Tuttnauer E-Series Repair manual (2004)

tuttnauer USA Co.

Sterilization & Infection Control Products

Technicians Service and

Repair Manual

for the

“E” Series Tuttnauer

Autoclave

This manual is intended for the qualified technician. The instructions and guidance go

into great detail, but basic trouble shooting and diagnostic skills are still required.

I want to thank all the members of the technical staff at Tuttnauer USA with out whose

help this manual could not have been completed

Written by Henry Dierschke

Illustrated by Edward A. Hendrickson

Revised Edition

November 18, 2004

First Edition

June 1, 2000

Section

Table of Contents

1 General Information

1.1 Tuttnauer Company

1.2 Warranty

1.3 Theory of Operation

2 Installation and Setup

2.1 Unpacking & Inspection

2.2 Location of Unit

2.3 Voltage Requirements

2.4 Setup

3 Front Panel Keypad

3.1 Front Panel Keypad

4 Display Messages

4.1 Display Messages

5 Operating Instructions

5.1 Preparation before Sterilizing

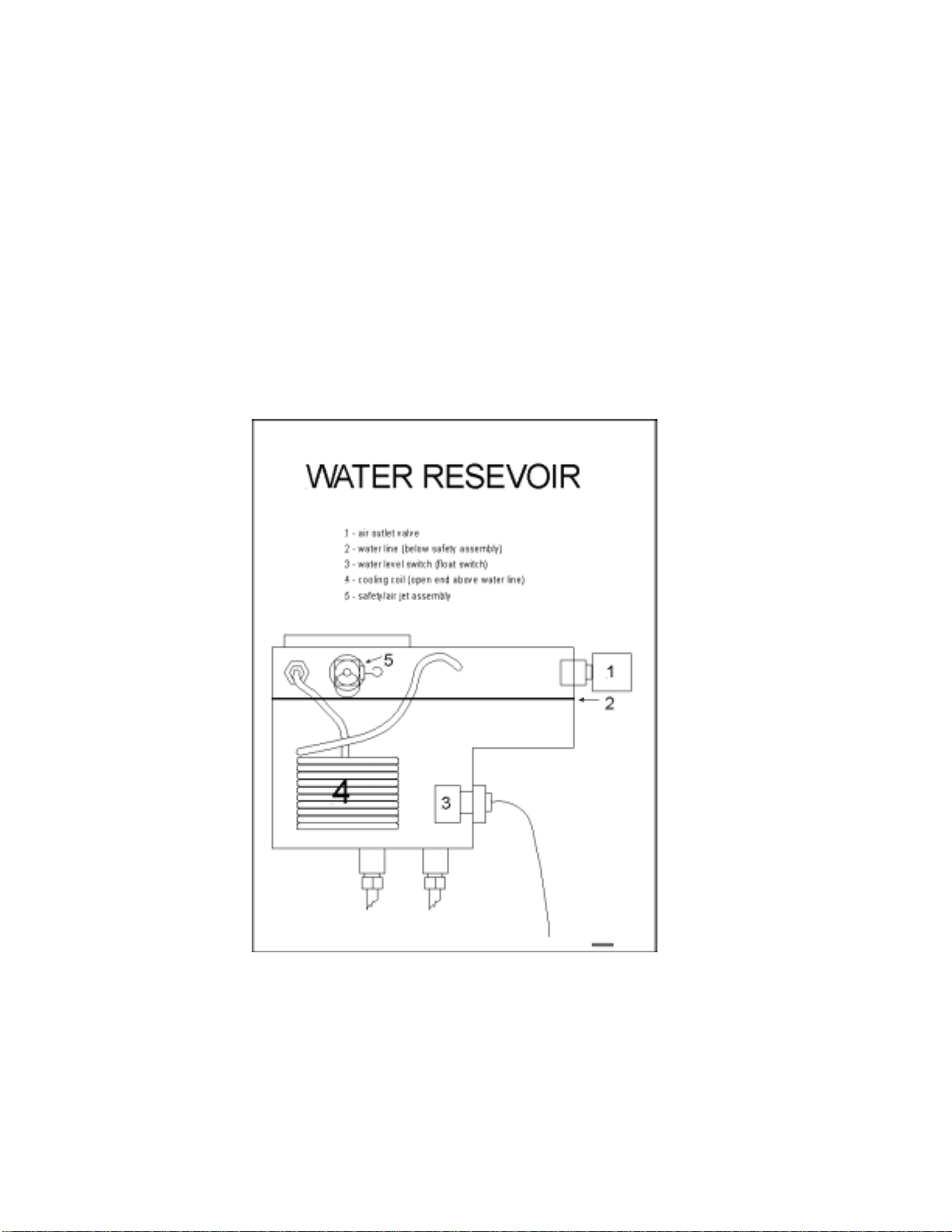

5.2 Filling the Reservoir

5.3 Sterilization Programs

5.4 Operating Instructions

5.5 Standard Sterilization Times

6 Maintenance

6.1 Cleaning

6.2 Door Assembly

6.3 Closing Device

6.4 Solenoid Valves

6.5 Air Jet

6.6 Water Sensing Electrode

6.7 Chamber

6.8 Dry Pump Filter

6.9 Safety Relief Valve

6.10 PC Board Maintenance

6.11 Filter Maintenance

7 Trouble Shooting

7.1 Power On Problem

7.2 Heat Up Problem

7.3 Pressure Problem

7.4 Temperature Problem

7.5 Keyboard Problem

7.6 Overheating Problem

7.7 Safety Thermostat Problem

7.8 Circuit Breaker or Fuse Problem

7.9 Dry Pump Problem

7.10 Drying Problem

7.11 Sterilizing Problem

7.12 Fan Problem

7.13 Unit Gives Off Odor

7.14 Door Problem

7.15 Water Filling Problem

7.16 Leaking Water Or Steam

7.17 Air Outlet Valve Problem

7.18 Display Problem

7.19 Power Supply Problem

7.20 Control Problem

7.21 Printer Problem

7.22 Add Water Indicator Problem

7.23 Door Closed Indicator Problem

7.24 Memory Problem

7.25 Exhaust Problem

7.26 Cut-Out Thermostat Problem

7.27 Water Pump Problem

8 Testing and Calibration

8.1 SSR (Solid State Relay)

8.2 Heating Elements

8.3 Solenoid Valves

8.4 Temperature Sensor

8.5 Pressure Sensor

8.6 Automatic Water Fill

8.7 Water Sensing Electrode

8.8 Safety Thermostat

8.9 Cut-Out Thermostat

8.10 Dip Switch Settings

8.11 Test Equipment and Use

8.12 Finding the Date Code

8.13 In – Out Test

9 Tables and Diagrams

9.1 Ohm and Amp Readings

9.2 Digital Predg board

9.3 Ajunc 2 board

9.4 Ajunc 3 board

9.5 Test Points for Ajunc 2

9.6 Test Points for Ajunc 3

9.7 Maximum Allowable Instrument Loads

9.8 Maximum Allowable Liquid Loads

9.9 Ajunc Board Schematics

9.10 Power Supply

9.11 LM34 Cross Reference Table

9.12 Solenoid Valve Layout

9.13 Autoclave Components Rear View

9.14 Autoclave Electronic Box Components

9.15 Chamber Brite Instructions

10 Replacement

10.1 Heating Elements

10.2 Safety Thermostat

10.3 Temperature Sensor

10.4 Pressure Sensor

10.5 Power Supply

10.6 Closing Device

10.7 Solenoid Valve

10.8 SSR (Solid State Relay)

10.9 Air Jet

10.10 Water Sensing Electrode

10.11 Door Bellows

10.12 Chamber

10.13 Printer

10.14 Dry Pump

10.15 Safety Relief Valve

10.16 Float Switch

10.17 Power Transistor

10.18 Ajunc Board

10.19 Digital Predg Board

10.20 Door Assembly

10.21 Fan Replacement

10.22 Water Pump Replacement

10.23 Fuse and Fuse Holder

10.24 Circuit Breaker

11 Component Function in the Autoclave

11.1 Safety Thermostat

11.2 Cut-Out Thermostat

11.3 Air Jet

