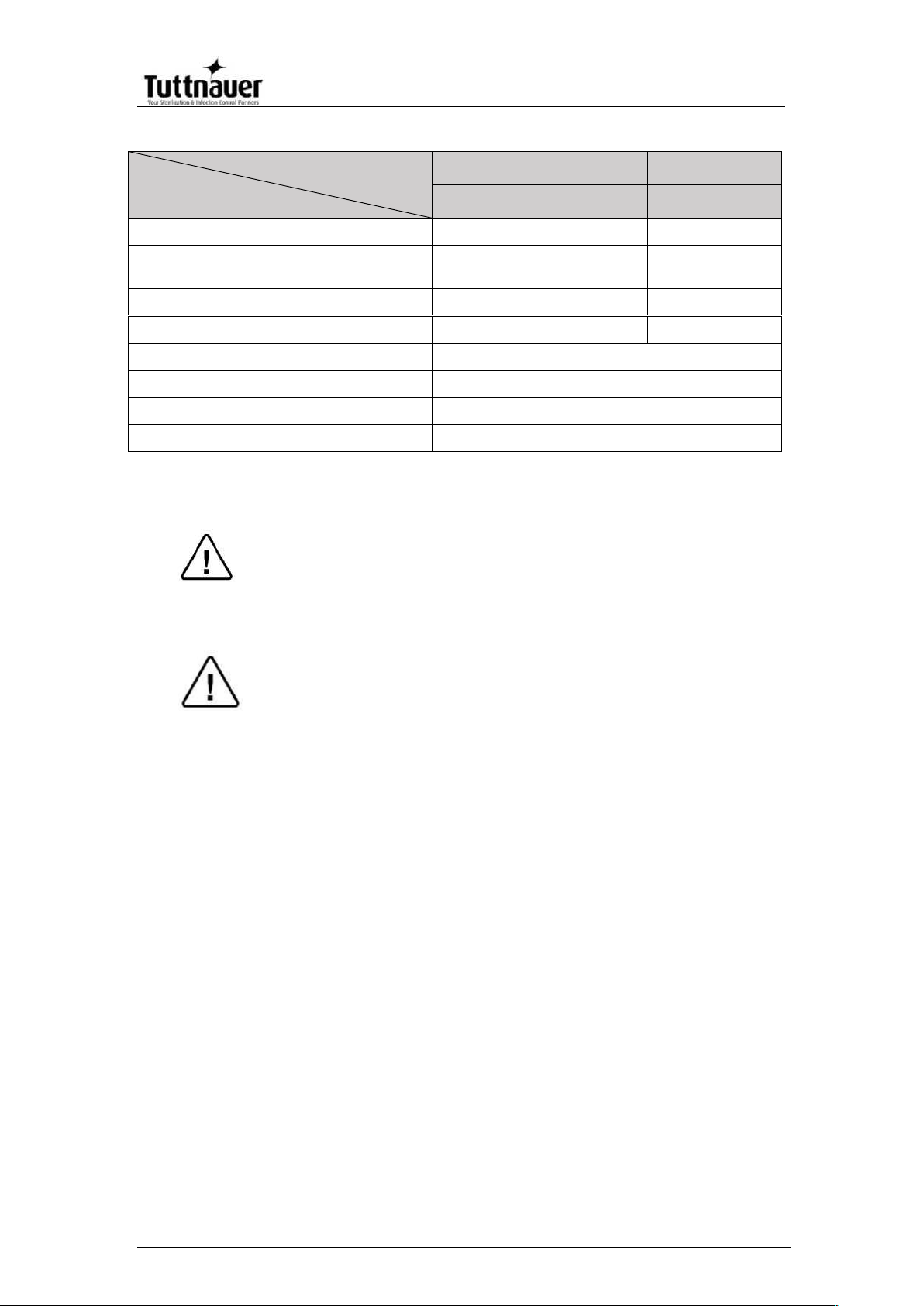

3.7. Symbol Description

3.8. Water Quality

Physical characteristics and contaminants levels

The distilled or mineral – free water supplied to the autoclave

should have the physical characteristics and maximum

acceptable level of contaminants indicated in the table below:

Physical Characteristics and Maximum acceptable

contaminants levels in steam for sterilizers

(According to EN 13060:2004).

Element

Condensate – allowable

content

Silicon dioxide SiO2

≤0.1 mg/kg

Iron

≤0.1 mg/kg

Cadmium

≤0.005 mg/kg

Lead

≤ 0.05 mg/kg

All other metals except iron,

cadmium, lead

≤0.1 mg/kg

Chloride (Cl)

≤0.1 mg/kg

Phosphate (P2O5)

≤0.1 mg/kg

Conductivity (at 20°C)

≤3

μs/cm

pH value (degree of acidity)

5 to 7

Appearance

Colorless clean without

sediment

Hardness (Σ Ions of alkaline

earth)

≤0.02 mmol/l

Caution! Consult accompanying documents

Caution! Hot surface.

Caution! Hot steam.

Protective earth (Ground)

Page 18

Page 16

Compliance with the above data should be verified by

testing in accordance with acknowledged analytical

methods, by an authorized laboratory.

Attention:

We recommend testing the water quality once a month. The

use of water for autoclaves that does not comply with the

table above may have severe impact on the working life of

the sterilizer and can invalidate the manufacturer’s

guarantee.

3.9. Directives and Standards

Every autoclave meets the provisions of the following Directives

and is in compliance with the following Standards:

3.9.1. Technical Directives

Medical Device Directive 93/42/EEC

Pressure Equipment Directive 97/23/EEC

3.9.2. Technical Standards

USA Standards:

