Tuttnauer 1730M, 2340M, 2540M, 3140M, 3850M, 3870M,1730MK, 2340MK, 2540MK, 3140MK, 3850MK, 3870MK,1730MK, 2340 MK, 2540 MK, 3140 MK, 3850 M Operation & Maintenance Manual

...

OPERATION

&

MAINTENANCE

MANUAL

Table-Top Autoclaves

models

1730, 2340, 2540, 3140, 3850, 3870 M & MK

1730MK Valueklave

Cat. No. MAN205-0007-000E Rev. K

Tuttnauer U.S.A., 25 Power Drive Hauppauge, NY, 11788, USA. Tel (631) 737 4850, (800) 624 5836, Fax: (631) 737 0720

Tuttnauer Europe b.v., Paardeweide 36, 4824 EH, Breda, P.O. Box 7191, 4800 GD Breda, Netherlands. +31/76-5423510,

Fax: +31/76-5423540

1

TABLE OF CONTENTS

PARAGRAPH PAGE NO.

1 GENERAL....................................................................................................3

1.1 Incoming Inspection .........................................................................3

1.2 Warranty............................................................................................3

1.3 Warranty Statement ..........................................................................3

2 TECHNICAL DATA ....................................................................................5

2.1 Introduction ......................................................................................5

2.2 Storage conditions.............................................................................6

2.3 Operating Condition..........................................................................6

2.4 Standards...........................................................................................6

2.5 Construction......................................................................................6

2.6 Utilities ..............................................................................................6

2.7 Waste Water Disposal .......................................................................7

2.8 Environment Emission Information.................................................7

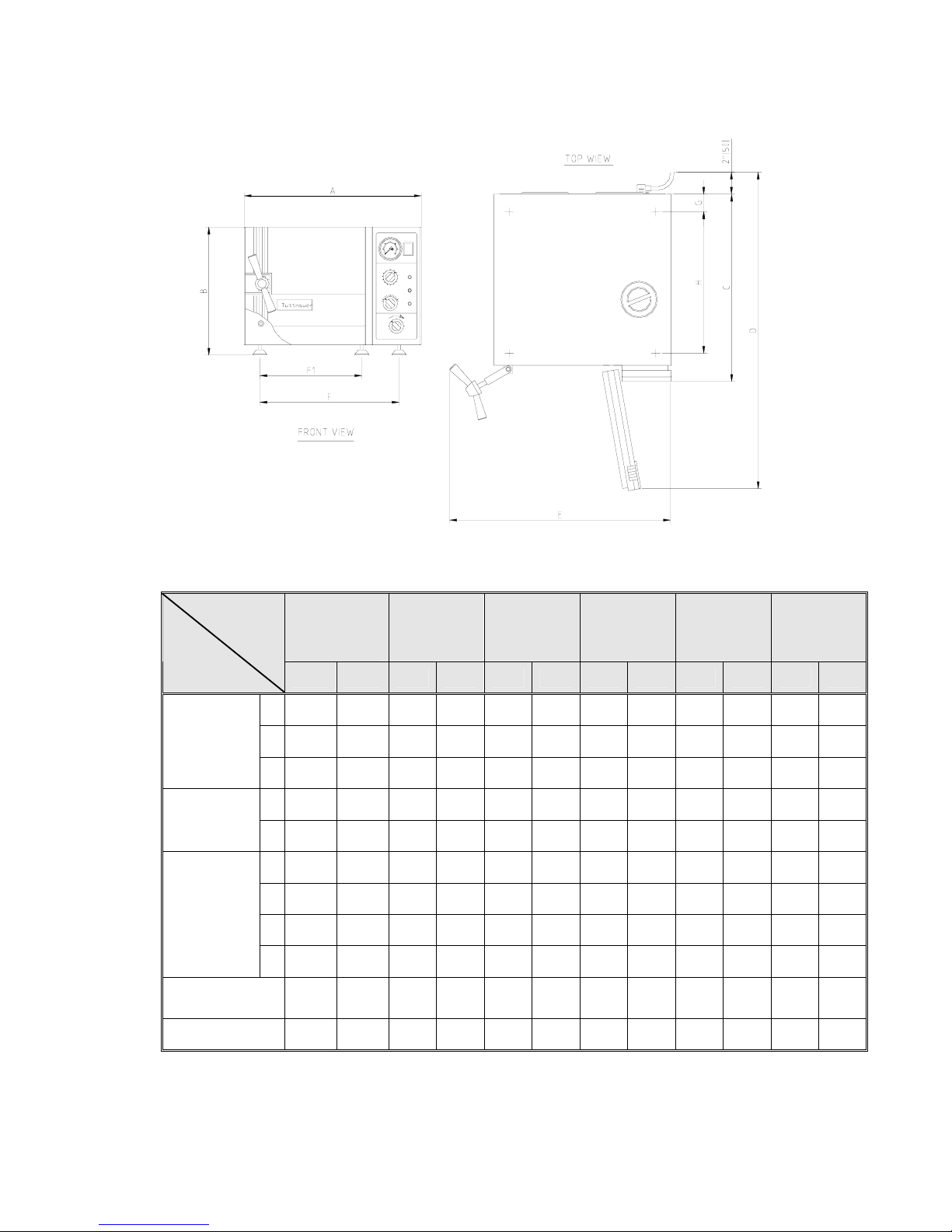

2.9 Dimensions........................................................................................8

2.10 Technical Specifications ...................................................................9

2.11 Electrical Data ................................................................................10

2.12 Maximum Load Sizes......................................................................10

2.13 Symbol Description ......................................................................... 10

3 DESCRIPTION OF COMPONENTS........................................................13

3.1 Control Panel ..................................................................................13

3.2 Other Components ..........................................................................13

4 INSTALLATION INSTRUCTIONS..........................................................14

4.1 Electrical ......................................................................................... 14

4.2 Setup................................................................................................14

4.3 Lifting and carrying ........................................................................15

5 WATER QUALITY ....................................................................................16

6 PREPARATION BEFORE STERILIZATION .........................................17

7 OPERATION .............................................................................................21

7.1 Loading and unloading the Device.................................................21

7.2 Fill the Water Reservoir..................................................................21

8 SERVICE AND MAINTENANCE INSTRUCTIONS............................... 26

8.1 Preventive and Scheduled Maintenance.........................................26

8.2 Draining the Reservoir....................................................................27

8.3 Cleaning Air Jet ..............................................................................28

8.4 Replacing the Door Gasket ............................................................. 29

8.5 Checking the Safety Valve ..............................................................30

8.6 Unclogging the multi-Purpose Valve or Fill piping. ......................31

9 CLEANING TABLE TOP AUTOCLAVES WITH CHAMBER BRITE™32

10 TROUBLESHOOTING .............................................................................34

