Page 1

OPERATION

&

MAINTENANCE

MANUAL

E-Type Electronic Table -Top Autoclaves

models 1730, 2340, 2540, 3140, 3850,3870

E, EK, EA & EKA

Cat. No. MAN205-0001 Rev. E

Tuttnauer Europe b.v., P.O. Box 7191, 4800GD Breda, The Netherlands. + 31/76-5423510

Tuttnauer USA Co. 25 Power Drive Hauppauge, NY, 11788, USA (800) 624 5836, (631) 737 4850, Fax: (631) 737 07 20

Email: info@tuttnauer.com

Page 2

TABLE OF CONTENTS

PARAGRAPH PAGE NO.

1 GENERAL............................................................................................................. 4

1.1 Incoming Inspection ................................................................................ 4

1.2 Warranty...................................................................................................4

1.3 Warranty Statement .................................................................................4

2 TECHNICAL DATA.............................................................................................6

2.1 Introduction.............................................................................................. 6

2.2 Stand – by heating mode..........................................................................6

2.3 Operating Conditions...............................................................................7

2.4 Utilities......................................................................................................7

2.5 Environment Emission Information .......................................................7

2.6 Electrical Data: ........................................................................................ 7

2.7 Specifications ........................................................................................... 8

2.8 Technical Specifications (for E, EK, EA, EKA models) ........................9

2.9 Construction ........................................................................................... 10

2.10 Directives and Standards ....................................................................... 10

2.11 Water quality .......................................................................................... 11

2.12 Symbol Description ................................................................................ 12

3 STERILIZATION PROGRAMS ........................................................................ 15

3.1 Program 1 (134ºC with no drying) .......................................................15

3.2 Program 2 (121ºC with no drying) .......................................................16

3.3 Program 3 (134ºC with drying) ............................................................17

3.4 Program 4 (121ºC with drying) ............................................................18

3.5 Program 5 (121ºC with slow exhaust)..................................................19

4 KEYBOARD (keys and display) .........................................................................20

4.1 Description and Functions of the Front Panel Keyboard.................... 21

4.2 Description of the Operational Messages .............................................24

4.3 Description of Displayed Error Messages and Safety Measures ......... 26

5 PRINTER ............................................................................................................ 28

5.1 Printer Operation ...................................................................................28

5.2 Printer Handling.................................................................................... 30

6 INSTALLATION PLACING AND LEVELING INSTRUCTIONS .................31

6.1 leveling.................................................................................................... 31

6.2 Water quantity for a cycle......................................................................32

6.3 Lifting and carrying............................................................................... 32

6.4 Loading and unloading the Device .......................................................32

6.5 Filling the Water Reservoir ................................................................... 33

7 PREPARATION BEFORE STERILIZATION .................................................34

8 OPERATING INSTRUCTIONS ........................................................................ 38

1

Page 3

TABLE OF CONTENTS (Cont.)

PARAGRAPH PAGE NO.

9 MAINTENANCE INSTRUCTIONS..................................................................40

9.1 Preventive and Scheduled Maintenance ...............................................40

9.2 Draining the Reservoir...........................................................................41

9.3 Cleaning Air Jet ..................................................................................... 42

9.4 Replacing the Door Gasket ....................................................................43

9.5 Replacing the Air Filter (models EA, EKA) .........................................44

9.6 Cleaning water outlet strainer ...............................................................45

9.7 Replacing the Cartridge Fuse................................................................46

9.8 Checking the Safety Valve .....................................................................47

9.9 Door Safety System ................................................................................48

9.10 Cleaning Table Top Autoclaves with Chamber Brite™....................... 49

10 TROUBLESHOOTING ..................................................................................51

11 ACSSESORIES LIST ..................................................................................... 57

12 SPARE PARTS LIST......................................................................................57

2

Page 4

TABLE OF CONTENT (Cont.)

DRAWINGS PAGE NO.

Front View...................................................................................................................13

Rear View ....................................................................................................................14

Front Panel Keyboard................................................................................................. 20

Pouch Rack .................................................................................................................54

Tray..............................................................................................................................55

Tray handle CMT240-0001 ........................................................................................55

Tray holder ..................................................................................................................56

Alternative tray holder ................................................................................................56

3

Page 5

1 GENERAL

Read the Operating Instructions carefully, before beginning any operation

on the autoclave!

1.1 Incoming Inspection

The autoclave should be unpacked and inspected for mechanical

damage upon receipt. Observe packing method and retain packing

materials until the unit has been inspected. Mechanical inspection

involves checking for signs of physical damage such as: scratched

panel surfaces, broken knobs, etc.

If damage is apparent, contact your dealer or point of purchase, so that

they may notify the manufacturer and file a claim with the appropriate

carrier.

All Tuttnauer products are carefully inspected prior to shipment and

all reasonable precautions are taken in preparing them for shipment to

assure safe arrival at their destination.

1.2 Warranty

We certify that this instrument is guaranteed to be free from defects in

material and workmanship for one year against faulty components and

assembly with the exception of glassware, lamps and heaters.

The warranty does not include and does not replace routine

treatment and preventive maintenance to be performed according

to instructions in paragraph 9.1 (Preventive and Scheduled

Maintenance).

Our obligation is limited to replacing the instrument or parts, after our

examination, if within one year after the date of shipment they prove to

be defective. This warranty does not apply to any instrument that has

been subjected to misuse, neglect, accident or improper installation or

application, nor shall it extend to autoclaves that have been repaired or

altered by an un-authorized person.

The Autoclave should not be used in a manner not described in this

manual!

1.3 Warranty Statement

The warranty registration must be completed and returned to our

service departments; within fourteen (14) days of purchase or the

warranty will be void.

Our Technical Service Depts can be reached at:

Tuttnauer Europe b.v., Paardeweide 36, P.C. Box 7191,

4800GDBreda, Netherlands. +31/76-5423510, Fax: +31/765423540, E-mail: Tuttnauer@tip.nl

Tuttnauer USA Co. 25 Power Drive Hauppauge, NY, 11788, USA

(800) 624 5836, (631) 737 4850, Fax: (631) 737 07 20

Email: info@tuttnauer.com

Rudolf Gunz & Co. PTY LTD:

Service Department, 26-34 Dunning Avenue, Ros, 2018, Sydney,

Australia.

Service Department, Locked bag 690, Beaconsfield, NSW 2014,

Australia.

+61-2-99356600 Fax: +61-2-99356650

4

Page 6

Note:

If there is any difficulty with this instrument, and the solution is not

covered in this manual, contact our representative or us first. Do not

attempt to service this instrument yourself. Describe the difficulty as

clearly as possible so we may be able to diagnose the problem and

provide a prompt solution.

If the autoclave is equipped with a printer, send along a copy of the last

printout for our inspection. If replacement parts are needed, stipulate

the model and serial number of the machine.

No autoclaves will be accepted for repair without proper authorization

from us. All transportation charges must be paid both ways by the

owner. This warranty will be void if the unit is not purchased from an

authorized full service Tuttnauer dealer.

5

Page 7

2 TECHNICAL DATA

2.1 Introduction

This E-Type table-top autoclave is designed for the sterilization of

medical and surgical solid instruments in dental, medical and

veterinary clinics, first aid rooms, laboratories etc.

Types E and EK are intended to sterilize non wrapped solid products.

Types EA and EKA are intended for sterilization of non-wrapped and

wrapped solid products.

The autoclave models E, EK, EA and EKA are electrically - heated

sterilizers of different dimensions, using steam as the sterilizing agent.

A computerized control unit ensuring a fully automatic sterilization

cycle and precise control and monitoring of physical parameters and a

Five automatic programs are available, according to the material to be

On all models (except 1730), a water pump is installed between the

The control system provides adequate protection, to ensure the safety

All models (except 1730) are equipped with a pressure gauge that is

On all models (except 1730), a printer is an optional addition to the

This manual is intended for the user and gives the user a general

After reading this manual, operating the autoclave will be easy.

Only technical personnel having proper qualifications and holding

2.2 Stand – by heating mode

The autoclave provides an option of heating the chamber in stand-by

clear documentation of the sterilization cycle controls the autoclave.

sterilized. All sizes (except 1730) have a model that includes a drying

stage (EA and EKA). The difference between EK and EKA is the air

compressor that, during the drying stage, pushes filtered air (0.2µm.)

through the chamber to pull out the humidity, the dry operation is

performed with the door closed.

water reservoir and the chamber. This pump intensifies the water flow

into the chamber. Entry of water may be accompanied by a noise for

approximately 30 seconds. This is normal noise generated by regular

operation of the pump.

of personnel and reliable operation with a minimum of shut down time.

used as a guide only. Should there be a power failure during the

operation of the autoclave, the pressure gauge indicates to the operator

that there is pressure in the chamber. The accuracy is ± 1.6%.

autoclave. The printer prints the preset and actual parameters of the

cycle (temperature, time and pressure/vacuum).

understanding of the instrument and the best ways to operate and take

care of it in order to obtain optimum effective results.

However since this instrument is built with high technology sensitive

components, no attempt should be made by the user or any other

unauthorized person to repair or recalibrate it.

technical documentation (including a technician manual) and

adequate information are authorized to service the apparatus.

mode between cycles with a very low power in order to reduce total

cycle time (1.6% of the total power only). The autoclave turns off

automatically if the interval between the sterilization cycles is more

than 2 hours. The stand-by feature is activated, as default, on cycles 1,

2, 3, 4 and not activated on cycle 5.

6

Page 8

The company – qualified technician can cancel this feature on EK or

EKA models, or activate it on E and EA models, according to customer

requirements.

2.3 Operating Conditions

This device is for indoor use only!

The sterilizer should be loaded only with autoclavable material!

The environment shall not exceed an ambient temperature of 40ºC and

a relative humidity of 85% respectively.

Caution!

Waste water should be brought into the public net in

accordance with the local rules or requirements i.e.

ONLY NON-HAZARDOUS LIQUIDS SHALL BE DISPOSED

IN PUBLIC SEWAGE!

2.4 Utilities

Utility Unit Value

Power supply (as appropriate)

V-A 1ph, 230/240V – 16A, 50 Hz

V-A 1ph, 120V – 16A, 60 Hz

Attention:

The electrical net must be protected with a current leakage safety

relay.

The electrical network must comply with local rules or

regulations.

2.5 Environment Emission Information

1. The peak sound level generated by the autoclave is less than 70

dBA with background noise of 60 dBa.

2. The total heat per hour transmitted by the autoclave is < 100 Wh

for all models.

