Page 1

TECHNICIAN

MANUAL

Laboratory Vertical Steam Sterilizers

models

2540, 3150, 3170, 3850, 3870, 5050, 5075

ELV Standard Autoclave

ELVC

ELVPRC

Cat. No. MAN205-0060000EN Rev.AA

Tuttnauer Europe B.V., Hoeksteen 11 4815 PR P.O. Box 7191 4800 GD Breda, The Netherlands

Tel: 31 (0) 765423510, Fax: 31 (0) 765423540

Including Preparation for Fast Cooling System

Including Fast Cooling System

Page 2

Page 3

TABLE OF CONTENTS

PARAGRAPH PAGE NO.

1. INTRODUCTION

2. SYMBOL DESCRIPTION

3. INSTALLATION INSTRUCTIONS

3.1 Installation Site.................................................................................................6

3.2 Connection of the pressure regulator................................................................6

4. TESTS

4.1 Installation Tests.............................................................................................11

4.2 Periodical Tests...............................................................................................11

5. WATER QUALITY

5.1 Water for Generating Steam ...........................................................................12

5.2 Water for the Vacuum pump and drain cooling..............................................12

5.3 Reverse Osmosis..............................................................................................12

6. DESCRIPTION OF THE CONTROL SYSTEM.

6.1 Digital Board DIG - T2...................................................................................13

6.2 Analog Board ANL-T2....................................................................................15

6.3 AC - Board - AC-T1........................................................................................16

7. CALIBRATION OF TEMPERATURE AND PRESSURE

7.1 Method of Calibration:....................................................................................17

7.2 Temperature Calibration Procedure...............................................................18

7.3 Pressure Calibration Procedure......................................................................20

.......................................................................................................................11

....................................................................................................4

......................................................................................4

.....................................................................5

................................................................................................12

............................................13

............................17

8. TEST POINTS

9. SOFTWARE PROGRAMMING PROCEDURES

9.1 General ...........................................................................................................22

9.2 Changing Cycle Parameters............................................................................22

9.3 Resetting the Autoclave...................................................................................30

9.4 Test Mode........................................................................................................30

10. REPLACING ELEMENTS

10.1 Safety Tests after Repair .................................................................................31

10.2 Replacing the Circuit Breaker.........................................................................32

10.3 Replacing the Safety Valve..............................................................................33

10.4 Replacing the Door Gasket .............................................................................34

10.5 Replacing the electronics board (control panel)..............................................35

10.6 Replacing the Electronics Box........................................................................36

10.7 Cut-Out Thermostat........................................................................................39

10.8 Replacing Heating elements............................................................................40

10.9 Safety Door Locking System for models 2540, 3150, 3170, 3850, 3870 ..........41

10.10 Safety Door Locking System for models 5050, 5075 .......................................43

10.11 Disassembling and Assembling the Door Cover, Models 2540, 3150, 3170,

3850, 3870.......................................................................................................44

........................................................................................................21

............................................22

..................................................................................31

Page 1 of 132 Pages

Page 4

TABLE OF CONTENT (Cont.)

PARAGRAPH PAGE NO.

10.12 Disassembling and Assembling the Door Cover, Models 5050, 5075..............46

10.13 Replacing the locking microswitch (Models 5050, 5075)................................49

10.14 Replacing the safety-opening valve (Models 5050, 5075)................................50

10.15 Replacing the “DOOR CLOSED” microswitch (Models 5050, 5075).............51

10.16 Replacing the solenoid lock (Models 5050, 5075)...........................................52

10.17 Cleaning and Replacing the Water Level Electrodes......................................53

10.18 Replacing the Printer......................................................................................54

10.19 Replacing the Door Switch (models 2540, 3150, 3170, 3850, 3870)................56

10.20 Replacing the Locking Device (models 2540, 3150, 3170, 3850, 3870)...........57

10.21 Replacing the Plunger or Coil of the BACCARA Solenoid Valve...................58

11. IN-OUT TEST

12. TROUBLESHOOTING

12.1 Displayed Messages and Reference to Trouble Shooting................................60

12.2 Pre-process malfunction .................................................................................61

12.3 In Process Malfunction...................................................................................67

12.4 Mechanical malfunction.................................................................................86

13. LIST OF SPARE PARTS

14. PRESSURE VS TEMPERATURE FOR SATURATED STEAM

15. XPCS Manual

16. VALVES NUMBERING

........................................................................................................59

.........................................................................................60

.....................................................................................87

.................97

.......................................................................................................101

.....................................................................................114

Page 2 of 132 Pages

Page 5

TABLE OF CONTENT (Cont.)

DRAWINGS PAGE NO.

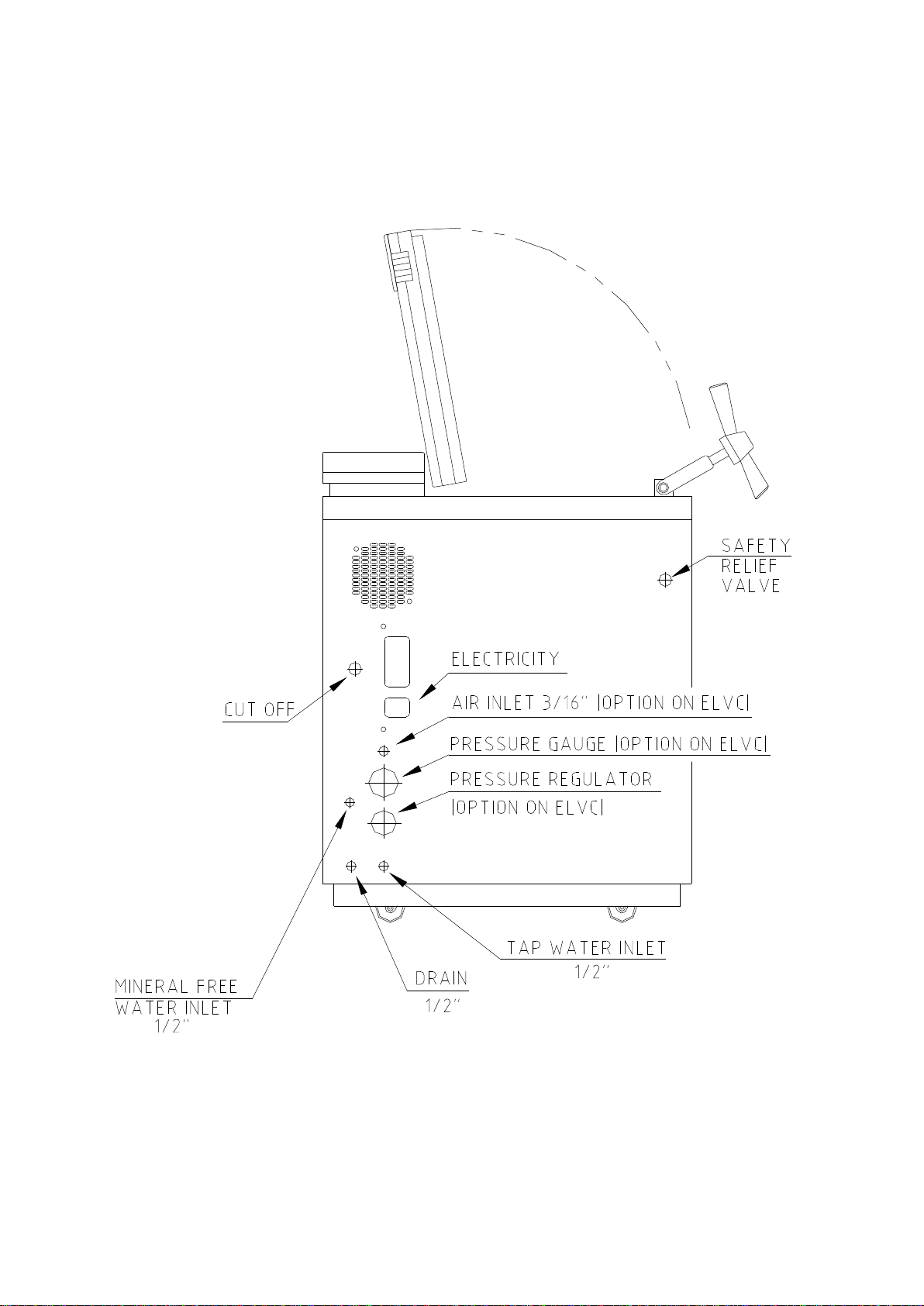

Rear View Model 2540........................................................................................................... 7

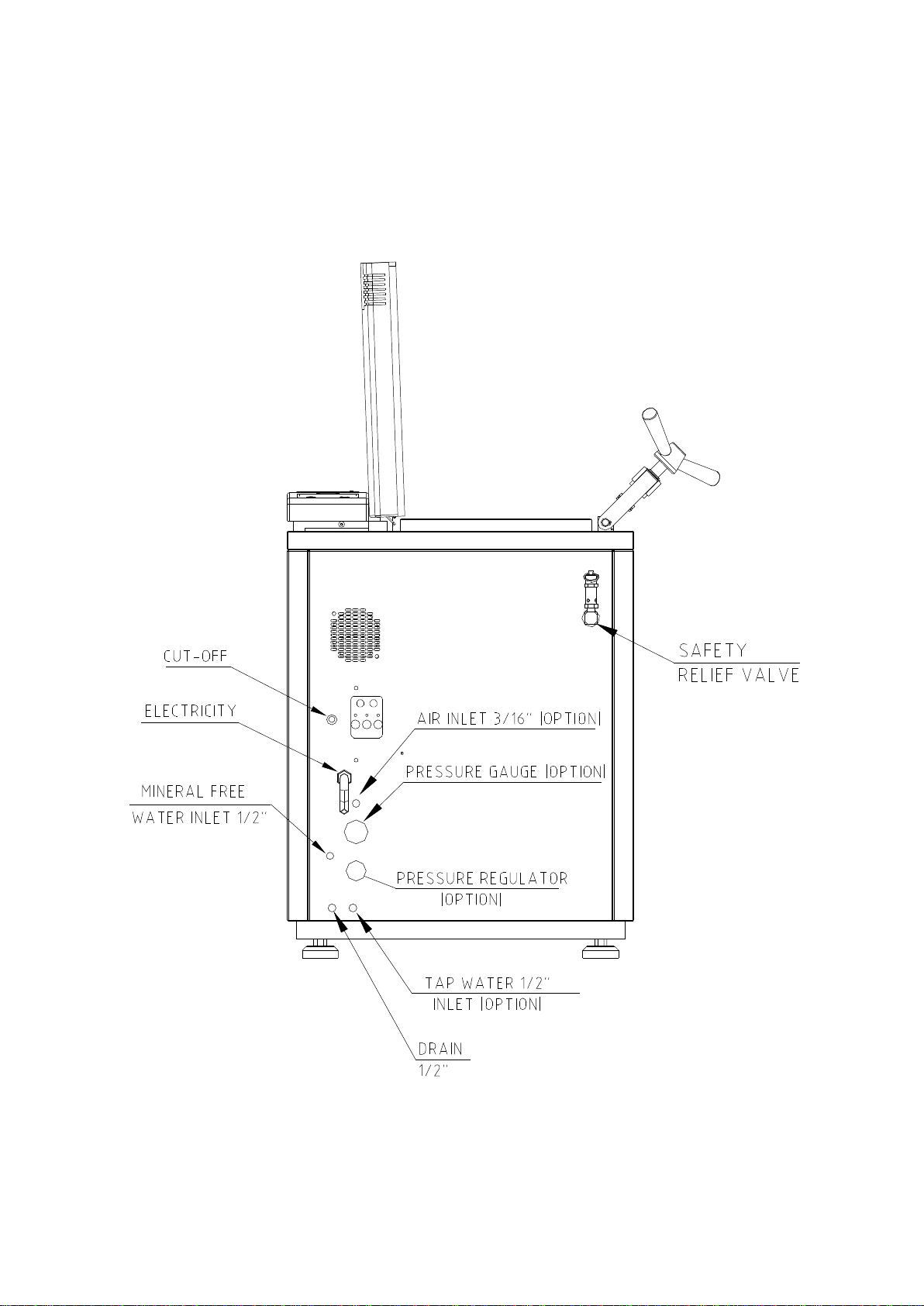

Rear View Models 3150, 3170 ............................................................................................... 8

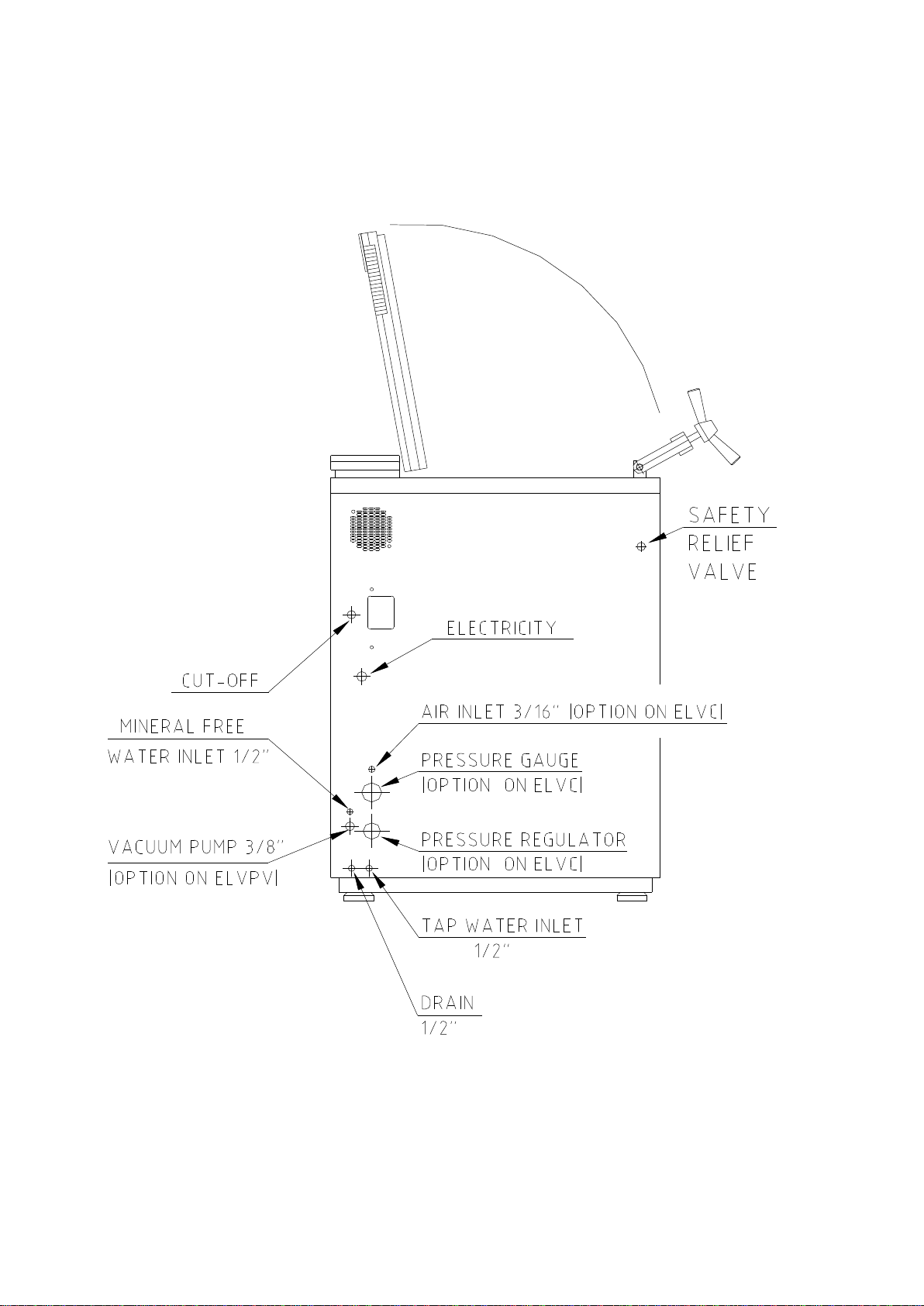

Rear View Models 3850, 3870 ............................................................................................... 9

