Page 1

Technician Manual

Electronic Laboratory Autoclaves

Models 3840, 3850, 3870 ELVG-D

ELVG-D: standard autoclave

C: optional system for fast cooling

PV: optional vacuum pump

BH: optional bio hazard filtration

F: optional fan for super-fast cooling

The Netherlands Tel: 31 (0) 765423510, Fax: 31 (0) 765423540

Cat. No. MAN205-0491000EN Rev. F

Tuttnauer Europe B.V.,

Hoeksteen 11 4815 PR P.O. Box 7191 4800 GD Breda,

Page 2

http://www.tuttnauerusa.com/

Page 3

Page 1

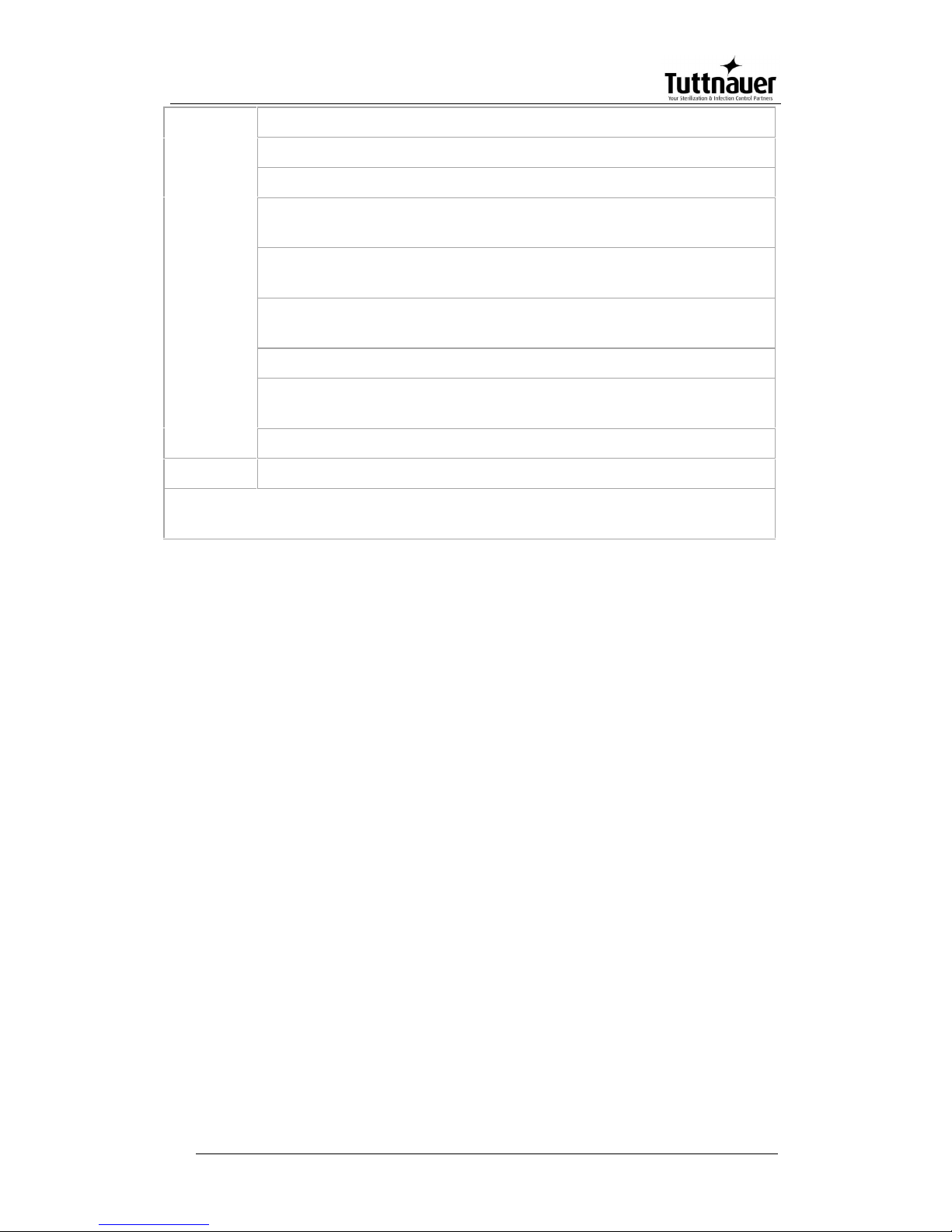

Table of Contents

Paragraph , page no.

1. Introduction 4

2. Installation Instructions 6

2.1 Installation Site 7

2.2 Connection of the pressure regulator 7

2.3 Front View 9

2.4 Front View for the Fan Configuration 10

2.5 Rear View 11

3. Tests 12

3.1 Installation Tests 12

3.2 Periodical Tests 12

4. Technical Data 14

4.1 Directives and Standards 14

4.2 Water Quality 14

4.3 Reverse Osmosis 15

4.4 Electrical data 16

4.5 Specifications 17

4.6 Overall Dimensions 18

4.7 Construction 18

4.8 Utilities 19

4.9 Symbol Description 20

5. Description of the Control System. 21

5.1 Hardware Control System Components: Block Diagram ................... 21

5.2 Application System Architecture 21

5.3 Interfaces to Users 22

5.4 Inputs and Outputs 22

5.5 Hardware Control System components 24

6. Checking and Changing Parameters and Other Data 28

6.1 Browsing through the menus 28

6.2 Changing a Parameter 29

6.3 Quick options screen 31

6.4 Logging in and entering the Main menu 37

6.5 Directories and subdirectories 38

6.6 System Parameters 41

6.7 Inputs/Outputs 43

6.8 Maintenance 49

6.9 Advanced Options 53

6.10 Version handling 59

Page 4

Page 2

6.11 Cycle parameters 61

6.12 Temperature sensors 63

6.13 Displayed inputs 64

6.14 Purge (generator models only) 65

6.15 Create Pulse 65

6.16 Keep Heat 67

6.17 Heating 68

6.18 Sterilization 68

6.19 Cooling (“C” models only) 69

6.20 Exhaust 70

6.21 Drying 70

6.22 Ending 72

6.23 Global (for some models only) 72

7. Generator description 75

7.1 Generator Electrical Safety System 76

7.2 The Water Pump for the Steam Generator 77

7.3 GICAR Water Level Controller 77

8. Maintenance and Replacement Procedures: the Autoclave 79

8.1 Preliminary Operations for Each Technician Call 79

8.2 Replacing the Circuit Breaker 80

8.3 Replacing the Safety Valve 81

8.4 Replacing the door gasket 83

8.5 Replacing the door cover 84

8.6 Replacing the Printer 89

8.7 Replacing the Door Micro-Switch 1 91

8.8 Replacing the Door Micro-Switch 2 91

8.9 Replacing the air filter 92

8.10 Replacing the locking motor 93

8.11 Replacing the Plunger or Coil of the 1/4" Solenoid Valve

9

5

8.12 Replacing the Plunger or Coil of the BACCARA Solenoid Valve 96

8.13 Replacing the Mechanic Pressostat 96

8.14 Replacing the Pressostat 0.2 (NC) 97

8.15 Replacing the power supplies, water level board and relays

98

9. Maintenance and Replacement Procedures: the Generator 103

9.1 Access to Generator 103

9.2 Draining the generator 103

9.3 Cleaning and Replacing the Water Level Electrodes 104

9.4 Replacing the Heating Elements 106

Page 5

Page 3

9.5 Replacing the Generator Side Gauge Glass Indicator Tube 106

9.6 Replacing the Generator Thermostat 108

9.7 The Water Pump Replacement 110

9.8 Releasing the Vacuum Pump Rotor 110

10. Troubleshooting 112

10.1 Autoclave Troubleshooting 112

10.2 Steam Generator Troubleshooting 117

11. List of Spare Parts 120

11.1 Water Outlet Strainer 128

12. Pressure vs Temperature for Saturated Steam 129

13. Valves Numbering 138

14. Drawings 140

14.1 Piping Drawing – Model 3840/3850/70 ELVCG-D 140

14.2 Piping Drawing – Model 3840/3850/70 ELVCPVG-D 141

14.3 Piping Drawing – Model 3840/3850/70 ELVCPVGBH-D

1

42

14.4 Electrical Drawing for The Autoclave 3840-50/3870

ELV(C)(PV)G 380V.......................................................................... 143

14.5 Electrical Wiring Diagram: The Generator 151

14.6 Generator Control Electrical Cascade Diagram 152

Page 6

Page 4

1. Introduction

This manual, together with the operator’s manual, forms the complete

edition of the Operation and Maintenance instructions. This manual is

intended for the use of the technician. It is forbidden for unqualified and

unauthorized personnel to service the autoclave in accordance with the

instructions in this manual. Any unauthorized service may result in the

invalidation of the manufacturer’s guarantee.

The qualified technician shall be an authorized electrician with the right

qualifications in electronics and shall be familiar with the local

technical/electrical regulations.

Available optional configurations

Models of 3870 ELVG-D model range are laboratory sterilizers

designed especially for the sterilization of instruments, liquids, and

other materials in hospital laboratories, medical laboratories, research

institutes, food laboratories and pharmaceutical facilities.

C

A special feature of the ELVCG-D models is the fast cooling stage for

liquids. In this stage pressure in the chamber is increased by means of

compressed air to compensate the fast decreasing of pressure due to

the fast cooling. The fast cooling shortens the time required for safe

handling of bottles.

Note: there is no cooling option for WR configuration

PV

Special feature of ELVCPV-D models is the vacuum pump that enables

air removal prior to sterilization and during the drying stage.

The advantages of the pre-vacuum sterilizer in comparison to the

regular gravity displacement steam sterilizer are as follows:

— Removal of air pockets from packs and porous loads and most kinds of

tubes (rubber, plastic etc.) by vacuum at the first stage of the cycle.

— Better steam penetration into the load; resulting in effective sterilization.

— Better temperature uniformity.

— Better drying of materials with closed doors due to the vacuum

achieved in the chamber at the end of the sterilization cycle.

Page 7

Page 5

A special feature of the autoclave is the fast cooling stage for liquids. In

this stage pressure in the chamber is increased by means of

compressed air to compensate the fast decreasing of pressure due to

the fast cooling. The fast cooling shortens the time required for safe

handling of bottles

There is a configuration equipped with fan that allows to shorten the

cooling operation.

BH

In ELVCPVBH-D (bio-hazard) models, a bio-hazard filter installed in the

chamber enables sterilizing bio-hazard load without contaminating the

surrounding.

Page 8

Page 6

2. Installation Instructions

The following utilities have to be connected (Refer to the drawing below

‘Rear View’ of the autoclave).

Power outlet, as detailed in the table below:

Power

3 Ph, 400V/50/60Hz

Recommended Circuit Breaker

20A

If the 3 phase autoclave has to be connected to a one phase power

network, 1 x 230V, 50/60Hz., connect the 1ph 230V power source to

the supplied switch box that has a 1 phase input (from the power

source) and a 3 phase output (to the autoclave). See details at the end

of this manual.

The power network must be protected by a current leakage relay.

Mineral-free water having a conductibility lower than 15µs

(microsiemens), through a 1/2” flexible hose.

To obtain water quality meeting requirements a deionization

column or reverse osmosis apparatus can be installed. The water must

be delivered at a pressure of 2-3bar. A pressure reducer shall be

installed at the water source outlet as instructed below.

For fast cooling (if this option is provided):

Feed water from the water network, pressure 2-3bars, connected

through a 1/2” pipe. A pressure reducer shall be installed at the water

source outlet as instructed below.

Compressed air, from a mobile compressor or compressed air network

at pressure 3-4 bars, will be set at 1.6-2bars at the autoclave inlet is to

be connected by a flexible conduit of 3/16”.

The air must be of instrumental quality filtered at 5µ and free of

humidity and oil drops.

Drain connected by 1/2” pipe, located at the rear of the unit. The

chamber exhaust and coolant water is evacuated to an open waste

funnel. The drainage piping must be heat resistant, to 80ºC, noncontinuous flow.

Attention:

Connection of water system to the autoclave must be performed

through "BACK FLOW PREVENTION SYSTEM" installation as per

EN 1717.

Page 9

Page 7

2.1 Installation Site

1. Install the autoclave according to the following guidelines:

2. Place the autoclave on the floor. Verify that the surface is leveled.

3. All utility supplies must be prepared in accordance with requirements,

before autoclave installation e.g. mineral-free and tap water,

compressed air, one or three-phase power network, connection to the

drain of the building.

4. Leave the space free around the autoclave for maintenance and

service requirements.

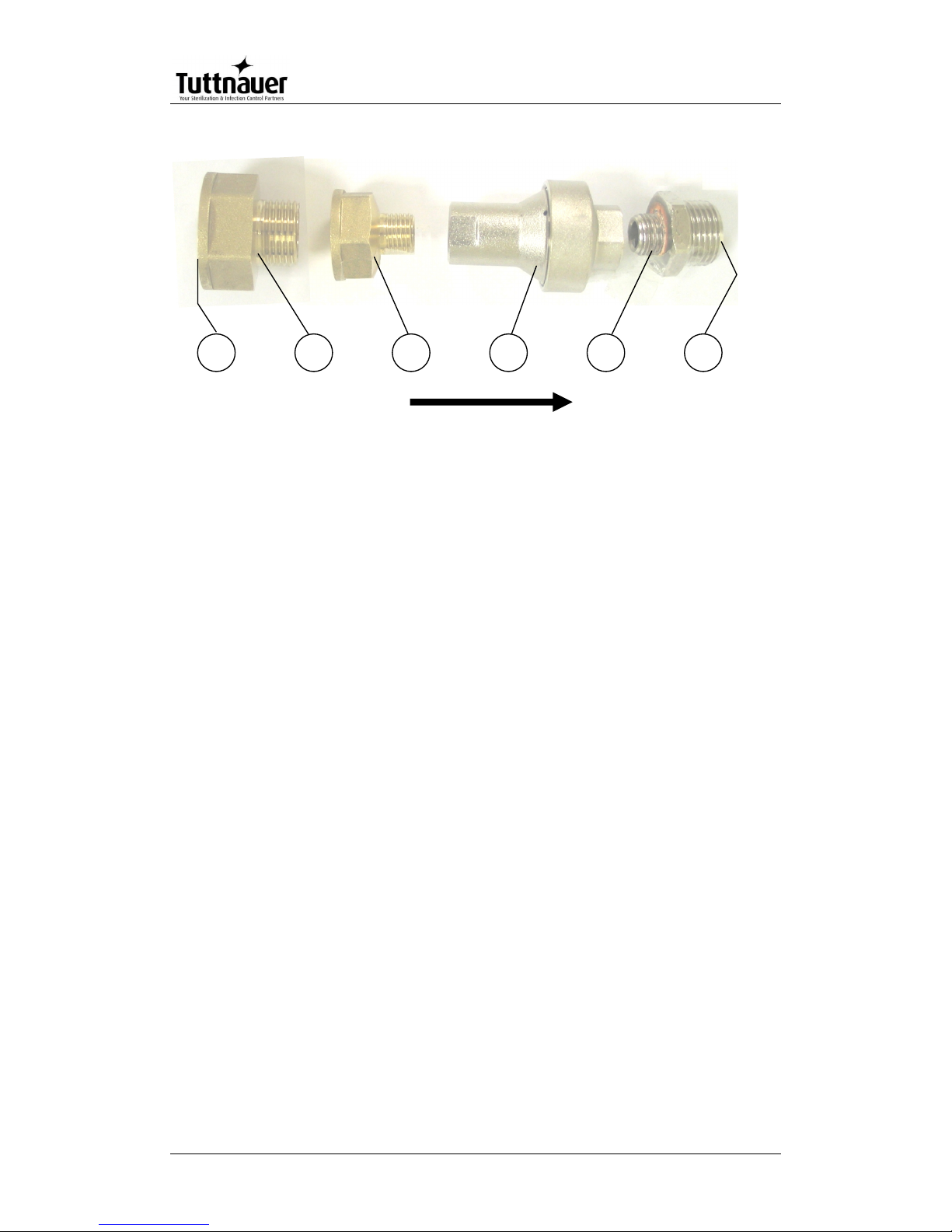

2.2 Connection of the pressure regulator

This paragraph refers to the pressure regulator of the feed water and to

the pressure regulator of the mineral free water.

1. Attach the pressure regulator to the facility's water outlet.

2. Connect the supplied flexible hose to the pressure regulator's assembly

outlet and to the autoclave's water inlet.

3. Verify that the pressure regulator is in right direction. The flow direction

is indicated by an arrow stamped on the pressure regulator.

4. Verify that water flows freely in the feed water and in the mineral free

water lines.

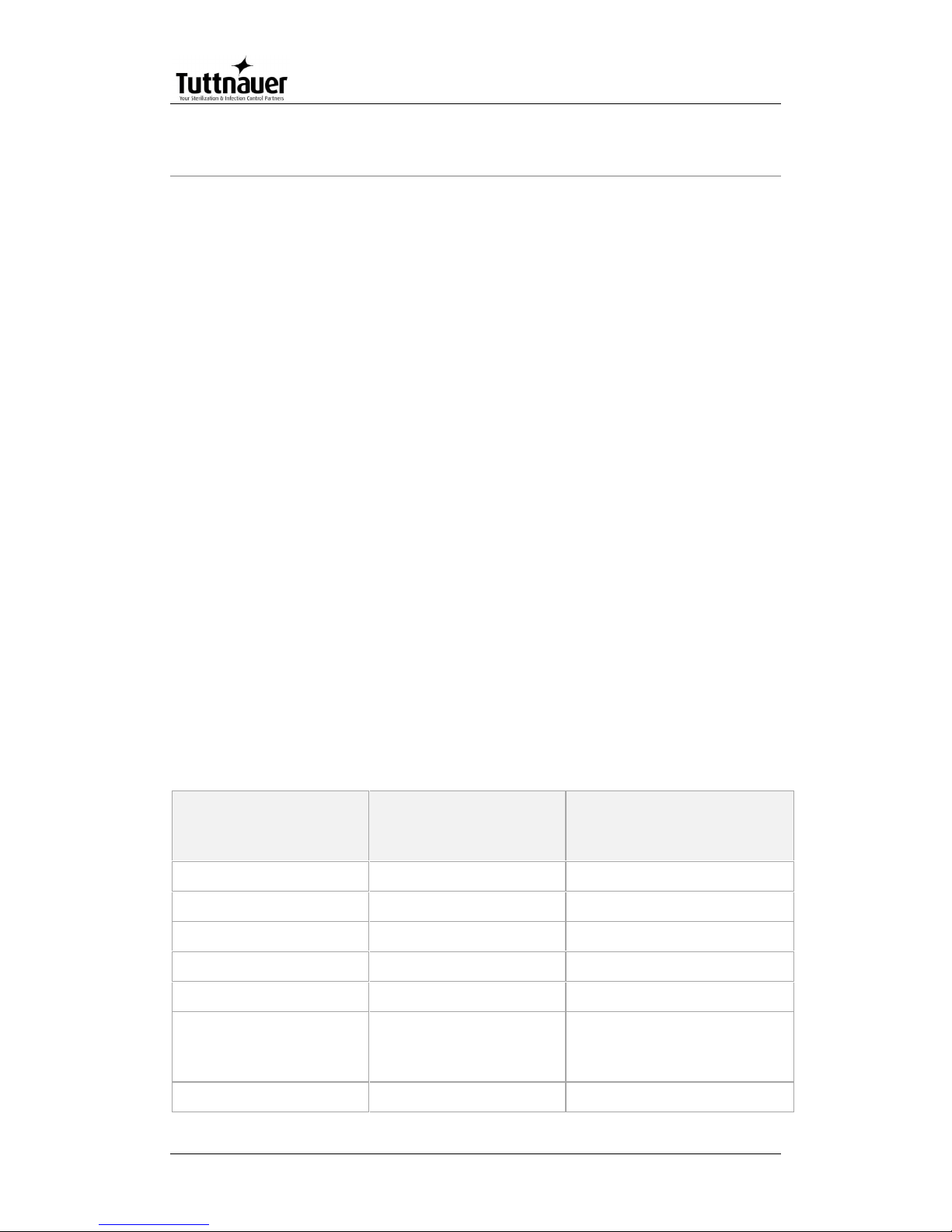

No.

Description

Cat No.

1

Side of water supply source

N/A

2

Reducer, Female 3/4" BSP to Male 1/2" BSP, Brass

FIT100-0424

3

Reducer, Female 1/2" BSP to Male 1/4" BSP, Brass

FIT100-0425

4

Pressure Regulator, Water, In-Line, with Strainer, 1/4

x 1.5 bar

GAU029-0059

5

Fitting, Adaptor, M 1/2" BSP x M 1/4" BSP, Brass Ni

plated

PNE100-0042

6

Side of flexible hose (to autoclave

N/A

Page 10

Page 8

FLOW DIRECTION

54321

6

Page 11

Page 9

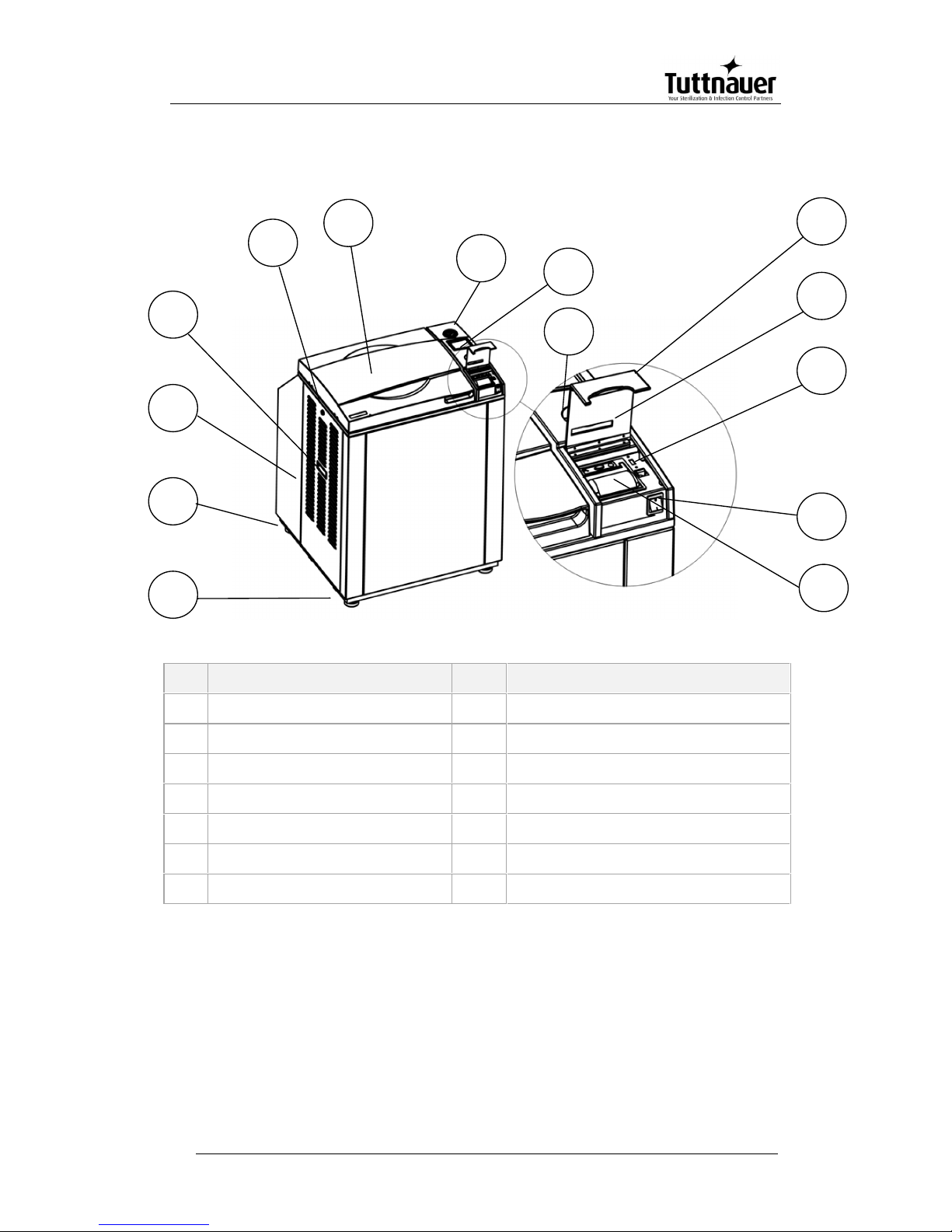

2.3 Front View

No.

Description

No.

Description

1

Front leg

8

Display

2

Rear leg

9

Keyboard

3

Left service door

10

Printer cover

4

Left service door grip

11

Paper slot and paper cutter

5

Left service door lock

12

USB socket

6

Door cover

13

Main switch

7

Pressure gauge

14

Printer

9

10

5

6

7

8

11

14

432

1

12

13

Page 12

Page 10

2.4 Front View for the Fan Configuration

There is a configuration equipped with a fan that allows shortening the cooling

operation. The fan is located on the door of the autoclave.

Fan

Page 13

Page 11

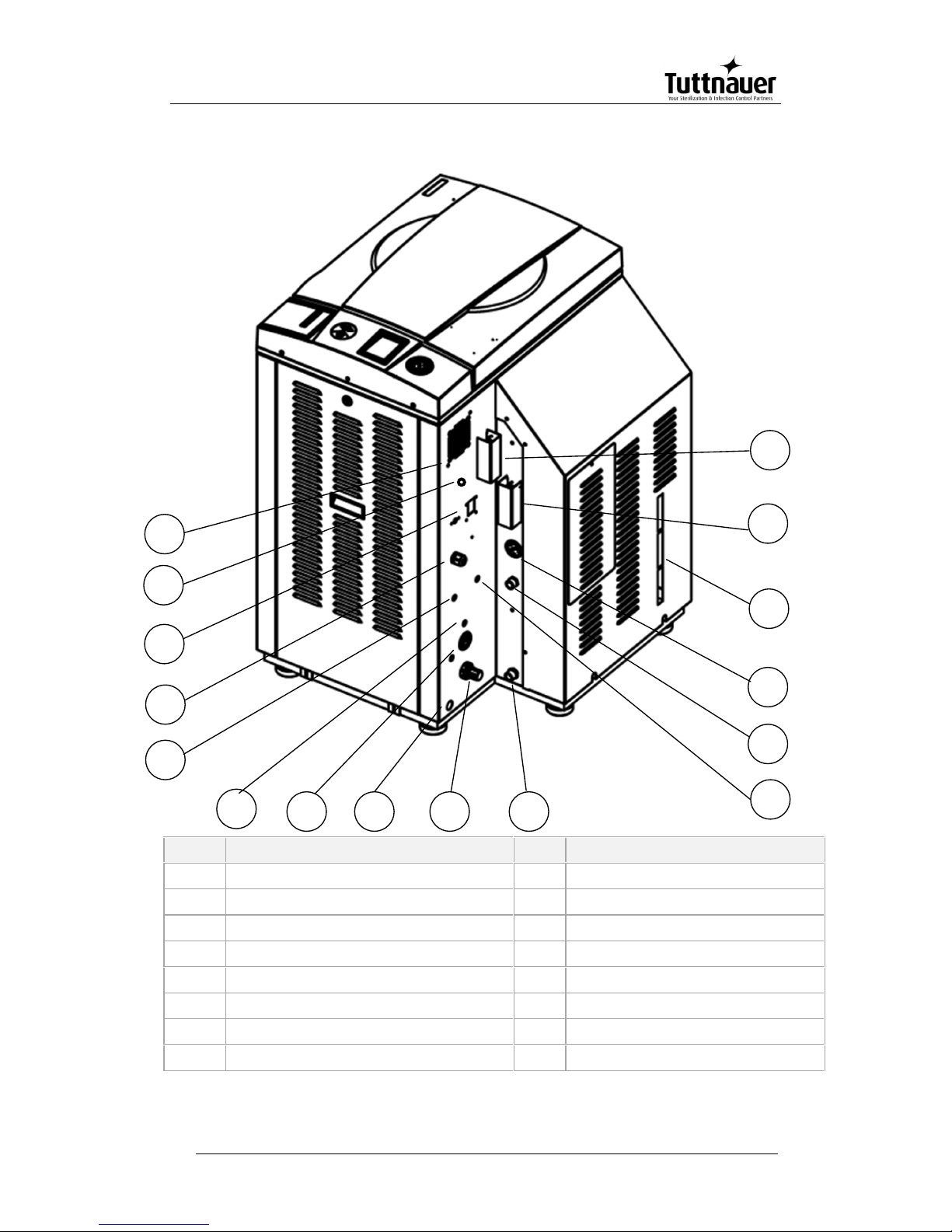

2.5 Rear View

No.

Description

No.

Description

1

fan grill

9

air pressure regulator

2

RJ45 connector

10

generator drain outlet

3

circuit breaker

11

tap water inlet

4

electrical socket

12

mineral free water inlet

5

gravitation valve for vacuum pump

13

generator pressure gauge

6

compressed air inlet

14

side gage glass indicator tube

7

autoclave air pressure gauge

15

generator safety relief valve

8

autoclave drain outlet

16

chamber safety relief valve

6

7

9

1

2

3

5

14

131215

81110

4

16

Page 14

Page 12

3. Tests

3.1 Installation Tests

The service technician shall perform the following preliminary

checks before operating the autoclave:

a. Integrity Check

Perform a visual check to verify that there are no dents, scratches,

broken gauges, etc.

b Leveling Check

Check that the autoclave is leveled.

c. Leakage current test

Check the precise operation of the earth leakage relay.

d. Continuity Check

Check the continuity of the grounding connection.

At this stage operate the autoclave and continue with the tests:

e. Safety Check

Check the safety elements; safety valve and the door locking

mechanisms.

f. Programs Check

Run basic programs of the autoclave and check the operation

sequences, the sterilization parameters etc.

g. Validation

Validate the sterilization cycles, taking in consideration the interface of

packaging/goods/autoclave.

After the above steps are performed, the autoclave is ready for

operation.

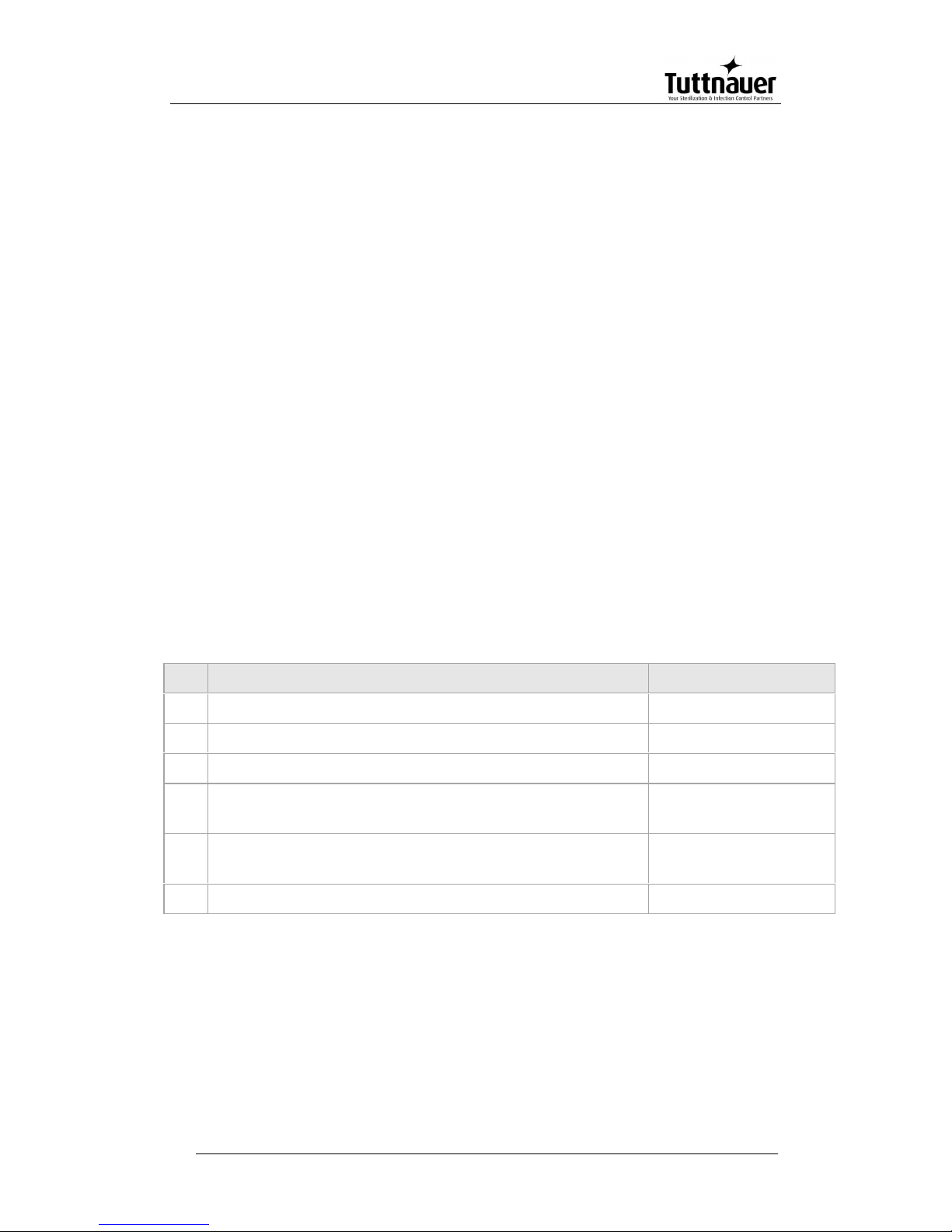

3.2 Periodical Tests

Period

Test

2 months

Test the safety valve by operating it.

6 months

Remove the cover of the autoclave, tighten the, valves and

connectors in the control box.

Year

Check the continuity of the grounding connections.

Check the temperature and pressure calibration.

Page 15

Page 13

Perform validation of the autoclave.

Check the precise operation of the earth leakage relay.

Check that the autoclave is leveled.

Check the safety elements; safety valve, safety and cut-off

thermostats door locking mechanisms.

Run basic programs of the autoclave and check the operation

sequences, the sterilization parameters etc.

Check the water reservoir, piping, plastic parts and electric

wires.

Check and tighten the piping joints to avoid leakage.

Check and tighten all screw connections in the control box,

valves and instrumentation.

Observe the closing device for excessive wear

5 years

Observe the closing device for excessive wear

Safety tests (pressure vessel, efficiency, electrical) shall be performed in

accordance with local rules or regulations, by an authorized inspector.

Only an authorized technician shall perform the 6-months and yearly tests!

Check connections to distilled or mineral free water. Open the

distilled or mineral free water valves. Manually test the distilled or

mineral free water valves by over-riding the appropriate solenoid

valves. If there are no leaks, –leave the water manual inlet taps

open.

Observe the gauge and see that the generator reaches working

pressure.

Check that the jacket pressure gauge, reaches 2.4 bars (35 psi).

Page 16

Page 14

4. Technical Data

4.1 Directives and Standards

Tuttnauer. Ltd. company meets the provisions of the following standards:

ISO 9001:2008 (Quality Systems)

Tuttnauer. Ltd. company also works in conjunction with and refers to:

ANSI/AAMI ST55 American Society of Mechanical Engineers

Section VIII, Division 1, for unfired pressure vessels.

EN 13060 Small Steam Sterilizers.

UL UL 61010-1

PED 97/23EEC

IEC IEC 61010-2-040 Safety

ISO 17665-1:2006 (Validation and Routine Control)

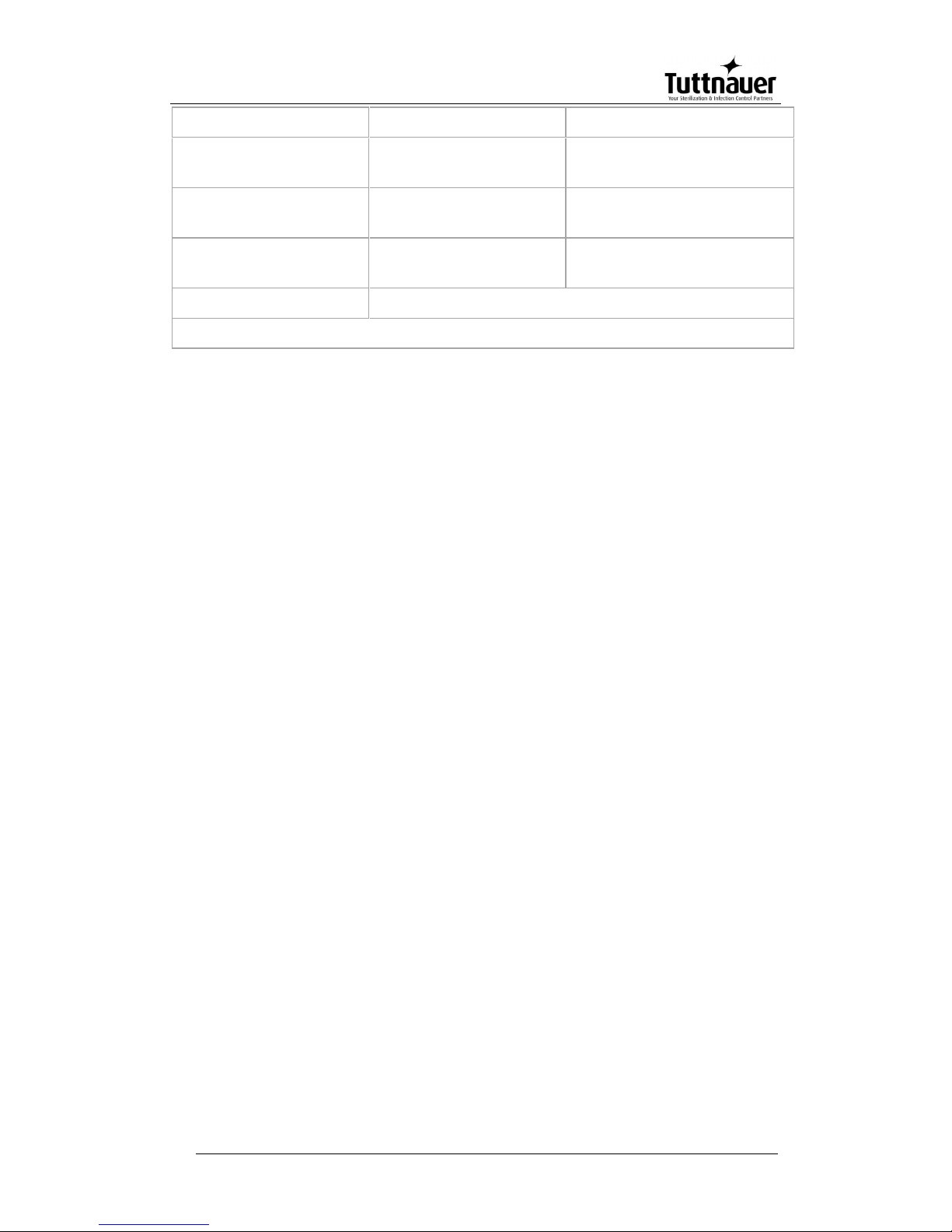

4.2 Water Quality

The distilled or mineral-free water supply shall be according to the table

below:

Physical Characteristics and Maximum acceptable contaminants

levels in water or steam, for steam generator and sterilizers

(According to EN 285: 2006)

Contaminants in

water supplied to

generator

Contaminants in

condensate at steam

inlet to sterilizer

Evaporate residue

≤ 10 mg/l

N/A

Silicate (SiO2)

≤ 1 mg/l

≤ 0.1 mg/l

Iron

≤ 0.2mg/l

≤ 0.1mg/l

Cadmium

≤ 0.005 mg/l

≤ 0.005 mg/l

Lead

≤ 0.05 mg/l

≤ 0.05 mg/l

Rest of heavy metals

except iron,

cadmium, lead

≤ 0.1 mg/l

≤ 0.1 mg/l

Chloride (Cl)

≤ 2 mg/l

≤ 0.1 mg/l

Page 17

Page 15

Phosphate (P2O5)

≤ 0.5 mg/l

≤ 0.1 mg/l

Conductivity (at

25°C)

≤5 µs/cm

≤ 3 µs/cm

pH value (degree of

acidity)

5 to 7.5

5 to 7

Hardness (Σ ions of

alkaline earth)

≤ 0.02 mmol/l

≤ 0.02 mmol/l

Appearance

Colorless, clean, without sediments

[Minimum specific resistivity of 1 megohm per cm (1 M

Ω/cm)]

Compliance with the above data should be tested in accordance with

acknowledged analytical methods, by an authorized laboratory.

Attention: The use of water for autoclaves that do not comply with the table

above may have severe impact on the working life of the sterilizer and

can invalidate the manufacturer’s guarantee.

Use Only deionized water, Having a maximum conductance of 1

microSiemen per cm (1 μS/cm) Tap Water supply

Maximum hardness value 0.7-2.0 mmol/l

The use of soft water is strictly forbidden!

Please consult a water specialist!

4.2.1 Water for the Vacuum pump and drain cooling

The feed water supplied to the liquid ring vacuum pump must meet the

following requirements:

Hardness: 0.7 - 0.2 mmol/l.

Water temperature: shall not exceed 15°C.

Note: The use of heavy scaled water for the vacuum pump cooling, can

cause blocking of the rotor and put the pump out of operation. This

invalidates the guarantee for the vacuum pump.

4.3 Reverse Osmosis

A Reverse Osmosis system may be used to improve the quality of the

water used to generate steam in the autoclave chamber. The use of

mineral free will contribute to better performance and longer life of the

autoclave.

Page 18

Page 16

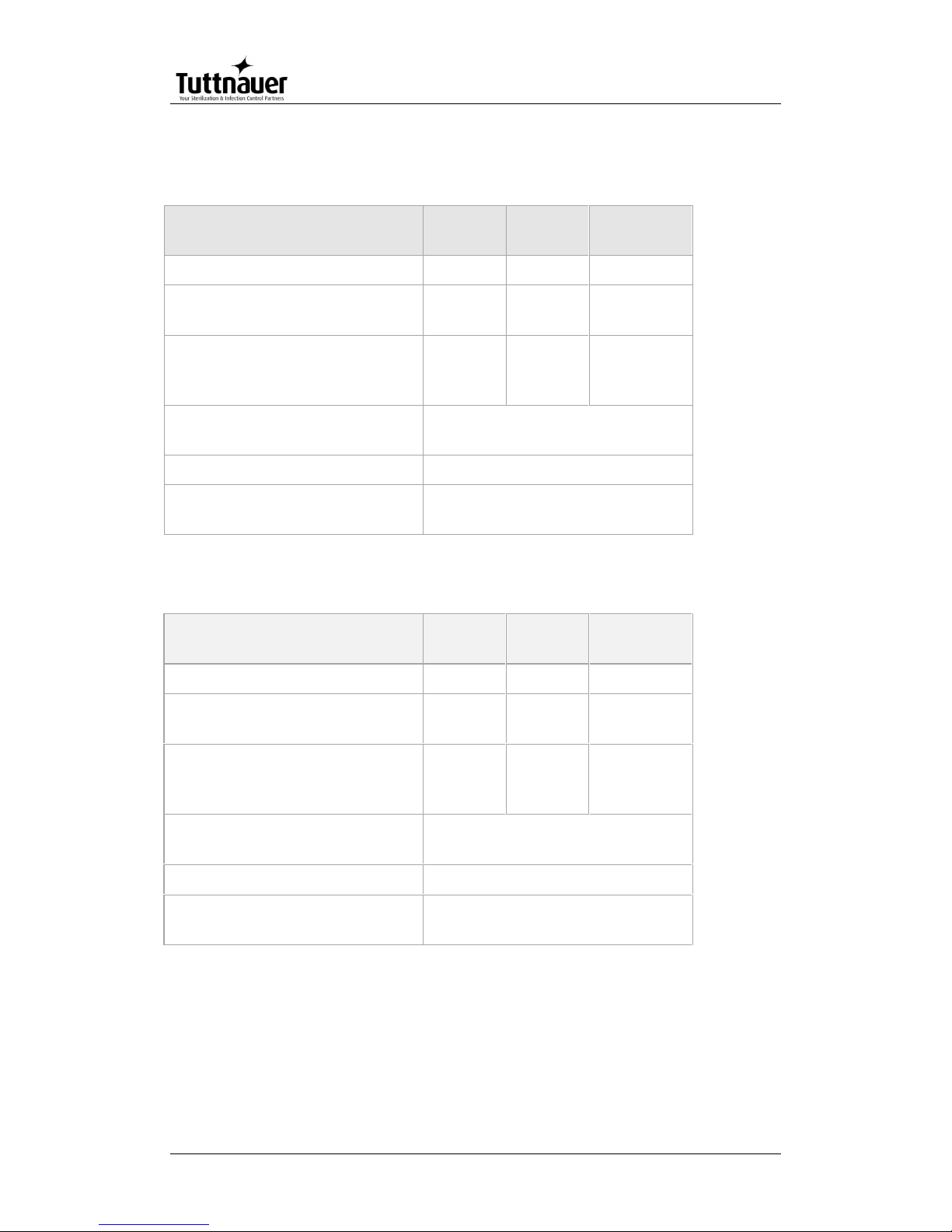

4.4 Electrical data

230V configuration

Property

Value:

3840

Value:

3850

Value:

3870

Total Power

9000

9000

9000

Voltage

1Ph,

230VAC

1Ph,

230VAC

1Ph,

230VAC

Amperage

22A w/o

PV, 25A

with PV

22A w/o

PV, 25A

with PV

22A w/o

PV, 25A

with PV

Protection against electrical

shock

Class I (IEC 60601-1)

Mains supply fluctuation

+/- 10%

Degree of protection by

enclosure

IP31

400V configuration

Property

Value:

3840

Value:

3850

Value:

3870

Total Power

9000

9000

9000

Voltage

3Ph,

400VAC

3Ph,

400VAC

3Ph,

400VAC

Amperage

13A w/o

PV, 16A

with PV

13A w/o

PV, 16A

with PV

13A w/o

PV, 16A

with PV

Protection against electrical

shock

Class I (IEC 60601-1)

Mains supply fluctuation

+/- 10%

Degree of protection by

enclosure

IP31

Page 19

Page 17

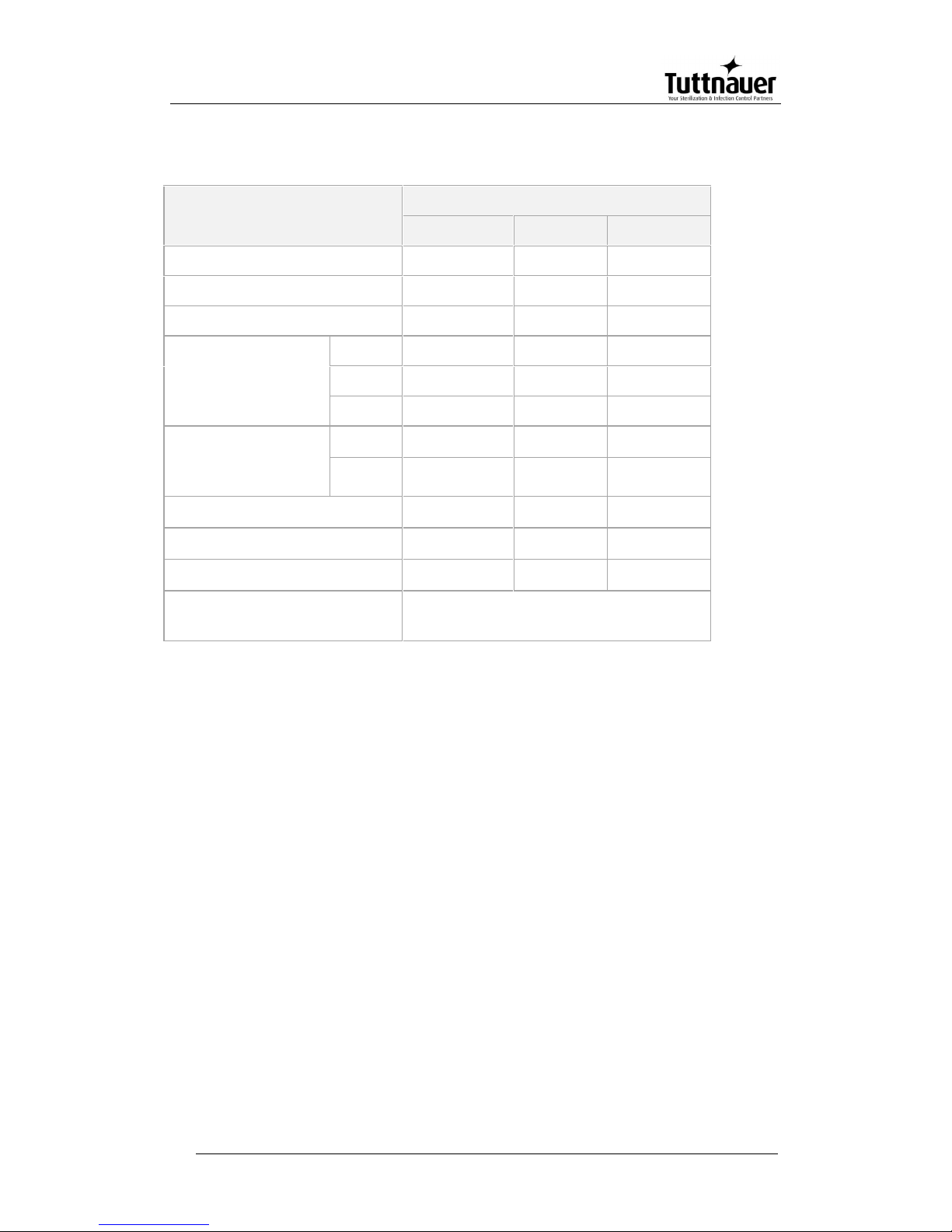

4.5 Specifications

Properties

Model

3840

3850

3870

Chamber diameter

380

380

380

Chamber depth

400

500

690

Chamber volume

52 liters.

65 liters.

85 liters.

Overall dimensions

Height

1000

1000

1000

Width

730

730

730

Length

700

700

700

Maximum

dimensions

(door open)

Width

800

800

800

Length

1500

1500

1500

Net weight (kg)

105kg

108kg

113kg

Shipping volume

0.9 m3

0.9 m3

0.9 m3

Shipping weight

133kg

136kg

141kg

Max. Allowable Working

pressure (MAWP)

2.8 bar (40 psi)

Page 20

Page 18

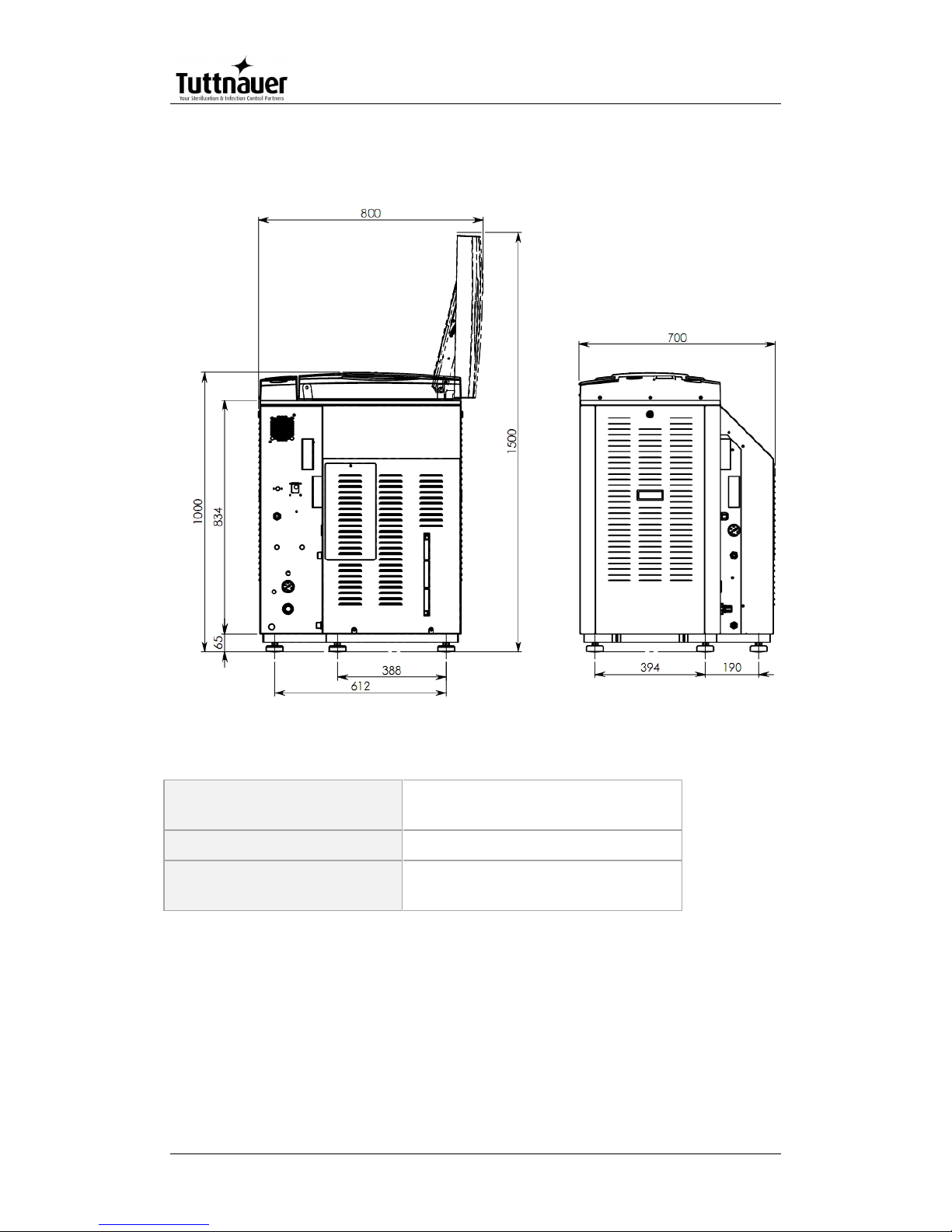

4.6 Overall Dimensions

4.7 Construction

Chamber and door

material

Stainless steel

Outer Cabinet

Stainless Steel

Chamber insulation

Fiberglass with reinforced

material

Page 21

Page 19

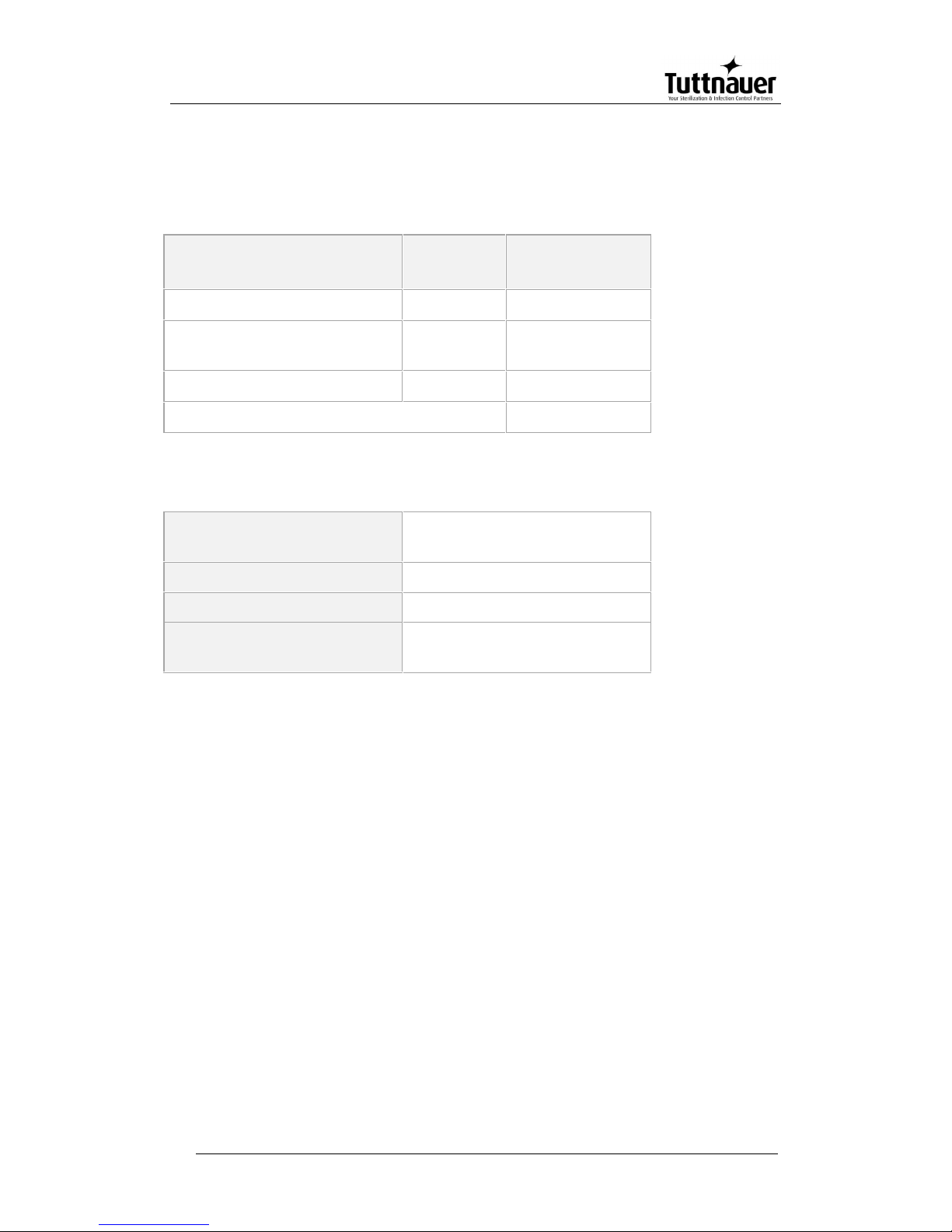

4.8 Utilities

4.8.1 Electrical utility

Power

Switch

box

Recommended

Circuit Breaker

208-220V (3 Ph + Earthing)

No

20A

380-400V(3 Ph + Neutral +

Earthing)

No

16A

230V 1ph

yes

32A

Frequency

50/60Hz

4.8.2 Other Utilities

Compressed Air

(ELVCPVG-D only)

1/2" 3-4 Bar (44-58 psi)

Tap water

1/2", 2-3 Bar (29-44 psi)

Mineral free water

1/2", 2-3 Bar (29-44 psi)

Drain

2" Minimum Withstanding

temp. of 80°C (176°F)

Attention:

A switch or circuit-breaker must be included in the building installation.

This switch or circuit-breaker shall be in close proximity to the

equipment, within easy reach of the operator; and marked as the

disconnecting device for the equipment.

The electrical net must be protected with a current leakage safety

relay.

The electrical network must comply with local rules or regulations.

Verify that there is an easy access to the main power switch, to the

water cut-off valve and to the current leakage safety relay.

Make sure while placing the autoclave, to leave space around the

machine, to give the technician access to service the machine.

All water connections to autoclave must be performed through "BACK

FLOW PREVENTION SYSTEM" only, as per IEC 61770.

Page 22

Page 20

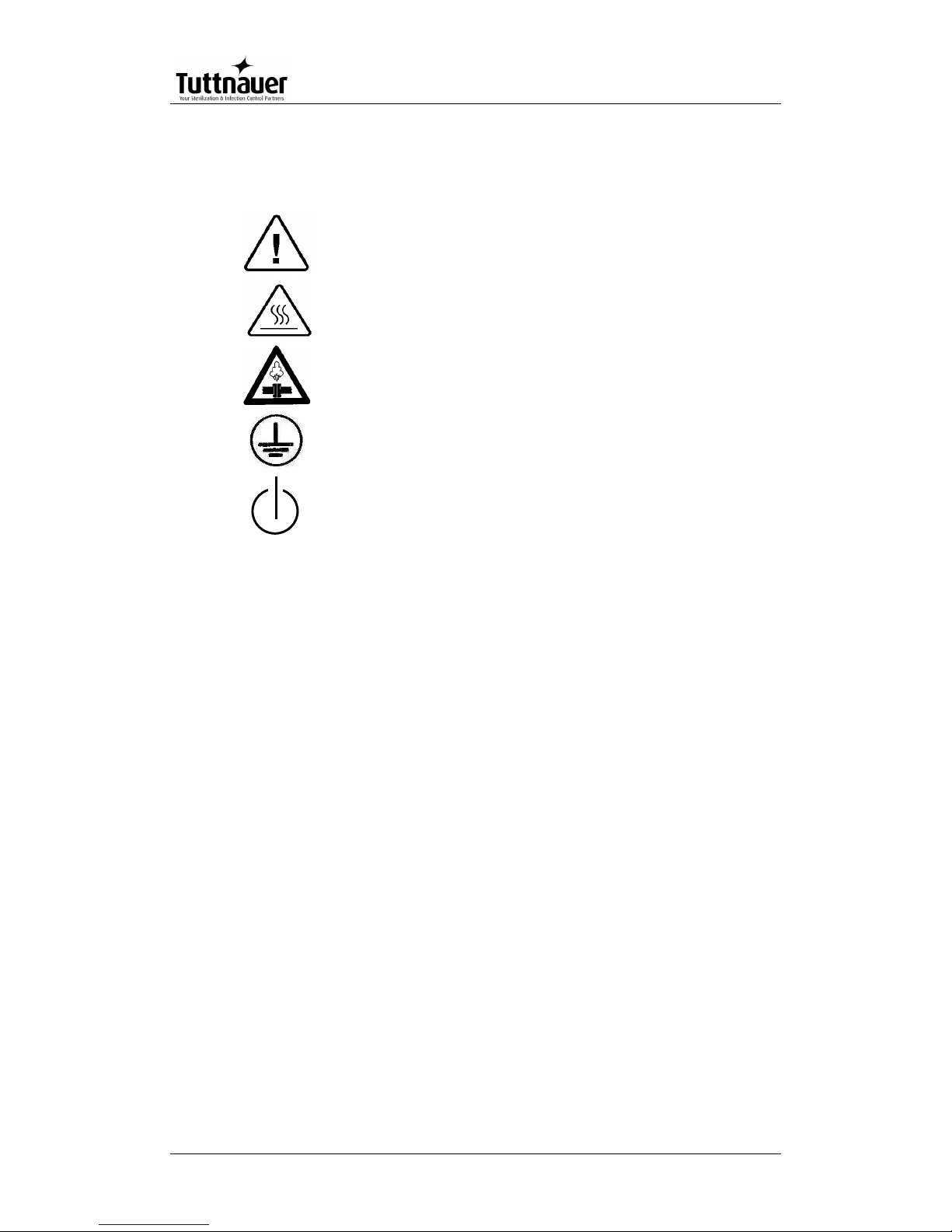

4.9 Symbol Description

Caution! Consult accompanying documents

Caution! Hot surface.

Caution! Hot steam.

Protective earth (Ground)

On-Off

Page 23

Page 21

5. Description of the Control System.

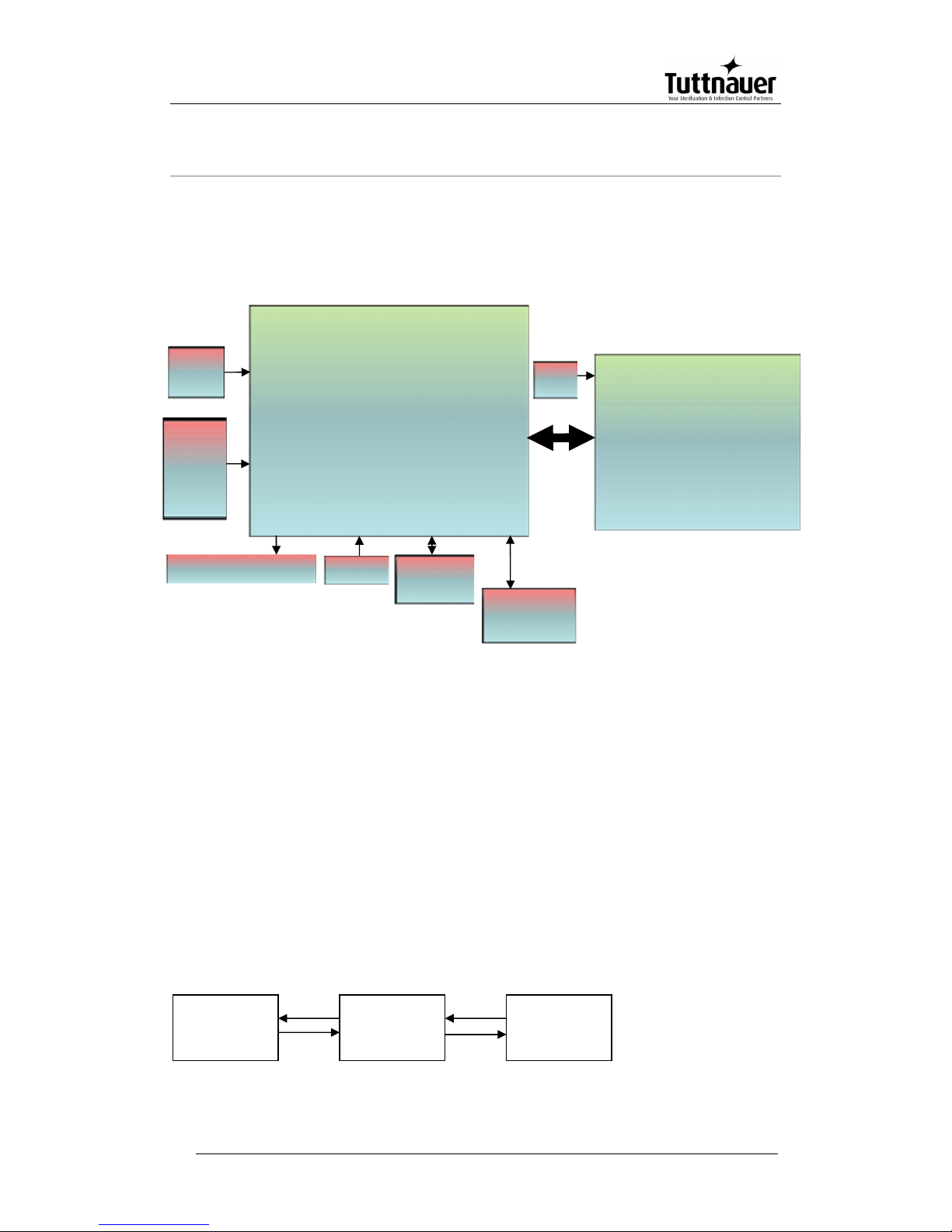

5.1 Hardware Control System Components: Block

Diagram

5.2 Application System Architecture

The system is divided into three main sections (dll)

1. GUI – holds all the Human Machine interface including the main

application screen and all the configuration screens which enable the

user to handle the machine.

2. Logic – holds all the application logic for running the machine.

3. Utilities – Holds general functionality which is used by the logic section

and the GUI section e.g: converting function for displaying different

pressure or temperature units type, languages etc.

Main board

- CPU +memory- Backup

power input

-MCIMX27LVOP4A+MC13783VK5

- R.T.C (including Battery)

M41T81SM6E

- Memory card expansion

MT46H32M16LFBF-

6:B+EPM570F256C5+S71WS256P

Ethernet

Am79C874

I/O Board

CPU- STM32F103R6T6

-24 Digital Outputs

-2 Analog outputs

-9 Digital inputs

-4 Analog Inputs 4-20mA

-6 Analog inputs Temp pt100

-3 Inputs water level

Keypad

Graphic Display 3.5"

USB Memory

socket

ISP1504ABS

24/12

VDC

Input

COM1

(RS232)

MAX323

2CSE+

Printer

24/12

VDC

GUI

LOGIC

UTILITY

Page 24

Page 22

Mapping of the software to the hardware – see Software Development

Plan.

The Hardware architecture is based on Freescale i.MX27 PDK

Evaluation Board.

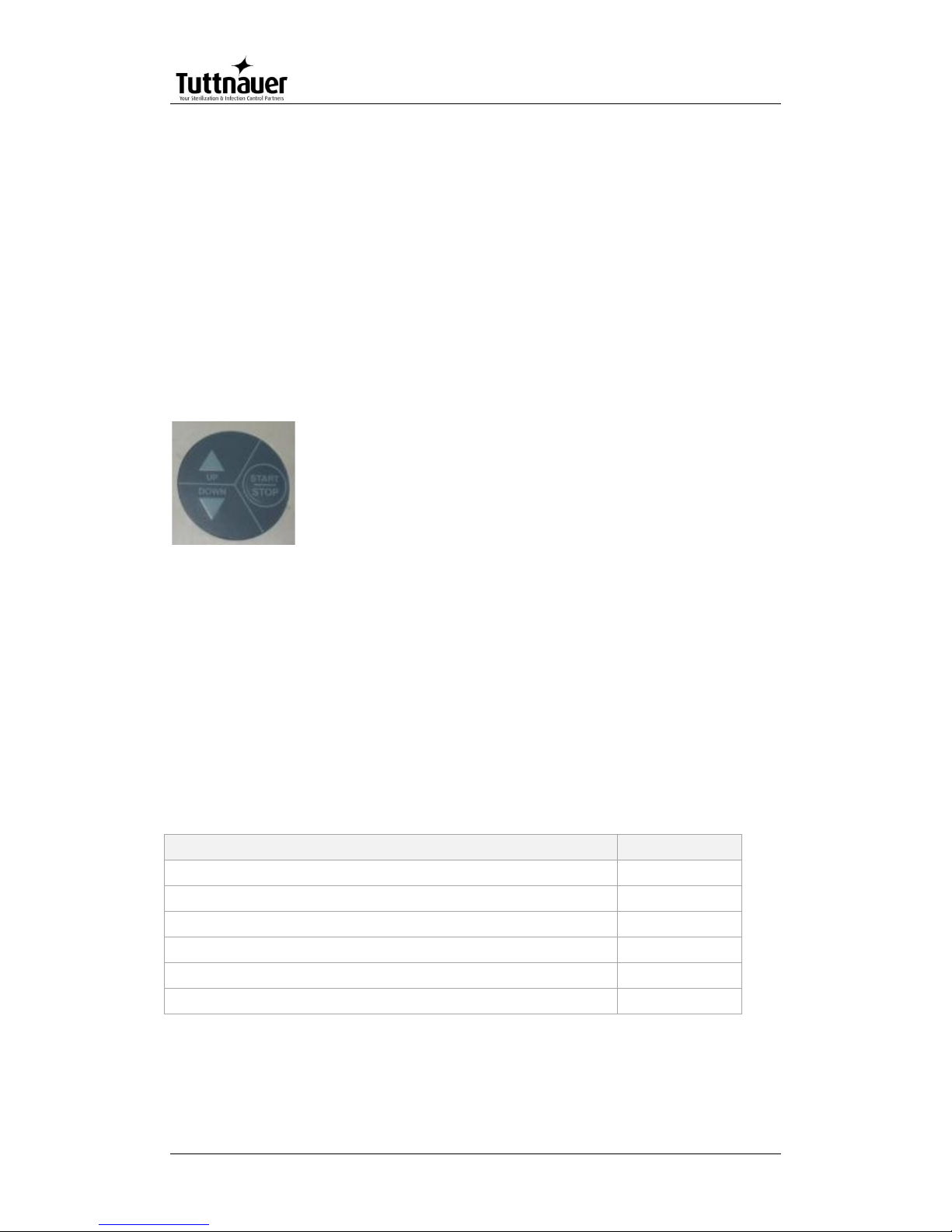

5.3 Interfaces to Users

Keypad: The keypad has three push buttons:

o Down key

o Up key

o Start/stop key

Display: The control system has a graphical display

USB socket:

The USB socket is intended to load cycles' history from flash a

memory (disk on key). The received file is in txt format that can be

loaded onto a PC.

5.4 Inputs and Outputs

Analog inputs

Analog inputs

JP

Drain temperature

J5

Chamber temperature

J2

Bio hazard filter temperature

J6

Ref temperature

J3

Jacket temperature

J4

Chamber pressure

J7/1

Page 25

Page 23

Digital inputs

Digital Inputs

JP

Door closed

J12/1

Door unlocked

J12/6

Door locked

J12/8

Digital outputs

Digital Outputs

JP

Steam to jacket

J13/8

Vacuum pump

J13/12

Exhaust to bio

J13/14

Main exhaust

J13/16

Atmospheric air valve

J14/2

Compressed air to chamber

J14/4

Slow exhaust

J14/6

Fast exhaust

J14/8

Vacuum valve

J14/10

Cool Drain

J14/12

Steam to chamber

J14/14

Cooling water

J14/16

Compressed air to jacket

J15/2

Close door

J15/4

Open door

J15/6

Air to door

J15/14

Actuators

The control system operates electrical valves (solenoids), Electric

cylinder motors, pneumatic cylinders, electric pumps, heaters.

On / off switch

A Rocker Switch 250V AC, 16A

Page 26

Page 24

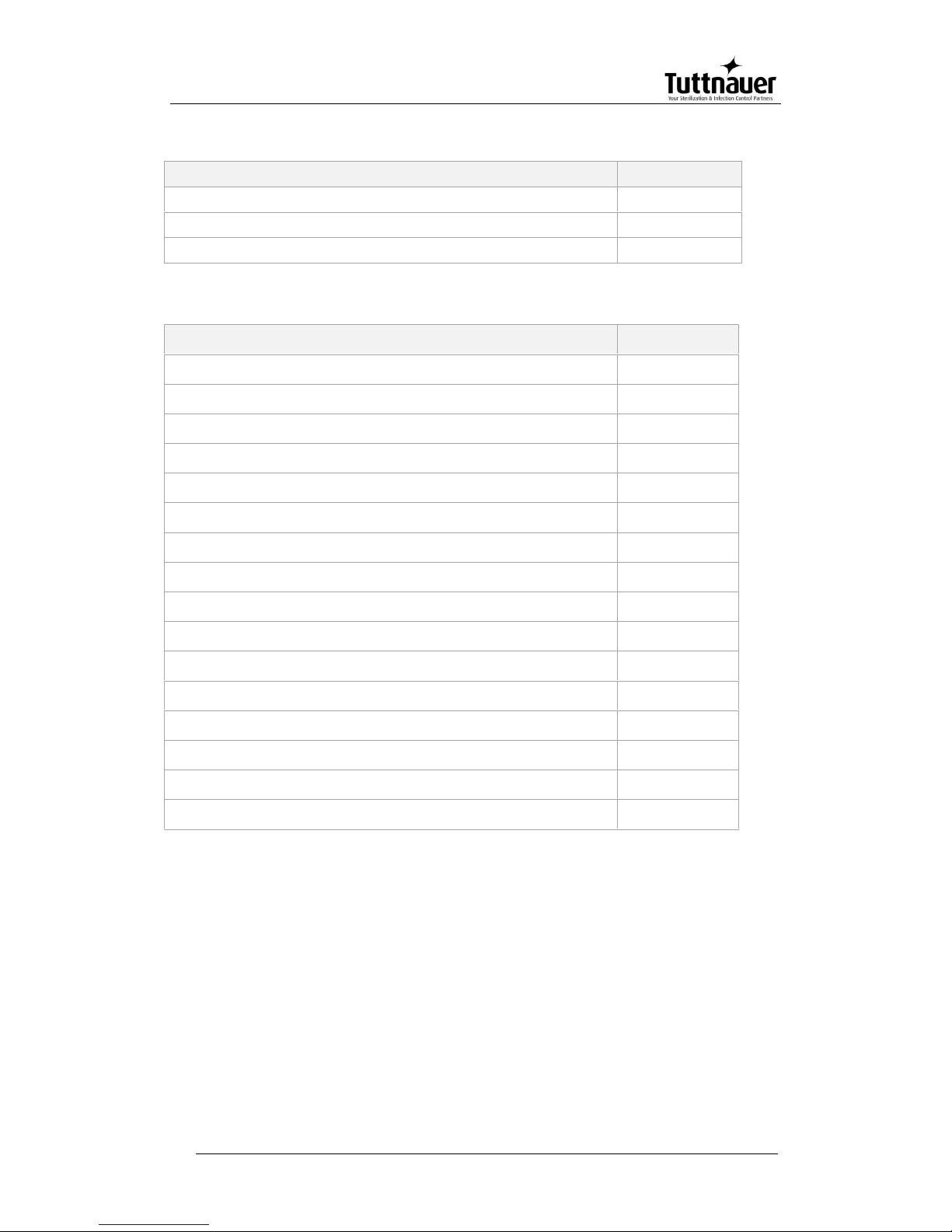

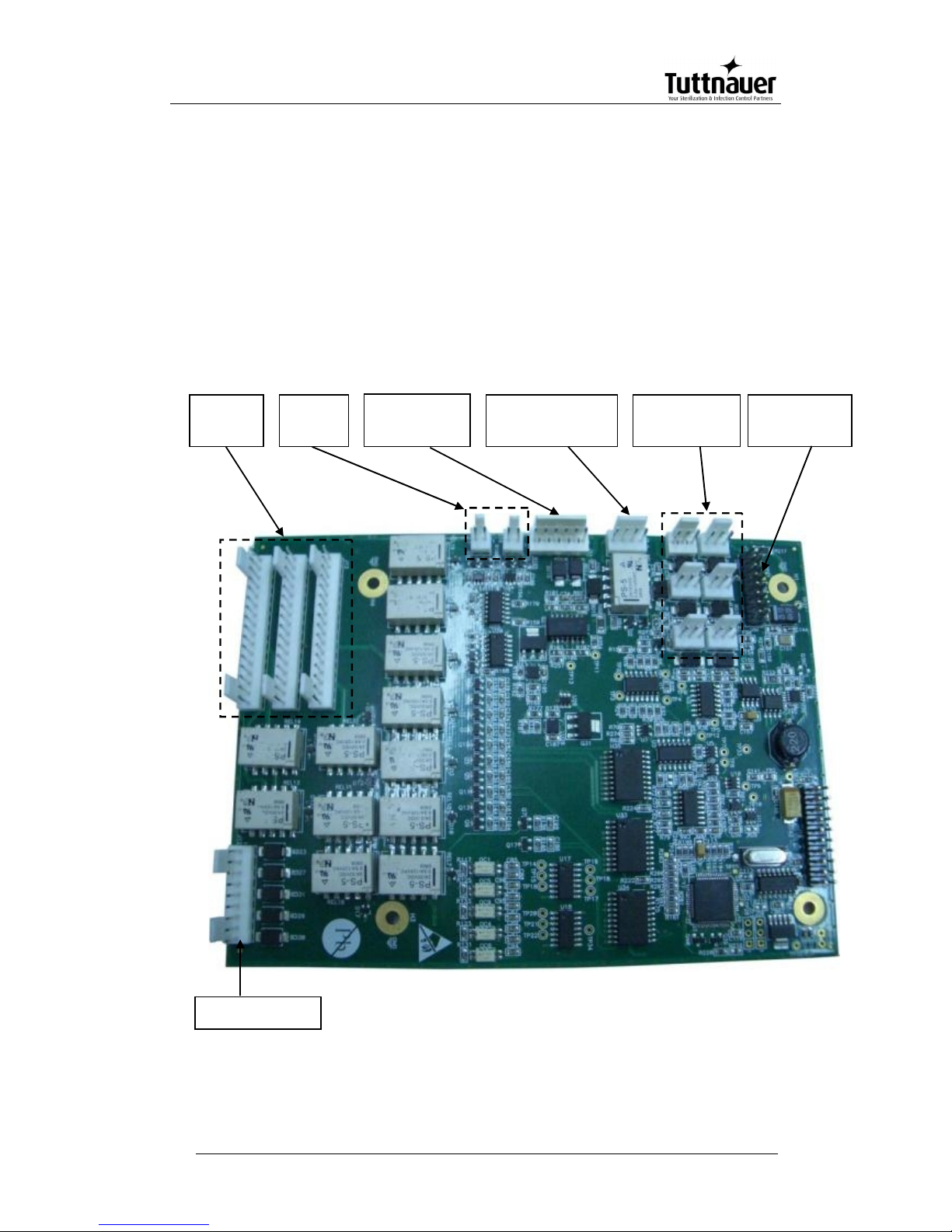

5.5 Hardware Control System components

The hardware is consisted of cards: MAIN and IO

Main card

Operating system (MAIN card)

The Operating system is Microsoft Windows CE version 6. The code to

the Operating system is supplied by Microsoft. The connection code

between the Operating system and the hardware components (BST –

Power Supply

Connector

(24V DC)

Connector to

printer

+

Ethernet

Connector

SD

Not in use

USB

Connector

-

Connector

to IO Board

Connector to

LCD display

Connector

to Keypad

Lithium coin

battery T.H

orizontal 3V

48mAh

J5

BT1

J8

J4

P2

P4

T1

P3

J3

Page 27

Page 25

Board Support Package) is supplied by FreeScale. Minimum suitability

for this "Tuttnauer" project is performed in this code.

Development tools (MAIN card)

The software develop environment is on Microsoft Visual Studio 2005

that includes the Microsoft Platform Builder for Windows CE 6.0. The

specific Tuttnauer system application is written in C Sharp.net on

Microsoft Compact Framework.net

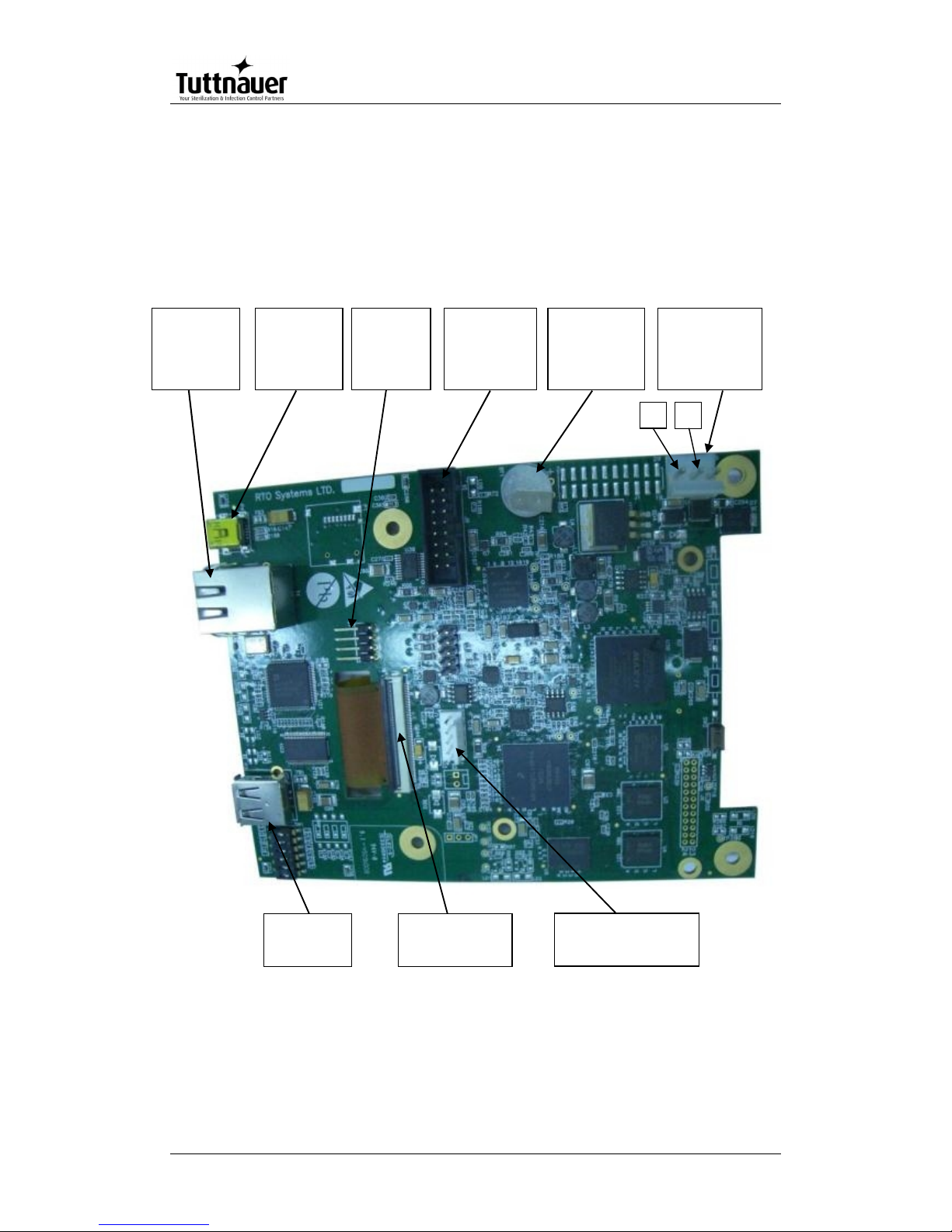

IO Card

Analog inputs

(PT-100)

Analog inputs

-

20mA)

Analog inputs

electrodes

J

J

J6

J3

J4

J1

J7

J11

J16

J17

J13

J15

J14

Connection to

MAIN Board

Analog

outputs

Digital

outputs

Digital Inputs

J12

Page 28

Page 26

IO card is an independent card. It checks the card by a method of a

continuous scan of all the ports, saving the data in the memory and

transporting this data according to the request in the communication

channel RS-232 to the personally adapted protocol.

At the end of the check process of the digital and analog ports, the

communication channel is checked, in case of receiving a request, the

request is checked and if the request is legitimate it will be taken care

of.

The IO card is controlled by the MAIN card. Only when requests are

received from the MAIN, the requests will be checked and performed.

The IO card will perform an electrical restart of the systems (IO card) if

it does not receive requests within 5 seconds. In the next request

received from the MAIN, the IO card will indicate to the requester of IO

card systems restart.

The "brain" in the IO card runs on microcontroller type:

STM32F103R6T6.

The Microcontroller is an electrical Integrated circuit with an actualized

complete system (SoC) including a processing unit, external interfaces,

memory, etc.

The Microcontroller is constructed of a number of main components:

Central processing unit – the main component in the microcontroller is

a central processing unit (CPU) This unit is in charge of receiving the

request (command) code from the memory, deciphering, receiving

variable data from the memories and performing the command.

Memory – divided into 2 sections.

• software memory – in this memory the software that samples the IO

card and request (command) from the user are saved. As this memory

is a flash memory it is possible to burn the code many times (efficient

to the development stage).

• information memory – in this memory the data and other variables

values are saved. This memory is not flash memory, but is RAM

memory.

Digital / Analog ports (in/out) – through them the microcontroller can

receive data of digital/analog signs from the system, save them and

pass them on respectively to the user request.

Ports (in / out) to the communication – in the IO card there is a UART

component. This component enables communication with the MAIN

card through the RS-232 in suitable protocol.

MAIN and IO cards :communication protocol between IO board to Main

Board

Page 29

Page 27

Communication protocol between IO to Main boards is described

below.

The communication manged by the Main board (master), the IO

functions as slave.

There are six communication functions.

The communication functions (to read or write) identified by number.

The communication functions listed below:

01 Read – command to IO send all the information of digital analog

inputs.

02 Write – Command to IO to activate analog and digital outputs.

03 Read version – IO software version to verify the version.

04 N.A.

05 Read number that identifies the ID of IO board and the software

version.

06 Write (only at the first time) to IO his ID and software number.

First Byte (Byte 1).

The first byte identifies ID functionality request. It can be one of the

numbers in a paragraph.

The second byte will present the data size if the main board asks to

write information to the IO. If the request is to read this byte will be 00.

The number of the request. This number is increased from 00-ff.

Check sum of the package – to prevent mail functionality of the board if

there is interference in communication.

The information package transfer. The information contains number of

the input or output and data for/from each I/O.

Bytes identify number of input or output followed by two bytes

containing the data of the input or outputs.

Last byte contains a check sum of the entire package that is

transferred. This is to verify that the information is not corrupted.

Example:

The main board sends:

01;00;0003;0004;

01 Ask to Read inputs.

00 not transfer information.

0003 Request number 3

0004 Checksum to verify the request

Page 30

Page 28

6. Checking and Changing Parameters

and Other Data

Bacsoft control panel allows changing parameters of the cycle and of

the system, exporting various data to, and importing from, a USB

device or to the printer, and some other options.

Cycle parameters are changeable for Custom programs only (see

Duplicate cycles), with the exception of the Temperature sensors,

Displayed inputs, and Dry Time.

6.1 Browsing through the menus

Now you will learn how to browse through the folders. When you read

the Directories and subdirectories chapter with links to specific menus,

you will need to know how to browse through the folders using the

autoclave control panel. Below is the instruction.

Login as Technician (see 6.4). The Main menu screen appears. To

browse through the menus:

1. Press the Up and Down keys to scroll through the menus.

2. Press the Start/Stop key to enter the next screen (i.e. to get one level

down).

3. Repeat steps 1 and 2 to enter the next screen until you get to required

screen.

Below are the example screens for the following menu: Cycle

Parameters\ Drying\ Dry Time:

Page 31

Page 29

Note: To exit every screen and to return to the previous screen (to get one

level up):

move the cursor to Exit by pressing the UP or DOWN keys and then

press the Start/Stop key.

- or-

press the UP and DOWN keys simultaneously.

In the next chapter you will see how to change the required parameter

as desired.

6.2 Changing a Parameter

You have browsed through the menus and reached the parameter

changing screen as explained above. Now you can change the

required parameter as desired. To do so:

1. Enter the required value as follows:

Press the Up and Down keys to change the value of the digit.

Press the Start/Stop key to move the cursor to the next digit to the left.

2. When finished, press the Start/Stop key repeatedly until you move the

cursor to Set.

3. Press the Up or Down key to confirm the new value and to exit the

parameter changing screen.

Below is the typical parameter changing screen:

Page 32

Page 30

Note: Please note the maximum and minimum values for this parameter

shown on the screen. Your value must be within these boundaries.

Below is the example of changing the Dry time parameter on the

screen used in the previous section:

Page 33

Page 31

Note: To exit every screen and to return to the previous screen:

move the cursor to Exit by pressing the UP or DOWN keys and then

press the Start/Stop key

- or-

press the UP and DOWN keys simultaneously

6.3 Quick options screen

When the autoclave is on and no cycle is running, press Up and Down

keys simultaneously to enter the Quick options screen. Most of the

options require login, and their availability depends on user authority

(user, or technician). Login command is the last line on this screen.

Quick options are options available without login.

Page 34

Page 32

Below you can find instructions how to login and enter the Main menu.

Section 7.1 above explains how to browse through the menus; section

7.2 explains how to change a parameter.

Below is the explanation of the Quick Options.

6.3.1 Export to USB

his subdirectory allows you to export settings and cycles history to the

USB device.

1. Insert the USB device into the USB socket.

2. Enter the Export to USB screen.

To export settings:

a. Choose Export all settings to USB device.

b. Press the Start/Stop key. The following screen will appear:

Page 35

Page 33

To export cycles history:

c. Choose All cycles history, 10 Cycles, or 50 Cycles.

d. Press the Start/Stop key. The following screen will appear:

3. Remove the USB device from the USB Socket.

6.3.2 Print cycles

This subdirectory allows printing out cycle reports for a number of

previous cycles (See the Printer handling section of the Operation and

maintenance manual).

1. Enter the Print Cycles screen.

Page 36

Page 34

1. Choose Print last cycle, Print last 5 cycles, or Print last 10 cycles.

2. Press the Start/Stop key. The cycle reports will be printed.

6.3.3 Version Information

This directory allows viewing information of the current, factory default,

and previous software versions.

1. Enter the Version information screen.

6.3.4 Start cycle by clock

This subdirectory enables the operator to start the cycle at the time set

by this paramter.

1. Enter the Start cycle by clock screen. The following screen will appear:

Serial

number

Software

version

Page 37

Page 35

On the Start cycle by clock screen, the time is displayed in the form

“HH:MM”. The hour range is 24 hours (i.e. from "0" to "24").

Setting the time to start the cycle

1. Move the cursor to the Time field.

2. Set the required time.

Enabling the Start Cycle by Clock

1. Set the starting time.

2. Move the cursor to Enabled. Press Up or Down key to enable starting

cycle by clock.

1. Exit the Enabling the Start Cycle by Clock. The start cycle by clock icon

appears on the display:

Page 38

Page 36

Disabling the START CYCLE BY CLOCK

2. On the Start Cycle by Clock screen, move the cursor to Disabled.

Press Up or Down key to disable Starting cycle by clock.

3. Exit the Enabling the Start Cycle by Clock.

6.3.5 Set date and time

This subdirectory enables the operator to set date and time.

On the Set date and time screen, the time is displayed in the upper row

in the form "HH:MM:SS". The hour range is 24 hour (i.e. from "0" to

"24"). The date is displayed in the lower row in the form "DD: MMM:

YYYY".

1. Set time and date

2. Exit the Set date and time screen. The following screen will appear:

Page 39

Page 37

Caution!

After setting time and date, turn the autoclave off and then on

again.

6.4 Logging in and entering the Main menu

Below you can find instructions how to login and enter the Main menu.

Section 7.1 above explains how to browse through the menus, section

7.2 explains how to change a parameter.

When the autoclave is on and no cycle is running, press the up and

down keys simultaneously to enter the Quick Options screen (see 6.3).

On this screen you can either proceed to login (see below) or choose

one of the quick options available without login. To login as technician:

1. On the Quick Options screen, choose login.

Select user screen appears.

Page 40

Page 38

2. Choose Technician, then press the Start/Stop key to enter. The

following screen will appear:

0000 is displayed on the screen with the cursor flashing on the right

digit.

Set the code to 0321. You will get to the Main menu.

Below is the list and the explanation of the options available on the

Main Menu.

6.5 Directories and subdirectories

Bacsoft control panel provides an interface that consists of control

screens available through an easy scrollable menu tree.

Page 41

Page 39

To learn how to scroll through the menus, change the parameters,

and perform some other functions using our three-button keypad,

see 6.1 and6.2.

The following table lists the options that the technician may perform.

Directory

Subdirectory

Cycle Parameters

1

Temperature sensors

Displayed inputs

Purge (generator models only)

Drying

Create Pulse

Keep Heat

For custom programs only

Heating

Sterilization

Cooling (“C” models only)

Exhaust

Drying

Ending

Global

System Parameters

Print Rate All

Print Rate Sterilization

Screen Saver

Pressure calibration high

Pressure calibration low

Temperature calibration high

Temperature calibration low

Cycle Print Gap

Inputs/Outputs

View digital inputs state

View digital outputs state

Test digital outputs

1

See cycle parameters in more detail in Cycle Parameters.

Page 42

Page 40

Directory

Subdirectory

View analog inputs state

Analog inputs calibration

Maintenance

Export gain offset to USB

Import gain and offset from USB

Reset atmospheric pressure

Test RTC

Printer test

Print all gain and offset

Advanced Options

Enable cycles

Set Language

Set temperature units

Set pressure units

Duplicate cycles

Delete custom cycles

Set external IP address

Version Handling

Import application from USB

Import all settings from USB device

Import application and setting from USB

Return to factory default settings

The following chapter explains meaning and usage of the control

screens.

Below is the typical parameter changing screen:

Page 43

Page 41

6.6 System Parameters

This menu is listing the system parameters that are the same for all

cycles. Browse to the following folder:

Main menu\System parameters

You will see the following screen:

Below is the instruction for changing the system parameters.

6.6.1 Print Rate All

In this menu you can define the time interval for printing out the cycle

status, for all the stages except sterilization: The default is 3 minutes.

See the Printer handling section of the Operation and maintenance

manual.

Page 44

Page 42

Browse to the following folder:

System parameters\Print Rate All

Change the parameter as desired

6.6.2 Print Rate Sterilization

In this menu you can define the time interval for printing out the cycle

status during the sterilization stage: The default is 1 minutes.

Browse to the following folder:

System parameters\Print Rate Sterilization

Change the parameter as desired

6.6.3 Screen Saver

In this menu you can define the screensaver delay time, i. e. how long

the keyboard will be untouched before the screensaver activates.

Browse to the following folder:

System parameters\Screen Saver

Change the parameter as desired.

6.6.4 Pressure calibration high

In this menu you can define the high calibration point for pressure.

Browse to the following folder:

System parameters\Pressure calibration high

Change the parameter as desired.

6.6.5 Pressure calibration low

In this menu you can define the low calibration point for pressure.

Browse to the following folder:

System parameters\Pressure calibration low

Change the parameter as desired.

6.6.6 Temperature calibration high

In this menu you can define the high calibration point for temperature.

Browse to the following folder:

System parameters\Temperature calibration high

Change the parameter as desired

Page 45

Page 43

6.6.7 Temperature calibration low

In this menu you can define the low calibration point for temperature..

Browse to the following folder:

System parameters\Temperature calibration low

Change the parameter as desired

6.6.8 Cycle Print Gap

This parameter defines the time interval between printing the current

values of the cycle (See the printer output section).

Browse to the following folder:

System parameters\Cycle Print Gap

Change the parameter as desired

6.7 Inputs/Outputs

It is important for the technician to control the system down to the level

of specific inputs and outputs. Viewing the outputs state at specific

stages of the cycle helps you diagnose the malfunctions. You can also

test and calibrate inputs and outputs.

Below is the typical screen for viewing/testing the inputs/outputs.

Below is the instruction for working with inputs/ outputs.

6.7.1 View digital inputs state

In this menu you can view, at any stage, which digital inputs are being

controlled at the moment.

Page 46

Page 44

Browse to the following folder:

Inputs/Outputs\View digital inputs state

6.7.2 View digital outputs state

In this menu you can view, at any stage, which digital outputs are being

controlled at the moment.

Browse) to the following folder:

Inputs/Outputs\View digital outputs state

6.7.3 Test digital outputs

In this menu you can view the normal function of all the autoclave

elements: valves, heating elements, pumps, etc.

Browse to the following folder:

Inputs/Outputs\Test digital outputs

Note: on the screen that appears, scroll down for more outputs.

Check the checkboxes of the outputs you want to test.

6.7.4 View analog inputs state

In this menu you can view, at any stage, the values of the analog

inputs at the moment.

Browse to the following folder:

Inputs/Outputs\View analog inputs state

6.7.5 Analog inputs calibration

In this menu you can calibrate water level, mineral water level,

pressure, and temperature sensors of the autoclave chamber.

1. Browse to the following folder:

Inputs/Outputs\Analog inputs calibration

The following screen will appear:

Page 47

Page 45

2. Press Up or down key to choose the input to calibrate and press

Start/Stop.

The following screen will appear:

See below description of each option.

6.7.6 Auto calibrate

Bacsoft software has an option for automatic calibration using the

PT100 simulator.

On the calibration options screen, choose Auto calibrate.

The following screen will appear:

Page 48

Page 46

6.7.7 Calibrate analog input

This menu allows calibrating analog inputs manually.

1. On the calibration options screen, choose Calibrate analog input.

The following screen will appear:

2. In the Actual field, change the high and low values of the input as

desired.

6.7.8 Set gain and offset

1. On the calibration options screen, choose Set gain and offset.

2. The following screen will appear:

Page 49

Page 47

Change gain and offset as desired.

6.7.9 Restore last calibration

There is an option to restore the gain and offset values set at previous

calibration.

1. On the calibration options screen, choose Restore last calibration.

The following screen will appear:

2. Using the up and down keys, move your cursor to confirm and press

Start/Stop.

The following screen will appear:

Page 50

Page 48

6.7.10 Restore default calibration

There is an option to restore the default (factory) gain and offset values

1. On the calibration options screen, choose Restore last calibration.

The following screen will appear:

2. Using the up and down keys, move your cursor to confirm and press

Start/Stop.

The following screen will appear:

Page 51

Page 49

6.8 Maintenance

Maintenance procedures provided by Bacsoft software allow you

additional tests and USB input/output options.

Browse to the following folder:

Main menu\Maintenance

You will see the following screen listing the maintenance options:

Below is the instruction for autoclave’s maintenance menu.

6.8.1 Export gain offset to USB

In this menu you can export to USB the gain and offset you have got as

a result of calibration.

Browse to the following folder:

Maintenance\ Export gain offset to USB

Page 52

Page 50

6.8.2 Import gain and offset from USB

In this menu you can import from the USB the gain and offset

documents you have got as a result of calibration to the autoclave.

Browse to the following folder:

Maintenance\Import gain and offset from USB

Press Start/Stop. The following screen will appear:

6.8.3 Reset atmospheric pressure

In this menu you can reset the atmospheric pressure value. To do so:

1. Browse to the following folder:

Maintenance\Reset atmospheric pressure

The following screen will appear:

Page 53

Page 51

2. Leave the door open for 2 minutes at least. Ambient temperature

should be less than 45°C.

Note: Please reset the atmospheric pressure when you install the autoclave

for the first time, and each time you relocate or calibrate the autoclave.

6.8.4 Test RTC

In this menu you can check the two clocks. The two clocks work during

the interval set by the Test RTC parameter, and the results are

displayed. If the results are different for more than 2 seconds, one of

the clocks is faulty.

1. Browse to the following folder:

Maintenance\Test RTC

The following screen will appear:

2. Set the time interval as desired. Then move the cursor to start and

press Start/Stop.

At the end of the test, the following screen will appear:

Page 54

Page 52

3. Using the Up and Down keys, move the cursor to Exit.

6.8.5 Printer test

In this menu you can check the normal function of the printer. The

printer will print the list of errors.

Browse to the following folder:

Maintenance\Printer test

The following screen will appear to confirm that the test has been done.

See the printout shown in the Printer handling chapter of the user

manual.

6.8.6 Print all gain and offset

In this menu you can print all the gain and offset for all the pressures

and temperatures in the autoclave (Chamber Temperature, Chamber

Pressure, Chamber Water Level, Mineral Free Water Level.

Page 55

Page 53

Browse to the following folder:

Maintenance\Print all gain and offset

See below the example of a printout:

Chamber Temperature

G:000.0385;O:-008.0976

Chamber Pressure

G:000.1238;O:-098.5985

Chamber Water Level

G:001.0000;O:000.0000

Mineral Free Water Level

G:001.0000;O:000.0000

6.9 Advanced Options

Advanced options menu gives you even more possibilities, including

interface customization, changing the settings, enabling, adding and

deleting cycles, etc.

Browse to the following folder:

Main menu\Advanced options

You will see the following screen listing the Advanced options:

Page 56

Page 54

Below is the instruction for the Advanced options menu.

6.9.1 Enable cycles

In this menu you can enable only the cycles you want to use. The

cycles you do not want to use will not appear on the screen.

Browse to the following folder:

Advanced Options\Enable cycles

Move cursor to the cycles you want to enable/disable and

check/unchek them as desired.

6.9.2 Set Language

In this menu you can choose the language for all the interface screens:

menus, cycle information, system messages.

1. Browse to the following folder:

Advanced Options\Set Language

Page 57

Page 55

Note: There are more languages than you see on the screen above. Just

scroll down to see more.

2. Move the cursor to the desired language and check it. The following

screen will appear:

The machine will be restarted and the main screen (current cycle) will

appear in the chosen language.

6.9.3 Set temperature units

In this menu you can set the temperature units (Celsius or Fahrenheit)

for screens and printouts.

Browse to the following folder:

Advanced Options\Set temperature units

Change the parameter as desired

Page 58

Page 56

6.9.4 Set pressure units

In this menu you can you can set the pressure units (kPa, Psia, Psig,

BarA, BarG) for screens and printouts.

Browse to the following folder:

Advanced Options\Set pressure units

Change the parameter as desired

6.9.5 Duplicate cycles

In this menu you can create a copy of one of the cycles with all its

parameters (the parameters can be changed then). You can give any

name to the new custom cycle.

Browse to the following folder:

Advanced Options\Duplicate cycles

1. Using the Up and Down keys, move the cursor to the cycle you want to

duplicate, then press Start/Stop to select the cycle. A custom program

has been created with the same settings. You will be able to change

the settings later. The following screen will appear:

Page 59

Page 57

1. Give the name to your cycle.

2. Exit the menus until you get to the main screen.

3. Select your newly created program.

Note: you can select the program only when the autoclave door is open.

4. Login again as Technician (see 6.4).

5. In the main menu, select Cycle parameters and enter the Cycle

Parameters screen.

The following screen will appear:

Page 60

Page 58

Now you can alter the cycle parameters as desired.

6.9.6 Delete custom cycles

In this menu you can delete the custom cycles that were created.

Browse to the following folder:

Advanced Options\Delete custom cycles

1. Move the cursor to the cycle you wish to delete. Press Start/Stop key to

select/deselect the cycles.

2. Move the cursor to Delete selected cycles and press Start/Stop key to

delete.

The following screen will appear:

The selected custom cycle is now deleted.

Page 61

Page 59

6.9.7 Set external IP address

This option allows to set specific external IP address to be used for

remote RCPR connection.

Browse to the following folder:

Advanced Options\Set external IP address

Set the External IP Address as desired.

6.10 Version handling

The version handling menu provides tools to import, export, and

restore the autoclave software.

Browse to the following folder:

Main menu\Version Handling

You will see the following screen listing the version handling options:

Below is the instruction for version handling.

6.10.1 Import application from USB

In this menu you can replace the autoclave software with the

application software from the USB device to the autoclave.

1. Browse to the following folder:

Version handling\Import application from USB

The system will prompt you to confirm import

2. Move the cursor to Confirm and press Start/Stop.

The application will be imported from the USB device.

Page 62

Page 60

6.10.2 Import all settings from USB device

In this menu you can import the autoclave’s individual settings from the

USB device. The settings include all the changeable parameters of the

cycle and the system.

1. Browse to the following folder:

Version handling\Import all settings from USB device

The following screen will appear:

On this screen, you will see the model name and parameters

checksum of the settings saved on the USB device.

2. Move the cursor to Confirm and press Start/Stop.

The following screen will appear:

3. There is an option to keep the old serial number or calibration data

while exporting all the rest from USB. Check/ uncheck respective

checkboxes as desired.

Page 63

Page 61

All the autoclave settings will be imported from the USB device with the

exception of the screen above.

6.10.3 Import application and setting from USB

In this menu you can replace both the application software and the

parameters of the autoclave with the software and parameters from the

USB device.

4. Browse to the following folder:

Version handling\Import application and setting from USB

5. Move the cursor to Confirm and press Start/Stop.

6.10.4 Return to factory default settings

In this menu you can restore the default values of all the changeable

parameters of the cycle and the system. Default settings are those your

autoclave had when it left the factory.

1. Browse to the following folder:

Version handling\Return to factory default settings

2. Move the cursor to Confirm and press Start/Stop. The default factory

settings will be restored.

6.11 Cycle parameters

The Cycle parameters menu includes parameters of a specific

sterilization program (cycle). Browse to the following folder:

Main menu\Cycle parameters

You will see the following screen listing the cycle parameters:

Page 64

Page 62

Note: For all the standard sterilization cycles, and for Bowie and Dick test, the

only changeable cycle parameter is dry time (you will not see other

parameters on your screen). For the custom cycles created by

duplication, and for the Warm Up cycle, all the options listed in table

below are changeable. Operator is not allowed to create custom

cycles; only authorized technician can do this.

Subdirectory

Property

Temperature sensors

Chamber Temperature

Displayed inputs

First

Second

Third

Purge (generator models only)

Purge time

Purge temperature

For custom programs only

Create

Puls

e

Pulse A Count

Pulse A Stay Time

Pulse A Low Pressure

Pulse A High Pressure

Pulse B Count

Pulse B Stay Time

Pulse B Low Pressure

Pulse B High Pressure

Keep Heat

Temperature 1 stay

Temperature 1 stay time

Temperature 2 stay

Temperature 2 stay time

Page 65

Page 63

Heating

Sterilization Temperature

Sterilization

Sterilization Temperature

Sterilization Time

For custom programs only

Cooling (“C”

mod

els

only)

Cool Mode

Cool End Temperature

Cool Exhaust Rate

Exhaust

Exhaust Mode

Drying

Dry Time

Dry Heat On 1

Dry Heat Off 1

Dry First Stage Time

Dry Heat On 2

Dry Heat Off 2

Add Dry Time

Ending

End Temperature

Global

FO Mode

Check RTC

Multiple Cycles

Multiple Cycles Gap

Jacket Temperature

The following chapters explain meaning and usage of the control

screens for the cycle parameters.