2.6 Electrical Data:

1730 2340 2540 3140 3850 3870

E EK E, EA

Ampere (A)

at 230/240V

Ampere (A)

at 120V

Watts (W) 1050 1350 1400 2200 1400 2200 2400 2400 3000

4.6 5.9 6 9.6 6 9.6 10.4 10.4 13

8.8 11.2 11.7

EK,

EKA

E, EA

11.7

EK,

EKA

E, EA E, EA E, EA

20.0

Frequency 50 / 60 Hz

Protection against electrical shock Class I (IEC 60601-1)

7

Page 9

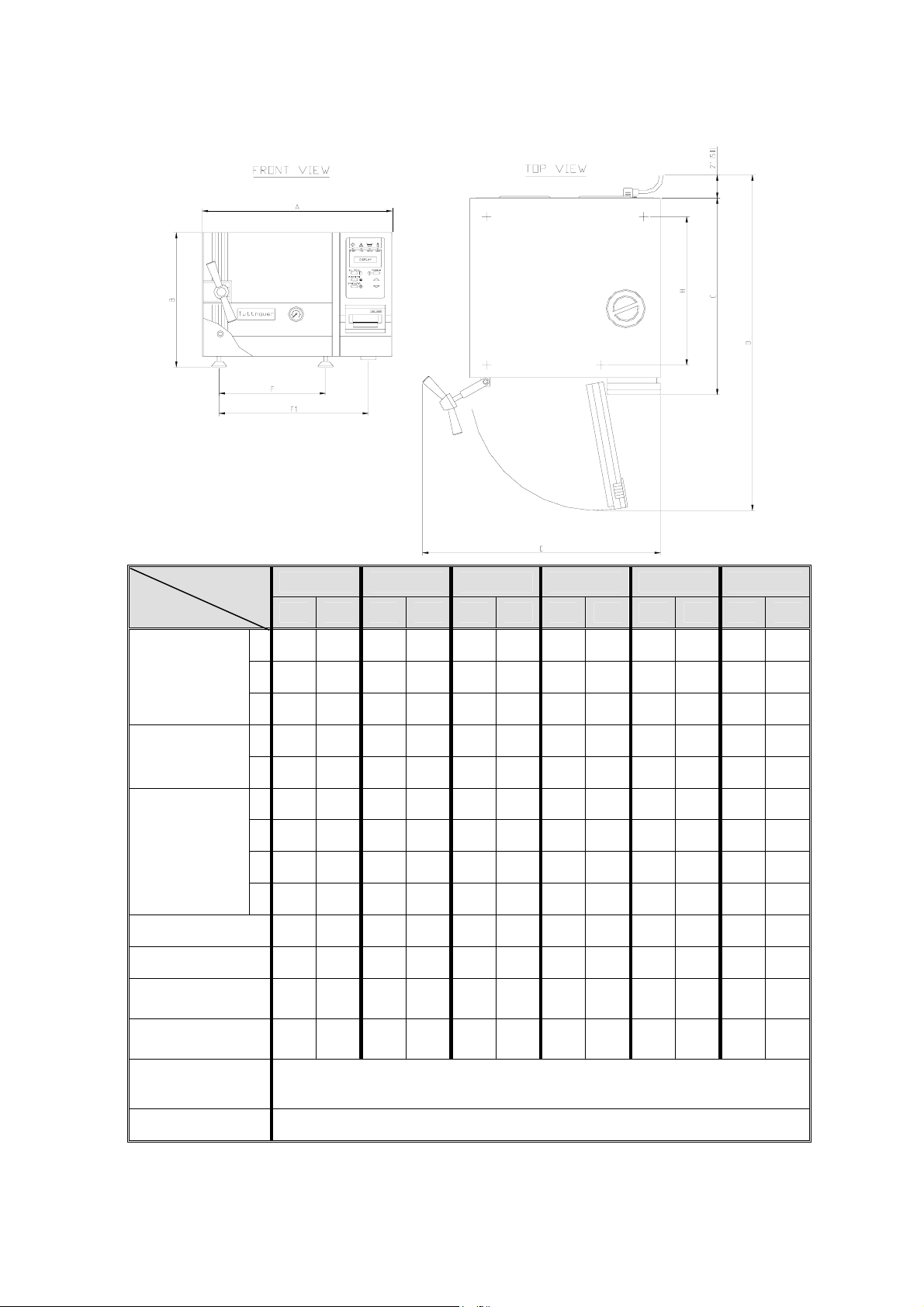

2.7 Specifications

Overall Dimensions

Model

1730 2340 2540 3140 3850 3870

Dimensions

Overall

Dimensions

Maximum

mm in mm in mm in mm in mm in mm in

A 440 17.4 510 20.0 510 20.0 590

B 305 12.0 365 14.4 365 14.4 450

C 455 17.9 545 21.5 545 21.5 566

D 750 29.5 900 35.8 900 35.8 990

23.2

17.7

21.9

660 26.0 660 26.0

525 20.7 525 20.7

695 27.5 875 34.5

39.0

1155 45.5 1335 53.0

dimensions

(door open)

E 560 22.0 655 25.8 655 25.8 755

29.7

815 32.0 815 32.0

F 350 13.8 415 16.4 415 16.4 488 19.2 450 2.0 450 2.0

Distance between

supporting legs

F1 - front legs

F - rear legs

F1 339 13.4 422 16.6 422 16.6 371 14.6 564 22.2 564 22.2

G 50 2.0 50 2.0 50 2.0 50 2.0 50 2.0 50 2.0

H 315 12.4 400 15.8 400 15.8 400 15.8 555 2.0 725 2.0

Chamber diameter 170 6.7 230 9.1 254 10.0 312 12.3 384 15.1 384 15.1

Depth 340 13.4 470 18.5 475 18.7 475 15.4 580 22.8 760 29.9

3.0

0.8

3.0

0.8

3.0

0.8

3.0

0.8

6.0

1.6

6.0

Reservoir volume

Minimum water

vol. in Reservoir

Max. Allowable

Working Pressure

(MAWP)

lit.

0.8

lit.

gal

0.21

gal

lit.

0.8

lit.

gal

0.21

gal

lit.

gal

0.8

0.21

lit.

gal

2.76 bar (40 psi)

lit.

0.8

lit.

gal

0.21

gal

lit.

2.0

lit.

gal

0.53

gal

lit.

2.0

lit.

1.6

gal

0.53

gal

Load No. counter Counting from 0 to 3000 and nullifies.

8

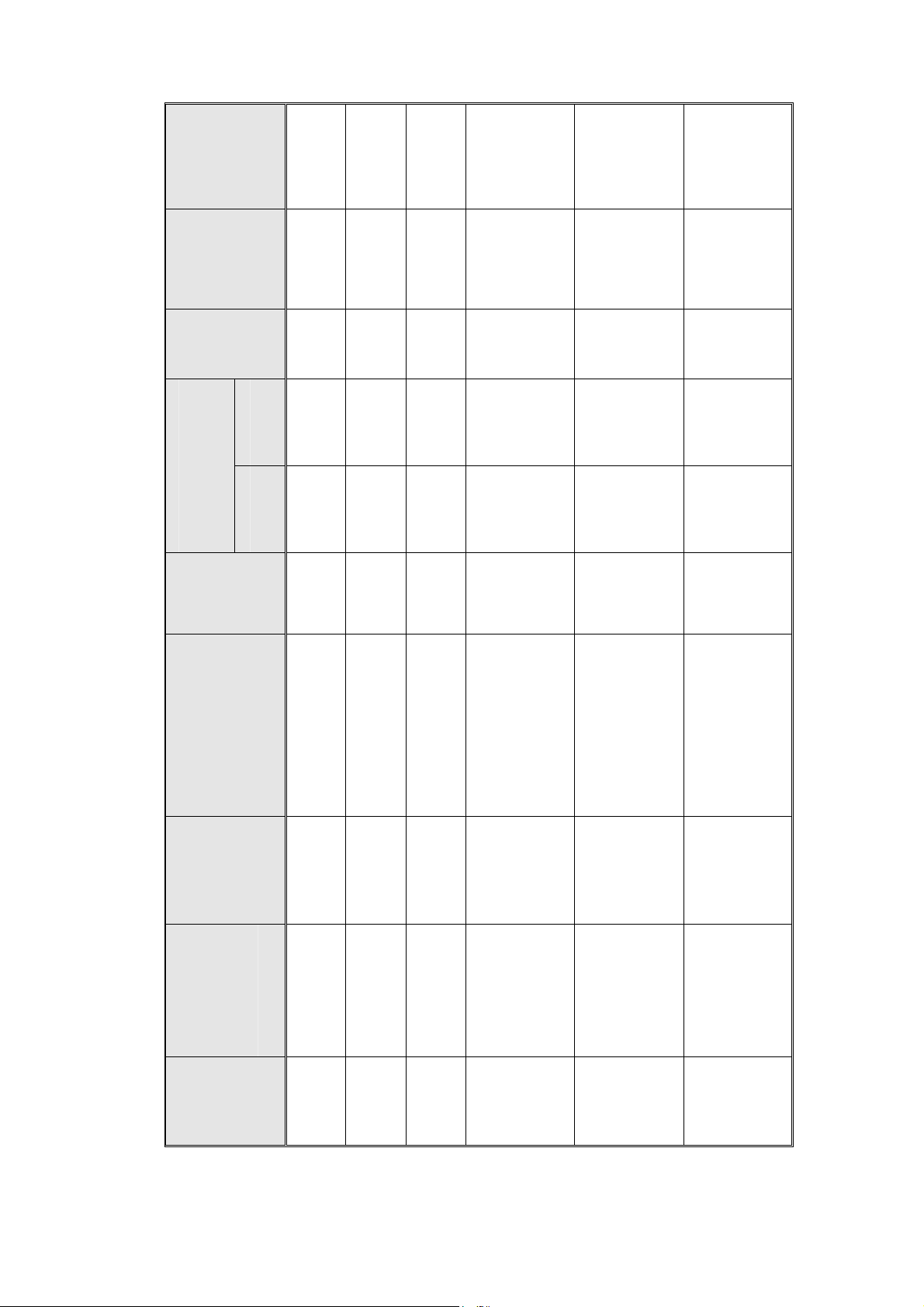

Page 10

3

Volume

Shipping

Weight

Shipping

0.18 m

25 kgs.

Printer

Full

No. of standard

Cassettes (Optional)

Half

No.

of trays

0.27m3

(6.35 cu.f.)

36 kgs.

(55 lbs.)

N/A

—

2

3

(9.4 cu.f.)

(79 lbs.)

Yes

2

2

3

0.27m3

(9.4 cu. f.)

48 kgs.

(106 lbs.)

Yes

3

3

4

0.35 m3

(12.4cu.f.)

60 kgs.

(132 lbs.)

Yes

4

4

2

0.63 m3

(22.2cu.f.)

89 kgs.

(196 lbs.)

Yes

—

10

2

0.76m3

(26.8cu.f)

102 kgs.

(225 lbs.)