11.4 Water Sensing Electrode

11.5 Door Bellows

11.6 Air Outlet Valve

11.7 Printer

11.8 Fuse and Circuit Breaker

1 General Information

1.1 The Tuttnauer Company

The Tuttnauer Company founded in 1925 produces infection control equipment

for the Dental, Medical,Veterinary and Laboratory markets. In addition Tuttnauer

produces large walk-in units for industrial, commercial and hospital applications.

Tuttnauer equipment is distributed worldwide and the Tuttnauer Company is considered a

leader in the field of Infection Control Apparatus

Our main product line consists of manually operated and automatic sterilizers. The

following list shows past as well as currently avaliable models of Tuttnauer sterilizers.

Manually operated models: M = Manual MK = Manual Kwiklave*

Chamber sizes: 7” x 12”; 9” x 18”;

(diameter x depth) 10” x 18”; 15” x 20”

and 15” x 27”

Automatic models:

E = Electronic EA & EZ = Electronic with Air Assisted Drying

EK = Electronic Kwiklave

EKA & EZ10k = Electronic Kwiklave with Air Assisted Drying*

Chamber sizes: 7” x 12”; 9” x 18”;

(diameter x depth) 10” x 18”; 15” x 20”

and 15” x 27”

Tuttnauer offers a wide variety of standard models of autoclave, as well as custom

designed units.

Additional Tuttnauer products,

• Chamber Brite autoclave clean er

• Clean & Simple ultrasonic enzymatic cleaning solution in tablet form

• Ultrasonic Cleaners - 1 & 3 gallon

• Water Distillers – 1gal, 3.5gal, 8gal and 12gal

* Kwiklave units have faster cycle times then a standard unit, while maintaining standard

sterilization exposure times.

1.2 Warranty

Tuttnauer’s warranty covers defects in materials and workmanship on every part in the

autoclave. For exact details see a formal copy of the Warranty Policy or call Tuttnauer at

1 800 624-5836.

This warranty for new autoclaves covers both parts and labor.

Tuttnauer warrantees chambers (on select models) for a period of ten (10) years against

any defects in materials and workmanship. This chamber warranty went into effect

January 1997. (for more details call 1 800 624-5836)

These warranties do not apply to any improper installation or application; nor shall it

extend to products which have been altered outside the factory without prior

authorization from Tuttnauer; nor to products which have been improperly maintained.

No product will be received or accepted for repair without proper return authorization

from Tuttnauer. All transportation charge to and from Tuttnauer are the responsibility of

the owner of the autoclave. During the first 30 days after purchasing a new autoclave

Tuttnauer will pay shipping costs on an individually evaluated basis and ONLY with pre

approval.

This warranty will be void if the unit is not purchased from an authorized Tuttnauer

dealer.

To activate the warranty, the registration card must be completed and returned to

Tuttnauer within fourteen (14) days of purchase or you may call customer service

at 1 800 624-5836.

Tuttnauer’s obligation is limited to repair or replacement of parts for the autoclave.

No other warranties or obligations are expressed or implied.

1.3 Theory of Operation

Theory of Operation – Electronic Steam Sterilizer Models E, EK, EA, EKA,

EZ and EZ10k

The Tuttnauer Steam Sterilizer is designed as a gravity displacement system. This means

that no other methods are used to move steam and air in or out of the Chamber other than

the natural forces of gravity.

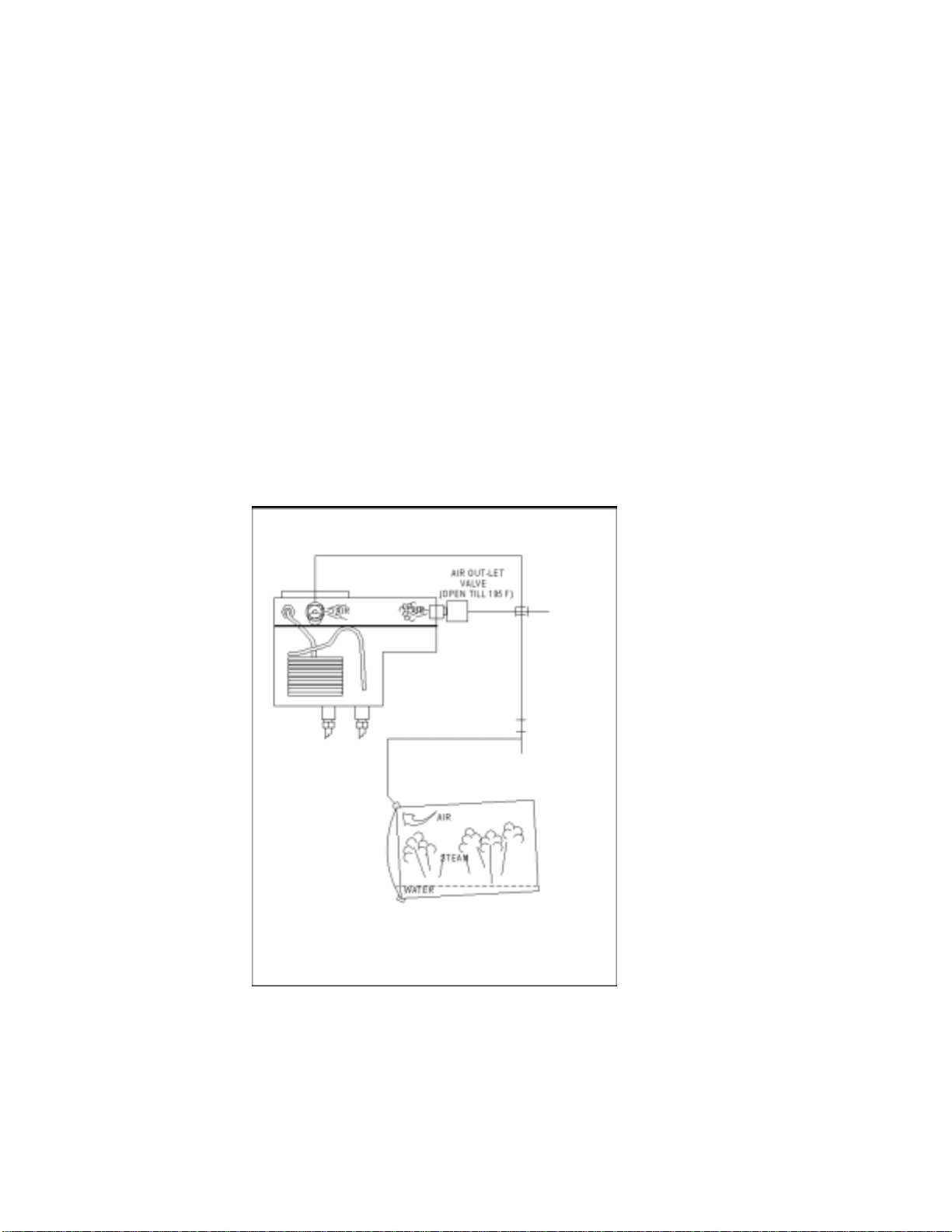

Water inside the autoclave Chamber is heated to produce steam. The rising steam forces

