Page 1

(CAT Controller)

TECHNICIAN

MANUAL

Pre/Post-vacuum Class B

Table–top Autoclave

Model ELARA 11

Cat. No. MAN205-0343001EN Rev. P 8-10-11

Manufactured by: Tuttnauer Co. Ltd., Har Tuv Industrial zone B P.O.Box 170, Beit Shemesh 99000, Israel

Tel: 972 2 9904611, Fax: 972 2 9904730

Tuttnauer U.S.A. Co, Ltd. 25 Power Drive Hauppauge, NY, 11788, USA. Tel (631) 737 4850, (800) 624 5836,

Fax: (631) 737 0720

Page 2

Page 3

TABLE OF CONTENTS

PARAGRAPH PAGE NO.

1 INTRODUCTION ................................................................................................... 4

2 SYMBOL DESCRIPTION ..................................................................................... 4

3 INSTALLATION .................................................................................................... 7

3.1 Lifting and carrying ...................................................................................... 7

3.2 Unpacking the autoclave ............................................................................... 7

3.3 Installation preparations ............................................................................... 7

3.4 Connections to Utility Supplies ..................................................................... 8

3.5 Final adjustments .......................................................................................... 8

3.6 Operating the autoclave ................................................................................ 9

4 PERIODICAL TESTS .......................................................................................... 10

5 WATER QUALITY ............................................................................................... 11

5.1 Water for Generating Steam ....................................................................... 11

6 CONTROL SYSTEM DESCRIPTION ................................................................ 12

6.1 The main board includes: ........................................................................... 12

6.2 The high voltage board (AC Board) includes: ........................................... 13

7 CHECKING AND CHANGING PARAMETERS AND OTHER DATA ........... 14

7.1 Menu ............................................................................................................ 15

7.2 Parameters ................................................................................................... 16

7.3 Digital Inputs ............................................................................................... 28

7.4 Digital Outputs............................................................................................. 29

7.5 Analog Inputs .............................................................................................. 30

7.6 Calibration ................................................................................................... 31

7.7 Setting the Clock .......................................................................................... 37

7.8 Printer Test .................................................................................................. 38

7.9 Language ..................................................................................................... 39

7.10 History .......................................................................................................... 40

7.11 More options ................................................................................................ 41

8 RESSETTING THE AUTOCLAVE ..................................................................... 43

9 MAINTENANCE AND REPLACEMENT PROCEDURES .............................. 44

9.1 Preliminary Operations for Each Technician Call .................................... 44

9.2 Safety tests after repair ................................................................................ 45

9.3 Dismantling the Outer Covers of the Autoclave ......................................... 46

9.4 Replacing the Safety Valve .......................................................................... 47

9.5 Replacing chamber heater .......................................................................... 48

9.6 Replacing steam generator heater .............................................................. 50

9.7 Replacing the steam generator cut-off thermostat ..................................... 51

9.8 Replacing and cleaning the generator’s water level electrode .................. 52

9.9 Replacing the Drain Valve .......................................................................... 54

9.10 Replacing the Door Cover ........................................................................... 55

9.11 Replacing the Front Panel .......................................................................... 56

Page 1 of 129 Pages

Page 4

9.12 Replacing the Printer Door ......................................................................... 57

9.13 Replacing the Door Handle......................................................................... 58

9.14 Replacing the Plastic Handle Cover ........................................................... 59

9.15 Replacing the Printer .................................................................................. 60

9.16 Replacing the Door Switch .......................................................................... 61

9.17 Replacing the fuse on the Electronic Board ............................................... 63

9.18 Replacing the fuses of the transformer ....................................................... 64

9.19 Replacing the water pump ........................................................................... 65

9.20 Replacing the vacuum pump ....................................................................... 66

9.21 Replacing the Plunger or Coil of the 1/4" Solenoid Valve ........................ 67

9.22 Replacing the Electronic Boards ................................................................ 68

9.23 Replacing the switch .................................................................................... 73

9.24 Draining the generator ................................................................................ 74

9.25 Emergency Door Opening ........................................................................... 75

9.26 Replacing the water reservoirs .................................................................... 77

9.27 Cleaning the water reservoirs ..................................................................... 79

9.28 Replacing the cut-of thermostat for the Chamber Heater ......................... 80

9.29 Replacing the PT100 temperature sensor for the Chamber Heater .......... 82

9.30 Replacing the internal PT100 ..................................................................... 84

9.31 Replacing the pressure transducer ............................................................. 86

9.32 Cleaning the steam generator ..................................................................... 87

9.33 Replacing the cooler and the cooler's fan .................................................. 88

9.34 Testing procedure for the chamber PT100 ................................................. 90

9.35 Testing procedure for the heating element PT100 ..................................... 92

9.36 Testing procedure for the chamber pressure transducer ........................... 94

9.37 Testing procedure for the Generator pressure transducer” ...................... 95

9.38 Door Locking Solenoid................................................................................ 97

10 IN-OUT TEST ....................................................................................................... 99

11 TROUBLESHOOTING ...................................................................................... 101

11.1 Preliminary Check ..................................................................................... 101

11.2 Troubleshooting procedure ....................................................................... 102

12 PRESSURE VS TEMPERATURE FOR SATURATED STEAM .................... 114

Page 2 of 129 Pages

Page 5

TABLE OF CONTENTS (Continue)

PARAGRAPH PAGE NO.

Front View ...................................................................................................................... 5

Rear View ....................................................................................................................... 6

Control System Block Diagram ................................................................................... 12

Assembled Nova4-D2 Board ........................................................................................ 69

Nova4-A2 Board ........................................................................................................... 70

Nova4-D2 Board .......................................................................................................... 71

Exploded Drawing – Rear.......................................................................................... 118

Table for Exploded Drawing – Rear ......................................................................... 119

Exploded Drawing – Door ......................................................................................... 120

Table for Exploded Drawing – Door ......................................................................... 121

Exploded Drawing – PT-100 and Cut-Off ................................................................ 122

Table for Exploded Drawing – PT-100 and Cut-Off ................................................ 123

Exploded Drawing – Generator ................................................................................. 124

Control Unit ............................................................................................................... 125

Partial Front View ..................................................................................................... 126

Electrical Diagram ..................................................................................................... 127

Piping Diagram .......................................................................................................... 128

Piping Layout ............................................................................................................. 129

Page 3 of 129 Pages

Page 6

1 INTRODUCTION

This Technician's Manual, together with the operator’s manual, forms the

complete set of the Operation and Maintenance instructions for the Elara 11 pre

and post vacuum autoclave. This manual is intended for the use of the

technician. It is strongly recommended that only qualified and Tuttnauer

factory trained personnel service this autoclave and do so in accordance with

the instructions in this manual. Any unauthorized service may result in the

invalidation of the manufacturer’s guarantee.

2 SYMBOL DESCRIPTION

Caution! Consult accompanying documents

Caution! Hot surface

Caution! Hot steam.

Protective earth (Ground)