Yes

—

15

2

35 x 67 x 2.5

28 x 67 x 2.5cm

( 11" x 26" x 1" )

(14" x 26" x 1")

W X D X H

Tray dimensions

12 x 29.5 x 2 cm

(4.7" x 11.6" x 0.8")

17 x 41.5 x 2cm

17 x 41.5 x 2 cm

(6.7" x 16.3" x 0.8")

(6.7" x 16.3" x0.8")

(10.1 x 16.1 x 1)

25.6 x 40.8 x 2.5

(7.8 x 16.1 x 1)

19.8 x 40.8 x 2.2

35 x 50 x 2.5cm

28 x 50 x 2.5 cm

(11" x 20 " x 1" )

(14" x 20 " x 1")

space

usable

Volume of

7.5 liters

(2 US gal.)

19 liters

23 l.

(5 US gal.)

(6 US gal.)

34.4 liters

(7.8 US gal.)

65 liters

(17US gal)

84 liters

(22 US gal)

DIA x D

Chamber

dimensions

17 x 34 cm

23 x 47 cm

(6.7" x 13.4")

(9" x 18.5")

(10" x 18.7")

25.4 x 47.5cm

31.2 x 39.1

(2.3” x 15.4”)

38 × 58 cm.

(15" × 23" )

38x76 cm

(15" x 30")

2.8 Technical Specifications (for E, EK, EA, EKA models)

Models

1730

2340

2540

3140

3850

3870

9

Page 11

2.9 Construction

The main parts of the autoclave are made of materials as indicated

below:

♦ Chamber is electro-polish and built of stainless steel 316 L.

♦ Door is made of stainless steel CF8.

♦ Trays are made of stainless steel 316.

♦ Water reservoir is made of hard plastic material.

♦ Door handle is made of hard plastic material, which is safe to

touch and thermo-insulated.

♦ Covers are made of aluminum sheet, coated with Epoxy paint.

2.10 Directives and Standards

Every autoclave meets the provisions of the following Directives and is

constructed in compliance with the following Standards:

2.10.1 Technical Directives

1. Medical device directive MDD/93/42/EEC.

2.10.2 Technical Standards

1. A.S.M.E. Code, section VIII division 1 for pressure

vessels.

2. EN 61010-1:93 – Safety of electrical equipment

…General requirement.

3. EN 61010-2-041:97 – Particular requirement for steam

autoclaves.

4. EN 50081-1:92 – (EMC) Emission compatibility…

5. EN 50082-1:97 – (EMC) Immunity compatibility….

6. prEN 13060-1:97-General requirements for all types of

small steam sterilizers.

7. prEN 13060-3 and 4:97-Particular requirements and

test method for type N and S sterilizers.

2.10.3 Quality standards

The manufacturing plant meets the following quality

standards:

1. EN ISO 9002 (7.94) – Quality System

2. EN 46002 (8.96) - Quality System - Medical device Particular requirements.

3. ISO 13488 – Quality systems – Medical devices –

Particular requirements for the application of ISO

9002.

The manufacturer retains all supporting documentation.

10

Page 12

2.11 Water quality

2.11.1 Water for generation of steam

The distilled or mineral – free water supplied to the

autoclave should have the physical characteristics and

maximum acceptable level of contaminants indicated in the

table below:

Physical characteristics and acceptable contaminants

Evaporate residue

levels in water, for sterlizers

< 15 mg/l

Silica

Iron

Cadmium

Lead

Rest of heavy metals

Chloride

Phosphate

Conductivity

< 2 mg/l

< 0.2mg/l

< 0.005 mg/l

< 0.05 mg/l

< 0.1 mg/l

< 3 mg/l

< 0.5 mg/l

< 50 µs/cm

pH 6.5 to 8

Appearance colourless, clean, without sediment

Hardness

< 0.1 mmol/l

Compliance with the above data should be tested in

accordance with acknowledged analytical methods, by an

authorized laboratory.

Attention:

We recommend testing the water quality once a month. The

use of water for autoclaves that do not comply with the

table above may have severe impact on the working life of

the sterilizer and can invalidate the manufacturer’s

guarantee.

2.11.2 Reverse Osmosis

A Reverse Osmosis (RO) system may be used to improve the

quality of the water used to generate steam in the steam

generator.

In RO, the water is forced through a semi-penetrable

membrane, which filters out contaminants to a high degree

of efficiency. In deionisation (DI) ions and charged particles

are removed either by electric fields or by ion exchange in

resin beds.

Although the RO cannot normally attain the degree of purity

possible with the DI methods, it is more than adequate for

the feed water intended for clean-steam generators.

Moreover the RO has several advantages:

11

Page 13

1. RO is cheaper to install and to run than DI.

2. RO removes particulate matter, organic molecules and pyrogens

that DI cannot remove

3. RO water is less corrosive to steel and copper than DI water.

4. RO maintenance requirements are less demanding than those of

the DI units.

Therefore the use of mineral free water will contribute to better

performance and longer life of the autoclave.

2.12 Symbol Description

Caution! Consult accompanying documents

Caution! Hot surface.

Caution! Hot steam.

Protective earth (Ground)