any air inside the Chamber to the top of the Chamber where it is bleed off by the Air Jet.

This event is due solely to the effect of gravity on the steam and air. As the pressure

builds within the Chamber the air is continuously expelled through the unit’s Air Jet. The

Air Jet is located in the water reservoir and connected by a copper tube to the top rear of

the Chamber. The process of removing the air and leaving only steam in the Chamber is

essential to the operation of the Sterilizer. Assisting the Air Jet in this function is the Air

Outlet Valve. This valve participates in removing the air until a temperature of 195° is

reached then the valve closes and any remaining air is removed by the Air Jet.

Steam temperature has a direct and important correlation to steam pressure. At every

level of pressure, steam has a specific corresponding temperature, this is a universally

accepted fact. There is one stipulation required to make this true, that is that there must be

0% air present. For this reason it is important that the air be removed as completely as

possible from the Chamber. Removing the air is what allows the temperature to rise

properly inside the Chamber.

The importance of a clean working Air Jet can not be understated. The Air Jet has two

important functions.

First is to remove the air from in side the Chamber while the unit is heating up. If air

were allowed to remain in the Chamber its presence would produce pockets of low and

high temperature. These uneven temperatures within the Chamber would result in areas

of no sterilization. Only by removing the air can more uniform temperatures be attained

and as a result even and complete sterilization.

In addition the Air Jet has a second function, that is to maintain circulation within the

Chamber. It does this by remaining open after all the air has been bled off and continuing

to purge the steam. This constant purging of steam causes motion within the Chamber.

This constantly moving, constantly circulating steam is important in maintaining uniform

temperature Uneven steam temperatures can be the result of the heating elements turning

on and off during the sterile cycle. This can cause hot and cold pockets of steam within

the Chamber. If an instrument is in one of these cold pockets it will not be sterilized even

though the rest of the load was and the spore test confirmed a sterile load. The end result

of keeping the steam in motion, because of the Air Jet, is that no pockets of uneven

temperature will form and the load will be completely sterilized.

Why use steam in the first place?

There are several reasons for preferring a steam Sterilizer.

The first is that steam is non-toxic.

The second is that steam sterilization is fast. Steam has excellent heat transfer properties.

It allows for tremendous amounts of heat energy to be transferred to the

instruments instantaneously. This flash of energy is what destroys the biological

contamination.

Third, steam is readily available and easy to make from any water source.

Forth, equipment designed for steam sterilization is simpler to manufacture and use

Basic operation of the autoclave

1. The operator closes the door and presses start

2. Water flows into the Chamber, the air outlet valve is open so that the water can flow in

smoothly. Water flowing into a hot sealed Chamber will build pressure

immediately exerting a force on the water that can slow or even stop it from

entering the Chamber. The open air outlet valve provides an escape for that

pressure, which allows the water to flow smoothly.

3. The autoclave heats to the proper temperature controlled by the temperature and

pressure sensor. The air outlet valve closes at 1950F. Air escapes the Chamber

through the Air Jet

4. Once temperature is reached the timer counts down the programmed amount of

sterilization time. Steam continues to purge through the Air Jet eliminating any

differences of temperature that can occur within the Chamber.

5. The autoclave exhausts and the sterilization is complete.

2 Installation and Setup

2.1 Unpacking and Inspection

Upon receiving the autoclave carefully inspect the outside of the shipping carton

for any signs of damage. If any damage to the shipping carton is found note the location

with respect to the autoclave and check that area of the autoclave carefully once it is fully

unpacked. In addition once the autoclave is fully unpacked carefully check for any signs

of physical damage such as; scratched panels, broken knobs, broken door covers etc…

If any damage is found contact the dealer as soon as possible so that they can file

a claim with the shipping carrier and also notify Tuttnauer.

All Tuttnauer products are carefully inspected prior to shipment and all

reasonable precautions are taken in preparing them for shipment, to assure safe arrival at

their destination

Note: Lifting and carrying should always be done by two people

2.2 Unit Location

The unit should be located on a stable, solid counter top. In the case of the 3850

and 3870 models a table is provided with the unit.

It is not recommended that units be stacked. Adequate clearance is required

above the autoclave for the purpose of filling the reservoir with distilled water. In

addition some steam escapes through the filling hole, if overhead cabinets are to close

steam damage can occur to the underside of the cabinets.

A minimum one inch clearance is required on each side and at the back of the

autoclave for access and ventilation.

Note: Lifting and carrying should always be done by two people

2.3 Voltage Requirements

All 110 volt units need to have a stable voltage between 110 and 125 volts AC.

All 220 volt units need to have a stable voltage between 220 and 235 volts AC.

For EK, EKA and EZ10k units check that the incoming voltage is between

220 volts and 235 volts AC. This is important because too high a voltage

will damage the heating elements and too low a voltage will cause the

sterilizer to run slower. In either case a Buck / Boost Transformer is

recommended to correct the voltage. A Buck / Boost Transformer is

relatively inexpensive and can be configured to either raise or lower the

voltage

It is recommended that all autoclaves be installed on a direct line.

The use of a surge suppressor is recommended especially in areas where there is a

large fluctuation in voltage or frequent lightning strikes.

2.4 Setup

There are two procedures for setup depending on if the autoclave has

a Water Pump or not.