Page 4 of 129 Pages

Page 7

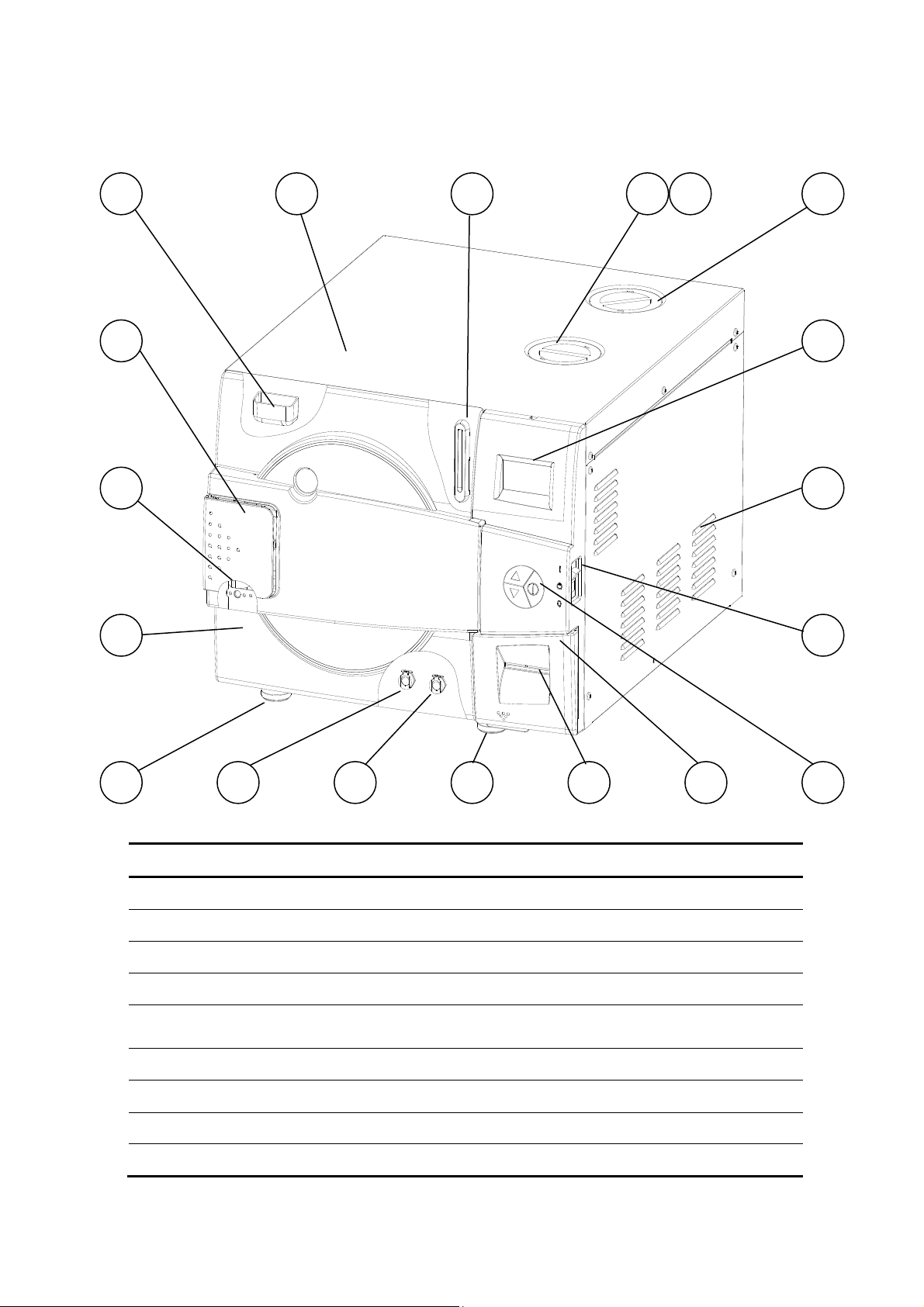

FRONT VIEW

1 2 3

17

16

5 4 6

718

8

9

13 14

No.Description No. Description

1 Water reservoir funnel 10 Operating keypad

2 Autoclave cover 11 Printer cover

3 Water level sight gauge 12 Printer (standard)

4 Mineral-free water reservoir cover 13 Legs

Chamber and steam generator safety

5

valves

6 Waste water reservoir cover 15 Waste water reservoir drain valve

Display 16 Door cover

7

8 Ventilation grill 17 Door switch

9 Main switch/Circuit breaker 18 Door closing device

Mineral-free water reservoir drain

14

valve

101115 13 12

Page 5 of 129 Pages

Page 8

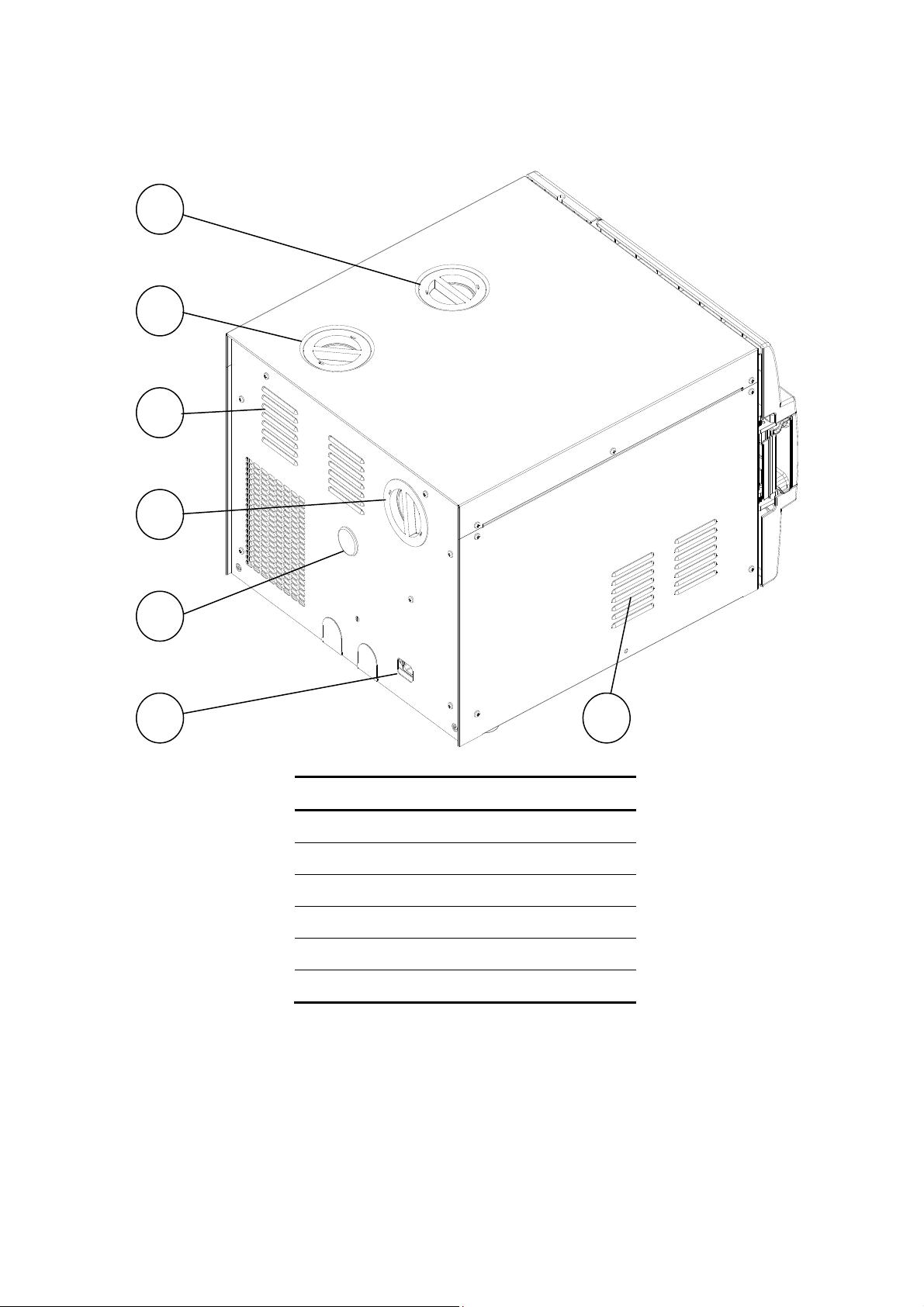

REAR VIEW

1

2

3

4

5

6

3

No.Description

1 Mineral-free water reservoir cover

2 Waste water reservoir cover

3 Ventilation grills

4 Air filter service cover

5 Opening for calibration

6 Main power electric cable socket

Page 6 of 129 Pages

Page 9

3 INSTALLATION

CAUTION:

Any operation described in section 3 shall be performed by a qua lified

technician only.

3.1 Lifting and carrying

CAUTION:

Before moving the a utoclave, Make sure that the electric cord is

disconnected from the pow er, and there is no press ure in th e

chamber and in the generator.

Attention! The pressure of th e generator does not decreas e

immediately when the equipment is turned off. Wait approx. ½ an

hour to ve rify that the pressu re has decreased to a tmospheric

pressure.

1. Disconnect the power supply cord.

2. Drain the water from both reservoirs.

To avoid injuries, lifting and carrying should be done with at least two

persons or by using a fork-lift or any other mechanical aid.

Do not drop the device!

3.2 Unpacking the autoclave

Unpack the autoclave and inspect for mechanical damage upon receipt.

Observe packing method and retain packing materials until the unit has

been inspected. Mechanical inspection involves checking for signs of

physical damage such as: scratched panel surfaces, broken knobs, etc.

To avoid injuries, lifting and carrying of the autoclave should be done

with at least two persons or by using a fork-lift or any other mechanical

aid.

3.3 Installation preparations

1. Check and verify that the counter carrying the autoclave is a rigid and

leveled surface and can carry a load of 225 lbs (102kg).

Attention:

The Elara11 is not designed for use on any standard slide out shelf. If

it is necessary to use a slide out shelf, it must be tested and/or rated for

225 lb (102kg) or more.

Check and verify that the counter dimensions are, at least, 22” wide x

24” deep (55cm x 63.5cm).

2. Keep

the back and the sides of the autoclave approximately 2” (5 cm)

away

from the wall to allow ventilation and facilitate the device

disconnection.

3. If placed in a cabinet, verify that the rear of the cabinet is open to

allow ventilation.

4. Insufficient space for ventilation may result in an increase of

the

autoclave's temperature that may cause a malfunction or damage the

instrument.

5. It is recommended that enough space be left around the autoclave to

give a technician access for servicing the machine.

6. Check and verify that the room ventilation is 10 cycles per hour

minimum.

Page 7 of 129 Pages

Page 10

7. Check and verify that the ambient temperature range is 41˚F - 104˚F

(5˚C - 40˚C), it is preferable not to exceed 86˚F (30˚C).

8. Check and verify that the ambient relative humidity does not exceed

85%.

3.4 Connections to Utility Supplies

1. Check and verify that the power supply is a 1 phase, 230Vac ±5%,

50/60Hz (as appropriate), 15A supply.

2. Check and verify that the autoclave is connected to separate power

source to avoid flickers of light or sensitive devices.

3. Check and verify grounding of the autoclave.

4. Check and verify that the electrical net is protected with a current

leakage safety relay.

3.5 Final adjustments

At the time of installation, befo re the autoclave can be okayed for

daily operation the service technician needs to perform the follow ing

preliminary checks:

a. Integrity Check

Perform a visual check to verify that there are no dents, scratches or

broken components on the autoclave.

b. Support surface check

Make a visual check that the surface is level and strong enough to

support the autoclave.

c. The leakage current test

Test the precise operation of the earth leakage relay.

d. Ground Check

Test the continuity of the grounding connection.

e. Safety Valve Check

Test the safety valve as per the instructions in "Checking the Safety

Valve" in the Operator’s Manual.

f. Door check

Ensure that the door locking mechanism is functioning properly

g. Setting clock and date

See instruction in the user manual clause. 7.3.

h. Atmospheric Pressure check: the unit is set from the factory at 100

kpa, this is atmospheric pressure at sea level. If the unit is located

more that 500 ft above or below sea level then the Atmos. Press

parameter must be set, see sec 7.2.7

i. Cycle check: run a B&D Test to ensure that all systems in the unit

are functioning properly.

j. Reset the autoclave see sec 8.

After the above steps are performed, the autoclave is ready for daily

operation.

Page 8 of 129 Pages

Page 11

3.6 Operating the autoclave

1 Plug the power cord into the power socket.

2 Turn on the Main Switch / Circuit Breaker (see front view).

3 Select "Vacuum Test" cycle to keep the steam generator and heating

elements from heating up. See Selecting a Program in the Operator’s

Manual.

4 Open the door of the autoclave and remove the trays and the

packaging material.

5 Fill the Mineral Free Water Reservoir with water meeting the quality

specs in section 5.1 as follows:

5.1. Fill with 4 liters of mineral free water by pouring it into the

front reservoir fill opening at the top of the machine (see front

view).

5.2. Fill the remaining quantity by pouring water gently, into the

front funnel until it reaches the required level on the water level

sight gauge (See Front View).

6 Insert a paper roll in the printer (see printer handling in the

Operator’s Manual).

7 Close the door and perform a Vacuum Test. If the test fails perform

another test since the fail may be a result of moisture in the air. If the

second test fails it may be necessary to run Program 2 with the long

drying cycle to remove any excess moisture that is causing the test to

fail.

8 If the Vacuum Test is successful then select the B&D Test cycle.

At this stage the chamber and steam generator will be heating up. It

will take approximately 15 minutes (from selecting the B&D Test).

9 While waiting for the unit to heat up explain and instruct the operator

as follows (use the operation manual as reference):

9.1. Operation principals of the autoclave.

9.2. Preparation for sterilizing instruction including loading

instructions.