Stand by

12

Page 14

L:\WORD-PLT\man035.doc

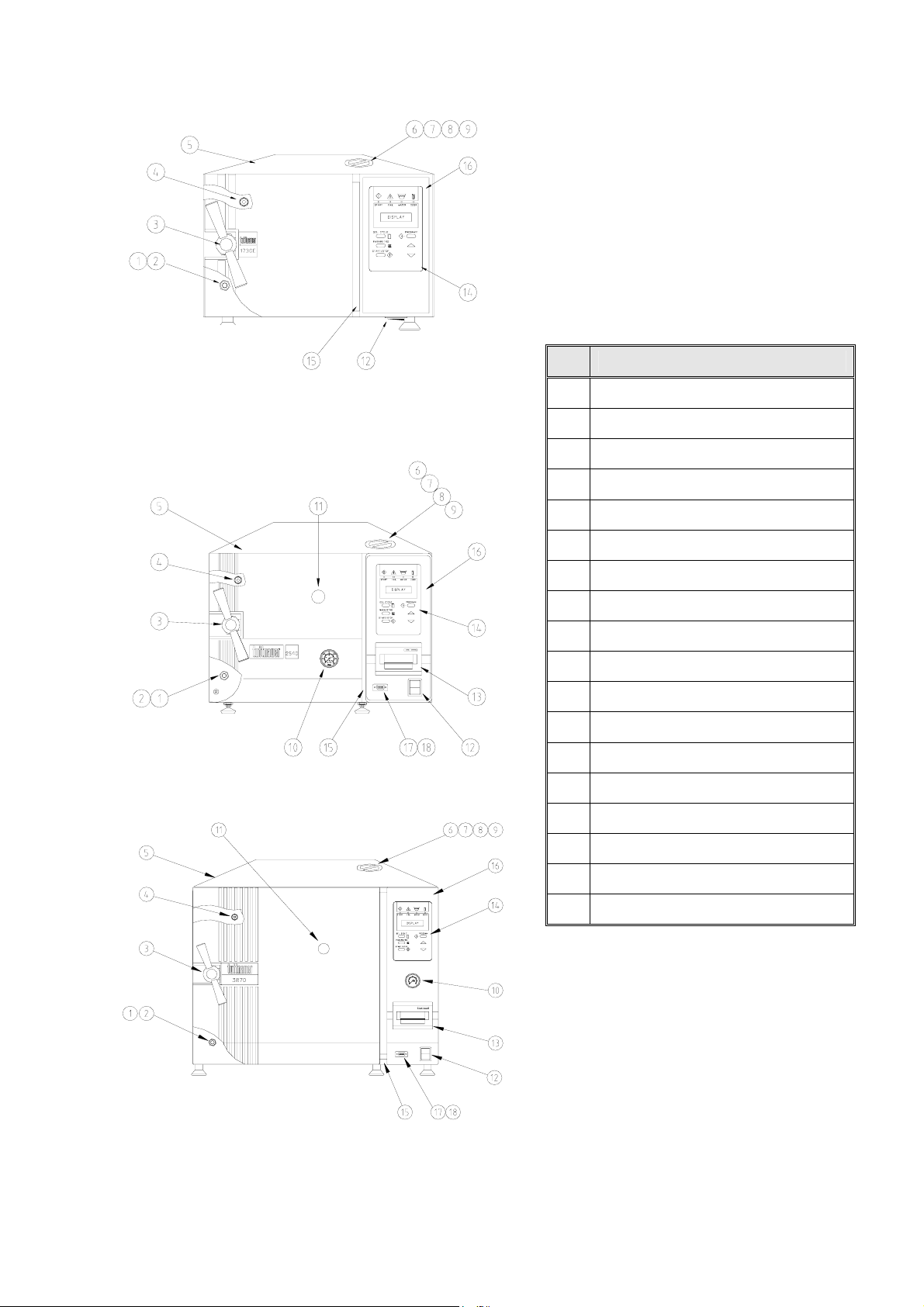

Front View

No. Description

Model 1730

Models 2340/2540

1 Reservoir water drain valve

2

Ring for drain valve

3

Door closing device

4

Door switch

5

Autoclave cover

6

Water reservoir cover

7

Water reservoir – assembly

8

Safety valve

9

Air relief valve

10

Pressure gauge

11

Validation port cover

12

Main switch

13

Printer

14

Front panel key board

15

Completion to panel

16

Panel base

17

Flat cable for ANL-T1 – RS232

18

RS232 port cover

2.12.1.1.1.1

Models 3140/3850/38/70

13

Page 15

Rear View

14

Page 16

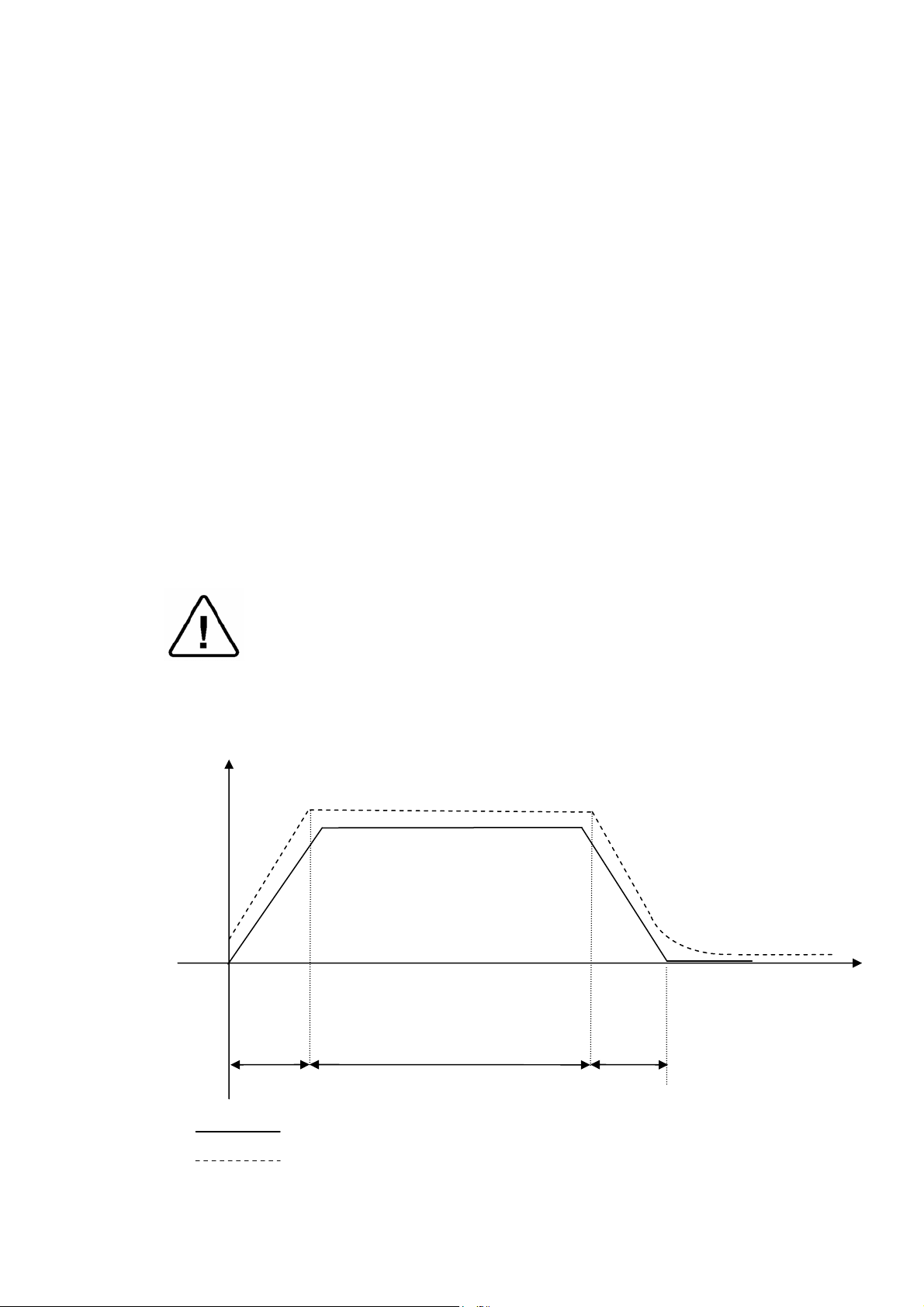

3 STERILIZATION PROGRAMS

The autoclave offers 5 sterilization programs, with or without drying stage.

3.1 PROGRAM 1 (134ºC with no drying)

For unwrapped instruments and materials when the manufacturer

recommends autoclaving at temperatures of 134ºC / 273ºF with no

drying.

Nominal Parameters

♦ Sterilization temperature: 134ºC (273ºF).

♦ Sterilization time: 3 mins.

Operation Sequence

♦ Steam is generated by electric heating elements heating the water

until the sterilization temperature is reached.

♦ Sterilization temperature is maintained constant for the preset

sterilization time.

♦ Fast exhaust; steam is exhausted out of the chamber at a fast rate

until pressure drops to atmospheric pressure.

Ambient Pressure

and Temperature

Attention:

The sterility of instruments processed in unwrapped cycles cannot

be maintained if exposed to non-sterile environment.

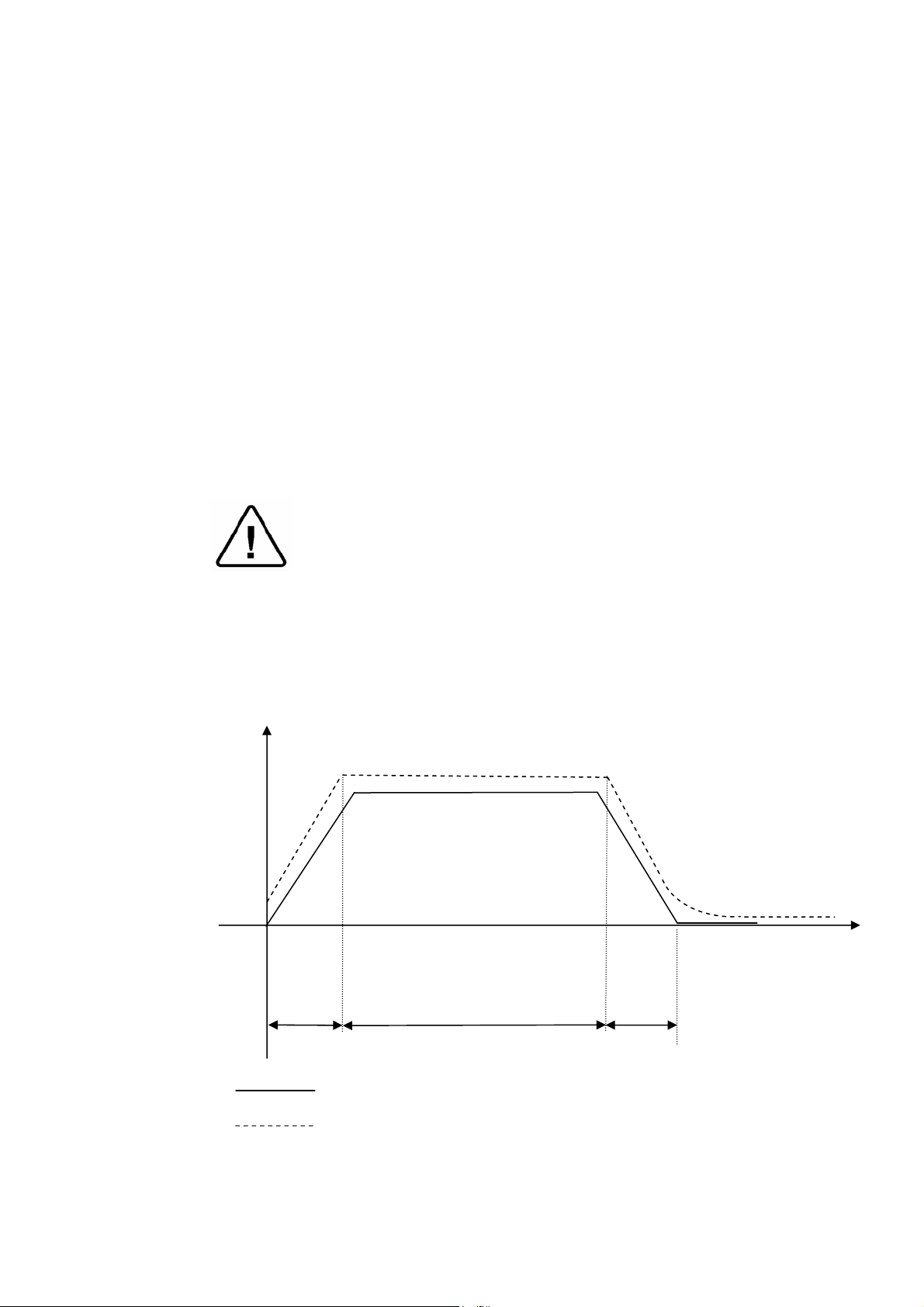

TEMPERATURE

PRESSURE (kPa)

t1 t2

= Pressure

= Temperature

t1 = steam generation stage

t2 = Sterilization stage

t3 = Fast exhaust Stage

15

Page 17

3.2 PROGRAM 2 (121ºC with no drying)

For unwrapped instruments and materials when the manufacturer

recommends autoclaving at temperatures of 121ºC / 250ºF with no

drying.

Nominal parameters

♦ Sterilization temperature: 121ºC (250ºF).

♦ Sterilization time: 15 mins.

Operation Sequence

♦ Steam is generated by electric heating elements heating the water

until the sterilization temperature is reached.

♦ Sterilization temperature is maintained constant for the preset

sterilization time.

♦ Fast exhaust; steam is exhausted out of the chamber at a fast rate

until pressure drops to atmospheric pressure.

Attention:

Ambient Pressure

and Temperature

TEMPERATURE

PRESSURE (kPa)

The sterility of instruments processed in unwrapped cycles

cannot be maintained if exposed to non-sterile environment.

t1 t2

= Pressure

= Temperature

t1 = Steam generation stage

t2 = Sterilization stage

t3 = Fast exhaust Stage

16

Page 18

t3

3.3 PROGRAM 3 (134ºC with drying)

For unwrapped instruments, paper packed instruments and other

materials when the manufacturer recommends autoclaving at

temperatures of 134ºC/ 273ºF with drying stage.

Nominal parameters

♦ Sterilization temperature: 134ºC (273ºF).

♦ Sterilization time: 12 mins.

♦ Dry time: 30mins.

Operations Sequence

♦ Steam is generated by electric heating elements heating the water

until the sterilization temperature is reached.

♦ Sterilization temperature is maintained constant for the preset

sterilization time.

♦ Fast exhaust; steam is exhausted out of the chamber at a fast rate

until pressure drops to atmospheric pressure.

♦ Drying; heating of chamber for 30 min. at a reduced power.

Venting the chamber with a pump (on EA, EKA model).

Notes:

1. On E, EK models the door shall be opened to reduce drying time.

2. On EA, EKA models the drying stage is performed with a closed

door. Filtered air is pumped into the chamber to ventilate the

chamber during the drying stage.

3. After operating the sterilizer, brown stains might appear on the

bottom of the chamber. These stains are a result of the heating

elements that are located at the lower external part of the chamber.

The brown color is a common phenomenon, can be easily be

removed, and will not have any effect on the steriliszed goods.

Attention

:

The sterility of instruments processed in unwrapped cycles

cannot be maintained if exposed to non-sterile environment.

TEMPERATURE

PRESSURE (kPa)

Ambient Pressure

and Temperature

= Pressure

= Temperature

t1 t2

t1 = Steam generation stage

t2 = Sterilization stage

t3 = Fast exhaust Stage

TIME

17

Page 19

t3

3.4 PROGRAM 4 (121ºC with drying)

For unwrapped instruments, paper packed instruments and other

materials when the manufacturer recommends autoclaving at

temperatures of 121ºC/250ºF with drying stage.

Nominal Parameters

♦ Sterilization temperature: 121ºC (250ºF).

♦ Sterilization time: 30mins.

♦ Dry time: 30mins.

Operations Sequence

♦ Steam is generated by electric heating elements heating the water

until the sterilization temperature is reached.

♦ Fast exhaust; steam is exhausted out of the chamber at a fast rate

until pressure drops to atmospheric pressure.

♦ Drying; heating of the chamber 30 mins. at a reduced power.