11 LIST OF ACCESSORIES..........................................................................44

12 CONVERSION TABLE .............................................................................45

2

TABLE OF CONTENT (Cont.)

DRAWINGS PAGE NO.

Front View...................................................................................................................11

Rear View ....................................................................................................................12

Tray Handle CMT240-0001........................................................................................42

Pouch Rack .................................................................................................................42

Tray ..............................................................................................................................42

Tray Holder ................................................................................................................. 42

Tray Holder ................................................................................................................. 43

Alternative Tray Holder .............................................................................................. 43

3

1 GENERAL

Read the Operating Instructions carefully, before beginning any operation

on the autoclave!

1.1 Incoming Inspection

Upon receiving your Tuttnauer Autoclave carefully inspect the outside

of the shipping carton for signs of damage. If any damage to the carton

is found note the location with respect to the autoclave and check that

area of the autoclave carefully once it is fully unpacked. Observe

packing method and retain packing materials until the unit has been

inspected. Mechanical inspection involves checking for signs of physical

damage such as: scratched panel surfaces, broken knobs, etc.

If any damage is found contact your dealer as soon as possible so

that they can file a claim with the shipping carrier and also notify

Tuttnauer.

All Tuttnauer products are carefully inspected prior to shipment and all

reasonable precautions are taken in preparing them for shipment to

assure safe arrival at their destination.

Note: Lifting and carrying should always be done by two people.

1.2 Warranty

We certify that this instrument is guaranteed to be free from defects in

material and workmanship for one year against faulty components and

assembly.

This warranty does not include routine cleaning and preventive

maintenance to be performed according to instructions in

section 8.1 (Preventive and Scheduled Maintenance).

Tuttnauer warrantees all new Manual autoclaves for a period of one full

year, covering both parts and labor. This one year warranty covers

defects in materials and workmanship on every part in the autoclave.

Tuttnauer warrantees all chambers for a period of ten (10) years against

defects in materials and workmanship. This chamber warranty went

into effect January 1997.

This warranty does not apply to any instrument that has been subjected

to misuse, neglect, accident or improper installation or application, nor

shall it extend to autoclaves that have been repaired or altered outside

the factory without prior authorization from Tuttnauer.

Tuttnauer’s obligation is limited to the repair or replacement of parts

for the autoclave. This warranty will be void if the unit is not purchased

from an authorized Tuttnauer dealer. No other warranties or obligations

are expressed or implied.

The Autoclave should only be used in a manner described in this

manual!

1.3 Warranty Statement

To activate the warranty, the registration card must be completed and

returned to Tuttnauer within fourteen (14) days of purchase or you may

call our customer service department at the number listed below.

No product will be received or accepted for repair without prior return

authorization from Tuttnauer. All transportation charges to and from

Tuttnauer must be paid by the owner of the autoclave. During the first

90 days after purchase of an autoclave, Tuttnauer will pay shipping

costs on an individually evaluated basis and ONLY with pre-approval.

4

Note:

If you have any questions or there are any difficulties with this

instrument and the solution is not covered in this manual, please

contact your dealer or our Technical Service Depts that can be reached

at one of the following addresses. Do not attempt to service this

instrument yourself.