ANSI/AAMI ST55:2010

ASME Sec. VIII. Div 1

UL 61010-1

UL 61010-2-040

FDA 510(K) Cleared

ISO 17665-1:2006

The Quality System complies with ISO 13485:2003

and ISO 9001:2008

Canada Standards: CMDR

Page 19

Page 17

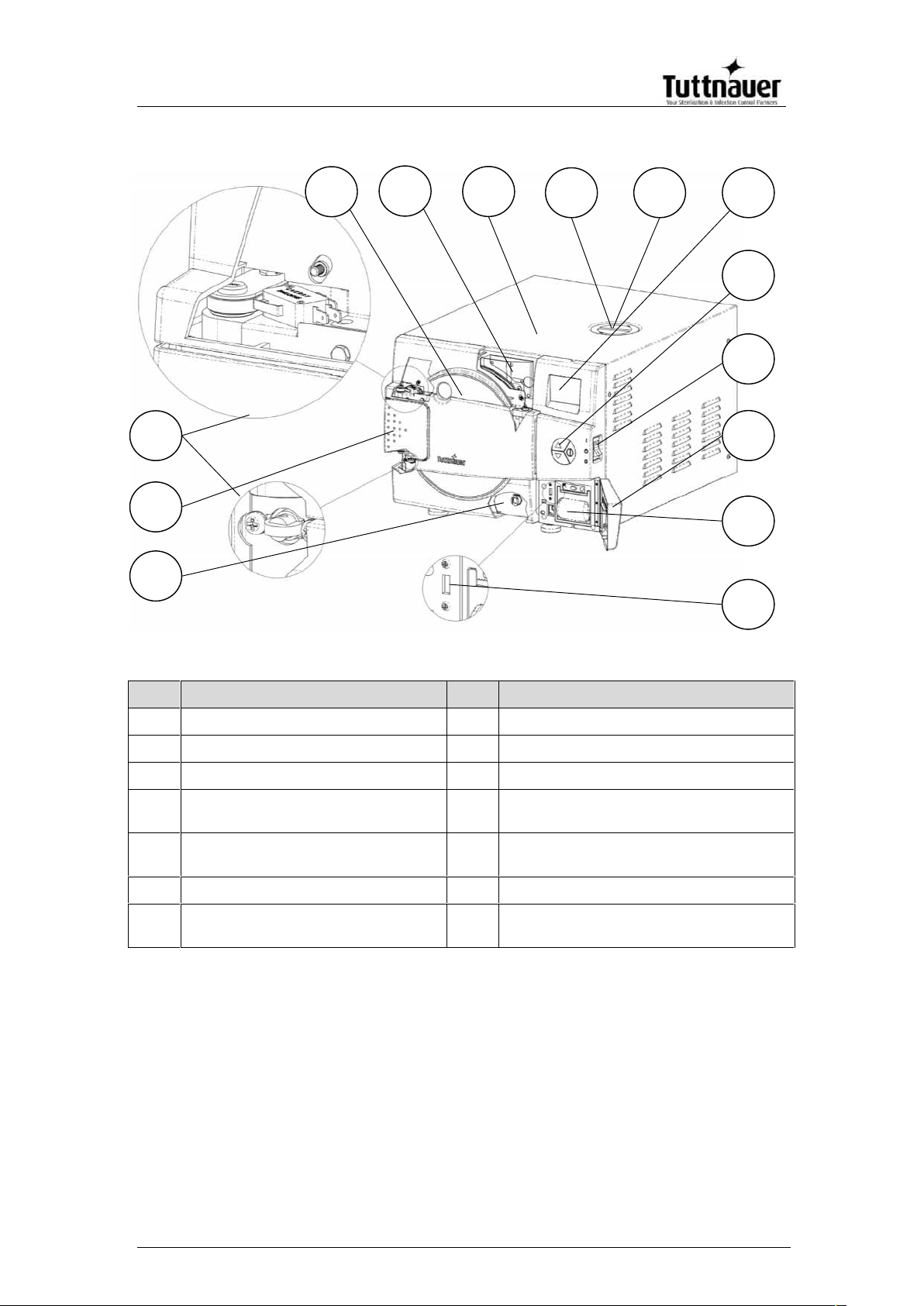

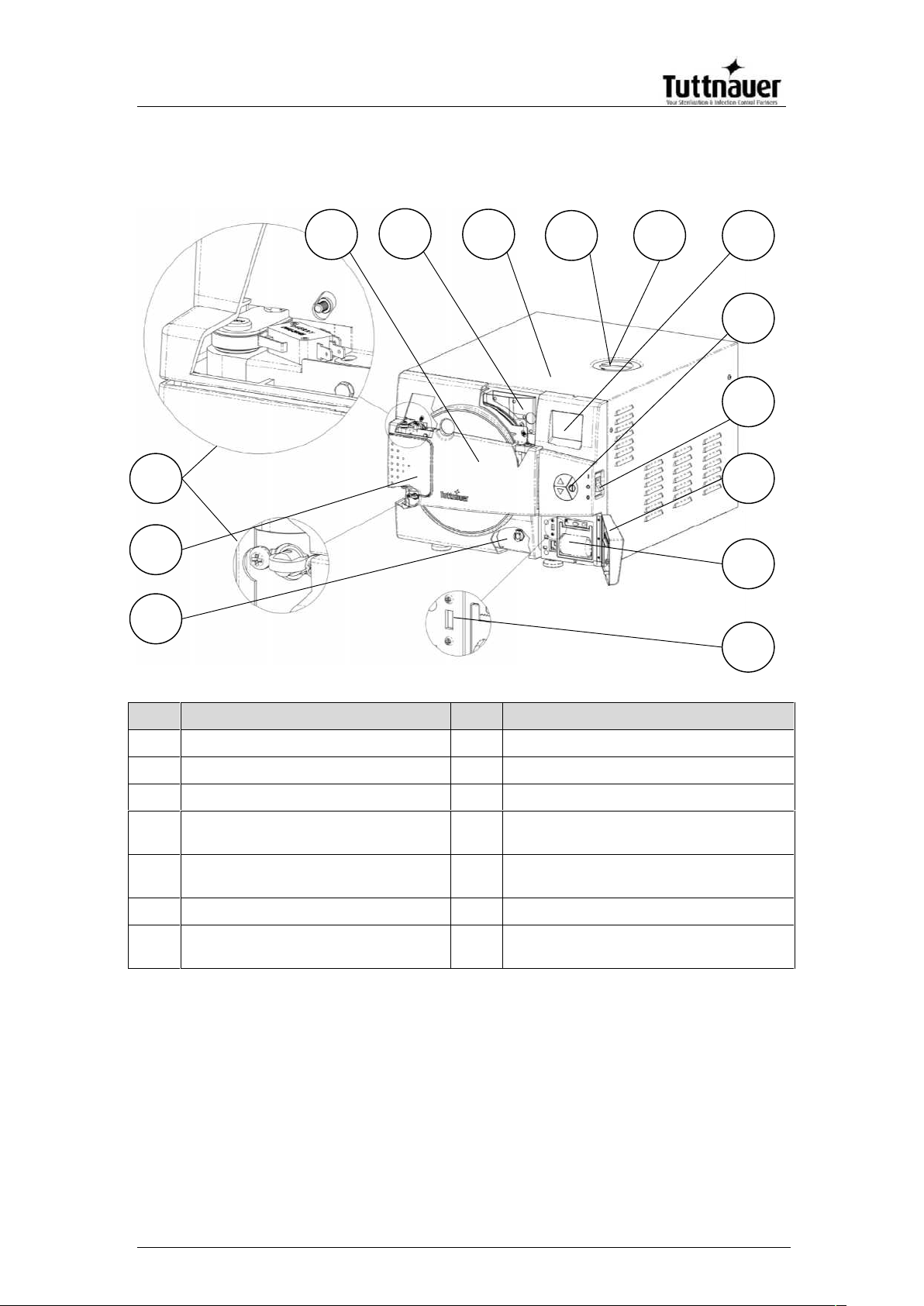

FRONT VIEW – EZ9Plus

No.

Description

No.

Description

1

Reservoir drain

8

Safety valve

2

Door opening grip

9

EZView display

3

Door micro-switches

10

EZPad keypad

4

Door cover

11

Autoclave On/Off switch & circuit

breaker

5

Water reservoir fill & level

gauge

12

Printer cover

6

Autoclave cover

13

Printer (optional)