2.4.1 Setup and Automatic Filling for units without Water Pumps

These units will have Microprocessors with date codes that do not contain

the letters WP. [see sec 8.12]

In these units the Chamber is filled from the Reservoir by gravity flow

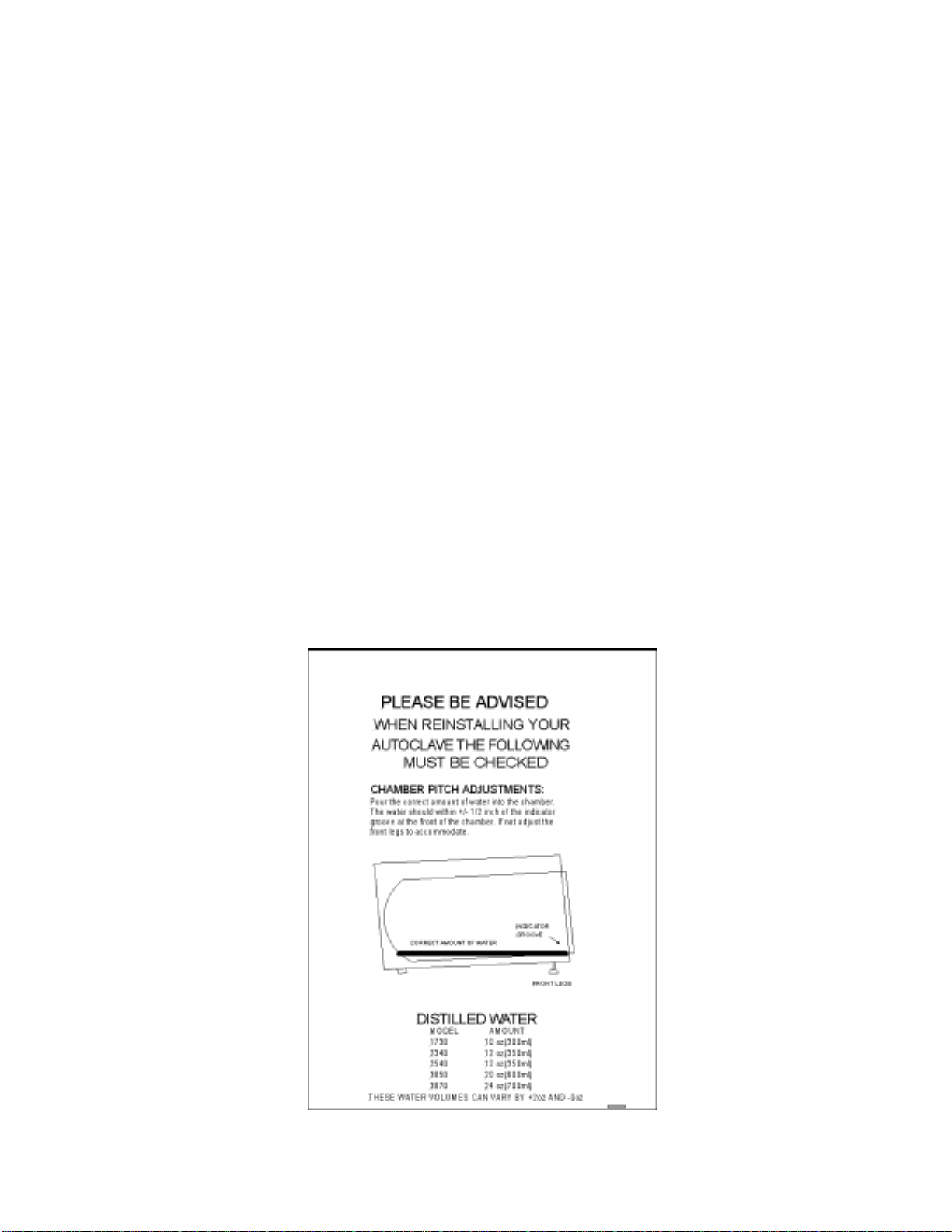

Adjusting The Chamber Pitch

Proper adjustment of the Chamber pitch is one of the most important

things you can do for the sterilizer. Proper Chamber pitch insures that among

other things the sterilizer will have the proper amount of water in the Chamber at

the beginning of each cycle. Insufficient water in the Chamber at the beginning

of the cycle will generate a LOW WATER message at some point during the

cycle when the water level becomes to low. If on the other hand there is too much

water in the Chamber this will extend the heating portion of the cycle. In cases

where the heating portion of the cycle is extended for more than 50 minutes (or 80

minutes for a 3850 / 3870) the sterilizer will abort that cycle.

Start with a sturdy, level counter.

Make sure all the feet are on the autoclave and none have been lost

Make sure the front feet are free to move in and out

Position the autoclave on the counter.

Fill the Reservoir with distilled water [see sec 5.2]

The Chamber should be empty of any instruments, trays or leftover water.

The autoclave should be turned off

The Chamber pitch now needs to be adjusted correctly

Measure out the proper amount of distilled water for the appropriate

model unit as listed below:

1730 = 10 oz – 12oz (300ml – 360ml)

2340 = 12 oz – 15oz (350ml – 440ml

2540 = 12 oz – 15oz (350ml – 440ml)

3850 = 20 oz – 23oz (600ml – 680ml)

3870 = 24 oz – 27oz (750ml – 800ml)

Pour the proper amount of water into the Chamber through the front door

of the unit.

This water should cover the bottom of the Chamber to within +/- ½ inch of

the grove in the front.

If necessary adjust the front Leveling Feet so that the water lays in the

Chamber correctly

Once the Chamber pitch adjustment is completed, empty the water from

the Chamber and check if the automatic filling is set correctly.

Checking the Automatic Fill

To check the automatic filling procedure, follow the next few steps:

Remove any water that is in the Chamber

Make sure the unit is turned on

With the Door open, press and hold the Door Switch

Then press the START Key.

When water starts flowing into the Chamber release the Door Switch.

Water should come up to the same spot as the measured amount had.

If the water fill is not working correctly then try the adjustment procedure

or check for a system problem [see sec 7.15]

Automatic Filling Adjustment Procedure

Make sure the power is off.

