Page 1

TECHNICIAN

MANUAL

Laboratory Vertical Steam Sterilizers

Models: 3840, 3850, 3870

ELVPVG-D

Standard Autoclave

ELVCPVG-D

Including Fast Cooling System

Cat. No. MAN205-0461000EN Rev. B

Tuttnauer Europe b.v., Hoeksteen 11, 4815 PR, Breda, P.O. Box 7191, 4800 GD Breda, Netherlands. +31/76-5423510,

Fax: +31/76-5423540

Page 2

Page 3

Page 1 of 102 Pages

TABLE OF CONTENTS

PARAGRAPH PAGE NO.

1. INTRODUCTION 4

2. SYMBOL DESCRIPTION 4

3. INSTALLATION INSTRUCTIONS 5

3.1 Installation Site............................................................................................ 5

3.2 Connection of the pressure regulator........................................................... 5

4. TESTS 9

4.1 Installation Tests.......................................................................................... 9

4.2 Periodical Tests............................................................................................ 9

5. WATER QUALITY 10

5.1 Water for the Vacuum pump and drain cooling......................................... 10

5.2 Reverse Osmosis......................................................................................... 11

6. DESCRIPTION OF THE CONTROL SYSTEM. 12

6.1 Application system architecture ................................................................. 12

6.2 Description of the programmable component:........................................... 13

6.3 Software development plan:....................................................................... 15

7. CHECKING AND CHANGING PARAMETERS AND OTHER DATA 19

7.1 Directories and subdirectories.................................................................... 19

7.2 Entering the main menu ............................................................................ 21

7.3 Cycle Parameters (Custom 1)..................................................................... 22

7.4 Inputs/Outputs ........................................................................................... 29

7.5 Calibration ................................................................................................ 31

Current value

31

7.6 History........................................................................................................ 33

7.7 Maintenance .............................................................................................. 35

7.8 Advanced Options ...................................................................................... 40

7.9 Version information................................................................................... 44

8. REPLACING ELEMENTS 47

8.1 Replacing the Circuit Breaker.................................................................... 47

8.2 Replacing the Safety Valve......................................................................... 48

8.3 Replacing the Door Gasket ........................................................................ 49

8.4 Replacing the door cover............................................................................ 50

8.5 Replacing the steam generator................................................................... 54

8.6 Replacing Heating elements....................................................................... 56

8.7 Cleaning and Replacing the Water Level Electrodes................................. 56

1.1. Generator Side Gauge Glass Indicator Tube ............................................ 57

1.2. Draining the generator............................................................................... 58

8.8 Replacing the Printer................................................................................. 59

8.9 Replacing the Door Switch......................................................................... 61

8.10 Replacing the air filter ............................................................................... 62

8.11 Replacing the locking motor ...................................................................... 63

Page 4

Page 2 of 102 Pages

8.12 Replacing the Plunger or Coil of the BACCARA Solenoid Valve.............. 64

8.13 Replacing the Mechanic Pressostat............................................................ 65

8.14 Replacing the Pressostat 0.2 (NC).............................................................. 65

8.15 Replacing the power supplies, water level board and relays....................... 66

8.16 The Water Pump Replacement................................................................... 67

1.3. Adjusting the Generator's Pressure Switches............................................. 69

9. TROUBLESHOOTING 70

9.1 No response when turning on the autoclave .............................................. 76

9.2 Solenoid valve always open........................................................................ 77

9.3 Door is closed but the locking motor does not work................................... 78

9.4 9.4 Steam Generator Troubleshooting....................................................... 79

10. LIST OF SPARE PARTS 81

11. PRESSURE VS TEMPERATURE FOR SATURATED STEAM 85

12. VALVES NUMBERING 89

Page 5

Page 3 of 102 Pages

TABLE OF CONTENT (Cont.)

DRAWINGS PAGE NO.

FRONT VIEW..................................................................................................................... 7

WATER OUTLET STRAINER......................................................................................... 84

PIPING DRAWING – MODEL 3840/3850/70 ELVPVG..................................................91

ELECTRICAL WIRING DIAGRAM FOR AUTOCLAVE WITH 380V – PAGE 1 OF 8. 92

ELECTRICAL WIRING DIAGRAM FOR AUTOCLAVE WITH 380V – PAGE 2 of 8...93

ELECTRICAL WIRING DIAGRAM FOR AUTOCLAVE WITH 380V – PAGE 3 of 8...94

ELECTRICAL WIRING DIAGRAM FOR AUTOCLAVE WITH 380V – PAGE 4 of 8...95

ELECTRICAL WIRING DIAGRAM FOR AUTOCLAVE WITH 380V – PAGE 5 of 8...96

ELECTRICAL WIRING DIAGRAM FOR AUTOCLAVE WITH 380V – PAGE 6 of 8...97

ELECTRICAL WIRING DIAGRAM FOR AUTOCLAVE WITH 380V – PAGE 7 of 8...98

ELECTRICAL WIRING DIAGRAM FOR AUTOCLAVE WITH 380V – PAGE 8 of 8... 99

ELECTRICAL WIRING DIAGRAM FOR THE GENERATOR.................................... 100

SWITCH BOX WIRING DIAGRAM .............................................................................. 100

OPEN SWITCH BOX...................................................................................................... 101

CLOSED SWITCH BOX................................................................................................. 102

Page 6

Page 4 of 102 Pages

1. INTRODUCTION

This manual, together with the operator’s manual, forms the complete edition of the

Operation and Maintenance instructions. This manual is intended for the use of the

technician. It is forbidden for unqualified and unauthorized personnel to service the

autoclave in accordance with the instructions in this manual. Any unauthorized

service may result in the invalidation of the manufacturer’s guarantee.

The qualified technician shall be an authorized electrician with the right

qualifications in electronics and shall be familiar with the local technical/electrical

regulations.

2. SYMBOL DESCRIPTION

Caution! Consult accompanying documents

Caution! Hot surface.

Caution! Hot steam.

Protective earth (Ground)

Stand by

Page 7

Page 5 of 102 Pages

3. INSTALLATION INSTRUCTIONS

The following utilities have to be connected (Refer to the drawing below ‘Rear View’

of the autoclave).

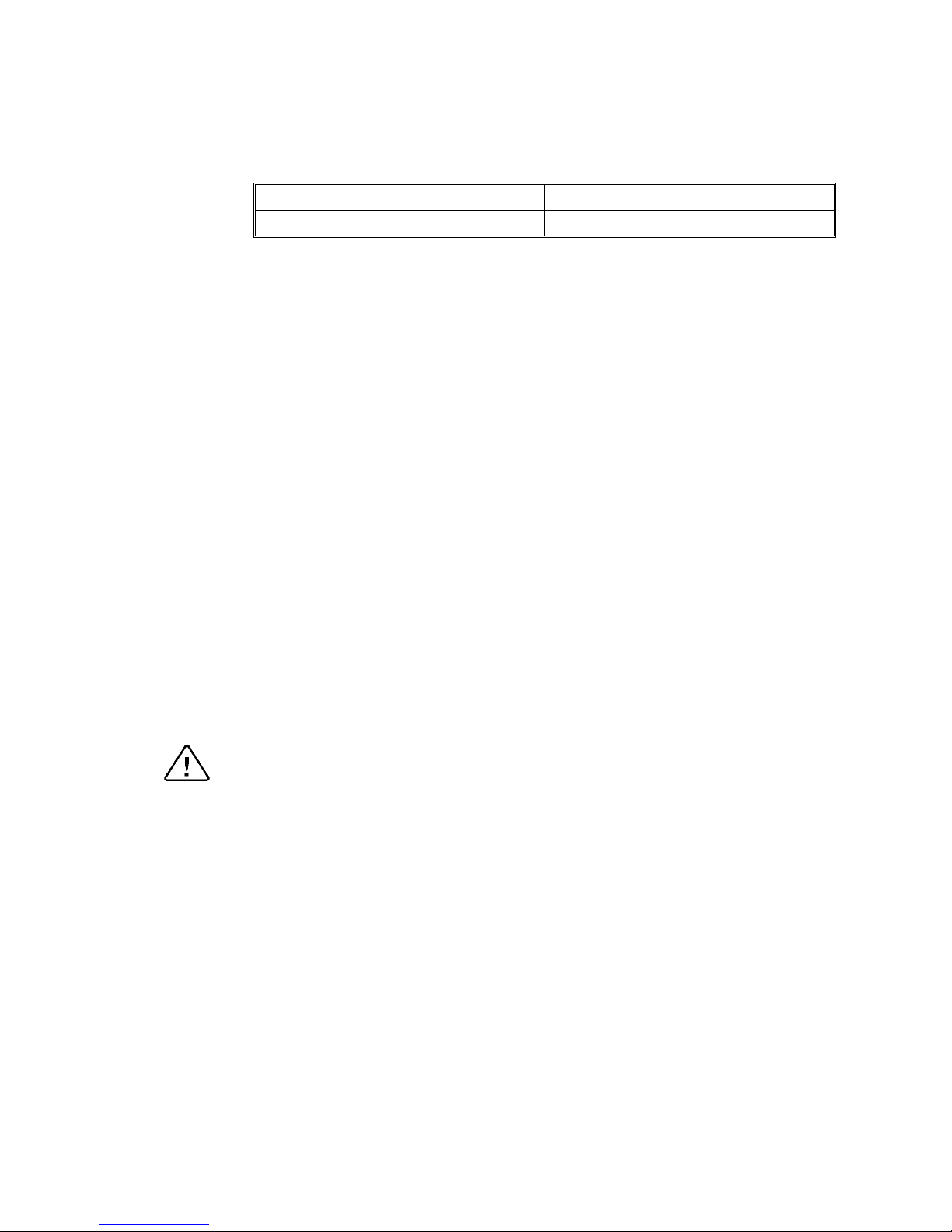

Power outlet, as detailed in the table below:

Power

3 Ph, 400V/50/60Hz

Recommended Circuit Breaker

20A

If the 3 phase autoclave has to be connected to a one phase power network, 1 x

230V, 50/60Hz., connect the 1ph 230V power source to the supplied switch box

that has a 1 phase input (from the power source) and a 3 phase output (to the

autoclave). See details at the end of this manual.

The power network must be protected by a current leakage relay.

Mineral-free water having a conductibility lower than 15µs (microsiemens),

through a 1/2” flexible hose.

To obtain water quality meeting requirements a deionization column or reverse

osmosis apparatus can be installed. The water must be delivered at a pressure of 23bar. A pressure reducer shall be installed at the water source outlet as instructed

below.

For fast cooling (if this option is provided):

Feed water from the water network, pressure 2-3bars, connected through a 1/2”

pipe. A pressure reducer shall be installed at the water source outlet as instructed

below.

Compressed air, from a mobile compressor or compressed air network at pressure

3-4 bars, will be set at 1.6-2bars at the autoclave inlet is to be connected by a

flexible conduit of 3/16”.

The air must be of instrumental quality filtered at 5µ and free of humidity and oil

drops.

Drain connected by 1/2” pipe, located at the rear of the unit. The chamber exhaust

and coolant water is evacuated to an open waste funnel. The drainage piping must

be heat resistant, to 80ºC, non-continuous flow.

Attention:

Connection of water system to the autoclave must be performed through "BACK

FLOW PREVENTION SYSTEM" installation as per EN 1717.

3.1 Installation Site

1. Install the autoclave according to the following guidelines:

2. Place the autoclave on the floor. Verify that the surface is leveled.

3. All utility supplies must be prepared in accordance with requirements,

before autoclave installation e.g. mineral-free and tap water, compressed

air, one or three-phase power network, connection to the drain of the

building.

4. Leave the space free around the autoclave for maintenance and service

requirements.

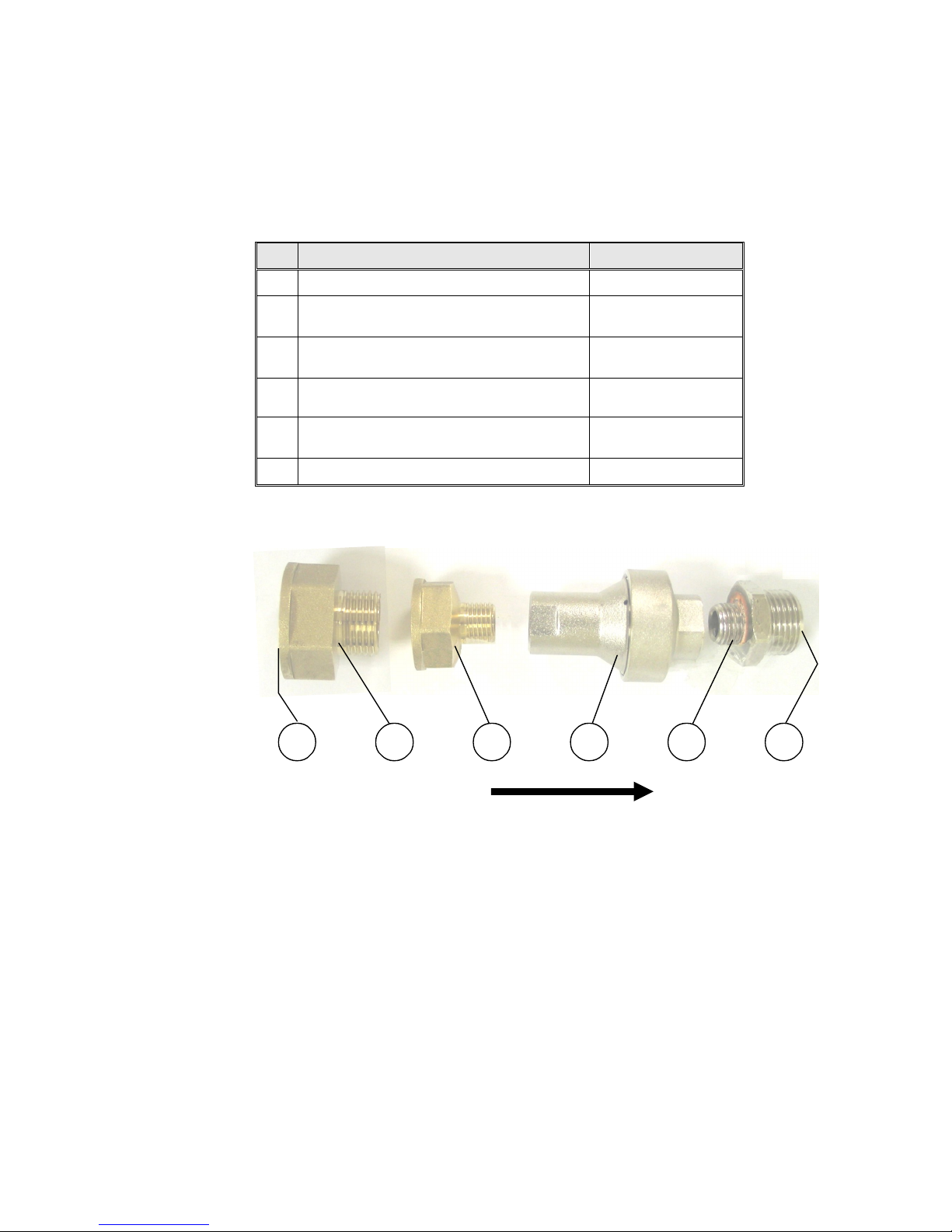

3.2 Connection of the pressure regulator

This paragraph refers to the pressure regulator of the feed water and to the

pressure regulator of the mineral free water.

1. Attach the pressure regulator to the facility's water outlet.

Page 8

Page 6 of 102 Pages

FLOW DIRECTION

54321

6

2. Connect the supplied flexible hose to the pressure regulator's assembly

outlet and to the autoclave's water inlet.

3. Verify that the pressure regulator is in right direction. The flow direction

is indicated by an arrow stamped on the pressure regulator.

4. Verify that water flows freely in the feed water and in the mineral free

water lines.

No. Description Cat No.