7

Mineral-free water reservoir

cover

14

USB port

13

2

1

5

4

3

9

10

12

6

7

8

14

11

Page 20

Page 18

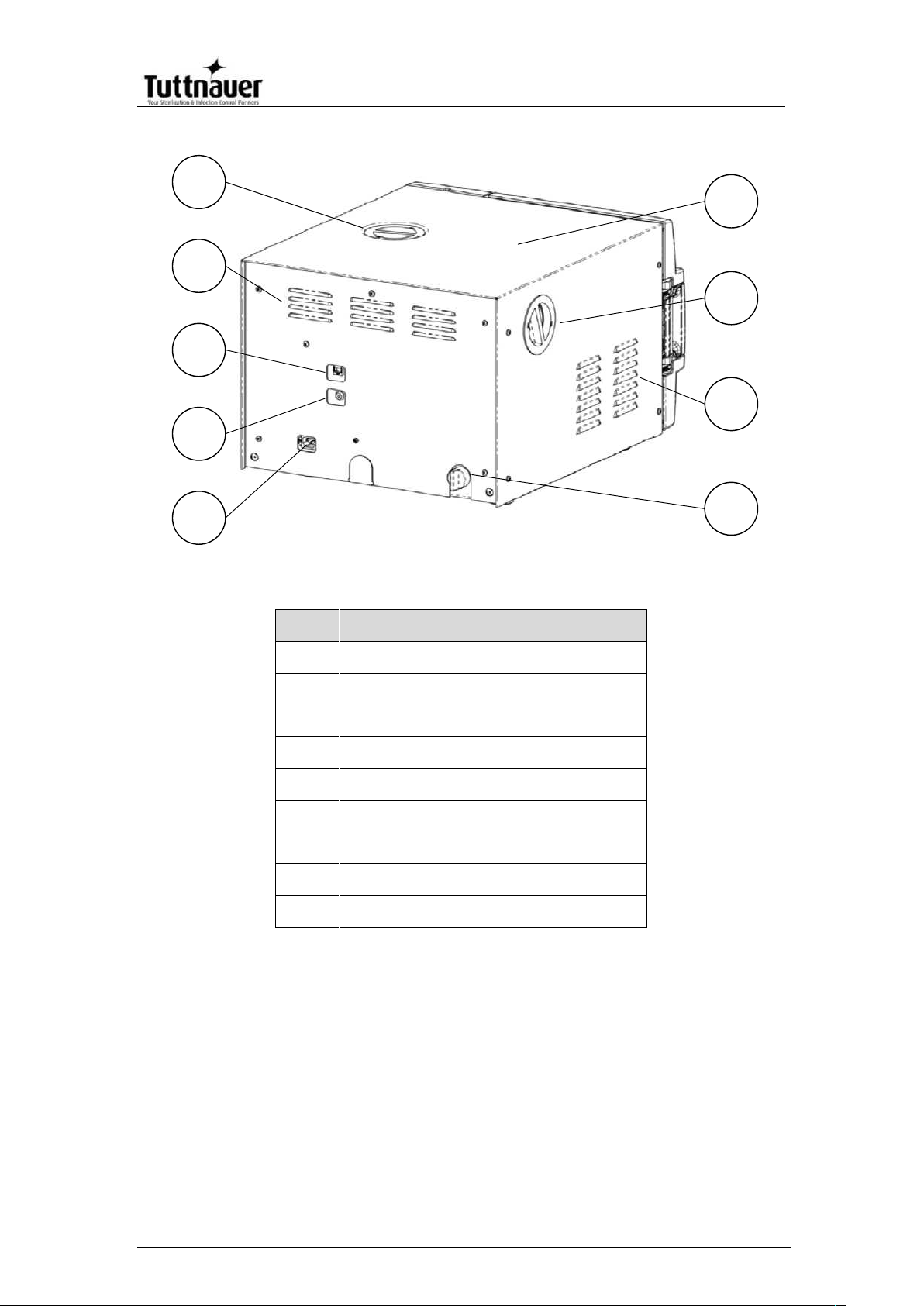

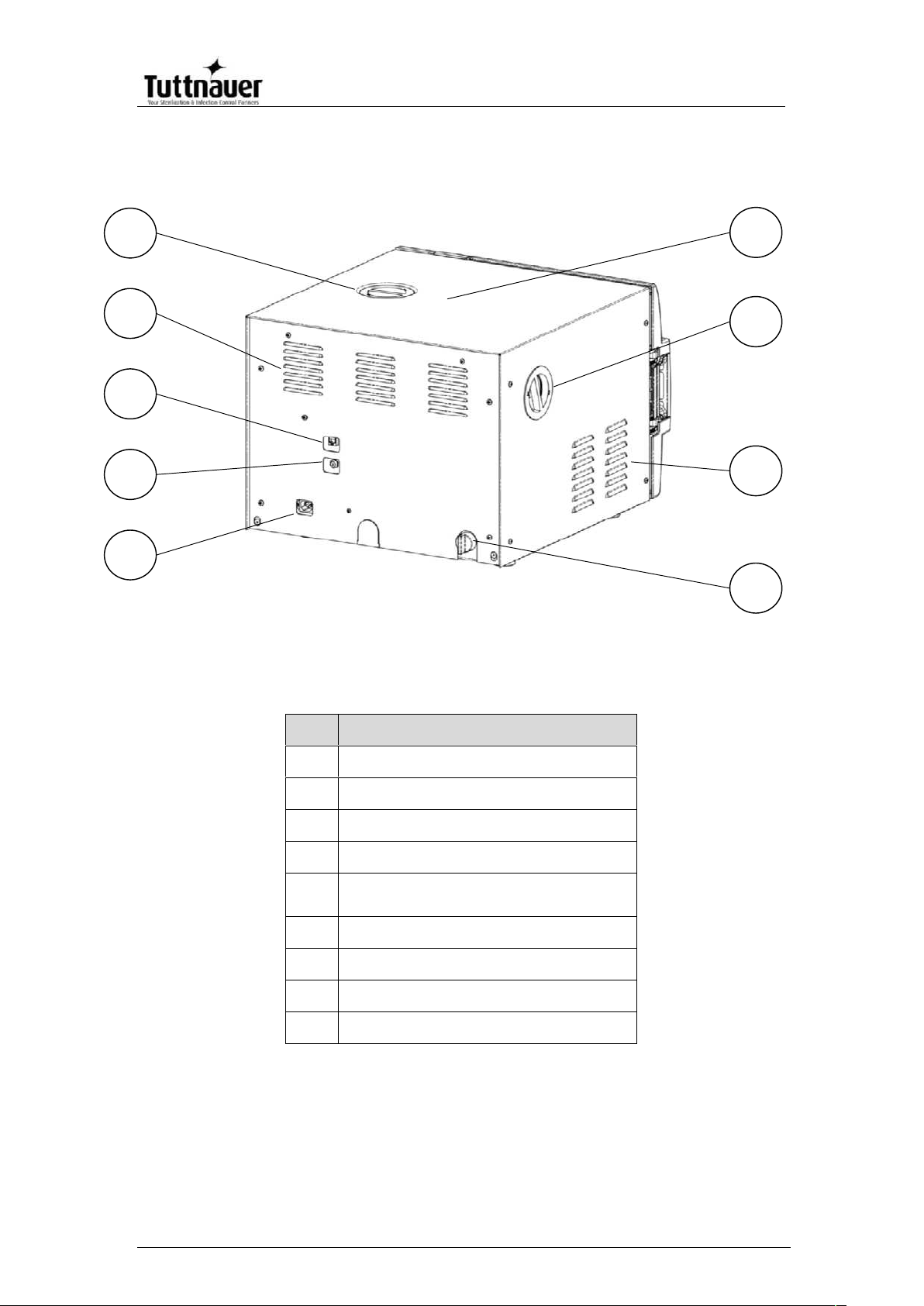

REAR VIEW – EZ9Plus

No.

Description

1

Main power electric cable socket

2

Cut-off thermostat

3

Network port

4

Ventilation grills

5

Mineral-free water reservoir cover

6

Autoclave cover

7

HEPA filter cover

8

Ventilation grills

9

Water outlet strainer

5

4

2

1

6

7

8

3

9

Page 21

Page 19

FRONT VIEW – EZ11Plus

No.

Description

No.

Description

1

Reservoir drain

8

Safety valve

2

Door opening grip

9

EZView display

3

Door microswitches

10

EZPad keypad

4

Door cover

11

Autoclave On/Off Switch &

circuit breaker

5

Water reservoir fill & level

gauge

12

Printer cover

6

Autoclave cover

13

Printer (optional)

7

Mineral-free water reservoir

cover

14

USB port

13

2

1

5

4

3

9

10

12

6

7

8

14

11

Page 22

Page 20

REAR VIEW – EZ11Plus

No.

Description

1

Main power electric cable socket

2

Cut-off thermostat

3

Network port

4

Ventilation grills

5

Mineral-free water reservoir

cover

6

Autoclave cover

7

HEPA filter cover

8

Ventilation grills

9

Water outlet strainer

6

5

4

7

2

1

9

3

8

Page 23

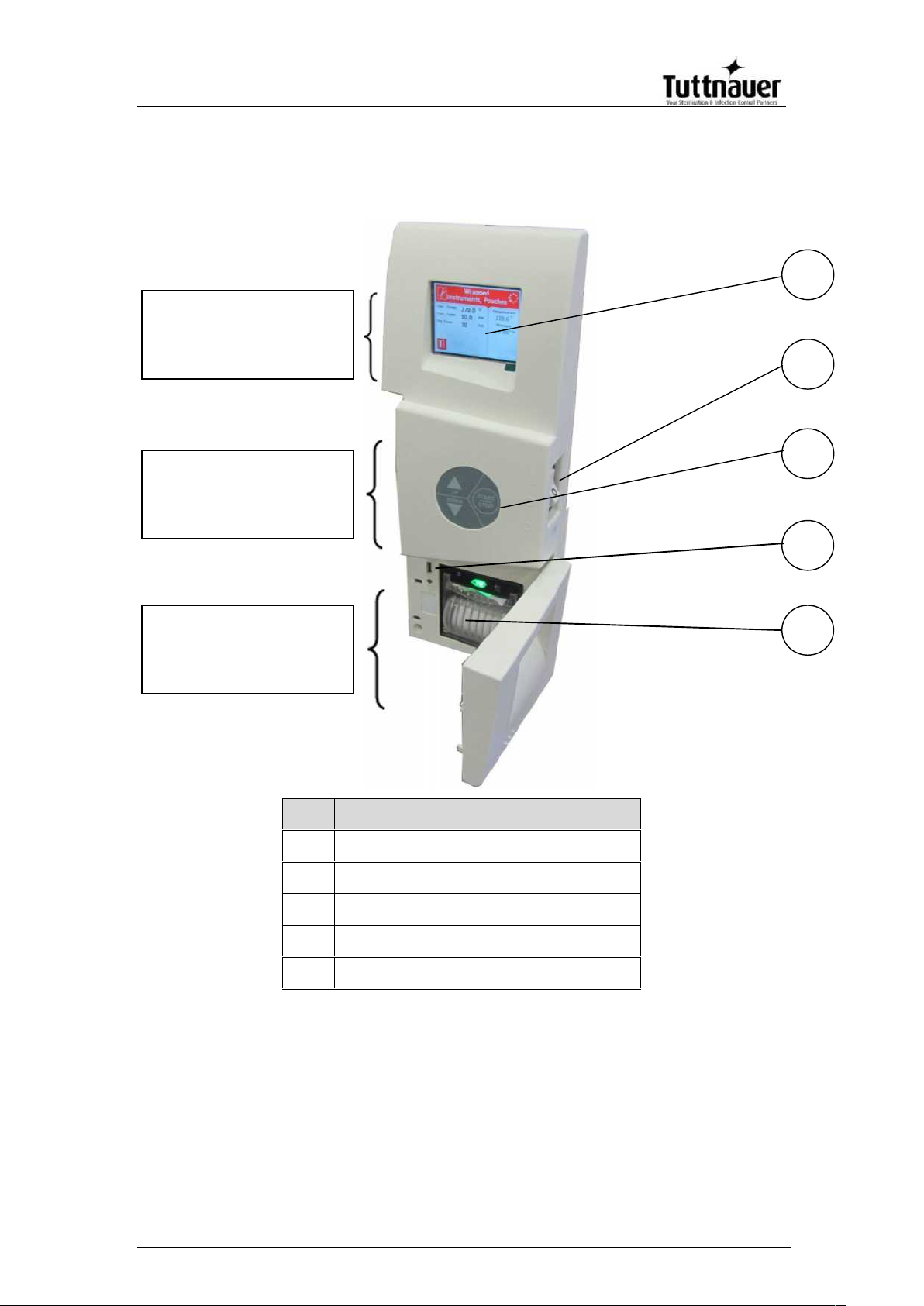

Page 21

4. CONTROL PANEL

No.