Rear View Models 5050, 5075 ............................................................................................. 10

Control System Block-Diagram........................................................................................... 13

DIG- T2 Board .................................................................................................................... 14

ANL - T2 Board................................................................................................................... 15

AC-T1 Board ....................................................................................................................... 16

Vessel Assembly Models 2540, 3150, 3170, 3850, 3870....................................................... 92

Vessel Assembly Models 5050, 5075.................................................................................... 93

Door Tightening Bolt – Assembly........................................................................................ 94

Door Locking System........................................................................................................... 95

Water Outlet Strainer .......................................................................................................... 96

Piping Drawing: 2540 ELV &, ELVPRC.......................................................................... 116

Piping Drawing: 2540 ELVC............................................................................................. 117

Piping Drawing: 3150, 3170, 3850, 3870 ELV & ELVPRC .............................................. 118

Piping Drawing: 3150, 3170, 3850, 3870 ELVC................................................................ 119

Piping Drawing: 5050, 5075 ELV & ELVPRC.................................................................. 120

Piping Drawing: 5050, 5075 ELVC................................................................................... 121

Electrical Wiring Diagram For Autoclave Model 2540 ELV ............................................ 122

Electrical Wiring Diagram for Autoclave Models 3150/3170 ELV ................................... 123

Electrical Wiring Diagram for Autoclave Models 3850/3870 ELV 3x400V ...................... 124

Electrical Wiring Diagram for Autoclave Models 3850/3870 ELV 3x230V ...................... 125

Electrical Wiring Diagram for Autoclave Models 3850/3870 ELV 3x208V ...................... 126

Electrical Wiring Diagram for Autoclave Models 5050/5070 ELV 3x400V ...................... 127

Electrical Wiring Diagram for Autoclave Models 5050/5070 ELV 3x230V ...................... 128

Electrical Wiring Diagram for Autoclave Models 5050/5070 ELV 3x208V ...................... 129

Switch Box Wiring Diagram.............................................................................................. 130

Open Switch Box............................................................................................................... 131

Closed Switch Box............................................................................................................. 132

Page 3 of 132 Pages

Page 6

1. INTRODUCTION

This manual, together with the operator’s manual, forms the complete edition of the

Operation and Maintenance instructions. This manual is intended for the use of the

technician. It is forbidden for unqualified and unauthorized personnel to service the

autoclave in accordance with the instructions in this manual. Any unauthorized service

may result in the invalidation of the manufacturer’s guarantee.

The qualified technician shall be an authorized electrician with the right qualifications

in electronics and shall be familiar with the local technical/electrical regulations.

2. SYMBOL DESCRIPTION

Caution! Consult accompanying documents

Caution! Hot surface.

Caution! Hot steam.

Protective earth (Ground)

Stand by

Page 4 of 132 Pages

Page 7

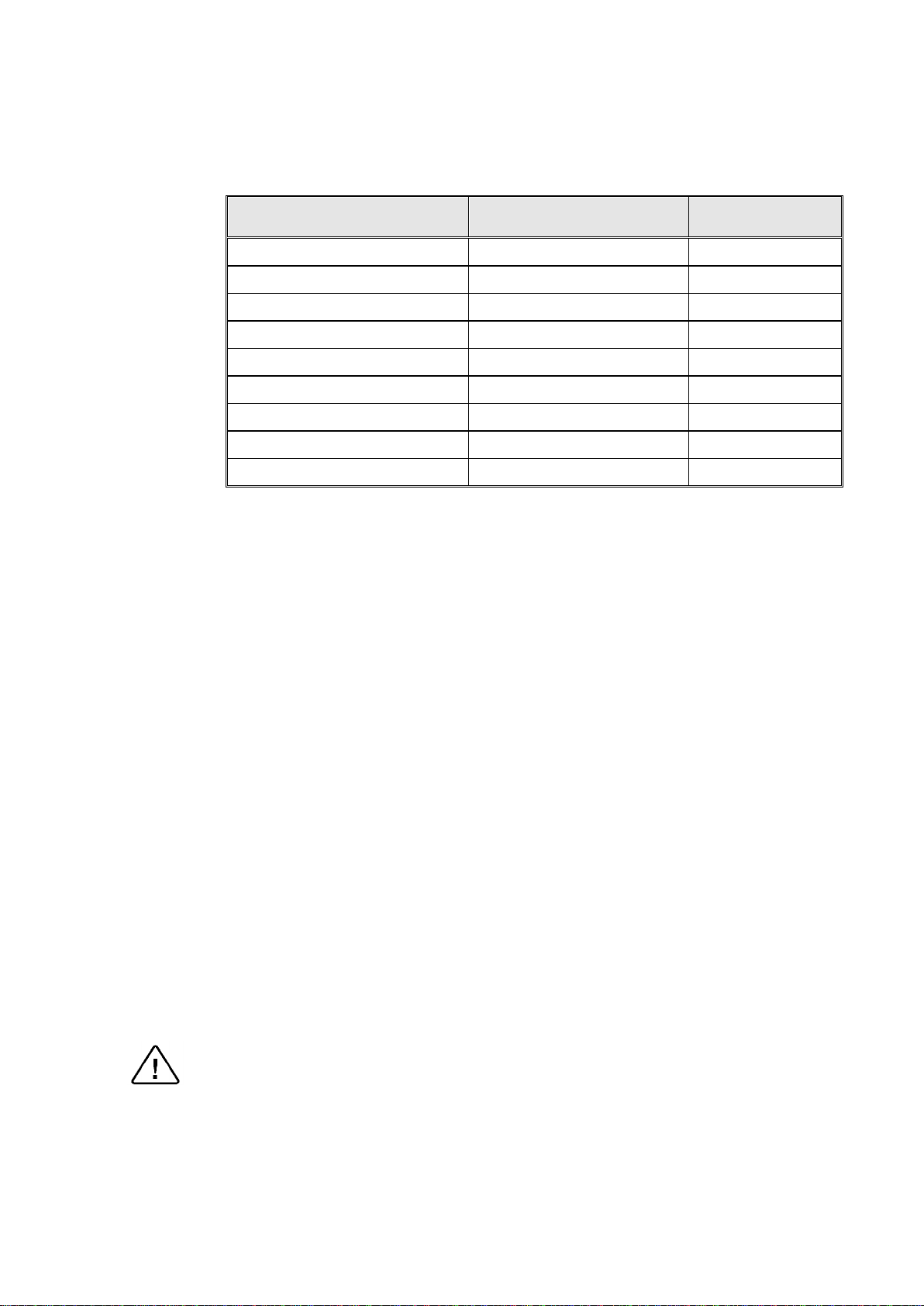

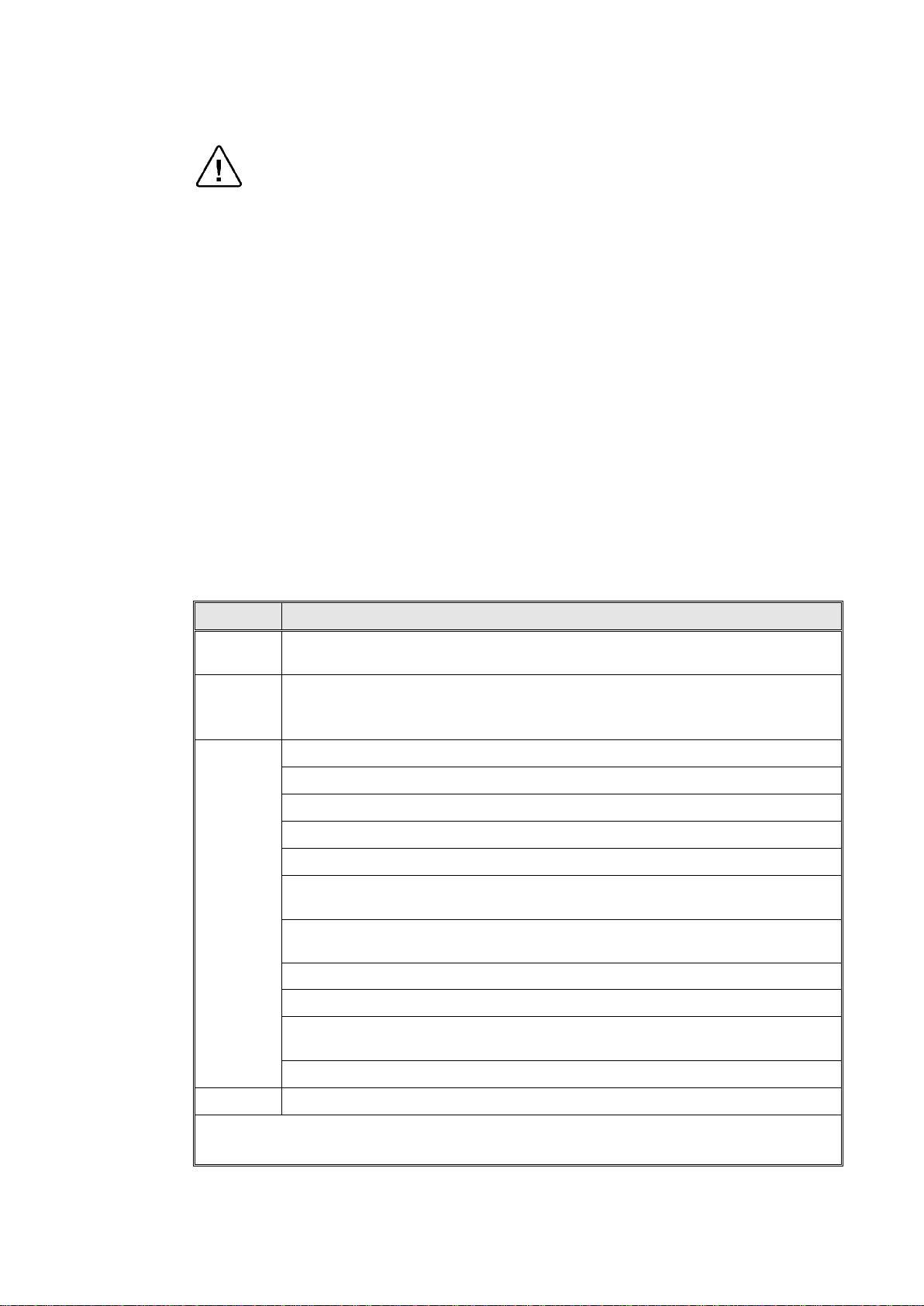

3. INSTALLATION INSTRUCTIONS

Recommended

For all the ELV models, the following utilities have to be connected (Refer to the

drawing below ‘Rear View’ of the autoclave).

Power outlet, as detailed in the table below:

Model Power

2540

3150/70

3850/70

3850/70

3850/70 with switching box

3850/70, 5050/75

5050/75

5050/75

5050/75 with switching box

If the autoclave is a 3 phase 3870, 5050 or 5075 autoclave and has to be connected

to a one phase power network, 1 x 230V, 50/60Hz., connected the 1ph 230V

power source to the supplied switch box that has a 1 phase input (from the power

source) and a 3 phase output (to the autoclave). See details at the end of this

manual.

The power network must be protected by a current leakage relay.

Mineral-free water having a conductibility lower than 15µs (microsiemens),

through a 1/2” flexible hose.

1Ph, 230V/50/60Hz 20A

1 or 2 Ph, 230V/50/60Hz 25A

3 Ph, 208V/50/60Hz 25A

3 Ph, 230V/50/60Hz 25A

1 or 2 Ph, 230V/50/60Hz 30A

3 Ph, 400V/50/60Hz 20A

3 Ph, 208V/50/60Hz 30A

3 Ph, 230V/50/60Hz 30A

1 or 2 Ph, 230V/50/60Hz 45A

Circuit Breaker

To obtain water quality meeting requirements a deionization column or reverse

osmosis apparatus can be installed. The water must be delivered at a pressure of 23bar. A pressure reducer shall be installed at the water source outlet as instructed

below.

For fast cooling (if this option is provided):

Feed water from the water network, pressure 2-3bars, connected through a 1/2”

pipe. A pressure reducer shall be installed at the water source outlet as instructed

below.

Compressed air, from a mobile compressor or compressed air network at pressure

3-4 bars, will be set at 1.6-2bars at the autoclave inlet is to be connected by a

flexible conduit of 3/16”.

The air must be of instrumental quality filtered at 5µ and free of humidity and oil

drops.

Drain connected by 1/2” pipe, located at the rear of the unit. The chamber exhaust

and coolant water is evacuated to an open waste funnel. The drainage piping must

be heat resistant, to 80ºC, non-continuous flow.

Attention:

Connection of water system to the autoclave must be performed through "BACK

FLOW PREVENTION SYSTEM" installation as per EN 1717:2001 regulations

and local regulations.

.