The Door should be open

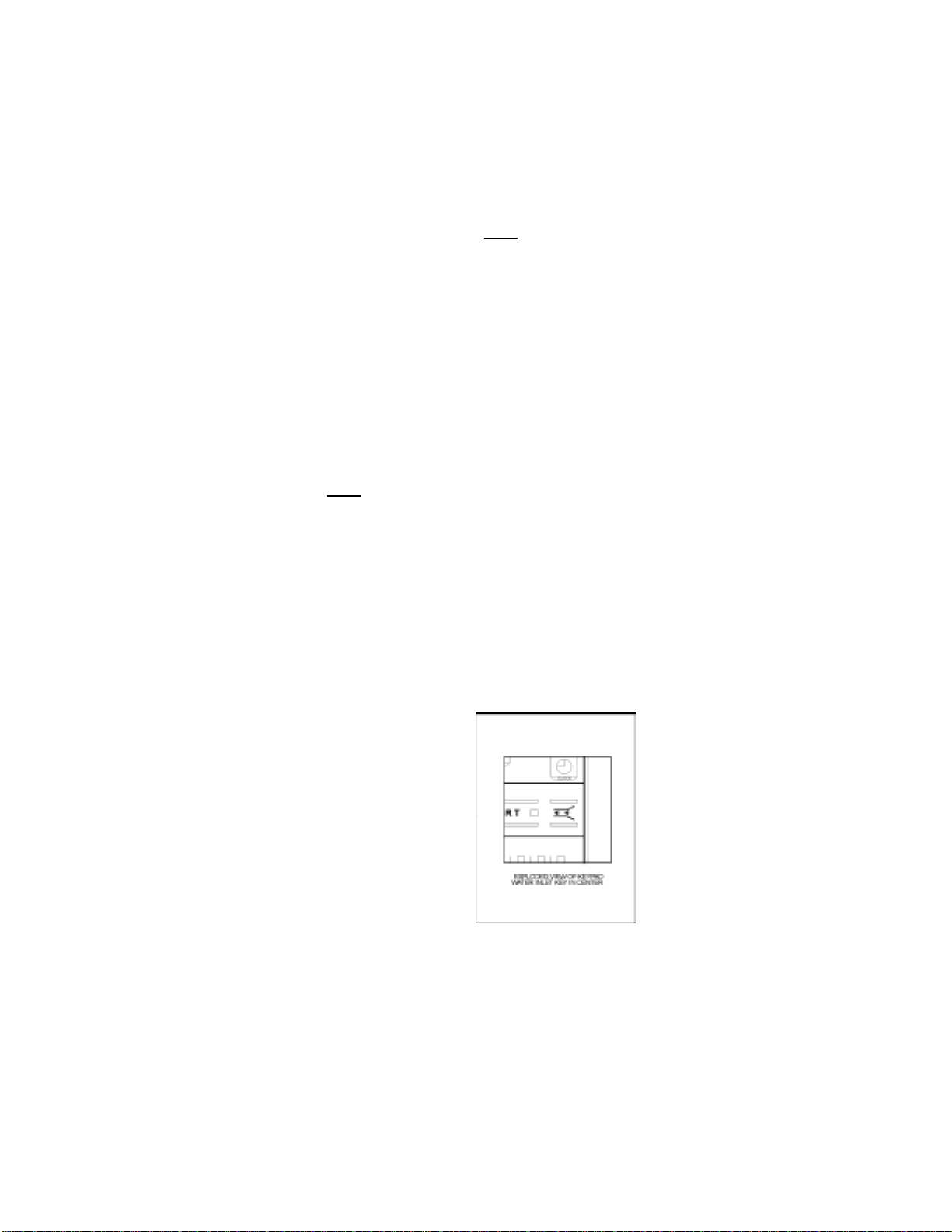

Press and hold the Water Inlet Key (this is the button on the

front Keypad with the two arrows).

Turn the power on

When the normal display screen appears release the Water Inlet

Key – wait one second and then press it in again.

Water should begin flowing into the Chamber

Monitor the water flow into the Chamber.

Hold the Water Inlet Key until water reaches the groove at the

front

Then release the button – wait ten seconds – the unit is now

reprogrammed.

2.4.2 Setup and Automatic Filling for units with Water Pumps

Any unit with a Microprocessor date code ending in WP [see sec 8.12]

will have a Water Pump installed to insure proper filling.

Start with a sturdy, level counter.

Make sure all the feet are on the autoclave and none have been lost

Make sure the front feet are free to move in and out

Position the autoclave on the counter.

Fill the Reservoir with distilled water [see sec 5.2]

The Chamber should be empty of any instruments, trays or leftover water.

To calibrate the automatic fill follow this procedure:

1. Press the STOP Key repeatedly until the message “Code: xxx”

appears.

2. Using the UP/DN arrow keys change the code to 105, then press

the STOP Key.

3. A message will be displayed saying “Water in = xx sec”

4. Using the UP/DN arrow keys change the seconds according to

the following table:

2340 = 30 sec

2540 = 35 sec

3870 = 65 sec

now press the STOP Key

5. The message “Ea Type:” will appear, using the UP/DN arrow

keys select either “0” for an E or EK type unit or “1” for an

EA or EKA type unit.

6. Press the STOP Key to finish

3 Front Panel Keypad

3.1 Front Panel Keypad

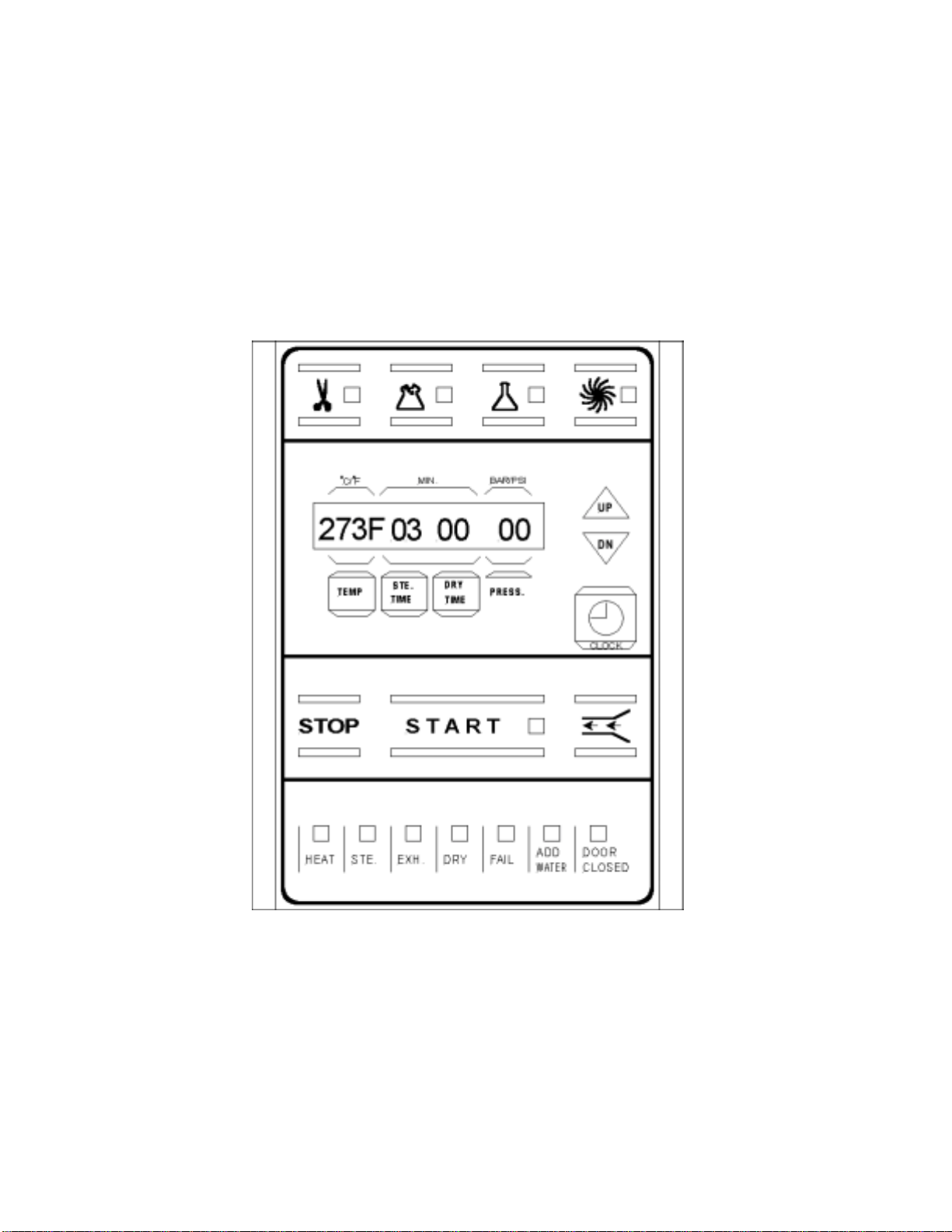

The Front Keypad is divided into four sections, top, upper middle, lower middle

and bottom

The Top Section has four lighted buttons, these represent the four available programs.