Description

1

EZView display

2

Main switch and circuit breaker

3

EZPad keypad

4

USB port

5

Printer (optional)

1

2

3

4

5

Visual Information

Center

Data Center

Control Center

Page 24

Page 22

4.1. Description and Functions of the Front Panel

The front panel is composed of 3 sections (see picture on

previous page):

1. Visual Information Center

2. Control Center.

3. Data Center

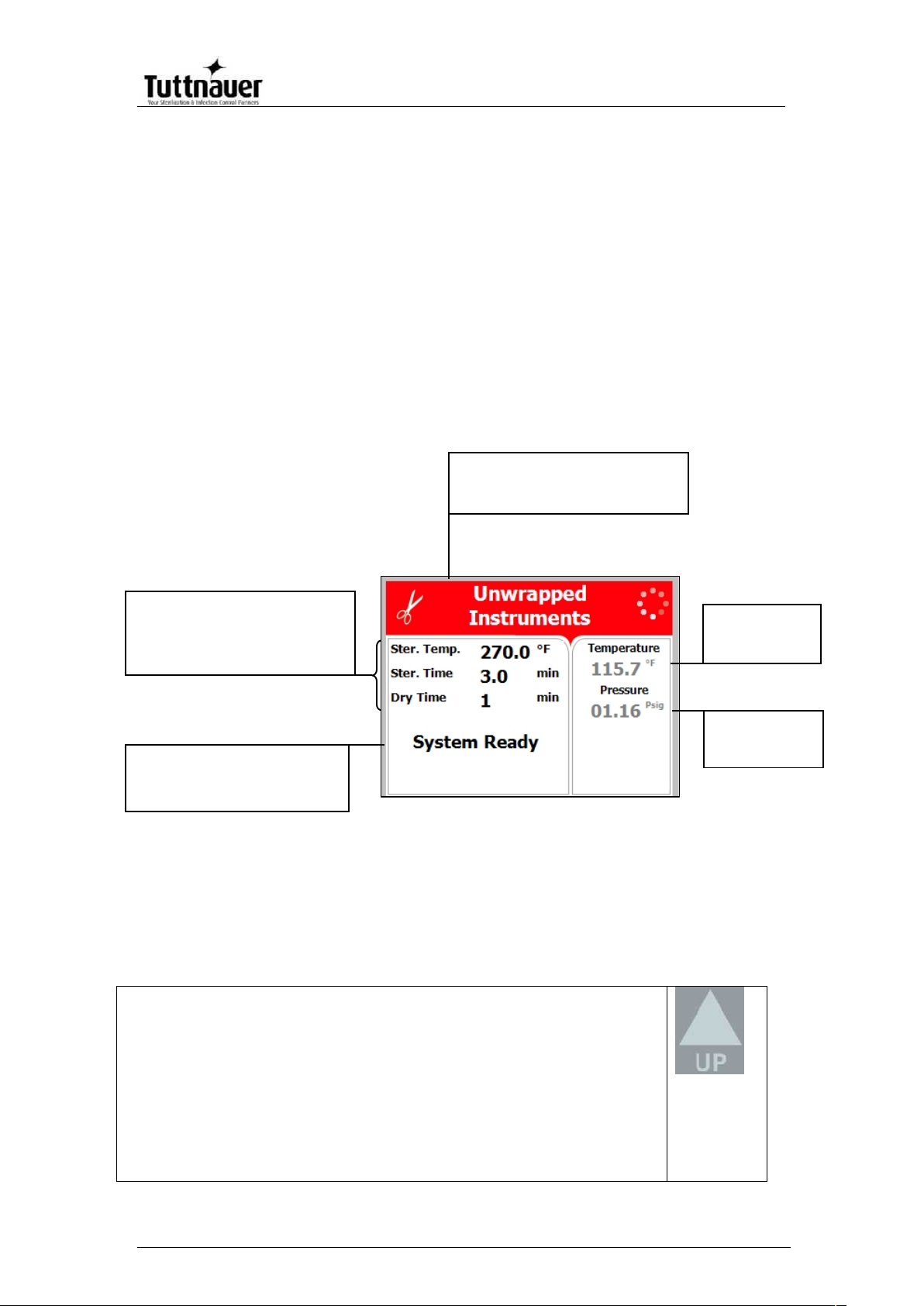

4.1.1. Visual Information Center

The information center contains the EZView display

which is an LCD panel used to display the current

status of the autoclave and any Operational Messages

or Error Messages.

4.1.2. The Control Center

The Control Center contains the ON/OFF switch/Circuit Breaker and the

EZPad keypad.

The keypad consists of 3 keys as described below:

UP key

This key has the following functions:

In the main screen:

o This key enables the operator to browse through the

cycles.

In the menu directories:

o When the cursor is blinking on a number, the UP ▲ key

increases its value.

o When the cursor is blinking on a menu selection, the UP

Program description:

Program icon and name

Chamber

temperature

Chamber

pressure

System status

Name of stage

Error and operational messages

Program Parameters:

Sterilization temperature

Sterilization time

Drying Time

Page 25

Page 23

▲ key allows browsing backward through the menu.

o When adjusting a parameter and the cursor is blinking on

SET or EXIT the UP ▲ key activates that procedure.

DOWN key

This key has the following functions:

In the main screen:

o This key enables the operator to browse through the

cycles.

In the menu directories:

o When the cursor is blinking on a number, the DOWN ▼

key decreases its value.

o When the cursor is blinking on a menu selection, the

DOWN ▼ key allows browsing forward through the menu.

o When adjusting a parameter and the cursor is blinking on

SET or EXIT the DOWN ▼ key activates that procedure.

START/STOP key

This key has the following functions:

In the main screen:

o Starts the process when the required program was

chosen.

o Stops the current process.

o Cancels the ERROR message displayed on the screen

and opens the electric door lock.

In the menu directories:

o When the cursor is blinking on a number, the

START/STOP key enables moving to the next position.

o When the cursor is blinking on a menu selection, the

START/STOP key activates that selection.

4.1.3. Data Center

The Data Center contains a USB port, a network port and an

optional printer.

The USB port can be used to upload or download

software and settings and download cycle history for

transferring to a PC for storage or printing.

The network port (located on the rear of the unit) can be

used to connect to a local network and download

information to Tuttnauer’s R.PC.R software.

The RPCR software has been developed especially for the

Tuttnauer autoclaves and is an excellent report generating tool.

This software will allow you to:

Monitor up to 8 autoclaves

Monitor the real time activity of any autoclave connected via

the network port.

Page 26

Page 24

Manage the history files of the cycles run on your autoclave.

The history files can be downloaded either directly through a

physical connection to the network port or transferred

manually using a USB device.

Store all the history of the processes that have been run on

your autoclave

Track the parameter settings that have been used in each of

the cycles and stages run.

Choose the style of the report to view; either graph, table, or a

print out

All reports can be saved as a PDF.

The graph style report offers the user an option to customize

the inputs and outputs used in the presentation.

For more information on the R.PC.R refer to the R.PC.R user

guide.

The printer is an optional device. It prints the detailed history of

each cycle performed by the autoclave. The printing is on

thermal paper with 24 characters per line and records the

sterilization cycle information for subsequent consideration.

4.2. Displayed Error Messages / Symbols

An error message is displayed when a failure occurs. The

failures are divided into two categories.

1. Failures that occur before completing the sterilization stage,

which in this case will leave the load unsterilized

2. Failures that occur after completing the sterilization stage,

which in this case will leave the load sterilized

For the list of Displayed Error Messages / Symbols

see sec. 13 Troubleshooting

Page 27

Page 25

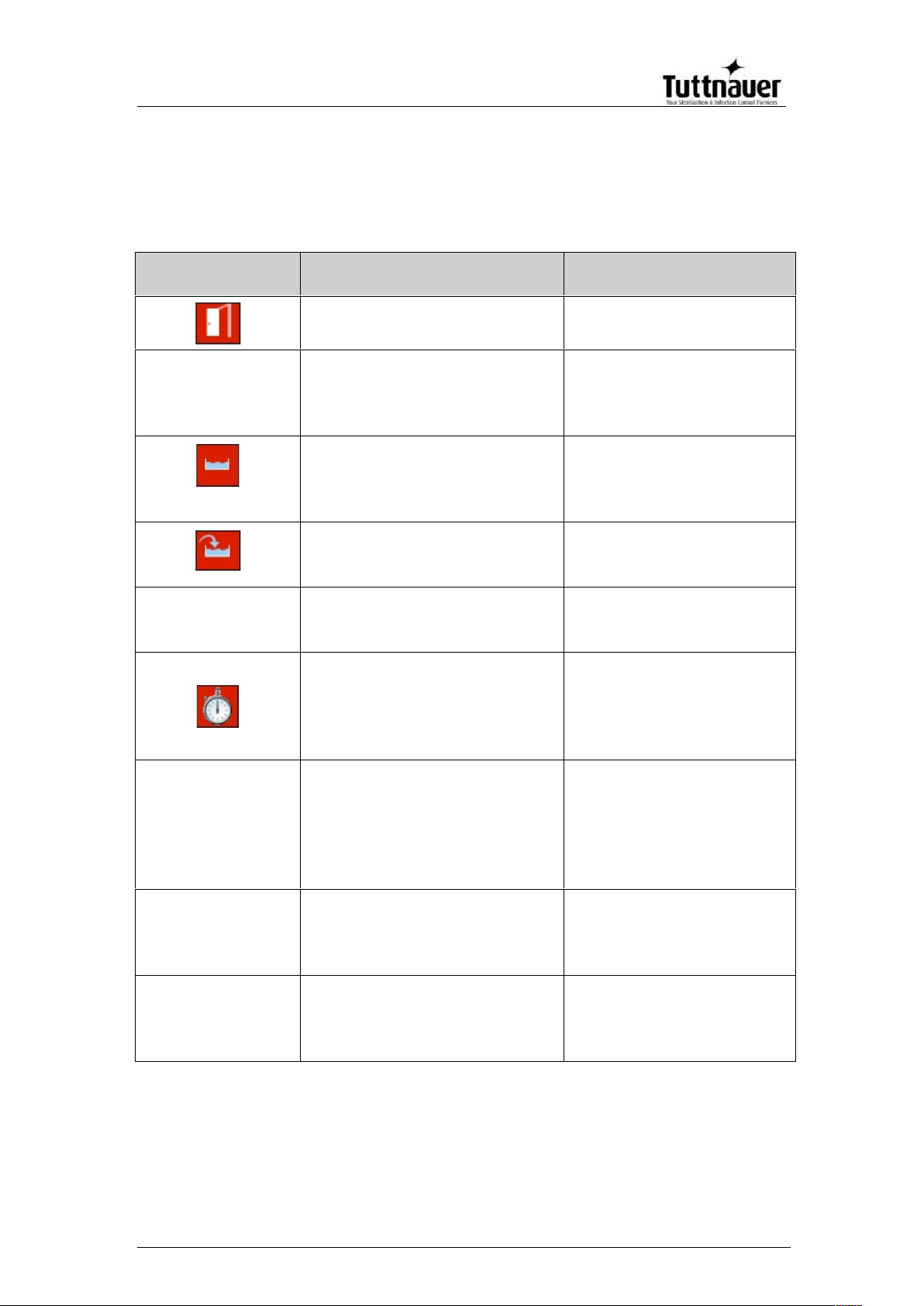

4.3. Displayed operational messages / symbols

Operational messages tell you the status of the machine before or after a

cycle.