Venting the chamber with a pump (on EA, EKA model).

Note:

1. On E, EK models the door shall be opened to reduce drying time.

2. On EA, EKA models the drying stage is performed with a closed

door. Filtered air is pumped into the chamber to ventilate the

chamber during the drying stage.

3. After operating the sterilizer, brown stains might appear on the

bottom of the chamber. These stains are a result of the heating

elements that are located at the lower external part of the chamber.

The brown color is a common phenomenon, can be easily be

removed, and will not have any effect on the steriliszed goods.

Attention:

The sterility of instruments processed in unwrapped cycles

cannot be maintained if exposed to non-sterile environment.

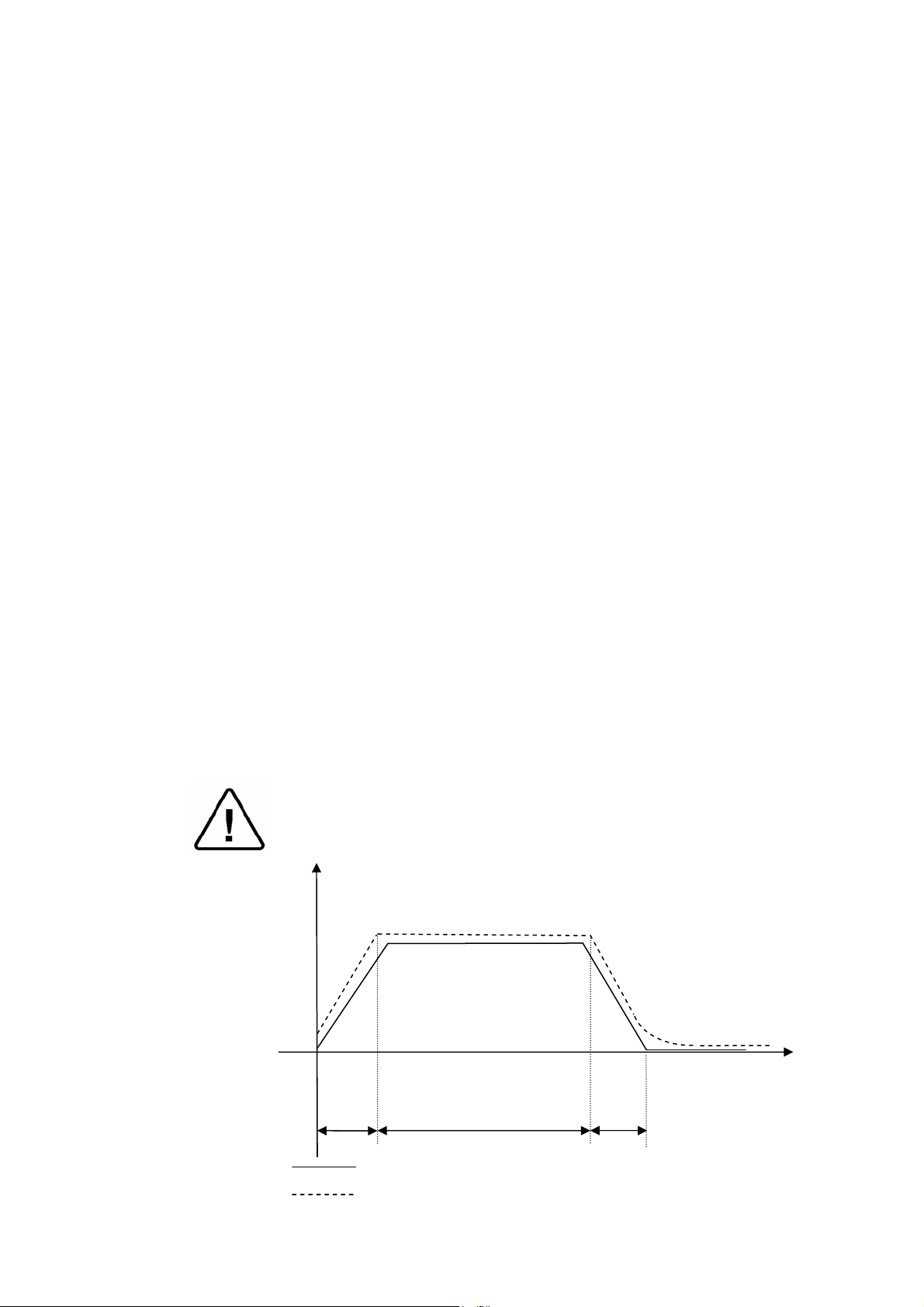

TEMPERATURE

PRESSURE (kPa)

Ambient Pressure

and Temperature

= Pressure

= Temperature

t1 t2

t1 = Steam generation stage

t2 = Sterilization stage

t3 = Fast exhaust Stage

TIME

18

Page 20

3.5 PROGRAM 5 (121ºC with slow exhaust)

For very delicate goods when the manufacturer recommends

autoclaving at 121ºC/250ºF with slow exhaust.

Nominal Parameters

♦ Sterilization temperature: 121ºC (250ºF).

♦ Sterilization time: 30mins.

Operations Sequence

♦ Steam is generated by electric heating elements heating the water

until the sterilization temperature is reached.

♦ Sterilization temperature is maintained constant for the preset

sterilization time.

♦ Slow exhaust; steam is exhausted out of the chamber at a slow rate

(natural cool down) until the temperature drops to 850C (1850F).

Ambient Pressure

and Temperature

= Pressure

TEMPERATURE

PRESSURE (kPa)

t1 t2 t3

= Temperature

TIME

t1 = Steam generation stage

t2 = Sterilization stage

t3 = Slow exhaust Stage

19

Page 21

4 KEYBOARD (keys and display)

Front Panel Keyboard

20

Page 22

4.1 Description and Functions of the Front Panel Keyboard

The command panel is comprised of 3 sections:

On the lower section there are 6 keys; 3 command keys and 3

programming keys.

The middle section consists of the LCD display with two rows and 16

characters on each line.

The top section consists of 4 signal lights that indicate the status of the

autoclave.

1. Sel. Cycle (select cycle) key

This key enables selecting the desired program out of 5 programs.

Pressing this key advances the selected program to the next

program (e.g. from program 2 to 3).

If the system is set to program 5, pressing

the key returns to program 1.

This autoclave has the following available programs:

1. Unwrapped instruments 134ºC (273ºF)/3min with fast

exhaust without drying.

2. Unwrapped instruments 121ºC (250ºF)/15min with fast

exhaust without drying.

3. Unwrapped and paper packed instruments, 134ºC

(273ºF)/12min. with 30min.and drying stage.

4. Unwrapped and paper packed instruments 121ºC

(250ºC)/30min. with 30min. and drying stage.

5. Very delicate goods 121ºC (250ºC)/30min. with slow

exhaust.

2. Parameters key

This key displays for 3 seconds the three parameters of the

program. After selecting the program, it is possible to have the

parameters displayed by pressing this key; the top line reads the

following data:

Sterilization Temp Sterilization Time Dry Time

134ºC S = 3m. D=1Ø

The data is erased automatically after 3 seconds, or if the

parameter key is pressed again during these three seconds.

3. Start/ Stop key

This key commands the following 3 functions:

♦ Starting the process.

♦ Stopping the process.

♦ Canceling the FAIL message from the command panel and

opening the electric door locking.

Note: “STOP” does not operate in EXH stage.

21

Page 23

Starting the process:

It is active while the autoclave is in standby position,

if the door is closed and water level in the reservoir is

normal. Pressing this key starts the selected process.

Stopping the process:

It is active while the autoclave is in process. Pressing

this key at any stage of the process stops operation.

Canceling the FAIL message

The end of an aborted process, the FAIL light is

turned on and an error message is displayed on the

screen indicating the cause of the failure.

Pressing this key cancels the displayed message and

switches off the FAIL light.

4. Program key

This key is designed for programming the clock and setting

different parameters by the service technician by means of the UP

(5) DOWN (6) keys.

When the PROGRAM key is pressed, the date is displayed with

the cursor under the day. Pressing the PROGRAM key again

moves the cursor under the month and then on to the year.

After pressing the PROGRAM key again the time of the day will

be displayed with the cursor under the hour. Pressing the

PROGRAM key again moves the cursor to the minutes parameter.

Each time the UP/DN key is pressed, the value of the parameter

above the cursor is changed.

After the date and time parameters are set, pressing the

PROGRAM key shows CODE: 000.

A code known to the technical personnel will be set to change

certain parameters and perform a digital calibration of the system,

as described in detail in the technician manual.

5. UP key

This key enables increasing the value displayed above the cursor,

at the clock programming and for setting of certain parameters by

the technician.

6. DN key

This key enables decreasing the value displayed above the cursor,

at the clock programming and for setting of certain parameters by

the technician.

22

Page 24

7. START LED indicator

When the “START” LED indicator is on it; indicates that the

system is running a program.

8. FAIL LED indicator

When the “FAIL” LED indicator is on; it indicates that the cycle

has failed either as a result of exceeding the allowable limits or the

STOP key has been pressed.

9. WATER LED indicator

When the “WATER” LED indicator is on; it indicates that there is

a lack of water in the reservoir.

10. DOOR LED indicator

If the “Start” key is pressed and the door is unlocked the light will

signal twice and the buzzer will sound four times.

If a cycle is in progress and fails on door unlocked “FAIL” LED

indicator will lit and a message “Door Unlock” will be displayed.

23

Page 25

4.2 Description of the Operational Messages

The display is comprised of 2 rows, each row has 16 characters.

4.2.1 The upper row:

On the right side of the upper row, 6 characters are allotted

for displaying the stage in progress

♦ WATER − water inlet stage.

♦ HEAT − heating stage.

♦ STER − sterilization stage.

♦ EXH − exhaust stage

♦ DRY − dry stage

On the left side of the upper row, 10 characters are allotted

for the selected programs.

♦ Fast 134 (FAST 273) − fast exhaust

♦ Fast 121 (FAST 250) − fast exhaust

♦ W.dry 134 (W.dry 273) − with drying stage.

♦ W.dry 121 (W.dry 250) − with drying stage.

♦ Slow 121 (Slow 250) − slow exhaust.

When the PARAMETERS key is pressed, the parameter of

the selected program is displayed on the upper row.

4.2.2 The lower row:

♦ On the right side of the lower row, 5 characters are

allotted for chamber pressure display.

♦ The actual pressure is continuously displayed at all

stages of the process and between processes (standby).

♦ On the left side, of the lower row the temperature is

displayed; 5 characters are allotted for the display of

temperature in ºC or ºF, in the form 134ºC or 273ºF.

♦ In case the process is aborted, the diagnosis of the fail

is displayed on the left, of the lower row, instead of the

temperature. 11 characters are allotted for this error

message.

♦ On completion of the process, the END message is

displayed in the interval between the readouts of

temperature and pressure.

♦ At the sterilization and dry stage, the countdown of the

time left to the completion of the stage will be

displayed in the interval between the readouts of

temperature and pressure. The format of the display

will be MM: SS (two digits for minutes and two digits

for seconds).

♦ The time between 2 complete cycles must be at least

10 minutes, in order to give the machine time to cool.

♦ When a cycle is started by means of pressing the

START key, the load number is displayed for 2

seconds on the left of the lower row.

24

Page 26

Examples

Example 1: Autoclave between processes, the program No.1

has been selected.

1 - Fast 134 ST.BY

35°C 100K

Example 2: The autoclave in the sterilization stage, program

No.3 is running. Time left to completion is 3 minutes and 14

seconds.

Selected program W.dry Stage

Temperature Timer

3 - W DRY 134 STER

135ºC 03:14 318K

Example 3: The process failed due to temperature drop in

the

sterilization stage in program No.2.

2 - FAST 121 EXH.

LOW TEMP. 178K

25

Page 27

4.3 Description of Displayed Error Messages and Safety Measures

Low Temp. Message is displayed, FAIL LED indicator lights and

cycle is aborted, if the temperature drops for more than

5 seconds below the sterilization temperature.

Low Heat Message is displayed and sterilization does not start if

the autoclave has not reached sterilization temperature

after heating for 30 minutes (except in slow exhaust

program), and 60 minutes for the slow exhaust program.

High Temp. Message is displayed, FAIL indicator lights and the

cycle is aborted in one of the following cases:

♦ If the temperature rises 3°C (6°F) above the

sterilization temperature during the sterilization

stage.

♦ If the temperature sensor is damaged, this message

appears during the HEAT stage.

Low Pres. Message is displayed, FAIL indicator lights, and the

cycle is aborted if the pressure drops for more than 5

seconds below the pressure correlated to the

sterilization

temperature.

High Pres. This message is displayed, FAIL indicator lights, and

the cycle is aborted if pressure rises above the pressure

correlated to the sterilization temperature +3°C (6°F)

for

more than 5 seconds.

Temp Error Message is displayed and FAIL indicator lights if the

temperature sensor PT100 is damaged or not calibrated.

Man. Stop Message is displayed and the FAIL indicator lights

after the STOP key is pressed for longer than 1 second.

Power Dn Message is displayed if a power failure occurred during

the STERILIZATION stage. When power resumes, the

system automatically returns to the point of power

failure. This message is displayed for several seconds

and the printer prints POWER DN. If the temperature

does not fall below the sterilization temperature,

sterilization resumes automatically. When power

returns, and if temperature falls below the sterilization

temperature, the cycle will stop, exhaust will be

performed according to the program requirements and

the POWER DN and FAIL messages will be displayed

and printed.

If a power failure occurred during Program 5 (slow

121), the system does not allow fast exhaust (as exhaust

valve is normally closed) during a power failure or

when power is back on.

If a power failure occurs during the HEAT stage,

heating resumes (provided there is enough water in the

chamber). If not, the cycle aborts. Dry and exhaust

stages automatically resume operation once the power is

back on.

26

Page 28

Add Water Message is displayed and the “WATER” LED is lit in

case of insufficient water in the water reservoir. After

water is added to the reservoir, the START/STOP

button must be pressed, to start the required sterilization

cycle.

Door Unlock Message is displayed and the DOOR LED indicator

flashes if the door is improperly closed. The START

button should be pressed to start the desired cycle. If the

door accidentally opens during any stage of the cycle,

the same message and indicator appears, and the system

reacts as if the START/STOP key was pressed.

Low Water Message is displayed, FAIL indicator lights and the

program is aborted.

♦ If the electrode sensor indicates no water and the

safety thermostat cuts-off during the heating stage.

♦ If the thermostat is cut-off, and the micro-controller

presumes the electrode sensor is damaged.

27

Page 29

5 PRINTER

The printer is an optional device. If the autoclave is not equipped with a

printer paragraph 5 is not applicable.

5.1 Printer Operation

The autoclave is equipped with a character printer, which prints a

detailed history of each cycle performed by the instrument (for the

record or for subsequent consideration).

The printing is made on thermal paper with 24 characters per line and

contains the following information:

♦ Software version

♦ Real time

♦ Selected program

♦ Sterilization pressure

♦ Sterilization temperature

♦ Sterilization time

♦ Summary of performed cycle and identification hints.

When the sterilization cycle begins the printer starts printing the above

data.

After the preliminary printing, the autoclave starts performing the

sequence of operations of the cycle. The measured values of

temperature and pressure are printed at fixed time intervals, according

to the phase of the process, as shown in the table below.

The data is printed from the bottom up, beginning with the program

name and ending with “cycle ended” for a complete cycle or “FAIL”

for an aborted cycle.

For an example of a typical printout, see next page.

28

Page 30

PRINTER OUTPUT DESCRIPTION

Autoclave:01 Number of autoclave.

Operator :___________ To be filled in manually by operator.

09/03/2000 09:45:01 Date and time sterilization cycle ended.

Load number: 0011 Load number. Useful to determine when to clean

the

chamber.

Cycle ended

−−−−−−−−−−−−−−−−−−−

D31:47 117.8°C 095k The time, temperature and pressure during drying.

----------------------E30:46 120.6°C 119k The time, temperature and pressure during exhaust.

-----------------------

S30:07 134.6°C 310k The time, temperature and pressure during sterilization.

*

* Prints sterilization data every 1 minute.

*

S16:06 134.3°C 310k The time, temperature and pressure during sterilization.

S15:06 134.1°C 312k The time, temperature and pressure during sterilization.

---------------------H00:50 073.2°C 094k The time, temperature and pressure during heating.

----------------------

W00:00 071.9°C 094k The time, temperature and pressure during water inlet.

−−−−−−−−−−−−−−−−−−−

09/03/2000 09:13:04 Date and time sterilization cycle begun.

Dry time: 001min Drying time for selected program.

Ster time: 015min Sterilization time for selected program.

Ster Temp: 134°C Sterilization temperature in chamber for selected

program.

PROGRAM: 1-Fast Selected program: 1-Fast 134 cycle

Ver-EAEn3WP20 Number and version of the program

Legend

W Water inlet stage

H Heating stage

S Sterilization stage

E Exhaust stage

D drying stage

k kPa

29

Page 31

5.2 Printer Handling

The printer is driven and controlled automatically by the control unit,

while the autoclave performs a sterilization program.

Figure 1 Figure 2

To set the paper roll in the printer perform the following steps:

5.2.1 Gently push the clips for removing the front panel, remove

the panel and pull out the printer gently.

5.2.2 Set the paper roll on the shaft (See Figure 1). Since the outer

and inner surfaces of the paper are different set the roll so

that the printing surface is the outer.

5.2.3 Gently push the paper face down into insertion opening (A)

in Figure 2. Keep pressing the feed switch (B) until the paper

comes out from the print head (C).

5.2.4 When the paper emerges from the print head, insert it in the

paper cutter (the slot in the front panel) and reassemble the

front panel on the unit.

The paper roll is set inside the unit and the printer is ready for use..

NOTE: If the paper is not pulled in by the rollers even when you

press the feed switch (B) push the paper in.

5.2.5 To ensure a reliable operation of the printer perform the

following:

5.2.5.1 Turn the main switch to the OFF position.

5.2.5.2 Turn the main switch to the ON position; press the

feed switch at the same time. Verify that the printer

performs an operation test by printing all the builtin characters

The following precautions have to be taken ensuring the proper

operation of the printer:

♦ Avoid contact between the paper and the hot parts of the

autoclave, as the paper will be blackened.

♦ Do not pull out the paper roll from the paper insertion

opening.

♦ Use only the 58mm. wide thermal paper rolls, supplied by

your dealer.

30

Page 32

6 INSTALLATION PLACING AND LEVELING INSTRUCTIONS

Network

Network and connection should comply to the devices consumption. It must

comply with local installation and safety rules and regulations. The voltage

supplied to the device must comply with the label ± 5%.

Caution:

The sterilizer must be placed on a rigid and leveled surface. The stand must

be able to hold the load of the device and loaded material.

Note:

Make sure while placing the autoclave, to leave space around the machine,

to give the technician access to service the machine.

In order to avoid any injury by electrical hazard, it is mandatory for the

customer to have installed an earth leakage relay in the electrical board to

which the autoclave is connected.

This relay disconnects all the poles of the electrical power line in case of

accidental contact with the instrument metal enclosure, by the operator or

another person, leading to a dangerous leakage current.

Note: Keep the back and the right side of the autoclave approximately 1”

(25mm) away from the wall to allow for ventilation.

Connect the power cord to the socket on the rear side of the autoclave; plug it

into the supply socket.

6.1 leveling

The legs (2) of the autoclave are factory set for the autoclave to hold

this amount of water when the autoclave stands on a level surface (3).

To check the water level fill a beaker (4) with the recommended

quantity of water, pour the water into the chamber. The water must

reach the indicator groove (1) in front of the chamber.

1730

E,EK

300

ml.

11

ozs.

2340/2540

E,EK

350

ml.

12

ozs.

400

ml.

3140

E

14

ozs.

500

ml.

3850

E

17

ozs.

650

ml.

3870

E

23

ozs.

If it is necessary, raise the front legs in order to get the proper amount

of water.

31

Page 33

6.2 Water quantity for a cycle

The amount of water in the autoclave chamber necessary for each

sterilization cycles as follows:

1730

E,EK

400

ml.

14

ozs.

2340/2540

E,EK

550

ml.

19

ozs.

700

ml.

3140

E

26

ozs.

3850

1000

ml.

E

32

ozs.

3870

1200

ml.

E

42

ozs.

It is imperative to have the correct amount of water for proper

operation of the autoclave!

6.3 Lifting and carrying

Caution:

Before moving the autoclave, Make sure that the electric

cord is disconnected from the power and there is no pressure in the

chamber.

1. Disconnect the power supply cord.

2. Drain the water from the reservoir and vessel.

To avoid injuries, lifting and carrying should be done by two people.

Do not drop this device!

6.4 Loading and unloading the Device

6.4.1 Safety

Protective equipment and clothes and other safety

instructions should be implemented in accordance with local

and national regulations and/or rules!

For proper sterilization - Do not overload the chamber. Only

autoclavable products shall be used. Please refer to the

manufacturer instructions for sterilization of unknown

materials or instruments.

6.4.2 Loading

Correct loading of the autoclave is essential to successful

sterilizing for several reasons. Efficient air removal from the

chamber and the load will permit steam penetration and

saturation, and allow proper drainage of condensate.

Additionally, correct loading will reduce damage to packs

and their contents and maximize efficient use of the

sterilizer.

For detailed loading instructions, see para. 7 (Preparation

before sterilization)

6.4.3 Unloading

On completion of the cycle, the load shall be immediately

removed from the sterilizer and a visual inspection made to

ascertain that the load is dry, and that sterilizing indicators

have made the required colour change.

32

Page 34

6.5 Filling the Water Reservoir

Remove the water reservoir cover. Pour distilled water into the

reservoir through the opening on top of the autoclave until it reaches

the base of the safety valve holder, approximately 0.7 gallons (3 liters).

Use water-having characteristics as per table in para 2.11

Caution:

Under no circumstance should water be filled above the safety

valve holder.

Use distilled water only. Tap water may block the hole of the air trap.

This causes increase of pressure, which prevent temperature from

rising. It is essential from time to time during heating and sterilization

phases that a spray of steam should escape, causing a hissing sound. If

no steam is evident, follow instructions in paragraph 9.4 (Air Trap Jet

Cleaning Procedure).

33

Page 35

7 PREPARATION BEFORE STERILIZATION

The purpose of packaging and wrapping of items for sterilization is to provide

an effective barrier against sources of potential contamination in order to

maintain sterility and to permit aseptic removal of the contents of the pack.

Packaging and wrapping materials should permit the removal of air from the

pack, penetration of the sterilizing water vapor into the pack and removal of

the sterilizing vapor.

The basic principle determining the size, mass and contents of instrument and

hollowware packs is that the contents are sterile and dry immediately on

completion of the drying cycle and removal of the pack from the sterilizer

chamber.

Instruments to be sterilized must be clean, free from any residual matter, such

as debris, blood, pads or any other material. Such substances may cause

damage to the contents being sterilized and to the sterilizer.

1. Immediately after use, clean instruments thoroughly to dispose of any

residue.

2. It is recommended to wash instruments with an ultrasonic cleaner, using

detergent and mineral-free water.

3. Launder textile wraps prior to reuse.

4. After cleaning, rinse instruments for 30 seconds. (Follow manufacturer’s

instructions on the use of products for cleaning and lubricating

instruments after using the ultrasonic cleaner).

5. Materials, including materials used for inner wraps, shall be compatible

with the item being packed and the sterilizing method selected.

6. Do not place materials to be sterilized directly on the chamber’s wall.

Place the material only on trays, rack, etc.

7. Before placing an instrument into the sterilizer tray, make sure that

instruments which are not of the same metal, (stainless steel, carbon

steel, etc.) are separated and placed on different trays.

Note: Check manufacturer’s instructions for the sterilization of each

item.

8. In case carbon steel instruments are placed on stainless steel trays, the

trays should be lined with a towel or paper wrap before placing the

instruments on the trays. There should be no direct contact between the

carbon steel and the stainless steel trays.

9. All instruments must be sterilized in an open position.

10. Use single-use wraps once only and discard after use.

34

Page 36

11. Verify that the packaging method is in accordance with good practice

approach and the packaging materials are in accordance with the

applicable standards (e.g. EN868 series).

12. Place a sterilization indicator strip in each tray.

13. Place instruments with ratchets opened and unlocked or clipped on the

first ratchet position.

14. Disassemble or sufficiently loosen multiple-part instruments prior to

packaging to permit the sterilizing agent to come into contact with all

parts of the instrument.

15. Tilt on edge items prone to entrap air and moisture, e.g. hollowware, so

that only minimal resistance to air removal, the steam passage and

condensate will be met.

16. Load items within the boundaries of the tray so that they do not touch

the chamber walls, or fall off when the loading car is in transit.

17. The operator may use racks to allow for adequate separation of packaged

instruments.

18. Load trays loosely to capacity.

19. Once a week, use a biological spore test indicator in any load to make

sure sterilization is performed.

20. Make sure that all instruments remain apart during the sterilization

cycle.

21. Empty canisters should be placed upside-down, in order to prevent

accumulation of water.

22. Allow a distance of approximately 2.5 cm (1”) between trays to permit

steam circulation.

23. Wrapped Instruments

Wrapped instruments should be packed in material that promotes drying

such as autoclave bag, autoclave paper, and muslin towels.

It is highly recommended to utilize the Tuttnauer Pouch Rack. This

rack allows the operator to place pouches on their side, thus increasing

the capacity of the autoclave significantly and promoting better drying of

the instruments. Contact your dealer for details.

Note:

A table “Suitability of steam sterilization processes for various goods and

method of packing” is added to the accompanying documents.

Pouch Rack

35

Page 37

24. Packs

1. Place packs upright on trays, side by side.

2. Packs should not touch the chamber walls.

3. Pack instrument sets in a manner that prevents damage to delicate

items.

4. Pack hollowware sets so that all openings face the same direction

and so that the contents cannot move inside the pack.

5. Load packs of folded operating room drapes with layers vertical,

allowing air to be removed from the packs rapidly.

6. Do not place packs of hollowware and trays of instruments above

textile packs or soft goods in order to avoid wetting caused by

condensation from items above.

7. Load items packed in flexible packaging materials on edge with

paper to laminate, or flat with the paper surface downwards.

Note:

The manufacturer’s recommendations shall be observed,

concerning the sterilization data for each type of material.

25. Tubing

When placing in a tray, make sure that both ends are open, without sharp

bends or twists.

Wrong

Right

36

Page 38

26. Liquids

Use only heat-proof glass, filled to 2/3 capacity. Ensure that the glass

container is covered, but not sealed to prevent pressure build-up.

Liquids

Note: A table of suitability steam sterilization process for various

goods and methods of packing is included with accompanying

documents.

37

Page 39

8 OPERATING INSTRUCTIONS

To avoid possible damage, do not leave the autoclave un-attended while in

operation

It is important to clean the hole of the air jet, as described in para. 9.3

before starting operation of the autoclave, for the first time.

1. Remove the water reservoir cover. Pour distilled water into the reservoir

through the opening on top of the autoclave, until it reaches the base of

the safety valve holder, approximately 0.7 gallons (3 liters).

2. Insert the plug into the electric socket.

3. Turn on the rocker switch mounted on the front panel to power control

circuits.

4. Set the clock for the proper date and time, by means of the PROGRAM

key (4), UP (5) and DOWN (6); see section 4.

5. Press the SELECT key (1) to select the required program. The name of

the program is displayed indicating the program that has been selected.

6. Press PARAMETERS key (2) to monitor the nominal parameters of the

program.

7. Load the material to be sterilized into the chamber according to

instructions in para. 7 (Preparation Before Sterilization), and close the

door, until hand-tight.

The Door signal light is turned off indicating door is closed. Once the

sterilization cycle is in progress, a safety device locks the door and

makes it impossible to open it until completion of the cycle.

Note:

Due to inherent elasticity of the door gasket, the Door indicator light

may be turned OFF before a complete seal is made between the door

and the chamber.

Therefore, in order to ensure the door is fully sealed, when the Door

light has been illuminated continue to tighten the door bolt until

“hand-tight”.

Do not over - tighten the bolt as this may result in damage to the

gasket.

Should the autoclave fail to reach the sterilizing

temperature/pressure, always check if the door is fully sealed. If not,

tighten the door bolt further, as described above, until completely

sealed.

8. Press the START/ STOP key to put the autoclave in operation.

The autoclave starts performing sequence of operations. The actual

measured values of pressure and temperature are displayed continuously

and printed (if equipped with a printer) every minute at STE stage, and

every 4 minutes at the other stages. The phase in progress is displayed at

the right side of the upper line as WATER, HEAT, STER., EXH., and

DRY.

If the operator presses the START key and the door is not completely

closed, the process will not start and the DOOR light will flash twice

then turn off and the buzzer will sound four times.

38

Page 40

9. To obtain better drying results at the E, EK

models, open the door partially– at an angle of

approx. 20-25 degrees-during the dry stage.

Unscrew the locking screw to maximum and let

the door to open to maximum feasible opening.

(see picture).

Note:

This is not necessary for the EA, EKA models

which ensure a continuous air circulation

through the chamber in the dry stage.

10. At the end of the cycle, the START light is put off, the END message is

displayed and the buzzer will ring a continuous sound for 7 seconds. In

case of a failed cycle, the diagnosis of the failure followed by the

“FAIL” message will be printed (if equipped with a printer) and the

buzzer will output an interrupted sound.

11. Open the door and unload the sterilized goods from chamber. In case of

fail press the START/STOP key to cancel the locking of the door.

12. The sterility of instruments processed in unwrapped cycles cannot be

maintained if exposed to non-sterile environment.

Note:

A minimum interval of 10 minutes will be observed between the end

of a cycle and the start of a new cycle.

For unloading hints – see para. 6.3.2 (Unloading).

Attention

Do not touch the strainer’s cover, mounted on the exhaust line,

during and short after operation.

Touching the hot strainer’s cover may cause severe injuries.

39

Page 41

9 MAINTENANCE INSTRUCTIONS

9.1 Preventive and Scheduled Maintenance

The maintenance operations described in this chapter have to be

fulfilled periodically to keep the device in good condition and to

reduce the breakdown time to a minimum.

The user maintenance personnel, in accordance with further

instructions can easily execute these operations.

The owner of the autoclave is responsible to call for an authorized

technician to perform the periodical tests and preventive maintenance

operations, as specified in the technician manual.

Use only mineral-free water as detailed in para. 2.11 (water quality).

9.1.1 Daily

Clean door gasket with a soft cloth. The gasket should be

clean and smooth.

9.1.2 Weekly

1. Take

out the tray holder and trays. Clean the tray

holder and trays with a cleaning agent & water and

with a cloth sponge. You may use diluted lemon acid

(25-50 CC lemon acid in 1 liter of water) as cleaning

agent. If detergent is used, rinse the tray holder and

trays immediately with water to avoid stains on then

metal.

2. Once a week clean and descale the chamber, copper

tubes and the reservoir using ‘Chamber Brite™’ (see

para. 9.11).

Caution

Do not use steel wool or steel brush as this can damage

the chamber!

3. Put a few drops of oil on the 2 door pins and door

tightening bolts.

4. Clean the outer parts of the autoclave with a soft cloth.

5. Once

a week, or after 20 cycles (whichever comes

first), drain the water from the reservoir, and refill with

fresh mineral-free water or distilled water (see para.

9.3).

6. Clean the electrode with a soft cloth.

7. Clean the air jet as per para. 9.4.

9.1.3 Periodically

1. Clean the strainer once a month as per para. 9.5.

Cleaning frequency may be reduced according to

previous maintenance.

2. Once every month activate the safety valve (see para.

9.8).

3. Once every month, check the air trap jet.

4. On EA, EKA replace the air filter, every 6 months (see

para. 9.5).

40

Page 42

5. Once every six months clean the fan grid with a

vacuum cleaner from the inside outward.

6. Replace the door gasket every 12 months (see para.

9.4).