Each program comes preset from the factory with default parameters. Each program can,

however, be modified by the operator. If necessary the default or modified parameters

can be lock-in [see sec 8.10]. When a program is selected the light in that button will

illuminate and the program parameters will appear in the display.

Moving from left to right the programs are:

Unwrapped Instruments – symbolized by a pair of scissors

the default parameters are

273 0F for temperature

3 minutes of sterilization time

rapid exhaust

no drying time

Wrapped Instruments – symbolized by a gown

the default parameters are

273 0F for temperature

7 minutes of sterilization time

rapid exhaust

30 minutes of drying time

Liquids – symbolized by a flask

the default parameters are

250

0

F for temperature

30 minutes of sterilization time

slow exhaust only

no dry time, drying is not allowed

Extra Drying Cycle – symbolized by the sun

the default parameter is

30 minutes of drying time

The purpose of the Extra Drying Cycle is to offer an alternative in

situations where the dry time in the wrapped or unwrapped cycle is insufficient. Rather

then wait for the items to air dry or run another complete cycle with a longer dry time just

select the Extra Drying Cycle to continue the heat assisted drying process.

The Upper Middle Section consists of a:

Display –

The Display is comprised of a single row of 16 characters, this row is divided

into four sections.

When the system is running a program the screen will display the current

temperature and pressure within the Chamber and the remaining time for

sterilization or drying

The first three sections from left to right are designed to show the parameters of

the selected program or any operating messages.

When the system is idle the display will show the parameters of the currently

selected program.

When the system is running a program the actual sterilization temperature is

If the program aborts as a result of a program check or manual stop a message

The last section of the screen on the right, will continually display the actual

TEMP Key –

The TEMP Key is used to change the temperature parameter of the Wrapped,

Unwrapped or Liquid programs. This can only be done while the autoclave is

not running a cycle. Press the TEMP Key and a cursor will appear under the

temperature parameter. Use the Up/Down Arrow Keys to change to the desired

temperature. After a few seconds of inactivity the cursor will disappear and the

parameter will be locked in. The acceptable range for proper sterilization of

wrapped and unwrapped items is between 2500F and 2740F (1210C and 1340C).

For liquids the maximum temperature is 2500F (1210C)

In addition the TEMP Key can be used to change the temperature display from

Fahrenheit to Centigrade. This can be accomplished by simply turning the power

off, press and hold the TEMP Key and turn the power on.

STE TIME –

The STE TIME Key is used to change the sterilization time parameter of the

Wrapped, Unwrapped or Liquid programs. This can only be done while the

autoclave is not running a cycle. Press the STE TIME Key and a cursor will

appear under the sterilization time parameter. Use the Up/Down Arrow Keys to

change to the desired sterilization time. After a few seconds of inactivity the

cursor will disappear and the parameter will be locked in.

DRY TIME –

The DRY TIME Key is used to change the dry time parameter of the Wrapped

and Unwrapped programs. This can only be done while the autoclave is not

running a cycle. Press the DRY TIME Key and a cursor will appear under the dry

time parameter. Use the Up/Down Arrow Keys to change to the desired dry time.

After a few seconds of inactivity the cursor will disappear and the parameter will

be locked in. The acceptable range for drying time is 0 to 99 minutes

In addition the DRY TIME Key can be used to change the pressure display from

psi to bar (on all machines up to an including Microprocessors dated T93N6) or

from psi to kpa (on all machines with Microprocessors dated T96DN1 or T97DN6

or later)

displayed above the TEMP Key. The remaining sterilization time will be

displayed above the STE TIME key and the remaining drying time will

be displayed above the DRY TIME Key.

will be displayed on the screen. When a message is displayed, pressing

any key will erase the message and redisplay the selected program.

current real pressure inside the Chamber, this occurs whether a program is

running or not (provided the main power is on).

CLOCK Key –

Pressing the CLOCK Key first displays the current date with a cursor under the

day parameter. Pressing the Up/Down Arrow Keys will change the day

parameter. Pressing the CLOCK Key once again will move the cursor underneath

the month and then the year parameters. Once the date has been updated pressing

the CLOCK Key again will display the time with the cursor under the hour. Use

the Up/Down Arrow Keys as before to change the hours then run through the

minutes and seconds pressing the CLOCK Key each time to make the advance.

After a few seconds of inactivity the cursor will disappear and the parameters will

be locked in.

UP / DOWN Arrow Keys

Pressing these keys will raise or lower the values on any of the parameters that are

user adjustable

The Lower Middle Section consists of a:

STOP Key –

This is the only key recognized by the system while a cycle is running. Pressing

the STOP Key for over one second will cause the current program to abort and

the MAN STOP message will be displayed.

In addition the STOP Key can be used to reset all the parameters back to their

factory defaults. This includes the Automatic Fill, in which case it will be

necessary to recalibrate the Automatic Fill.

Turn the power off

Press and hold the STOP Key

turn the power on

START Key –

Pressing this key will start which ever program cycle has been selected and cause

the START Key light to turn on.

Water Inlet Key–

This key is symbolized by the two horizontal arrows pointing in through a

channel. Pressing and holding this key allows for the manual filling of the

Chamber with water. This is useful for calibrating the Automatic Fill, also during

cleaning to flush out the Chamber and in case it becomes necessary to bypass the

Automatic Fill before running a cycle. Water will flow into the Chamber only as

long as the key is depressed.

The Bottom Section consists only of indicator lights. Looking from left to right they are

the:

HEAT Light – a steady illumination is given when the autoclave is heating up at the

beginning of the cycle.

Also this light will flash during the preheat / standby mode on units in

which that option has been activated (all EK, EKA, EZ, EZ10k, 3850 and

3870 machines).

STE Light – a steady illumination is given while the autoclave is in the sterilization

portion of the cycle.

EXH Light – a steady illumination is given when the autoclave is exhausting the

Chamber

DRY Light - a steady illumination is given while the autoclave is in the Drying mode.

CYCLE FAIL Light – will illuminate anytime the autoclave detects a problem that

results in an aborted cycle.

ADD WATER Light – this indicator will light when the Reservoir is low on water. If the

indicator lights, after the Start Key has been pressed, the system will

continue with the cycle. There is sufficient water in the reservoir to

complete this cycle. The next cycle will not be allowed to begin until

sufficient water is in the reservoir.

DOOR CLOSED Light – this indicator lights to signal that the Door of the autoclave

has been closed.

4 Display Messages

4.1 Display Messages

Any time a cycle is aborted the Tuttnauer autoclave will give an error message.

These messages are in the form of words that describe the problem the unit has

encountered.

The following is a list of those Error Messages with descriptions of what they

mean and indications where the problem may be.

LOW WATER – This message will be displayed if during a normal Heat Up stage the

system determines that there is insufficient water in the Chamber

to complete the cycle. This determination is made by the combined

input of two sensors, the Water Electrode and the Safety

Thermostat.