Message /

Symbol Name

Message / Symbol

Description

Required Action

This symbol is displayed

when the door is open.

Close the door.

"Door is open"

This message is displayed in

stand-by when the door is

opened and the

START/STOP key is pressed.

Close the door to perform

a new cycle.

If the problem persists,

call the technician.

This message is displayed if

the electrode in the chamber

senses water.

DO NOT open the door,

water will spill out. Run a

new cycle to drain the

chamber.

This symbol is displayed

when there is no water in the

mineral-free water reservoir.

Pour water in the front

funnel until it reaches the

full level.

"Cycle Ended"

This message is displayed

when the cycle has ended

successfully.

Open the door. The

Instruments are ready to

be removed.

This symbol is displayed

when Cycle by Clock mode is

active.

Enter the Quick Options

menu as described in this

manual to change the

time or to cancel this

option.

"Start cycle by

clock is active”

This message is displayed if

the user presses

START/STOP key while the

"start cycle by clock" mode is

active. Starting another cycle

is not allowed.

Enter the Quick Options

menu as described in this

manual to change the

time or to cancel this

option.

"Atmospheric

pressure not set"

This message is displayed

when the ATM needs to be

set.

Opening the door for 2

minutes will allow the

Atmospheric pressure to

be set automatically.

"Please restart

machine in order

for changes to be

updated"

Changes to the system

software require that the

autoclave be restarted.

Restart the autoclave in

order for changes to be

updated.

Page 28

Page 26

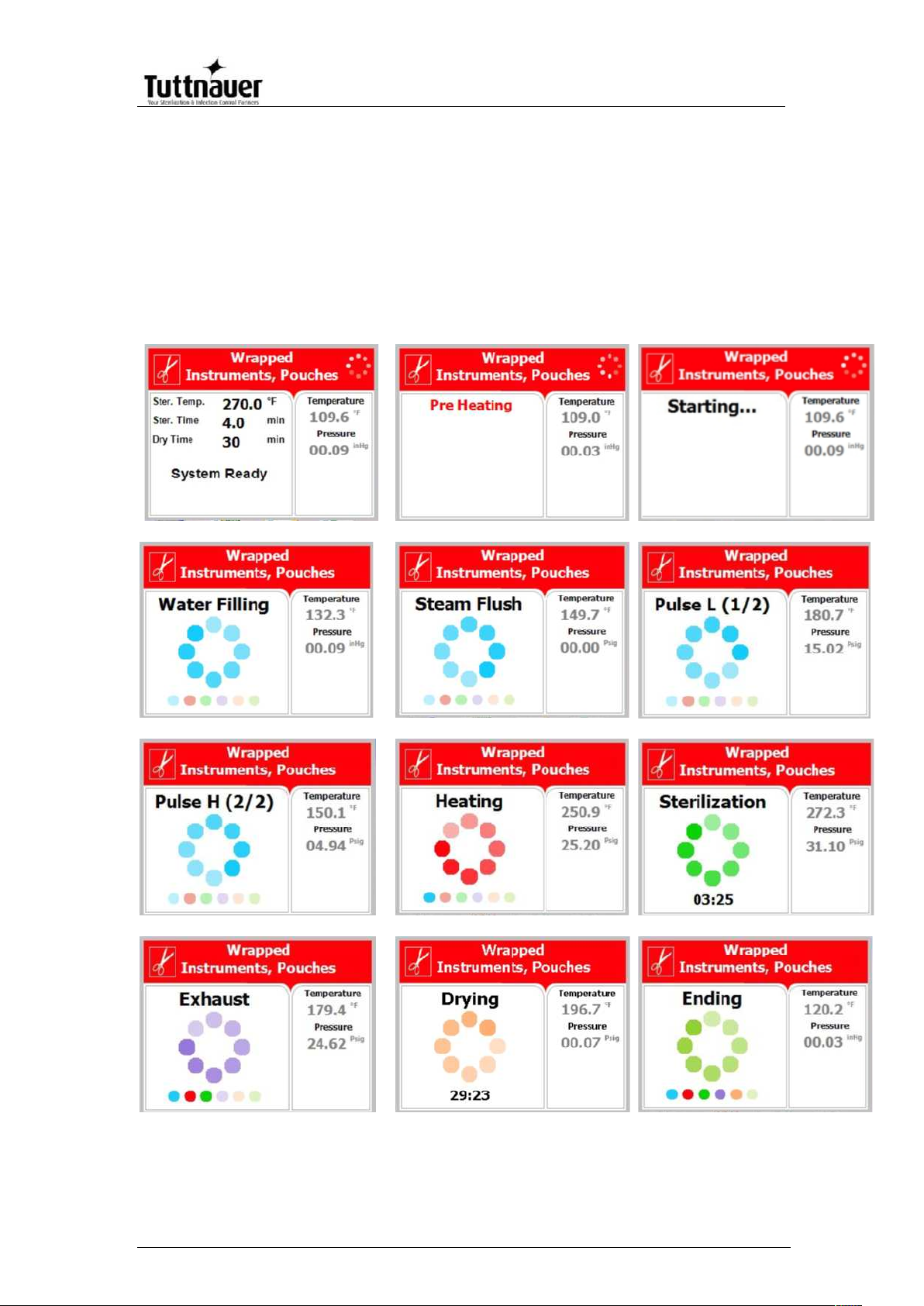

5. EZView SCREENS

During the cycle the EZView screen will change to let you know how the cycle

is progressing. The following screens are a representation of what will be seen

during a cycle.