9.3. Intended use of each cycle.

9.4. Selecting a cycle.

9.5. Water filling method.

9.6. Displayed error and operational messages.

9.7. Monitoring and changing parameters.

9.8. Printer handling.

9.9. Maintenance instructions

10 Perform a B&D test with a chemical indicator.

11 The operator shall perform a cycle under supervision of the

technician.

Page 9 of 129 Pages

Page 12

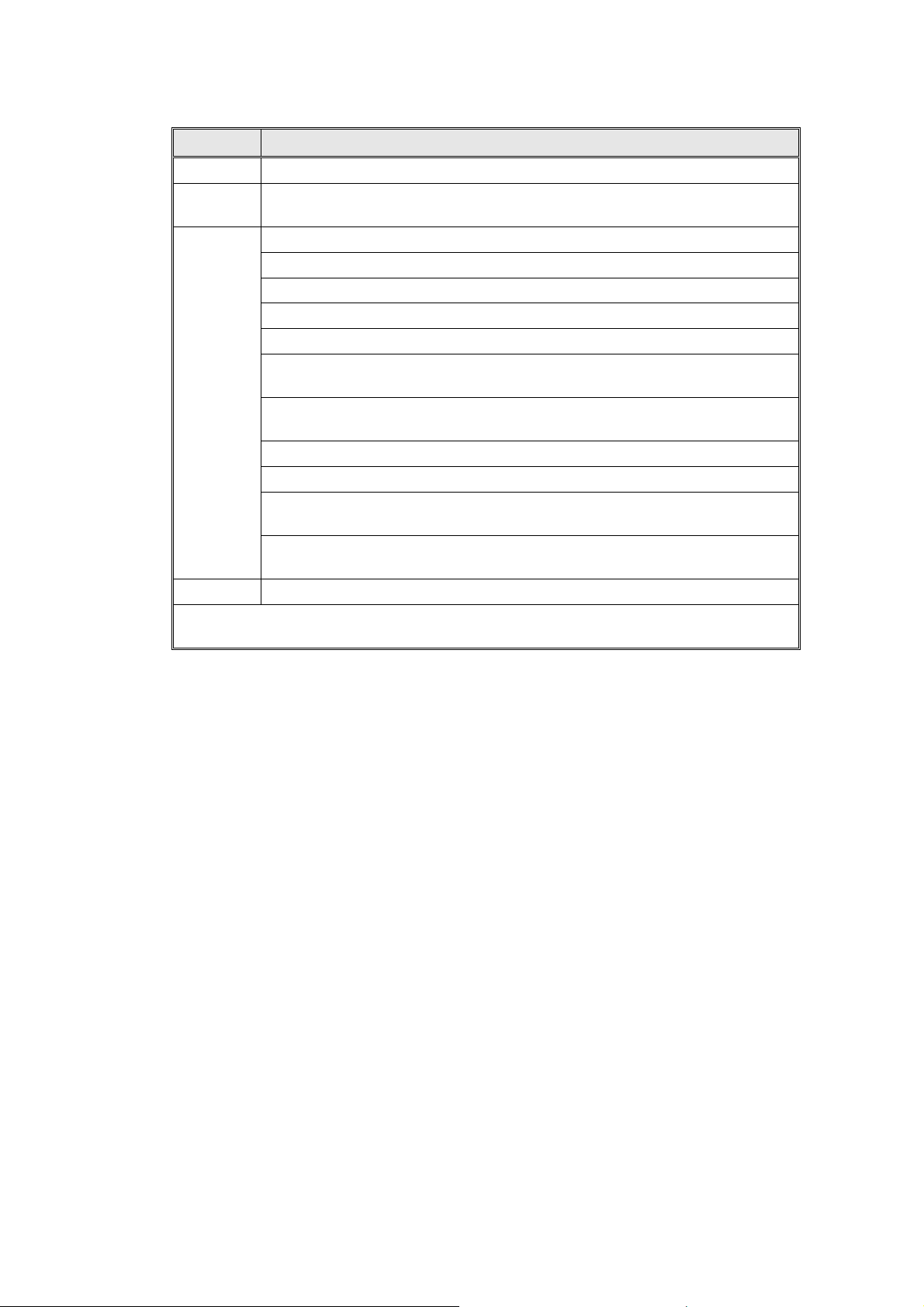

4 PERIODICAL TESTS

PERIOD TEST

1 month Test the safety valve by operating it.

6 months

Remove the autoclave’s cover, tighten the heaters’ screws and

electrical connections, valves and connectors in the control box.

Check the continuity of the grounding connections.

Check the temperature and pressure calibration.

Perform validation of the autoclave.

Check the precise operation of the earth leakage relay.

Check that the autoclave is leveled.

Check the safety elements; safety valve, safety and cut-off

thermostats door locking mechanisms.

Year

Run basic programs of the autoclave and check the operation

sequences, the sterilization parameters etc.

Check the water reservoir, piping, plastic parts and electric wires.

Check and tighten the piping joints to avoid leakage.

Check and tighten all screw connections in the control box, heaters

and valves and instrumentation.

Calibrate the temperature and pressure once a year or in reference to

local rules or regulations (refer to the section on Calibration).

5 years Observe the closing device for excessive wear

Safety tests (pressure vessel, efficiency, electrical) shall be performed in

accordance with local rules or regulations, by an authorized inspector.

Only an authorized technician shall perform the 6-months and yearly tests!

Page 10 of 129 Pages

Page 13

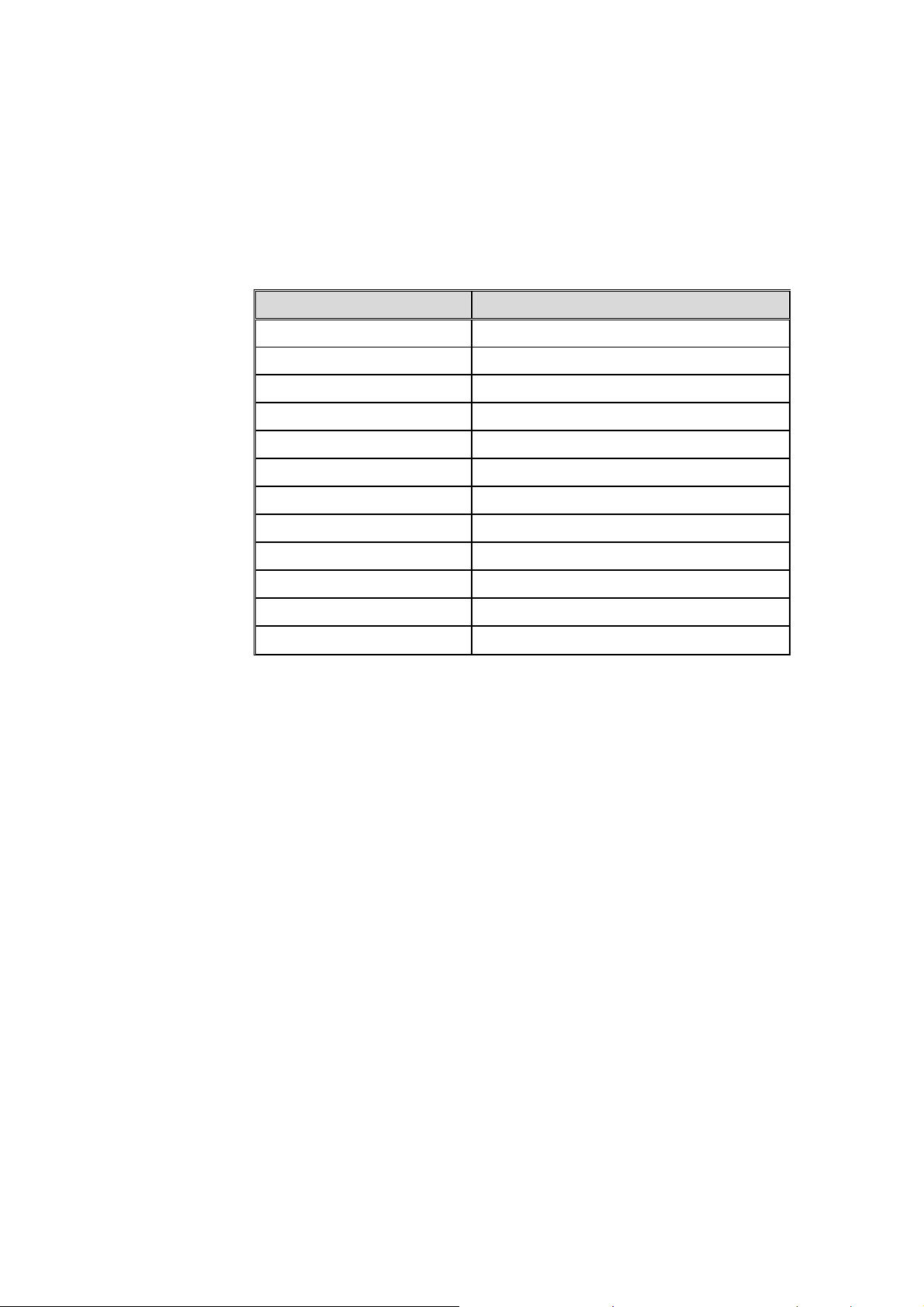

5 WATER QUALITY

5.1 Water for Generating Steam

The distilled or mineral – free water supplied to the sterilizer shall be

according to the table below:

Physical Characteristics and Maximum acceptable contaminants

Evaporate residue ≤15 miligrams/liter (mg/l)

Silica ≤2 mg/l

Iron ≤0.2 mg/l

Cadmium ≤0.005 mg/l

Lead ≤ 0.05 mg/l

Rest of heavy metals ≤0.1 mg/l

Chloride ≤3 mg/l

Phosphate ≤0.5 mg/l

Conductivity ≤50 μs/cm

levels in water for sterlizers

(According to ANSI/AAMI ST79:2006).

Element Condensate – allowable content

pH value 6.5 to 8

Appearance Colorless, clean, without sediment

Hardness ≤0.1 mmol/l

Compliance with the above data should be tested in accordance with

acknowledged analytical methods, by an authorized laboratory.

Attention:

We recommend testing the water quality once a month. The use of

water that does not comply with the table above may have severe

impact on the working life of the sterilizer and can invalidate the

manufacturer’s guarantee.