1 Side of water supply source N/A

2

Reducer, Female 3/4" BSP to Male

1/2" BSP, Brass

FIT100-0424

3

Reducer, Female 1/2" BSP to Male

1/4" BSP, Brass

FIT100-0425

4

Pres

sure Regulator, Water, In

-

Line,

with Strainer, 1/4 x 1.5 bar

GAU029-0059

5

Fitting, Adaptor, M 1/2" BSP x M 1/4"

BSP, Brass Ni plated

PNE100-0042

6 Side of flexible hose (to autoclave N/A

Page 9

Page 7 of 102 Pages

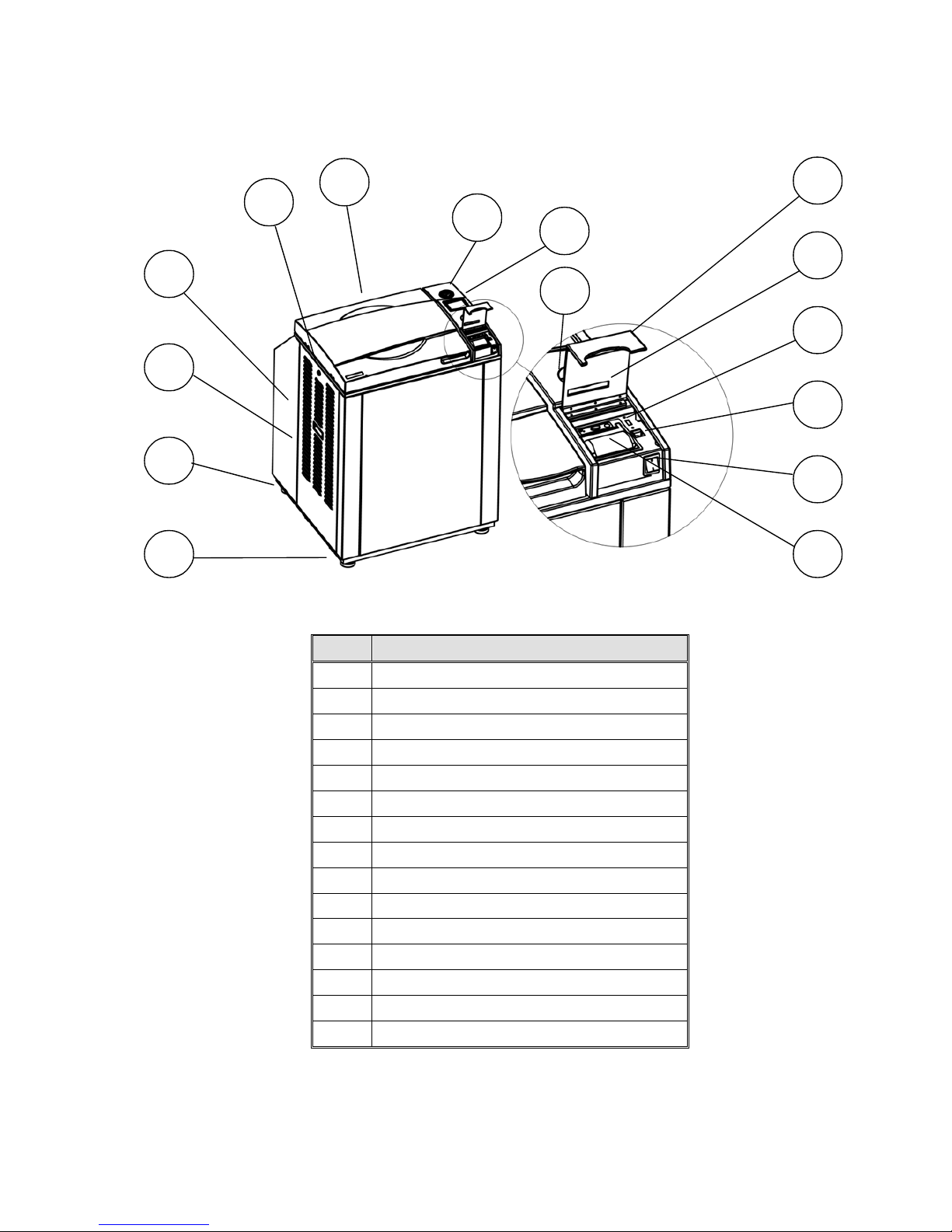

FRONT VIEW

No. Description

1 Front leg

2 Rear leg

3 Left service door

4 Left service door grip

5 Left service door lock

6 Door cover

7 Pressure gauge

8 Display

9 Keyboard

10 Printer cover

11 Paper slot and paper cutter

12 USB socket

13 RJ45 connector

14 Main switch

15 Printer

9

10

5

6

7

8

11

14

15

4

3

2

1

12

13

Page 10

Page 8 of 102 Pages

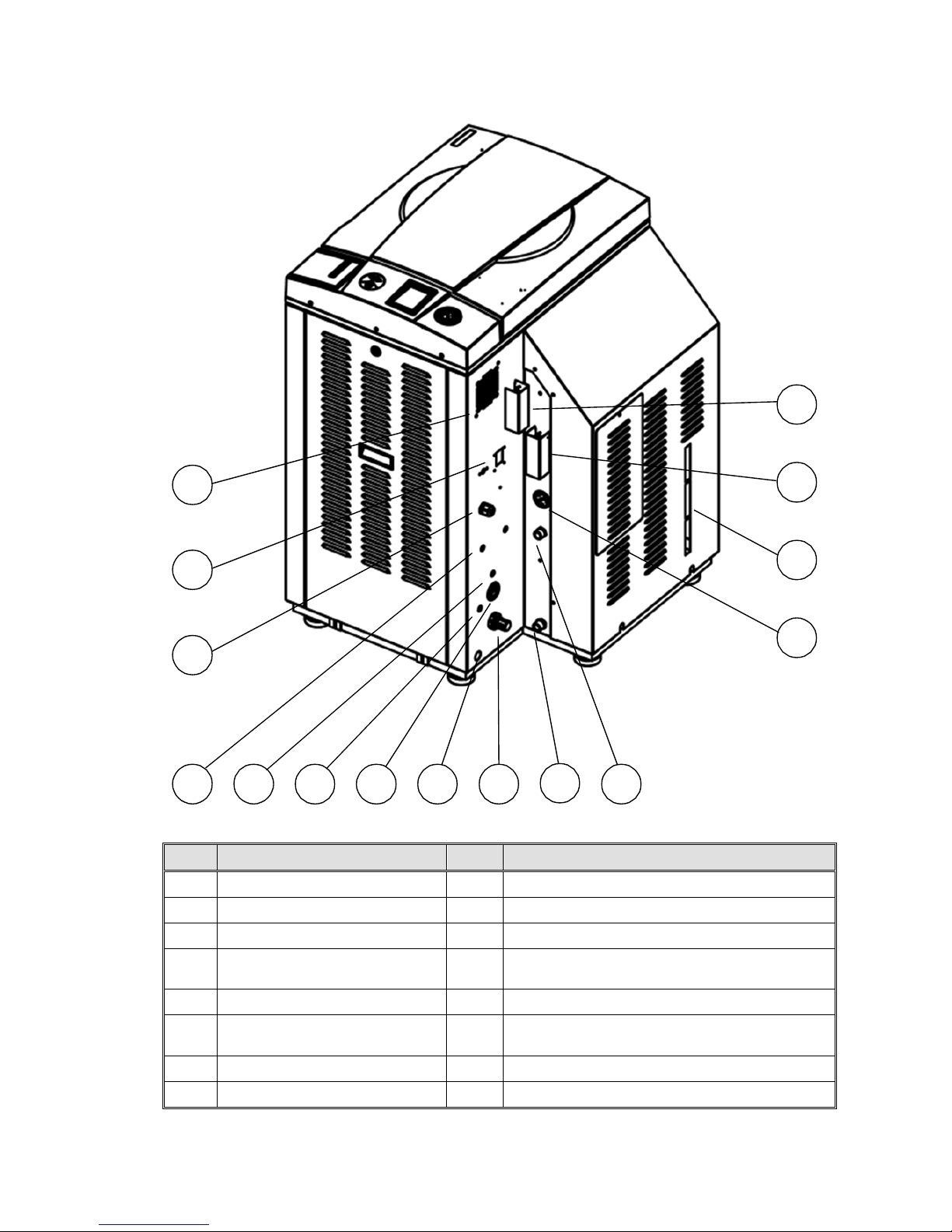

REAR VIEW

No. Description

No. Description

1 fan grill 9

air pressure regulator

2 circuit breaker 10

generator drain outlet

3 electrical cord

11 Generator mineral free water inlet

4

Vacuum pump city (tap)

water inlet

12 generator pressure gauge

5 compressed air inlet

13 side gage glass indicator tube

6

Tap water inlet for cooling

coil and drain

14 generator safety relief valve

7 autoclave air pressure gauge

15 chamber safety relief valve

8 autoclave drain outlet

7810111 2

3

4

5

6

14 131215

9

Page 11

Page 9 of 102 Pages

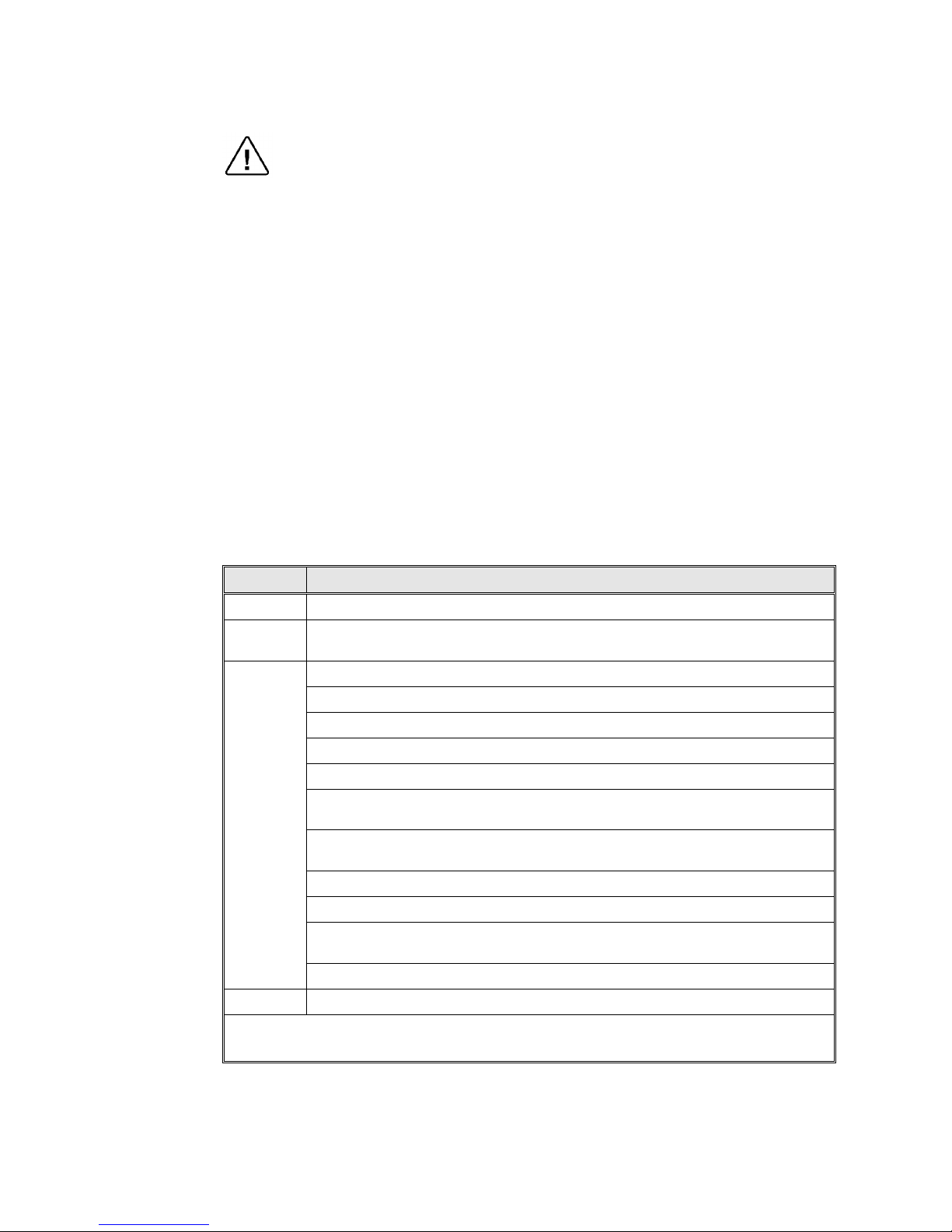

4. TESTS

4.1 Installation Tests

The service technician shall perform the following preliminary checks

before operating the autoclave:

a. Integrity Check

Perform a visual check to verify that there are no dents, scratches,

broken gauges, etc.

b Leveling Check

Check that the autoclave is leveled.

c. Leakage current test

Check the precise operation of the earth leakage relay.

d. Continuity Check

Check the continuity of the grounding connection.

At this stage operate the autoclave and continue with the tests:

e. Safety Check

Check the safety elements; safety valve and the door locking mechanisms.

f. Programs Check

Run basic programs of the autoclave and check the operation

sequences, the sterilization parameters etc.

g. Validation

Validate the sterilization cycles, taking in consideration the interface of

packaging/goods/autoclave.

After the above steps are performed, the autoclave is ready for operation.

4.2 Periodical Tests

PERIOD TEST

2 months Test the safety valve by operating it.

6 months

Remove the cover of the autoclave, tighten the, valves and connectors in

the controlbox.

Year

Check the continuity of the grounding connections.

Check the temperature and pressure calibration.

Perform validation of the autoclave.

Check the precise operation of the earth leakage relay.

Check that the autoclave is leveled.

Check the safety elements; safety valve, safety and cut-off thermostats

door locking mechanisms.

Run basic programs of the autoclave and check the operation sequences,

the sterilization parameters etc.

Check the water reservoir, piping, plastic parts and electric wires.

Check and tighten the piping joints to avoid leakage.

Check and tighten all screw connections in the control box, valves and

instrumentation.

Observe the closing device for excessive wear

5 years Observe the closing device for excessive wear

Safety tests (pressure vessel, efficiency, electrical) shall be performed in accordance

with local rules or regulations, by an authorized inspector.

Only an authorized technician shall perform the 6-months and yearly tests!

Page 12

Page 10 of 102 Pages

Check connections to distilled or mineral free water. Open the distilled or

mineral free water valves. Manually test the distilled or mineral free water

valves by over-riding the appropriate solenoid valves. If there are no leaks, –

leave the water manual inlet taps open.

1. Observe the gauge and see that the generator reaches working pressure.

Check that the jacket pressure gauge, reaches 2.4 bars (35 psi).

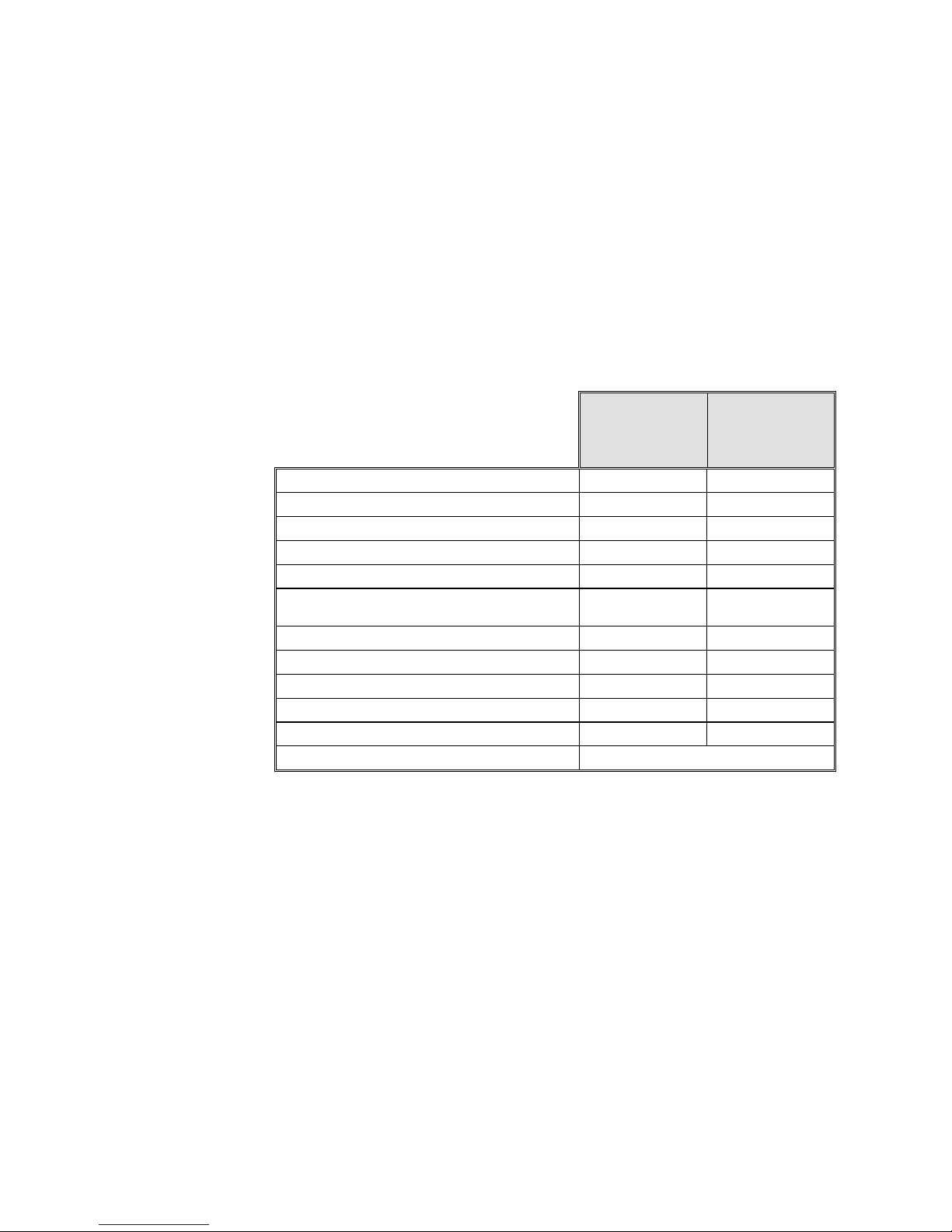

5. WATER QUALITY

Physical Characteristics and Maximum acceptable

contaminant levels in water or steam, for steam generator and

sterilizers

(According to EN 285:2006).