5.1. Screens showing a successfully completed cycle

1. System Ready

2. Pre-heating

3. Starting

4. Water Filling

5. Steam Flush

6. Pulse L

7. Pulse H

8. Heating

9. Sterilization

10. Exhaust

11. Drying

12. Ending

Page 29

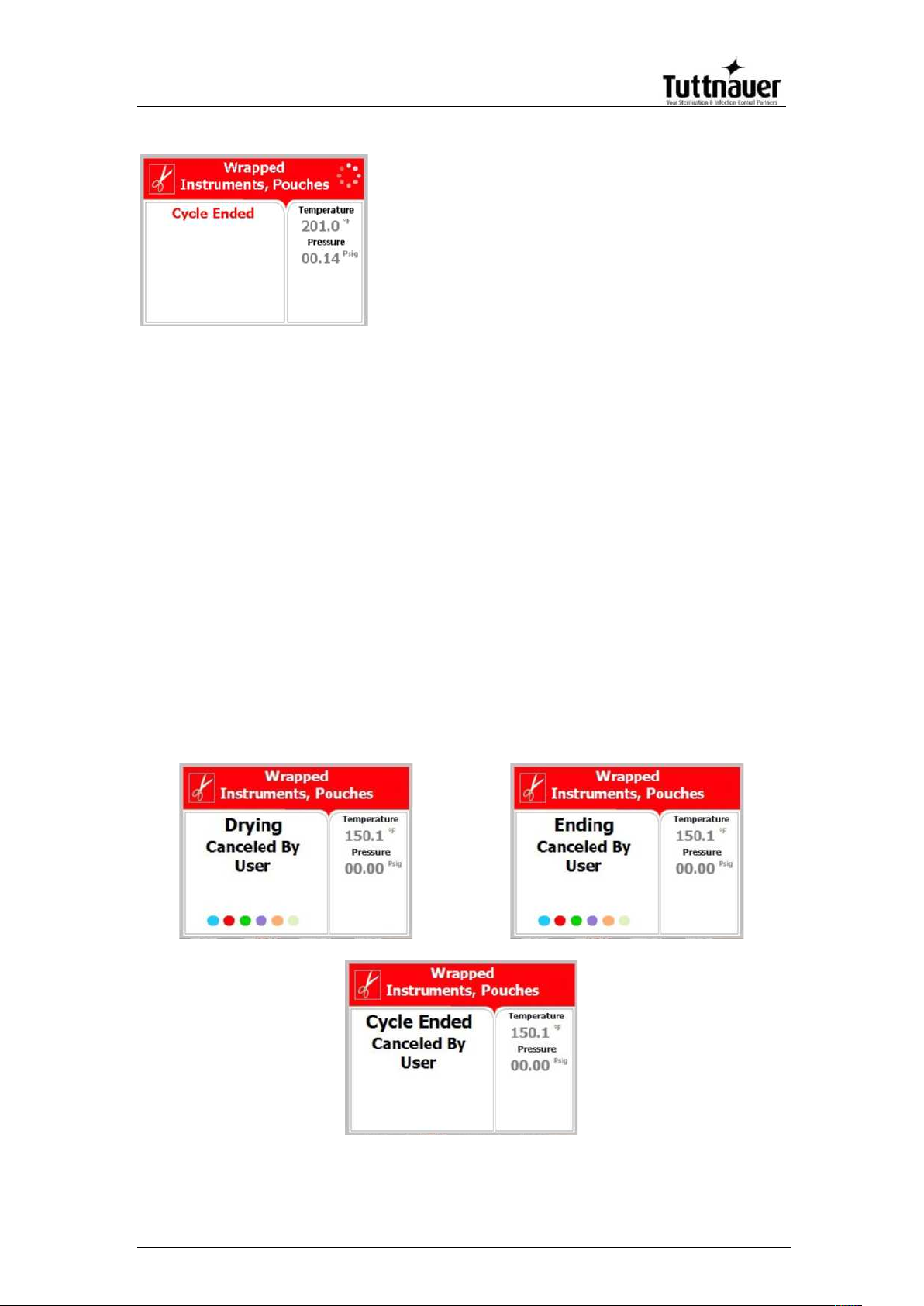

Page 27

13. Cycle Ended (successful

cycle)

5.2. Screens showing aborted cycles AFTER a completed

sterilization stage

The sterilization phase ended successfully – the cycle was

aborted and the reason for the failure is displayed. When the

sterilization portion of the cycle is successful the EZView display

remains white even though the cycle was aborted.

Note: There is a mandatory 1 minute of drying at the end of any

aborted cycle.

The next three scenarios show examples of possible error

messages:

5.2.1. Canceled by user AFTER complete sterilization

stage

The sterilization stage ended successfully, however

the operator manually aborted the remainder of the

cycle, by pressing the START/STOP key. This resulted

in the following sequence of screens showing the

reason for the aborted cycle.

Page 30

Page 28

Note: The user will have to press the START/STOP key, after the mandatory

1 minute drying, to clear the message and unlock the door.

5.2.2. Door is open AFTER the sterilization stage has

finished

The sterilization stage ended successfully, however

the door switch indicated that the door was opened.

This resulted in the following sequence of screens

showing the reason for the aborted cycle.

Note: The user will have to press the START/STOP key, after the mandatory

1 minute drying, to clear the message and unlock the door.

5.2.3. Screens showing a High Pressure Failure AFTER a

completed sterilization stage

The sterilization stage ended successfully, however

the chamber indicated that there was high pressure

during the exhaust phase. This resulted in the

following sequence of screens showing the reason for

the aborted cycle.

Note: The user will have to press the START/STOP key, after the mandatory

1 minute drying, to clear the message and unlock the door.

Page 31

Page 29

5.3. Screens showing a failed cycle:

When the machine fails BEFORE the sterilization phase is

completed the EZView display becomes yellow, a warning sign

and the reason for the failure will appear.

Note: There is a mandatory 1 minute of drying at the end of any

aborted cycle.

An explanation of how the EZView display screen will look when

a cycle has failed:

The next two scenarios show examples of possible error messages:

5.3.1. Screens showing a failure because of a Heat Time

Error

The machine was not able reach the proper

temperature. This resulted in the following sequence of

screens showing the reason for the aborted cycle.

Note: The user will have to press the START/STOP key, after the mandatory

1 minute drying, to clear the message and unlock the door.

Cycle failed

Reason of failure

Warning symbol

The screen color

changed from white to

yellow

Page 32

Page 30

5.3.2. Failure due to Cancellation by user BEFORE

completing the sterilization stage

Note: The user will have to press the START/STOP key, after the mandatory

1 minute drying, to clear the message and unlock the door.

Page 33

Page 31

6. STERILIZATION PROGRAMS

The control system incorporates a safety feature that prevents

changing programs if the door is closed.

This protection is intended to prevent running an inappropriate program

if the autoclave is loaded, but the cycle is not immediately started.

If the operator for example inserts the load into the chamber, closes the

door and leaves the room and another operator/user tries to change

the program, the operator/user will not be able to do this unless the

door is opened and the type of load inside the chamber can be seen.

The autoclave offers four preset FDA cleared sterilization programs, a

dedicated cleaning program (for cleaning the chamber using Chamber

Brite), a calibration program (for use by a technician) and two custom

programs. The custom programs are not FDA cleared and it is the

user’s responsibility to validate these programs.

Spore testing is your only assurance of complete sterilization.

Using the UP OR DOWN keys enables the user to select the various

programs as seen in the following list:

Sterilization Programs

Temp

Sterilization

time

(minutes)

Dry time

(minutes)

Program

Icon

Description

1

Unwrapped

Instruments

270°F

(132°C)

3

1 (default)

Range: 1-99

2

Wrapped

Instruments,

Pouches

270°F

(132°C)

4

30 (default)

Range: 30-99

3

Unwrapped

Delicate

Instruments

250°F

(121°C)

30

1 (default)

Range: 1-99

4

Handpieces

270°F

(132°C)

4

30 (default)

Range: 30-99

5

Chamber

Brite

Cleaning

270°F

(132°C)

3

Keep

temperature

0 (default)

6

Calibration

cycle

270°F

(132°C)

15

1

Page 34

Page 32

7

Extra Drying

Time

5

8

Custom A

270°F

(132°C)

4

30 (default)

Range: 0-99

9

Custom B

250°F

(121°C)

30

1 (default)

Range: 0-99

During the process, the various stages of the cycle will be displayed on

the screen, as shown in this example and in sec. 5.1.

The user should use only those sterilizer accessories

(Biological Indicators, Chemical Indicators. etc.) that have

been cleared by the FDA for the specific cycle time and

temperature of this device.

The stages names are as follows:

Starting

Water Filling

Steam Flush

Pulse L

Pulse H

Heating

Sterilization

Exhaust

Drying

Ending

Page 35

Page 33

6.1. Program 1: Unwrapped Instruments

For unwrapped instruments and materials, when the instrument

manufacturer recommends autoclaving at temperatures of 270F

(132C) and no drying stage is required.

Nominal parameters default settings

Sterilization temperature: 270F (132C)

Sterilization time: 3 minutes.

Drying time: 1 minute (may be increased by the operator (see

sec. 7.1.1), other parameters are set and cannot be altered).

Operations Sequence

Automatic water fill into the chamber and heating by actuation

of electrical heaters until completion of the steam flush

process.

Positive air-removal pulses in the EZ11Plus to complete

removing air from the chamber (not applicable to the EZ9Plus

in this program).

Heating by actuation of electrical heaters until the sterilization

temperature is reached.

Sterilization temperature is maintained constant for the preset

sterilization time.

Fast exhaust, steam is exhausted out of the chamber at a fast

rate until pressure decreases to ambient pressure.

Drying for 1 minute to remove residual steam from the

chamber.

CAUTION!

The sterility of instruments processed in unwrapped cycles

cannot be maintained if exposed to non-sterile

environment.

Page 36

Page 34

6.2. Program 2: Wrapped Instruments, Pouches

For wrapped instruments, pouches and materials, when the

instrument manufacturer recommends autoclaving at

temperatures of 270F (132C) with a drying stage.

Nominal parameters default settings

Sterilization temperature: 270F (132C)

Sterilization time: 4 minutes

Drying time: 30 minutes (may be increased by the operator

(see sec. 7.1.1), other parameters are set and cannot be

altered).

Operations sequence:

Automatic water fill into the chamber and heating by actuation

of electrical heaters until completion of the steam flush

process.

Positive air-removal pulses to complete removing air from the

chamber.

Heating by actuation of electrical heaters until the sterilization

temperature is reached.

Sterilization temperature is maintained constant for the preset

sterilization time.

Fast exhaust, steam is exhausted out of the chamber at a fast

rate until pressure decreases to ambient pressure.

Drying by heating of chamber and air circulation to remove

leftover moisture from the instruments and wraps.

Page 37

Page 35

6.3. Program 3: Unwrapped Delicate Instruments

For unwrapped delicate instruments, when the instrument

manufacturer recommends autoclaving at temperatures of 250F

(121C) and no drying stage is required.

Nominal parameters default settings

Sterilization temperature: 250ºF (121ºC)

Sterilization time: 30 minutes.

Drying Time: 1 minute (may be increased by the operator (see

sec. 7.1.1), other parameters are set and cannot be altered).

Operations sequence:

Automatic water fill into the chamber and heating by actuation

of electrical heaters until completion of the steam flush

process.

Positive air-removal pulses in the EZ11Plus to complete

removing air from the chamber (not applicable to the EZ9Plus

in this program).

Heating by actuation of electrical heaters until the sterilization

temperature is reached.

Sterilization temperature is maintained constant for the preset

sterilization time.