Page 11 of 129 Pages

Page 14

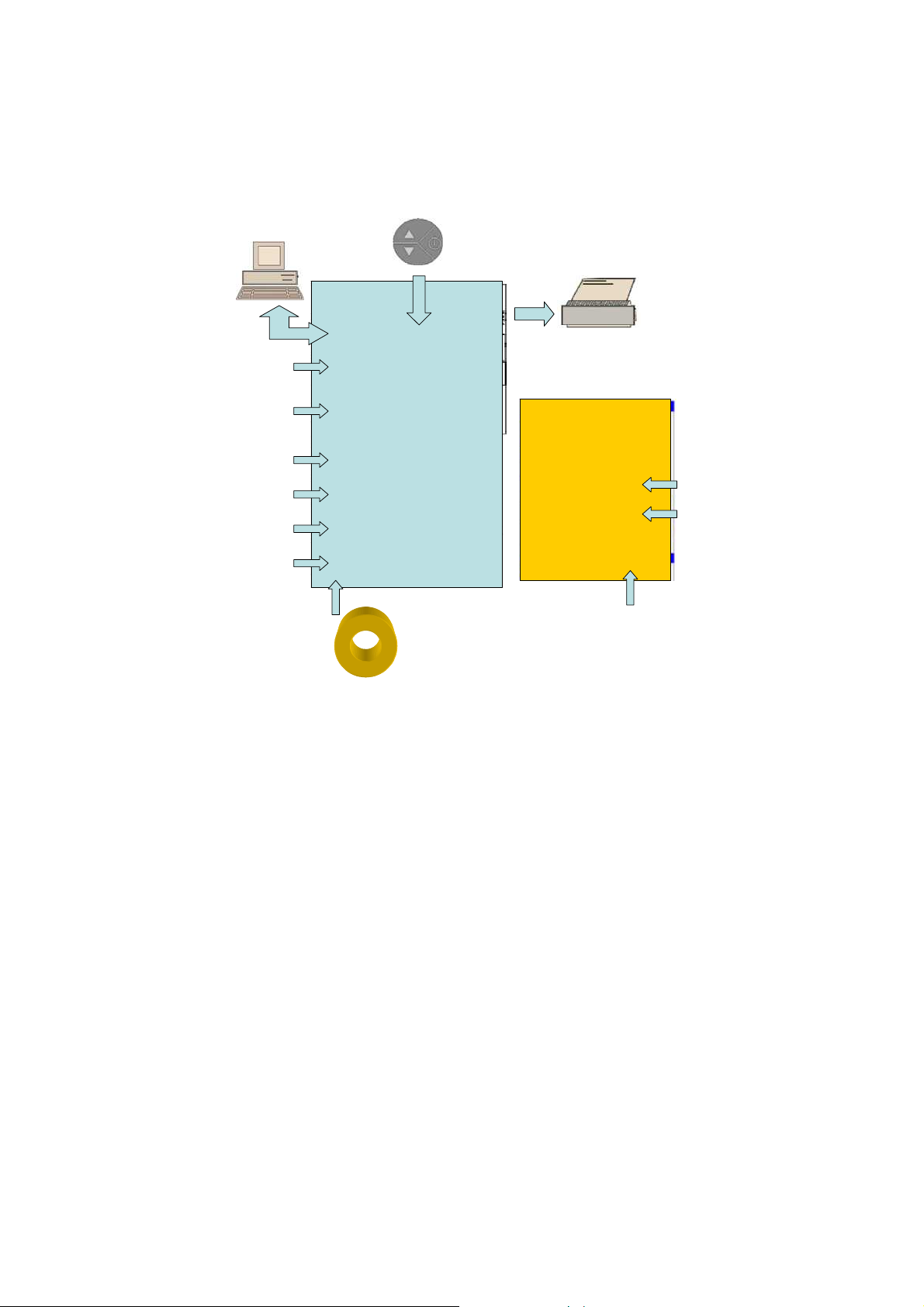

6 CONTROL SYSTEM DESCRIPTION

The control system is based on 2 electronic boards, see the diagram below.

Control system block diagram

PC

Keypad

Main Board

Digital input

Press. Sensors

electrodes

Jack. temp

Chamb. Temp

Door Lock

Solenoid valves

Power Transformer

DISPLAY

AC Board

Heaters

Vacuum Pump

L N GND Power Inlet

The control system contains the parts listed below:

Main board

AC high voltage power board

Transformer (230VAC primary / 6, 12, 18, 24VAC secondary)

Electrical wires

6.1 The main board includes:

Stabilized power supply 24VAC & 5VAC

Analog inputs for reading the analog sensors (temperature sensors,

pressure sensor, water level electrodes)

Digital inputs for reading the digital indicators (door switch, float

reservoir if available)

Digital outputs to control the solenoid valves and the door lock.

Digital outputs to send signal to high voltage board or power

element drivers to control power elements.

Display

A memory logging the previous cycles

Drivers for printer

Real time clock to serve as clock to the system

Connection to the printer. It is connected directly to this board

through a flat cable 24 pins.

DPU30 Printer

Water Pump

Power Circuit

Breaker

Page 12 of 129 Pages

Page 15

6.2 The high voltage board (AC Board) includes:

High power outputs to control the heaters and the pumps.

Circuit breaker

The board provides four outputs for four high AC devices as

follows:

1. Steam generator heater (2200 Watt).

2. Chamber wall heater (500 Watt).

3. Vacuum pump.

4. Water pump.

Connection between the 2 cards

Page 13 of 129 Pages

Page 16

7 CHECKING AND CHANGING PARAMETERS AND OTHER DATA

For special application it may be required to change parameters.

Note!

The autoclave is sent from the manufacturer with validated parameters.

Any change of the parameters requires a validation of the autoclave.

The device is identified by its software and parameter versions.

Any change of the parameters will increase the parameter version number.

In order to change parameters and check various components, you can enter a

few sub-directories and check or change the required data.

These sub-directories include the following:

Sub-directory Operation

Parameters Changing parameters

Digital Inputs Checking digital inputs

Digital Outputs Checking digital outputs

Analog Inputs Checking analog inputs

Calibration Calibration temperature and pressure

Set Clock Setting the clock (time and date)

Printer Test Testing the printer

History Printing the last cycles

Page 14 of 129 Pages

Page 17

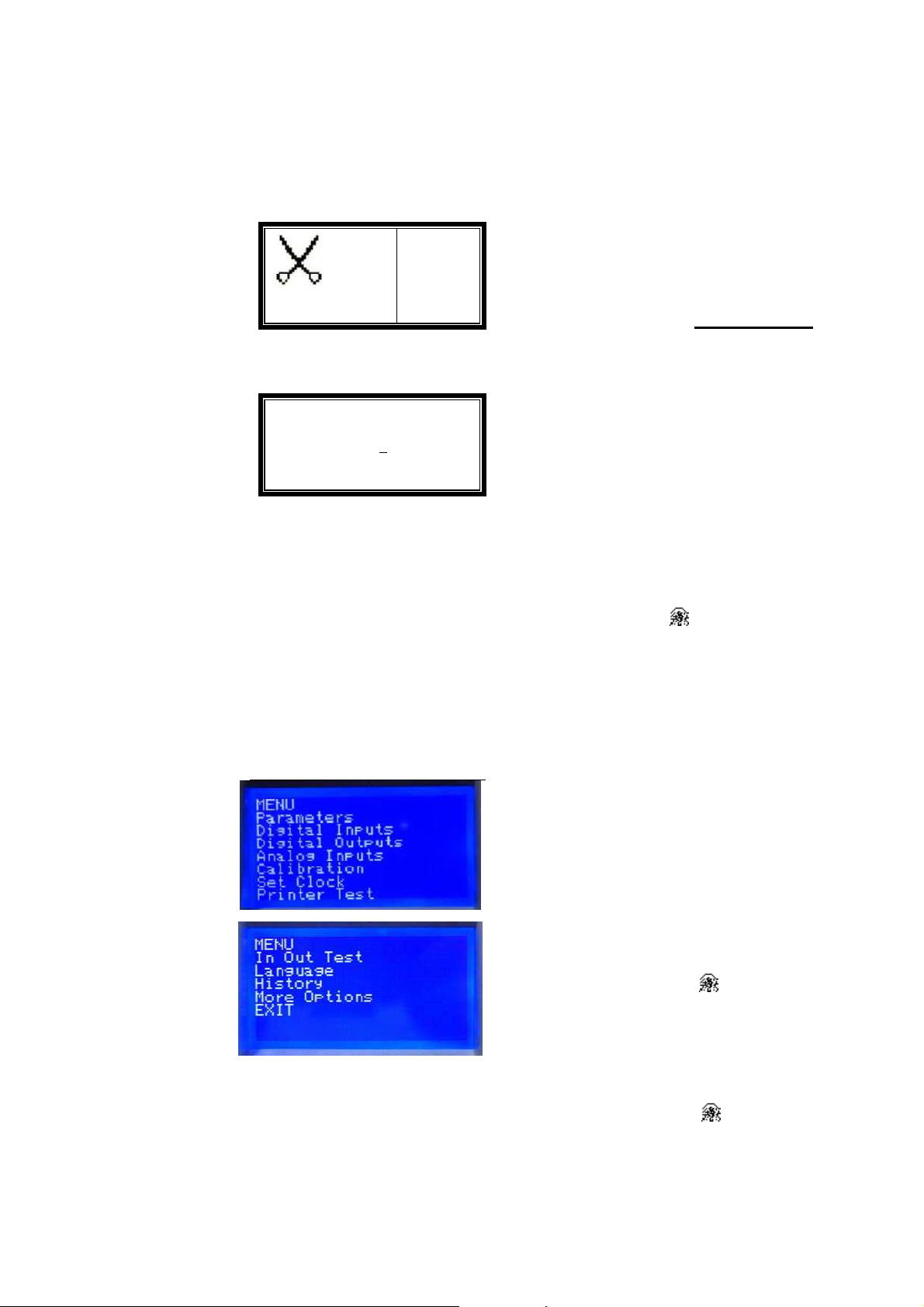

7.1 Menu

Follow the instructions below for entering the sub-directories and

performing the menu operation.

1. Main screen

134°C

004’

001’

30.0°C

100kPaG

08:03:06

Turn on the autoclave with the main

power switch located on the right side of

the autoclave (see FRONT VIEW).

The main screen is displayed.