9.2 Draining the Reservoir

Caution

Before starting, ensure that the electric cord is disconnected and

there is no pressure in the autoclave.

Note:

On the front left side is the drain valve of the mineral-free water

reservoir.

1. Turn drain valve counter clockwise (1 turn). Use the supplied

silicone hose.

2. Turn drain valve clockwise to the close position.

3. Connect the electric cord to power source.

4. To fill the reservoir with mineral - free water and feed water,

switch on the main power switch.

5. The autoclave is now ready for use.

41

Page 43

9.3 Cleaning Air Jet

(Located in the water reservoir.)

The elimination of air pockets from the sterilization chamber during

heating and sterilization phases is achieved by means of the air trap jet.

This device consists of a small orifice that is obtrusive and opened by a

small wire moving forth and back.

The air pockets and small steam quantities are pushed up by the steam

pressure and evacuated through this orifice.

Caution:

Before proceeding, make sure that the electric cord is disconnected

and that there is no pressure in the autoclave. Allow the instrument

to cool and the pressure to drop to atmospheric pressure, before

cleaning the jet.

1. Remove the water reservoir cover.

2. Clean the hole of the jet, by manipulating the air trap wire back

and forth.

3. In case it is necessary to replace the air trap jet, use Teflon tape to

seal the thread.

It is important to clean the hole of the air trap, as described at point 2

before starting operation of the autoclave, for the first time.

42

Page 44

9.4 Replacing the Door Gasket

Pull off the gasket from the door groove, thereby installing the new

gasket referring to the drawings above 1, 2 and 3.

Caution!

This gasket is designed with a trapezoidal cross section. The gasket

should be placed with the widest side towards the door.

43

Page 45

9.5 Replacing the Air Filter (models EA, EKA)

In order to ventilate the chamber during the dry phase and to assist in

cooling the chamber at the end of the cycle, filtered atmospheric air

enters the chamber via a solenoid valve. The filtration of the air is

performed by the bacteriological filter that is placed at the inlet of the

chamber.

The filter is mounted near an opening on the right sidewall of the

autoclave enclosure, to ease access for replacing it.

To replace the filter proceed as follows:

1. Remove the securing screws (see “REAR VIEW”) and the filter

cover by turning the cover counter- clockwise until the handle is at

a vertical position.

2. Pull out the cover.

3. Cut the tie wrap fixing the flexible tubing connecting the filter to

the copper pipe, and pull off the filter.

4. Pull out the filter through the opening.

5. Replace the filter with a new one connecting it with the flexible

tubing and tightening it with a tie wrap.

6. Re-assemble the cover and lock it into position by turning it a ¼

turn. Fasten the securing screws.

44

Page 46

9.6 Cleaning water outlet strainer

Caution!

Before proceeding, Make sure that the electric cord is disconnected

and there is no pressure in the autoclave.

1. Open the strainer cover.

2. Remove the strainer element.

3. Rinse the strainer with water, using a brush if necessary.

4. Reinstall the strainer element.

5. Close the strainer cover.

CAUTION

Do not touch the strainer’s cover, mounted on the exhaust line, during

and short after operation.

Touching the hot strainer’s cover may cause severe injuries.

If maintenance operation is performed while strainer cover is hot, use

heat resistant gloves to avoid injuries.

Cap Teflon

gasket

Strainer

element

45

Strainer

Housing

Page 47

9.7 Replacing the Cartridge Fuse

Caution

Make sure that the electrical power cord is disconnected!

Use a screwdriver to unlock the fuse holder cover by turning it counter

clockwise a little, and pull it out.

Insert a new cartridge into the holder and turn the cover clockwise until

locked.

Make sure that the correct fuse is installed as marked in the following

table

AUTOCLAVE TYPE

DESCRIPTION

E EA EK EKA

120V 230V 120V 230V 120V 230V 120V 230V

2340/2540

Air pump fuse (A)

Water pump fuse (A)

1.25 1.25 1.25 1.25

Air pump fuse (A)

Water pump fuse (A)

1.25

2 1.25

3140/3850/3870

1.25

1.25

1.25

1.25

1.25

Note:

The drawing below refers to models EK, EKA. On models E, EA

there is no air pump fuse.

46

Page 48

9.8 Checking the Safety Valve

(Located in the water reservoir)

In order to prevent the safety valve from blockage, it is necessary to

allow the steam pressure to escape (every month) as follows:

1. Operate the sterilization cycle according to the manual.

2. Allow a pressure of approximately 200 kPa (29-psi) to build up in

the chamber.

3. Remove water reservoir cover

4. Pull the ring of the safety valve using a tool, i.e. screwdriver, hook

etc and lift the safety valve ring for 2 seconds. Be careful not to

burn your hands.

5. Press the STOP key to pause operation, and exhaust steam from

chamber.

6. Wait until pressure goes down to zero, only then can the door be

opened.

47

Page 49

9.9 Door Safety System

The door opening is ensured by two means:

1. The closing device prevents an incidental opening of the door.

2. A pull-type solenoid that in inactivated position locks the door and

must be electrically powered to release the locking and enable the

opening of the door.

9.9.1 Solenoid locking device

The solenoid locks the door in the following situations:

1. When the control unit is not powered.

2. If power failed or has been turned off while the

autoclave is in operation, even if power has been

restored.

3. If operation was stopped before completion of the

cycle as a result of a failure or a manual stop.

4. When the temperature inside the autoclave chamber is

higher than the end of the cycle temperature, preset by

the operator. The opening of the door is possible only

when the temperature has dropped below the preset

value (this case refers to program 5 only).

For cases described at points 2 and 3, press the

START/STOP key to cancel the door locking at the end of

the operation.

If, for any reason, the locking mechanism does not open, do

not use force to open the door. Turn the door a quarter

(1/4) turn clockwise (closing direction) and re-try to open the

door. Do not use force to open the door.

If, despite operating according to the instructions above, the

door does not open, call an authorized technician.

9.9.2 Emergency door opening

In order to facilitate initial installation, the door locking

position is taped in this retracted position at the factory. On

completion of all installation activities this tape must be

removed.

If for any reason the door locking mechanism is permanently

locked, it is possible to open the door and provide access for

eventual repairs to the locking mechanism. The swing bolt

has a drilled opening located in the lock catch. By pushing

the piston back with a 2mm. pin, the swing bolt may be

turned another 3/4 position until the position catches again.

Repeat these steps until the bolt is swung, and the door

opened.

48

Page 50

9.10 Cleaning Table Top Autoclaves with Chamber Brite™

CHAMBER BRITE™ is a cleaning and descaling agent designed

specifically for the cleaning and removal of water deposits, oxides and

other sediments that are found in steam sterilizers. The material is a

combination of acidic salts and additional cleaning materials.

Cleaning Procedure

1. Important – all steps in this procedure must be completed without

interruption.

2. When the autoclave chamber is

cold, remove instruments and trays

from the autoclave.

3. Open the door and spread the

contents of a packet in a straight

even line along the bottom of the

chamber, from back to front.

4 Select and start program No. 1.

When the cycle is finished exhaust

the unit.

5. At the end of the exhaust cycle

drain the water from the reservoir.

6. Fill the water reservoir with

distilled water.

7. Repeat a sterilization cycle without

Chamber Brite™ powder, to

remove any excessive dirt in the

pipes. Select and start program No.

1. When the cycle is finished

exhaust the unit

8. At the end of the exhaust cycle

drain the water from the reservoir.

9. Turn the autoclave off and allow

chamber to cool.

10. Remove the tray holder; wipe the

interior of the chamber with a damp

cloth.

11. Fill the reservoir with distilled

water or mineral free water only.

12. The instrument is ready to use.

IMPORTANT:

DO NOT sterilize instruments during

the cleaning process!!!

49

Page 51

CAUTION:

Keep out of reach of children. Contains mildly acidic ingredients.

Avoid contact with the skin, eyes or clothing. Wash hands well

after touching the powder, in the case of eye contact flush with

continuous running water for at least 15 minutes. If irritation

persists get medical attention. If accidentally swallowed, do not

induce vomiting, drink large amounts of water and obtain medical

attention. MSDS available upon request.

For models 1730, 2340, 2540 use one packet of CHAMBER BRITE™.

For models 3140, 3850, 3870 use two packets of CHAMBER

BRITE™.

Clean every 20 cycles or as needed.

50

Page 52

Solution

1.1 Make sure the main switch is in the ‘On’ position.

(see front view drawing).

1.2 Make sure the power cord is properly connected to the machine and the mains.

(see rear view drawing)

1.3 Check the reset button on the cut-out thermostat. (see para. 9.7 Replacing the

Cartridge Fuse)

1.4 Make sure the circuit breaker has not tripped. Lift the circuit breaker lever.

2.1 Check the air trap (inside the water reservoir).

(see para. 9.3 Air Trap Cleaning Procedure)

2.2 Make sure the machine has the proper amount of sterilization load.

3.1 Add water to the reservoir

3.2 Clean the water level electrode inside the vessel.

Check the leveling of the machine.

(see para. 6, Installation).

4.1 Check the air trap inside the water reservoir.

(see para. 9.3 Air Trap Cleaning Procedure)

4.2 Check the leveling of the machine.

(see para. 6, Installation).

4.3 Check the door for leakage and replace the door gasket if necessary.

(see para. 9.4 Replacing the Door Gasket)

Problem

This troubleshooting chart enables the user to solve minor malfunctions, prior to contacting our service department.

Only technical personnel having proper qualifications and holding technical documentation (including a technician

10 TROUBLESHOOTING

manual) and adequate information are authorized to service the apparatus.

1. The machine is not responding

2. ‘Low Heat’ is displayed

3. ‘Low Water’ is displayed

4. ‘Low Pres’ is displayed

51

Page 53

Solution

5.1 Check the air trap inside the water reservoir.

(see 9.3 Air Trap Cleaning Procedure)

5.2 Check the leveling of the machine.

(see para. 6, Installation)

6.1 Clean the water level electrode inside the vessel.

Check leveling of the machine.

(see para. 6, Installation)

7.1 Clean the water level electrode inside the vessel.

Check the leveling of the machine.

(see para. 6, Installation)

Problem

5. ‘Low Temp’ is displayed

6. ‘High Temp’ is displayed

7. ‘High Pres’ is displayed

8.1 Make sure the paper is mounted in the right way. Only one side of the paper is

printable.

(see para. 5.2, Printer handling)

9.1 Make sure the paper is inserted in the printer.

(see para. 5.2, Printer handling)

9.2 Switch off the machine and switch it back on while pressing the feed button on

the printer. If the printer prints a test printout, the printer is O.K. and there is a

problem with the electronics. Contact your dealer to solve the problem.

If the printer does not print the test printout, there is a problem with the printer.

Contact your dealer to solve the problem.