Also if a power failure occurs during the Heat or Sterilization stage

after the power returns the system will check the Water Electrode

to see if there is sufficient water in the Chamber in order to

resume the cycle. If not the cycle will be aborted, the message

LOW WATER will be displayed, and the Cycle Fail indicator will

light.

Possible causes for this message are:

a. Insufficient water entered the Chamber at the beginning of

the cycle.

Check for proper leveling, a dirty or shorted Water Sensing

Electrode, a clogged Water Pump, a partially clogged line

or that the Air Outlet Valve is stuck closed

b. A leaky Solenoid Valve, Safety Valve, Air Jet, Door Gasket,

Door Bellows or a pipe fitting is allowing water or steam to

escape at a higher than normal rate.

c. A power down has occurred and on power up if the water

Electrode tip is dry the Low Water message will be

displayed

LOW HEAT – This message is displayed, the Cycle Fail indicator lights and the cycle is

aborted if the autoclave has not reached sterilization temperature

after heating for 50 minutes in either Wrapped or Unwrapped

programs (80 minutes in the Liquid program).

Low Heat refers to the temperature in the Chamber before

sterilization has begun.

Possible causes for this message are:

a. No power to the Heating Elements

b. Bad Heating Elements

c. Very low line voltage delaying heat up

d. Safety Thermostat is opening prematurely, turning off the

Heating Elements -- this only applies to units with

Microprocessors dated earlier than T93N5 or T93N6.

e. A clogged Air Jet

f. An Air Outlet Valve stuck closed.

LOW TEMP - This message is displayed, the Cycle Fail indicator lights and the cycle is

aborted if the temperature drops 2.5 0C (4.5 0F) below the required

sterilization temperature.

Possible causes for this message are:

a. Insufficient water in the Chamber (see Low Water message)

b. The sterilization phase of the cycle has been set for too long

a period of time, allowing the Chamber water to boil away,

and the Chamber to run dry.

c. The Safety Thermostat is opening prematurely, turning off the

Heating Elements -- this only applies to units with

Microprocessors dated earlier than T93N5 or T93N6

d. A bad Temperature Sensor

LOW PRES – This message is displayed, the Cycle Fail indicator lights, and the cycle is

aborted if the pressure drops 4 PSI (0.27 BAR) below the required

sterilization pressure.

Possible causes for this message are:

a. Insufficient water in the Chamber ( see Low Water message)

b. The Heating Elements not cycling on and off properly.

1. Problem is with the Solid State Relay

2. Problem with the control circuit

c. Bad Heating Elements -- not producing enough wattage

d. The Safety Thermostat is opening prematurely, turning off the

Heating Elements -- this only applies to units with

Microprocessors dated earlier than T93N5 or T93N6

e. A bad Pressure Transducer

HIGH TEMP – This message is displayed, the Cycle Fail indicator lights and the cycle

is aborted if the temperature rises 9 0F (5 0C) above the required

sterilization temperature during the Sterilization phase of the

cycle.

This message will also be displayed if the Temperature Sensor is

damaged. In this case the message will appear just before the Heat

phase starts

Possible causes for this message are:

a. The Heating Elements are remaining on instead of cycling on

and off.

Check for a shorted Solid State Relay, shorted Heating

Element or other short circuit

b. This message can ALSO indicate a bad Temperature Sensor

-- the message will display any time during the Heat Up

phase.

HIGH PRES – This message is displayed, the Cycle Fail indicator lights, and the cycle

is aborted if the pressure rises 10 PSI (0.6 BAR) above the

required sterilization pressure.

Possible causes for this message are:

a. The Heating Elements are remaining on instead of cycling on

and off.

Check for a shorted Solid State Relay, shorted Heating

Element or other short circuit

b. The Sterilization temperature has been set above 274 0F

MAN STOP - This message will be displayed and the Cycle Fail indicator will light

after the STOP Key is depressed for longer than 1 second.

RENEW WATER - This message is displayed only as information to the operator, that

the Water Reservoir should be drained and refilled with clean

distilled water. This message will only appear on units with

Microprocessors date coded earlier than and including T93N5.

POWER DN – This message is displayed once the power is restored, after a power

failure occurs during the running of a cycle. The POWER DN

message will be displayed for several seconds, and if present the

Printer will print POWER DN on the print out.

Once power has been restored the autoclave will make an attempt to

resume the current cycle from the point at which it was interrupted.

If a power failure occurs during the Heat Up phase, then heating will

resume (provided there is enough water in the Chamber. If not, the

cycle will be aborted.)

Exhaust and Dry phases will automatically resume operation once power

is restored.

If the power down occurred during the Sterilization portion of the cycle,

then when power is restored, the autoclave will check if the

temperature in the Chamber has fallen more than 4.5 0F (2.5 0C).

If not then the Sterilization Cycle will resume automatically. If

however, when the power returns, the system determines that the

temperature has fallen more than 4.5 0F (2.5 0C), the Sterilization

Cycle will abort and the Exhaust Cycle will start.

If a power failure occurs during the Liquids program, the system

will not allow a fast exhaust (as the exhaust valve is normally

closed), nor will it fast exhaust when power comes back on.

ADD WATER - This message is displayed and the ADD WATER indicator lights to

show insufficient water in the Water Reservoir. If this message is

displayed after the START Key has been pressed then the system

is not allowed to proceed. After water is added to the Reservoir,

the START Key must be depressed again in order for the selected

cycle to begin.

DOOR UNLOCK – This message will be displayed and the DOOR CLOSED indicator

will remain unlit if the door is improperly closed when the START

Key is depressed. Once the door is properly closed, the DOOR

CLOSED indicator will light and the START Key should be

depressed to start the desired cycle. If the door accidentally opens

during any stage of the cycle, the same message and indicator will

appear, and the system will abort, the Cycle Fail indicator will

light and the DOOR UNLOCK message will be displayed.

WATER INLET – This message will be displayed as information to the operator while

water is entering the Chamber, during the Automatic Water Filling

process.

CYC FINISHED – This message is displayed at the end of a successfully completed

cycle

5 Operating Instructions

5.1 Preparation Before Sterilizing

Instruments to be sterilized must be free from all residual matter, such as blood or

organic tissue. Instruments must also be dry and free from mineral deposits. Such

substances may cause damage to the instruments themselves or the Sterilizer.

1. Clean instruments immediately after use to remove any residue. It is

recommended that all instruments be ultrasonically cleaned using Tuttnauer's

CLEAN AND SIMPLE enzymatic cleaning tablets or other suitable solution.

2. After cleaning, rinse instruments for 30 seconds & pat or air dry.

3. Follow the instrument manufacturer’s instructions on the use of products for

cleaning and lubricating instruments that have been ultrasonically cleaned.

4. Be sure that instruments of dissimilar metals (stainless steel, carbon steel, etc.) are

separated. Carbon steel instruments should be bagged or placed on autoclavable

towels and not directly on stainless steel trays.

5. When using a paper / plastic bag the plastic side should always be down.

6. Check the instructions of the item manufacturer as to the proper procedure for

sterilizing each item.