To enter the menu press simultaneously

the UP and DOWN pushbuttons.

2. Enter Code

ENTER CODE

0333

SET EXIT

ENTER CODE will be displayed.

Enter the technician code (0333) as

follows:

The cursor is under the right digit. To

change the right digit, press the UP or

DOWN pushbuttons. Each press on

the UP pushbutton will increase the

digit by 1 and each press on the DOWN

pushbutton will decrease it by 1.

Change this digit as required and press

the START/STOP pushbutton to

move the cursor to the second digit from

the right.

Repeat this until the curser is under SET

(SET is blinking), and then press the UP

pushbutton to enter the MENU.

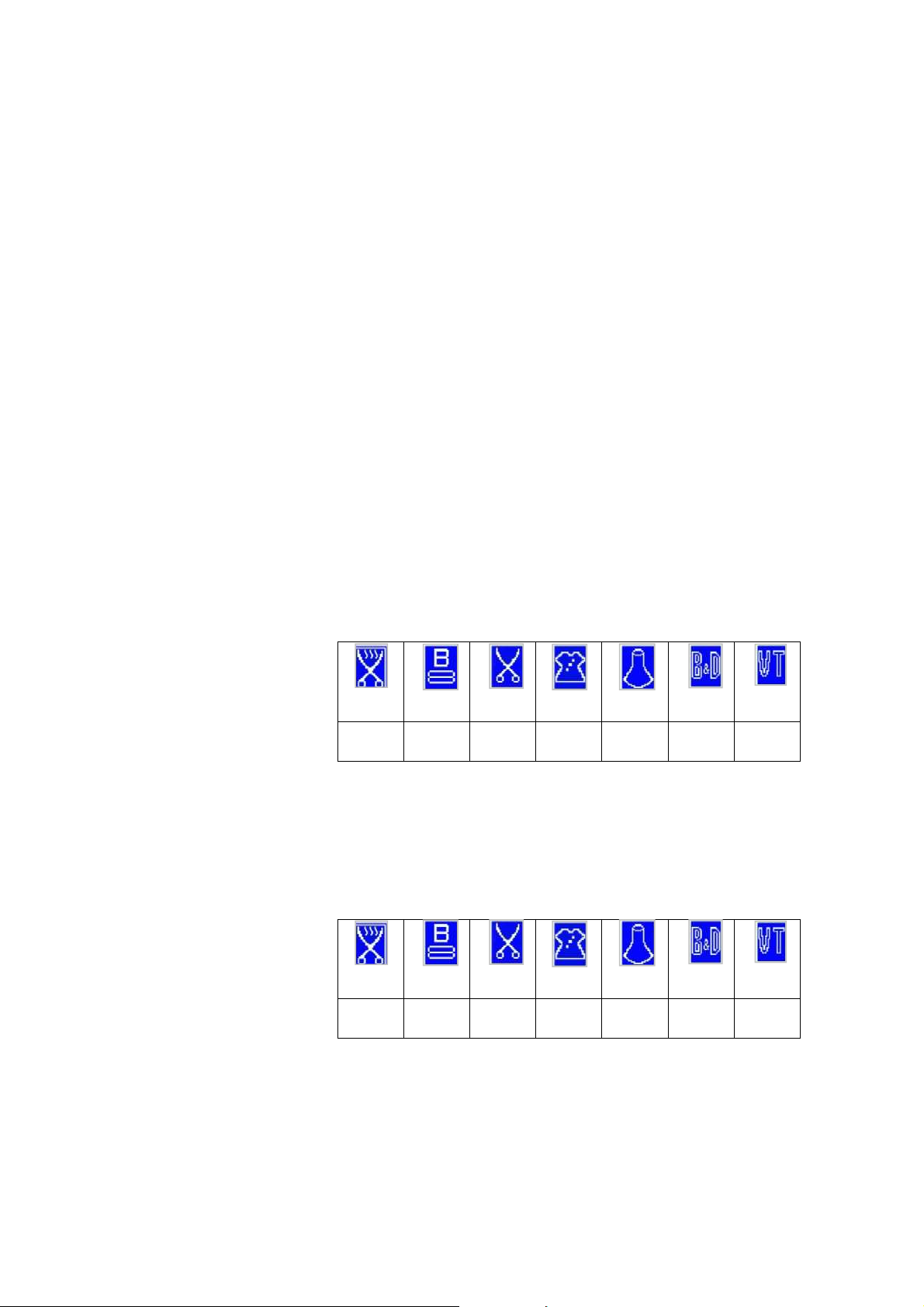

3. Menu

The MENU contains 1 1 sub-directories

(see display on the left).

The 7 top sub-director ies are disp layed

when entering "Menu" and the

remaining 4 directories are displayed

when rolling dow n. Move to the

required sub-directory using the UP

and DOWN pushbutton. The pointed

sub-directory is blinking.

Pressing START/STOP pushbutton

will select the blinking directory and the

required directory will be displayed.

To return to the previous display press the

UP and DOWN pushbuttons until

reaching EXIT. When EXIT is blinking,

press the START/STOP pushbutton

and the previous screen will be displayed.

Page 15 of 129 Pages

Page 18

7.2 Parameters

This section describes the parameters, how they affect the process and

the way to change them.

Listed bellow are all the available parameters.

Each section describes the parameter, the minimum and maximum

allowed values and the changing resolution. Also included are the pre-

set values of the parameters for each cycle (default value).

NOTE:

If a parameter is modified, the only way to return to the original

value is to manually reenter it.

A global parameter is a parameter that by changing its value in

one program, it is changed in all the other programs to receive the

same value.

To change a non-global value, i.e. specific parameter for each

program, choose first the required sterilization program in the

main screen of the autoclave and then enter the MENU and the

sub-directory PARAMETERS.

7.2.1 Ster Temp - sterilization temperature -

This parameter will set the desired temperature for sterilization

Resolution: 0.1°C

Minimum value: Default value

Maximum value: 136°C

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

Delicate

121

134 134 121 121 121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.2 Ster Time – sterilization time

This parameter will set the time desired for sterilization.

Resolution: 0.1 min

Minimum value: Default value

Maximum value: 99.9 min

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

Delicate

121

4 4 20 20 20

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 16 of 129 Pages

Page 19

7.2.3 Dry Time – drying time

This parameter will set the time desired for drying.

Resolution: 0.1 min

Minimum value: Default value

Maximum value: 99.9 min

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

1 20 0 20 0

7.2.4 Vac Pulses – number of pulses

This parameter sets the number of vacuum pulses during the air

removal stage..

Resolution: 1

Minimum value: 0

Maximum value: 5

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

2 3 2 3 2

7.2.5 SterPressAdd - addition to the sterilization pressure

This defines the required addition to the sterilization pressure in

kPa in order to increase the sterilization temperature.

For example, for a sterilization temperature of 121°C the

required pressure is 205 kPa. Since the system controls the

sterilization process according to pressure, if SterPressAdd

equals “0”, the system will maintain the pressure at 205 kPa . If

the value is at 5 kPa, the system will be maintained at 210 kPa

and the temperature will be 121.8°C, and so on.

Resolution: 0.1 kPa

Minimum value: 0 kPa

Maximum value: 40 kPa

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

9 9 9 9 9

Delicate

121

Delicate

121

Delicate

121

B&D

Test

Fixed

value

B&D

Test

Fixed

value

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Vacuum

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 17 of 129 Pages

Page 20

7.2.6 End Temp - temperature at the end of the cycle

This parameter will set the temperature that the chamber must

reach before the cycle can end.

Resolution: 0.1°C

Minimum value: 50°C

Maximum value:136°C

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

Delicate

121

120 120 110 110 110

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.7 ATMPressure – ambient pressure

This parameter tells the unit the atmospheric pressure of the

location in which the autoclave is installed. The pressure entered

must be with an accuracy of 5% of the actual atmospheric

pressure for that location. It is a global parameter that means that

you only need to enter this parameter once in anyone cycle and

all cycles will be updated.

This value can easily be calculated by knowing the altitude of

your location. The atmospheric pressure at Sea Level is 100 kPa

For every 100 meter above sea level, the atmospheric pressure

drops 1 kPa.

For every 100 meter below sea level, the atmospheric

pressure increases 1 kPa.

Changes in pressure do to weather will not affect the accuracy of

this unit.

Resolution: 0.1 kPa

Minimum value: 70 kPa

Maximum value: 110 kPa

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

100 kPa (global parameter)

Wdry

121

Delicate

121

B&D

Test

Vacuum

Test

7.2.8 Pulse vac 1 – Vacuum value in the first pulse

This parameter defines the vacuum value in pulse no.1 of the

prevacuum stage.

Resolution: 0.1°kPa

Minimum value: 5kPa

Maximum value:100kPa

Cycle

Default

Value

Flash

134

25.0 15.0 25.0 15.0 25.0

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 18 of 129 Pages

Page 21

7.2.9 Pulse vac T1 – vacuum time after Pulse vac 1

This parameter defines the period that vacuum is built after

reaching the value defined in Pulse vac 1.

Resolution: 1sec

Minimum value: 5sec

Maximum value:360sec

Cycle

Default

Value

Flash

134

10

Wdry

134

10 30 10 30 10

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.10 Pulse press 1 - Pressure value in the first pulse

This parameter defines the pressure value (above zero) in pulse

no.1 of the prevacuum stage.

Resolution: 0.1kPa

Minimum value: 70kPa

Maximum value:200kPa

Cycle

Default

Value

Flash

134

140.0 140.0 140.0 140.0 140.0

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.11 Pulse vac 2 – Vacuum value in middle pulses

This parameter defines the vacuum value in all pulses except

first and last pulse of the prevacuum stage.

Resolution: 0.1kPa

Minimum value: 5kPa

Maximum value:100kPa

Cycle

Default

Value

Flash

134

25.0 20.0 25.0 20.0 25.0

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.12 Pulse vac T2 - vacuum time after Pulse vac 2

This parameter defines the period that vacuum is built after

reaching the value defined in all pulses defined by Pulse vac 2.

Resolution: 1sec

Minimum value: 1sec

Maximum value:300sec

Cycle

Default

Value

Flash

134

10 30 10 30 10

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 19 of 129 Pages

Page 22

7.2.13 Pulse press 2 - Pressure value in the middle pulses

This parameter defines the pressure value (above zero) in the

middle pulses of the prevacuum stage.