Fast exhaust, steam is exhausted out of the chamber at a fast

rate until pressure decreases to ambient pressure.

Drying for 1 minute to remove residual steam from the

chamber.

CAUTION!

The sterility of instruments processed in unwrapped cycles

cannot be maintained if exposed to non-sterile

environment.

Page 38

Page 36

6.4. Program 4: Handpieces

For wrapped Handpieces when the instrument manufacturer

recommends autoclaving at temperatures of 270F (132C) with

a drying stage.

Note: Tuttnauer recommends all Handpieces be wrapped for

sterilization.

Nominal parameters default settings

Sterilization temperature: 270F (132C).

Sterilization time: 4 minutes.

Drying time: 30 minutes (may be increased by the operator

(see sec. 7.1.1), other parameters are set and cannot be

altered).

Operations Sequence

Automatic water fill into the chamber and heating by actuation

of electrical heaters until completion of the steam flush

process.

Positive air-removal pulses to complete removing air from the

chamber.

Heating by actuation of electrical heaters until the sterilization

temperature is reached.

Sterilization temperature is maintained constant for the preset

sterilization time.

Fast exhaust, steam is exhausted out of the chamber at a fast

rate until pressure decreases to ambient pressure.

Drying by heating of chamber and air circulation to remove

leftover moisture from the instruments and wraps.

Page 39

Page 37

6.5. Program 5: Chamber Brite Cleaning

This is a maintenance cycle used with Tuttnauer’s Chamber

Brite

TM

cleaner for cleaning the chamber and piping of the

autoclave. We recommend using Chamber BriteTMand cleaning

the autoclave every 20 cycles or once per week whichever is

longer. (see sec. 12.1.2 for detailed instruction on cleaning the

chamber).

CAUTION! This is not a sterilization program! This program

has not been cleared by the FDA for sterilization.

Nominal parameters default settings

Cleaning temperature: 270F (132C).

Cleaning time: 3 minutes.

Operations sequence:

Automatic water fill into the chamber and heating by actuation

of electrical heaters until completion of the steam flush

process.

Heating by actuation of electrical heaters until the cleaning

temperature is reached.

Cleaning temperature is maintained constant for the preset

cleaning time.

Fast exhaust, steam is exhausted out of the chamber at a fast

rate until pressure decreases to ambient pressure.

No Drying

The turquoise color of the screen, when the cycle is running,

is intended to remind the user that the program is not a

sterilization program.

Page 40

Page 38

6.6. Program 6: Calibration Cycle

This program is only for use by a technician with the proper test

equipment to aid in calibrating the autoclave. This is a shortened

cycle with a long sterilization phase at 270F (132C) and no

drying to facilitate the calibration process.

CAUTION! This is not a sterilization program! This program has

not been cleared by the FDA for sterilization.

Nominal parameters default settings

Calibration temperature: 270F (132C)

Calibration time: 15 minutes.

Drying time: 1 minute is the minimum value set when no

drying is required.

Operations Sequence

Automatic water fill into the chamber and heating by actuation

of electrical heaters until completion of the steam flush

process.

Positive air-removal pulses to complete removing air from the

chamber

Heating by actuation of electrical heaters until the calibration

temperature is reached.

Calibration temperature is maintained constant for the preset

calibration time.

Fast exhaust, steam is exhausted out of the chamber at a fast

rate until pressure decreases to ambient pressure.

Drying for 1 minute to remove residual steam from the

chamber.

Page 41

Page 39

6.7. Program 7: Extra Drying Time

For all loads, when the load requires additional drying after the

cycle is completed.

Nominal parameters default settings

Drying time: 5 minute (may be changed by the operator (see

sec. 7.1.1)).

Operations Sequence

Drying for 5 minutes.

Page 42

Page 40

6.8. Program 8: Custom A (may be altered by the user)

This program allows the user to adjust all cycle parameters in

order to sterilize items that cannot be sterilized in any of the

preceding default programs.

This is not an FDA cleared program and validation of

sterility when using this program is the responsibility of the

user.

See section 7 for instructions on how to create a custom

program.

Nominal parameters default settings

Sterilization temperature: 270°F (132°C).

Sterilization time: 4 minutes.

Drying time: 30 minutes

Operations sequence:

Automatic water fill into the chamber and heating by actuation

of electrical heaters until completion of the steam flush

process.

Positive air-removal pulses to complete removing air from the

chamber.

Heating by actuation of electrical heaters until the sterilization

temperature is reached.

Sterilization temperature is maintained constant for the preset

sterilization time.

Fast exhaust, steam is exhausted out of the chamber at a fast

rate until pressure decreases to ambient pressure.

Drying by heating of chamber and air circulation to remove

leftover moisture from the instruments and wraps.

Page 43

Page 41

6.9. Program 9: Custom B (may be altered by the user)

This program allows the user to adjust all cycle parameters in

order to sterilize items that cannot be sterilized in any of the

preceding default programs.

This is not an FDA cleared program and validation of

sterility when using this program is the responsibility of the

user.

See section 7 for instructions on how to create a custom

program.

Nominal parameters default settings

Sterilization temperature: 250F (121C).

Sterilization time: 30 minutes.

Drying time: 1 minute.

Operations sequence:

Automatic water fill into the chamber and heating by actuation

of electrical heaters until completion of the steam flush

process.

Positive air-removal pulses to complete removing air from the

chamber.

Heating by actuation of electrical heaters until the sterilization

temperature is reached.

Sterilization temperature is maintained constant for the preset

sterilization time.

Fast exhaust, steam is exhausted out of the chamber at a fast

rate until pressure decreases to ambient pressure.

Drying for 1 minute to remove residual steam from the

chamber.

Page 44

Page 42

7. CHECKING AND CHANGING PARAMETERS AND OTHER

DATA

This section shows how to access system data and modify parameters.

The Cycle Parameters directory containing parameters for controlling

the sterilization process is locked for programs 1 thru 4 and not

available for modification from the default values (except for drying).

Program 5 is a cleaning program and all parameters are locked.

Program 6 is a calibration program for use by a technician and all

parameters are locked.

Two programs are available for the user to modify as needed, Custom

A and Custom B. These custom programs are not FDA cleared and it is

the users responsibility to validate these programs.

Spore testing is your only assurance of complete sterilization.

Once entering the programming mode, the operator will see and have

access to the following directory items.

Directory

Subdirectory

Quick Options see sec. 7.1

Add extra dry time

Export to USB

Print cycles

Version information

Start cycle by clock

Set date and time

Login

Exit

Main Menu

(requires

login) see

sec. 7.2

Cycle

Parameters –

applicable

only for

Custom

programs

(except Dry

Time) See

sec. 7.2.1

Cycle Parameters

System

Parameters

See sec. 7.2.3

Print Rate All

Print Rate Sterilization

Screen Saver

Cycle Print Gap

Maintenance

See sec. 7.2.4

Export gain and offset to USB

Reset atmospheric pressure

Printer test

Print all gain and offset

Page 45

Page 43

7.1. Quick Options Directory

To take advantage of the system features it is necessary to access the

programming mode. Some subdirectories enable the operator to see

and change an individual cycle’s parameters. Therefore it is necessary

to choose the required cycle before entering the programming mode.

1. Enter the programming mode by pressing the UP and DOWN

keys simultaneously for 1-2 seconds. When released the “Quick

Options” screen will be displayed. Scroll up or down the list and

press the START/STOP key to select.

Some features will require an access code. The operator’s access

code is 0001.

2. To exit this screen or any screen in this section, press the UP or

DOWN key to move the cursor to Exit and press START/STOP

key.

7.1.1. Add extra dry time

Accessing this parameter allows the operator to ADD

additional drying time to the default drying time of the

cycle selected.

As an example: If the program default is 30 minutes

drying selecting 10 additional minutes will give a total

drying time of 40 minutes. The additional drying time

will remain as part of the cycle until changed back. To

return to the original 30 minutes, select 0 additional

minutes, now the total drying time will be 30 minutes.

Scroll up or down the list and press the START/STOP

key to select.

Page 46

Page 44

7.1.2. Export to USB

Note: The USB flash drive needs to use FAT formatting.

Scroll up or down the list and press the START/STOP

key to select.

1.Export current version to USB

Accessing the Export current version feature allows

the operator to export the machines current

application for evaluation by a technician.

a.Insert the USB device into the USB Socket

located behind the printer door (See Sec. 4)

b.Move the cursor to Export current version to

USB device.

c.Press the START/STOP key

The following screen will be displayed:

Page 47

Page 45

2.Export all settings to USB

Accessing the Export all settings feature allows the

operator to export all the machines cycle settings for

evaluation by a technician using Tuttnauer’s R.PC.R

software.

a.Insert the USB device into the USB Socket

located behind the printer door (See Sec. 4)

b.Move the cursor to Export all settings to USB

device.

c.Press the START/STOP key

The following screen will be displayed:

3.All cycle history

4.Last 10 cycles

5.Last 50 cycles

Accessing the export cycle history feature allows the

operator to export cycle history of the previous 100

cycles to a USB device for evaluation or digital

storage. Cycle data is exported in individual text file

Page 48

Page 46

format (.txt) for viewing on a PC or with Tuttnauer’s

R.PC.R software. Exporting the cycle history will not

automatically delete the cycle history.

a.Insert the USB device into the USB socket

located behind the printer door (see sec. 4)

b.Move the cursor to select the number of

cycles to export

c.Press the START/STOP key.