Contaminants

in water

supplied

to generator

Contaminants

in condensate

at steam inlet

to sterilizer

Evaporate residue

≤ 10 mg/l N/A

Silicate (SiO

2

≤ 1 mg/l ≤ 0.1 mg/l

Iron

≤ 0.2mg/l ≤ 0.1mg/l

Cadmium

≤ 0.005 mg/l ≤ 0.005 mg/l

Lead

≤ 0.05 mg/l ≤ 0.05 mg/l

Rest of heavy metals except iron,

cadmium, lead

≤ 0.1 mg/l ≤ 0.1 mg/l

Chloride (Cl)

≤ 2 mg/l ≤ 0.1 mg/l

Phosphate (P2O5)

≤ 0.5 mg/l ≤ 0.1 mg/l

Conductivity (at 25°C)

≤ 5 µs/cm ≤ 3 µs/cm

pH value (degree of acidity)

5 to 7.5 5 to 7

Hardness (Σ ions of alkaline earth)

≤ 0.02 mmol/l ≤ 0.02 mmol/l

Appearance

Colourless, clean, without sediments

Compliance with the above data should be tested in accordance with

acknowledged analytical methods, by an authorized laboratory.

Attention:

We recommend testing the water quality once a month. The use of water

that do not comply with the table above may have severe impact on the

working life of the sterilizer and can invalidate the manufacturer’s

guarantee.

5.1 Water for the Vacuum pump and drain cooling

The feed water supplied to the liquid ring vacuum pump must meet the

following requirements:

Hardness: 0.7 - 0.2 mmol/l.

Water temperature: shall not exceed 15°C.

Page 13

Page 11 of 102 Pages

Note:

The use of heavy scaled water for the vacuum pump cooling, can cause

blocking of the rotor and put the pump out of operation. This invalidates the

guarantee for the vacuum pump.

5.2 Reverse Osmosis

A Reverse Osmosis system may be used to improve the quality of the water

used to generate steam in the autoclave chamber. The use of mineral free will

contribute to better performance and longer life of the autoclave.

Page 14

Page 12 of 102 Pages

6. DESCRIPTION OF THE CONTROL SYSTEM.

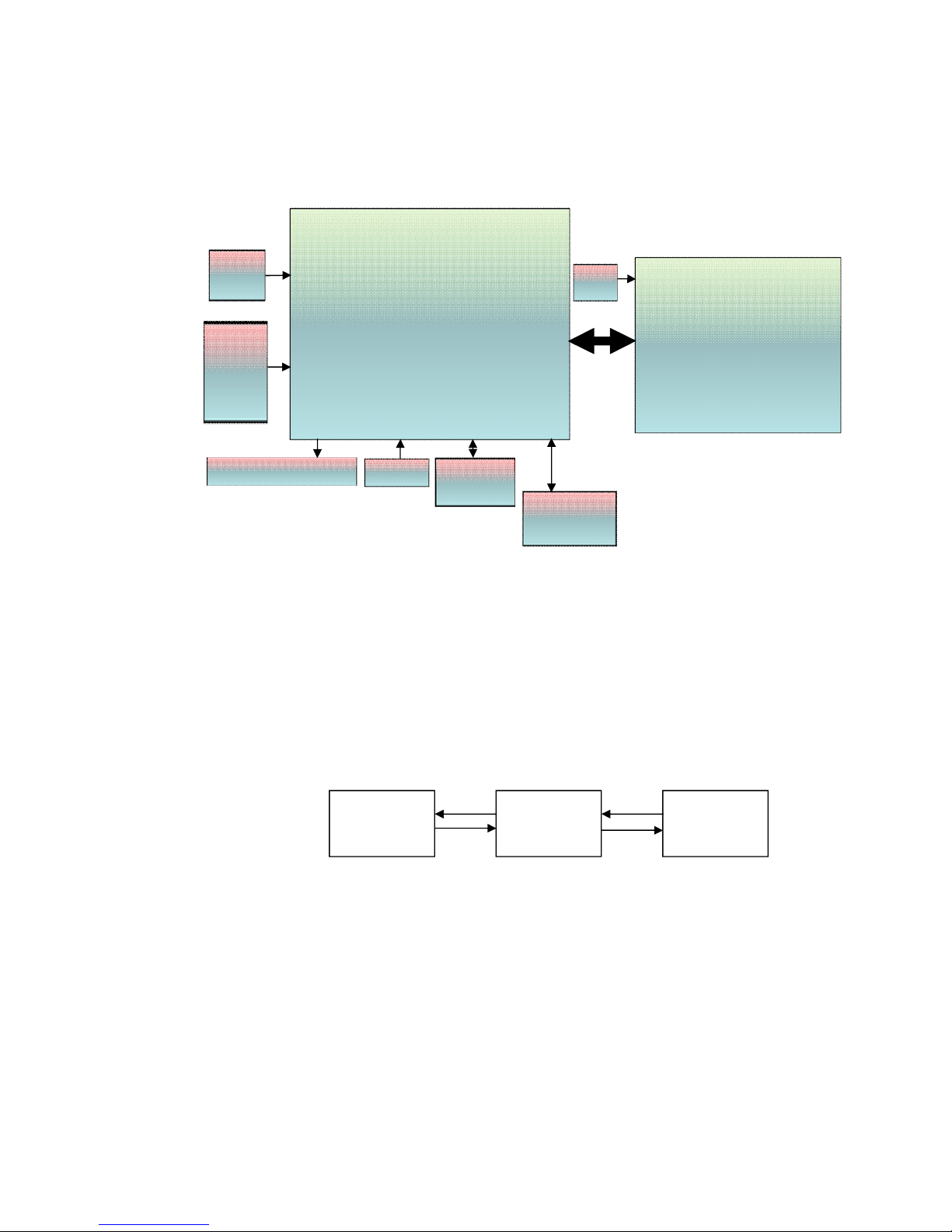

BLOCK DIAGRAM HARDWARE SOFTWARE COMPONENTS

6.1 Application system architecture

The system is divided into three main sections (dll)

1. GUI – holds all the Human Machine interface including the main

application screen and all the configuration screens which enable the user

to handle the machine.

2. Logic – holds all the application logic for running the machine.

3. Utilities – Holds general functionality which is used by the logic section

and the GUI section e.g: converting function for displaying different

pressure or temperature units type, languages etc..

Mapping of the software to the hardware – see Software Development Plan

The Hardware architecture is based on Freescale i.MX27 PDK Evaluation

Board.

GUI LOGIC UTILITY

Main board

-CPU +memory- Backup power input

-MCIMX27LVOP4 A+MC13783VK5

-R.T.C (including Battery) M41T81SM6E

-Memory card expansion

MT46H32M16LFBF-

6:B+EPM570F256C5+S71WS256PD0HF3SR0C+K

9F1G08ROB-JIB000

Ethernet

Am79C874

I/O Board

CPU- STM32F103R6T6

-24 Digital Outputs

-2 Analog outputs

-9 Digital inputs

-4 Analog Inputs 4-20mA

-6 Analog inputs Temp pt100

-3 Inputs water level

Keypad

Graphic Display 3.5 "

USB Memory

socket

ISP1504ABS

24/12

VDC

Input

COM1

(RS232)

MAX323

2CSE+

Printer

24/12

VDC

Page 15

Page 13 of 102 Pages

6.2 Description of the programmable component:

6.2.1 Interfaces to users

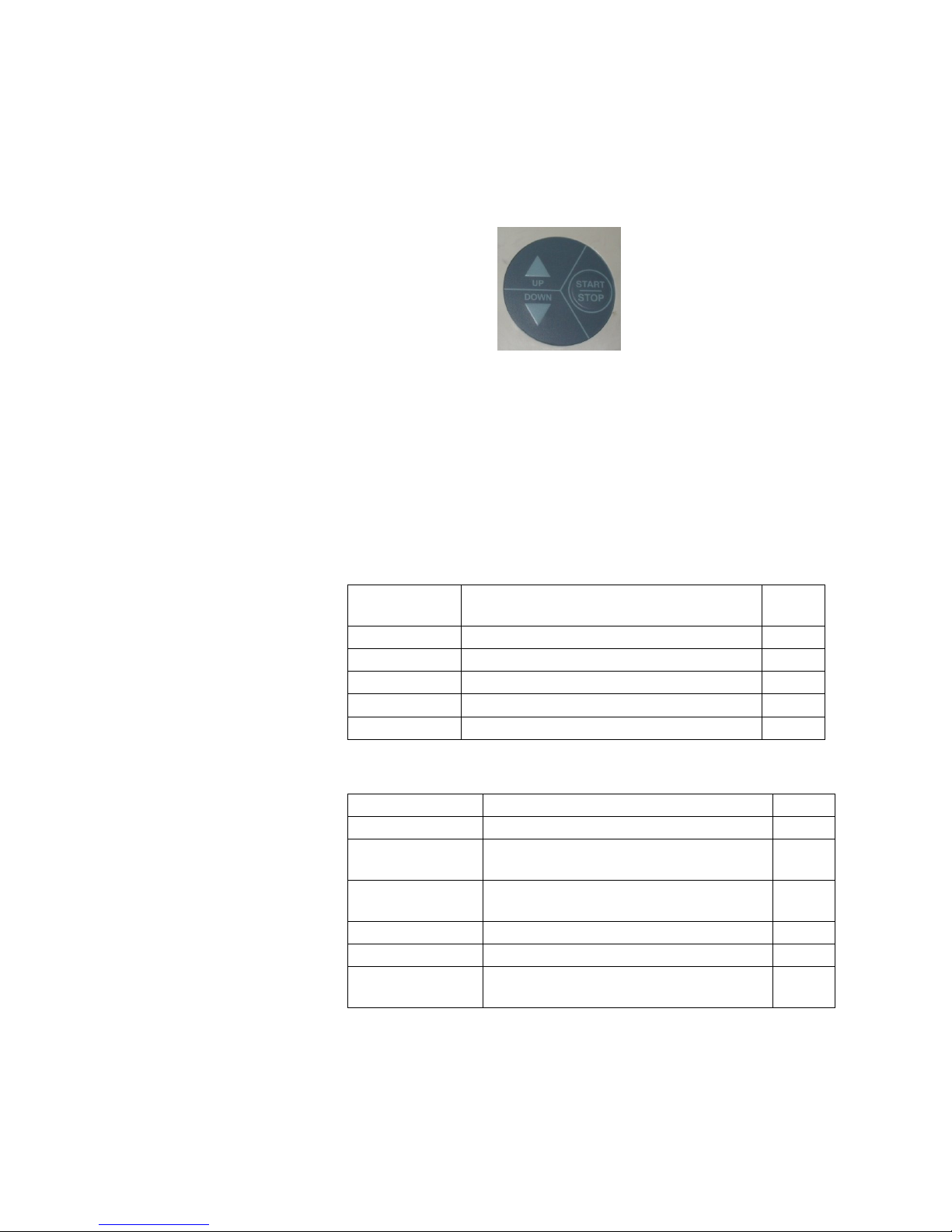

Keypad: The keypad has three push buttons:

o Down key

o Up key

o Start/stop key

Display: The control system has a graphical display

USB socket: The USB socket is intended to load cycles'

history from flash a memory (disk on key). The

received file is in txt format that can be loaded

onto a PC.

6.2.2 Inputs and Outputs

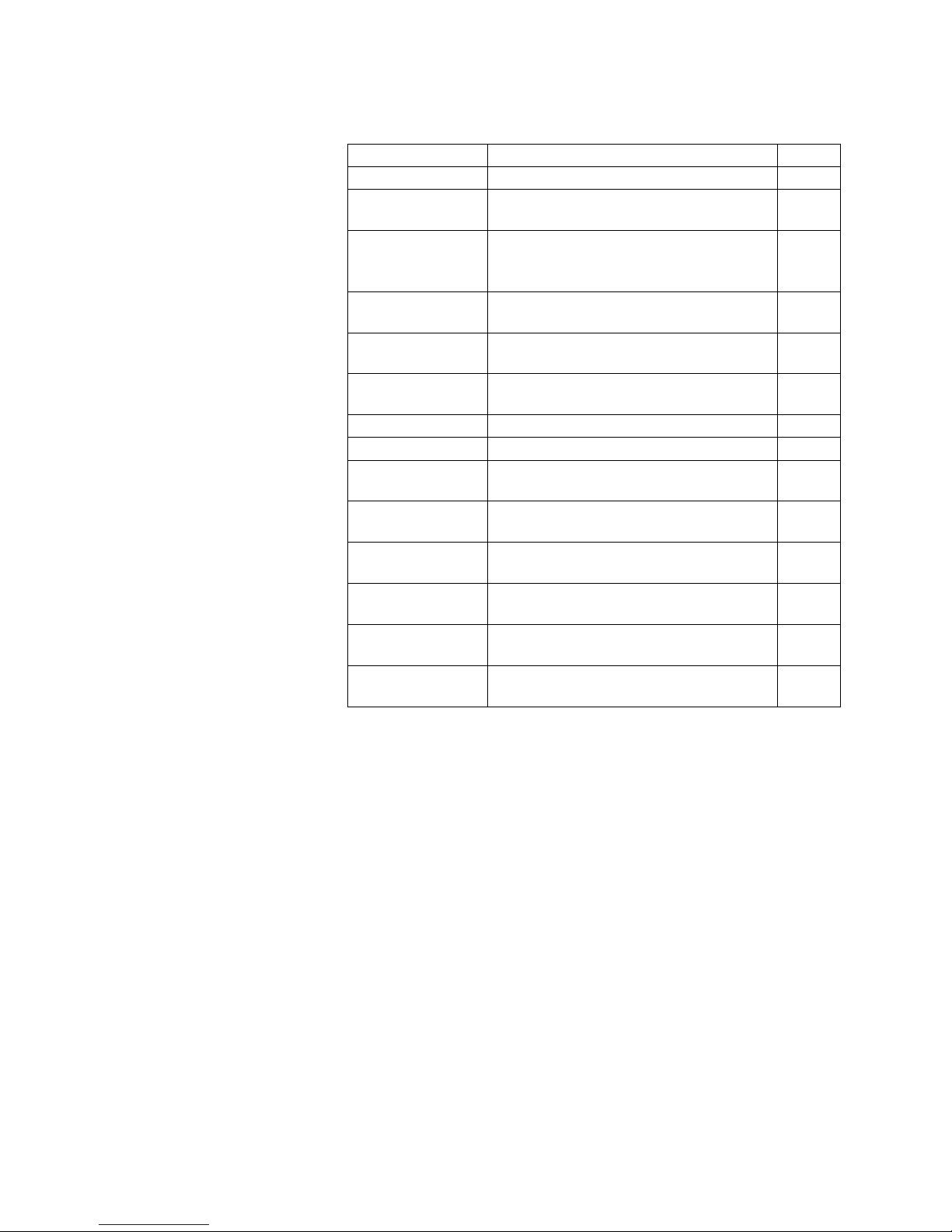

6.2.2.1 Analog inputs

Analog

inputs

Description JP

PT100-1 PT-100 Chamber Temperature J2

PT100-2 PT-100 Ref Temperature1 J3

PT100-4 PT-100 Drain (option) J5

Pressure 1 4-20mA main chamber pressure control J7/1

Electrode 1 Water level camber/generator control 1 J11/1

6.2.2.2 Digital inputs

Digital Inputs Description JP

Door 1 closed Indicate door 1 closed J12/1

Door 1 locked

Indicate door 1 locked (3850/70

models)

J12/8

Door1 open

switch

Indicate to command to close / open

Door1 (3850/70 models)

J12/6

Water supply Indicate water supply (Cooling option) J12/2

Air supply Indicate Air supply (Cooling option) J12/4

Distilled water

supply

Indicate distilled water supply J12/3

Page 16

Page 14 of 102 Pages

-

6.2.2.3 Digital outputs

Digital Outputs Description JP

Generator heaters SSR that operates the chamber heaters J13/6

Water pump /

water valve

Option , relay that operates the water

pump / water valve

J13/10

Vacuum pump /

water to vacuum

pump

Option , relay that operates the

vacuum pump / water to vacuum

pump

J13/12

Vacuum

Option, vacuum valve for pre vacuum

option

J14/2

Compressed air

to chamber

Option, compressed air to chamber

valve for cooling option

J14/4

Top/slow

exhaust

Top/slow exhaust valve J14/6

Fast exhaust Fast exhaust valve J14/8

Atmospheric air Atmospheric air valve J14/10

Cool drain

Option, cool drain valve for cooling

option

J14/12

Steam to

chamber

Steam to chamber valve J14/14

Water to coil

Option, water to coil valve for cooling

option

J14/16

Compressed air

to coil

Option, compressed air to coil valve

for cooling option

J15/2

Closed door 1

Relay that operates the electrical

cylinder to close the door

J15/4

Open door 1

Relay that operates the electrical

cylinder to open the door

J15/6

6.2.3 Actuators

The control system operates electrical valves (solenoids), Electric

cylinder motors, pneumatic cylinders, electric pumps, heaters.

6.2.4 On / off switch

A Rocker Switch 250V AC, 16A

Page 17

Page 15 of 102 Pages

6.3 Software development plan:

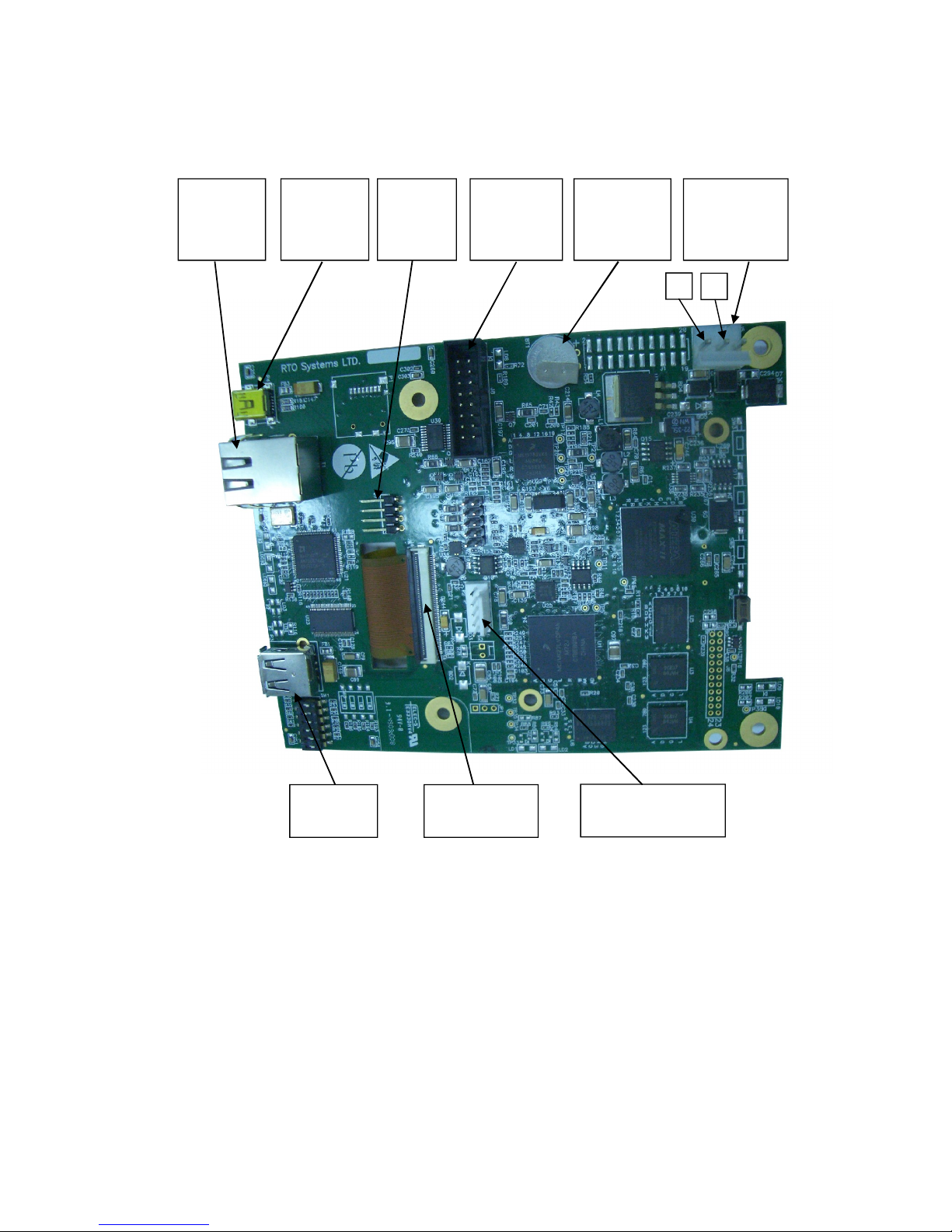

The hardware is consisted of cards: MAIN and IO

6.3.1 Main card

Operating system (MAIN card)

The Operating system is Microsoft Windows CE version 6. The

code to the Operating system is supplied by Microsoft. The

connection code between the Operating system and the

hardware components (BST – Board Support Package) is

supplied by FreeScale. Minimum suitability for this

"Tuttnauer" project is performed in this code.

Development tools (MAIN card)

The software develop environment is on Microsoft Visual

Studio 2005 that includes the Microsoft Platform Builder for

Windows CE 6.0. The specific Tuttnauer system application is

written in C Sharp.net on Microsoft Compact Framework .net

Power Supply

Connector

(24V DC)

Connector to

printer

+

Ethernet

ConnectorSDNot in use

USB

Connector

-

Connector

to IO Board

Connector to

LCD display

Connector

to Keypad

Lithium coin

battery T.H

Horizontal

3V 48mAh

J5

BT1

J8

J4

P2

P4

T1

P3

J3

Page 18

Page 16 of 102 Pages

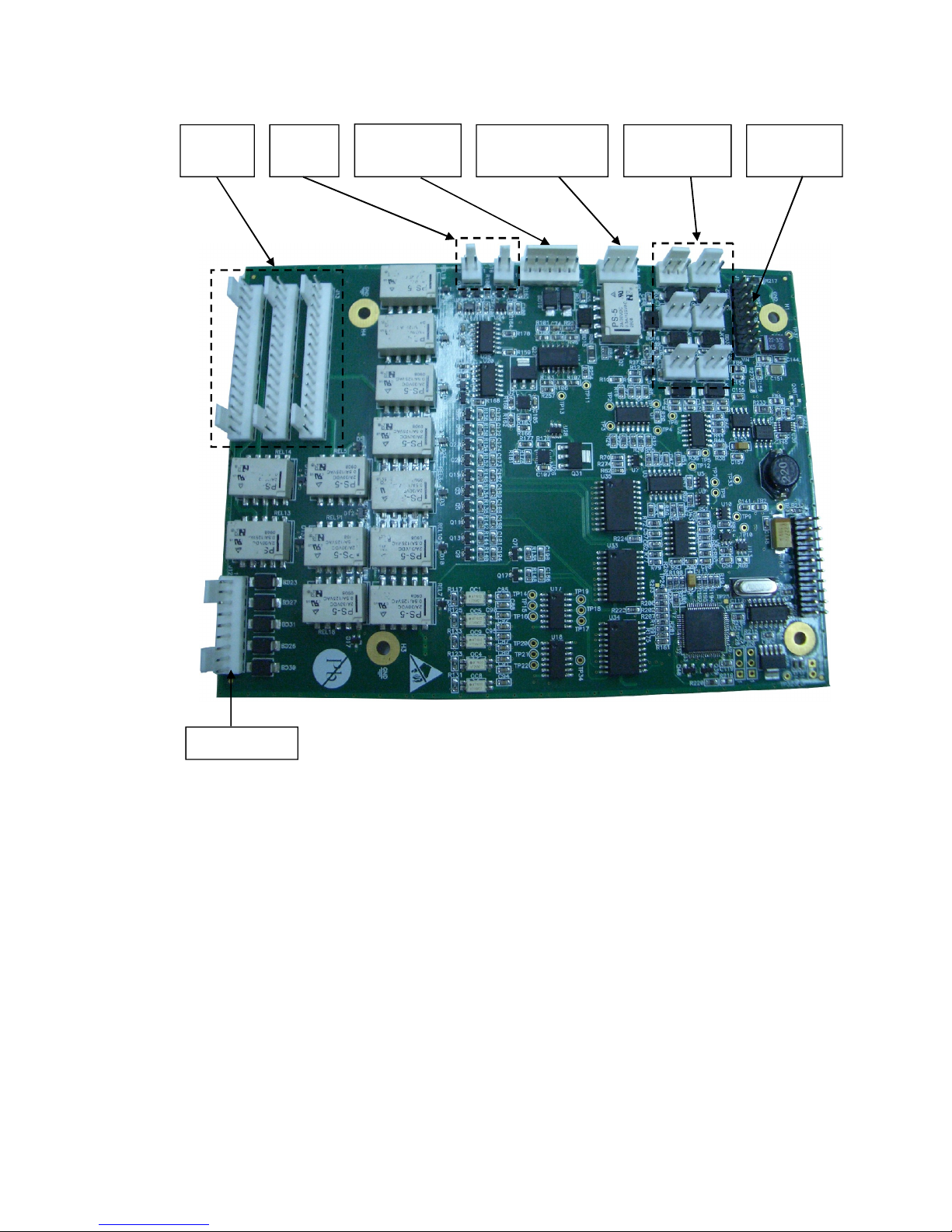

6.3.2 IO Card

IO card is an independent card. It checks the card by a method of a

continuous scan of all the ports, saving the data in the memory and

transporting this data according to the request in the communication

channel RS-232 to the personally adapted protocol.

At the end of the check process of the digital and analog ports, the

communication channel is checked, in case of receiving a request,

the request is checked and if the request is legitimate it will be taken

care of.

The IO card is controlled by the MAIN card. Only when requests

are received from the MAIN, the requests will be checked and

performed.

The IO card will perform an electrical restart of the systems (IO

card) if it does not receive requests within 5 seconds. In the next

request received from the MAIN, the IO card will indicate to the

requester of IO card systems restart.

Analog inputs

(PT-100)

Analog inputs

Pressure (4

-

20mA)

Analog inputs

electrodes

J

J

J6

J3

J4J1

J7J11

J16J17

J13J15J14

Connection to

MAIN Board

Analog

outputs

Digital

outputs

Digital outputs

J12

Page 19

Page 17 of 102 Pages

The "brain" in the IO card runs on microcontroller type:

STM32F103R6T6.

The Microcontroller is an electrical Integrated circuit with an

actualized complete system (SoC) including a processing unit,

external interfaces, memory, etc.

The Microcontroller is constructed of a number of main

components:

1. Central processing unit – the main component in the

microcontroller is a central processing unit (CPU) This unit is

in charge of receiving the request (command) code from the

memory, deciphering, receiving variable data from the

memories and performing the command.

2. Memory – divided into 2 sections.

2.1 software memory – in this memory the software that

samples the IO card and request (command) from the

user are saved. As this memory is a flash memory it is

possible to burn the code many times (efficient to the

development stage).

2.2 information memory – in this memory the data and other

variables values are saved. This memory is not flash

memory, but is RAM memory.

Digital / Analog ports (in/out) – through them the

microcontroller can receive data of digital/analog

signs from the system, save them and pass them on

respectively to the user request.

Ports (in / out) to the communication – in the IO card

there is a UART component. This component enables

communication with the MAIN card through the RS232 in suitable protocol.

Page 20

Page 18 of 102 Pages

6.3.3 MAIN and IO cards :communication protocol between IO board

to Main Board

Communication protocol between IO to Main boards is described

below.

The communication manged by the Main board (master), the IO

functions as slave

1. There are six communication functions.

The communication functions (to read or write) identified by

number.

The communication functions listed below:

1.1 01 - Read – command to IO send all the information of

digital analog inputs.

1.2 02 - Write – Command to IO to activate analog and

digital outputs.

1.3 03 - Read version – IO software version to verify the

version.

1.4 04 – N.A.

1.5 05 - Read number that identifies the ID of IO board and

the software version.

1.6 06 - Write (only at the first time) to IO his ID and

software number.

2. First Byte (Byte 1).

The first byte identifies ID functionality request. It can be one

of the numbers in a paragraph.

3. The second byte will present the data size if the main board

asks to write information to the IO. If the request is to read this

byte will be 00.

4. The number of the request. This number is increased from 00ff.

5. Check sum of the package – to prevent mail functionality of the

board if there is interference in communication.

6. The information package transfer. The information contains

number of the input or output and data for/from each I/O.

Bytes identify number of input or output followed by two bytes

containing the data of the input or outputs.

7. Last byte contains a check sum of the entire package that is

transferred. This is to verify that the information is not

corrupted.

Example

The main board sends:

01;00;0003;0004;

01 Ask to Read inputs.

00 not transfer information.

0003 Request number 3

0004 Checksum to verify the request

Page 21

Page 19 of 102 Pages

7. CHECKING AND CHANGING PARAMETERS AND OTHER DATA

The control system prevents changing programs if the door is closed. This protection

is intended to avoid program changes if the autoclave is loaded. If the operator for

example inserts the load into the chamber, closes the door and leaves the room and

another operator/user tries to change the program, the operator/user will not be able to

do this unless the door is opened and the load inside the chamber can be seen.

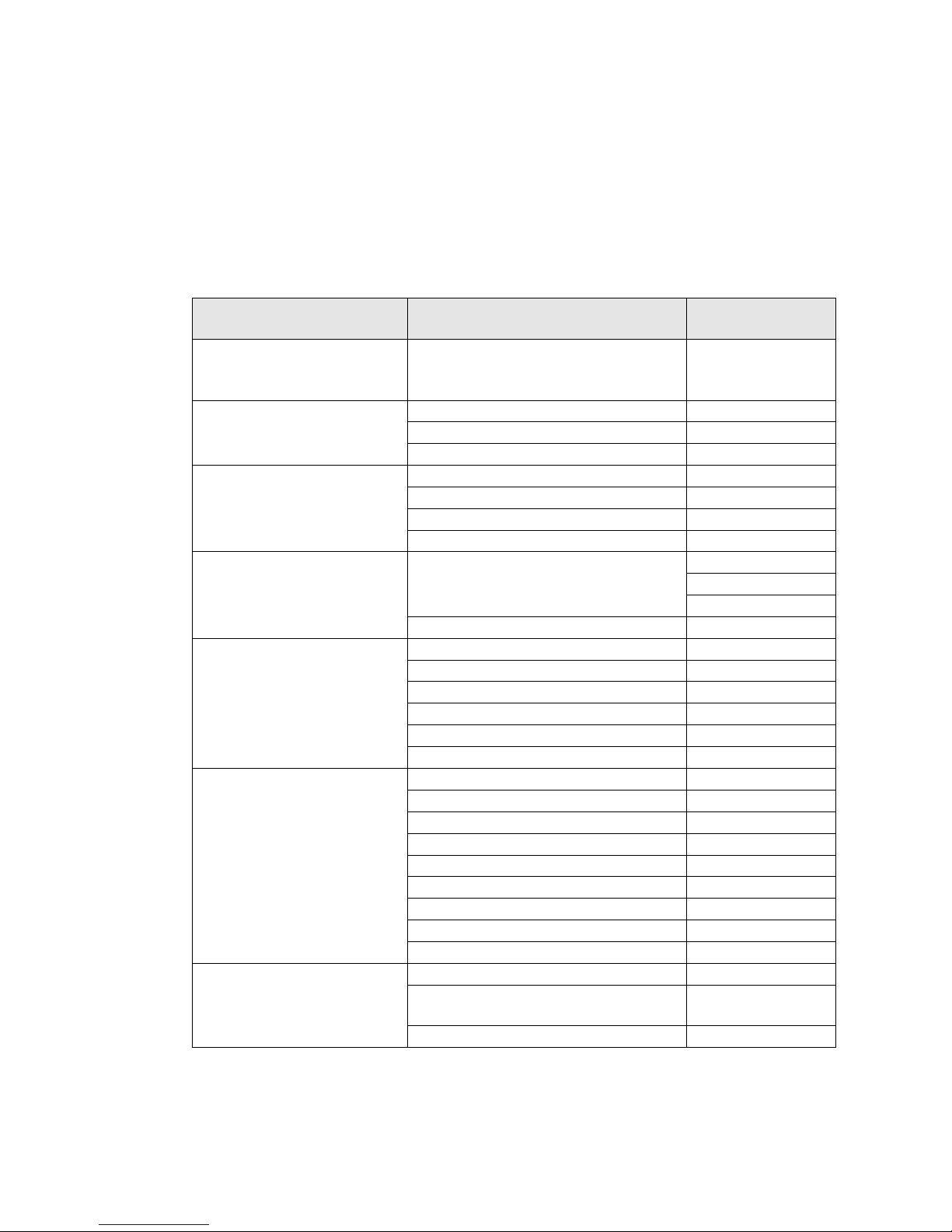

7.1 Directories and subdirectories

The Technician may perform the following:

DIRECTORY SUBDIRECTORY

SECOND

SUBDIRECTORY

Cycle Parameters –

applicable only for Custom

1 and Custom 2 programs

See sec. 6.4 “Cycle Parameters

(Custom 1)”

System Parameters

Print Rate All

Print Rate Sterilization

Screen Saver

Inputs / Outputs

View digital inputs state

View digital outputs state

Test digital outputs

View analog inputs state

History

View old cycle history

Last 10 cycles

Last 50 cycles

All cycles history

Export history to USB

Maintenance

set date and time

Export gain offset to USB

Reset atmospheric pressure

Test RTC

Printer test

Print all gain and offset

Advanced options

Start cycle by clock

Enable cycles

Set language

Set Temperature units

Set pressure units

Export all settings to USB device

Add Custom Program

Set Master IP address

Set mac address

Version information

View current version information

View factory default version

information

View previous version information

Page 22

Page 20 of 102 Pages

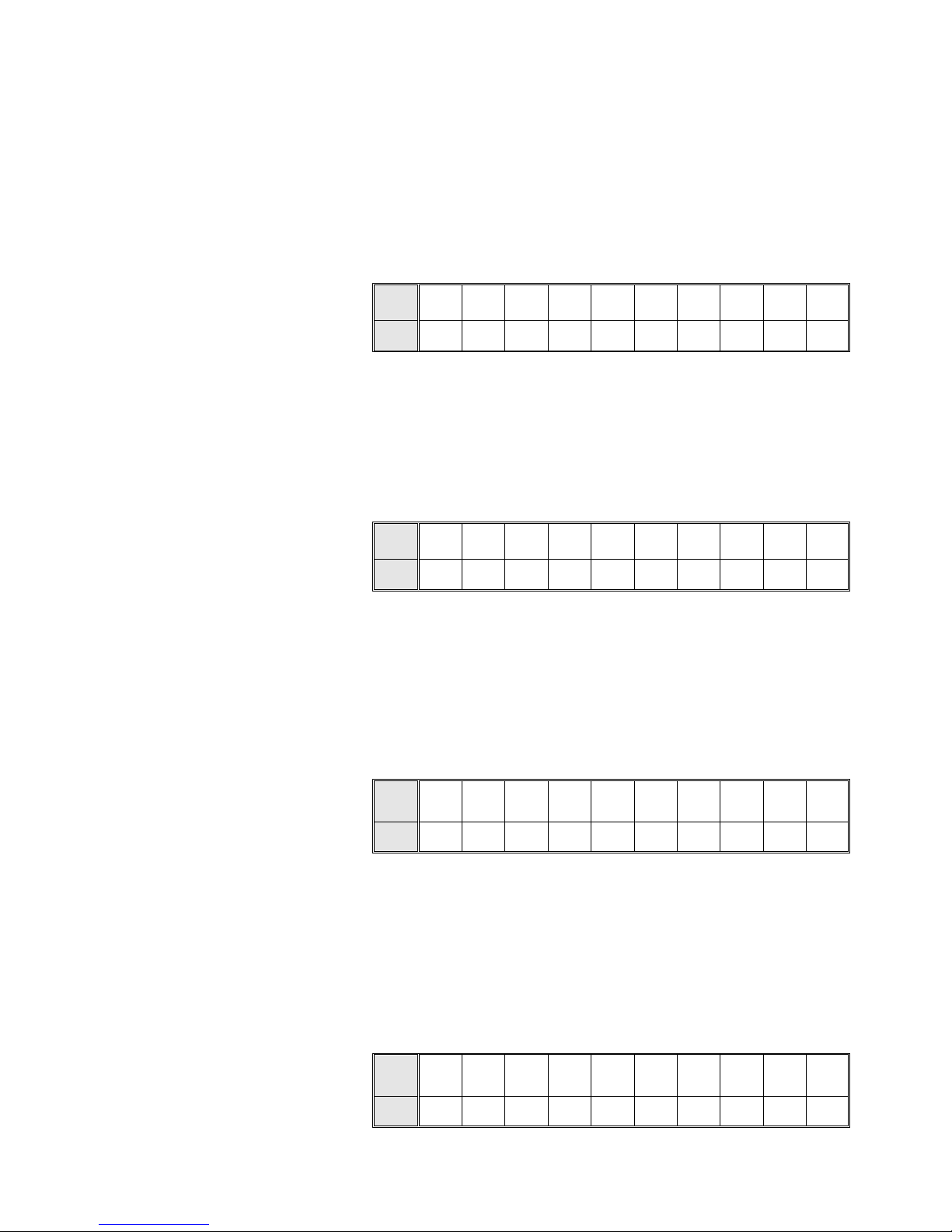

9.3.1 PulsNum. – No. of pulses in the prevacuum stage

If the autoclave is not equipped with a vacuum pump – the parameter

value is "0".

Entry Code – 11

Resolution – 1

Minimum Value – 1

Maximum Value – 5

Set

value

Cycle 1-2 3 4 5 6-7

8-9

-

10

11 12 13 14

Value

1 1 1 3 1 1 1 1 1 1

9.3.2 VacDip1 – Vacuum value in the first pulse

Defines the vacuum value in pulse no.1 of the prevacuum stage.

Entry Code – 11

Resolution – 1kpa

Minimum Value – 1kpa

Maximum Value – 90kpa

Set

value

Cycle

1-2 3 4 5 6-7

8-9

-

10

11 12 13 14

Value

25 25 25 25 25 25 25 25 25 18

9.3.3 VacDip2 – Vacuum value in the remaining pulses

This value defines the vacuum in the remaining pulses in the

prevacuum stage (not just pulse no. 2)

Entry Code – 11

Resolution – 1kpa

Minimum Value – 1kpa

Maximum Value – 90kpa

Set

value

Cycle 1-2 3 4 5 6-7

8-9-

10

11 12 13 14

Value

25 25 25 25 25 25 25 25 25 18

9.3.4 Vac Time 1 – Vacuum Time in the First Pulse

This value defines the time the system will continue to maintain

vacuum for the first pulse after reaching Vac Dip1

Entry Code – 11

Resolution – 30sec

Minimum Value – 1sec

Maximum Value – 1800sec

Set

value

Cycle 1-2 3 4 5 6-7

8-9-

10

11 12 13 14

Value

120 120 120 120 240 120 120 120 120 3

Page 23

Page 21 of 102 Pages

9.3.5 Vac Time2– Vacuum Time in the remaining pulses.

This value defines the time the system will continue to maintain

vacuum after reaching Vac Dip2 for the remaining pulses.

Entry Code – 11

Resolution – 30sec

Minimum Value – 1sec

Maximum Value – 1800sec

9.3.6 Puls Press – pulse pressure during pre-vacuum stage.

This parameter is used to set the maximum pressure in each pulse of

the pre-vacuum stage.

Access Code – 13

Resolution – 5

Minimum Value – 75

Maximum Value – 200

Set

value

Cycle

1-2 3 4 5 6-7

8-9-

10

11 12 13 14

Value

140 140 140 140 140 140 140 140 140 140

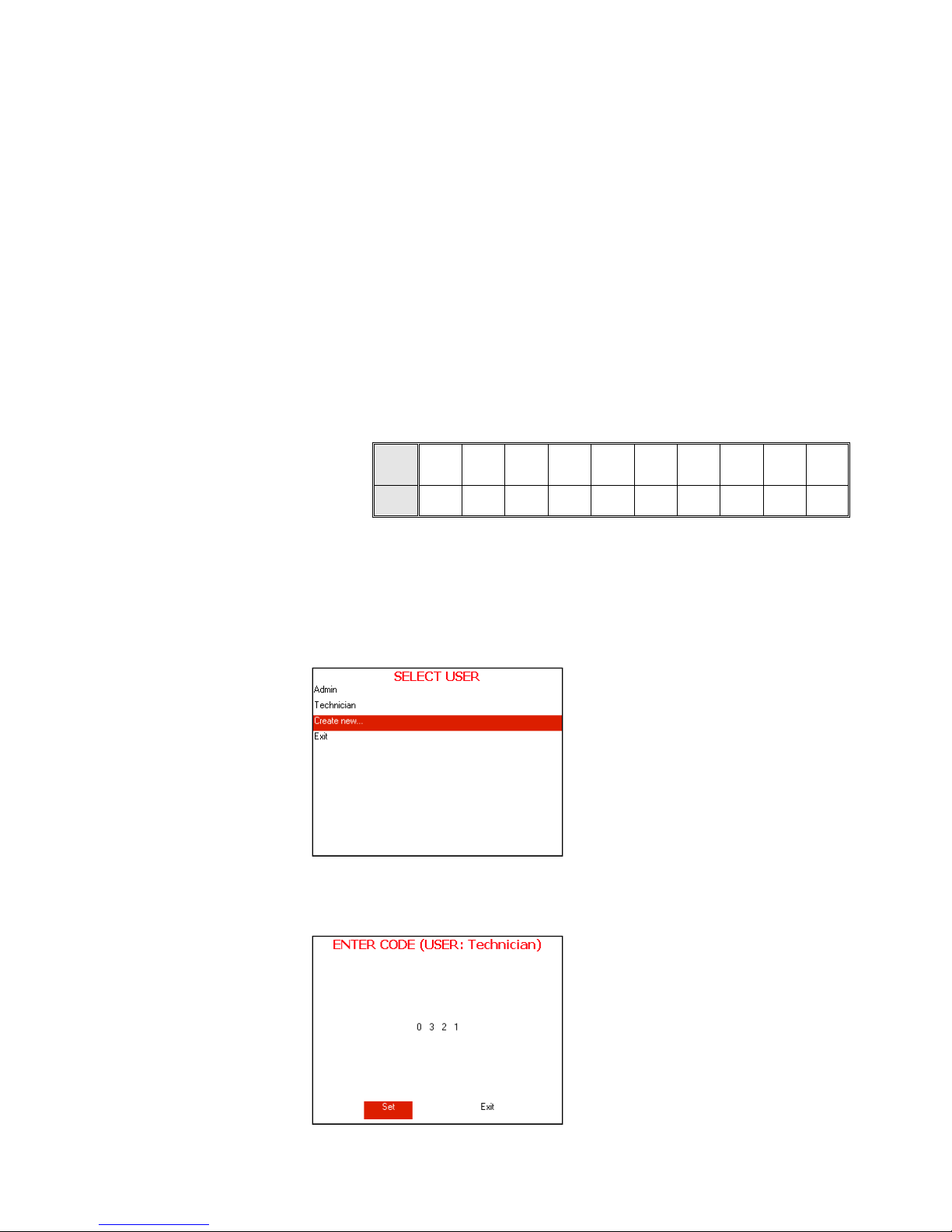

7.2 Entering the main menu

1. Enter the SELECT USER screen by pressing the UP and DOWN keys

simultaneously.

To exit the SELECT USER screen move the cursor to Exit by pressing

UP or DOWN keys and then press START/STOP key.

SELECT USER screen will be displayed.

2. Move the cursor to Admin and press START/STOP key. The following

screen will be displayed:

Page 24

Page 22 of 102 Pages

3. 0000 is displayed on the screen with the cursor blinking on the right

digit.

4. To increase or decrease the digits, press the UP or DOWN keys.

5. After changing the code to 0321 move the cursor to Set by pressing the

START/STOP key.

6. When Set is blinking, press the UP or DOWN keys to enter the MAIN

MENU of the autoclave.

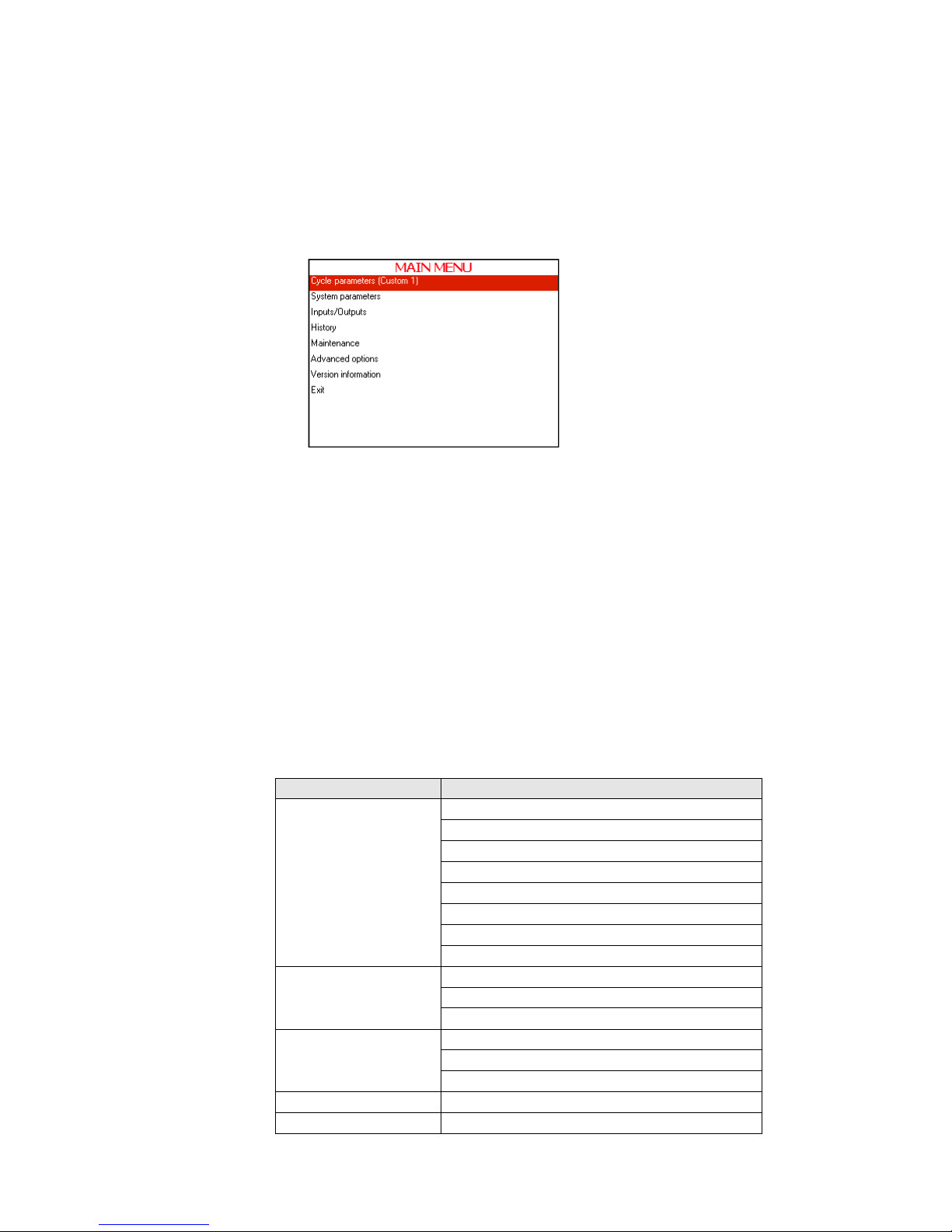

The following screen will be displayed:

In order to exit the ENTER CODE screen move the cursor to Exit by

pressing START/STOP Key. when Exit is blinking press UP or

DOWN keys.

7. To browse through the directories, use the UP or DOWN keys.

8. When the required directory is blinking, press the START/STOP key.

The required screen will be displayed.

9. In order to exit this screen follows one of the next:

Move the cursor to Exit with the UP or DOWN keys and select it

by pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

7.3 Cycle Parameters (Custom 1)

This directory applicable only for custom 1 and custom 2 programs

Subdirectory Property

Create Pulse

Pulse A Count

Pulse A Stay Time

Pulse A Low Pressure

Pulse A High Pressure

Pulse B Count

Pulse B Stay Time

Pulse B Low Pressure

Pulse B High Pressure

Sterilization

Sterilization Temperature

Sterilization Time

F0 Mode

Cooling

Cool mode

Cool End Temperature

Cool Exhaust Rate

Exhaust Exhaust Mode

Dry Dry Heat On 1

Page 25

Page 23 of 102 Pages

Dry Heat Off 1

Dry first stage time

Dry Heat On 2

Dry Heat Off 2

End

End Temperature

Multiple Cycles

Multiple Cycles Gap

This directory includes seven subdirectories

These subdirectories enable to see and change the cycle parameters.

Therefore it is necessary to choose the required cycle before entering the

"MAIN MENU".

For seeing or changing the parameters proceed as follows:

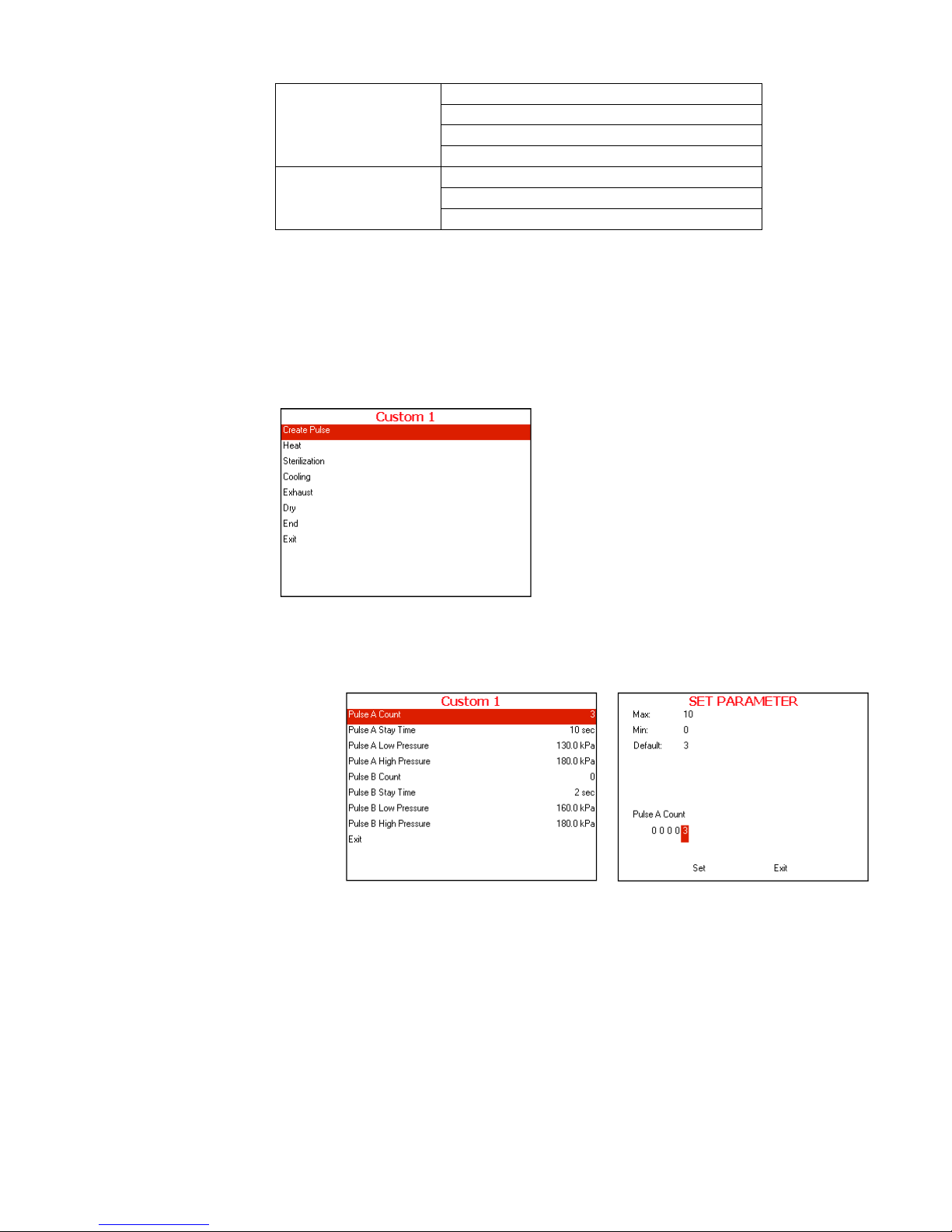

Choose and enter cycle parameters

The following screen will display:

7.3.1 Create Pulse

7.3.1.1 Pulse A Count

Choose and enter Pulse A Count

SET PARAMETER screen will be displayed

Set the required value, move to Set and press UP or

DOWN keys to confirm the parameter value.

In order to exit move the cursor to Exit and press UP or

DOWN keys

7.3.1.2 Pulse A Stay Time

Repeat the action mention in 7.4.1.1 Pulse A Count

Typical display for

Create Pulse

subdirectory

Page 26

Page 24 of 102 Pages

7.3.1.3 Pulse A Low Pressure

Repeat the action mention in 7.4.1.1 Pulse A Count

7.3.1.4 Pulse A High Pressure

Repeat the action mention in 7.4.1.1 Pulse A Count

7.3.1.5 Pulse B Count

Repeat the action mention in 7.4.1.1 Pulse A Count

7.3.1.6 Pulse B Stay Time

Repeat the action mention in 7.4.1.1 Pulse A Count

7.3.1.7 Pulse B Low Pressure

Repeat the action mention in 7.4.1.1 Pulse A Count

7.3.1.8 Pulse B High Pressure

Repeat the action mention in 7.4.1.1 Pulse A Count

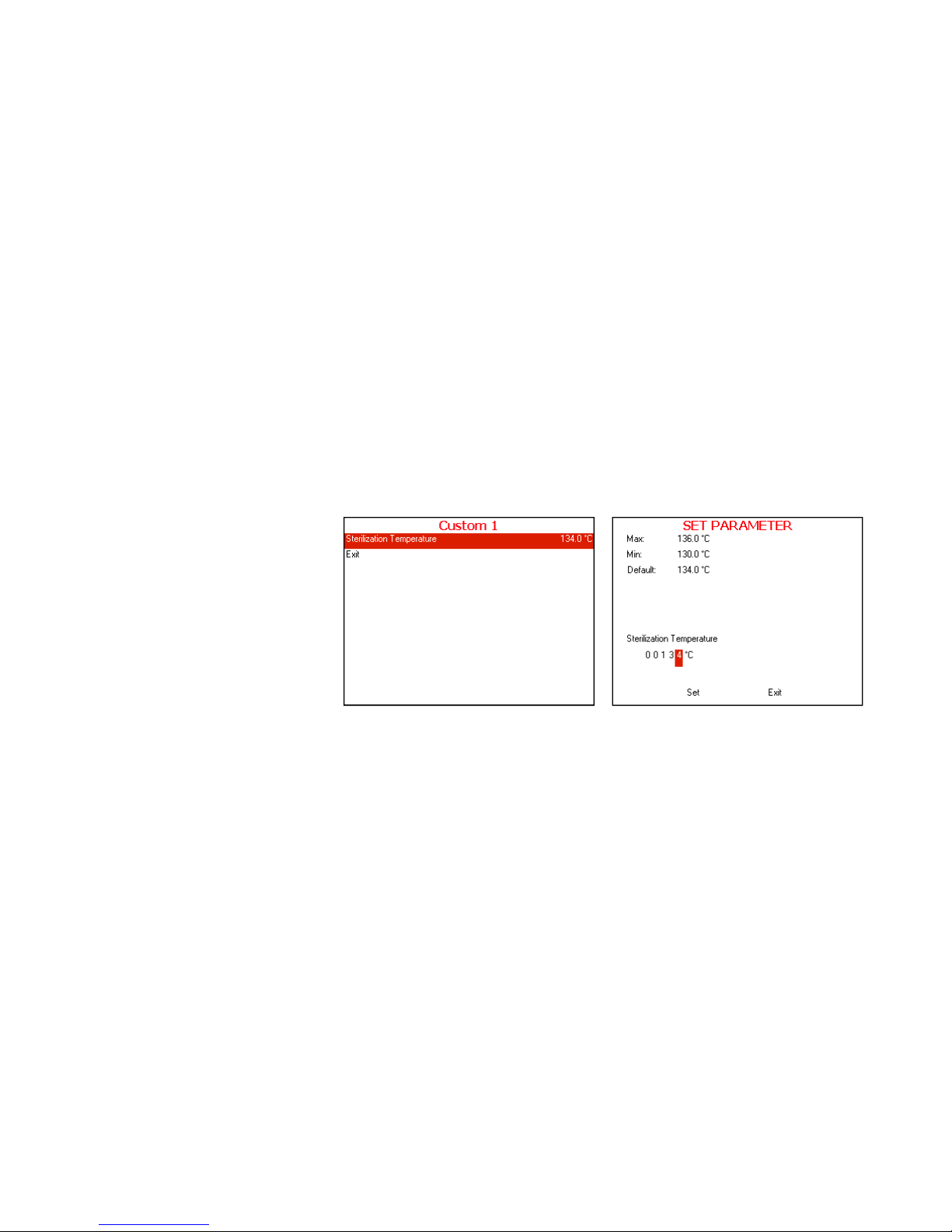

7.3.2 Heat

7.3.2.1 Sterilization Temperature

Choose and enter Sterilization Temperature

SET PARAMETER screen will be displayed

Set the required value, move to

Set and press UP or

DOWN keys to confirm the parameter value.

In order to exit move the cursor to Exit and press UP or

DOWN keys

7.3.3 Sterilization

7.3.3.1 Sterilization Temperature

See 7.4.2.1 Sterilization Temperature

7.3.3.2 Sterilization Time

Repeat the action mention in 7.4.2.1 Sterilization

Temperature

7.3.3.3 F0 Mode

Repeat the action mention in 7.4.2.1 Sterilization

Temperature

Typical display for

Sterilization Temperature

subdirectory

Page 27

Page 25 of 102 Pages

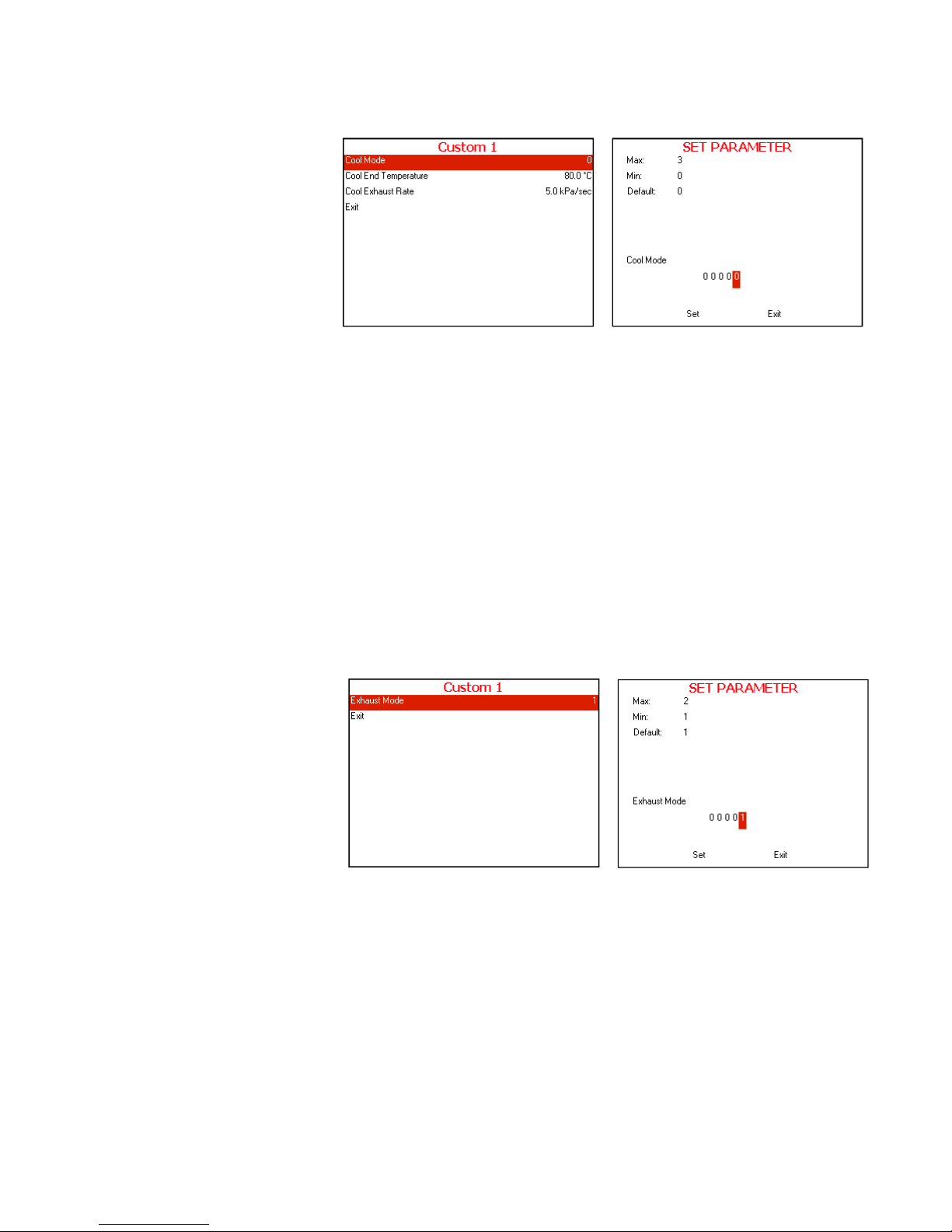

7.3.4 Cooling

7.3.4.1 Cool Mode

Choose and enter Cool Mode

SET PARAMETER screen will be displayed

Set the required value, move to Set and press UP or

DOWN keys to confirm the parameter value.

In order to exit move the cursor to Exit and press UP or

DOWN keys

7.3.4.2 Cool End Temperature

Repeat the action mention in 7.4.4.1 Cool Mode

7.3.4.3 Cool Exhaust Rate

Repeat the action mention in 7.4.4.1 Cool Mode

7.3.5 Exhaust

Exhaust Mode

Choose and enter Exhaust Mode

SET PARAMETER screen will be displayed

Set the required value, move to Set and press UP or

DOWN keys to confirm the parameter value.

In order to exit move the cursor to Exit and press UP or

DOWN keys

Typical display for

Cool Mode

subdirectory

Typical display for

Exhaust Mode

subdirectory

Page 28

Page 26 of 102 Pages

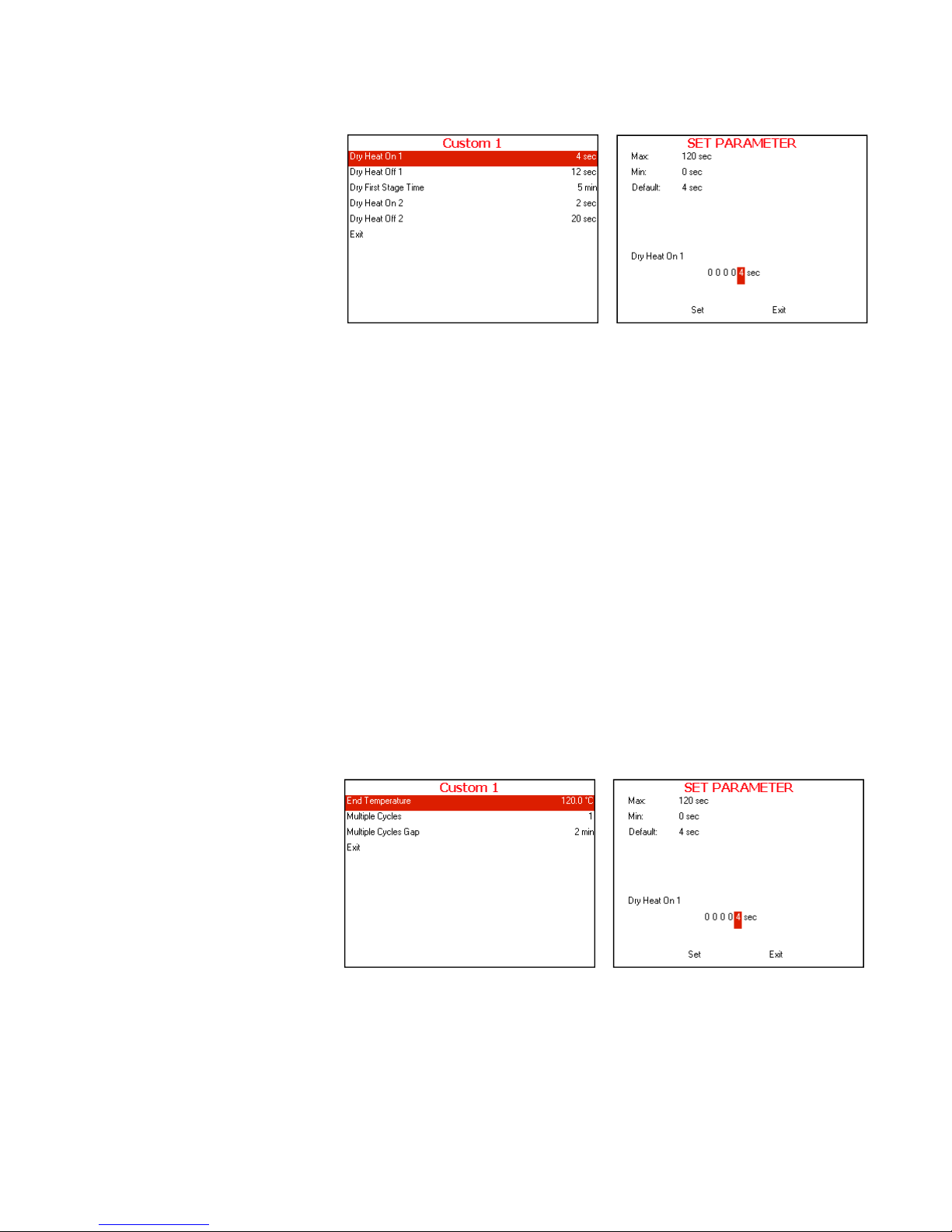

7.3.6 Dry

7.3.6.1 Dry Heat On 1

Choose and enter Dry Heat On 1

SET PARAMETER screen will be displayed

Set the required value, move to Set and press UP or

DOWN keys to confirm the parameter value.

In order to exit move the cursor to Exit and press UP or

DOWN keys

7.3.6.2 Dry Heat Off 1

Repeat the action mention in 7.4.6.1 Dry Heat On 1

7.3.6.3 Dry first stage time

Repeat the action mention in 7.4.6.1 Dry Heat On 1

7.3.6.4 Dry Heat On 2

Repeat the action mention in 7.4.6.1 Dry Heat On 1

7.3.6.5 Dry Heat Off 2

Repeat the action mention in 7.4.6.1 Dry Heat On 1

7.3.7 End

7.3.7.1 End Temperature

Choose and enter End Temperature

SET PARAMETER screen will be displayed

Set the required value, move to Set and press UP or

DOWN keys to confirm the parameter value.