Resolution: 0.1kPa

Minimum value: 70klPa

Maximum value:200kPa

Cycle

Default

Value

Flash

134

140.0 140.0 140.0 140.0 140.0

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.14 Pulse vac 3 - Pressure value in the last pulses

This parameter defines the vacuum value in the last pulse of the

prevacuum stage.

Resolution: 0.1kPa

Minimum value: 5kPa

Maximum value:200kPa

Cycle

Default

Value

Flash

134

30.0 20.0 30.0 20.0 30.0

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.15 Pulse vac T3 - vacuum time after Pulse vac 3

This parameter defines the period that vacuum is built after

reaching the value defined in all pulses defined by Pulse vac 3.

Resolution: 1sec

Minimum value: 1sec

Maximum value:360sec

Cycle

Default

Value

Flash

134

10 30 10 30 10

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.16 Pulse press 3 - Pressure value in the last pulse

This parameter defines the pressure value (above zero) in the last

pulse of the prevacuum stage.

Resolution: 0.1kPa

Minimum value: 7kPa

Maximum value:200kPa

Cycle

Default

Value

Flash

134

140.0 140.0 140.0 140.0 140.0

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 20 of 129 Pages

Page 23

7.2.17 Heat Exh on – Opening time of exhaust valve

This parameter defines the period that the exhaust valve is open,

during the heating stage, in order to remove the condensate.

Resolution: 0.1sec

Minimum value: 1sec

Maximum value: 50sec

Cycle

Default

Value

Flash

134

10 10 10 10 10

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.18 Heat Exh off - Closing time of exhaust valve

This parameter defines the period that the exhaust valve is

closed, during the heating stage.

Resolution: 0.1sec

Minimum value: 0sec

Maximum value: 1000sec

Cycle

Default

Value

Flash

134

200 200 200 200 200

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.19 Ster Exh on - Opening time of exhaust valve

This parameter defines the period that the exhaust valve is open,

during the sterilization stage.

Resolution: 0.1sec

Minimum value: 0sec

Maximum value: 50sec

Cycle

Default

Value

Flash

134

5 5 5 5 5

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.20 Ster Exh off - Closing time of exhaust valve

This parameter defines the period that the exhaust valve is

closed, during the sterilization stage.

Resolution: 0.1sec

Minimum value: 0sec

Maximum value: 1000sec

Cycle

Default

Value

Flash

134

200 200 200 200 200

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 21 of 129 Pages

Page 24

7.2.21 Exh Shoot on - Opening time of exhaust valve

This parameter defines the period that the exhaust valve is open,

during the exhaust stage.

Resolution: 0.1sec

Minimum value: 0sec

Maximum value: 1000sec

Cycle

Default

Value

Flash

134

1 1 1 1 10

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.22 Exh Shoot off - Closing time of exhaust valve

This parameter defines the period that the exhaust valve is

closed, during the exhaust stage.

Resolution: 0.1sec

Minimum value: 0sec

Maximum value: 1000sec

Cycle

Default

Value

Flash

134

0 0 0 0 100

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.23 Dry Air on - Opening time of air valve

This parameter defines the period that the air valve is open,

during the drying stage.

Resolution: 0.1sec

Minimum value: 0sec

Maximum value: 1000sec

Cycle

Default

Value

Flash

134

20 20 20 20 20

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.24 Dry Air off - Closing time of air valve

This parameter defines the period that the air valve is closed,

during the drying stage.

Resolution: 0.1sec

Minimum value: 0sec

Maximum value: 1000sec

Cycle

Default

Value

Flash

134

200 200 200 200 200

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 22 of 129 Pages

Page 25

7.2.25 SterGenPrsAd – Maximum pressure in the generator

The value of this parameter plus the sterilization pressure define

the maximum pressure in the generator in each program.

Resolution: 0.1kPa

Minimum value: 0kPa

Maximum value:50kPa

Cycle

Default

Value

Flash

134

20.0 20.0 20.0 20.0 20.0

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

7.2.26 Ster PrintT – printing rate during the sterilization stage

Test

Fixed

value

This parameter will set the interval between printings during the

sterilization stage.

Resolution: 1 sec

Minimum value: 10 sec

Maximum value: 360 sec

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

Delicate

121

60 sec (global parameter)

B&D

Test

Vacuum

Test

7.2.27 Print Rate - printing rate except during the sterilization stage

This parameter will set the interval between printings during the

other stages.

Resolution: 1 sec

Minimum value: 10 sec

Maximum value: 360 sec

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

180 sec (global parameter)

121

Wdry

121

Delicate

121

B&D

Test

Vacuum

Test

7.2.28 HeatSter Time – Pre-sterilization heating time

This parameter defines the heating time before sterilization.

Increasing the value of this parameter will decrease the heating

gradient define.

Resolution: 1 sec

Minimum value: 0 sec

Maximum value: 1000 sec

Cycle

Default

Value

Flash

134

1 1 1 1 1

Wdry

134

No Dry

121

Wdry

121

Delicate

121

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 23 of 129 Pages

Page 26

7.2.29 WaterGen Time – Addition time for adding w ater into the

generator

This parameter defines the addition time that water enters the

generator after the generator's water level electrode senses

water..

Resolution: 1 sec

Minimum value: 0 sec

Maximum value: 30 sec

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

10 10 10 10 10

7.2.30 SterPrsLimAd - maximum pressure in the chamber

This parameter plus the sterilization pressure define the

maximum pressure in the chamber.

Resolution: 0.1kPa

Minimum value: 0kPa

Maximum value: 40kPa

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

14.0 14.0 14.0 14.0 14.0

7.2.31 Heat Time Err - maximum time of the heating stage

This parameter defines the maximum time of the heating stage

until the beginning of the sterilization stage. If the heating

continues beyond this limit "ERROR 15" message will be

displayed and the cycle will fail.

Resolution: 1 sec

Minimum value: 1000 sec

Maximum value: 3600 sec

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

1500 1500 1500 1500 1500

Delicate

121

Delicate

121

Delicate

121

B&D

Test

Fixed

value

B&D

Test

Fixed

value

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Vacuum

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 24 of 129 Pages

Page 27

7.2.32 Vac Time Err - maximum time of the vacuum stage

This parameter defines the maximum time of the vacuum stage.

If the vacuum stage continues beyond this limit "ERROR 14"

message will be displayed and the cycle will fail.

Resolution: 1 sec

Minimum value: 600 sec

Maximum value: 3600 sec

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

1000 1000 1000 1000 1000

7.2.33 WaterTimeErr - maximum generator water filling time.

This parameter defines the maximum time for filling water in the

generator. If, before a cycle, the water pump has operated as

long as defined by this parameter and the water level electrode

did not sense water, "ERROR 20" will be displayed and a cycle

cannot be started. If this will be during a cycle – the cycle will

fail with "low temp" or "low pres".

Resolution: 1 sec

Minimum value: 10 sec

Maximum value: 200 sec

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

90 90 90 90 90

7.2.34 Sleep Power - time until the autoclave turns into "sleep

mode"

This parameter defines the time until the autoclave turns into

"sleep mode". This time is counted from the last operation of the

autoclave or the last time a pushbutton has been pressed.

Resolution: 0.1hour

Minimum value: 0.1hour

Maximum value: 999.9hour

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

4.0 4.0 4.0 4.0 4.0

Delicate

121

Delicate

121

Delicate

121

B&D

Test

Fixed

value

B&D

Test

Fixed

value

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Vacuum

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 25 of 129 Pages

Page 28

7.2.35 TempInF – units of the temperature

This parameter enables the technician to set the displayed

temperature in ºC or in ºF.

Changing this parameter in one of the cycles will change this

parameter in all the other cycles to the value.

Access Code – available upon request

Resolution – 1

Value – 0 or 1

If TemInf = 1 the temperature is expressed in ºF.

If TemInf = 0 the temperature is expressed in ºC.

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

0 (global parameter)

Delicate

121

B&D

Test

7.2.36 PressInPSI – units of the pressure

Vacuum

Test

This parameter enables the technician to set the displayed

pressure in Kpa, psig or psia.

Changing this parameter in one of the cycles will change this

parameter in all the other cycles to the value.

Access Code – available upon request

Resolution – 1

Value – 0, 1 or 2

If PresInPSI = 0 the pressure is expressed in kPa.

If PresInPSI = 1 the pressure is expressed in psia.

If PresInPSI = 2 the pressure is expressed in psig.

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

0 (global parameter)

Delicate

121

B&D

Test

Vacuum

Test

7.2.37 Auto Add Water – automatic water filling

This parameter defines the possibility for automatic mineral free

water filling.

NOTES: 1. Automatic water filling requires connection to

mineral free water supply and to drain.

2. Not applicable on this unit

Automatic water filling 1

Manual water filling 0

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

Delicate

121

0 0 0 0 0

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

Page 26 of 129 Pages

Page 29

7.2.38 ElectFillWtr – water conductivity

This parameter defines the conductivity level of the mineral free

water in which the water level electrode senses water. .

Resolution: 1

Minimum value: 0 – infinite conductivity

Maximum value:9999 – infinite resistance (zero conductivity)

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

Delicate

121

6000 6000 6000 6000 6000

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.39 JackTempStBy - temperature during the Stand-By mode

This parameter defines the temperature of the chamber's heating

element during the Stand-By mode.

Resolution: 0.1°F

Minimum value: 68°F

Maximum value:284°F

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

Delicate

121

140.0 140.0 140.0 140.0 140.0

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.40 JackTempProc – temperature of the chamber's heating element

This parameter defines the temperature of the chamber's heating

element during the sterilization stage.

Resolution: 0.1°F

Minimum value: 32.1°F

Maximum value:284°F

Cycle

Default

Value

Flash

134

Wdry

134

No Dry

121

Wdry

121

Delicate

121

248.8 248.0 239.0 239.0 239.0

B&D

Test

Fixed

value

Vacuum

Test

Fixed

value

7.2.41 FixGenPress

N/A

Page 27 of 129 Pages

Page 30

e

This directory enables monitoring the status of the digital inputs. It is

possible to view the digital inputs during cycle.

7.3 Digital Inputs

1. To move from one item to another item use the UP and DOWN

pushbuttons.

2. To exit to the menu go to EXIT and when it is blinking press the

START/STOP pushbuttons.