The following screen will be displayed.

7.1.3. Print cycles

Select this option and the following screen will be displayed.

This subdirectory offers the following options:

Print last cycle

Print last 5 cycles

Print last 10 cycles

Page 49

Page 47

The Print cycles feature requires that the machine have a

printer installed. This feature allows the operator to print

out the last cycle, the last 5 cycles or the last 10 cycles.

Scroll down to the desired option and press the

START/STOP key. Once the printer has finished scroll to

Exit and pressing the START/STOP key will return to the

main screen

7.1.4. Version information

This subdirectory allows viewing of the current version of

software running the machine.

Select this option and the following screen will be

displayed.

7.1.5. Start cycle by clock

This option allows for scheduling the selected cycle to

start at a later time (The maximum possible delay is 24

hours). No other program can be run while the Start

Cycle by Clock is active.

Select this option and the following screen will be

displayed:

Page 50

Page 48

The time is displayed in the form “HH:MM”. The time is

in a 24 hour format (i.e. 14:30 = 2:30 PM).

Enabling the Start Cycle By Clock

1. Select the cycle to be scheduled from the Main

Screen before enabling this option.

2. Set the start time by using the UP and DOWN

keys to change the blinking digit. Use the

START/STOP key to move to the next digit.

3. Use the START/STOP key to move the cursor to

Enable.

4. Use the UP or DOWN key to select Enable.

5. Use the START/STOP key to move the cursor to

exit.

6. Use the UP or DOWN key to exit.

7. The cycle is now enabled.

Note: When Start Cycle by clock is enabled this icon

will be displayed on the main screen.

Once the cycle has run the option will automatically

return to disabled

Page 51

Page 49

Cancelling the Start Cycle By Clock

Select the Start Cycle by Clock option from the Quick

Options menu.

1.Use the START/STOP key to move the cursor to

Disable

2.Use the UP or DOWN key to select Disable

3.Use the START/STOP key to move the cursor to exit

4.Use the UP or DOWN key to exit.

5.The cycle is now disabled.

7.1.6. Set date and time

Note: It is important to set the date and time when setting

up a new machine for the first time.

The internal battery is turned off for shipping. Setting the

date and time will restart that battery.

Note: Failure to set the Date and Time will cause a Time

Error and the unit will not run properly.

This option enables the operator to set the date and time.

The following screen will be displayed:

Page 52

Page 50

The time is displayed in the upper row in the form

“HH:MM”. The time is in a 24 hour format (i.e.

14:30 = 2:30 PM)

To set the time use the UP and DOWN keys to

change the blinking digit. Use the START/ STOP

key to move to the next digit.

The date is displayed in the lower row in the form

“DD/MMM/YYYY” (e.g. 05/APR/2012)

To set the date use the UP and DOWN keys to

change the blinking digit. Use the START/ STOP

key to move to the next digit.

When all changes are completed, use the START/

STOP key to move to SET, then use the UP or

DOWN key to save the new date and time.

When saving is completed, the Set Date and Time

screen is still displayed.

Move the cursor to Exit and press the UP or DOWN

key.

Selecting exit will return to the Main screen where

the next option can be selected.

Note: After setting time and date, the autoclave will

restart automatically.

7.1.7. Login

Accessing additional feature requires entering a

password, follow these steps

1. Select Login and press the START/STOP key.

2. The SELECT USER screen is displayed

Page 53

Page 51

3. Move the cursor to User, if it is not already

highlighted, and press START/STOP key

4. Enter Code screen is now displayed

5. 0000 is displayed on the screen with the cursor

blinking on the right digit.

6. To increase or decrease the right digit, press the

UP or DOWN keys.

7. Change the code to 0001 and move the cursor to

SET by pressing the START/STOP key four

times.

8. When SET is blinking, press the UP or DOWN key

to enter the MAIN MENU screen.

The following screen is displayed:

Page 54

Page 52

See section 7.2 for more details on the MAIN MENU.

7.1.8. Exit

Selecting Exit and pressing the START/STOP key, will

bring you back to the main screen.

7.2. Main Menu

1. To browse through the subdirectories, use the UP and

DOWN keys.

2. When the desired directory is blinking, press the

START/STOP key. The required screen (see the following

paragraphs) will be displayed.

3. To exit the MAIN MENU screen, press the UP or DOWN key

to move the cursor to EXIT and then press START/STOP.

4. An explanation of the various directories, subdirectories and

parameters can be found on the following pages.

Page 55

Page 53

7.2.1. Cycle Parameters for Custom A and B cycles

This directory enables the operator to see and change all the

cycle parameters for Custom A and Custom B cycles. To modify

a program it is necessary to select that program from the Main

Screen before entering the "MAIN MENU" directory

This directory includes seven subdirectories. A description of

each parameter can be found in see section 7.3

Subdirectory

Property

Create Pulse

Pulse A Count

Pulse A Stay Time

Pulse A Low Pressure

Pulse A High Pressure

Pulse B Count

Pulse B Stay Time

Pulse B Low Pressure

Pulse B High Pressure

Pulse C Count

Pulse C Stay Time

Pulse C Low Pressure

Pulse C High Pressure

Pulse D Count

Pulse D Stay Time

Pulse D Low Pressure

Pulse D High Pressure

Heating

Sterilization Temperature

Sterilization

Sterilization Temperature

Sterilization Time

Exhaust

Exhaust Mode

Drying

Dry Time

Dry Heat On 1

Dry Heat Off 1

Dry first stage time

Dry Heat On 2

Dry Heat Off 2

Additional Dry Time

Ending

End Temperature

Global

Jacket Temperature

Page 56

Page 54

7.2.2. Modifying a parameter for the Custom A and B

cycles

In the following example Pulse A Count will be modified

1. Using the UP or DOWN keys select the Custom A

program from the Main Screen.

2. Enter the programing mode by pressing the UP

and DOWN keys simultaneously for 1-2 seconds

and then release.

3. Login using the User code 0001.

4. Select Cycle Parameters (Custom A) from the

Main Menu.

Page 57

Page 55

5. Use the UP or DOWN keys to move to the Create

Pulse subdirectory as shown in the table in sec.

7.2.1. Pressing the START/STOP key will allow

the user to enter that subdirectory.

6. Pressing the START/STOP key again will select

the individual parameter for modification.

Page 58

Page 56

7. The Set Parameter screen will appear as shown

with the current parameter setting highlighted.

This screen is representative of a typical Set Parameter

screen.

The Set Parameter screen shows the name of the

parameter to be changed; it shows the maximum,

minimum, and default values for this parameter. It also

shows the current parameter setting.

8. Use the UP and DOWN keys to change the

desired value. See the table in sec. 7.3 to

determine the appropriate value to use.

9. Use the START/STOP key to advance the

blinking cursor to SET. Use UP or DOWN key to

enter the new value.

10. Selecting SET or EXIT will return you to the

previous screen where the next parameter can be

selected for modification.

11. Selecting EXIT before selecting SET will return to

the previous screen without changing the

parameter.

The custom programs are not FDA cleared

and it is the user’s responsibility to validate

any custom cycles

Spore testing is your only assurance of

complete sterilization.

7.2.3. System Parameters

This directory allows for the modification of four

parameters. These parameters apply to all programs.

Page 59

Page 57

Print Rate all – defines the printing rate during all

stages of the cycle except the sterilization stage.

This feature requires a printer to be installed.

Print Rate Sterilization – Defines the printing rate

during the sterilization stage. This feature requires

a printer to be installed.

Screen Saver – defines the time interval from the

last use of the Keypad until the screen saver is

activated. Setting this parameter to 0 minutes will

disable the screen saver.

Cycle Print Gap – Defines the number of blank

lines to advance at the end of the cycle. This

feature requires a printer to be installed.

Modifying a system parameter

Every parameter can be changed as follows:

1. Select any program to modify the System

Parameters

2. Enter the programing mode by pressing the UP

and DOWN keys simultaneously for 1-2 seconds

and then release.

3. Login using the User code 0001

4. Select System Parameters from the Main Menu

and press the START/STOP key. The System

Parameters screen will appear.

Page 60

Page 58

5. Use the UP or DOWN keys to move to the

appropriate parameter from the system

parameters screen.

6. Use the START/STOP key to select this

parameter. The set parameter screen will appear.

Page 61

Page 59

The Set parameter screen shows the name of the

parameter to be changed; it shows the maximum,

minimum, and default value for this parameter. It also

shows the current parameter setting.

7. Use the UP and DOWN keys to change the

desired value.

8. Use the START/STOP key to advance the

blinking cursor to SET. Use UP or DOWN key to

enter the new value.

9. Selecting SET or EXIT will return you to the

previous screen where the next parameter can be

selected for modification.

10. Selecting EXIT before selecting SET will return to

the previous screen without changing the

parameter.

7.2.4. Maintenance

This directory offers the following options. These options apply

to all programs.

1. Select any program from the Main Screen to

access the Maintenance options.

2. Enter the programing mode by pressing the UP

and DOWN keys simultaneously for 1-2 seconds

and then release.

3. Login using the User code 0001

4. Select Maintenance from the Main Menu and

press the START/STOP key.

The following screen will appear: