Page 1

TECHNICIAN

MANUAL

Electronic Table - top

Pre and Post Vacuum Autoclaves

models 2540 & 3870 EHS

Cat. No. MAN205-0063-005E Rev. D

Page 2

1

TABLE OF CONTENTS

PARAGRAPH PAGE NO.

1 INTRODUCTION..................................................................................................4

2 SYMBOL DESCRIPTION ....................................................................................4

3 INSTALLATION INSTRUCTIONS .....................................................................5

3.1 Site requirements for installation of a 2540 EHS

.......................................

5

3.2 Site requirements for installation of a 3870 EHS

.......................................

6

3.3 Suggested Site Drain Drawing

.....................................................................

7

3.4 Electrical Specifications

...............................................................................

8

3.5 Placing the Autoclave

...................................................................................

8

3.6 Connections to Utility Supplies

....................................................................

8

3.7 Installation Tests

........................................................................................

10

3.8 Water Quality

..............................................................................................

11

4 DESCRIPTION OF THE CONTROL SYSTEM. ..............................................12

4.1 System Summary

........................................................................................

12

4.2 Keyboard

.....................................................................................................

13

4.3 Digital Board DIG - T2

..............................................................................

13

4.4 Analog Board ANL-T2

...............................................................................

15

4.5 AC - Board - AC-T1

....................................................................................

17

5 CALIBRATION OF PRESSURE AND TEMPERATURE ...............................19

5.1 Calibration Overview

..................................................................................

19

5.2 Calibration Theory - Error Compensation:

..............................................

20

5.3 Equipment needed for calibration

.............................................................

20

5.4 Calibration Procedure

................................................................................

20

6 TESTING AND RESETTING.............................................................................26

6.1 Test Points

...................................................................................................

26

6.2 In – Out Test mode:

....................................................................................

27

6.3 Resetting the Autoclave:

.............................................................................

28

6.4 Input Output Graph:

..................................................................................

29

7 PROPERTIES OF SATURATED STEAM ........................................................ 35

8 SOFTWARE PROGRAMMING PARAMETERS .............................................36

8.1 General

........................................................................................................

36

8.2 Changing Parameters

.................................................................................

36

9 MAINTENANCE AND REPLACEMENT PROCEDURES .............................47

9.1 Safety Tests after Repair

............................................................................

47

9.2 Removing the Autoclave’s Outer Covers

...................................................

48

9.3 Replacing the Safety Valve

.........................................................................

49

Page 3

2

TABLE OF CONTENT (Cont.)

PARAGRAPH PAGE NO.

9.4 Replacing the DIG-T2 board

......................................................................

50

9.5 Drain Valve Repair

.....................................................................................

52

9.6 Replacing the Pressure Gauge

...................................................................

54

9.7 Replacing the Door Bellows (Located in the door bridge)

........................

55

9.8 Replacing the Printer

.................................................................................

56

9.9 Replacing the Door Switch

.........................................................................

57

9.10 Replacing the circuit breaker

.....................................................................

58

9.11 Replacing the water pump

..........................................................................

59

9.12 Pressure Switch

..........................................................................................

60

9.13 The Heaters

.................................................................................................

61

9.14 The Dual Compartment Water Reservoir

..................................................

62

9.15 The Water Sensing Electrodes

...................................................................

64

9.16 The Vacuum Pump

.....................................................................................

66

9.17 Draining the Jacket

....................................................................................

68

9.18 Replacement of the Door Cover

.................................................................

69

9.19 Replacing the Closing Device

....................................................................

70

9.20 PT100 Temperature Sensor Replacement

.................................................

71

10 TROUBLESHOOTING .......................................................................................72

10.1 Preliminary Check

......................................................................................

72

10.2 Preliminary Troubleshooting

.....................................................................

73

10.3 Pre-process malfunction

............................................................................

79

10.4 In Process Malfunction

..............................................................................

84

10.5 Mechanical malfunction

..........................................................................

111

10.6 Water pump malfunction

.........................................................................

113

11 SPARE PARTS LIST......................................................................................... 114

12 VALVES NUMBERING....................................................................................124

Page 4

3

TABLE OF CONTENT (Cont.)

DRAWINGS PAGE NO.

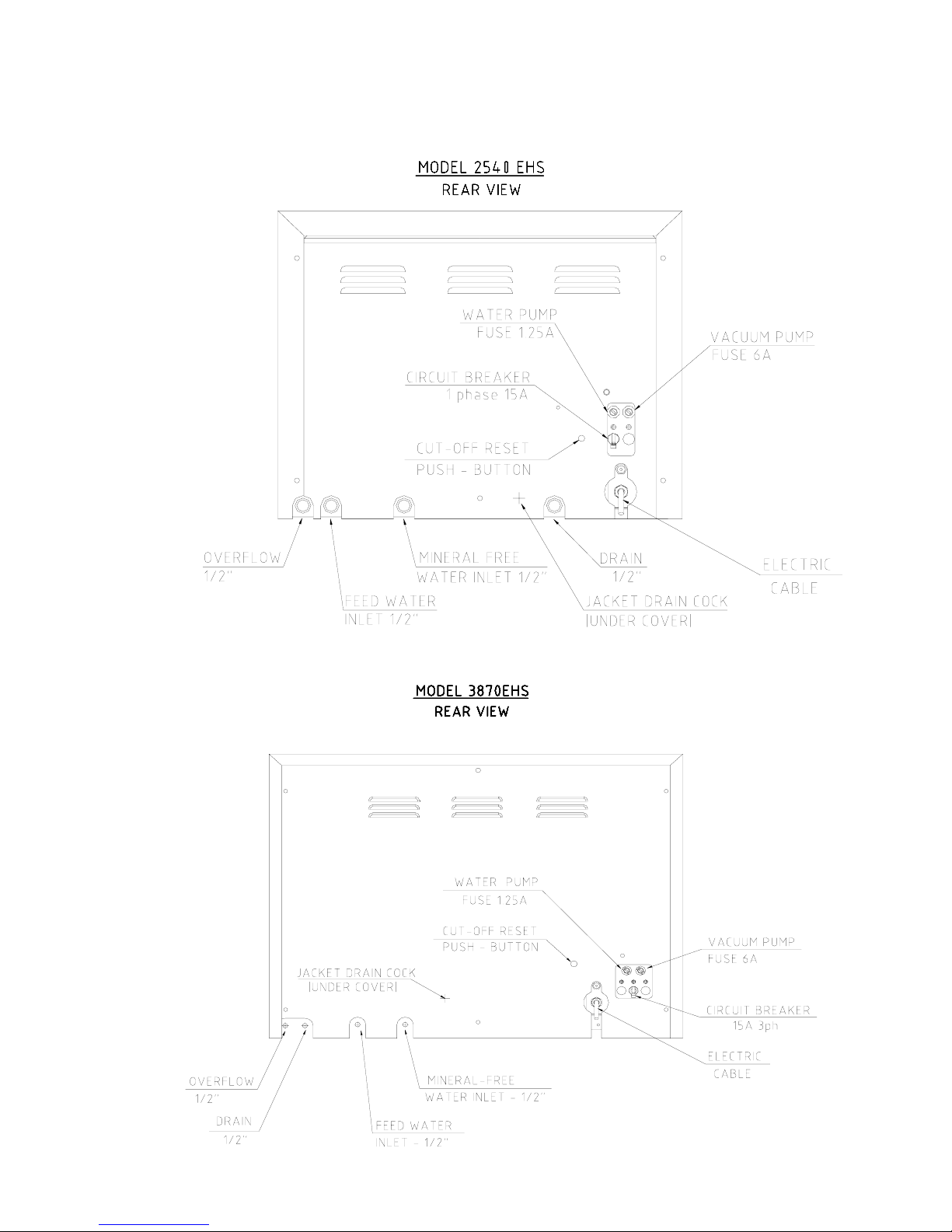

REAR VIEW

..................................................................................................................

9

CONTROL SYSTEM BLOCK – DIAGRAM

............................................................

12

DIG- T2 BOARD

.........................................................................................................

14

ANL- T2 BOARD

........................................................................................................

16

AC-T1 BOARD

............................................................................................................

18

EXTERNAL CONNECTION OF THE 2540EHS AUTOCLAVES

ELECTRONICS

BOX

...............................................................................................

117

EXTERNAL

CONNECTION OF THE 3870EHS AUTOCLAVES

ELECTRONICS BOX

...............................................................................................

118

VESSEL ASSEMBLY

...............................................................................................

118

VESSEL ASSEMBLY

...............................................................................................

119

OUTER CABINET – ASSEMBLY

...........................................................................

120

TRAY HOLDER

........................................................................................................

121

TRAY

.........................................................................................................................

122

TRAY HANDLE (CMT240-0001)

............................................................................

122

DOOR TIGHTENING BOLT – ASSEMBLY

..........................................................

123

PIPING DRAWING FOR 2540 EHS

.......................................................................

125

PIPING DRAWING FOR 3870 EHS

.......................................................................

126

ELECTRICAL DRAWING FOR 2540 EHS

............................................................

127

ELECTRICAL DRAWING FOR 3870 EHS (TILL S/N 2307039)

..........................

128

ELECTRICAL DRAWING FOR 3870 EHS (AFTER S/N 2307040)

......................

129

Page 5

4

1 INTRODUCTION

This Technician’s Manual, together with the Operator’s Manual, forms the

complete set of Operation and Maintenance instructions for the EHS pre and

post vacuum autoclave. This manual is intended for the use of the technician.

It is strongly recommended that only qualified and Tuttnauer factory trained

personnel service this autoclave and do so in accordance with the instructions

in this manual. Any unauthorized service may result in the invalidation of the

manufacturer’s warranty.

2 SYMBOL DESCRIPTION

Caution! Consult accompanying documents

Caution! Hot surface.

Caution! Hot steam.

Protective earth (Ground)

Stand by

Page 6

5

3 INSTALLATION INSTRUCTIONS

For proper operation, these are the required utilities that need to be

supplied for each model EHS:

3.1 Site requirements for installation of a 2540 EHS

Caution

The sterilizer must be placed on a rigid and leveled surface and

must be able to hold the weight of the device and loaded material.

1. Counter top able to support a minimum 200 lb. * (the unit is

shipped with a suitable stand - 26”W x 33”D x 34”H)

2. Counter space minimum 20”W x 32”D x 20”H * (see unit

dimensions below)

3. City water supply 15 - 58 psi with shut off valve having ½" NPT

male end.

Higher rates of pressure will require the installation of a pressure

reducer (58 psi max).

A regulator and pressure gauge are supplied with the unit

The minimum flow rate required is 0.66 gal/min. (2.5 lit./min.).

Installation of the valve should be 2" above counter height at the

rear of the unit.

4. Mineral Free water supply 7 - 30 psi with shut off valve and ½"

NPT male end.

Higher rates of pressure will require the installation of a pressure

reducer.

A regulator and pressure gauge are supplied with the unit

The minimum rate of flow is 0.26 gal/min (1 lit/min).

Installation of the valve should be 2" above counter height at the

rear of the unit. * (an optional R.O. water system is available).

5. Electrical power 20A – 208V single phase. Connection required;

flush mount receptacle 6-20R, within 1 foot of the rear of the unit.

6. Drainage should be to a 4” high 4” diameter air break, reducing

down to a 1 ½” vented line with a trap. All drainage components

must be able to withstand a non-continuous temperature of 140°F

(60°C). Drain opening should be within 1 foot of the rear of the

unit and no higher than 16” above the floor. The use of two ½”x 6"

Milford Type Copper Coated Hangers is required for the

positioning of the two drain hoses over the center of the air break

and a 4” metal worm gear clamp to secure the hangers. The hangers

will need to be bent at a 90º angle to allow for proper positioning

and securing with the clamp. * (see attached drawing)

Page 7

6

3.2 Site requirements for installation of a 3870 EHS

Caution

The sterilizer must be placed on a rigid and leveled surface and

must be able to hold the weight of the device and loaded material.

1. Counter top able to support a minimum 400 lb. * (the unit is

shipped with a suitable stand - 26”W x 33”D x 34”H)

2. Counter space minimum 26”W x 39”D x 24”H * (see unit

dimensions below)

3. City water supply 15 - 58 psi with shut off valve having ½" NPT

male end.

Higher rates of pressure will require the installation of a pressure

reducer (58 psi max).

A regulator and pressure gauge are supplied with the unit

The minimum flow rate required is 0.66 gal/min. (2.5 lit./min.).

Installation of the valve should be 2" above counter height at the

rear of the unit.

4. Mineral Free water supply 7 - 30 psi with shut off valve and ½"

NPT male end.

Higher rates of pressure will require the installation of a pressure

reducer.

A regulator and pressure gauge are supplied with the unit

The minimum rate of flow is 0.26 gal/min (1 lit/min).

Installation of the valve should be 2" above counter height at the

rear of the unit. * (an optional R.O. water system is available).

5. Electrical power 20A - 208V three phase, three power lines plus a

ground. Connection required; flush mount receptacle or drop line

with NEMA # L15-20R, this is a twist lock connector, within 1

foot of the rear of the unit.

6. Drainage should be to a 4” high 4” diameter air break, reducing

down to a 1 ½” vented line with a trap. All drainage components

must be able to withstand a non-continuous temperature of 140°F

(60°C). Drain opening should be within 1 foot of the rear of the

unit and no higher than 16” above the floor. The use of two ½”x 6"

Milford Type Copper Coated Hangers is required for the

positioning of the two drain hoses over the center of the air break

and a 4” metal worm gear clamp to secure the hangers. The hangers

will need to be bent at a 90º angle to allow for proper positioning

and securing with the clamp. * (see attached drawing)

Page 8

7

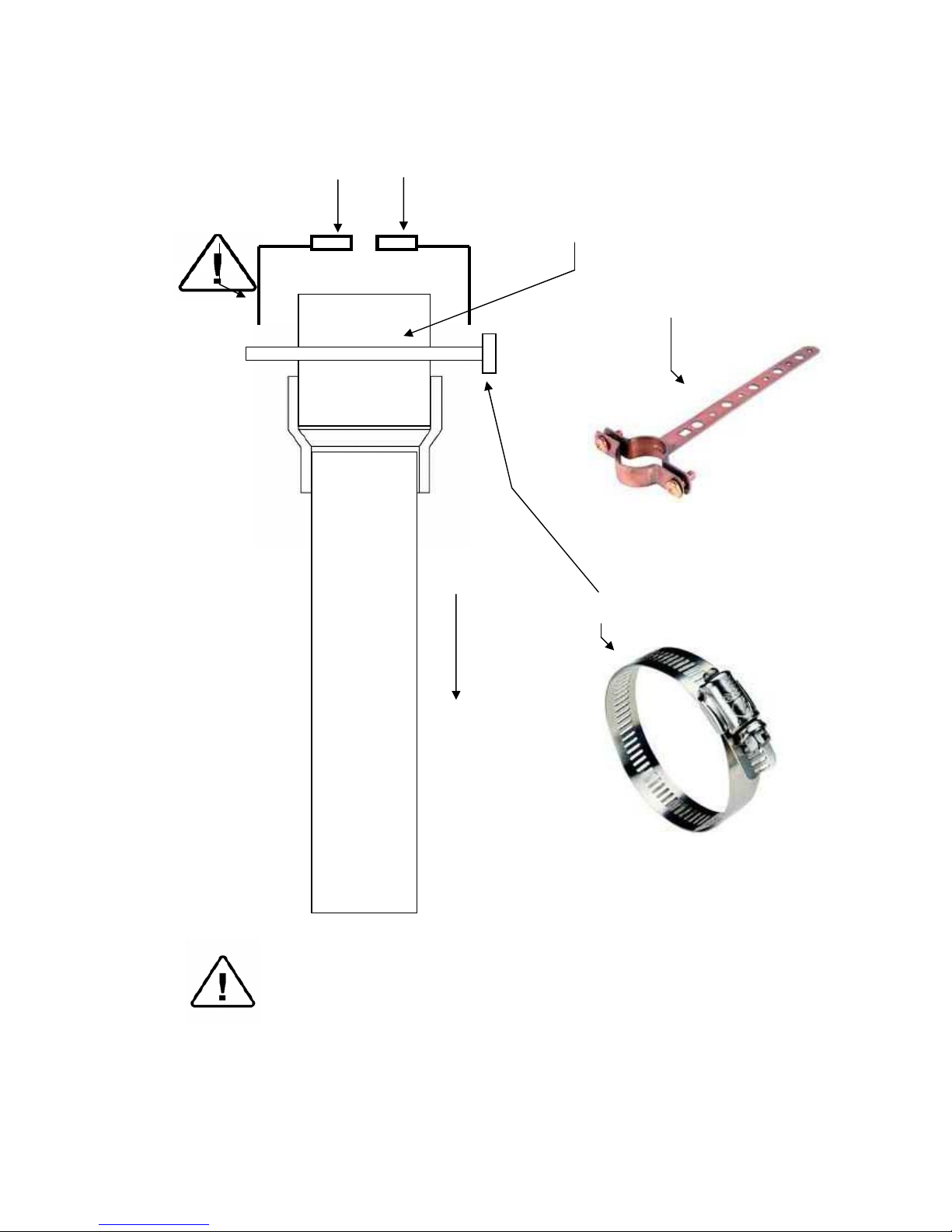

3.3 Suggested Site Drain Drawing

Caution!

Wastewater should be brought into the public sewage network in

accordance with the local rules or requirement i.e. only nonhazardous liquids shall be disposed of in public sewage!

Network and connection should comply with the devices

consumption, local installation and safety rules and regulations.

Discharge hoses from EHS

Hanger with

90º ben

d

Coated Hanger

4” x 4” PVC air brea

k

1 ½” PVC

To trap

4” Metal worm gear clamp

Milford Type Copper

Page 9

8

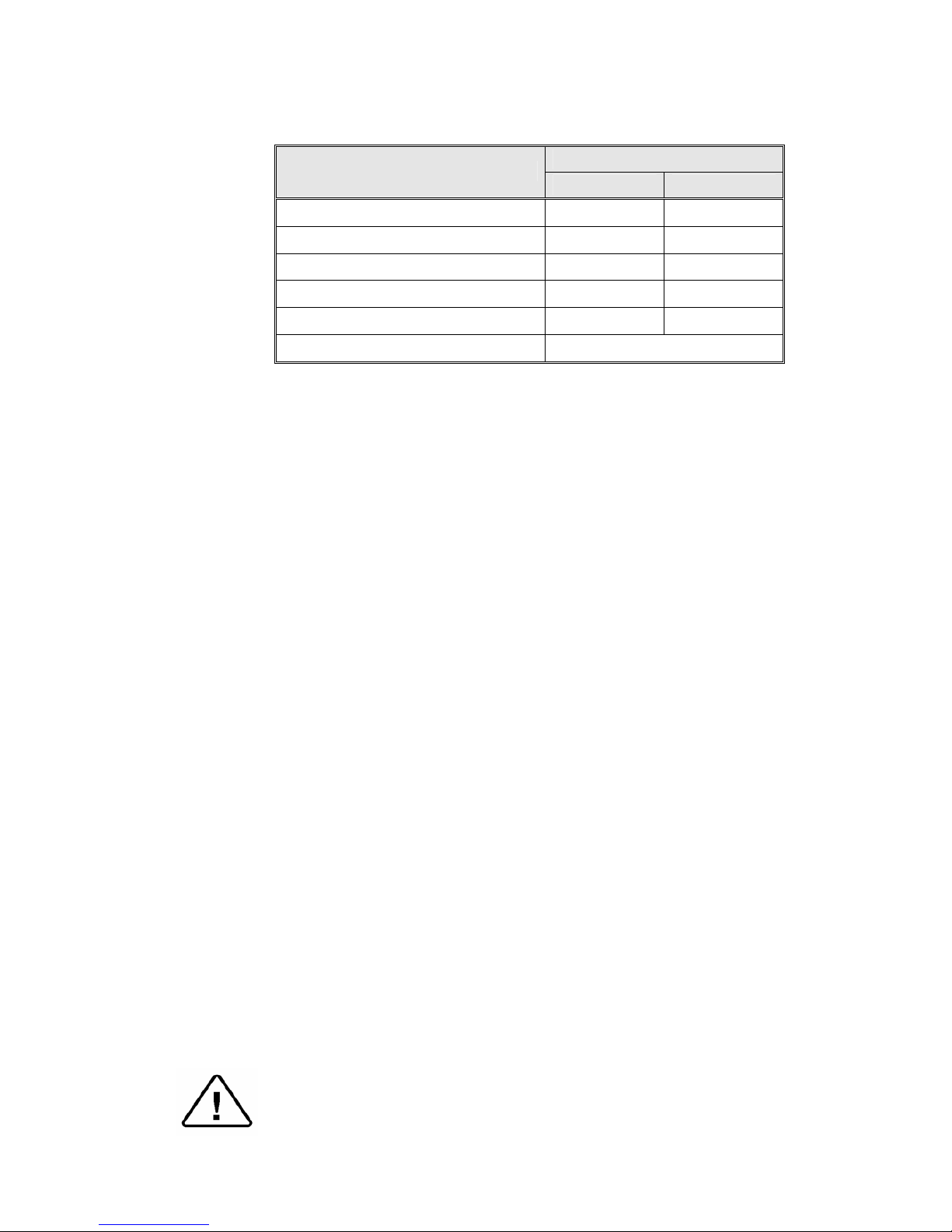

3.4 Electrical Specifications

Value

Property

2540 3870

Heaters Power 3000W 6000W

Total Power 3200W 6200W

Voltage (V) 1 ph / 208 3 ph / 208

Amperage (A) 15 15

Frequency (Hz) 50/60 50/60

Protection against electrical shock Class I (IEC 60601-1)

Note: In order to avoid any injury by electrical hazard, it is

recommended that a ground fault protection device be installed in

the electrical panel feeding the autoclave (local codes may make

this mandatory).

3.5 Placing the Autoclave

Set the rear legs so that the chamber pitches down in the front at a rate

of 1/8” per foot. This ensures that water is completely drained out of

the chamber through the opening at the bottom front of the chamber.

To check, pour a glass of water into the bottom rear of the autoclave

and observe the water flow out of the chamber.

NOTE: Keep the back and the sides of the autoclave

approximately 1” (25 mm) away from the wall to allow ventilation.

It is recommended that enough space be left around the autoclave

to give a technician access for servicing the machine.

3.6 Connections to Utility Supplies

Using the ½” hoses and washers supplied with the unit

1. Connect the tap water inlet on the back of the autoclave to the feedwater supply (city water supply).

2. Connect the mineral -free water inlet on the back of the autoclave

to a source of mineral-free water.

3. Connect the exhaust outlet on the back of the autoclave (using the

black hose supplied with the unit) to a suitable drain as described

above. Be sure to observe local codes for discharge of this type.

Note:

The drain hose from the exhaust outlet must be fixed very

securely to the drain, ensuring that when steam and water are

exhausted the hose is not allowed to recoil and cause injury to

personnel.

4. Connect the reservoir overflow on the back of the autoclave to a

suitable drain as described above.

5. Plug the power cord into the supply socket.

Attention! The pressure of the jacket does not decrease when the

equipment is turned off.

Page 10

9

REAR VIEW

Page 11

10

3.7 Installation Tests

At the time of installation, before the autoclave can be okayed for

daily operation the service technician needs to perform the

following preliminary checks:

♦ Integrity check: perform a visual check to verify that there are no

dents, scratches or broken components on the autoclave

♦ The leakage current check: test the precise operation of the earth

leakage relay

♦ Ground check: test the continuity of the grounding connection

♦ Power supply check: check that proper power is being supplied to

the machine. See sec. 3.4.

♦ Pitch check: confirm that the autoclave has a downward pitch back

to front of 1/8" per foot. (see sec. 3.5)

♦ Exhaust and Feed hose check: ensure that all hoses are free

flowing and not restricted.

♦ Water Pressure Check: verify that the city water pressure into the

unit is between 15 - 58 psi. Verify that the mineral free water

pressure into the unit is between 7 - 30 psi.

♦ Door check: ensure that the door locking mechanism is

functioning properly

♦ Reset the Unit: turn power off using the green power button at the

bottom of the front panel, press and hold the Sel. Cycle button on

the keypad, turn power on, continue to hold the Sel. Cycle button

until the message Program Wait appears on the screen.

♦ Atmospheric Pressure check: the unit is set from the factory at

14.5 psia, this is atmospheric pressure at sea level. If the unit is

located more that 500 ft above or below sea level then the Atmos.

Press parameter must be set, see sec 8.2.17

♦ Safety Valve check: test the safety valve as per the instructions in

sec 8.6 of the Operator's Manual

♦ Cycle check: run a B&D Test to ensure that all systems in the unit

are functioning properly.

After the above steps are performed, the autoclave is ready for

daily operation

Page 12

11

3.8 Water Quality

3.8.1 Built-in Steam Generator

The distilled or mineral – free water supplied to the steam

generator shall be according to the table below:

A Reverse Osmosis system meeting the qualifications below

may be used to provide water for the steam generator. The

better the quality of the water, the better performance, the less

maintenance and the longer the life of the autoclave.

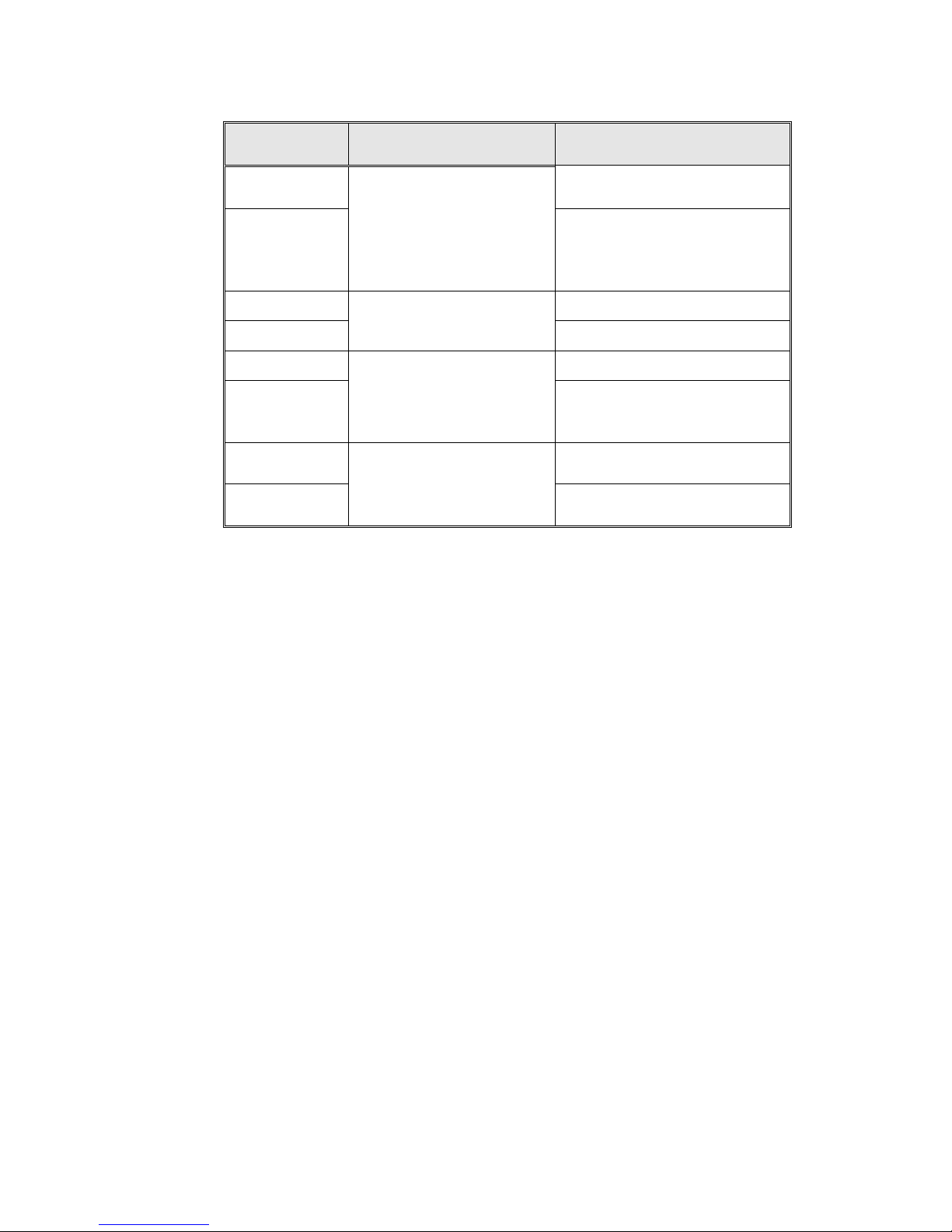

Mineral Free Water qualifications

(In compliance with ISO 11134 and ISO 13683)

Evaporate residue

≤ 15 mg/l

Silica

≤ 2 mg/l

Iron

≤ 0.2mg/l

Cadmium

≤ 0.005 mg/l

Lead

≤ 0.05 mg/l

Rest of heavy metals

≤ 0.1 mg/l

Chloride

≤ 3 mg/l

Phosphate

≤ 0.5 mg/l

Conductivity

≤ 50 µs/cm

pH

6.5 to 8

Appearance

Colorless, clean, without sediment

Hardness

≤ 0.1 mmol/l

Attention:

The use of water in the autoclave that does not comply with

the table above may have severe impact on the working life

of the sterilizer and can invalidate the manufacturer’s

warranty.

The suitability of the mineral free water to be used should be

verified by testing in accordance with the above table; at an

authorized laboratory using acknowledged analytical

methods. We recommend testing the water quality once a

month.

3.8.2 Water for the Vacuum System and the Drain Cooling

The feed water supplied, typically from a public water system,

to the liquid ring vacuum pump must meet the following

requirements:

♦ Hardness: 0.7 - 2 mmol/l.

♦ Water temperature: shall

not exceed 59°F (15°C).

Note: The use of hard water in the vacuum pump may invalidate

the warranty for the vacuum pump, since it can cause

blocking of the rotor, which can damage the pump.

Page 13

12

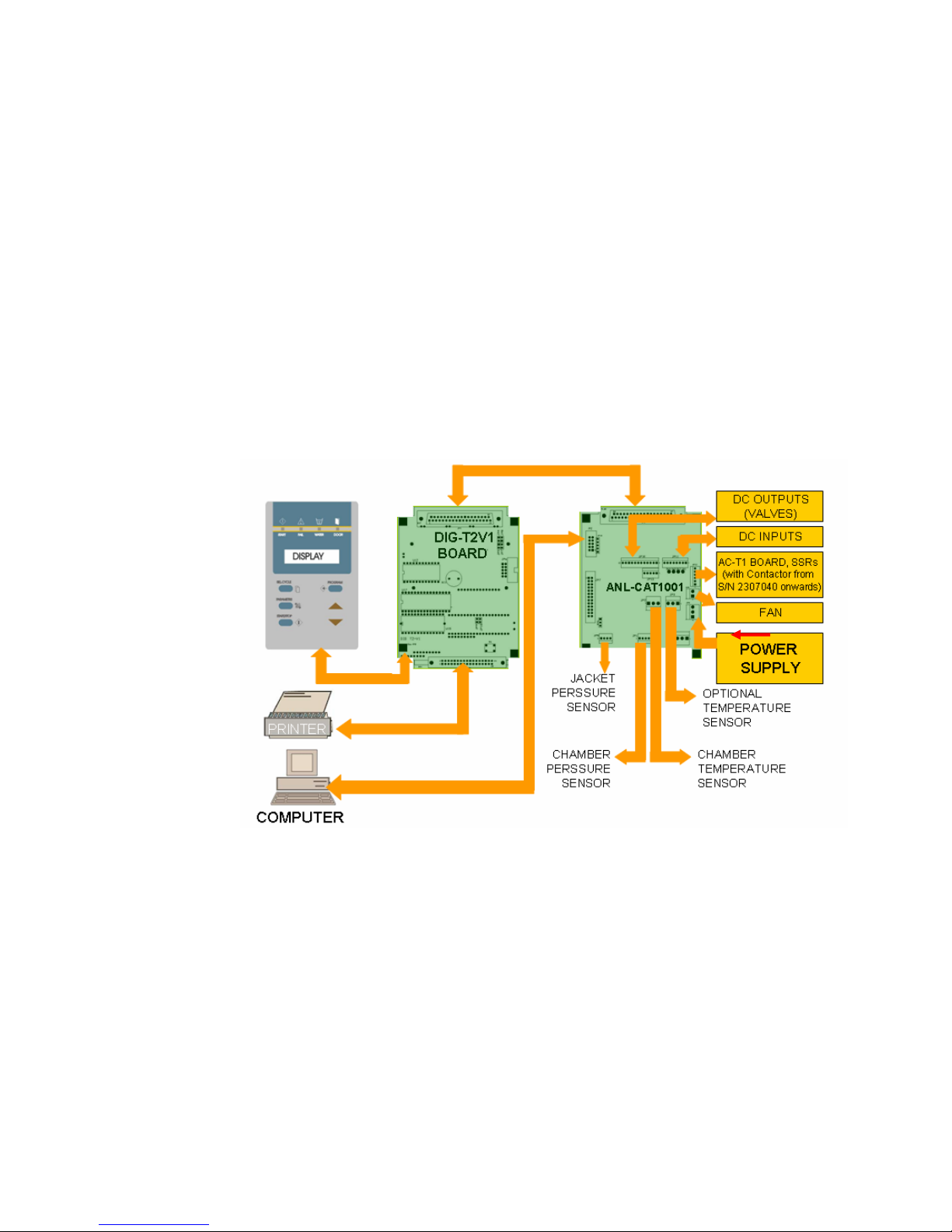

4 DESCRIPTION OF THE CONTROL SYSTEM.

4.1 System Summary

The hardware portion of the control system consists of a keyboard and

3 additional electronic boards designed specifically to match the

requirements of the EHS autoclave. The main board is the digital

board, DIG-T2, which contains the microprocessor and is responsible

for controlling the system. The analog board, ANL-T2, interfaces with

the DIG-T2 board and the various system components processing

signals traveling to and from these areas. The AC-T1 board consists of

AC power filters and drivers for the AC components in the system. DC

power (12V and 5V) for all the DC components is supplied by a

switching type power supply. In addition the system is capable of

direct communication with a printer over a parallel interface and/or a

PC via an RS 232 port (for more detail see individual descriptions

below).

CONTROL SYSTEM BLOCK – DIAGRAM

The following paragraph applies only to the 3870EHS

From S/N 2307040, a Varistor is connected, in parallel, to each of the

SSR’s contacts, in order to decrease the voltage spikes, caused by the

operation of the power devices (pumps and heating elements).

In the 3 phase system (in our case, the 3870EHS) the current, to the

heating elements, is supplied via a contactor. A “CUT OFF” thermostat

is connected to the contactor's coil. If the temperature of the heating

elements exceeds the alarm value, the “CUT OFF” thermostat

disconnects the contactor coil, the contactor's contacts open ("off"

position) and the heating elements are disconnected from the electrical

power.

Page 14

13

4.2 Keyboard

The keyboard is mounted to and directly connected to the DIG-T2

board and functions as an MMI (Man-Machine Interface). The keypad

serves as a control panel containing the command and programming

keys. It also includes an LCD display with two rows of 16 characters

for cycle progress updates and error messages. In addition it contains

the following light indicators:

— START (autoclave in process),

— FAIL (the process failed),

— WATER (no water in the reservoir),

— DOOR (blinks with buzzer sound when START is

pressed and the door is not closed).

For more detail on the control keys and error messages please see the

EHS Operators Manual

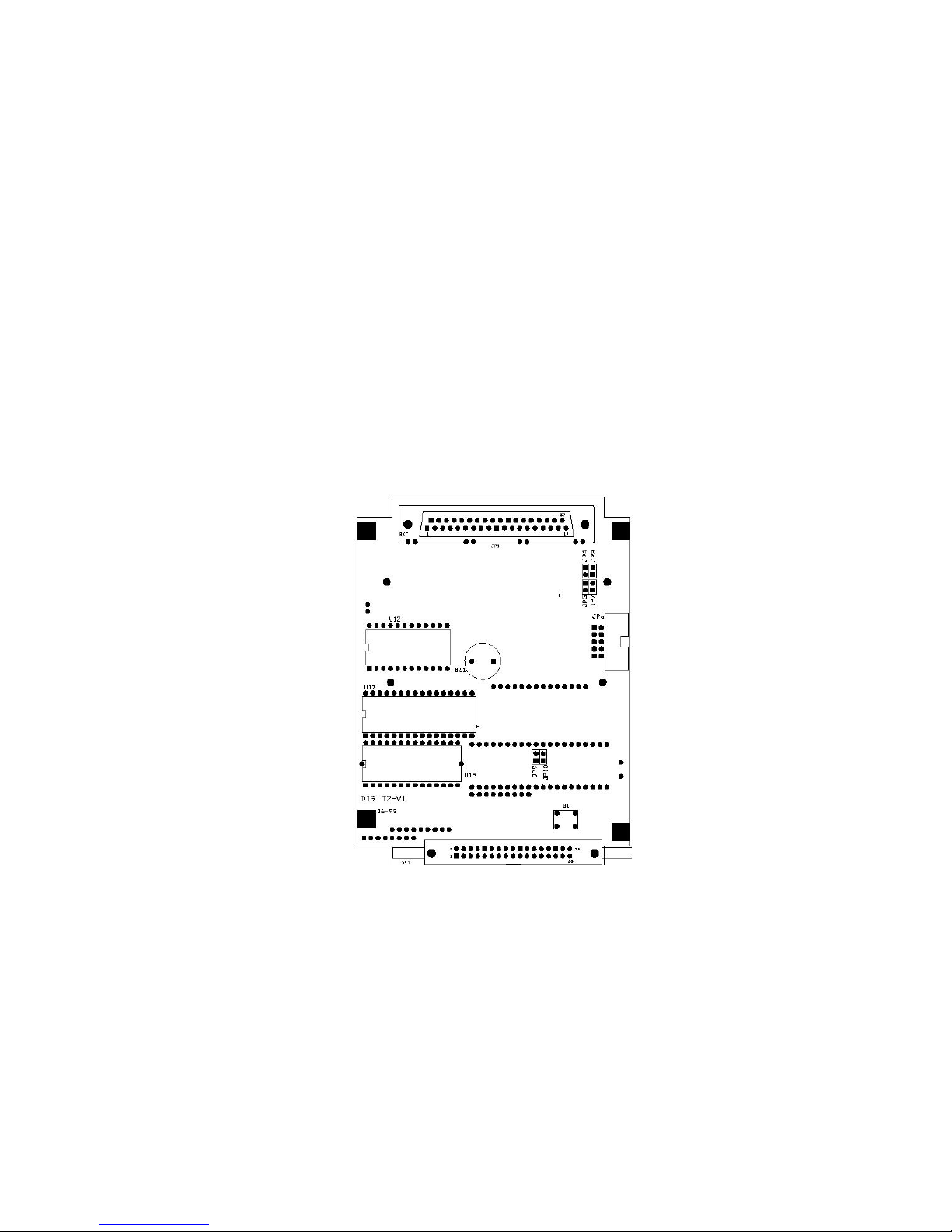

4.3 Digital Board DIG - T2

The digital board contains the microprocessor that runs the system

software program and controls all the functions of the EHS autoclave.

It is connected to the Keypad and digital display for interactive

communication with the operator. It is also connected to the ANL-T2

analog board for communication with the rest of the EHS autoclave. In

addition the DIG-T2 board has PC and printer communication abilities.

— The digital board is connected to the keypad and the ANL-T2

analog board via ribbon cables.

The DIG-T2 board receives human commands through the Keypad

and transmits visual information back, through the Keypad display

The DIG-T2 board receives sensory information, from system

sensors, in the form of digital signals through the ANL-T2 board. It

also transmits operational commands, in the form of digital signals,

to the various system components through the ANL-T2 board.

Power for the DIG-T2 is provided by the ribbon cable connected to

the ANL-T2

— The digital board also contains a parallel printer port for connection

to a proprietary printer. The printer is connected directly to this

board through connector DS1 via a ribbon cable. The printer

receives data and operating voltage directly from this connector.

— The PC interface establishes two-way communication between the

DIG-T2 board and a stand-alone personal computer, utilizing

proprietary software. This communication is via a connector

located on the ANL-T2 board and ribbon cable leading to an

external connector on the front panel.

— On the board, are three types of memories:

1) EPROM memory (U15) for storing the program codes.

2) RAM memory (U9) with a capacity of 64KB for the storage of

temporary data during the running of the program that is

located on the opposite side. This information is only for

general knowledge.

Page 15

14

3) FLASH memory (U17) serves as a non-volatile memory,

enabling the system to change follow-up tables during running

of program codes, and ensuring this data is not lost in case of

power failure.

— The board contains a Real Time Clock element (U12), which

serves as a clock to the system. It includes a back-up battery, which

ensures that the clock runs continuously even when the autoclave is

not powered.

— The back-up battery RAM includes a 113-byte memory component

for storing the parameters currently in use.

— The board contains a solid-state component (U18) that acts as a

system watchdog. This component detects any faulty situation

while the program code is running. It forces the micro-controller to

recheck system inputs every 1.5 seconds, this prevents the software

from becoming stuck in a program loop, that would lead to the

software crashing and a loss of control of the machine.

The layout of the DIG-T2 board components is provided below

DIG- T2 BOARD

— The system provides two types of communication with PC

software, RS232 and RS485. Jumpers on the DIG-T2 board need

to be set differently for each type. The default is RS232 (see also

ANL-T2 board):

1. RS232 – JP4, JP5, JP9 are closed. RS232 allows a single

communications port on the computer to communicate with a

single EHS autoclave.

2. RS485 – JP7, JP8, JP10 are closed. RS485 allows a single

communications

port, with RS485 capability, to

communicate with multiple EHS autoclaves daisy chained

together.

— The system is equipped with a hardware-reset switch (S1).

Page 16

15

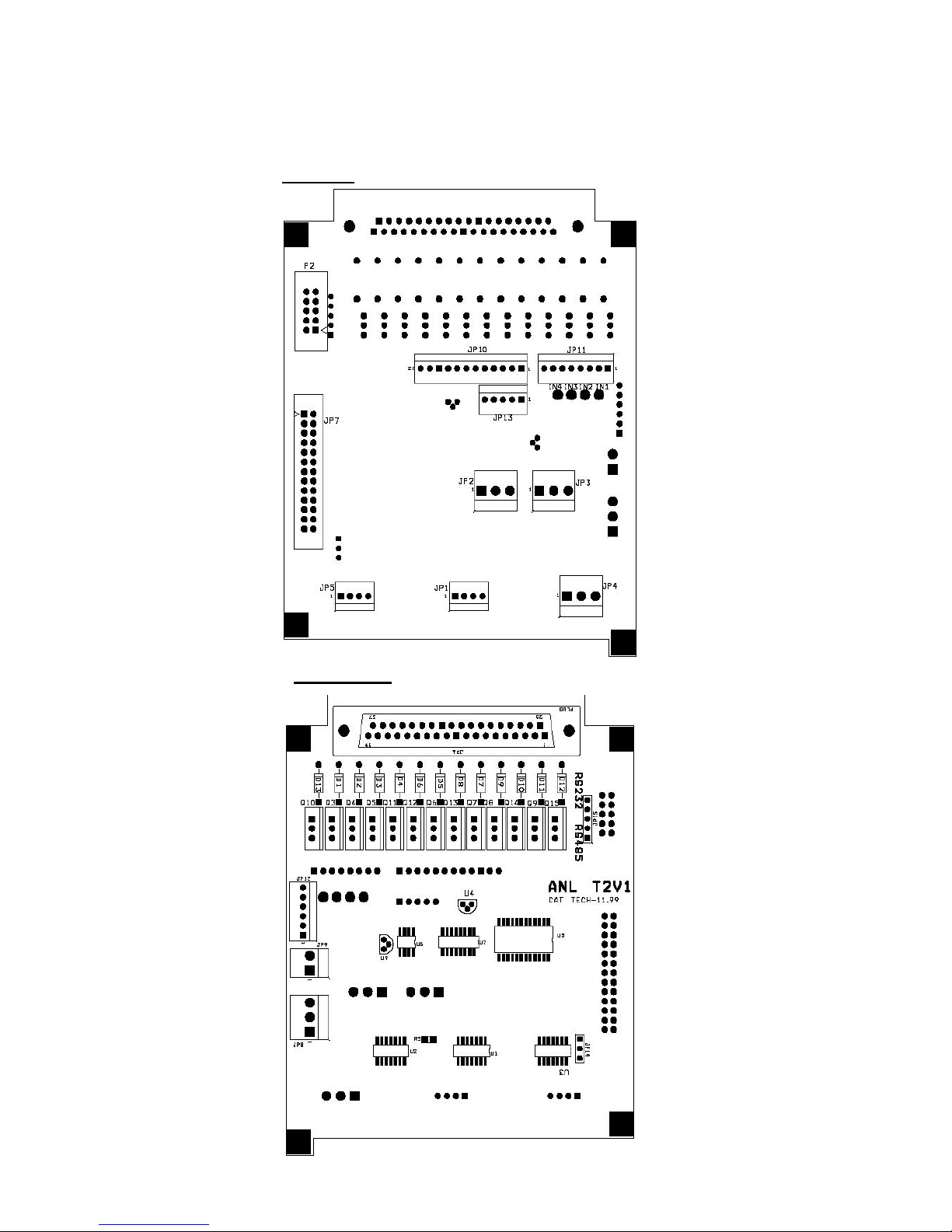

4.4 Analog Board ANL-T2

The analog board contains the DC power transistors that drive the

valves, heaters and pumps. It contains the sensor circuits that decode

the information from the temperature and pressure sensors before

passing that information on to the DIG-T2 board. All the systems

electronic components are connected through the ANL-T2 board. The

analog board is connected to the AC-T1 board that controls the AC

voltage devices. The power supply supplies 12 VDC and 5 VDC to the

analog board and the ANL-T2 distributes that power to the remaining

electronic components.

— JP1 & JP5 are connected to the two MPX2200 pressure sensors that

measure the chamber & jacket pressure.

— JP2 receives the digital input from the PT-100 temperature sensor

— JP8 is connected to the Power Supply and receives the 12VDC and

the 5VDC.

— JP6 provides a connection to the DIG-T2 board

— JP7 provides a connection for the Test Point board needed in

troubleshooting.

— JP9 provides control for the cooling fan

— JP10 connects the DC output drivers to the solenoid valves.

— JP11 is connected to the various digital inputs, such as the water

electrodes, door switch, float switches, etc.

— JP12 is directly connected to the SSR controlling the heaters. It

also provides a digital connection to the AC_T1F board, which

controls the water and vacuum pumps and the steam valve.

— JP13 is not applicable in the EHS Machine.

— JP14 is not applicable in the EHS Machine.

— JP15 is used to match the communication connector configuration

to either RS232 or RS485. The default is RS232 (see also DIG-T2

board):

1. RS232 – JP15, short pins 2 & 3, 4 & 5.

2. RS485 – JP15, short pins 1 & 2, 3 & 4.

— P2 provides a link to the serial port on the front of the unit, via a

ribbon cable.

Page 17

16

Layout diagram of the ANL-T2 is provided below.

ANL- T2 BOARD

Top View

Bottom View

Page 18

17

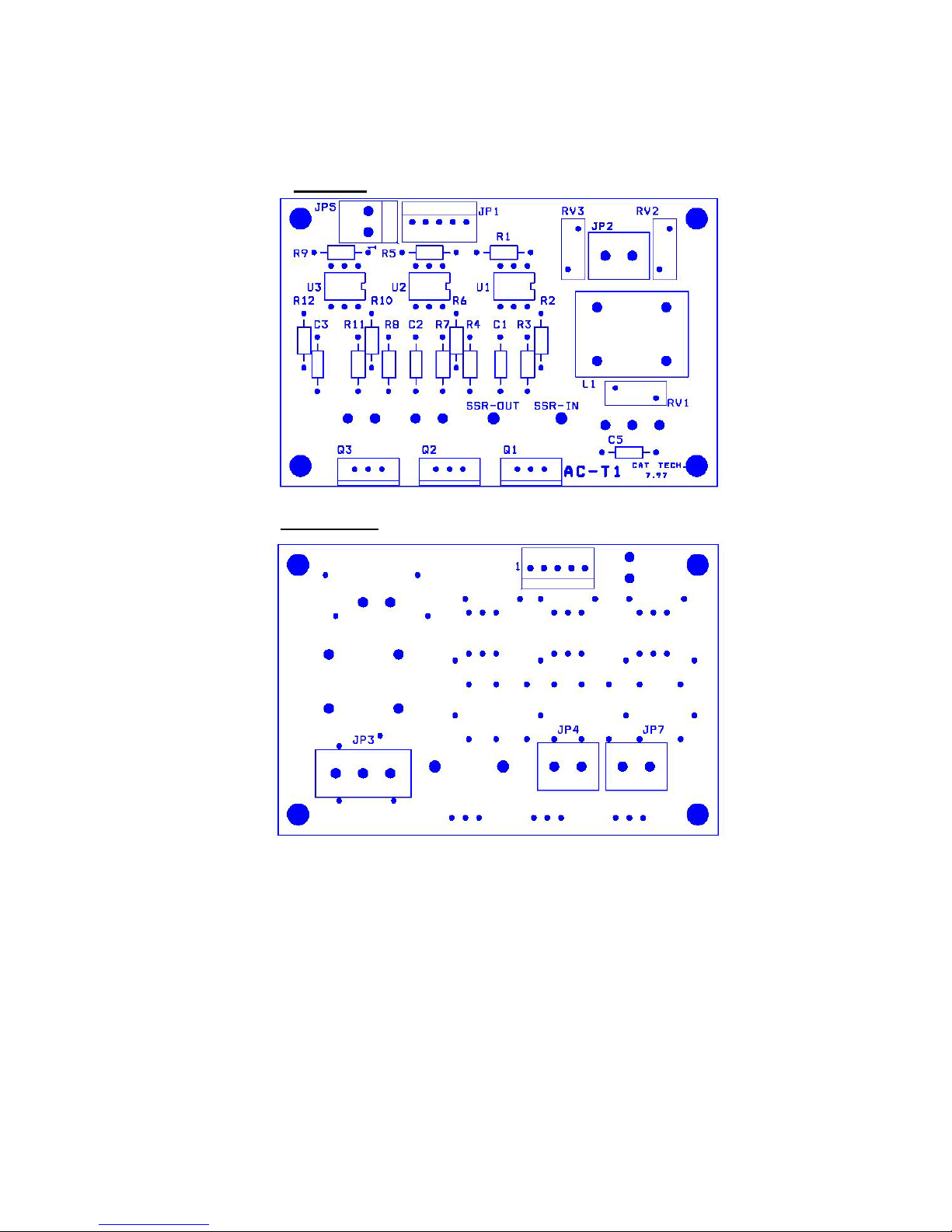

4.5 AC - Board - AC-T1

The AC-T1 board provides AC filtering to protect the power supply

and the control system from voltage spikes. This board contains the AC

voltage drivers that control the AC devices in the system. This is done

by accepting command signals indirectly from the DIG-T2 board

through the ANL-T2 analog board and then turning the devices on or

off.