Displayed

item

Thermostat

(not

applicabl

on this model)

Float

RESERV

(not

applicable on

this model)

Door Switch

Float Res

(not

applicable on

this model)

Displayed

symbol

Operation Status

Thermostat

disconnects the

The temperature is above the

acceptable temperature.

heaters.

The temperature is below the

acceptable temperature.

Senses water in

the clean water

The float doesn’t sense water in

the clean water reservoir.

reservoir.

The float senses water in the

clean water reservoir.

Senses if the door

is open or closed.

The sensor senses the door is

closed.

The sensor senses the door is

open.

Senses water in

the waste water

The float doesn’t sense water in

the waste water reservoir.

reservoir.

The float senses water in the

waste water reservoir.

Page 28 of 129 Pages

Page 31

This directory enables monitoring the status of the digital Outputs. It is

possible to view the Digital Outputs during cycle.

7.4 Digital Outputs

1. To move from one item to another item use the UP and DOWN

pushbuttons.

2. To exit to the menu go to EXIT and when it is blinking press the

START/STOP pushbuttons.

Displayed

item

Air

Vac valve

Chamb

Steam

Fast exh

Displayed

symbol

Operation Remarks

Not operating

Operating

Not operating

Operating

Not operating

Operating

Air valve

(valve 43)

Vacuum valve

(valve 52)

Steam inlet valve to the chamber

(valve 93)

Not operating Fast exhaust valve to the

Operating

reservoir

(valve 73)

Dig Out #5

Not operating

Operating

Optional

Wtr to Res

Air

VacPump

Water Valve

Dig Out #9

Door lock

Heater 1

Heater 2

Vacuum

pump

Water pump

Buzzer

Backlight

Not operating

Operating

Not operating

Operating

Not operating

Not operating

Operating

Locked position

Unlocked position

Not operating

Operating

Not operating

Operating

Not operating

Operating

Not operating

Operating

Off

Buzzing

On

Off

N/A

Air inlet valve to the vacuum

pump (valve 44)

Mineral free water to generator

(valve 21)

Optional

Door locking pin

Steam generator heating element

Chamber heating element

Vacuum pump

Water pump

Buzzer

Screen

Page 29 of 129 Pages

Page 32

7.5 Analog Inputs

n

n

This directory enables checking the analog Inputs. It is possible to enter

this directory while the autoclave is performing a cycle in order to check

the devices sending these inputs.

1. To move from one item to another item use the UP and DOWN

pushbuttons.

2. To exit to the menu go to EXIT and when it is blinking press the

START/STOP key.

Displayed item Description

ChambPress Pressure inside the chamber

Chamb Temp Temperature in the chamber

Coil Temp Temperature in jacket of the chamber

Gen Press Pressure in the steam generator

Electr Gen Level of water in the steam generator

ElectrLow

ElectrLow2

This analog input measures the level of water i

the clean water reservoir.

This analog input measures the level of water i

the waste water reservoir.

Page 30 of 129 Pages

Page 33

7.6 Calibration

7.6.1 Calibration components

This directory describes the calibration of

the following 4 sensors:

Sensor name Sensor function

1.

ChambPress

2. ChambTemp

3. CoilTemp

4. GenPress

7.6.2 Required equipment for calibration

Reads the pressure in the chamber.

Reads the temperature in the chamber.

Reads the temperature in the jacket.

Reads the pressure in the steam generator.

Reference temperature tool: (a bead probe thermocouple)

Single element sealing gland (to insert the thermocouple

through the validation port).

¼” BSP adaptor (for the validation port)

Reference pressure tool: vacuum / pressure gauge in kPa.

7.6.3 Calibrating the sensors

Choose the sensor required to

calibrate among the 4 sensors

available with the UP and

DOWN keys.

When it is blinking select it by

pressing the START/STOP

key.

Move to Calc. GainOffset with

the UP and DOWN

keys, and then when it is

blinking select it with the

START/STOP key

This is a typical calibration screen.

There are two rows of data, each

row has two values.

RH, AH are for calibrating the

upper end of the range

RL, AL are for calibrating the

lower end of the range

AH, AL are the values from your

test equipment

RH, RL are the values from the

autoclaves display

7.6.4 Calibration port

In order to perform the calibration it is required to measure the

temperature or pressure inside the chamber. This is done as

follows:

1. Remove the rear cover of the autoclave (see para. 9.3).

2. Unscrew the plug sealing the validation port.

3. The validation port size is ¼”BSP

Page 31 of 129 Pages

Page 34

4. Assemble to this port the required measuring tool

(temperature sensor or vacuum/pressure gauge) as specified

in the calibration instruction.

Validation port plug

7.6.5 Calibration operation

Calibration can be preformed in psi and °F, HOWEVER, it is

recommended that the calibrations be performed in kPa and °C

(see changing parameters sec 7.2.35 & 7.2.36).

Make sure the insulation is securely wrapped around the chamber.

The side and top panels should also be attached.

When calibrating the autoclave you will:

First, acquire the appropriate data, as instructed below.

Second, access the calibration page of the software (see sec 7.1 &

7.6.3)

Third, use the START/STOP key to move from digit to digit

and the UP / DOWN keys to increase and decrease the

values according to your data.

7.6.5.1 Calibrating

“ChambPress”

the pressure in the chamber

Calibrate the low pressure of the chamber

Attach your reference pressure gauge to the validation

port on the back of the chamber and operate a vacuum

test. When the unit has reached its lowest vacuum level

record the reading of your gauge and the pressure

reading for the chamber on the screen of the autoclave.

It is not necessary to abort the cycle, the calibration can

be done while the unit is running the cycle. access the

calibration page for ChambPress then enter the data as

follows (if necessary refer back to 7.6.3):

AL (actual pressure low value): change the AL to the

value shown by your reference pressure gauge. RL

(displayed pressure low value): change the RL to the

value read from the autoclave display.

Page 32 of 129 Pages

Page 35

To save the data move to SET by pressing the

START/STOP key and when it is blinking press

the UP key.

If you did not abort the cycle then the chamber

pressure on the screen should match your reference

gauge.

Calibrate the high pressure of the chamber

Attach your reference pressure gauge to the validation

port on the back of the chamber and operate a program

of 134°C. When the unit has reached sterilization

record the reading of your gauge and the pressure

reading for the chamber on the screen of the autoclave.

It is not necessary to abort the cycle, the calibration can

be done while the unit is running the cycle. access the

calibration page for ChambPress then enter the data as

follows (if necessary refer back to 7.6.3):

AH (actual pressure high value): change the AH to

the value shown by your reference pressure gauge.

RH (displayed pressure high value): change the RH

to the value read from the autoclave display.

To save the data move to SET by pressing the

START/STOP key and when it is blinking press

the UP key.

If you did not abort the cycle then the chamber

pressure on the screen should match your reference

gauge.

7.6.5.2 Calibrating the temperature in the ch amber

“ChambTemp”

Calibrate the low temperature of the chamber

When the autoclave is cold, using the sealing gland

insert your reference thermocouple through the

validation port and into the chamber. Position it near

the Pt100 inside the chamber. Close the chamber door

to allow the temperature inside the chamber to stabilize,

then record the reading of your thermocouple and the

reading on the screen of the autoclave. Access the

calibration page for Chamb Temp then enter the data as

follows (if necessary refer back to 7.6.3):

AL

(actual temperature low value): change the AL

to the value shown by your reference thermocouple.

(displayed temperature low value): change the

RL

RL to the value read from the autoclave display.

To save the data move to SET by pressing the

START/STOP key and when it is blinking press

the UP key.

Now chamber temperature on the screen should

match your reference thermocouple.

Page 33 of 129 Pages

Page 36

Calibrate the high temperature of the chamber

Using the sealing gland, insert your reference

thermocouple through the validation port and into the

chamber. Position it near the PT100 and operate a

program of 134°C. When the unit has reached

sterilization record the reading of your thermocouple

and the reading on the screen of the autoclave.

It is not necessary to abort the cycle, the calibration can

be done while the unit is running the cycle. access the

calibration page for Chamb Temp then enter the data as

follows (if necessary refer back to 7.6.3):

AH

(actual temperature high value): change the AH

to the value shown by your reference thermocouple.

RH (displayed temperature high value): change the

RH to the value read from the autoclave display.

To save the data move to SET by pressing the

START/STOP key and when it is blinking press

the UP key.

If you did not abort the cycle then the chamber

temperature on the screen should match your

reference thermocouple.

7.6.5.3 Calibrating the temperature in the jacket “CoilTemp”

Calibrate the low temperature of the jacket

When the autoclave is cold and turned off, peel back the

insulation at the back top of the chamber. On your right

will be a PT100 inserted under the heating element (see

picture). Insert the reference thermocouple between the

heating element and the chamber next to the PT100.

Turn the unit on and immediately select the Vacuum

Test Cycle, this will keep the heaters from turning on.

Access the calibration page for Coil Temp calibration.

Record the reading of your thermocouple and the

reading on the screen of the autoclave then enter the

data as follows (if necessary refer back to 7.6.3):

AL (actual temperature low value): change the AL

to the value shown by your reference thermocouple.

RL (displayed temperature low value): change the

RL to the value read from the autoclave display.

Page 34 of 129 Pages

Jacket PT100

Page 37

To save the data move to SET by pressing the

START/STOP key and when it is blinking press

the UP key.

Now the jacket temperature on the screen should

match your reference thermocouple.

Calibrate the high temperature of the chamber wall

Peel back the insulation at the back top of the chamber.

On your right will be a PT100 inserted under the

heating element (see picture). Insert the reference

thermocouple between the heating element and the

chamber next to the PT100.

Select a cycle of 134°C and wait for the autoclave-

preheating icon to go off the screen. Access the

calibration page for Coil Temp calibration. Record the

reading of your thermocouple and the reading on the

screen of the autoclave then enter the data as follows (if

necessary refer back to 7.6.3):

AH (actual temperature high value): change the AH

to the value shown by your reference thermocouple.

RH (displayed temperature high value): change the

RH to the value read from the autoclave display.

To save the data move to SET by pressing the

START/STOP key and when it is blinking press

the UP key.

Now the jacket temperature on the screen should

match your reference thermocouple.