Tuttnauer USA Co. 25 Power Drive Hauppauge, NY, 11788, USA

: (800) 624 5836, (631) 737 4850, Fax: (631) 737 0720

e-mail:info@tuttnauer.com

Tuttnauer Europe b.v., Paardeweide 36, 4824 EH, Breda,

P.O. Box 7191, 4800 GD Breda, Netherlands. +31/76-5423510,

Fax: +31/76-5423540, E-mail: Tuttnauer@tip.nl

5

2 TECHNICAL DATA

2.1 Introduction

This table-top autoclave is designed for the sterilization of wrapped and

unwrapped instruments and related items found in dental, medical and

veterinary clinics, first aid rooms, hospitals, laboratories etc.

This autoclave is an electrically - heated sterilizer using steam as the

sterilizing agent. It is a manually operated devise, with a control system

based upon steam pressure.

The operator can select a sterilization temperature from within a range

of 212ºF - 273ºF (100ºC - 134ºC). This allows for the sterilization of

heat sensitive material at a low sterilization temperature, as well as

providing for faster sterilization at higher temperatures for materials

able to withstand the higher sterilization temperatures.

All models feature an easy to use control panel. The machines are

ruggedly built using 316L stainless steel, copper, brass and aluminum.

To guard against rusting no iron components are used. All models

include a fully functioning drying system for wrapped items.

2.1.1 Safety features

The safety features include a double locking door

mechanism (door tightening bolt and locking bellows), a

mechanical pressure relief valve, over temperature

thermostats and a double pole circuit breaker.

Pressure Door Lock System (Door Bellow)

The Door Bellows is a safety device that prevents the door

from opening when the chamber is pressurized.

The system utilizes the build up of pressure in the chamber

to expand a flexible Silicon-rubber bellows. The bellows

then pushes a metal pin into a grove on the tightening bolt

of the Door Closing Device.

This prevents the operator from opening the door when

there is pressure in the chamber. When the steam is

released, this bellow returns to its original position, drawing

the pin with it and releasing the tightening bolt.

This manual is intended for the user and gives the user a general

understanding of the instrument and the best ways to operate and take

care of it in order to obtain optimum effective results.

After reading this manual, operating the autoclave will be easy.

However since this instrument is built with high technology sensitive

components, no attempt should be made by the user or any other

unauthorized person to repair or recalibrate it.

Only technical personnel having proper qualifications and holding

technical documentation (including a technician manual) and

adequate information are authorized to service the apparatus.

6

2.2 Storage conditions

The packed or unpacked autoclave shall be stored in “indoor

conditions” (protected from rain and water).

2.3 Operating Condition

This device is to be used for indoor use.

This autoclave is intended for NORMAL environment conditions as

follows:

● - Altitude up to 2000m.

● - Minimum room temperature 41ºF (5ºC).

● - Installation Category II.

● - Pollution Degree 2.

The environment shall not exceed an ambient temperature of 40ºC and

a relative humidity of 50% up to a temperature of 31ºC and a humidity

of 80%.

The sterilizer should be loaded only with autoclavable material.

2.4 Standards

2.4.1 Technical standards

1. A.S.M.E. Code, Section VIII div.1 for unfired pressure

vessels.

2. AAMI/ANSI ST-55:2001 Table-Top steam sterilizers.

3. UL61010-1 General Safety.

4. UL61010-2-041 Particular Safety for Autoclaves.

2.4.2 Quality standards

1. EN ISO 9001:2000– Quality System

2. ISO 13485 – Quality systems – Medical devices –

Particular requirements for the application of ISO 9001.

2.5 Construction

The main parts of the autoclave are made of materials as indicated

below:

♦ Chamber is built of stainless steel 316 L.

♦ Door is made of stainless steel CF8.

♦ Trays are made of stainless steel 316.

♦ Door handle is made of hard plastic material that is safe to touch

and thermo-insulated.

♦ Water reservoir is made of hard plastic material.

2.6 Utilities

Utilities Unit Value

V-A 1ph, 120V – 16A,50/60 Hz

Power supply (as appropriate)

V-A 1ph, 230V – 16A,50/60 Hz

Attention:

1. The electrical net must be protected with a current leakage safety

relay.

2. The electrical network must comply with local rules or regulations.

3. The autoclave must be connected to a properly grounded outlet

7

2.7 Waste Water Disposal

Caution !

Waste-water may be brought into the public water piping in accordance

with the local rules or requirements. I.e. only non-hazardous liquids

may be disposed in public sewage!

2.8 Environment Emission Information

A. The peak sound level generated by the sterilizer is « 78 / dBA with

background noise of 60 dB.

B. The total heat transmitted by the sterilizer is < 100 W/h for

1730/2340/2540 models and < 150 W/h for 3140/3850/3870

models.

8

2.9 Dimensions

1730

M, MK

MK-Valueklave

2340

M, MK

2540

M, MK

3140

M

3850

M

3870

M

Model

Dimensions

in mm in mm in mm in mm in mm in mm

A 17.4 440 20.0 510 20.0 510 23.2 590 26.0 660 26.0 660

B 12.0 305 14.4 365 14.4 365 17.7 450 20.7 525 20.7 525

Overall

Dimensions

C 17.9 455 21.5 545 21.5 545 21.9 556 27.5 695 34.5 875

D 29.5 750 35.8 910 35.8 910 39.0 990 45.5 1155 53.0 1335

Maximum

dimensions

(door open)

E 22.0 560 25.8 655 25.8 655 29.7 755 32.0 815 32.0 815

F1 13.7 347 11.8 299 11.8 299 19.2 488 17.7 450 17.7 450

F 13.4 339 16.6 422 16.6 422 14.6 371 22.2 564 22.2 564

G 2.0 50 2.0 50 2.0 50 2.0 50 2.0 50 2.0 50

Distance

between

supporting

legs

F1-front legs

F -rear legs

H 12.4 315 15.8 400 15.8 400 15.2 386 21.8 555 30.5 725

Chamber

Diameter

6.7 170 9.1 230 10 254 12.3 312 15.1 384 15.1 384

Chamber Depth 13.4 340 18.5 470 18.7 475 15.4 391 22.8 580 29.9 760

9

Shipping

Volume

0.18 m

3

(6.35 cu.f.)

0.27m

3

(9.4 cu.f.)

0.27m

3

(9.4 cu. f.)

0.35 m

3

(12.4 cu.f)

0.63 m

3

(22.2cu.f.)

0.76m

3

(26.8cu.f)

Shipping

Weight

24.8 kgs.

(54.7 lbs.)

35.7 kgs.

(78.7 lbs.)

47.8 kgs.

(83.3 lbs.)

60 kgs

(132 lbs.)

89 kgs.

(196 lbs.)

102 kgs.

(225 lbs.)

full

2

3

4

10

15

No. of

standard

Cassettes

(Optional)

Half

2

2

3

4

No.

of trays

3

3

4

2

2

2

Tray dimensions

W X D X H

12 x 29.5 x 2 cm

(4.7" x 11.6" x 0.8")

17 x 41.5 x 2cm

(6.7" x 16.3" x 0.8")

17 x 41.5 x 2 cm

(6.7" x 16.3" x0.8")

25.6 x 40.8 x 2.5 cm

(10.1” x 16.1” x 1”)

19.8 x 40.8 x 2.5 cm

(7.8” x 16.1” x 1”)

28 x 50 x 2.5 cm

(11" x 20 " x 1" )

35 x 50 x 2.5cm

(14" x 20 " x 1")

28 x 67 x 2.5cm

( 11" x 26" x 1" )

35 x 67 x 2.5

(14" x 26" x 1")

Volume of

chamber

7.5 liters.

(2 US gal.)

19 liters.

(5 US gal.)

23 liters.

(6 US gal.)

34.4 liters

(7.8 US gal.)

65 liters.

(17US gal)

84 liters.

(22 US gal)

Chamber

dimensions

DIA x D

17 x 34 cm

(6.7" x 13.4")

23 x 47 cm

(9" x 18.5")

25.4 x 47.5cm

(10" x 18.7")

31.2 x 39.1

(12.3” x 15.4”)

38 × 58 cm.

(15" × 23" )

38x76 cm

(15" x 30")

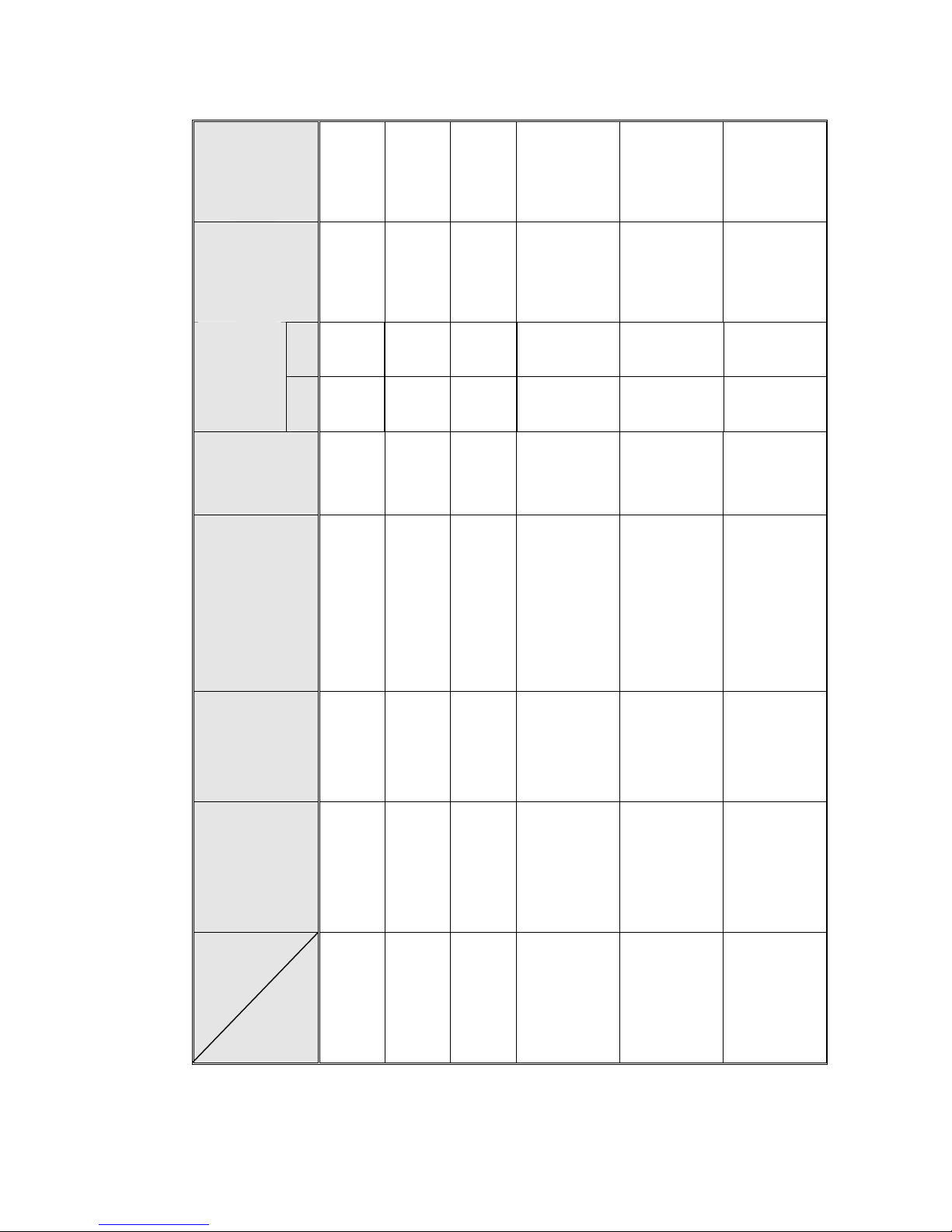

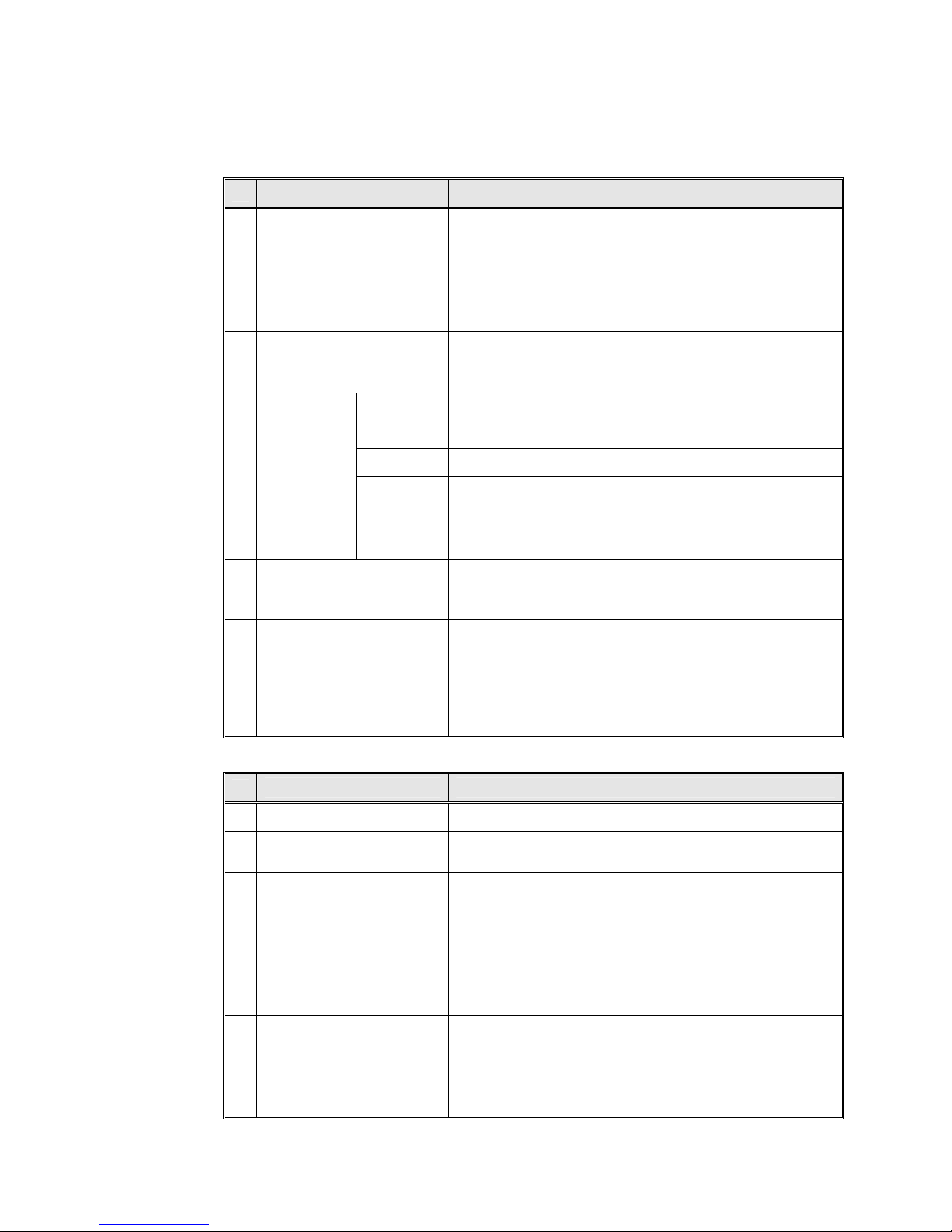

2.10 Technical Specifications

Model

Specifications

1730 M, MK

MK-Valueklave

2340 M, MK

2540 M, MK

3140 M

3850 M

3870 M

10

2.11 Electrical Data

1730 2340 2540 3140 3850 3870

Model

Specifications

M

MK

MK-V

M MK M MK M M M

Total power

model 120V

8.8A 11.2A 11.7A - 11.7A -

20.0

A

- -

Total power

model 230V

4.6A 5.9A 6.0A 9.6A 6.0A 9.6A

10.4A 10.4

A

13A

Heaters W 1050 1350 1400 2200 1400 2200 2400 2400 3000

Degree of protection by enclosure IP31

2.12 Maximum Load Sizes

Loads

Models

lbs kg

1730 3.3 1.5

2340 7.0 3.2

2540 8.8 4.0

3140 11.0 5.0

3850 13.6 6.0

3870 17.5 8.0

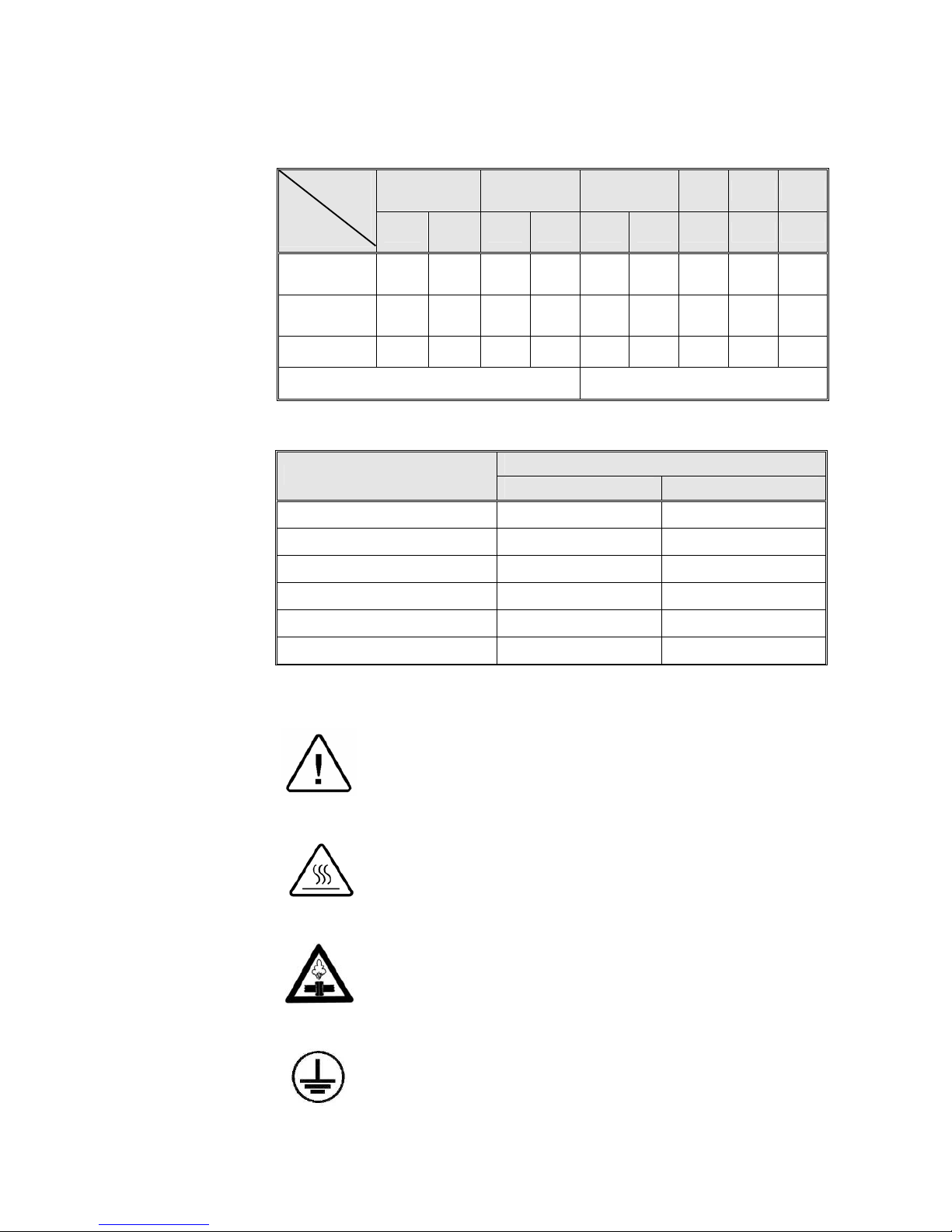

2.13 Symbol Description

Caution! Hot steam.

Caution! Consult accompanying documents

Caution! Hot Surface.