6.12 Temperature sensors

6.12.1 Temperature sensors \Chamber Temperature

In case a machine has a number of temperature sensors, there is an option to

assign every chamber temperature sensor to be one of the following:

main, reference, not in use,.

1. Browse to the following folder:

Cycle parameters\Temperature sensors\Chamber Temperature

The following screen will appear:

Page 66

Page 64

2. Using Up and Down keys, move the cursor around the screen and

check the desired radio buttons by pressing Start/Stop.

3. Using Up and Down keys, move the cursor to Save and press

Start/Stop.

6.13 Displayed inputs

This menu defines 2 (or 3, according to the cycle type) input values to

be shown on the display.

You can choose, for each of them: chamber temperature, chamber

pressure, chamber water level, and mineral free water level. Below is

the example of setting the first input.

1. Browse to the following folder:

Cycle parameters\Displayed inputs\First

The following screen will appear:

Using the Up and Down keys, choose first, second, or third.

2. The following screen will appear:

Page 67

Page 65

3. Using Up and Down keys, move the cursor to the desired radio button

and choose it by pressing Start/Stop.

6.14 Purge (generator models only)

There is an option to remove the air from the chamber before

sterilization. Saturated steam is introduced into the chamber and it

pushes the air out through a valve. Purge is usually used for Isothermal

cycle.

1. Browse to the following folder:

Cycle parameters\Purge

The following screen will appear:

2. Change the parameters as desired.

6.15 Create Pulse

This menu allows to set parameters for each pulse of the program (see

below).

Page 68

Page 66

6.15.1 Pulse A Count

This parameter defines how many times the pulse of each type (A, B)

is repeated. For example, if the Pulse count for pulse A (low) is 4, and

the Pulse count for pulse B (high) is also 4, the cycle will have the

following pulses: low-high-low-high-low-high-low-high.

1. Browse (to the following folder:

Cycle parameters\Create Pulse\Pulse A Count

Change the parameter as desired.

Note: Pulse A and B counts for standard programs equal one, with the

exception of Hollow load, Waste, and Bowie and Dick test (pre-vacuum

models only), whose pulse count equals four.

6.15.2 Pulse A Stay Time

This parameter defines the value of delay after the required pressure

for the pulse is reached.

1. Browse to the following folder:

Cycle parameters\Create Pulse\Pulse A Stay Time

Change the parameter as desired.

Note: Same parameters are available for other pulses. The following cycles

have four pulses pre-vacuum models only): Hollow load, Waste, and

Bowie and Dick test. Other cycles have only one pulse.

6.15.3 Pulse A Low Pressure

This parameter defines the lower pressure value for the A pulse.

1. Browse to the following folder:

Cycle parameters\Create Pulse\Pulse A Low Pressure

2. Change the parameter as desired.

Note: Same parameters are available for other pulses. The following cycles

have four pulses pre-vacuum models only): Hollow load, Waste, and

Bowie and Dick test. Other cycles have only one pulse.

Page 69

Page 67

6.15.4 Pulse A High Pressure

This parameter defines the higher pressure value for the A pulse

Browse to the following folder:

Cycle parameters\Create Pulse\Pulse A High Pressure

Change the parameter as desired.

Note: Same parameters are available for other pulses. The following cycles

have four pulses pre-vacuum models only): Hollow load, Waste, and

Bowie and Dick test. Other cycles have only one pulse.

6.16 Keep Heat

There are two optional stages, within the sterilization cycle, when constant

temperature (Temperature 1 or 2 stay) is maintained for certain time

period (Temperature 1 or 2 stay time). Keep Heat starts before heating

and is used to melt solid loads of substances such as agar. Keep Heat

is needed for such loads to become completely liquid before

sterilization starts.

Below is the example of changing the Temperature 1 stay/stay time.

6.16.1 Temperature 1 stay

This parameter allows you to set two temperatures at which the process will

be paused (Keep Heat). It is possible to set the 2 values (Temp 1 stay

and Temp 2 stay).

Browse to the following folder:

Cycle parameters\Keep Heat\Temperature 1 stay

Change the parameter as desired.

6.16.2 Temperature 1 stay time

Page 70

Page 68

This parameter allows you to set two temperatures at which the process will

be paused (Keep Heat). Pause duration is set by Temperature 1 (2)

stay time parameter.

1. Browse to the following folder:

Cycle parameters\Keep Heat\Temperature 1 stay time

Note: same parameters are available for temperature 2.

2. Change the parameter as desired.

6.17 Heating

6.17.1 Sterilization Temperature

This parameter defines the heating temperature for the cycle. At

reaching this temperature, sterilization stage starts. This parameter is

equal to the sterilization temperature of the sterilization section (see

below).

1. Browse to the following folder:

Cycle parameters\Heating\Sterilization Temperature

2. Change the parameter as desired.

6.18 Sterilization

6.18.1 Sterilization Temperature

This parameter defines the sterilization temperature for the cycle.

1. Browse to the following folder:

Cycle parameters\ Sterilization\Sterilization Temperature

2. Change the parameter as desired.

Page 71

Page 69

6.18.2 Sterilization Time

This parameter defines duration of the sterilization stage for the cycle.

3. Browse to the following folder:

Cycle parameters\ Sterilization\Sterilization Time

4. Change the parameter as desired.

6.19 Cooling (“C” models only)

This menu defines parameters for the cooling stage.

6.19.1 Cool Mode

If the setup of your model has the cooling option, and the cycle has the

cooling stage, the Cool mode parameter equals 1, otherwise it equals

0. You can set this parameter as 0 or 1 therefore enabling or disabling

the cooling option.

1. Browse to the following folder:

Cycle parameters\Cooling\Cool Mode

2. Change the parameter as desired.

6.19.2 Cool End Temperature

When the Cool end temperature is reached, the cooling stage is

finished.

1. Browse to the following folder:

Cycle parameters\Cool Mode\Cool End Temperature

2. Change the parameter as desired.

Page 72

Page 70

6.19.3 Cool Exhaust Rate

This parameter defines how quickly the pressure will go down during

exhaust after cooling.

1. Browse to the following folder:

Cycle parameters\Cool Mode\Cool Exhaust Rate

2. Change the parameter as desired.

6.20 Exhaust

This menu defines parameters for the exhaust stage.

6.20.1 Exhaust Mode

The Exhaust mode parameter equals:

1 for fast exhaust in the end,

2 for slow exhaust in the end plus opening the fast exhaust when the

pressure equals 30 kPa above the ambient pressure,

3 for slow exhaust opened during the entire cycle,

4 for BH exhaust mode (see BH cycles explanation).

You can set this parameter and thereby change the exhaust mode.

Browse to the following folder:

Cycle parameters\Exhaust\Exhaust Mode

Change the parameter as desired.

6.21 Drying

This menu defines parameters for the drying stage.

Page 73

Page 71

6.21.1 Dry Time

This parameter defines duration of the drying stage for the cycle.

1. Browse to the following folder:

Cycle parameters\Drying\Dry Time

2. Change the parameter as desired.

Drying stage is divided into two stages. For each stage you can set the

total time, on time and off time. So during the Dry First Stage, the

heating elements are on for the time set in Dry Heat On 1, then they go

off for the time set in Dry Heat Off 1, and then this sequence is

repeated during the entire Dry First Stage Time. The same is true for

the Dry Second Stage.

6.21.2 Dry Heat On 1

This parameter defines how long will the heating elements be on for

the Dry First Stage.

Browse to the following folder:

Cycle parameters\Drying\Dry Heat On 1

Change the parameter as desired.

Note: There are Dry heat On 2 and Dry heat Off 2 parameters for the Dry

Second Stage of the drying.

6.21.3 Dry Heat Off 1

This parameter defines how long will the heating elements be off for

the Dry First Stage.

1. Browse to the following folder:

Page 74

Page 72

Cycle parameters\Drying\Dry Heat Off 1

2. Change the parameter as desired.

Note: There are Dry heat On 2 and Dry heat Off 2 parameters for the Dry

Second Stage of the drying.

6.21.4 Dry First Stage Time

This parameter defines duration of the Dry First Stage. The Dry

Second Stage time is calculated as Dry Time minus the Dry First Stage

Time, that is why there is no Dry Second Stage Time menu.

1. Browse to the following folder:

Cycle parameters\Drying\Dry First Stage Time

2. Change the parameter as desired.

6.21.5 Add Dry Time

This subdirectory allows you to change the Dry Time parameter for the

current cycle.

Browse to the following folder:

Cycle parameters\Drying\Add Dry Time

Change the parameter as desired.

6.22 Ending

This menu defines the End temperature parameter for the Ending

stage.

6.22.1 End Temperature

This parameter defines the temperature when the cycle ends. The

cycle will not end and the door will not open unless the autoclave

chamber is cooled down to this temperature.

1. Browse to the following folder:

Cycle parameters\Ending\End Temperature

2. Change the parameter as desired

6.23 Global (for some models only)

This menu defines the global cycle parameters.

Page 75

Page 73

6.23.1 F0 mode

This parameter checks how long has the load been in sterilization

conditions (pressure, temperature) before the sterilization stage

actually begins. This data helps preventing damage to the load by

excessive exposure to heat and high pressure.

1. Browse to the following folder:

Cycle parameters\Global\F0 mode

2. Change the parameter as desired

6.23.2 Check RTC

In this menu you can set the time interval for checking the two clocks.

The two clocks work during this interval, and the results are displayed.

If the results are different for more than 2 seconds, one of the clocks is

faulty. For the procedure of the check itself, see Maintenance\Test

RTC.

1. Browse to the following folder:

Cycle parameters\Global\Check RTC

2. Change the parameter as desired).

6.23.3 Multiple Cycles

This parameter allows you to repeat, for testing purposes, the same

cycle several times without reloading the autoclave. The number or

repetitions is defined by this parameter.

1. Browse to the following folder:

Cycle parameters\Global\Multiple Cycles

2. Set the parameter as desired.

Page 76

Page 74

6.23.4 Multiple Cycles Gap

This parameter allows you set the time interval between the multiple

cycles (see above).

1. Browse to the following folder:

Cycle parameters\Global\Multiple Cycles Gap

2. Change the parameter as desired.

6.23.5 Jacket Temperature

This parameter defines the temperature of the jacket (for the relevant

models only). The system is not ready unless the jacket reaches this

temperature.

1. Browse to the following folder:

Cycle parameters\Global\Jacket Temperature

2. Change the parameter as desired

Page 77

Page 75

7. Generator description

A built-in steam generator supplies the steam for the sterilization

process. The steam generator is an electrically-heated type, equipped

with immersion heaters, divided into three-phases. The power

consumption of the generator is 9kW.

Water to the steam generator is supplied by a one-phase pump, from a

water reservoir, which is connected to a source of distilled or demineralized water. The electrical system of the steam generator is

located in a separate electric box.

The three-phase heating elements of the steam generator are

controlled by DILM32 contactor for 230V and protected by 20A circuit

breakers.

The water level control system consists of three electrodes connected

to the GICAR 2DRLHG controller, which commands the operation of

the water pump and servo solenoid valve to switch OFF the heating

current in case of lack of water or low water level.

Use only distilled or mineral-free water for the operation of the

generator!

Caution!

It is strictly forbidden to use soft water; this may results in

corrosion of the generator.

Page 78

Page 76

Warning:

Only a qualified electrician may perform the electrical

connections!

The electrical units should not be placed near water sources.

When servicing the generator, disconnect all the electrical power

supplies to the unit. This is done by switching OFF the main

power supply switch, or by un-plugging the electrical power main

supply cords.

It is important to achieve an electrical good grounding connection

to the sheet metal enclosure of the electric box and metal parts of

the generator.

The earth installation at the customer’s site must be built in

compliance with the laws and regulations in force, and should

meet international electrical safety standards, and be certified by

competent authorities.

7.1 Generator Electrical Safety System

There is an electrical safety system to protect the heating elements if a

fault condition is detected by any one of the safety devices, namely:

• Water level too low

• Pressure too high

• Temperature too high, (if applicable)

The fault light on the generator box will light up, and the main heater

circuit breakers will be switched OFF.

If this happens, do not try to correct the fault yourself, but call for

assistance.

Page 79

Page 77

7.2 The Water Pump for the Steam Generator

The water pump supplies the distilled or mineral-free water to the

steam generator.

The supply line of the pump is connected to the upper water reservoir

filled with distilled or mineral-free water and mounted on side of the

autoclave.

A float valve keeps a constant level of water and prevents an overflow

of water out of the reservoir.

A lower float switch stops the operation of pump, when the water level

drops below the lower level limit.

The water pump is protected by a pressure switch. When there is no

compressed air pressure supply to the autoclave the water pump is

disconnected.

7.3 GICAR Water Level Controller

The water level control system consists of three electrodes. (HIGH and

LOW water level), and a reference electrode, all connected to the

GICAR 2DRLHG controller.

Page 80

Page 78

The long electrode which is

continuously immersed in the water,

acts as a reference and is

connected to ground.

The medium electrode (LOW level

electrode) controls the water

heaters. When it stops sensing

water, the GICAR controller stops

the current to the water heaters.

When it senses water, the GICAR

controller restores current to the

water heaters.

The short electrode (HIGH level

electrode), controls the water pump.

When it senses water, the GICAR

controller stops the current to the

water pump and simultaneously

closes water supply shut off valve.

When it stops sensing water, the

GICAR controller restores the

current to the water pump and

simultaneously opens water supply

shut off valve.

Measuring steam generator pressure

The measurement range is 100-600 kPa absolute (14.5–87 psi)

The resolution measurement and display is 1 kPa (0.15 psi).

The accuracy of the measurement is a maximum 1% of the range, i.e. 5 kPa

(0.7 psi)

Calibration of the pressure circuit requires a special engineer access code.

Page 81

Page 79

8. Maintenance and Replacement

Procedures: the Autoclave

Warning!

Do not touch door microswitches in case of malfunction! Call

Tuttnauer service.

8.1 Preliminary Operations for Each Technician Call

In order to maintain efficient service, the technician must perform

the following:

1. Inspect and clean if needed, the following:

Chamber, trays and trays holder (see Maintenance Instructions in the

Operator’s Manual).

Filters (see 8.9 )

Seats and plungers of the solenoid valves (see 8.11 and 8.12 )

Water reservoir.

2. Visual inspection for leaks or corrosion in the piping elements

3. Tightening loose screws and piping joints.

4. Visual inspection of the wiring.

5. Calibration and logging the calibration of the temperature and pressure.

After completing the work, the technician must perform the

following cycles:

6. A Vacuum Test

7. A B&D Test.

Note: The warranty does not cover cleaning or maintenance. These

procedures are the responsibility of the equipment owner.”

By a qualified technician

Page 82

Page 80

Every 6 months

Tighten the bolts of the heater bands and the electrical connections of

the heaters, valves and connectors in the control box.

Drain the generator and refill with mineral free water.

Once a year

Check the grounding continuity.

Calibrate the temperature and pressure.

Perform validation of the autoclave.

Check the precise operation of the earth leakage relay.

Check the safety elements; safety valve, cut-off thermostat, door

locking mechanisms.

Check the operation sequences, the sterilization parameters etc.

Check the water reservoir, piping, plastic parts and electric wires.

Check and tightening the piping joints to avoid leakage.

Check and tighten all screw connections in the control box, heaters and

valves and instrumentation.

Once in 5 years

Check the door closing system for excessive wear.

Performing safety tests: pressure vessel, efficiency, electrical,

according to local rules or regulations.

safety tests shall be perform only, by an authorized inspector.

8.2 Replacing the Circuit Breaker

Caution!