7.6.5.4 Calibrating the pres sure in the steam generato r

“GenPress”

Calibrate the low pressure of the steam generator

When the unit is off and the steam generator is cold and

there is no pressure in it, attach your reference pressure

gauge to the calibration port on the generator manifold

(see picture). Turn the unit on and immediately select

the Vacuum Test Cycle, this will keep the heaters from

turning on. Access the calibration page for GenPress

calibration. Record the reading of your reference

pressure gauge and the pressure reading for the

generator on the screen of the autoclave then enter the

data as follows (if necessary refer back to 7.6.3):

AL (actual pressure low value): change the AL to the

value shown by your reference pressure gauge.

RL (displayed pressure low value): change the RL

to the value read from the autoclave display.

To save the data move to SET by pressing the

START/STOP key and when it is blinking press

UP key.

the

The steam generator pressure on the screen should

match your reference gauge.

Page 35 of 129 Pages

Page 38

Calibrate the high pressure of the steam generator

When the unit is off and the steam generator is cold and

there is no pressure in it, attach your reference pressure

gauge to the calibration port on the generator manifold

(see picture). Select a program of 134°C the generator

will begin to heat. When the unit has reached the ready

state record the reading of your gauge and the reading

for the generator on the screen of the autoclave.

Access the calibration page for GenPress then enter the

data as follows (if necessary refer back to 7.6.3):

AH (actual pressure high value): change the AH to

the value shown by your reference pressure gauge.

RH (displayed pressure high value): change the RH

to the value read from the autoclave display.

To save the data move to SET by pressing the

START/STOP key and when it is blinking press

UP key.

the

The steam generator pressure on the screen should

match your reference gauge.

Generator

Page 36 of 129 Pages

Calibration port

Page 39

7.7 Setting the Clock

This directory enables the operator to set the time and date.

The SET CLOCK screen is displayed when entering the SET CLOCK

directory:

When entering the directory the curser will be blinking on the "hour"

digit.

The time is displayed in the upper row in the form “hh:mm:ss”. The

hour range is 24 hour (i.e. from “0” to “24”).

The date is displayed in the lower row in the form “DD:MM:YYYY”.

1. To increase or decrease the time or the date use the UP and

DOWN keys.

2. To move the curser from one digit to another press the

START/STOP key.

3. After changing the time and the date move the curser to “SAVE”.

4. Confirm the new time and date by pressing the UP key. While the

new time and date are being saved the following screen is

displayed:

5. After saving is completed, the SET CLOCK screen is displayed

again, move the cursor to EXIT and press UP to return to the

previous MENU screen.

6. The printer will print the date in the format DD:MM:YYYY if the

chamber temperature is being displayed in ˚C. It will print the date

in the format MM:DD:YYYY if the chamber temperature is being

displayed in ˚F.”

Page 37 of 129 Pages

Page 40

7.8 Printer Test

This option checks the good functioning of the printer.

1. Select "Printer Test" as described in section 7.1 "Menu".

2. Press the START/STOP key to perform the Printer Test.

3. Check that the message “Printer Test” is written on the paper.

Page 38 of 129 Pages

Page 41

7.9 Language

THIS OPTION IS NOT AVAILABLE YET

Page 39 of 129 Pages

Page 42

This directory enables you to print the 40 previous cycles.

The HISTORY screen is displayed when entering the HISTORY

directory:

1. Choose the required cycle according to its number (Log Load Nu)

with the UP and DOWN key

2. The words "Log Load Nu" are replaced by "printing" and the

required cycle data is printed by the built in printer.

3. In order to leave this screen go to the EXIT option by using the

DOWN key and select it by pressing the START/STOP key.

7.10 History

Page 40 of 129 Pages

Page 43

7.11 More options

This sub-directory enable the technician to perform a few additional

operation.

1. To enter this sub-directory Select "more options" as described in

section 7.1 "Menu".

2. Use UP and DOWN keys to browse through the 4 options +

"EXIT".

7.11.1 Calib Default

This option enables the technician to return to the default

calibration data as defined at the factory.

Caution

This operation is a non-retur n operation. Activating this

option will delete all calibration data and it will be impossible

to retrieve it.

1. Press the START/STOP key to return to the default

calibration values..

2. To return to the main menu– move the cursor to "EXIT"

7.11.2 Set Serial Num

This option enables the technician to set the autoclave's serial

number. This is necessary after replacing the electronic unit.

1. Press the START/STOP key to enter the "SERIAL

NUMBER" display.

2. Press the START/STOP key to move the cursor from the

right digit leftward.

3. Use UP and DOWN keys to change the value of each

digit.

4. Complete the change by moving the cursor to "SAVE" and

save the number by pressing UP or DOWN keys.

Page 41 of 129 Pages

Page 44

7.11.3 Reset Load Nu.

This option enables the technician to reset the autoclave's load

number.

Caution

This operation is a non-retur n operation. Activating this

option will reset the load num ber to "0" and it w ill be

impossible to return to the previous setting it.

1. Press the START/STOP key to reset the load number.

2. The load number will reset to "0" and the following will be

displayed.

7.11.4 Enable Programs

This option enables the technician to choose the programs that

will be enabled or disabled.

When entering this option the following is displayed.

1. Use UP and DOWN keys to browse through the

programs.

2. The number on the right side of the program name defines the

status of the program.

1 – enabled

0 – disabled

Press the START/STOP key to switch between 1 and 0.

3. It is possible to enable or disable any program, but at least

one program must remain enabled.

4. To exit this option press both UP and DOWN keys

simultaneously.

Page 42 of 129 Pages

Page 45

8 RESETTING THE AUTOCLAVE

Whenever it becomes necessary to restore the system to normal operation, the

system must be reset. This will remove corrupted data from memory and

restore a healthy program. On occasion other situations require that a reset be

performed, they are as follows:

When the machine is operated for the first time.

If the machine has been sitting unused for a long period of time.

To reset the system proceed as follows:

Turn-off the main power switch on the right side of the autoclave.

Turn-on the main switch while pressing and holding the DOWN ▼key

until the message “RESET DONE!!!” is displayed.

This will not erase any settings or history.

Page 43 of 129 Pages

Page 46

9 MAINTENANCE AND REPLACEMENT PROCEDURES

9.1 Preliminary Operations for Each Technician Call

1. In order to mainta in efficient service, the technician must

perform the following:

1. Inspect and clean if needed, the following:

Chamber, trays and trays holder (see Maintenance

Instructions in the Operator’s Manual).

Filters.

Seats and plungers of the solenoid valves (see sec. 9.21).

Water level electrode in the generator (see sec. 9.8).

Water reservoir(see sec. 9.27).

Steam generator (including descaling) (see sec. 9.32).

2. Visual inspection for leaks or corrosion in the piping elements

3. Tightening loose screws and piping joints.

4. Visual inspection of the wiring.

5. Calibration and logging the calibration of the temperature and

pressure.

2. After completing the work, the technician must perfo rm the

following cycles:

1. A Wdry 134 cycle with out load

2. A Vacuum Test

3. A B&D Test.

Note:

The warranty does not cover cleaning or maintenance. These procedures

are the responsibility of the equipment owner.”

Page 44 of 129 Pages

Page 47

9.2 Safety tests after repair

ATTENTION!

After every repair or dismantling of the enclosure, the technician

should perform the following two electrical safety tests.

1. Enclosure Leakage Current Test.

Every autoclave should pass this test as follows:

1. Connect the electrical cord to the autoclave. DO NOT plug

into the power outlet.

2. Turn on the main switch on the right side of the autoclave.

3. Short-circuit the L and L pins on the cord's plug.

4. Connect the Short-circuit pins to the L pole on the Megger.

5. Connect the GND pin to the GND pole on the Megger.

6. Impose an electrical potential of 1000V±10% on the tested

autoclave. The insulation resistance should be at least 2 MΩ.

The test is successful if there was no leakage.

2. Protective Earth Impedance Test

1. Connect the grounding pin of the power cord plug to one pole

of an Ohmmeter.

2. Connect any other metallic part (preferable – the metallic part

of the locking screw) to the second pole of the Ohmmeter.

3. The resistance should not exceed 0.3 Ω.

After performing these tests, the Service Engineer should complete

and sign the Work Order.

Page 45 of 129 Pages

Page 48

9.3 Dismantling the Outer Covers of the Autoclave

Caution!

Before starting, disconnect the instrument from the po wer source

and ensure that there is no pressure in the autoclave.

Allow the autoclave to cool before removing outer covers.

1. Unscrew the screws (2) holding the upper cover (1).

2. Remove the upper cover.

3. Unscrew the screws (4) holding the side covers (3).

4. Remove the side covers (3).

5. Disconnect the air filter (6) from the air filter cover (7).

6. Unscrew the screws (5) holding the rear covers (8).

7. Remove the rear cover (8).

8. Remove the grounding wires from the rear cover.

1

2

3

4

8 7

6

5

Page 46 of 129 Pages

Page 49

9.4 Replacing the Safety Valve

Caution!

Before starting, be sure that the electric cord is disconnected and that

there is no pressure in the chamber or generator.

Allow the autoclave to cool before removing outer covers.

The safety valve is installed to protect the system from over pressurizing

should all the electrical controls fail.

1. Take off the autoclave cover (see para. 9.3 “Removing the

Autoclave’s Outer Covers”).

2. Remove the water reservoir cover.

3. Unscrew the safety valve (2) and remove it from the safety valve

base (1).

4. Replace the valve with a new safety valve (install only an original

equipment replacement!). Use liquid thread seal on the threads to

seal it. Tighten the safety valve to prevent leaking.

5. To check the new safety valve, perform the following:

1 2

43

No. Description

1 Safety valve base

2 Safety valve

3 Pulling device

4 Pressure relief ring

6. Operate the sterilization cycle according to the manual but with no

instruments.

7. Allow a pressure of approximately 300 kPa (29-psig) to build up in

the generator and the chamber.

8. Remove water reservoir cover.

9. Pull the ring (4) of each safety valve in turn using a tool, i.e.

screwdriver, hook etc. (3). Pull the safety valve ring for 2 seconds.

Be careful not to burn your hands.

10. Press the STOP key to stop operation, and exhaust steam from

chamber.

11. Wait until pressure decreases to zero, only then can the door be

opened.

Page 47 of 129 Pages

Page 50

9.5 Replacing chamber heater

Be careful not to bend the tubing or over-tighten with tie wraps.

Kinking the tubing will weaken that area of the tube and it will leak.

Replace any tubes that become damaged.

1. Perform this procedure only when the unit is cool and there is no

pressure in the chamber.

2. Unplug the unit

3. Drain the steam generator using a 6 mm Allen wrench to remove