Ground

11

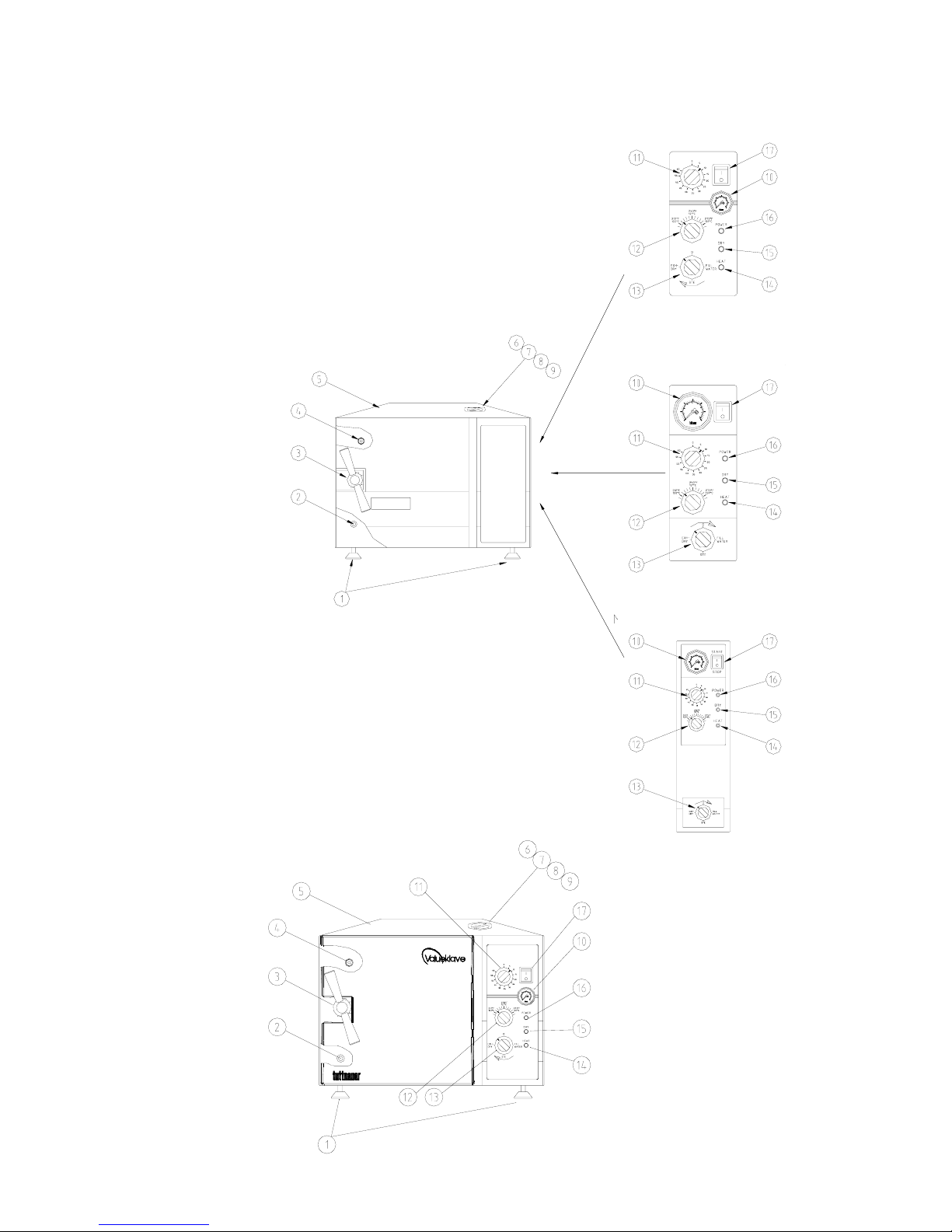

FRONT VIEW

1. Front legs 9. Air trap jet

2. Reservoir water drain 10. Pressure gauge

valve. 11. Timer

3. Door Closing Device 12. Thermostat (B10) knob

4. Door Micro-switch 13. Multipurpose valve

5. Autoclave cover 14. Heat indicator light

6. Water reservoir cover 15. Dry indicator light

7. Water reservoir 16. Power indicator light

8. Safety valve 17. Main power switch

Model 1730 MK Valuelave

Models 3140/3850/3870 M, MK

Models 2340/2540 M, MK

Models 1730 M, MK

12

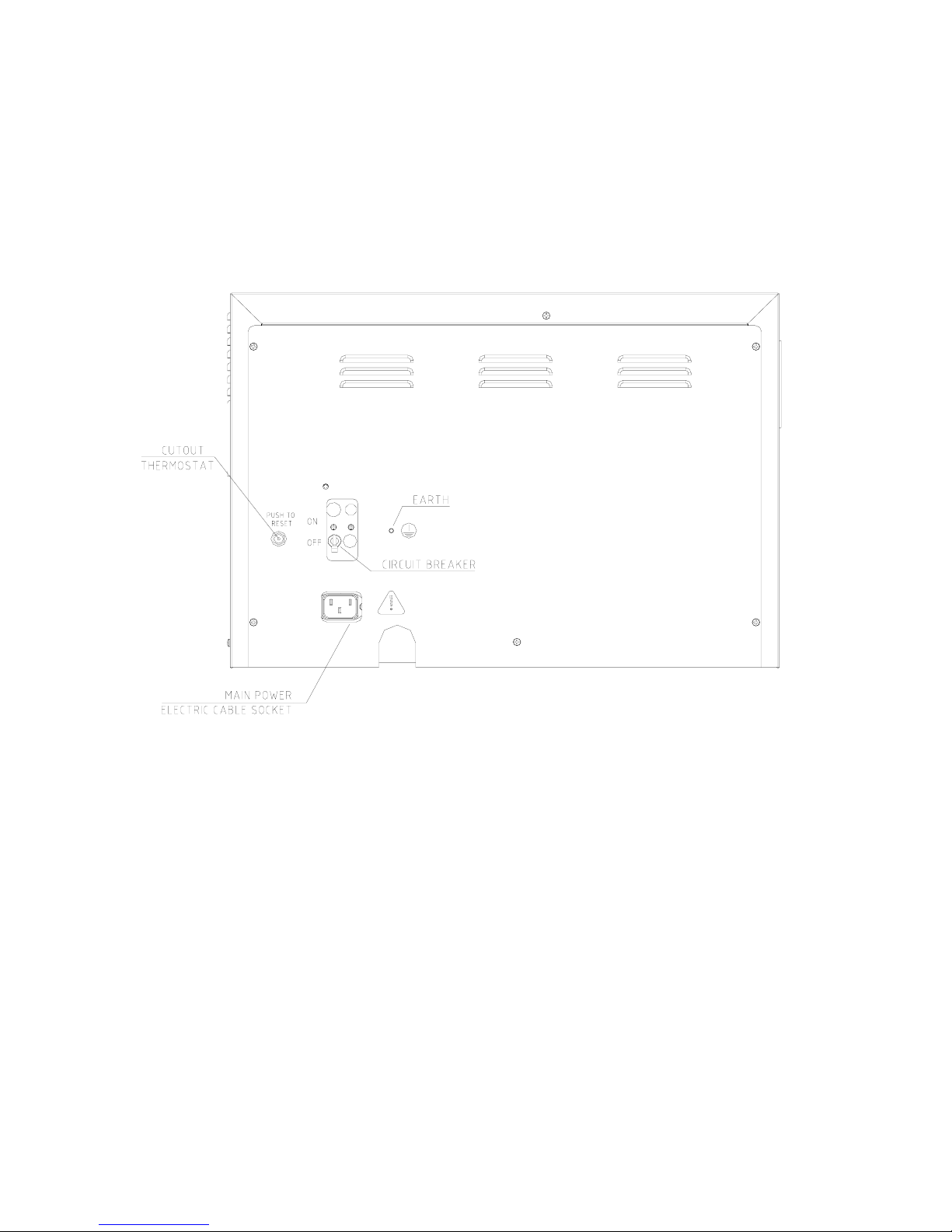

REAR VIEW

13

3 DESCRIPTION OF COMPONENTS

The item numbers refer to the front view in the previous page

3.1 Control Panel

Item

Description Operation

10.

PRESSURE GAUGE

0-60 psi, (0-4bar) indicates the chamber pressure and

includes maximum point indicator.

11.

TIMER 0-60 min.

Sets the time for sterilization and drying cycles

(see section 7 for correct cycle time settings). Note:

The power to the heating elements is switched off

when the Timer reaches 0 minutes.

12.

THERMOSTAT

Sets the desired sterilization temperature for each

cycle within the range of 212ºF - 273ºF (100ºC 134ºC).”

Position

1. FILL

Water

flows from the water reservoir into the chamber.

2. STE.

Valve closed to all directions.

3. EXH.&

DRY

Exhausts the steam from the chamber into the water

reservoir after the sterilization cycle is finished.

13.

MULTIPURPOSE

VALVE

4. “ 0 ”

Heating elements are disconnected, no cycle is in

progress.

14.

HEAT INDICATOR

LIGHT

Lights to indicate that the heaters are activated. It will

cycle off and on when the temperature reaches the

preset valve.

15.

DRY INDICATOR

LIGHT

Lights to indicate that drying cycle is in process.

16.

POWER INDICATOR

LIGHT

Light to indicate that the main switch is on.

17.

MAIN SWITCH-

Main power switch, which supplies electric power to

the autoclave.

3.2 Other Components

Item

Description Operation

2.

WATER DRAIN VALVE

Enables the drainage of water from the reservoir.

7.

WATER RESERVOIR

Holds water for sterilization and also serves as a

condenser for the hot steam during the exhaust phase.

8.

SAFETY VALVE

Located in the water reservoir. Protects the chamber

by releasing any pressure above 40psi (2.7bar). This

Safety Valve is required and approved by ASME.

9.

AIR TRAP JET

Located in the water reservoir. Eliminates air during

heat up phase to insure correct sterilization

temperature is reached. Also prevents air pockets and

pockets of cold steam from forming in the chamber.

♦

SAFETY THERMOSTAT

Prevents over-heating during the sterilization and

drying stages, will automatically reset itself

♦

CUT-OUT

THERMOSTAT

Cuts off the power in case of overheating if the safety

thermostat does not operate. This thermostat does not

reconnect automatically but must be reset.

Loading...

Loading...