Page 5 of 132 Pages

Page 8

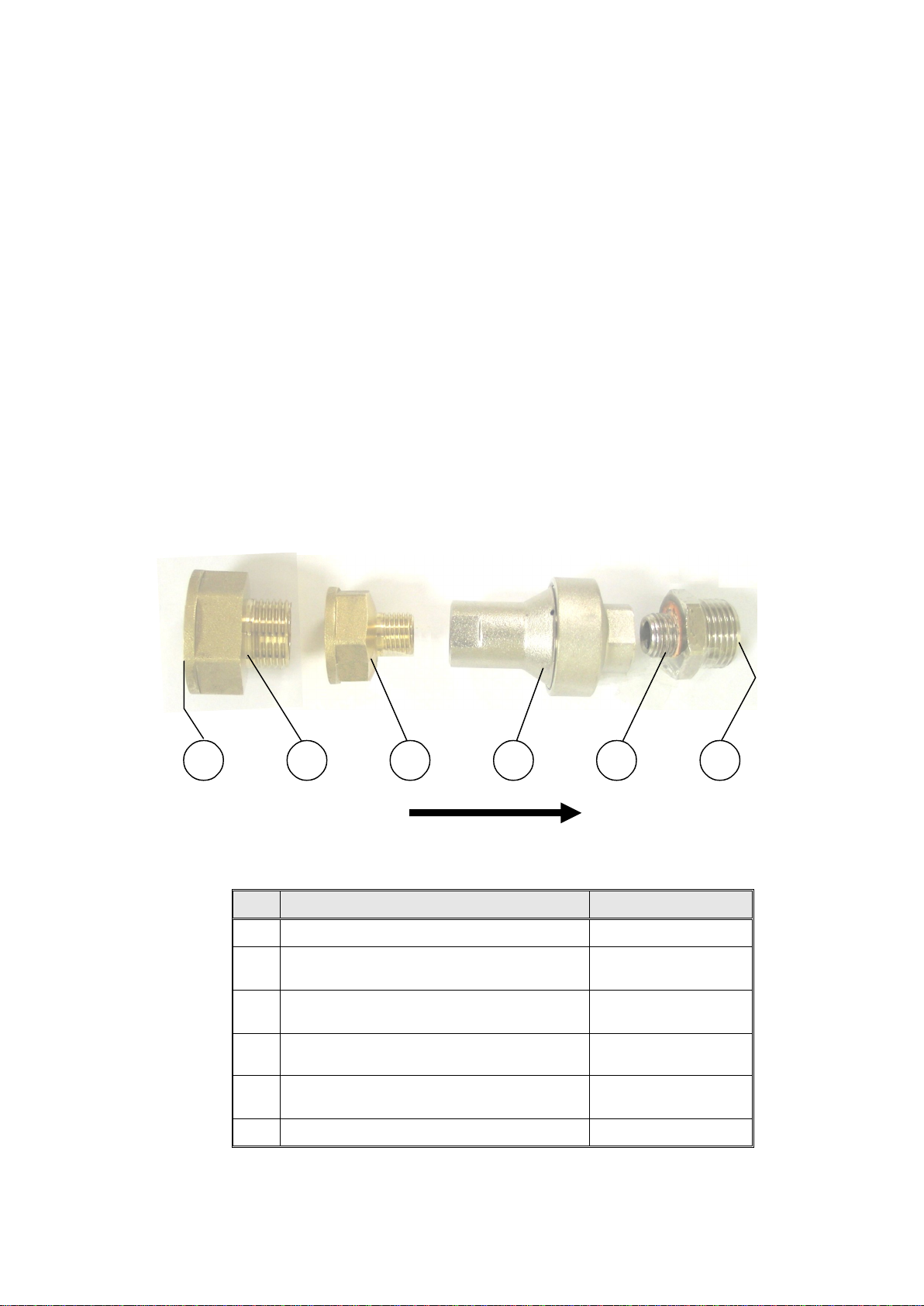

54321

6

3.1 Installation Site

Pressure Regulator, Water, In

-

Line,

1. Install the autoclave according to the following guidelines:

2. Place the autoclave on the floor. Verify that the surface is leveled.

3. All utility supplies must be prepared in accordance with requirements,

before autoclave installation e.g. mineral-free and tap water, compressed

air, one or three-phase power network, connection to the drain of the

building.

5. Leave the space free around the autoclave for maintenance and service

requirements.

3.2 Connection of the pressure regulator

This paragraph refers to the pressure regulator of the feed water and to the

pressure regulator of the mineral free water.

1. Attach the pressure regulator to the facility's water outlet.

2. Connect the supplied flexible hose to the pressure regulator's assembly

outlet and to the autoclave's water inlet.

3. Verify that the pressure regulator is in right direction. The flow direction is

indicated by an arrow stamped on the pressure regulator.

4. Verify that water flows freely in the feed water and in the mineral free

water lines.

FLOW DIRECTION

No. Description Cat No.

1 Side of water supply source N/A

Reducer, Female 3/4" BSP to Male

2

1/2" BSP, Brass

Reducer, Female 1/2" BSP to Male

3

1/4" BSP, Brass

4

with Strainer, 1/4 x 1.5 bar

Fitting, Adaptor, M 1/2" BSP x M

5

1/4" BSP, Brass Ni plated

FIT100-0424

FIT100-0425

GAU029-0059

PNE100-0042

6 Side of flexible hose (to autoclave N/A

Page 6 of 132 Pages

Page 9

REAR VIEW MODEL 2540

Page 7 of 132 Pages

Page 10

REAR VIEW MODELS 3150, 3170

Page 8 of 132 Pages

Page 11

REAR VIEW MODELS 3850, 3870

Page 9 of 132 Pages

Page 12

REAR VIEW MODELS 5050, 5075

Page 10 of 132 Pages

Page 13

4. TESTS

4.1 Installation Tests

The service technician shall perform the following preliminary checks

before operating the autoclave:

a. Integrity Check

b Leveling Check

c. Leakage current test

d. Continuity Check

At this stage operate the autoclave and continue with the tests:

e. Safety Check

f. Programs Check

g. Validation

After the above steps are performed, the autoclave is ready for operation.

Perform a visual check to verify that there are no dents, scratches,

broken gauges, etc.

Check that the autoclave is leveled.

Check the precise operation of the earth leakage relay.

Check the continuity of the grounding connection.

Check the safety elements; safety valve and the door locking mechanisms.

Run basic programs of the autoclave and check the operation

sequences, the sterilization parameters etc.

Validate the sterilization cycles, taking in consideration the interface of

packaging/goods/autoclave.

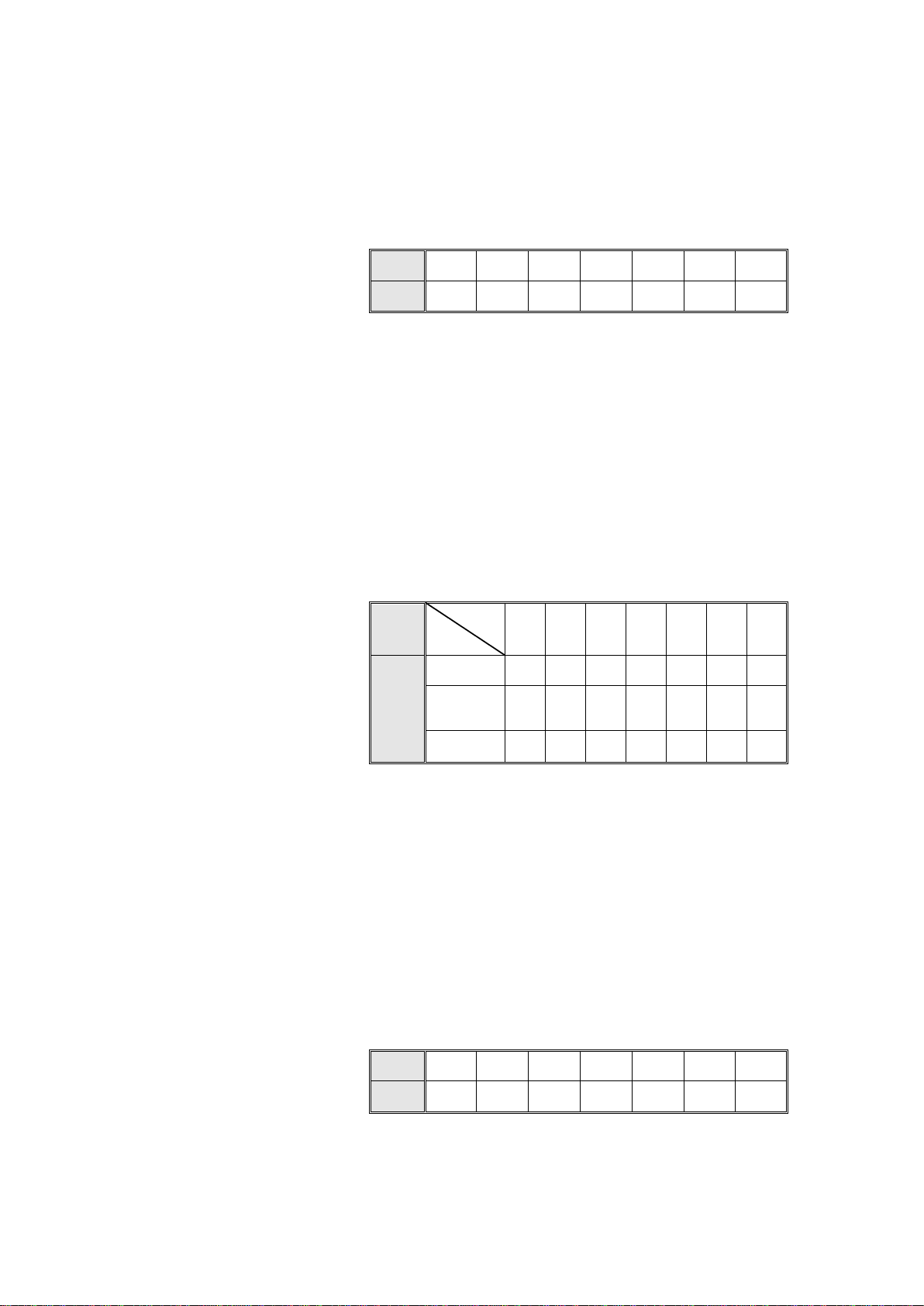

4.2 Periodical Tests

PERIOD TEST

2

months

6

months

Test the safety valve by operating it

Remove the cover of the autoclave, tighten the screws of the heaters and

the electrical connections at the heaters, valves and connectors inthe

control box.

Check the continuity of the grounding connections.

Check the temperature and pressure calibration.

Perform validation of the autoclave.

Check the precise operation of the earth leakage relay.

Check that the autoclave is leveled.

Check the safety elements; safety valve, safety and cut-off thermostats

Year

door locking mechanisms.

Run basic programs of the autoclave and check the operation sequences,

the sterilization parameters etc.

Check the water reservoir, piping, plastic parts and electric wires.

Check and tighten the piping joints to avoid leakage.

Check and tighten all screw connections in the control box, heaters and

valves and instrumentation.

Observe the closing device for excessive wear

.

5 years Observe the closing device for excessive wear

Safety tests (pressure vessel, efficiency, electrical) shall be performed in accordance

with local rules or regulations, by an authorized inspector.

Only an authorized technician shall perform the 6-months and yearly tests!

Page 11 of 132 Pages

Page 14

5. WATER QUALITY

5.1 Water for Generating Steam

The distilled or mineral – free water supplied to the sterilizer shall be according

to the table below:

Physical Characteristics and Maximum acceptable contaminants levels

Element Condensate – allowable content

in steam for sterilizers

(According to EN 13060:2004).

Silicium oxide. SiO

2

≤0.1 mg/kg

Iron ≤0.1 mg/kg

Cadmium ≤0.005 mg/kg

Lead ≤ 0.05 mg/kg

Rest of metals except iron,

cadmium, lead

≤0.1 mg/kg

Chloride (Cl) ≤0.1 mg/kg

Phosphate (P2O5) ≤0.1 mg/kg

Conductivity (at 20°C) ≤3 μs/cm

pH value (degree of acidity) 5 to 7

Appearance Colourless clean without sediment

Hardness (Σ Ions of alkaline earth) ≤0.02 mmol/l

Compliance with the above data should be tested in accordance with

acknowledged analytical methods, by an authorized laboratory.

Attention:

We recommend testing the water quality once a month. The use of water that

do not comply with the table above may have severe impact on the working

life of the sterilizer and can invalidate the manufacturer’s guarantee.

5.2 Water for the Vacuum pump and drain cooling

The feed water supplied to the liquid ring vacuum pump must meet the

following requirements:

Hardness: 0.7 - 0.2 mmol/l.

Water temperature: shall not exceed 15°C.

Note:

The use of heavy scaled water for the vacuum pump cooling, can cause

blocking of the rotor and put the pump out of operation. This invalidates the

guarantee for the vacuum pump.

5.3 Reverse Osmosis

A Reverse Osmosis system may be used to improve the quality of the water

used to generate steam in the autoclave chamber. The use of mineral free will

contribute to better performance and longer life of the autoclave.

Page 12 of 132 Pages

Page 15

6. DESCRIPTION OF THE CONTROL SYSTEM.

1

JP8

(See CDR Control diagram).

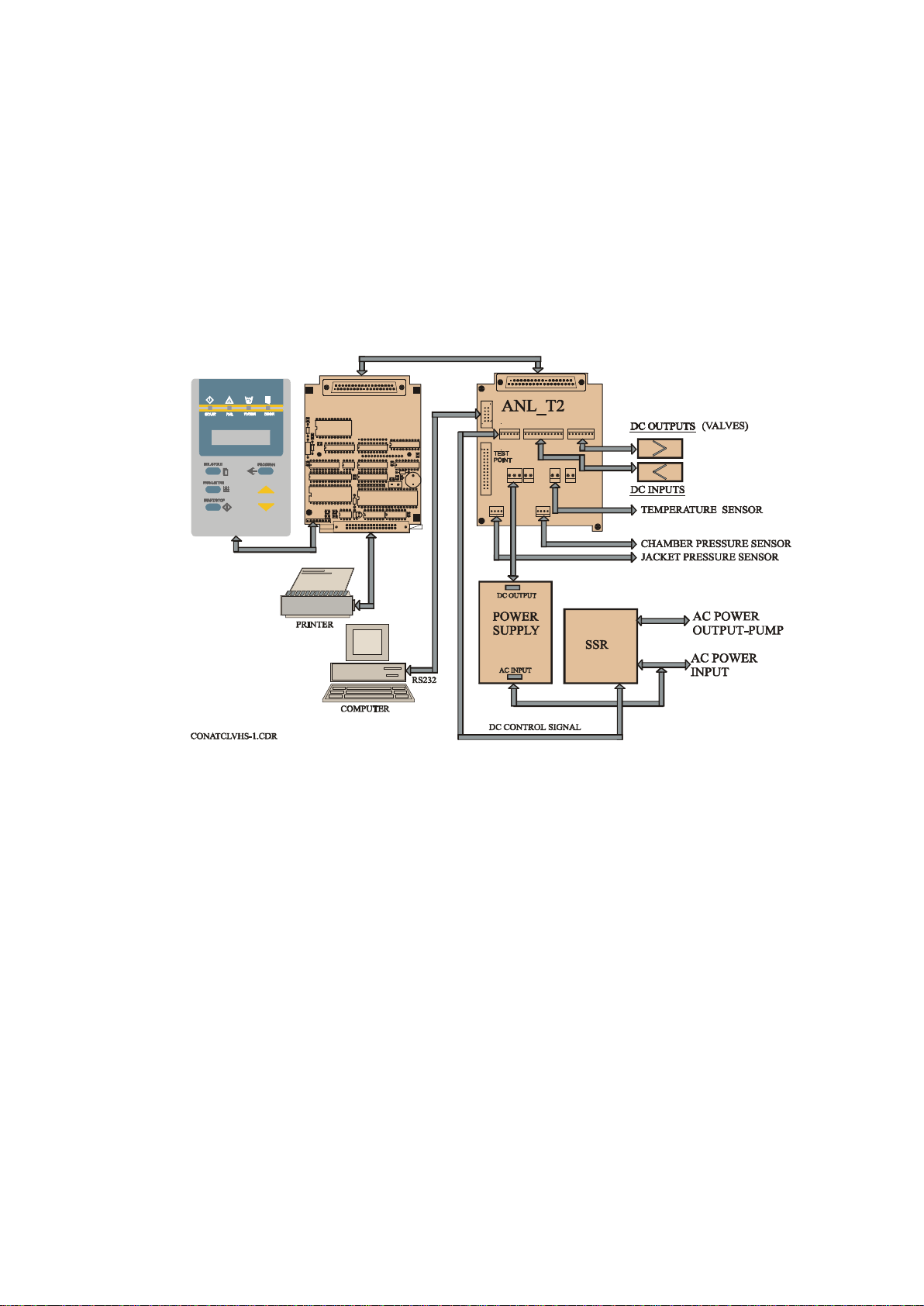

The control system is based on 3 electronic boards designed according to the autoclave

requirements, the digital board DIG-T2 containing the micro-controller memories,

buffers and digital ICs and the analog board ANL-T2 which performs the processing

of signals coming from the sensors and switches. The AC-T1 board consists of filters

and AC drivers. DC voltages 12V and 5V, supplied by a switching type power supply,

powers the 3 electronic boards.

CONTROL SYSTEM BLOCK-DIAGRAM

SKT

20

1

DIG-T2 BOARD

C2

+

U12

R3

C9

U8

R2

U16

R1

U11

U14

C5

U21

U17

DIG T3

1

U3

C3

+

RP1

U15

R9

U22

97-05

C24

C25

D1

C15

8

C23

JP3

C22

U1

2

DS1

1

PLUG

37

JP1

19

C7

U18

C4

R4

U4

C16

C17

Q1

Y1

BZ1

U19

C6

34

33

20

1

P1

1

JP7

JP2

JP3

1

JP12

1

37

19

JP1

12

1

JP6

JP5

JP4

1

1

1

JP9

JP10

1

The system is provided with communication interfaces RS 232 to PC and to parallel

printer.

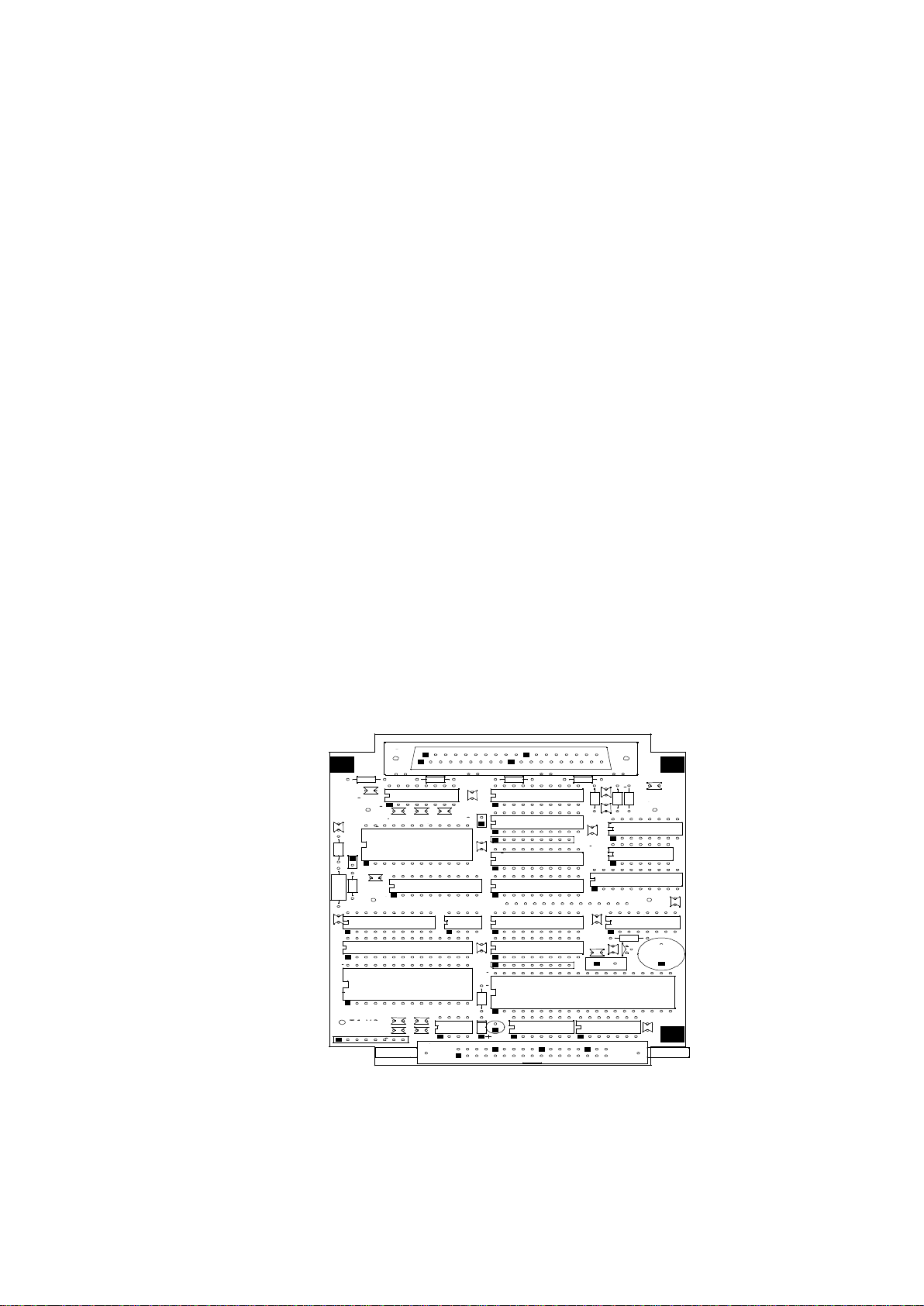

6.1 Digital Board DIG - T2

— The digital board is connected to the keypad panel, to the parallel printer

and to the analog board ANL-T2.

— The board contains the micro-controller (U15) type 80C32 that runs the

software program of the system.

— On the board, are three types of memories:

1) EPROM memory (U17), part no. 27512 storing the program codes.

2) RAM memory (U21) with a capacity of 32KB for the temporary data

during the running of the program.

3) EPROM memory (U22) that is a fixed serial memory with an

electrical writing and erasing.

— This EPROM serves as a non-volatile memory, enabling the system to

change follow-up tables during running of program codes, and ensuring

this data is not lost in case of power failure.

— The board contains an optimal Real Time Clock (U12), which serves as a

clock to the system, including a back-up battery, which ensures the clock,

runs continuously even when the autoclave is not powered.

Page 13 of 132 Pages

Page 16

This component is optimal because it is related to the operation of the

BZ

1

1

RP

8

1

+

printer, which is also an optional item.

— The board contains a watchdog, which detects any faulty situation in the

running program code. It performs an automatic reset of the microcontroller and stops all the commands to avoid an uncontrolled activation

of any of the heating elements or the valves.

— The board functions as an MMI (Man-Machine Interface). It is connected

to a LCD display of two rows with 16 characters on each row and to the

following light indicators:

— START (autoclave in process),

— FAIL (the process failed),

— WATER (no water in the reservoir),

— DOOR (the door is not closed).

A keyboard connected to the digital board, serves as a control panel containing

the command and programming keys.

— The digital inputs and outputs are transferred to the system, as follows:

— Through the digital board to the analog board by means of buffers

74HC377.

— RS232 interface is performed on the board by the U13 component, the

signal is transmitted to the communication connector located on the ANLT2 board.

— The printer is connected directly to this board, connector DS1 enables to

connect the DPU-20 printer manufactured by SEIKO.

The printer receives the data and the supply voltage directly from this

connector.

The layout of the DIG-T2 board components is provided below

DIG- T2 BOARD

SK

20

R8

JP 3

DIG

U1

C1

U1

C9

U1

U1

C2

R7 R6

C1

C2

C2

C2

DS

C1

+

C2

R3

R2

R1

C5

U2

U1

H2

97 -0 5

1

C1

U5

U1

C1

JP

C8

U 7

U8

U1

U3

C3

RP

U1

R9

U2

D

C1

2

1

U1

37

R5

R1

+

C1

U6

C4

U4

C1

Y1

JP 1

19

C1

C2

U2

R4

C1

C2

R1

R1

U2

C7

U1

Q 1

U1

C6

34

33

Page 14 of 132 Pages

Page 17

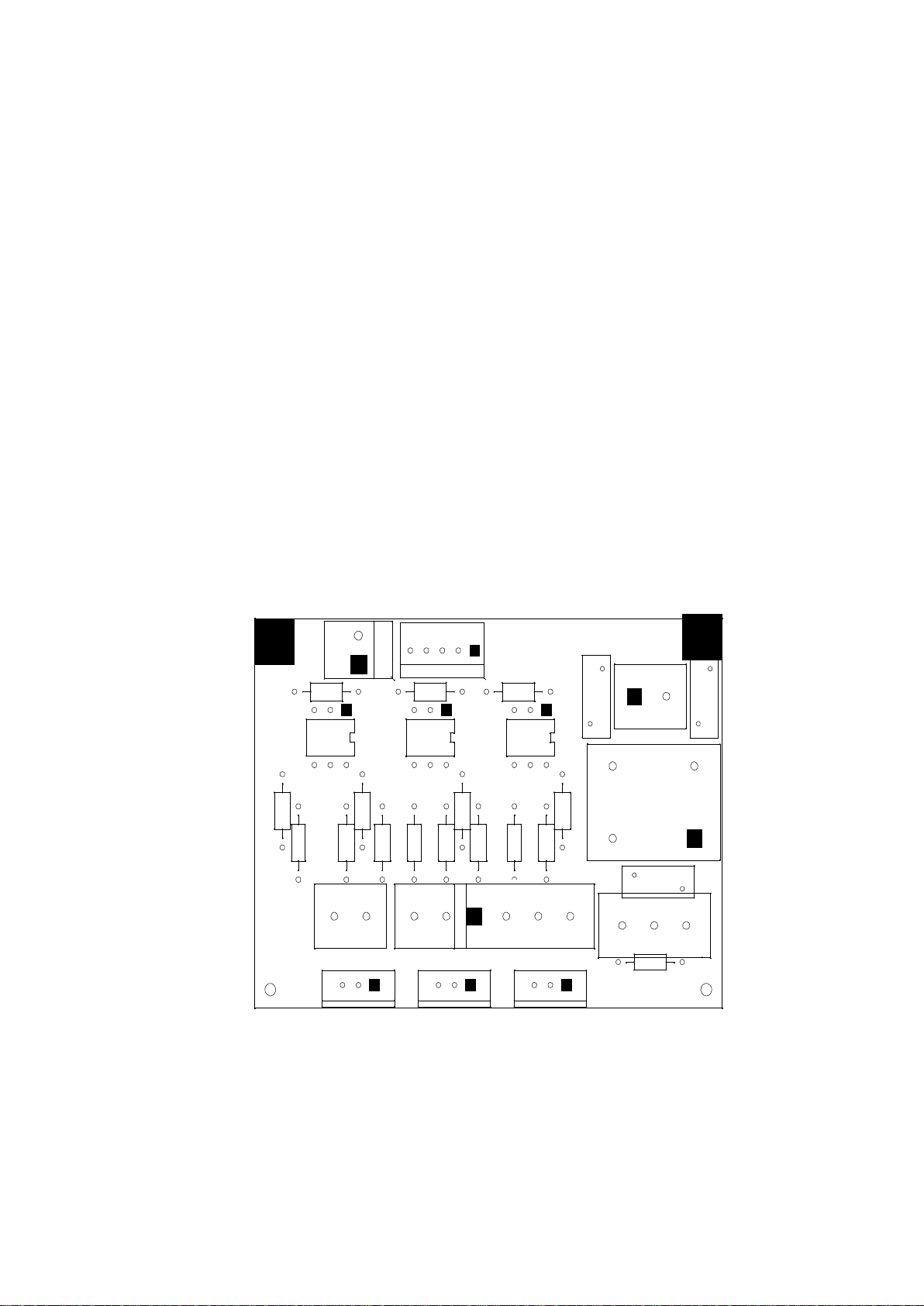

6.2 Analog Board ANL-T2

The analog board contains the drivers of the valves, heaters and pump. It

contains the sensors circuits connected to the control system, and serves as a

junction to the autoclave connections.

The input is 12VDC & 5VDC and the output is for all the signals to the

autoclave.

— The power supply provides the DC voltages 12V and 5V through the

connector JP3 to the board and further to the DIG-T2 board.

— The computer is connected to the board through the connector P1, by

RS232 interface.

— The analog and digital inputs, from the temperature sensor, electrode door

switch, etc. are connected through connector JP6, the conversion circuits

of the sensors are located on this board.

— The pressure sensor MPX2200 that measures the chamber pressure is

connected to the board through connector JP8, to the conversion circuit of

the sensor that is located on this board.

— The analog to digital conversion circuit A/D (U5) and the analog

multiplexer (U6) for 8 analog inputs (temperature, pressure, and electrode)

are located on this board and transfer digital signal to the DIG-T2 board.

— All the drivers and power circuits to the solenoids (valves, door locking)

are included on this board.

Layout diagram of the ANL-T2 is provided below.

ANL - T2 BOARD

PLUG

P1

JP2

JP12 JP8

1

ANL T1 BOARD

20

1

JP1

12 1 1

1

JP7

JP3

1

1

JP5

JP4

1

JP9

1

37

19

JP6

JP10

1

JP11

1

Page 15 of 132 Pages

Page 18

6.3 AC - Board - AC-T1

This board receives command signals from ANL-T2 board designated to

activate AC devices. It converts them to AC mode.

The AC-T1 board provides AC filtering for the power supply to the control

system and protection from sharp current fluctuations.

The AC-T1 board includes:

— AC drivers for the AC devices (pump, heaters, etc.) up to 6A.

— AC - input connector JP3.

— Filter circuit based on L1C5, the power transfer from the filter to power

supply via JP2.

— Spike protection - RV1÷3.

— Three - 230/115 VAC output channels, triac control circuit.

Q1 - 16Amp - JP4/1,2

Q2 - 8 Amp - JP7/1

Q3 - 8 Amp - JP7/2

AC-T1 BOARD

(JP3,JP4,JP7 ON THE BOTTOM SIDE OF THE BOARD)

U3

R12

JP5

R9

C3

R11

Q3

1

R10

R8 C2

JP7

U2

JP1

R5

R6

R7 C1

JP4

1

Q2

R4

1

R1

U1

R3

Q1

RV3 RV2

JP2

R2

L1

JP6

JP3

C5

ETYPEAC-97

CAT TECH.

RV1

Page 16 of 132 Pages

Page 19

7. CALIBRATION OF TEMPERATURE AND PRESSURE

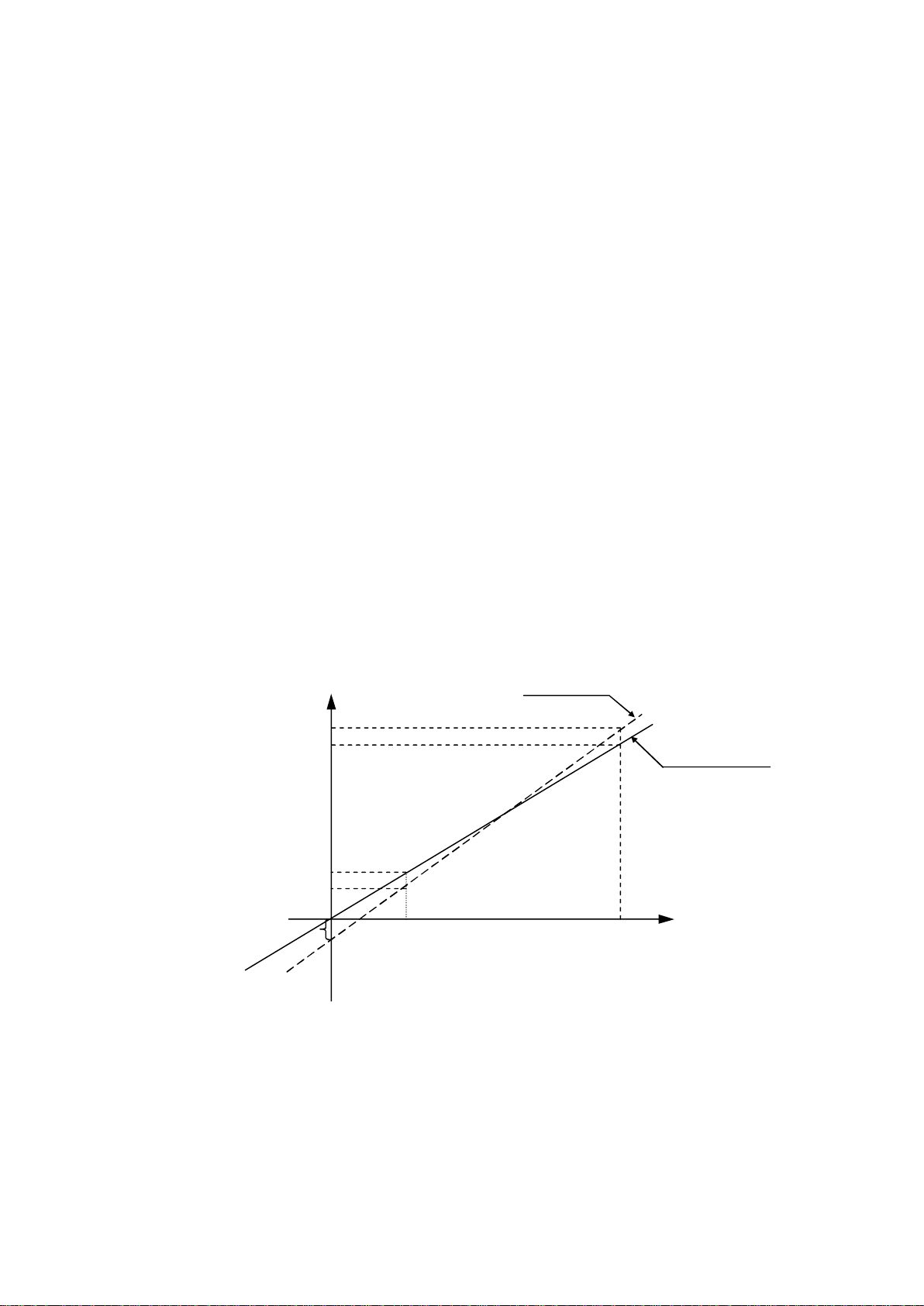

a X

Y

310

100

7.1 Method of Calibration:

The calibration of temperature and pressure is performed digitally.

The temperature and pressure measuring circuits are designed with components

having 1% accuracy.

The temperature circuit is linear and has an output of 100mV÷2400mV for a

temperature range 20°C÷150°C.

The pressure circuit is also linear and has an output of 100mV÷2400mV for a

pressure range 0÷400 kPa.

The measuring at the A/D is limited for values higher than 2400mV or below

100mV.

It is obvious that although the accuracy of the circuit components is 1%, the

sum deviation may reach 5%. Therefore calibration is necessary.

The system has a non-volatile memory in which the offset and gain data of the

sensors are stored.

Calibration is performed by use of the keyboard (or the communication port for

computer use).

Following is a description of the calibration of temperature and pressure using

the keyboard. The calibration procedure is identical to all autoclave models.

Definition of Gain and Offset:

Every straight line can be defined by the equation ax+b=y. “a” is the deviation

from y=0 and “b” is the slope of the line. In our case a=Gain and b=Offset.

The system is based on calculation of offset and gain of two points as in the

following example

If the actual measured pressures are 100 kPa & 300 kPa and the displayed

pressure are 90 kPa & 310 kPa respectively, the ‘input Vs pressure” graph will

be as follows.

READ

300

90

PRESURE

V

1

INPUT FROM SENSOR

V

2

ACTUAL

The calibration method enables to input this data into the system in order to

perform automatic correction of OFFSET and GAIN.

It is necessary to define the two points, which have to be input to the system,

prior to performing calibration.

Page 17 of 132 Pages

Page 20

7.2 Temperature Calibration Procedure

— Press the PROGRAM key.

— The system enables to set the system’s date the time.

— This operation is skipped by pressing PROGRAM key six times.

—

CODE: will be displayed.

— Select Technician Code (011) by the UP/DN keys and press the

PROGRAM key.

— Select CALIB CODE: 107 to calibrate the system by means of the UP/DN

keys and press the PROGRAM key again until TEMP CAL:

will be displayed.

— Set calibration code to TEMP CAL: 1

— Press the PROGRAM key again and do not change the code.

— The following data will be displayed:

UPPER ROW:

LOWER ROW: A 130.0 R130.0

Enter the actual data (A) and the displayed data (R) for two known points as in

the following example:

The actual temperatures are 70°C & 120°C and the displayed temperatures are

68°C & 120°C respectively. the

Proceed as follows:

— On the upper row, change A60.0 to A 70.0 by means of UP/DN keys.

— Press the PROGRAM key.

— The cursor on the upper row will move to R60.0, change to

R68.0 by means of UP/DN keys.

— Press the PROGRAM key.

— The cursor moves to the lower row to A 130.0, change it to A 120.0 by

means of UP/DN keys.

— Press the

— The cursor on the lower row will move to R130.0

means of keys UP/DN, then press the PROGRAM key

PROGRAM key.

A 60.0 R 60.0

, change to R123.0 by

This completes calibration procedure for temperature.

Page 18 of 132 Pages

Page 21

Remarks:

— When cursor is set under any figure, pressing the START/STOP key stops

calibration.

— When the cursor is set under any figure, it enables to feed this value to the

reading of temperature by pressing the

Example:

If the cursor is set under R68.0 on the upper row and the actual temperature of

the autoclave is now 66.0ºC, by pressing the PARAMETERS key, the

temperature reading will be

corrected from R68.0 to R 66.0.

This calibration method enables the technician to change a certain point

without affecting a second point.

Example:

When the working temperatures are 134ºC and 121ºC but the actual

temperature are 132ºC and 121ºC

The measured temperature for 134ºC must be corrected without changing the

temperature at 121ºC,

Considering the above example, the setting of data can be done as follows:

A 121.0 R 121.0

A 132.0 R 134.0

The system will calibrate the new offset and gain and retain them into the nonerasable memory.

As a result, while running a 134ºC program the correction is automatically

made, while at 121ºC no change is felt.

PARAMETERS key.

Page 19 of 132 Pages

Page 22

7.3 Pressure Calibration Procedure

To perform the pressure calibration two points have to be defined allowing the

calculation of new OFFSET and GAIN values.

— Press the PROGRAM key.

— Skip date and the time setting by pressing the PROGRAM key six

times.

— CODE: will be displayed.

— Select the Technician Code (011) by the UP/DN keys and press the

PROGRAM key.

— Select CALIB CODE: 107 to calibrate the system by means of the

UP/DN keys and press the PROGRAM key again until the system

displays: PRES CAL:

— Press the PROGRAM key.

The following is displayed:

Point 1 – Upper Row A 100 R 100

Point 2 - Lower Row A 300 R 300

— Open the door, do not alter A 100.

— Press the PROGRAM key, the cursor will move to R 100.

— Press the PARAMETERS key. The system performs reading

pressure and displays it instead of R100. E.g. R97 (i.e. the

system reads out 97kPa, when the door is open).

— Press the PROGRAM key.

— The cursor moves to the lower row to A300.

If the system reads out 280kPa, do not change A300. Press the PROGRAM

key to move to R300 and change it to the actual

pressure value 280kPa by means of the keys UP/DN.

— Press the PROGRAM key again.

The system calculates the new values for offset and gain and stores these

values in the non-volatile memory.

This completes the calibration procedure for the pressure.

Page 20 of 132 Pages

Page 23

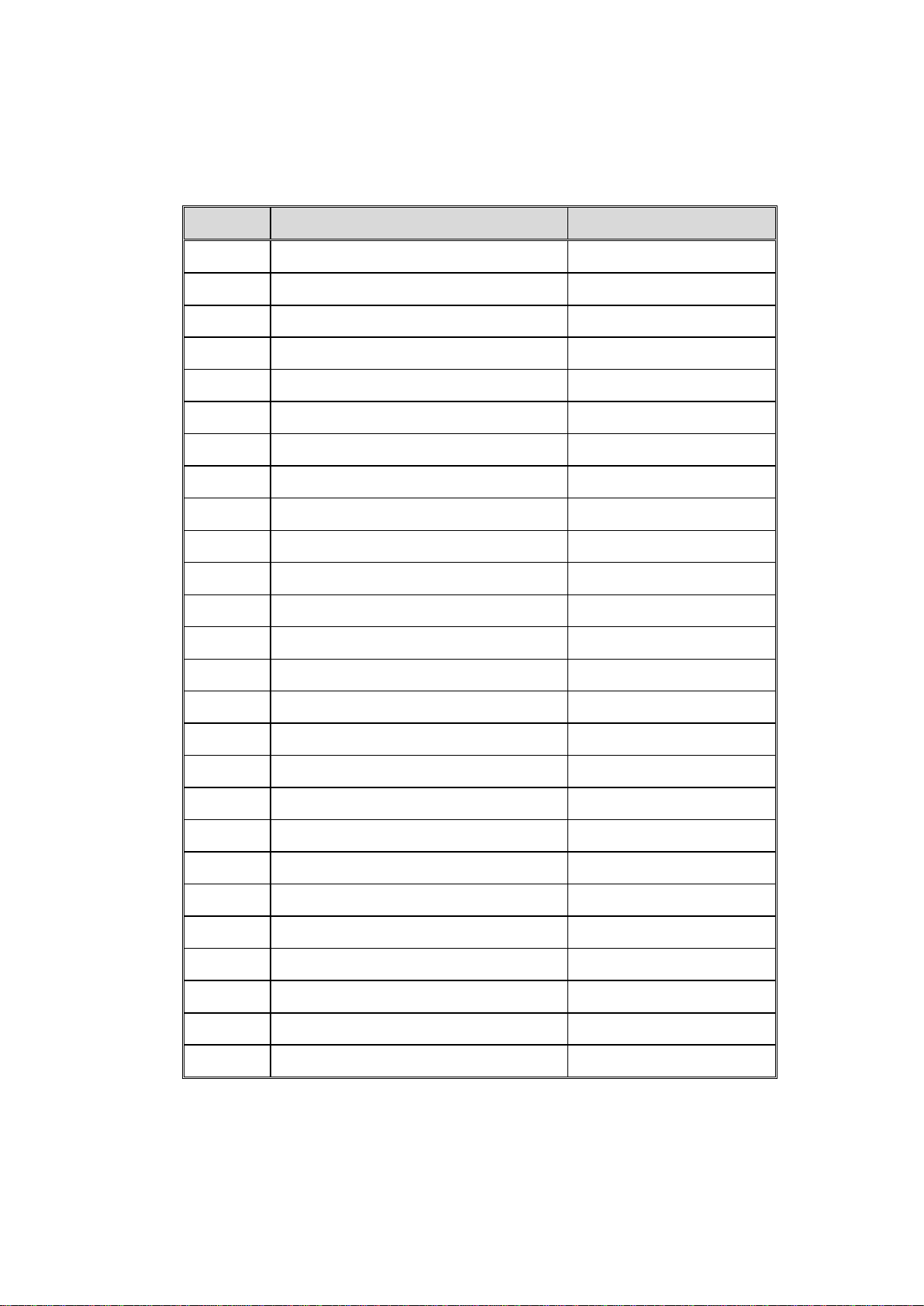

8. TEST POINTS

The test point list provides testing points on the junctions on board to assist in locating

the malfunction.

NU TP FUNCTION VALVE

TP1

TP2

TP3

TP4

TP5

TP6

TP7

TP8

TP9

TP10

TP11

TP12

TP13

TP14

GND

+5V DC

+12V DC

OUT - HEATERS ON – 5V; OFF –0V

OUT-VACUUM PUMP ON – 5V; OFF –0V

OUT-EXH-2 VALVE ON – 5V; OFF –0V

OUT-AIR VALVE ON – 5V; OFF –0V

OUT-EXH-1 VALVE ON – 5V; OFF –0V

OUT-WATER TO CHAMB. ON – 5V; OFF –0V

OUT-DOOR LOCK ON – 5V; OFF –0V

OUT-AIR RELEASE ON – 5V; OFF –0V

OUT-COMPR. AIR ON – 5V; OFF –0V

OUT-WATER COOLING ON – 5V; OFF –0V

TP15

TP16

TP17

TP18

TP19

TP20

TP21

TP22

TP23

TP24

TP25

TP26

IN –TEMPERATURE (OPTION) 134ºC-1.97v

IN –TEMPERATURE (MAIN) 134ºC-1.97v

IN – PRESSURE 2.0B – 2.031v

IN – ELECRODE LOW ‘0V’ – YES, ‘2.5V’ – NO

IN – ELECTRODE HIGH ‘0V’ – YES, ‘2.5V’ - NO

Page 21 of 132 Pages

Page 24

9. SOFTWARE PROGRAMMING PROCEDURES

9.1 General

The software for the control system of laboratory autoclaves is constructed as

one software for all types of laboratory autoclaves (table and vertical), version

LAB00VN1.

The software contains a table of parameters of which part of them defines the

autoclave, and part defines the processes in the autoclave. This document

describes parameters and their task in the software.

9.2 Changing Cycle Parameters

Access to the program is achieved by inserting the access code.

Access code 1 – This access code enables change of the sterilization

time, sterilization temperature and the drying time.

Access code 11 – changes that may be done by the supervisor.

Enables to change a few parameters

Access code 33 – changes that may be done by the technician.

Enables to change all the parameters

To change the parameters listed below, proceed as follows:

a. Select the cycle.

b. Enable the operation by entering the ACCESS CODE (11).

c. Set the parameter that has to be modified, by pressing successively the

PROGRAM key.

d. Set the desired data by means of the UP/DN keys.

e. Pressing the PROGRAM key enters the modified data into memory, and

moves to the next parameter.

The pre-set parameters values will replace the last default values and become

the updated default values.

9.2.1 STER Temp – Required sterilization temperature

Entry Code – 1

Resolution – 1ºC

Minimum value for the change – 60ºC

Maximum value for the change – 137ºC

Set

value

9.2.2 STER Time – Required sterilization time for the process

Entry code – 1

Resolution – 1 minute

Minimum value – 3 minutes

Cycle

Value

1 2 3 4 5 6 7

134 121 121 121 105 121 0

Maximum value – 99 minutes

Set

value

Cycle

Value

1 2 3 4 5 6 7

3 15 20 20 18 30 0

Page 22 of 132 Pages

Page 25

9.2.3 Dry Time – Required drying time for the process

Entry Code – 1

Resolution – 1 minute

Minimum Value – 0 minutes

Maximum Value – 99 minutes

Set

value

9.2.4 Water Time – Time for entering water to the autoclave

This value defines the entry time of the water to the autoclave to

locate the electrode touching the water.

This time will change from process to process and even for different

autoclaves.

When the autoclave is vertical and the defined time is Ø seconds, the

water valve will not open at all.

Entry Code – 11

Resolution – 1 second

Minimum Value – 1 second

Maximum Value – 200 seconds

Set

value

Cycle

Value

Cycle

Value

1 2 3 4 5 6 7

0 0 0 0 0 0 0

1 2 3 4 5 6 7

20 20 20 20 20 20 20

9.2.5 Heat T.O. - The maximum time allowed for the heating stage

(testing)

After this time, if the system does not enter the sterilization stage, it

will receive a ‘Low Heat’ message and the process will abort.

Entry Code – 11

Resolution – 1min

Minimum Value – 20min

Maximum Value – 300 min

Set

value

Cycle

Value

1 2 3 4 5 6 7

60 60 60 90 90 90 0

Page 23 of 132 Pages

Page 26

9.2.6 End Temp - The ending temperature of the process

If at the end of the process the temperature is higher than this

temperature, the process will not end and the door will remain closed.

Entry Code – 11

Resolution – 1ºC

Minimum Value – 40ºC

Maximum value – 137ºC

Set

value

9.2.7 PulsNum. – No. of pulses in the prevacuum stage

Entry Code – 11

Resolution – 1

Minimum Value – 1

Maximum Value – 5

Set

value

9.2.8 VacDip1 – Vacuum value in the first pulse

Defines the vacuum value in pulse no.1 of the prevacuum stage.

Entry Code – 11

Resolution – 1kpa

Minimum Value – 1kpa

Cycle

Value

Cycle

Value

1 2 3 4 5 6 7

120 120 100 85 85 85 134

1 2 3 4 5 6 7

2 1 2 1 1 1 1

Maximum Value – 90kpa

Set

value

9.2.9 VacDip2 – Vacuum value in the remaining pulses

This value defines the vacuum in the remaining pulses in the

prevacuum stage (not just pulse no. 2)

Entry Code – 11

Resolution – 1kpa

Minimum Value – 1kpa

Maximum Value – 90kpa

Set

value

Cycle

Value

Cycle

Value

1 2 3 4 5 6 7

12 20 20 20 20 20 20

1 2 3 4 5 6 7

20 20 20 20 20 20 20

Page 24 of 132 Pages

Page 27

9.2.10 Vac Time 1 – Vacuum Time in the First Pulse

This value defines the time the system will continue to maintain

vacuum after reaching Vac Dip1 for the first pulse.

Entry Code – 11

Resolution – 30sec

Minimum Value – 1sec

Maximum Value – 1800sec

Set

value

9.2.11 VacTime2 – Waiting time for the remaining pulses

In the remaining pulses starting from pulse no. 2 in the prevacuum

stage, after arriving at the VacDip2, stage there is a time delay,

defined as VacTime2 (in seconds), that the vacuum system continues

working.

Entry Code – 11

Resolution – 30 seconds

Minimum Value – 1 second

Maximum Value – 1800 seconds (30 minutes)

Default Value – 240 seconds

Set

value

9.2.12 Ex Mode – The method for exhausting the steam at the end of the

process

Entry Code – 11

Cycle

Value

Cycle

Value

1 2 3 4 5 6 7

30 30 30 30 30 30 30

1 2 3 4 5 6 7

30 30 30 30 30 30 30

Resolution – 1

Ex Mode

Fast Ex 1

N.A. 2

Slow Ex (Waste) 3

Slow Ex (Liquids) 4

Cooling with compressed air 5

Cooling with water circulation 6

Set

value

Cycle

Value

1 2 3 4 5 6 7

1 1 3 4 4 6 1

Page 25 of 132 Pages

Page 28

9.2.13 LimitP add – The allowable addition to the maximum pressure in

every process

If the maximum pressure is 225kpa, the system will not heat beyond

this pressure. If LimitP add will be Ø , the maximum pressure will

remain 225kpa. If LimitP add equals 10, the maximum pressure will

be 235kpa.

Entry Code – 11

Resolutio – 1kpa

Minimum Value – Ø kpa

Maximum Value – 30kpa

Set

value

9.2.14 Calib Code – Calibration Code

This allows entry to the calibration mode.

It must be set on 107 in order to allow the code to be entered.

Entry Code – 11

Resolution – 1

Minimum Value – Ø

Maximum Value – 255

Set

value

9.2.15 Ex Time

This defines the time the exhaust valve should remain open after

reaching a pressure of 127kpa for removing the water in the chamber.

In some autoclaves 15 seconds is enough, and in the large autoclaves

it is possible that there will be a need to extend this to 40 seconds.

Cycle

Value

Cycle

Value

1 2 3 4 5 6 7

0 0 0 0 5 0 0

1 2 3 4 5 6 7

100 100 100 100 100 100 100

Entry Code – 11

Resolution – 10 sec

Minimum Value – Ø sec

Maximum Value – 240 sec

Set

value

Cycle

Model

2540 45 45 30 30 30 30 30

3150/70 45 45 30 30 30 30 30

Value

3850/70 45 45 30 30 30 30 30

5050/75 60 60 60 60 30 45 30

Page 26 of 132 Pages

1 2 3 4 5 6 7

Page 29

9.2.16 VacPump – Does the autoclave have a vacuum pump?

VacPump

There is no vacuum pump in the autoclave Ø

There is a vacuum pump in the autoclave 1

Entry Code – 33

Resolution – 1

Set

value

9.2.17 AutoSize – Size of the Autoclave:

This parameter defines the size of the autoclave by the following

details:

2540 Ø

3850,3870 1

3150,3170 1

5050,5070 2

Entry Code – 33

Resolution – 1

Set

value

Cycle

Value

Value

1 2 3 4 5 6 7

0 0 0 0 0 0 0

AutoSize

Cycle

Model

2540 0 0 0 0 0 0 1

3150/70

3850/70

1 2 3 4 5 6 7

1 1 1 1 1 1 1

9.2.18 Req Prs+

This defines the required addition to the sterilization pressure in kpa.

For example, for a sterilization temperature of 121ºC the required

pressure is 204kpa. Since the system controls the sterilization process

according to pressure and temperature, if Req Prs+ equals Ø , the

system will maintain the pressure at 204kpa. If the value is at 5kpa,

the system will be maintained at 209kpa, and so on.

Entry Code – 33

Resolution – 1

Minimum Value – 0kpa

Maximum Value – 15kpa

Set

value

Cycle

Value

505075 2 2 2 2 2 2 2

1 2 3 4 5 6 7

5 3 1 1 1 1 1

Page 27 of 132 Pages

Page 30

9.2.19 NO Drain

This is intended for vertical autoclaves only, and defines if the water

will drain at the end of the process or not.

Water drains at end of process – Ø

Water remains in the chamber – 1

Entry Code – 11

Resolution – 1

Minimum Value – 0

Maximum Value – 1

Set

value

9.2.20 Water Max

The maximum allowable time in seconds for water entery (generally it

will be 180 seconds).

Entry Code – 11

Resolution – 1 sec.

Minimum Value – 1 sec.

Maximum Value – 1200 sec.

Set

value

9.2.21 Ex Rate

It sets the rate of the exhaust in the slow exhaust. It is possible in

autoclaves that have a top exhaust valve. A combination of natural

exhaust (through the condense valve) and the operation of the top

exhaust valve in Shoot Mode when:

Cycle

Value

Cycle

Value

1 2 3 4 5 6 7

0 0 0 0 0 0 0

1 2 3 4 5 6 7

400 400 400 400 400 400 180

Entry Code – 11

Resolution – 1 (step)

Minimum Value – 0

Maximum Value – 5

Ex Rate Top Exhaust

0 = Closed

1 = 5% of the time Open

2 = 20% of the time Open

3 = 35% of the time Open

4 = 50% of the time Open

5 = 70% of the time Open

Set

value

Cycle

Value

1 2 3 4 5 6 7

0 0 0 0 0 0 0

Page 28 of 132 Pages

Page 31

9.2.22 Factor

This sets the air pressure in the chamber during sterilization and

cooling in the Hot Water method.

For example: if the temperature in the chamber is 121ºC, and the

suitable steam pressure is 205kPa, if the selected factor is 1.5, the

pressure that will be kept in the chamber will be 205 x 1.5 = 307.5kPa.

Entry Code – 33

Resolution – 0.1

Minimum Value – 1

Maximum Value – 2

Set

value

9.2.23 Hot Wtr

Entry Code – 33

Resolution – 1

Minimum Value – 0

Maximum Value – 1

Selections:

Ø – Regular sterilization with water heating the steam

1 – The sterilization will be with a circulation of hot

Set

value

9.2.24 Temp2+

For Hot Water systems, there is an extra sensor placed outside of the

liquid media to measure the temperature of the hot water. If this

temperature rises above the value of the Ster. Temp and

Temp2+combined, then the heating elements will shut down.

Cycle

Value

water and a backup of compressed air.

Cycle

Value

1 2 3 4 5 6 7

1.5 1.5 1.5 1.5 1.5 1.5 1.5

1 2 3 4 5 6 7

0 0 0 0 0 0 0

For example, if Ster Temp is 121C, and Temp2 is 3C, if the hot

water temperature outside the liquid rises above 124C (i.e. 124.1C

or above), the heaters will not activate.

Entry Code – 33

Resolution – 1C

Minimum Value – 1C

Maximum Value – 5C

Set

value

Cycle

Value

1 2 3 4 5 6 7

3 3 3 3 3 3 3

Page 29 of 132 Pages

Page 32

9.2.25 DryPulss

If the system contains a vacuum pump (i.e. the Vac Pump parameter =

1), and a dry stage is required, the air valve will open or close

according to the value of DryPulss.

If DryPulss = 0, the air valve remains closed.

If DryPulss = 1, after 4 minutes of evacuating the chamber during the

dry Stage, the air valve will open in shoot mode of 10 seconds on and

50 seconds off.

Entry Code – 33

Resolution – 1

Minimum Value – 0

Maximum Value – 1

Set

value

9.3 Resetting the Autoclave

Whenever certain data, stored in the back-up memory, must be erased the

system must be reset, in order to restore the system to normal operation or for

situations that follow:

— When the machine is operated for the first time or after a long interruption,

and disorders appear in the operations sequence.

— When operation was stopped in the middle of the cycle, as a result of a

power failure or manual stop and the cycle has not been completed.

To reset the system; proceed as follows:

— Turn the main power switch OFF.

— Turn the main power switch ON, while pressing the SEL. CYCLE key,

until the program parameters are displayed.

After resetting the autoclave, the autoclave is in stand-by mode

9.4 Test Mode

Turn on the main power switch, while pressing the UP key continuously, to

enter the Test mode.

The output test will start (valves, heater, pump), each output will be activated

for one second and its name will be displayed. To switch from one output to

another, press each time the UP key.

Keep pressing the UP key, the inputs test is performed, pressing each time the

UP key the next input is selected.

The same way the temperature and pressure values are displayed.

Cycle

Value 0 0 0 0 0 0 0

1 2 3 4 5 6 7

Page 30 of 132 Pages

Page 33

10. REPLACING ELEMENTS

10.1 Safety Tests after Repair

ATTENTION!

After every repair or dismantling the enclosure, the autoclave should pass

two safety electrical test by the Service Engineer. The following shall be

performed:

1. Enclosure Leakage Current Test.

Every autoclave should pass this test as follows:

1. Remove the service doors.

2. Disconnect receptacle from JP3.

3. Remove all fuses.

4. Connect the electrical cord to the autoclave.

5. Turn on the circuit breaker.

6. Short-circuit the L and N pins on the cord's plug.

7. Connect the Short-circuit pins to the L pole on the Megger.

8. Connect the earth pins to the earth pole on the Megger.

9. Impose an electrical potential of 500-1000V on the tested autoclave.

The insulation resistance should be at least 2 MΩ.

The test is successful if there was no leakage.

2. Protective Earth Impedance Test

1. Connect the grounding pin of the power cord plug to one pole of an

Ohmmeter.

2. Connect any other metallic part (preferable – the metallic part of the

locking screw) to the second pole of the Ohmmeter.

3. The resistance should not exceed 0.3 Ω.

After performing these tests, the Service Engineer should complete and sign

the Work Order.

Page 31 of 132 Pages

Page 34

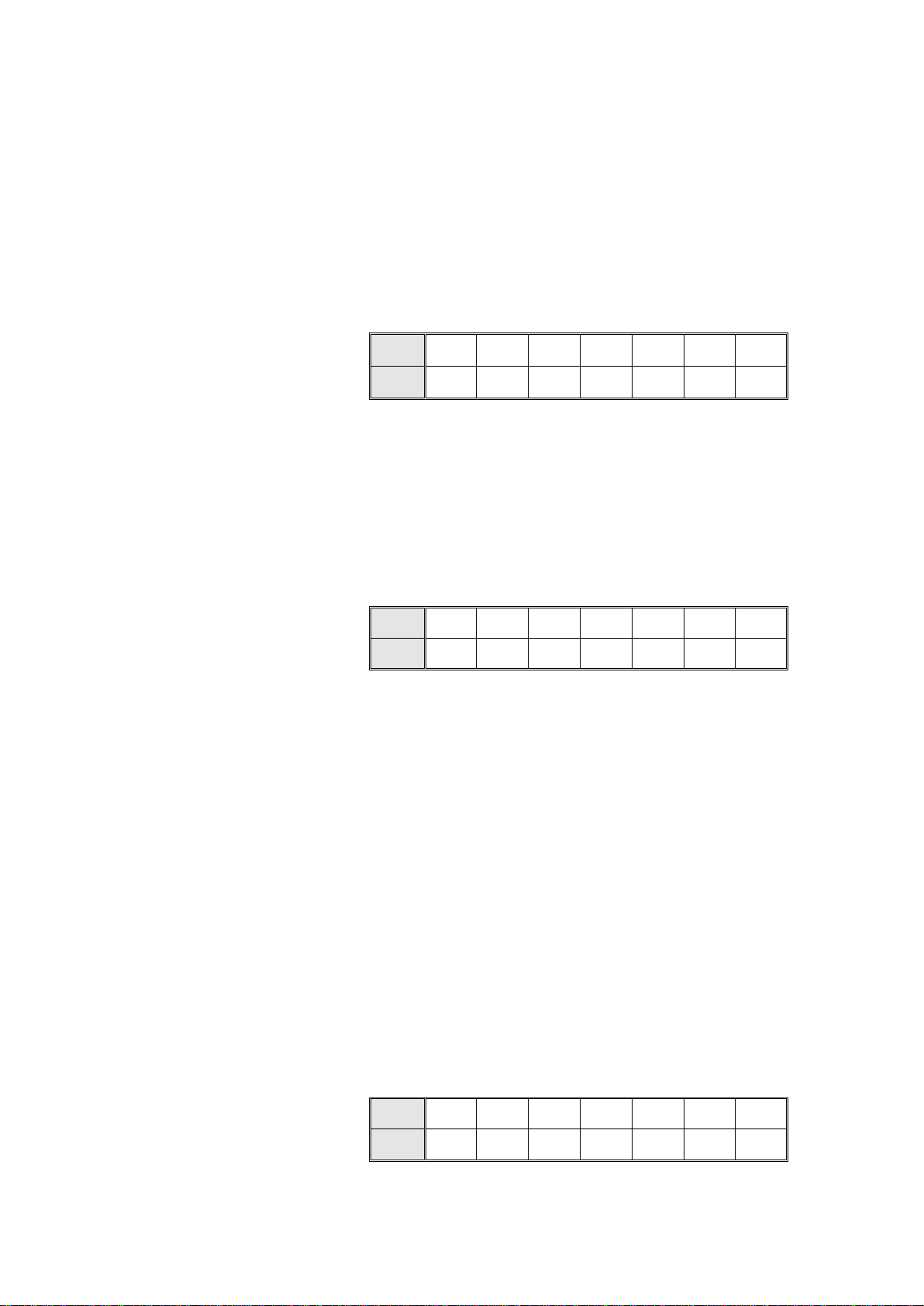

10.2 Replacing the Circuit Breaker

Caution!

Before starting, disconnect the instrument from the power source.

1. Open the right door.

2. Disconnect the wires from the circuit breaker.

3. Remove four screws connecting the circuit breaker to the panel (1).

4. Replace the circuit breaker with a new one.

5. Reconnect the electrical wires.

6. Reassemble the cover.

7. Turn on the autoclave and verify it operates correctly.

8. Move the circuit breaker’s lever to the “tripped” position and verify

that the autoclave turns off.

Make sure that the correct circuit breaker is installed according to the

table below!

Model Power

2540

3150/70

3850/70

3850/70

3850/70 with switching box

3850/70, 5050/75

5050/75

5050/75

5050/75 with switching box

Circuit breaker

1Ph, 230V/50/60Hz 1Ph/15A

1 or 2 Ph, 230V/50/60Hz 1Ph/20A

3 Ph, 208V/50/60Hz 3Ph/20A

3 Ph, 230V/50/60Hz 3Ph/20A

1 or 2 Ph, 230V/50/60Hz 3Ph/15A

3 Ph, 400V/50/60Hz 3Ph/15A

3 Ph, 208V/50/60Hz 3Ph/25A

3 Ph, 230V/50/60Hz 3Ph/25A

1 or 2 Ph, 230V/50/60Hz 3Ph/15A

For models

2540, 3150, 3170

For models

3858, 3870, 5050, 5075

Page 32 of 132 Pages

Page 35

10.3 Replacing the Safety Valve

For models 5050, 5075

Warning:

Before starting, disconnect the instrument from the power source and

ensure that there is no pressure in the autoclave chamber.

Note:

These instructions are valid for both, CE-marked (as in the drawing

below) and ASME type safety valves.

1. Open the right door.

2. Disconnect the pipe connection.

3. Unscrew the safety valve (including the base For models 2540, 3150,

3170, 3850, 3870 or elbow for models 5050, 5075) and remove from the

autoclave.

4. Replace it with a new safety valve (use an original only).

5. Test autoclave cycles.

1

1

4332

6 3 5

For models 2540, 3850, 3870

Cat. No.

Description

1

CE-marked

2540, 3150,

3170, 3850, 3870

5050, 5075

SVL029-0028 SVL029-0005

Safety valve

1

2 Safety valve base CMV100-0004

ASME

SVL029-0004 SVL029-0007

3 Washer CMT240-0022 LOK505-0001

4 Nut CMT240-0020

5 Street elbow F*M ½*½ 90

6 Male connector ½*½

Page 33 of 132 Pages

FIT100-0065

FIT100-0296

Page 36

10.4 Replacing the Door Gasket

10.4.1 For models 2540, 3150, 3170, 3850, 3870

1. Pull off the gasket from the door groove.

2. Clean the slot

3. Install the new gasket referring to the drawings above 1, 2 and

3.

Caution!

This gasket is designed with a trapezoidal cross section. The

gasket should be placed with the widest side towards the door.

10.4.2 For models 5050, 5075

1. Disassemble the 12 segments (1) attaching the gasket to the

door.

2. Remove the gasket (5) from the door.

3. Clean the door surface.

4. Lay the new gasket on the door.

5. Assemble the segments loosely. Verify that the rim of the

gasket (4) is in the groove in the segments (3).

6. After all the segments are assembled loosely verify that the

gasket lies evenly.

7 tighten all the screws (2) of the segments.

1

2

5

3

4

Page 34 of 132 Pages

Cat. No.DescriptionNo.

LOK507-0021Segment1

BOL191-0092Screw M5 x 122

GAS080-0005Gasket5

Page 37

10.5 Replacing the electronics board (control panel)

Caution!

Make sure that the power cord is disconnected!

If the electronic box was damaged by any liquid that entered the box, do not

attempt to replace it. In this case only the factory technicians may repair the

autoclave.

Allow the autoclave to cool before removing outer covers.

For description of items numbered in brackets see table in para. 10.6.

1. Open the right service door.

2. Unscrew the screws of the electronic box cover (8) and remove the cover

(12).

3. Remove the screws that connected the plastic panel with the digital

electronic board to the autoclave (2).

On model 2540 remove 2 screws placed on the “head” and the “foot”

of the panel.

On models 3150, 3170, 3850, 3870 remove 3 screws placed on the

“head”, the “foot” and the side of the panel

On models 5050, 5075 remove 6 screw both sides of the keyboard

panel

4. Disconnect the flat cable from JP1-DIG-T2 to JP1 ANL-T2 (4).

5. Disconnect the flat cable of communicator from P1-ANL-T2 (6).

6. Disconnect the grounding cable shoe (green cable) (5).

7. If the autoclave is equipped with a printer, disconnect the printer cable.

8. Remove the main switch.

On autoclave model 2540, 3170, 3850, 3850, 3870 disconnect the

main switch (7).

On models 5050, 5075 remove the main switch (7) from the panel

without disconnecting it.

9. Remove the plastic panel, including the electronics board (control panel),

from the autoclave.

10. If replacement of the control panel is required, unscrew four fastening

screws located on the rear of the panel. Remove the control panel from the

plastic panel and replace it with a new one.

Page 35 of 132 Pages

Page 38

10.6 Replacing the Electronics Box

BOL194

-

BOL194

-

BOL194

-

BOL191

-

BOL194

-

BOL194

-

BOL194

-

BOL194

-

BOL194

-

BOL194

-

BOL194

-

BOL194

-

BOL194

-

BOL194

-

BOL194

-

BOL194

-

NUT192

-

NUT192

-

NUT193

-

NUT193

-

NUT193

-

BOL191

-

CMT254

-

CMT315

-

CMT240

-

CMT507

-

Caution!

Make sure that the power cord is disconnected!

If the electronic box was damaged by any liquid that entered the box, do not

attempt to replace it. In this case only the factory technicians may repair the

autoclave.

Allow the autoclave to cool before removing outer covers.

1. Open the right service door.

2. Unscrew the screws adjacent to the fan grid (3).

3. Disconnect all the electric system connectors from the electronics base

(including the MPX connectors).

4. If the autoclave is equipped with a printer, disconnect the printer cable.

5. Unscrew the screws fastening the circuit breaker panel (9) and release the

panel.

On model 2540 release the panel.

On models 3150, 3170, 3850, 3870 remove 2 nuts, washers and spring

washers (10).

On models 5050, 5075 remove 2 screws, nuts, washers and spring

washers (10).

6. Remove electronics box and replace with new one.

7. Re-assemble the instrument. Verify that the grounding connections are

connected correctly.

8. Test any cycle and verify that the autoclave operates as required.

0340

0341

0340

0340

0185

0276

0317

Cat No.

0340

0341

0340

0340

0185

0276

NUT193-

0317

0140

0341

0340

0340

N

o.

Description

2 Screw

3 Screw

8 Screw

9 Screw

Nut

Washer

Spring Washer

10

¼

2540 3150, 3170 3850, 3870 5050, 5075

0340

0341

0340

0340

NUT193-

Star Disk

Screw

Sheet Nut

11

4.8x1.25

12 Cover

NUT192-

0230

0020

NUT192-

0230

0001

NUT192-

Page 36 of 132 Pages

0230

0031

0291

0140

NUT192-

0230

0008

Page 39

11

7

8

12

52

2

1

2

4

3

6

Electronic box 3850, 3870

Page 37 of 132 Pages

Page 40

3870ELV Rear Side

3

9

10

Electronic Box – Internal Front Side

Page 38 of 132 Pages

Page 41

10.7 Cut-Out Thermostat

Warning:

Before starting, disconnect the instrument from the power source and ensure

that there is no pressure in the autoclave chamber.

This thermostat cuts out the power to the autoclave, in the event that all other

safety systems malfunction. For example: if the autoclave operates without

water in the chamber, the PT100 detect this and the control unit cuts the

electricity to the heaters.

If the temperature still rises, then the cut-out thermostat will cut-out the power

to the autoclave. In order to restart the operation press the RESET Button. If

the autoclave is operated according to instructions, and the thermostat cuts out

again, a service technician should be called.

10.7.1 Replacing the Cut-Out Thermostat

1. Disconnect the cut-out sensor (3) from the heating elements

(2).

1. Unscrew the nut fastening the reset button (1).

2. Unscrew the nut (6) from the bushing (5).

3. Remove the faulty thermostat and replace it with a new one

(use an original only).

4. Reconnect the cut-out sensor to the heating elements, using the

fasteners (4).

4. Reinstall the bushing. Use a sealant to ensure sealing.

4 3

1

2

5

Cut-Out Thermostat

Reset button

6

Page 39 of 132 Pages

Page 42

10.8 Replacing Heating elements

HEA012

-

HEA012

-

HEA012

-

HEA012

-

SPR177

-

SPR177

-

SPR177

-

SPR177

-

GAS083

-

GAS083

-

GAS083

-

GAS083

-

Caution:

Before starting, be sure that the electric cord is disconnected from the power

source and that there is no pressure in the autoclave chamber.

1. Turn the autoclave and lay it on its side.

2. Disconnect the cut-out sensor (2) from the heating elements (1).

3. Disconnect the electrical wires (7) from the heating elements.

4. Unscrew the nut fastening the heating element (5) and remove the gasket

(3).

5. Push the heating element inward and take it out.

6. Replace the heating element.

7. Reconnect the cut-out sensor to the heating elements, using the fasteners

(3).

8. Reconnect the electrical wires to the heating elements. Verify that the

isolating tubes (6) are assembled too.

9. After replacing the heating element run a cycle and verify that it operates

as required and that there is no leakage.

10. Close the autoclave’s service door.

11. Test the autoclave by performing a full cycle.

7

.

6 5 34 2

Description 2540

1 Heating element

2 Cut-out sensor

3 Cut-out sensor fastener

4 Gasket ring

3150/31703850/38705050/507

0005

N/A N/A N/A N/A

0014

N/A N/A N/A N/A

0006

0014

0007

0014

0008

0014

1

5

Heating element fastening

5

nut

6 Isolating tubes

Heating elements

7

electrical wire

N/A N/A N/A N/A

0003

N/A N/A N/A N/A

0003

0003

Page 40 of 132 Pages

0003

Page 43

10.9 Safety Door Locking System for models 2540, 3150, 3170, 3850, 3870

Door locking is achieved by means of two safety devices, a pull type solenoid

which must be powered to enable the opening of the door and a pressure activated door locking.

10.9.1 Solenoid Locking Device

The solenoid locks the door in the following situations:

When the control unit is not powered.

a. If power failed or has been turned off while the autoclave is in

operation, even if power has been restored.

b. If operation was stopped before completion of the cycle as a

result of a failure or a manual stop.

c. When the temperature inside the autoclave chamber is higher

than the end of the cycle temperature, preset by the operator;

the opening of the door is possible only when the temperature

has dropped below the pre-set value.

The release of the door locking is done automatically at the

completion of a normal cycle. In case of failure or manual stop,

release the door locking by pressing the STOP key.

For model 2540

For models

3150, 3170,

Page 41 of 132 Pages

Page 44

10.9.2 Replacing the Solenoid Locking Device

Caution!

Before starting, disconnect the instrument from the power source

and ensure that there is no pressure in the autoclave.

For description of the locking device see next page.

1. Remove the door cover.

2. Disconnect the wires from the connector.

3. Unscrew the tightening nut (cat. No. CMT201-0004).

4. Remove the pin, the spring and the solenoid.

5. Replace the damaged items and reinstall according to drawing

below.

6. Operate the autoclave and verify that the pin is retracted when

the cycle reaches “stand-by” stage.

10.9.3 Emergency Door Opening

In order to facilitate the initial installation, the door locking position

is taped in this retracted position at the factory. On completion of all

installation activities this tape must be removed. If for any reason the

door locking mechanism is permanently locked, it is possible to open

the door and provide access for eventual repairs to the locking

mechanism. The swing bolt has a drilled opening located in the lock

catch. By pushing the piston back with a 2mm. pin, the swing bolt

may be turned another 3/4 turn until the position catches again.

Repeat these operations until the bolt can be swung away and the

door opened.

Page 42 of 132 Pages

Page 45

10.10 Safety Door Locking System for models 5050, 5075

To release the door locking to cancel the door locking at the end of operation;

press the UP key

An additional door safety device is fitted to the models, 5050, 5075, which

work with a central closing mechanism. This device is a piston-cylinder

assembly valve, activated by one of the radial locking arms and connecting the

chamber to the open atmosphere, through a small nozzle.

When the first step of opening the door is performed and arms are unlocked

turning the handle counter-clockwise, the arms change direction, the piston is

released and valve opens, chamber is aerated and residual pressure discharged

from the chamber.

Following this, opening the door by pulling it, can be done safely, with no risk

for the operator, of steam or hot water burst.

Safety locking device

Safety opening device

Locking solenoid

Two microswitches ensure that operation cannot be started if autoclave door is

unlocked; one is activated by the door, when it is lowered down to the frame,

the second by one of the arms in position locked. When the two micro-switches

are pressed, the light “DOOR” on the keyboard panel is OFF and operation can

be initiated.

Page 43 of 132 Pages

Page 46

10.11 Disassembling and Assembling the Door Cover, Models 2540, 3150, 3170,

3850, 3870

Caution:

Before starting, be sure that the electric cord is disconnected from the power

source and that there is no pressure in the autoclave chamber.

1. Unscrew the four screws attaching the door cover and remove the door

cover. Since the screw pressing the door microswitch includes two washers

and a spring, be aware not to lose them.

2. Reassemble the new cover.

3. When assembling covers on models 3850/3870 place a washer (7) between

the door cover (6) and the door flange (5) – on all 4 flanges (in the drawing

below the washer is hidden).

4. To assemble the screw that is pressing the door switch, insert screw (1)

until dimension A is approximately 15 mm.

4.1 Please note that on models 3150/70 two washers (3) are placed

between the spring (4) and the door.

5. Perform final adjustment of the screw as follows:

5.1 While the autoclave is disconnected from electricity turn on the

circuit breaker.

5.2 Connect the electrical plug to a multi-meter.

5.3 Press the microswitch and verify that the microswitch functions as

required.

5.4 Close the door and verify that the microswitch operates.

5.5 If the microswitch does not operate unscrew the screw one turn

counter- clockwise and check per para. 4.4. Repeat until microswitch

operates.

5.6 Connect the autoclave to electricity.

5.7 Close the door until the microswitch indicates that the door is closed.

Operate the autoclave and verify that there is no steam or pressure

leak.

5.8 If there is steam leak, stop the autoclave’s operation, reduce steam

pressure, open the door and turn the screw one turn clockwise and

check per para. 5.7. Repeat until leakage ceases.

6. After assembling the door cover stick the model label (see spare parts list)

in the sunken surface.

Page 44 of 132 Pages

Page 47

2540

POL065

-

0053

washer

A

7

6

2

15343

No. Description Model

2540 BOL191-0032 3 washer All models ELE036-0009

1 screw

2 screw

3150, 3170

3850, 3870

2540 BOL191-0033 3150, 3170 COV314-0001

3150, 3170 BOL191-0115 3850, 3870 POL065-0044

3850, 3870 BOL191-0082 7

Cat. No.

BOL191-0091

No. Description Model

4 spring All models SPR177-0012

6 door cover

(hidden)

3850, 3870 NUT193-0270

Cat. No.

Page 45 of 132 Pages

Page 48

10.12 Disassembling and Assembling the Door Cover, Models 5050, 5075

10.12.1 Disassembling the Door Cover

Warning:

Before starting, disconnect the instrument from the power source

and ensure that there is no pressure in the autoclave chamber.

1. Release the two (2) fastening screws (1).

2. Remove the locking handle (10) and the Teflon ring (9).

3. Remove the screws covers (2).

4. Unscrew the cover fastening screws (3, 5) and remove the

screws and the washer (4).

5. Remove the door cover. Be careful not to loose the springs (6)

and the washers (4a) located beneath the door cover. Washer

(7) is a disposable nut and must be replaced buy a new nut

when the door cover is re-assembled.

10.12.2 Assembling the Door Cover

1. Place the Teflon disk (9) on the door handle axis.

2. Place and hold the spring (6) and the washer (4a) on the spacer

(8). Place the door as near as possible to its place and insert the

screw (3) with the washer (4) on the screw, through the hole in

the door, into the spacer (8). Do not tighten the screw.

3. Repeat this operation with the second screw.

4. Open the door.

5. Insert the screw (5) with the washer (4b) on the screw, through

the holes in the door and in the hinge. Screw nut (7) slightly

(do not tighten it).

6. Adjust the door and tighten all four screws.

7. Place the screw caps (2)

8. Place the second Teflon disk (9) on the door handle axis.

9. Install the door handle on the axis and fasten the fastening

screws (1).

Page 46 of 132 Pages

Page 49

Page 47 of 132 Pages

Page 50

No. Description Cat. No.

1 Screw BOL191-0002

2 Screw cover ARM067-0004

3 Screw M5 x 35 mm BOL191-0143

4 Washer 3/16 NUT193-0275

5 Screw M5 x 1” BOL191-0155

6 Spring SPR177-0010

7 Self locking nut M5 NUT192-0221

9 Teflon washer LOK507-0035

11 Cover, Door POL065-0005

Page 48 of 132 Pages

Page 51

10.13 Replacing the locking microswitch (Models 5050, 5075)

Caution!

Before starting, disconnect the instrument from the power source and ensure

that there is no pressure in the autoclave.

1. Remove the door cover (see 10.12 “Disassembling and Assembling the

Door Cover”).

2. Unscrew the 2 screws (6) of the microswitch cover and remove the cover

(7).

3. Disconnect the electrical wires in the microswitch (8).

4. Unscrew the two nuts attaching the microswitch to the door (3) and

remove it.

5. Open the cover of the new microswitch (7).

6. Connect the electrical wires to the new microswitch and close the cover.

7. Assemble the new microswitch to the door.

8. Close, but do not tighten, the fastening nuts (3).

9. Close and lock the door. Adjust the location of the microswitch. Verify

that the door lock LED indicates that the door is closed.

10. Tighten the fastening nuts (3).

11. Reassemble the door cover.

1 2 3

No. Description Cat. No.

2 Washer 3/16 NUT193-0275

3 Nut M5 NUT192-0192

5 Microswitch ELE036-0019

4 Spring washer M5 NUT193-0315

4

5

6

7

8

Page 49 of 132 Pages

Page 52

10.14 Replacing the safety-opening valve (Models 5050, 5075)

3

4

5

621

9

8

7

Caution!

Before starting, disconnect the instrument from the power source and ensure

that there is no pressure in the autoclave.

1. Remove the door cover (see 10.12 “Disassembling and Assembling the

Door Cover”).

2. Unscrew the locking arm guide (1).

3. Unscrew the screw assembled on the valve’s piston rod (9).

4. Remove the side bracket (7).

4. Remove the screw fastening the valve to the side bracket (3, 4, 10).

5. Remove the faulty safety valve (2) by turning it counter-clockwise and

unscrewing it from the autoclave’s cover.

6. Install the new valve

7. Install the screw (9) (with the nut (8) on it) on the piston rod.

8. Re-install the locking arm guide (1). Verify that the right guide is installed,

since this guide and the guide of the arm attached to the safety locking

microswitch defers from the other.

9. Re-install the side bracket (7).

10. Set the locking devise to “lock” position.

11. Adjust the screw on the piston rod (9). Turn the screw while the screw

head touches the bracket welded on the locking arm. When the piston rod

is pressed completely inward secure the setting with the nut (8).

12. Reassemble the door cover.

.

Description Cat. No.

1 Arm guide

-0031 6

No

.

Description Cat. No.

Spring washer

M5

2 Valve PNE195-0054 7 Side bracket

Spring washer

3

¼”

4 Nut ¼”

-0317 8 Nut M6

-0185 9 Screw M6

-0315

-0001

-0193

-0150

5 Nut M5

-0192 10 Screw ¼ x 1½

-0174

Page 50 of 132 Pages

Page 53

10.15 Replacing the “DOOR CLOSED” microswitch (Models 5050, 5075)

325

8

1

476

A

Caution!

Before starting, disconnect the instrument from the power source and ensure

that there is no pressure in the autoclave.

1. Open the left service door.

2 unscrew the two nuts fastening the bracket to the autoclave (1).

3. Remove the bracket with the microswitch and unscrew the two screws

connecting the microswitch to the bracket (2).

4. Unscrew the 4 screws of the microswitch cover (3) and remove the cover.

5. Disconnect the electrical wires in the microswitch (4).

6. Open the cover of the new microswitch.

7. Connect the electrical wires to the new microswitch and close the cover.

8. Assemble the microswitch to the bracket. Verify that the distance between

the microswitch and the edge of the bracket (A

) is 5-6 mm.

9. Reassemble the bracket with the microswitch on the autoclave.

10. Turn on the autoclave and close the door.

11. Verify that the display indicates that the door is closed.

12. If the display does not indicate that he door is closed disassemble the

bracket and increase the gap (A) by 1 mm.

13. Repeat steps 10, 11.

.

Description Cat. No.

1 Nut M5

.

Description Cat. No.

-0192 4 Bolt ¼ x ¾

-0142

2 Washer 3/16

3 Spring washer M5

-0275 5 Nut ¼ with flange

-0315 8 Microswitch ELE036-0004

Page 51 of 132 Pages

-0155

Page 54

10.16 Replacing the solenoid lock (Models 5050, 5075)

3

Caution

Before starting, disconnect the instrument from the power source and ensure

that there is no pressure in the autoclave.

1. Remove the door cover (see 10.12 “Disassembling and Assembling the

Door Cover”).

2. Disconnect the electrical wire from the porcelain connectors (1).

3. Unscrew the locking solenoid (2) from the lock housing.

4. Remove the locking pin (3) with the Teflon ring (4).

5. Remove the spring (5) from the solenoid.

6. Insert the spring in the new solenoid.

7. Check the Teflon ring and verify that it is not damaged. If it is damaged

replaced it with a new Teflon ring. Verify that the ring is placed on

shoulder side facing the solenoid.

8. Insert the solenoid into the lock housing and screw it tightly.

9. Connect the electrical wires.

10. Check the solenoid by connecting one wire to a 12V source and the other

wire to ground. Verify that the pin is retracted.

54

No. Description Cat. No.

1 porcelain connectors ELE039-0049

2 locking solenoid SOL027-0001

3 locking pin LOC507-0001

4 Washer, locking Solenoid Pin LOK387-0017

2

5 Spring, Door Lock, Solenoid SPR177-0017

Page 52 of 132 Pages

Page 55

10.17 Cleaning and Replacing the Water Level Electrodes

The water level electrodes are located at the bottom part of the chamber wall.

10.17.1 Replacing

Caution

Before starting, disconnect the instrument from the power source

and ensure that there isno pressure in the autoclave.

Allow the autoclave to cool before removing outer covers.

1. Open the right service door.

2. Disconnect the wire from the electrode connection.

3. Open the nut that tightens the electrode.