7. Items must be sterilized in an open position. Surfaces that are hidden because the

item is in a closed position will not be exposed to the steam and will not be

sterilized

8. Place a sterilization indicator in each tray or inside each wrapped pack.

9. At least once a week use a biological spore test (Bacillus Stearothermophilus) in

any load to insure proper sterilization. (Be aware testing standards may vary)

Always follow the spore test manufacturer’s instructions

10. Make sure that all instruments remain apart during the sterilization cycle. Surfaces

that are hidden because items are covering other items will not be exposed to the

steam and will not be sterilized

11. Empty canisters should be placed upside-down in order to prevent the

accumulation of water.

12. Do not overload the Sterilizer trays. Overloading will cause inadequate

sterilization & drying. (see table 9.7 for loading limits for each model)

13. Allow a distance of approximately 1" between trays to permit steam circulation.

14. Wrapped instruments should be placed in material which will allow steam

penetration and promote drying, such as autoclave bag, autoclave paper, or muslin

towels.

15. Do not stack pouches. It is recommended that a pouch rack such as the Tuttnauer

Pouch Rack be used to insure proper steam penetration and adequate drying.

Surfaces that are hidden because the items are being stacked will not be exposed

to the steam and will not be sterilized

16. Tubing should be rinsed after cleaning. When placed in the tray make sure that

both ends of the tubing are open and there are no sharp bends or twists

17. Packs should be placed upright on the tray. They should not be touching each

other or the Chamber walls. There should be about 1” between packs for proper

steam circulation.

18. Liquids should only be sterilized in heat proof glass. The beaker should only be

filled 2/3 full and the lid should be on loosely to allow for expansion (see the table

9.8 for the maximum liquid capacity for each model)

19. If spotting is detected on the instruments the first step would be to use an ordinary

eraser to remove the spot. If there is no pitting under the spot then the spot was

only dirt. Dirt spots on an instrument may be an indication that the autoclave

needs to be cleaned or that the instruments were not adequately cleaned or dried.

If removal of the spot reveals pitting then the spot was most likely rust. Rust spots

on an instrument are not uncommon on inexpensive instruments. It may also be

an indication that the instruments were rinsed in tap water with a high content of

minerals. These minerals when exposed to high temperature and steam will

accelerate the oxidation of the metal. One suggestion would be to final rinse the

instruments in a distilled water or alcohol bath.

20. If the instruments exhibit a discoloration this can be due to the mixing of carbon

steel and stainless steel. When these two metals come into contact with each

other an electrolysis occurs that breaks down the metal. The best solution is to

separately wrap the carbon steel to insulate it from other instruments or the trays.

21. Items should not be allowed to touch the walls of the Chamber as the hot metal

can damage the item.

5.2 Filling The Reservoir

Always use DISTILLED WATER in the autoclave for sterilizing. Using water

of a poorer quality will cause increased maintenance due to the mineral residue that

accumulates in the various parts of the autoclave.

The Reservoir is filled from the top of the autoclave. Remove the Reservoir

Cover and pour water through the opening. Continue filling until the water reaches the

base of the Safety Valve Holder. Under no circumstances should the Reservoir be

filled above the Safety Valve Holder. The Reservoir should never be filled while the

autoclave is running a cycle. If the Reservoir is filled while the Autoclave is running then

at the end of the cycle water exhausted from the Chamber can cause the Reservoir to

overflow.

Overfilling or the failure to use Distilled Water will lead to clogging of the hole

in the Air Jet. This will be evidenced by the lack of both a hissing sound and a stream of

steam coming from the Air Jet during sterilization. When this situation occurs follow the

instructions in sec 6.5 for cleaning the Air Jet.

5.3 Sterilization Programs

Program 1 – Unwrapped Instruments

This program is for sterilizing unwrapped instruments and materials that

the manufacturer of these items has recommended autoclaving at a

temperature between 2500F and 2740F (1210C and 1340C).

This program comes set with these default parameters:

Sterilization temperature 2730F

Sterilization time 3 minutes

Dry time none

These values can be altered to fit the needs of a particular office

The parameters can only be changed while the autoclave is not running a

cycle.

Press the TEMP Key and a cursor will appear under the temperature

parameter. Use the Up/Down Arrow Keys to change to the desired

temperature. The acceptable range for proper sterilization of unwrapped

items is between 2500F and 2740F (1210C and 1340C).

*** Caution – in no case should the temperature be set higher than

Any change of temperature must be coordinated with a corresponding

change is sterilization time.

Press the STE TIME Key and a cursor will appear under the sterilization

time parameter. Use the Up/Down Arrow Keys to change to the desired

sterilization time.

If drying is desired then press the DRY TIME Key and a cursor will

appear under the dry time parameter. Use the Up/Down Arrow Keys to

change to the desired dry time. The acceptable range for drying time is 0

to 99 minutes

After a few seconds of inactivity the cursor will disappear and the

parameter will be locked in.

0

F (1340C) ***

274

Program 2 – Wrapped Instruments

This program is for sterilizing wrapped instruments and materials that the

manufacturer of these items has recommended autoclaving at a

temperature between 2500F and 2740F (1210C and 1340C)

This program comes set with these default parameters:

Sterilization temperature 2730F

Sterilization time 7 minutes

Dry time 30 minutes

These values can be altered to fit the needs of a particular office

The parameters can only be changed while the autoclave is not running a

cycle.

Press the TEMP Key and a cursor will appear under the temperature

parameter. Use the Up/Down Arrow Keys to change to the desired

temperature. The acceptable range for proper sterilization of unwrapped

items is between 2500F and 2740F (1210C and 1340C).

*** Caution – in no case should the temperature be set higher

0

than 274

Any change of temperature must be coordinated with a corresponding

change is sterilization time.

Press the STE TIME Key and a cursor will appear under the sterilization

time parameter. Use the Up/Down Arrow Keys to change to the desired

sterilization time.

If a longer or shorter drying is desired then press the DRY TIME Key and

a cursor will appear under the dry time parameter. Use the Up/Down

Arrow Keys to change to the desired dry time. The acceptable range for

drying time is 0 to 99 minutes

After a few seconds of inactivity the cursor will disappear and the

parameter will be locked in.

F (1340C) ***

Program 3 – Liquids

This program is for sterilizing liquids solutions, distilled water, medicines

and other liquid preparations. For proper liquid sterilization it is

recommended that only the default parameters be used.

This program comes set with these default parameters:

Sterilization temperature 2500F

Sterilization time 30 minutes

Dry time drying is not allowed

Program 4 – Extra Drying Cycle

The purpose of the Extra Drying Cycle is to offer an alternative in

situations where the dry time in the wrapped or unwrapped cycle is

insufficient. Rather then wait for the items to air dry or run another

complete cycle with a longer dry time, just select the Extra Drying Cycle

to continue the heat assisted drying process.

This program comes set with these default parameters:

Dry time 30 minutes

These values can be altered to fit the needs of a particular office

If a longer or shorter drying is desired then press the DRY TIME Key and

a cursor will appear under the dry time parameter. Use the Up/Down

Arrow Keys to change to the desired dry time. The acceptable range for

drying time is 0 to 99 minutes

After a few seconds of inactivity the cursor will disappear and the

parameter will be locked in.

Loading...

Loading...