The AC-T1 board includes:

— A filter circuit utilizing the L1C5 isolation transformer.

— JP2 provides filtered power to the power supply.

— Three 230/115 VAC triac control circuits. These are the AC

drivers used in controlling the water and vacuum pumps and the

steam valve.

— The maximum amperage this board is capable of controlling is 6A.

— Spike protection is provided by three components, RV1, RV2 and

RV3. These components provide a resistibility proportional to the

spike level. The resistibility decreases when the spike level

increases, so that the current will be transferred to the ground

instead of damaging the autoclave’s system.

— JP1 is the control signal input from the ANL-T2 board

— JP3 is the AC input connector.

— JP4 is the output to the steam valve if an AC valve is used

— JP7 is the output to the water and vacuum pumps

Page 19

18

AC-T1 BOARD

Top View

Bottom View

Page 20

19

5 CALIBRATION OF PRESSURE AND TEMPERATURE

5.1 Calibration Overview

The calibration of temperature and pressure is performed digitally. This

system does not have adjustment pots. All calibrations are preformed

through the keypad. The calibration procedure is identical on all EHS

models.

The electronic temperature and pressure measuring circuits built into

the EHS are designed with components having 1% accuracy.

The pressure circuit produces a linear output and has an electrical

output range of 100mv - 2400mv, which corresponds to a pressure

range of 0 - 58 psia.

The temperature circuit also produces a linear output and has an

electrical output range of 100mv - 2400mv, which corresponds to a

temperature range of 68°F (20°C) - 302°F (150°C).

The temperature and pressure circuits provide analog input voltages

that are converted to digital signals by the A/D converter. The

performance of the Analog to Digital converter (A/D) is limited for

values greater than 2400mv or less than 100mv.

The system has a non-volatile memory in which the offset and gain

data of the sensors are stored, as well as any error compensation factors

that are calculated. Storage in the no-volatile memory means that even

if the main power is turned off the information is saved for use the next

time the machine is run.

Calibration is performed by entering data through the keypad or a

stand-alone computer when the PC communication port is used.

Page 21

20

5.2 Calibration Theory - Error Compensation:

The system’s error compensation is based on a calculation involving

two points. These points represent the low and high end of the

autoclaves operating temperature or pressure range.

Each point has two values; one value is the “A” actual (measured)

reading of either temperature or pressure (from a PT simulator,

independent thermometer or pressure gauge). The other value is the

“R” the reading from the autoclave’s digital display of either

temperature or pressure. By entering these values into the unit through

the keypad the system is able to calculate a compensation factor that

will correct the digital display and allow it to accurately return the

actual temperature or pressure.

Note: The two points that are selected will define the range of the error

compensation. Although points above and below are not part of

the compensation, the calibration produces a linear compensation

and these values will be accurate.

Note: The temperature can be calibrated in either °F or °C, depending

on what units the machine is set to display.

Note: The pressure calculations are always done in Absolute pressure

(Absolute pressure = atmospheric pressure + 14.5)

The calibration steps that follow will allow you to automatically

correct the displayed temperature and pressure so it accurately reflects

the actual temperature and pressure. All you need do is input the

appropriate data (actual and displayed values) into the system through

the keypad and the on board computer will do the rest.

Note: It is necessary to know the actual and displayed values prior to

entering the calibration mode.

5.3 Equipment needed for calibration

— A PT100 simulator

— Saturated Steam Table (para 7)

5.4 Calibration Procedure

Calibration consists of three (3) parts and needs to be preformed in the

following order. It is not advisable to perform only a partial calibration

1. Check that the atmospheric pressure parameter is set correctly (see

sec 8.2.17)

2. Collect and enter temperature data

3. Collect and enter pressure data

5.4.1 Connecting the test equipment

Remove the outer cabinet

Disconnect the PT100 temperature sensor from the JP2

connector on the ANL_T2 board

Connect the PT100 simulator to JP2

Page 22

21

5.4.2 Collecting and entering temperature data

When collecting data, keep in mind that “A” is always the

actual temperature and “R” is always what is being displayed

on the digital screen of the autoclave.

Once in the calibration mode, the calibration screen will look

similar to this:

Upper Row: A 140.0 R 140.0 (lower temp reading °F)

Lower Row: A 266.0 R 266.0 (higher temp reading °F)

When entering data, remember that the upper row will

represent the lower temperature of the chamber and the bottom

row will represent the higher temperature of the chamber.

5.4.2.1 Collecting temperature data

— Select the low setting on the PT100 simulator

(it is suggested to use 158°F)

This will be the “A” value for the upper row.

— Record the temperature displayed on the screen

(there can be a slight delay in updating the screen

when changing values on the PT100 simulator)

This will be the “R” value for the upper row.

— Repeat this procedure for the high setting using

the PT100 simulator (it is suggested to use

266°F)

These values will be for the bottom row

— Once the data is collected disconnect the PT100

simulator from JP2 and reconnect the PT100.

5.4.2.2 Entering temperature data

Access the calibration mode as described in para

5.4.4.

— The cursor will appear flashing under the value

for “A” in the upper row.

— Using the UP/DN arrow keys, enter the value

for “A”. This will be the first temperature value

that the PT100 simulator was set for.

— Press the PROGRAM key to advance to the

next value.

— The cursor on the upper row will move one

position to “R”; now enter the first temperature

value recorded from the display

— Press the PROGRAM key to advance to the

next value that will be in the bottom row.

— The cursor will be positioned under the value

for “A” in the bottom row.

Page 23

22

— Enter the value for “A”. This will be the second

temperature value that the PT100 simulator was

set for.

— Press the PROGRAM key to advance to the

next value.

— The cursor on the bottom row will move one

position to “R”. Now enter the second

temperature value recorded from the display

— Press the PROGRAM key one final time.

If PROGRAM WAIT has not been displayed

then continue to press the PROGRAM key until

it appears.

After a brief period the unit will return to a

Ready state

5.4.3 Collecting and entering pressure data

When collecting data, keep in mind that “A” is always the

actual pressure and “R” is always what is being displayed on

the digital screen of the autoclave. Under normal

circumstances calibration only needs to be done at the high

end of the pressure range.

Once in the calibration mode, the calibration screen will look

similar to this:

Upper Row: A 15 R 15 (atmospheric pressure reading)

Lower Row: A 45 R 45 (high pressure reading)

When entering data, remember that the upper row represents

atmospheric pressure and the bottom row represents the high

pressure of the chamber. And that all entrees are in absolute

pressure.

“If the display reads a chamber pressure of 00, with the door

of the autoclave open, then proceed directly to 5.4.3.2.

If the reading is not 00 then proceed as follows.

5.4.3.1 Atmospheric pressure calibration

Set the Atmospheric pressure parameter (see 8.2.17)

— If the read out on the display is at least 1psi

above or 1Ih below 00 then access the

calibration mode as described in para 5.4.4

The cursor will appear flashing under the value

for “A” in the upper row.

— Press the Program key to advance to the next

value “R” in the upper row

Page 24

23

— Using the UP/DN arrow keys raise the value of

“R” if the display reads high. Lower the value

of “R” if the display reads low.

(Example: if the display reads 2 psi, then raise

the value of “R” by 2; if it reads 2Ih then lower

the value of “R” by 2)

— Press the program key until PROGRAM WAIT

is displayed. The autoclave will recalibrate and

return to the Ready state.

— If the display now reads 00, with the door of the

autoclave open, then continue on to sec 5.4.3.2”

5.4.3.2 Collecting pressure data

— Select a program with a sterilization

temperature of 273 °F (134 °C), make sure the

door is closed securely and press START.

— Let the unit cycle to maximum pressure that will

be reached once the unit has entered the

sterilization mode.

— Record the temperature and pressure from the

digital display.

— Abort the cycle by pressing the STOP key.

— Consult the Saturated Steam Table for the

Absolute pressure that corresponds to the

temperature recorded in the previous step and

record that value.

— Add 14.5 to the pressure reading from the

digital display and record this value

5.4.3.3 Entering pressure data

Access the calibration mode as described in para

5.4.4.

— The cursor will appear flashing under the value

for “A” in the upper row.

— Press the PROGRAM key to advance to the next

value.

— The

cursor on the upper row will move one

position to “R”.

— Press the PROGRAM key to advance to the next

value that will be in the bottom row.

— The cursor will be positioned under the value for

“A” in the bottom row.

— Enter the value for “A”. This will be the value

of absolute pressure recorded from the Saturated

Steam Table

Page 25

24

— Press the PROGRAM key to advance to the next

value.

— The cursor on the bottom row will move one

position to “R”; now enter the pressure value

recorded from the digital display to which you

have already added 14.5.

— Press the PROGRAM key one final time

If PROGRAM WAIT has not been displayed then

continue to press the PROGRAM key until it appears.

After a brief period the unit will return to a Ready

state

This completes the calibration procedure for

temperature e and pressure. A sterilization cycle

should be performed to verify that the system is

calibrated and running properly.

Page 26

25

5.4.4 Accessing the calibration mode

— With the unit turned on press the PROGRAM key.

— Pressing the PROGRAM key will bring you to its

first function of setting the system’s date the time.

— Setting the date and time can be bypassed by pressing the

PROGRAM key six times.

— On the seventh press of the PROGRAM key CODE:

∅∅∅ will be displayed.

— Advance the code to 011 by pressing the UP arrow key

(this is a technician level code) then press the

PROGRAM key.

— Continue pressing the program key until CALIB CODE:

1∅∅ is displayed.

— Using the UP arrow key select CALIB CODE: 107.

— Press the PROGRAM key again until Program Wait is

displayed, this is an intermediate calibration phase. Once

the program wait is completed TEMP CAL: ∅∅∅ will

be displayed.

— Using the UP arrow key advance to TEMP CAL: ∅∅1

— Press the PROGRAM key again. This is the Temperature

Calibration mode and the data is ready to be entered

— Press the PROGRAM key one additional time and the

display will show PRESS CAL: ∅∅∅.

— Using the UP arrow key advance to PRESS CAL: ∅∅1

— Press the PROGRAM key again. This is the Pressure

Calibration mode and the data is ready to be entered

Page 27

26

6 TESTING AND RESETTING

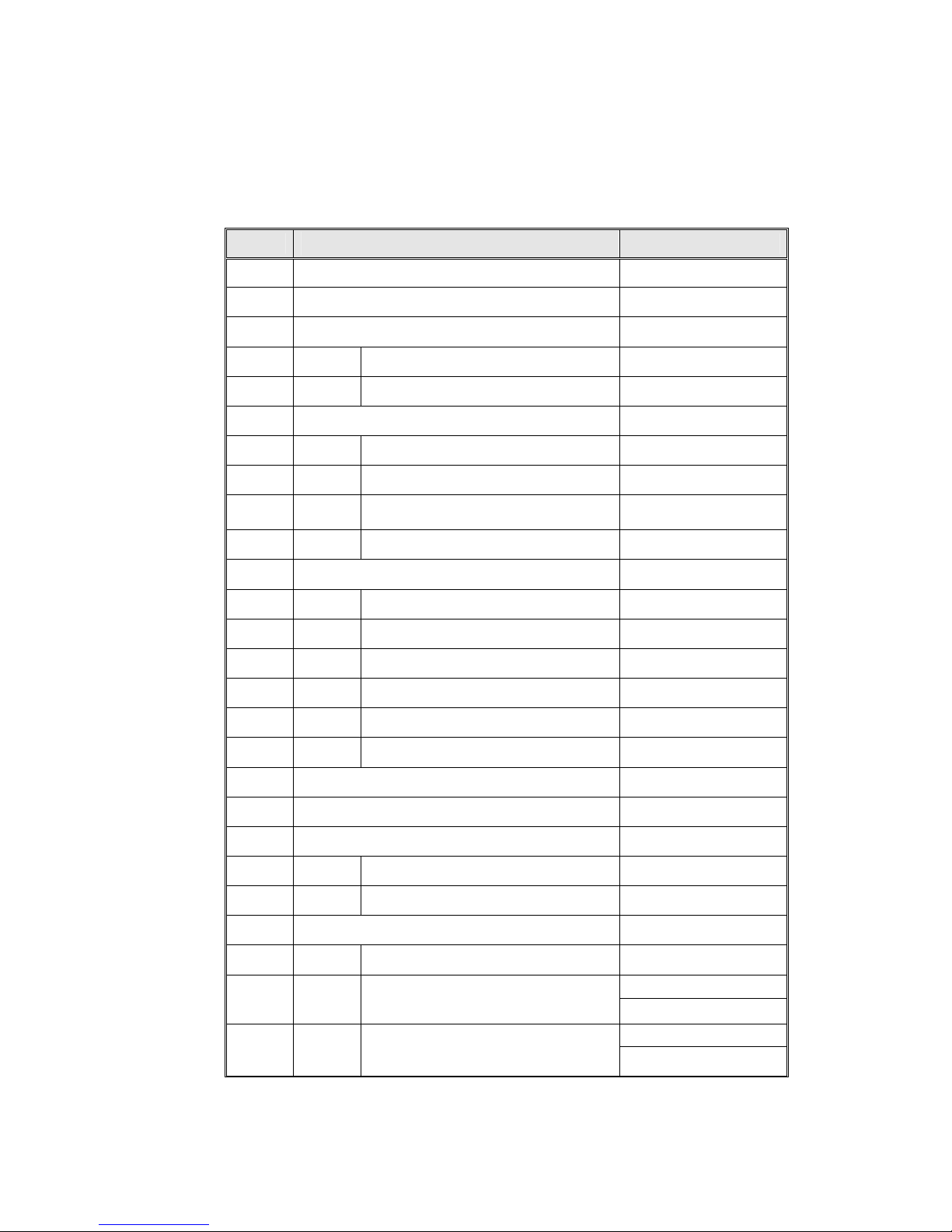

6.1 Test Points

These test points are provided to assist in trouble shooting the

autoclave. A test point board is needed to be able to read these test

points.

NU TP

FUNCTION

VALVE

TP1

GND

TP2

+5V DC

TP3

+12V DC

TP4

OUTPUT HEATERS 0V-Off; 5V-On

TP5

OUTPUT VACUUM PUMP 0V-Off; 5V-On

TP6

TP7

OUTPUT AIR INLET VALVE (43) 0V –CLOSE; 5V-OPEN

TP8

OUTPUT VACUUM VALVE (52) 0V –CLOSE; 5V-OPEN

TP9

OUTPUT

MINERAL FREE WATER TO

RESERVOIR (21)

0V-Off; 5V-On

TP10

OUTPUT WATER TO VAC PUMP (15) 0V-Off; 5V-On

TP11

TP12

OUTPUT STEAM TO CHAMBER (93) 0V –CLOSE; 5V-OPEN

TP13

OUTPUT SLOW EXHAUST (74) 0V –CLOSE; 5V-OPEN

TP14

OUTPUT DRAIN COOLING WATER (13) 0V-Off; 5V-On

TP15

OUTPUT WATER TO VAC PUMP RES. (14) 0V-Off; 5V-On

TP16

OUTPUT FAST EXHAUST (73) 0V –CLOSE; 5V-OPEN

TP17

OUTPUT WATER PUMP 0V-Off; 5V-On

TP18

TP19

TP20

TP21

INPUT TEMPERATURE-1 (PT100) 273ºF = 1.97V

TP22

INPUT JACKET PRESSURE 29.4 psi = 2.031V

TP23

TP24

INPUT CHAMBER PRESSURE 29.4 psi = 2.031V

0V = SATISFIED

TP25

INPUT LOW WATER ELECTRODE

2.5V = NOT SATISFIED

0V = SATISFIED

TP26

INPUT HIGH WATER ELECTRODE

2.5V = NOT SATISFIED

Page 28

27

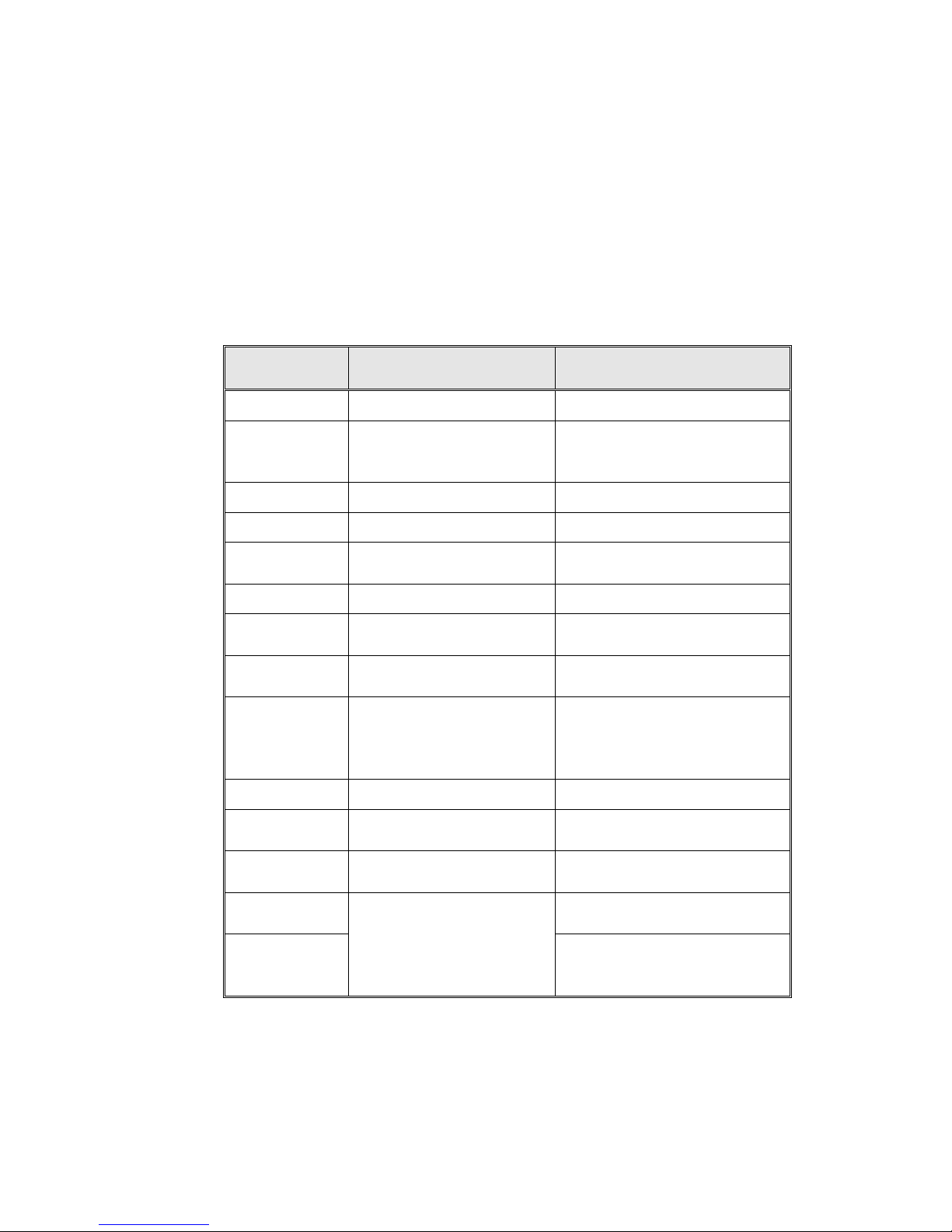

6.2 In – Out Test mode:

To enter the test mode –

• Turn off the main power switch

• While pressing and holding the UP arrow key, turn on the main

power switch.

The output test starts immediately

Each output (valves, heaters, pumps), will be activated and the name of

that device will be displayed.

To switch from one output to another, press the UP arrow key.

When all the outputs have been tested the input tests will begin again.

To leave the In – Out test mode, turn off the main power switch.

DISPLAYED

NOTICE

ITEM ACTIVATED REMARKS

Heaters ON Heating Elements Heating elements are activated.

Pump On Vacuum pump

Pump is operating only if there

is water in the vacuum pump

reservoir

Water ON Water pump for jacket ULKA water PUMP operates.

Air On Air valve (43) Air valve is open.

Water Res On

Mineral free water reservoir

valve (21)

Water valve to mineral free

reservoir is open.

Exh Res On Vacuum exhaust valve (52) Vacuum exhaust valve is open.

Steam On Steam valve (93)

Steam valve from jacket to

chamber is open.

Vacum Wtr On Water valve (15)

Water valve from reservoir to

vacuum pump is open.

Door Lock ON Door locking solenoid

Door locking solenoid is

activated (retracted). (only on

units with an electric door

lock)

Slow Ex On Slow Exhaust valve (74) Slow exhaust valve is open.

Exh Drain On Fast Exhaust valve (73)

Fast Exhaust valve from

chamber to drain is open

Cool wtr On Cooling water valve (13)

Exhaust Cooling water valve is

open

Electrd –h 0

Electrode senses water in the

jacket

Electrd –h 255

High water level electrode

Electrode does not sense water

in the jacket and activates the

water pump

)continued on next page(

Page 29

28

DISPLAYED

NOTICE

ITEM ACTIVATED REMARKS

Electrd –l 0

Electrode senses water above

minimum level in the jacket

Electrd –l 255

Low water level electrode

Electrode does sense water

above minimum level in the

jacket and disconnects heating

elements

Door Sw “0” Door switch activated

Door Sw “1”

Door switch

Door switch not activated

Float -l “0” Float switch senses water

Float -l “1”

Lower mineral free float

switch. (move the float

switch and verify that it

operates)

Float switch does not sense

water and stops operation of

water pump

Float –H “0”

Float switch senses water and

closes valve 21

Float –H “1”

Upper mineral free float

switch. (move the float

switch and verify that it

operates)

Float switch does not sense

water and opens valve 21

6.3 Resetting the Autoclave:

Whenever it becomes necessary to restore the system to normal

operation, the system must be reset. This will remove corrupted data

from memory and restore a healthy program. On occasion other

situations require that a reset be preformed, they are as follows:

— When the machine is operated for the first time

— If the machine has been sitting unused for a long period of time.

— When the cycle has not been completed, as a result of a power

failure or manual stop

To reset the system; proceed as follows:

Turn power off using the green power button at the bottom of the front

panel, press and hold the Sel. Cycle button on the keypad, turn power

on, continue to hold the Sel. Cycle button until program wait appears

on the screen then release.

After resetting, the autoclave will be in the stand-by

mode

Page 30

29

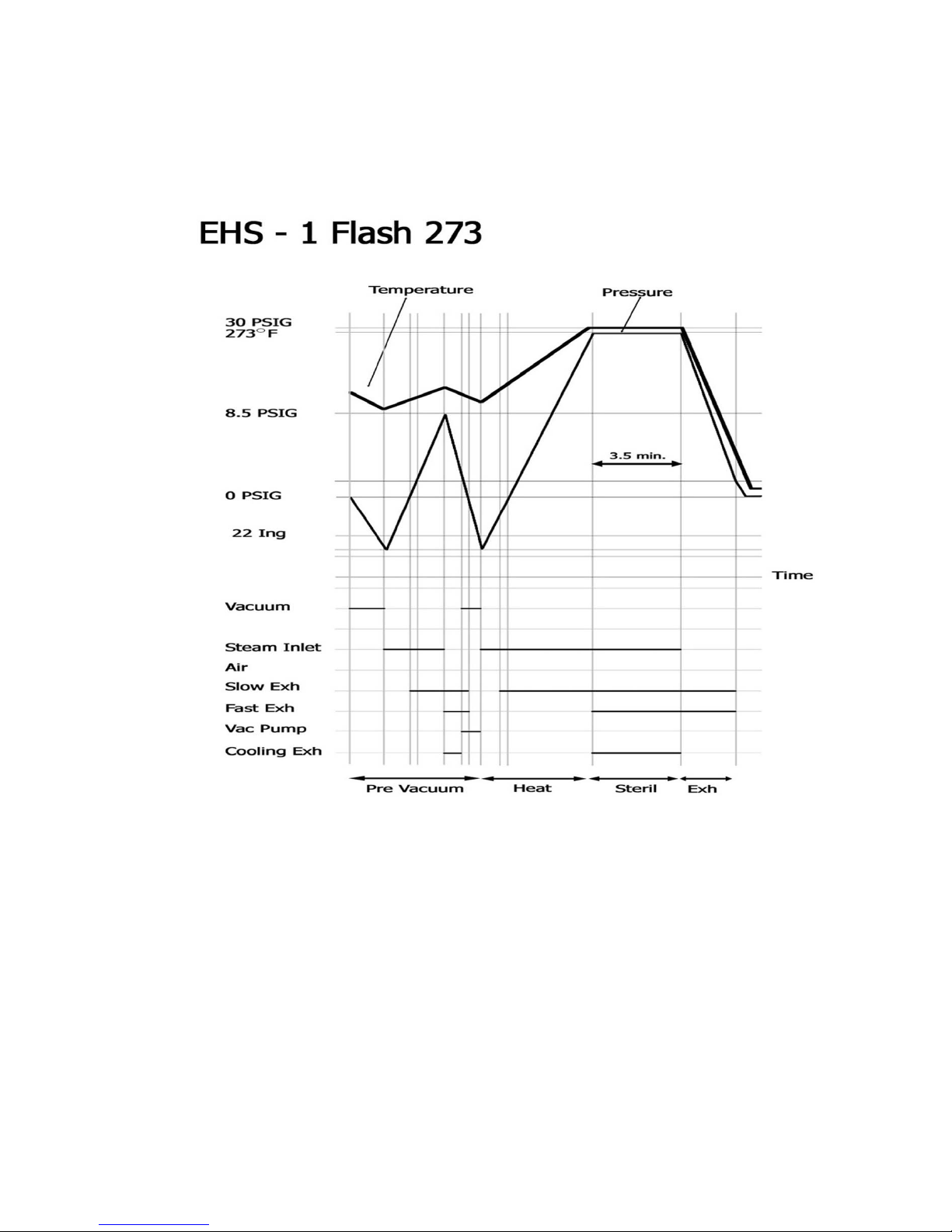

6.4 Input Output Graph:

Page 31

30

Page 32

31

Page 33

32

Page 34

33

Page 35

34

Page 36

35

7 PROPERTIES OF SATURATED STEAM

(From Baumiester & Marks “Standard Handbook for Mechanical Engineers”

7th Edition)

Gauge

Pressure

Absolute

Pressure

Temp °F

Gauge

Pressure

Absolute

Pressure

Temp °F

0

14.7

212.00 31

45

274.44

1

15

213.03 32

46

275.80

2

16

216.32 33

47

277.13

3

17

217.44 34

48

278.45

4

18

222.41 35

49

279.74

5

19

225.24 36

50

281.01

6

20

227.96 37

51

282.26

7

21

230.57 38

52

283.49

8

22

233.07 39

53

284.70

9

23

235.49 40

54

285.90

10

24

237.82 41

55

287.07

11

25

240.07 42

56

288.23

12

26

242.25 43

57

289.37

13

27

244.36 44

58

290.50

14

28

246.41 45

59

291.61

15

29

248.40 46

60

292.71

16

30

250.33 47

61

293.79

17

31

252.22 48

62

294.85

18

32

254.05 49

63

295.90

19

33

255.84 50

64

296.94

20

34

257.08 51 65 297.97

21

35

259.28 52

66

298.99

22

36

260.95 53

67

299.99

23

37

262.57 54

68

300.98

24

38

264.16 55

69

301.96

25

39

265.72 56

70

302.92

26

40

267.25 57

71

303.88

27

41

268.74 58

72

304.83

28

42

270.21 59

73

305.76

29

43

271.64 60

74

306.68

30

44

273.05

Page 37

36

8 SOFTWARE PROGRAMMING PARAMETERS

8.1 General

The software version that runs the control system of the EHS autoclave

can be found by turning the unit on and watching the display. The

version number is also printed if a printer is installed.

The software contains a table of parameters of which some of them

define the autoclave, and some of them define the processes in the

autoclave. This section of the manual describes the parameters and how

they control the software.

8.2 Changing Parameters

An access code is needed to change any parameters other than the date

and time.

Two access codes are currently available and each one gives a different

level of access.

Access code 1 – This is the first level of access. This code enables

changing of the sterilization time, sterilization

temperature and the drying time. This level of access

is suitable for a senior office person in the medical

facility.

Access code 13 – This is the second level of access. This code is for the

technician and allows access to make changes such as

calibrations.

To change the parameters listed below, proceed as follows:

a. Select the program cycle, to be modified, by pressing the

SEL.CYCLE key.

b. Press the PROGRAM key until CODE: ∅∅∅ appears

c. Using the UP/DN keys enter the access code for the level of access

desired. (i.e. CODE:013)

d. Select the parameter to be modified, by pressing the PROGRAM

key until the parameter name appears on the display.

e. Set the desired data by means of the UP/DN keys.

f. Pressing the PROGRAM key will enter the modified data into

memory, and move to the next parameter.

g. When finished press the PROGRAM key until the message

PROGRAM WAIT appears. The software is reprogramming itself

with the modifications that were made.

Note: Each of the 6 program cycles has a set of the following

parameters. Changing a specific parameter in one program will

not change it any other program.

Listed below are all the available parameters for the EHS. Each section

describes the parameter, shows the access code required to be able to

make modifications, it shows the minimum and maximum allowed

values and the increments (resolution) by which these values can be

changed. Also included are the pre-set values of the parameters for

each cycle.

Note: If a parameter is modified the only way to return to the original value is

to manually reenter it.

Page 38

37

8.2.1 SteTemp – Temperature required for sterilization

This parameter will set the desired temperature for sterilization

Access Code - 1

Resolution - 1ºF

Minimum value - 250ºF

Maximum value - 280ºF

Cycle

1 2 3 4 5 6

Default

Values

Value

273 273 250 273 273 -

8.2.2 Ster Time – Time required for sterilization

This parameter will set the time desired for sterilization

Access code - 1

Resolution - 1 minute

Minimum value - 3 minute

Maximum value - 59 minutes

Cycle

1 2 3 4 5 6

2540

3.5 8 30 4 3.5 -

Default

Values

Value

3870

3.5 8 30 8 3.5 -

8.2.3 Dry Time – Time required for drying

This parameter will set the time desired for drying

Access Code - 1

Resolution - 1 minute

Minimum Value - Ø minutes

Maximum Value - 59 minutes

Cycle

1 2 3 4 5 6

Default

Values

Value

0 20 20 20 2 -

8.2.4 HeatT.O. – Sterilization temperature time out

This parameter will set the maximum time allowed, from the

beginning of the cycle, for the chamber to reach sterilization

temperature. When the HeatT.O is exceeded, the program aborts

with the message ‘Low Heat’.

Access Code - 13

Resolution - 30 seconds

Minimum Value - 1200 seconds

Maximum Value - 3180 seconds

Cycle

1 2 3 4 5 6

Default

Values

Value

3000 3000 3000 3000 3000 0

Page 39

38

8.2.5 Ex.Mode – Rate of steam discharge during the exhaust stage

This parameter sets the rate at which steam is discharged during

the exhaust stage.

Access Code - 13

Resolution - 1

Value - 1 or 4

Fast Exhaust = 1

Slow Exhaust = 4

Cycle

1 2 3 4 5 6

Default

Values

Value

1 1 1 1 1 1

8.2.6 End Temp – Cycle End Temperature

This parameter sets the finish temperature of the exhaust stage.

The unit will signal a Cycle End only when the exhaust timer

has reached zero and the unit is below the End Temp. This also

indicates the proper time to open the door and unload the

chamber.

Access Code - 13

Resolution - 1ºF

Minimum Value - 104ºF

Maximum value - 280ºF

Cycle

1 2 3 4 5 6

Default

Values

Value

273 273 250 273 273 280

8.2.7 Puls num

.–

No. of vacuum pulses in the prevacuum stage

This parameter sets the number of vacuum pulses during the

prevacuum stage.

Access Code - 13

Resolution - 1

Minimum Value - 1

Maximum Value - 7

Cycle

1 2 3 4 5 6

Default

Value

Value

2 4 4 4 4 1

Page 40

39

8.2.8 Vac dip1

–

Vacuum value of the first vacuum pulse

This parameter sets the value of the vacuum that pulse no.1

needs to achieve in the prevacuum stage. This parameter is

expressed in psia (atmospheric pressure at sea level is =

14.7psia). A psia lower than 14.7 indicates a vacuum. (During a

cycle the autoclave displays vacuum as Ih (inches of mercury).

29.93 Ih = 14.7 psia (atmospheric pressure at sea level))

Access Code - 13

Resolution - .1 psi

Minimum Value - 1 psia

Maximum Value - 13 psia

Cycle

1 2 3 4 5 6

Default

Value

Value

2.9 3.7 3.7 3.7 2.9 2.7

8.2.9 Vac dip2

–

Vacuum value of each of the remaining pulses

This parameter sets the value of the vacuum that the remaining

pulses (starting from pulse no. 2) need to achieve in the

prevacuum stage. This parameter is expressed in psia

(atmospheric pressure at sea level is = 14.7psia). A psia lower

than 14.7 indicates a vacuum. (During a cycle the autoclave

displays vacuum as Ih (inches of mercury). 29.93 Ih = 14.7 psia

(atmospheric pressure at sea level))

Access Code - 13

Resolution - 0.1 psi

Minimum Value - 1 psia

Maximum Value - 13 psia

Cycle

1 2 3 4 5 6

Default

Values

Value

2.9 3.7 3.7 3.7 2.9 2.7

8.2.10 VacTime1

–

Waiting time at the end of the first pulse

This parameter sets the wait time at the end of the first vacuum

pulse, during the prevacuum stage. After reaching VacDip1,

there is a waiting time to allow the unit to stabilize. This time is

defined as VacTime1 and during this time the vacuum system

continues working.

Access Code - 13

Resolution - 1 second

Minimum Value - 3 seconds

Maximum Value - 1800 seconds (30 minutes)

Cycle

1 2 3 4 5 6

Default

Values

Value

3 3 3 3 3 3

Page 41

40

8.2.11 VacTime2

–

Waiting time at the end of each of the remaining

pulses

This parameter sets the wait time at the end of each of the

remaining vacuum pulses, during the prevacuum stage. After

reaching VacDip2, there is a waiting time to allow the unit to

stabilize. This time is defined as VacTime2 and during this time

the vacuum system continues working.

Access Code - 13

Resolution - 1 second

Minimum Value - 3 seconds

Maximum Value - 1800 seconds (30 minutes)

Cycle

1 2 3 4 5 6

Default

Values

Value

3 3 3 3 3 3

8.2.12 WtrResTime – Timed extension for pumping mineral free

water

This parameter sets the length of time to continue pumping

mineral free water into the steam generator after the upper

electrode senses water.

This is necessary to prevent a situation where the water pump

would cycle on and off as the water level rises and falls around

the upper water-sensing electrode.

Access Code - 13

Resolution - 1 minute

Minimum Value - Ø minutes

Maximum Value - 90 minutes

Cycle

1 2 3 4 5 6

Default

Values

Value

5 5 5 5 5 5

Page 42

41

8.2.13 limitP add

–

defines the upper limit of the pressure in the

jacket

This parameter is designed as a safety measure that defines the

maximum pressure in the jacket during heating and sterilization

stages. The maximum working pressure in he jacket is defined

as the pressure that correlates to the sterilization temperature

+ 5.4°F. Parameter limitP add allows to increase the pressure

above the maximum working pressure and defines the value of

this pressure.

Caution:

Setting this parameter to 4 psi may cause the Pressure Switch

and / or the Safety Valve to be activated.”

Example:

If the sterilization temperature is 273°F, the maximum pressure

will be 34 psig that correlates to 278.4°F (273°F + 5.4°F). If

limitP add is 2 the maximum allowable pressure will be 36. If

the pressure reaches the upper limit as defined by limitP add

(i.e. 36 in our example) the heating element will be switched off

and the pressure will begin to decrease. When the pressure

decreases below the maximum allowable pressure, the heating

element will be switched on again.

Access Code - 13

Resolution - 0.1 psi

Minimum Value - Ø psi

Maximum Value - 4 psi

Cycle

1 2 3 4 5 6

Default

Values

Value

0 0 0 0 0 0

8.2.14 Calib Code – Calibration Code 107

This parameter is used to set the calibration code. The correct

code is needed to calibrate the autoclave. After calibration the

code should be set back to the default value (100) to prevent any

unqualified person from altering the calibration

Access Code - 13

Resolution - 1

Minimum Value - 0

Maximum Value - 255

Cycle

1 2 3 4 5 6

Default

Values

Value

100 100 100 100 100 100

Page 43

42

8.2.15 ReqPrs+ - Overrides the pressure calculated for sterilization

This parameter is used to insure that during sterilization the

temperature is correctly maintained. It does this by raising the

value of the sterilization pressure necessary to maintain a

sterilization temperature. The sterilization pressure is calculated

by the unit based upon the SteTemp parameter.

For example; if the required temperature is 250ºF, the required

pressure calculated by the program is 16 psig.

This pressure can be increased by changing the value of

ReqPrs+. If this value is set to ø, the system will be maintained

at 16 psig during the sterilization stage if this value is set to 1.5,

the system will be maintained at 17.5 psig in the sterilization

stage.

Access Code - 13

Resolution - 0.1 psi

Minimum Value - Ø

Maximum Value - 3 psi

Cycle

1 2 3 4 5 6

Default

Values

Value

0.8 0.8 0.6 0.8 0.8 0

Page 44

43

8.2.16 Dry Vac

–

Pressure during the Dry Stage

This parameter is intended to control the vacuum pressure

during the Drying Stage. It does this by opening and closing the

Air Inlet Valve. In all cases the vacuum pump runs continuously

and the Jacket is heated until the end of the Dry stage, as set by

the Dry time parameter.

This parameter is expressed in kpa, where 1 kpa = 0.145 psia

Access Code - 13

Resolution - 1 kpa

Minimum Value - 0 kpa

Maximum Value - 90 kpa

If Dry Vac = 0, the Air Inlet Valve will be closed during the

Dry Stage.

If Dry Vac is between 1 & 5, the Air Inlet Valve will be

operated in a shoot mode, 30 seconds open and 30 seconds

closed. This process will begin 4 minutes after the start of the

Dry Stage and continue until the Dry stage is completed

If Dry Vac ≥6, the Air Inlet Valve will be used to regulate the

pressure during the Dry Stage so that the value of the pressure

will not fall below the Dry Vac value. E.g., if Dry Vac = 20 (1

kpa = 0.145 psia), then when the pressure reaches 2.9 psia, the

air valve will open and remain open until the pressure rises to

3.6 psia at which point is will close again. When the pressure

drops back to 2.9psia, the valve opens again to allow the

pressure to rise. This process continues until the end of the Dry

stage. In this example the pressure fluctuates between 2.9 psia

and 3.6 psia. The Air Inlet Valve is not working in a shoot

mode, but it opens and closes around the requested Dry Vac

value.

Cycle

1 2 3 4 5 6

Default

Values

Value

5 5 5 5 5 1

Page 45

44

8.2.17 Atmos. Press

–

Atmospheric Pressure

This parameter tells the unit the atmospheric pressure of the

location in which it is installed. The pressure entered must be

with in 5% of the actual atmospheric pressure for that location.

Unlike the other parameters you only need to enter this

parameter once in any one cycle and all cycles will be updated.

This value can easily be calculated by knowing the altitude of

your location. The atmospheric pressure at Sea Level is 14.5

psia. For every 100m above sea level, the atmospheric pressure

drops 0.14 psia, and for every 100m below sea level, the

atmospheric pressure increases 0.14 psia.

Changes in pressure do to weather will not affect the accuracy

of this unit.

Access Code - 13

Resolution - 0.1 psi

Minimum Value - 8 psia (for +4500m)

Maximum Value - 15.7 psia (for –800m)

Cycle

1 2 3 4 5 6

Default

Values

Value

14.5 14.5 14.5 14.5 14.5 14.5

8.2.18 PulsPress – pulse pressure during pre-vacuum stage.

This parameter is used to set the maximum pressure in each

pulse of the pre-vacuum stage. This parameter is expressed in

psia. During St.By (Stand By) and while running a cycle the

display shows pressure in psig. (Psig + 14.5 equals psia).

Access Code – 13

Resolution – 1 psi

Minimum Value – 7 psia

Maximum Value – 30 psia

Cycle

1 2 3 4 5 6

Default

Values

Value

22 23.5 23.5 23.5 23.5 23.5

Page 46

45

8.2.19 Heat Step – sterile temperature overshoot control

This parameter is used to reduce overshoot of the sterilization

temperature by controlling the sterilization pressure. The

sterilization pressure is calculated by the unit based upon the

SteTemp parameter. When the cycle starts the heating rate in

the chamber is constant until the pressure in the chamber

reaches the sterilization pressure minus the Heat Step. From

this point on heating is performed in pulses. Each pulse lasts

15 seconds and increases the pressure in the chamber by a

small amount until the proper sterilization pressure is reached.

Access Code – 13

Resolution – 0.1 psi

Minimum Value – 0.1 psi

Maximum Value – 2 psi

Cycle

1 2 3 4 5 6

Default

Values

Value

0.7 0.7 0.7 0.7 0.7 0.4

8.2.20 PresInPsig – selects the pressure display units.

This parameter sets the units of pressure that are printed by the

printer and used on the digital display during St.By (Stand By)

and while running a cycle. The two choices are psia (absolute

pressure) or psig / InHg (gauge pressure and inches of

mercury) Changing this parameter does not effect the units of

calibration used in any other parameter.

Access Code – 13

Resolution – 1

Pressure is displayed in

Psig and vacuum in InHg – 1

Pressure is displayed in psia – 0

Cycle

1 2 3 4 5 6

Default

Values

Value

1 1 1 1 1 1

8.2.21 TempInC – selects the temperature units.

This parameter sets the units of temperature that are used by

the autoclave.

Access Code – 13

Resolution – 1

Temperature is displayed in °C – 1

Temperature is displayed in °F – 0

Cycle

1 2 3 4 5 6

Default

Values

Value

0 0 0 0 0 0

Page 47

46

8.2.22 Flash – Heating over-pressure control

This parameter is designed to regulate over pressure during the

heat up stage. The system constantly monitors the temperature

and pressure and compares both values to the Saturated Steam

Curve. If the pressure is found to exceed the corresponding

temperature by more than 0.7 psi then the fast exhaust valve is

opened for 1 second in an attempt to realign the temperature

and pressure. The system will wait 15 seconds and check

temperature and pressure again. If needed the fast exhaust will

be opened again for 1 second. This process will continue until

the temperature and pressure are correctly aligned.

Access Code – 13

Resolution – 1

Value – 0 or 1

If Flash = 0 This feature is not activated.

If Flash = 1 This feature is activated.

Cycle

1 2 3 4 5 6

Default

Values

Value

1 1 1 1 0 0

8.2.23 Auto. Num – Autoclave Identification number

This parameter is used to set the identification number relative

to other autoclaves in the facility. This number only appears on

the printout of a unit with a printer installed. It enables the

operator to link the printout with a specific autoclave. This

parameter need only be set once, while in any of the 6

programs.

Access Code – 13

Resolution – 1

Minimum Value – 1

Maximum Value – 99

Page 48

47

9 MAINTENANCE AND REPLACEMENT PROCEDURES

9.1 Safety Tests after Repair

ATTENTION!

After every repair or dismantling of the enclosure, it is

recommended that the following tests be performed:

1. Enclosure Current Leakage Test.

The test should be performed using a Megger. Make sure the

autoclave is unplugged. The electrical potential of the testing

instrument should be 500V. The insulation resistance should be at

least 2 MΩ.

The test is successful if there was no leakage.

2. Protective Earth Impedance Test

The test should be performed using an Ohmmeter. Make sure the

autoclave is unplugged from the wall outlet. Next measure the

resistance between the grounding screw on the rear plate (or any

other unpainted metallic part) and the grounding pin of the power

cord plug. The resistance should not exceed 0.3 Ω, a high

resistance would indicate a faulty ground connection.

Page 49

48

9.2 Removing the Autoclave’s Outer Covers

Caution!

Before starting, disconnect the instrument from the power

source and ensure that there is no pressure in the

chamber or jacket.

Allow the autoclave to cool before removing outer covers.

1. Remove the screws holding the rear cover (1).

2. Remove the screws holding the cover to the base (2).

3. Dismantle the air filter from the service opening cover (3).

3.1. Remove the screws holding the filter cover.

3.2 Disconnect the filter from the silicone tube

4. Remove the grounding wires from the cover.

5. Pull the cover upwards.

Note:

The following picture refers to model 2540

3

21

Page 50

49

9.3 Replacing the Safety Valve

The safety valve is installed to protect the Jacket from over

pressurizing should all the electrical controls fail.

Caution!

Before starting, be sure that the electric cord is disconnected and that

there is no pressure in the chamber or jacket.

1. Take off the autoclave cover (see para. 9.2 “Removing the

Autoclave’s Outer Covers”).

2. Remove the water reservoir gasket.

3. Unscrew the safety valve and remove it from the safety valve base.

4. Replace the valve with a new safety valve (install only an original

equipment replacement!). Use a hydraulic sealant to seal the

threads to ensure that the assembly is leak free.

5. Perform one cycle and verify that the valve operates correctly.

Page 51

50

9.4 Replacing the DIG-T2 board

The DIG-T2 board contains the software program and controls all the

functions of the autoclave. See sec 4.3.

Caution!

Make sure that the power cord is disconnected!

Allow the chamber and jacket to cool before removing outer covers.

Refer to the picture below when following this procedure.

1. Take off the autoclave cover (see para. 9.2 “Removing the Outer

Covers of the Autoclave”).

2. On model 3870 disconnect the flat cable from the printer.

3. Disconnect the flat cable from JP1-DIG-T2 to JP1 ANL-T2 (4).

4. Disconnect the flat cable from the PC port to P1-ANL-T2 (6).

5. Disconnect the green grounding cable (5).

6. Remove the screws that connect the plastic panel, housing the

DIG-T2 board, to the autoclave (2).

7. Disconnect the main switch (7).

8. Remove the DIG-T2 and keypad from the plastic panel.

9. Disconnect the DIG-T2 from the keypad.

10. Install a new DIG-T2 to the keypad and reinstall it into the plastic

housing

11. Follow the previous instructions in reverse to reassemble the unit

9.5 Replacing the Electronics Box

Caution!

Make sure that the power cord is disconnected!

Allow the chamber and jacket to cool before removing outer covers.

Refer to the picture below when following this procedure.

1. Take off the autoclave cover (see para. 9.2 “Removing the Outer

Covers of the Autoclave”).

2. Remove the screws from the bottom and top of the electronic box

(1, 3).

3. Disconnect all the electric system connectors connecting the

electronic box to the base (including the MPX connectors).

4. Remove electronics box and replace with new one.

5. Re-assemble the instrument. Verify that the grounding connections

are connected correctly.

6. Test any cycle and verify that the autoclave operates as required.

Page 52

51

Electronic box: 3870

Electronic box: 2540

Control panel

7 2

63 2

4

5

7

1 1

Electronic

box

Electronic

box

1 17

2

5

6

4

2 3

Control panel

2

7

Page 53

52

9.5 Drain Valve Repair

There are two drain valves on the front of the autoclave. One drains the

mineral free water from the front section of the reservoir and the other

drains the vacuum pump water from the back section of the reservoir.

Caution!

Before starting, disconnect the instrument from the power source and

ensure that there is no pressure in the chamber or jacket.

Allow the autoclave to cool before removing outer covers.

9.5.1 Replacing the O rings

1. Open the manual drain cock on the front of the machine

and drain any water left in the reservoir

2. Continue turning the drain cock in a counterclockwise

direction. Some resistance will be felt, but eventually the

drain cock assembly will come out.

3. Replace the two O rings on the drain cock (see drawing).

4. Reinstall the drain cock in the drain valve body by

turning clockwise.

5. After a few turns press the large O ring (1) into the

recess on the drain valve body.

6. Continue turning clockwise until the drain cock is seated.

Item Cat No.

1 SRV000-0224

2 SRV000-0232

Page 54

53

9.5.2 Replacing the drain valve assembly

1. Take off the autoclave cover (see para. 9.2 “Removing

the Outer Covers of the Autoclave”).

2. Disconnect the drain tube from the valve, using a 9/16”

wrench.

3. Remove the nut (3) and the “ring for drain valve” (2).

4. Remove the drain valve (1) from the panel.

5. Install a new valve according to the drawing below.

6. Verify that there is no leakage.

CMT240-0020 CMT240-0003 VLV170-0066

Page 55

54

9.6 Replacing the Pressure Gauge

Caution!

Before starting, disconnect the instrument from the power source

and ensure that there is no pressure in the autoclave’s chamber

and jacket.

9.6.1 Model 2540

1. Take off the door cover (see para. 9.18 Replacement of

the Door Cover).

2. Remove the pressure gauge from the door by unscrewing

it from the door

3. Install the new pressure gauge using Teflon tape to seal

the threads. Verify that the gauge’s tube does not

protrude from the doors inner surface.

4. Operate the autoclave and verify that there are no leaks.

5. Reinstall the door cover.

9.6.2 Model 3870

The gauge is located in the plastic housing adjacent to the door

and directly in front of the electronic box.

1. Take off the autoclave cover (see para. 9.2 “Removing

the Autoclave’s Outer Covers”).

2. Disconnect the copper tube at the back of the gauge.

3. Remove the pressure gauge.

4. Install the new pressure gauge.

5. Reconnect the copper tube. (The copper tube uses a

compression fitting so no Teflon tape is needed).

6. Operate the autoclave and verify that there are no leaks

7. Reassemble the autoclave’s cover

Page 56

55

9.7 Replacing the Door Bellows (Located in the door bridge)

The door bellows is designed to work with the closing device

providing a double lock that keeps the door closed while there is

pressure inside the chamber.

Caution!

Before starting, disconnect the instrument from the power source

and ensure that there is no pressure in the autoclave’s chamber.

1. Open the door.

2. Unscrew and remove the locking bolt (5).

3. Remove the Bellows assembly, using one of these two methods