In order to exit move the cursor to Exit and press UP or

DOWN keys

Typical display for

Dry Heat On 1

subdirectory

Typical display for

End

Temperature

subdirectory

Page 29

Page 27 of 102 Pages

7.3.7.2 Multiple Cycles

Repeat the action mention in 7.4.7.1 End Temperature

7.3.7.3 Multiple Cycles Gap

Repeat the action mention in 7.4.7.1 End Temperature

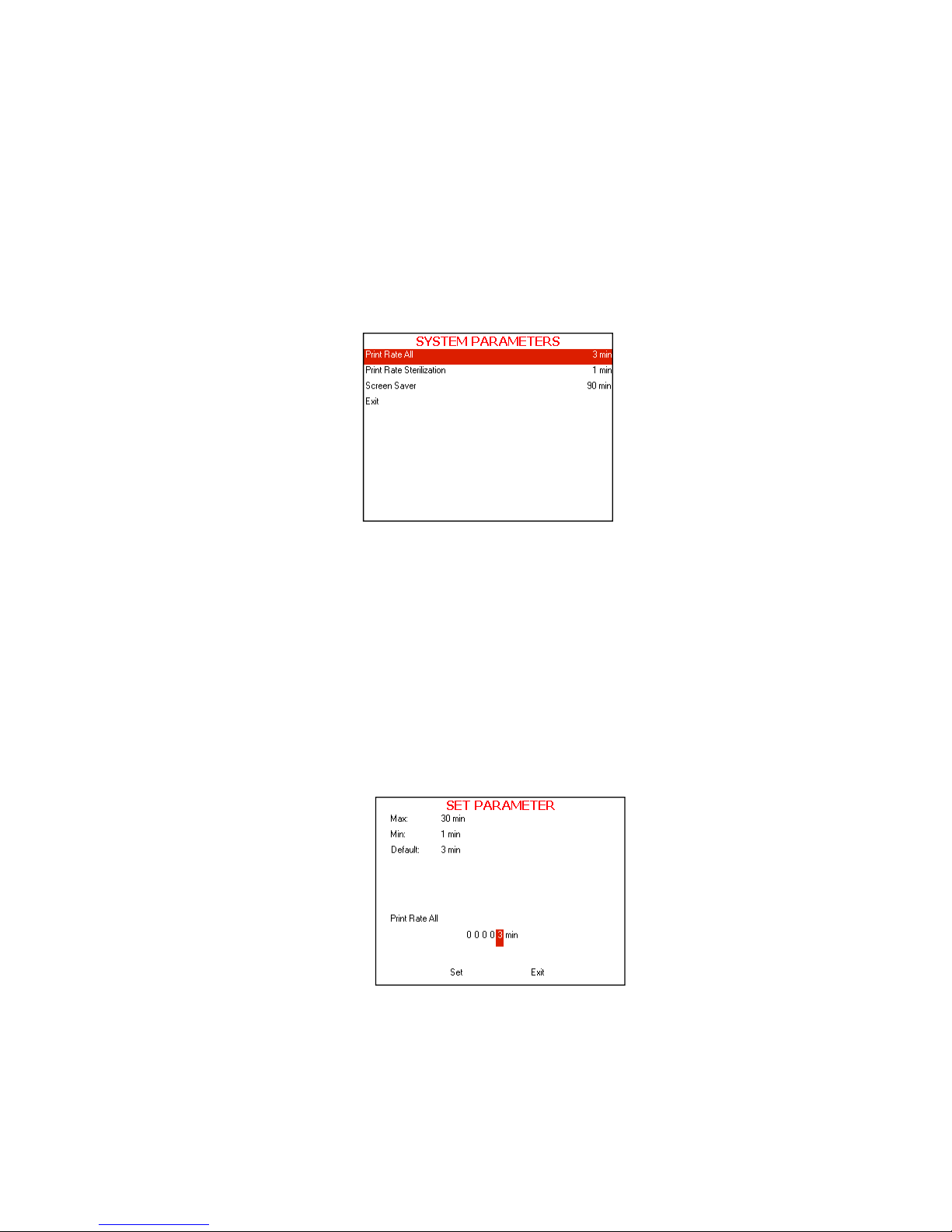

7.3.8 System Parameters

This directory includes three subdirectories

The following screen will be displayed when entering SYSTEM

PARAMETERS

directory:

1. In order to enter to the sub directories move the cursor by

pressing

UP or DOWN keys to the required item and press

START/STOP key

2. In order to exit this screen follows one of the next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

7.3.9 Print Rate All

This subdirectory enables to change the printing rate during the

whole cycle except sterilization stage

1. To increase or decrease the digits, press the UP or DOWN

keys.

2. After changing the value move the cursor to Set by pressing the

START/STOP key.

3. When Set is blinking, press the UP or DOWN keys in order to

confirm changes and return to the previous screen.

4. In order to exit this screen follows one of the next:

Page 30

Page 28 of 102 Pages

In order to exit this screen move the cursor to Exit with the

START/STOP key and select it by pressing the UP or

DOWN keys.

Press the UP and DOWN keys simultaneously.

7.3.10 Print Rate Sterilization

This subdirectory enables to change the printing rate during

sterilization stage

1. To increase or decrease the digits, press the UP or DOWN

keys.

2. After changing the value move the cursor to Set by pressing the

START/STOP.

3. When Set is blinking, press the UP or DOWN keys in order to

confirm changes and return to the previous screen.

4. In order to exit this screen follows one of the next:

In order to exit this screen move the cursor to Exit with the

START/STOP key and select it by pressing the UP or

DOWN keys.

Press the UP and DOWN keys simultaneously.

7.3.11 Screen Saver

This subdirectory enables the operator to set the screen saver time.

The default time value is 90 minutes. It is possible to increase or

decrease the time value up to a maximum of 600 minutes or down

to a minimum 0 minutes.

When entering the Screen Saver screen, t he time will be

displayed. The cursor is blinking on the "minute" digit.

The time is displayed in the form “0000” min.

Page 31

Page 29 of 102 Pages

1. To increase or decrease the digits, press the UP or DOWN

keys.

2. After changing the value move the cursor to Set by pressing the

START/STOP.

3. When Set is blinking, press the UP or DOWN keys in order to

confirm changes and return to the previous screen.

4. In order to exit this screen follows one of the next:

In order to exit this screen move the cursor to Exit with the

START/STOP key and select it by pressing the UP or

DOWN keys.

Press the UP and DOWN keys simultaneously.

7.4 Inputs/Outputs

This directory includes four subdirectories

The following screen will be displayed when entering

INPUTS/OUTPUTS

directory:

1. In order to enter to the sub directories move the cursor by pressing

UP

or DOWN keys to the required item and press START/STOP key

2. In order to exit this screen follows one of the next:

Move the cursor to Exit with the UP or DOWN keys and select it

by pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

7.4.1 View digital inputs state

1. In order to exit this screen follows one of the next:

Page 32

Page 30 of 102 Pages

In order to exit this screen move the cursor to Exit with the

START/STOP key and select it by pressing the UP or

DOWN keys.

Press the UP and DOWN keys simultaneously.

7.4.2 View digital outputs state

This subdirectory enables to view the digital outputs state

1. In order to exit this screen follows one of the next:

In order to exit this screen move the cursor to Exit with the

START/STOP key and select it by pressing the UP or

DOWN keys.

Press the UP and DOWN keys simultaneously.

7.4.3 Test digital outputs

This subdirectory enables to test the digital outputs state

1. In order to test the digital output move the cursor by pressing

UP or DOWN keys to the required item and press

START/STOP key and verified that the required item

operates.

2. In order to exit this screen follows one of the next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

Page 33

Page 31 of 102 Pages

7.4.4 View analog inputs state

This subdirectory enables to view the analog inputs state

1. In order to exit this screen follows one of the next:

In order to exit this screen move the cursor to Exit with the

START/STOP key and select it by pressing the UP or

DOWN keys.

Press the UP and DOWN keys simultaneously.

7.5 Calibration

7.5.1 Calibration components

This directory describes the calibration of 4 sensors in the

Sensor name Sensor function

1.

ChambPress

Reads the pressure in the chamber.

2. ChambTemp

Reads the temperature in the chamber.

7.5.2 Required equipment for calibration

PT Simulator (for temperature calibration).

Reference temperature sensor.

Reference pressure tool: pressure gauge.

7.5.3 Calibrating the sensors

ANALOG INPUTS

ChambPress 113.4

Chamb Temp 082.8

EXIT

Choose the sensor required to calibrate

among the 4 sensors available with the

UP

and DOWN keys.

When it is blinking select it by pressing

the START/STOP

key.

CALIBRATION

Change

GainOffset

Calc.

GainOffset

Restore Last

Restore Default

EXIT

Sensor name Current value

Move to Calc. GainOffset with the UP

and DOWN keys, and then when it is

blinking select it with the START/STOP

key.

Page 34

Page 32 of 102 Pages

Calibrating the pressure in the chamber “ChambPress”

Calibrate the low pressure of the chamber

To perform the low pressure calibration, insert your reference

pressure tool in the autoclave and operate a vacuum test.

Open the autoclave’s door and read the

value displayed on

your tool.

AL (actual pressure low value): change the AL with the

value read by your reference tool (use UP and DOWN

keys to increase and decrease the value and the

START/STOP key to move ahead from digit to digit).

RL (read pressure low value): change the RL with this

same value (use UP and DOWN keys to increase and

decrease the value and the START/STOP key to move

ahead from digit to digit).

To save the data move to SET by pressing the

START/STOP key and when it is blinking press the UP

key.

Calibrate the high pressure of the chamber

To perform the calibration of the high pressure, insert your

reference pressure tool in the autoclave and operate a

program of 134°C. Perform the calibration when the

autoclave reaches the sterilization stage.

AH (actual pressure high value): change the AH with the

value read by your reference tool (use UP and DOWN

keys to increase and decrease the value and the

START/STOP key to move ahead from digit to digit).

RH (read pressure high value): change the RH with this

same value (use UP and DOWN keys to increase and

decrease the value and the START/STOP key to move

ahead from digit to digit).

To save the data move to SET by pressing the

START/STOP key and when it is blinking press the UP

key.

Calibrating the temperature in the chamber “ChambTemp”

Calibrate the low temperature of the chamber

To perform the calibration of the low temperature, insert your

reference temperature tool in the autoclave, near of the Pt100

of the chamber when the autoclave is cold.

AL (actual temperature low value): change the AL with

the value read by your reference tool (use UP and

DOWN keys to increase and decrease the value and the

START/STOP key to move ahead from digit to digit).

RL (read temperature low value): change the RL with this

same value (use UP and DOWN keys to increase and

decrease the value and the START/STOP key to move

ahead from digit to digit).

To save the data move to SET by pressing the

START/STOP key and when it is blinking press the UP

key.

Page 35

Page 33 of 102 Pages

Calibrate the high temperature of the chamber

To perform the calibration of the high temperature, insert

your reference pressure tool in the autoclave, near of the

PT100 and operate a program of 134°C. Perform the

calibration when the autoclave reaches the sterilization stage.

AH (actual temperature high value): change the

AH

with

the value read by your reference tool (use

UP

and

DOWN

keys to increase and decrease the value and the

START/STOP

key to move ahead from digit to digit).

RH (read temperature high value): change the RH with

this same value (use UP and

DOWN

keys to increase

and decrease the value and the

START/STOP

key to

move ahead from digit to digit).

To save the data move to

SET

by pressing the

START/STOP

key and when it is blinking press the

UP

key.

7.6 History

This directory includes two subdirectories

The following screen will be displayed when entering HISTORY directory:

1. In order to enter to the sub directories move the cursor by pressing UP or

DOWN keys to the required item and press START/STOP key

2. In order to exit this screen follows one of the next:

Move the cursor to Exit with the UP or DOWN keys and select it by

pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

7.6.1 View old cycle history

This subdirectory enables to print the 100 previous cycles.

The following screen will be displayed when entering View old

cycle history subdirectory:

Page 36

Page 34 of 102 Pages

1. Choose the required cycle according to cycle number, date

and time with the

UP or DOWN keys

2. Press the START/STOP key. The printer will print the

printout of the required cycle

3. In order to exit this screen follows one of the next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the

START/STOP key.

Press the UP and DOWN keys simultaneously.

7.6.2 Export history to USB

This subdirectory enables to Export history to USB device.

1. Insert the USB device into the USB Socket

2. Move the cursor to

Export history to USB

3. Press the START/STOP key.

4. The following screen will be displayed:

5. Move the cursor to the required item and press

START/STOP

key

6. The following screen will be displayed:

7. Remove the USB device from the USB Socket

8. In order to exit this screen and return to HISTORY OPTIONS

screen press START/STOP key.

9. In order to exit the HISTORY OPTIONS screen follows one

of the next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

Page 37

Page 35 of 102 Pages

7.7 Maintenance

This directory includes six subdirectories

The following screen will be displayed when entering

MAINTENANCE

directory:

1. In order to enter to these subdirectories move the cursor by pressing

UP

or DOWN keys to the required item and press START/STOP key

2. In order to exit this screen follows one of the next:

Move the cursor to Exit with the UP or DOWN keys and select it by

pressing the

START/STOP key.

Press the UP and DOWN keys simultaneously.

7.7.1 Set date and time

This subdirectory enables the operator to set the date and time.

This SET DATE AND TIME screen will be displayed when

entering the subdirectory:

When entering the SET DATE AND TIME screen, the time and

date are displayed. The cursor is blinking on the "second" digit.

The time is displayed in the upper row in the form "HH:MM:SS".

The hour range is 24 hour (i.e. from "0" to "24")

The date is displayed in the lower row in the form

"DD:MMM:YYYY".

1. To increase or decrease the time or the date use the UP or

DOWN keys.

2. To move the cursor from one digit to another press the

START/STOP key.

3. After changing the time and the date move the cursor to Set.

Page 38

Page 36 of 102 Pages

4. Confirm the new time and date by pressing UP or DOWN

keys.

5. After saving is completed, SET DATE AND TIME screen is

still displayed, move the cursor to Exit and press UP or

DOWN keys to return to MAINTENANCE screen.

7.7.2 Export gain offset to USB

This subdirectory enables to Export gain offset to USB device.

1. Insert the USB device into the USB Socket

2. Move the cursor to Export gain offset to USB

3. Press the START/STOP key

4. The following screen will be displayed:

5. Remove the USB device from the USB Socket

6. In order to exit this screen and return to MAINTENANCE

directory press START/STOP key.

7. In order to exit the

MAINTENANCE directory follows one of

the next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the

START/STOP key.

Press the UP and DOWN keys simultaneously.

7.7.3 Reset atmospheric pressure

This subdirectory enables to reset the atmospheric pressure.

Page 39

Page 37 of 102 Pages

1. In order to exit the MAINTENANCE directory follows one of the

next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

7.7.4 Test RTC

This subdirectory enables the operator to test the RTC (Real Time

Clock)

The Test RTC screen is displayed when entering the directory

:

When entering the Test RTC screen, the time is displayed. The

cursor is blinking on the right "minute" digit.

The time is displayed in the form "mm".

1. To increase or decrease the time use the UP or DOWN keys.

2. To move the cursor from one digit to another press the

START/STOP key.

3. After choosing the required time move the cursor by pressing

START/STOP key to start and press UP or DOWN keys

4. The test will start, the following screen is an example to

completed test for 1 minute

5. There is an option to stop the test before it is finished by

moving the cursor to Stop and pressing UP or DOWN keys.

The test will stop at this point and the results w ill displayed in

the screen.

Page 40

Page 38 of 102 Pages

6. In order to exit this screen move the cursor to EXIT by pressing

START/STOP key and select it by pressing the UP or DOWN

Keys

7.7.5 Print Test

This subdirectory enables the operator to test the printer.

When pressing START/STOP key on the Printer Test item the

printer will print out the following print out:

And the following screen will be displayed.

In order to exit this screen and return to MAINTENANCE

directory press START/STOP key.

In order to exit the MAINTENANCE directory follows one of the

next:

Cycle errors:

None

Canceled By User

Door is open

Analog Input Error

I/O Card Failed

Power Down

Invalid Parameter Value

No Water

Heat Time Error

Vacuum Time Error

Pressure Time Error

Heat Time Error (Keep)

Heat Time Error

Low Pressure

High Pressure

Low Temp

High Temp

Time Error

Low Pressure (Cooling)

High Temp. (Cooling)

High Pressure (Exhaust)

High Pressure (Dry)

High Pressure (Ending)

Air Error

High Temp. (Ending)

Error Open Door

Error Close Door

Accessory Timeout

Page 41

Page 39 of 102 Pages

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

7.7.6 Print All Gain and Offset

This subdirectory enables the operator to print all the gain and

offset values.

When pressing START/STOP key on the Print all gain and offset

item the printer will print out the following:

And the following screen will be displayed.

In order to exit this screen and return to MAINTENANCE

directory press START/STOP key.

In order to exit the MAINTENANCE directory follows one of the

next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the START/STOP key.

Press the UP and DOWN keys simultaneously

Drain Temperature

G:000.0400;O:-004.0000

Chamber Temperature

G:000.0400;O:-004.0000

Ref Temperature 1

G:000.0400;O:-004.0000

Chamber Pressure

G:000.1250;O:-100.0000

Page 42

Page 40 of 102 Pages

7.8 Advanced Options

This directory includes eight subdirectories

The following screen will be displayed when entering ADVANCED

OPTIONS directory:

1. In order to enter to the sub directories move the cursor by pressing UP or

DOWN keys to the required item and press START/STOP key

2. In order to exit this screen follows one of the next:

Move the cursor to Exit with the UP or DOWN keys and select it by

pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

7.8.1 Start cycle by clock

This subdirectory enables the operator to postpone the operation by

a pre-set time.

This Start cycle by clock screen will be displayed when entering

the START CYCLE BY CLOCK subdirectory:

When entering the START CYCLE BY CLOCK screen, the time

is displayed. The cursor is blinking on the "minute" digit.

The time is displayed in the form “HH:MM”. The hour range is 24

hours (i.e. from "0" to "24").

Enabling the START CYCLE BY CLOCK

1. To increase or decrease the time use the UP or DOWN keys.

2. To move the cursor from one digit to another press the

START/STOP key.

Page 43

Page 41 of 102 Pages

3. After changing the time move the cursor to Enabled

4. Confirm the START CYCLE BY CLOCK by pressing UP

or DOWN keys.

5. Move the cursor by pressing START/STOP key to Exit and

press UP or DOWN keys to return to ADVANCED

OPTIONS screen.

Canceling the START CYCLE BY CLOCK

1. To cancel the START CYCLE BY CLOCK move the cursor

by pressing START/STOP key to Disable and press UP or

DOWN keys.

2. Move the cursor to EXIT by pressing START/STOP key and

press UP or DOWN keys, the START CYCLE BY CLOCK

will be canceled.

7.8.2 Enable cycles

Page 44

Page 42 of 102 Pages

This subdirectory enables to enable or disable cycles.

In order to enable or disable a cycle move the cursor to the

required item and press START/STOP key to check or uncheck

the required cycle.

1. In order to exit this subdirectory follow one of the next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the

START/STOP key.

Press the UP and DOWN keys simultaneously.

7.8.3 Set Temperature units

This subdirectory enables to change the temperature units from

Celsius to Fahrenheit and vice versa.

In order to change the temperature units move the cursor to the

required item and press START/STOP key.

1. In order to exit this subdirectory follow one of the next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the

START/STOP key.

Press the UP and DOWN keys simultaneously.

7.8.4 Set pressure units

This subdirectory enables to change the pressure units

In order to change the pressure units move the cursor to the

required item and press START/STOP key.

1. In order to exit this subdirectory follow one of the next:

Move the cursor to Exit with the UP or DOWN keys and

select it by pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

Page 45

Page 43 of 102 Pages

7.8.5 Export all settings to USB device

1. This subdirectory enables to export all settings to USB device

2. Insert the USB device into the USB socket.

3. Press

START/STOP key on the Export all settings to USB

device item.

4. In order to exit this subdirectory, press the

START/STOP key.

7.8.6 Add Custom Program

1. This subdirectory enables to insert 18 additional Custom

programs.

2. In order to insert new custom program press

START/STOP

key.

7.8.7 Set Master IP address (102.0.0.1)

This subdirectory enables to change the IP address in order to

enable connection to the device via remote control.

Page 46

Page 44 of 102 Pages

7.8.8 Set mac address (0.50.C2.89.70.0)

This subdirectory enables to change the mac address in order to

connect an additional device and connect both of them (or even

more) via remote control.

7.9 Version information

This directory includes two subdirectories

The following screen will be displayed when entering VERSION

INFORMATION directory:

1. In order to enter to the sub directories move the cursor by pressing UP or

DOWN keys to the required item and press START/STOP key

2. In order to exit this screen follows one of the next:

Move the cursor to Exit with the UP or DOWN keys and select it by

pressing the START/STOP key.

Press the UP and DOWN keys simultaneously.

7.9.1 View current version information

In order to view this subdirectory press START/STOP key

on the View current version information item.

This subdirectory enables the operator to see the current

version information as described below:

1. GUI Graphic user interface – Holds the entire Human

Machine interface including the main application

Page 47

Page 45 of 102 Pages

screen and all the configuration screens, which

enables the user to handle the machine.

2. Software Logic – Holds all the application logic for running

the machine.

3. Data Code section that handle the entire data storage in

the application.

4. Utilities – Utilities – Holds general functionality which is

used by the logic section and the GUI section e.g.:

converting function to display different pressure

or temperature units, languages types etc.

5. OS Operational System – Microsoft Windows CE.

Version 6.0.

Major change Concept change eg: changing the

operating system, Changed by the in

accordance with the change programmer

sequence.

Minor change Feature change or function change,

changed by the programmer in

accordance with the change sequence.

Bugs repair Software bugs repair changed by the

programmer in accordance with the

change sequence.

Automatic builder Changed (updated) automatically after

each source code compilation

DLL size Dynamic-Link Library size

Major

change

Minor

change

Bugs

repair

Automatic

builder

DLL size

Software

update date

Page 48

Page 46 of 102 Pages

7.9.2 View factory default version information

This subdirectory enables the operator to see the factory

default version information.

In order to see this subdirectory press START/STOP key on

the View factory default version information item.

The following screen will be displayed:

7.9.3 View previous version information

This subdirectory enables the operator to see the previous

version information.

In order to see this subdirectory press START/STOP key on

the View previous version information item.

Major

change

Minor

change

Bugs

repair

Automatic

builder

DLL size

Software

update date

Page 49

Page 47 of 102 Pages

8. REPLACING ELEMENTS

8.1 Replacing the Circuit Breaker

Caution!

Before starting, disconnect the instrument from the power source.

The circuit breaker is located on the rear of the autoclave (See Rear View).

1. Disconnect the wires (1, 2) from the circuit breaker.

2. Remove four screws connecting the circuit breaker to the panel (3).

Note: the (4) must be on 250°.

3. Replace the circuit breaker with a new one and assemble it to the

autoclave with the 4 screws (3).

Attention:

Make sure that a 15A 3ph circuit breaker is installed!

4. Reconnect the electrical wires (1, 2).

5. Reassemble the service door.

6. Turn on the autoclave and verify it operates correctly.

7. Move the circuit breaker’s lever to the “tripped” position and verify that

the autoclave turns off.

3

21

Page 50

Page 48 of 102 Pages

8.2 Replacing the Safety Valve

Warning:

Before starting, disconnect the instrument from the power source and

ensure that there is no pressure in the autoclave chamber.

This paragraph refers to the chamber's and the generator's safety valves

This paragraph refers to PED and ASME approved safety valves

Note:

The safety valve is located on the rear of the autoclave.

1. Remove the safety vale cover (2) by pressing both sides of the cover

inwards (1) and pulling it out (3) of its seats (slots in the rear wall of the

autoclave -4) to reveal the safety valve (5).

2. Open the right door.

3. Disconnect the pipe connection.

4. Unscrew the safety valve (including the base) and remove from the

autoclave.

5. Replace it with a new safety valve (use an original only).

6. Test autoclave cycles.

5

87

7

6

Rear wall

5

87 76

Rear wall

ASME

CE

3

2

5

4

1

Page 51

Page 49 of 102 Pages

No. Description Cat. No.

1 Safety valve

CE-marked

SVL029-0028

ASME

SVL029-0004

2 Safety valve base CMV100-0004

3 Washer CMT240-0022

4 Nut CMT240-0020

8.3 Replacing the Door Gasket

Caution!

This gasket is designed with a trapezoidal cross section. The gasket should

be placed with the widest side towards the door.

1. Disassemble the 10 segments (1) attaching the gasket to the door.

2. Remove the gasket (5) from the door.

3. Clean the door surface.

4. Lay the new gasket on the door.

5. Assemble the segments loosely. Verify that the rim of the gasket (4) is

in the groove in the segments (3).

6. After all the segments are assembled loosely verify that the gasket lies

evenly.

7. Insert screws (2, 6). See picture below for the location of screws (6).

8. Assemble the Spring lock washers (7) and the nuts (8) to the screws (6).

9. Tighten all the screws (2, 6) of the segments.

Cat. No.DescriptionNo.

LOK387-0062Segment1

BOL191-0162Screw M5 x 162

GAS080-0203Gasket5

BOL191-0240Screw M5 x 256

NUT193-0325Spring lock washer M57

NUT192-0192Nut M58

3

2

1

8

5

7

6

4

2

Page 52

Page 50 of 102 Pages

8.4 Replacing the door cover

8.4.1 Disassembling the door cover

1. The opening of the door is limited by two stoppers assembled

on the door's hinges. To disassemble and remove the door

cover it is necessary to enable the door to open more than 90º.

This is achieved by releasing these stoppers.

2. With a screwdriver, inserted through the holes in the rear of the

door cover (3), release the 4 screws fastening the door stoppers.

Be careful not to disassemble the stopper.

3. Open the door

4. Lift the door and release the edge of the spring holder (16)

from the slot (15).

1

1

2

2

3

15

16

Page 53

Page 51 of 102 Pages

5. Unscrew the screws assembling the axis bridge (11) to the door

bracket (5).

6. Remove the door cover

8.4.2 Assembling the door cover

1. Assemble door bracket (5) to the door cover (4) with 10 screws

(6).

2. Assemble the axis bridge (10) to the axis seat (7) with a pin (9)

and cotter pin (8).

6

4

5

9

7

8

10

4

11

5

Page 54

Page 52 of 102 Pages

3. Place the door cover (4) on the door (12) so that the axis bridge

(11) will cover the door bracket (5) and assemble the door to

the axis bridge with screws.

4. Lift the spring holder (13) and place the spring holder support

P/N CMT387-0148 (14, supplied with the autoclave), as shown

in the picture below. Perform this on the right and on the left

spring holder.

5. Lift the door and insert the edge of the spring holder (16) into

the slot (15).

4

11

5

12

13

14

Page 55

Page 53 of 102 Pages

6. After the edge of the spring holder is in the slot the door cover

is attached to the door. At this stage remove the spring holder

supports (14).

7. Close the door.

8. With a screwdriver, inserted through the holes in the rear of the

door cover (3), fasten the 4 screws of the door stoppers.

15

16

3

Page 56

Page 54 of 102 Pages

8.5 Replacing the steam generator

Warning!

Before starting:

Make sure that the electric cord is disconnected from the power source and

that there is no pressure in the autoclave chamber and generator.

Open the generator drain valve and let the water flow.

Drain the generator (see …).

Close the water tap and disconnect the water inlet pipes.

1. Unscrew the screws (1) fastening the generator compartment cover and

remove it.

2. Disconnect the wires (2) from the water level electrodes.

3. Disconnect the neutral heating element electric wires (3) from the

porcelain terminal.

4. Disconnect the piping as follows:

a. Disconnect the water inlet pipe (5)

b. Disconnect the steam-to-chamber Teflon tube (6).

c. Disconnect the drain tube.

d. Verify that all the pipes are disconnected (?)

5. Unplug the solenoid (7) from the solenoid valve (8) mounted on the top

of the generator.

6. Pull out the thermostat (4).

7. Unscrew and remove the screws (9) connecting the generator bracket to

the autoclave base frame.

8. Disconnect the Generator Side Gauge Glass Indicator Tube (see replacing

the Generator Side Gauge Glass Indicator Tube).

9. Remove the generator from the autoclave.

10. Replace the generator with a new one.

1

Page 57

Page 55 of 102 Pages

11. Reassemble the screws (9) fastening the bracket to the base frame.

12. Reconnect the piping to the generator (see above).

13. Reconnect the electrical wiring to the generator (see above).

14. Close and fasten the generator compartment cover.

32467

8

910

Page 58

Page 56 of 102 Pages

8.6 Replacing Heating elements

Warning!

Before starting:

Make sure that the electric cord is disconnected from the power source and

that there is no pressure in the autoclave chamber and generator.

Open the generator drain valve and let the water flow.

Drain the generator (see …).

Close the water tap and disconnect the water inlet pipes.

1. Perform steps 1-6 of the procedure 8.5 Replacing the steam generator.

2. Unscrew the hexagon nut (10, above) from the heating elements base.

3. Replace the heating elements.

4. Reconnect all the elements and close the service door.

8.7 Cleaning and Replacing the Water Level Electrodes

The three electrodes of the water level control system are located on top of the

steam generator.

8.16.1 Cleaning

1. Take the generator out of the autoclave (see para. 8.13

"Replacing the generator").

2. Unscrew the big nuts (1).

3. Note which wire belongs to which electrode and remove the

three electrodes.

4. Clean the electrodes.

5. Reassemble the three electrodes into their places.

6. Tighten the nuts to avoid leakage.

7. Verify that the electrodes height did not change. If there was any

change in the electrodes height, loosen the small nut (3), adjust

the height and tighten the nut.

8. Return the generator to the autoclave and reconnect the piping

and wiring as required (see para. 8.13 "Replacing the

generator").

9. Test the unit.

8.16.2 Replacing

1. Take the generator out of the autoclave (see para. 8.13

"Replacing the generator").

2. Unscrew the big nuts (1).

3. Note which wire belongs to which electrode and remove the

three electrodes.

Page 59

Page 57 of 102 Pages

4. Insert new electrodes and tighten the fixing nut (1).

5. Adjust the electrodes height according the drawing and fix the

height by tightening the small nuts (2).

6. Return the generator to the autoclave and reconnect the piping and

wiring as required (see para. 8.13 "Replacing the generator").

7. Test the unit.

Note: See electrodes on the piping diagram (end of this manual).

1.1. Generator Side Gauge Glass Indicator Tube

1. Unscrew the screws (1) fastening the generator compartment cover and

remove it.Turn the electric power off and release the steam pressure from

the autoclave and the steam generator.

2. Drain the water.

3. Remove the protective rod (4) that protects the glass tube (5).

4. Loosen the two nuts (3) on both sides of the glass tube. Slip the upper

one down, and then remove the tube

5. Replace the tube with a new one.

1

1

2

Page 60

Page 58 of 102 Pages

6. Verify that there is a bronze washer (1) and a new silicon gasket (2) in

each nut. After every replacement of the glass tube install a new silicon

washer. Do not use the old silicon washer

7. Reassemble the two nuts and tighten gently.

8. Close the service doors.

NOTE:

On each side of the glass tube, there are stainless steel balls that act as a

safety device by preventing the escape of steam and boiling water if the glass

is broken.

No. Description Cat. No.

1 Bronze washer CMT254-0072

2 Silicon gasket GAS082-0005

3 Nut N/A

4 Protecting Rod PIP221-0023

5 Water level glass tube SRV000-0125

1.2. Draining the generator

! This operation shall be done with pressure in the generator.

1. Open the right service door.

2. Open the drain (1) valve for approx. 15 seconds.

3. Close the drain valve

4. Close the service door.

2 543

1

Page 61

Page 59 of 102 Pages

8.8 Replacing the Printer

Caution

Before starting, disconnect the instrument from the power source and

ensure that there is no pressurein the autoclave.

Allow the autoclave to cool before removing the outer cover.

1. Unscrew 2 screws (1) fastening the control panel.

2. Turn the panel to reveal the internal part and the electrical connectors.

3. Unplug the board connectors (3) and the printer connectors (2). Verify

that you know where plug each is connected.

1

1

Page 62

Page 60 of 102 Pages

4. The printer is fastened (6) to its seat with two fasteners (5). To release

the fasteners, press slightly on the part marked (4) and pull the fattener

upward. Repeat this with the second fastener.

5. Pull the printer out of its seat (the hole in the panel).

6. Replace the printer with a new printer.

7. Inset the fasteners. Verify that they are inserted firmly.

8. Connect the printer's connectors

9. Connect all the connectors of the board.

10. Lay the control panel on its place.

11. Fasten the panel with the screws (1).

23

4

5

6

Page 63

Page 61 of 102 Pages

8.9 Replacing the Door Switch

Caution!

Before starting, disconnect the instrument from the power source and

ensure that there is no pressure in the autoclave.

Allow the autoclave to cool before removing the outer cover.

1. Open the right service door

2. Disconnect the wires (2), (5) from the door switch (4).

3. Unscrew nut (1) and remove the microswitch

4. Replace the microswitch with a new one.

5. Reconnect the wires the microswitch. Verify that the wire is placed on the

isolating cover (3) and does not touch the chamber.

6. Reassemble the door cover.

7. Test the connection with an ohmmeter. In “open” position the ohmmeter

shows disconnection and in “close” position the ohmmeter shows

connection.

23514

Page 64

Page 62 of 102 Pages

8.10 Replacing the air filter

Caution!

Before starting, disconnect the instrument from the power source and

ensure that there is no pressure in the autoclave.

Allow the autoclave to cool before removing the outer cover.

1. Open right service door.

2. Disconnect the elbow (2).

3. Unscrew and remove the filter (1) from its seat.

4. Replace the pressure switch with a new one, use only an original filter

supplied by Tuttnauer.

5. Assemble the filter (1) to its seat.

6. Connect the elbow (2).

7. Close left service door.

1

2

Page 65

Page 63 of 102 Pages

8.11 Replacing the locking motor

Note:

The locking motor can be replaced with an open door or with a closed

door.

1. Open left service door.

2. Move the sleeve covering the wires connection (8) to reveal the

connections and disconnect the wires of the electric motor.

3. Remove cotter pin (6).