Turnkey iGAS Operating Instructions Manual

1

iGAS Operating Instructions, Issue 6, Apr 2018

TURNKEY ® iGAS® OPERATING INSTRUCTIONS

The following associated documentation is available from www.iGASES.uk

• iGAS Installation Instructions

• Installing the Power Portal

• Connecting iGAS to AirQWeb

BEFORE YOU START

iGAS® is supplied with its air filters removed. It is important these are refitted before you start to

use the instrument. Please refer to Figure 7 of the iGAS Installation Instructions. The larger Zero

Filter screws into the adaptor on the left, the twin o-rings of the smaller PTFE sample filter push

into the adaptor on the right. Before you begin, please make sure both filters are installed

correctly.

IMPORTANT: REMOVE THE END CAPS FROM A NEW ZERO FILTER AND IT ALLOW TO VENT FOR

24 HOURS BEFORE FITTING. OTHERWISE, WHEN A NEW ZERO FILTER IS FITTED, IT CAN TAKE

SEVERAL HOURS FOR THE READINGS TO STABILIZE, ESPECIALLY CO, H2S and SO2

It is recommended that the filters are changed at 3-monthly intervals, however, filter life may

vary depending on local ambient conditions. iGAS is supplied with one spare set of filters. It good

practice to mark the filters with their installation date.

A Filter Shield is provided with the instrument and this should be fitted when the instrument is

installed. It prevents the filters rapidly heating-up in direct sunshine and provides some

additional anti-tamper security. Please refer to the installation guide for more information.

iGAS is supplied in a weather proof case and, providing the Manifold temperature does not

exceed 45⁰ C, will operate unshielded in most temperate climates. However, if the instrument is

to be installed in tropical locations, a full Sun Shield is available. This prevents the instrument

case overheating by reflecting away direct sunlight and is fitted in place of the standard Filter

Shield. Please contact Turnkey for more information

2

iGAS Operating Instructions, Issue 6, Apr 2018

PREAMBLE

iGAS® operates automatically under the control of AirQWeb and associated programs and

Apps. The instrument is supplied pre-configured so that it will start operating automatically as

soon as it is connected to AirQWeb.

iGAS is factory set to measure the following

• Measurements are in SI units

• Reporting interval is 1 minute

• Viewing interval is 2 seconds

• Zero phase length is 1 minute

• Continuous zero correction is enabled

Visit www.iGASES.uk to download more information.

The rest of this document gives deeper knowledge of the instrument to allow the operator to

change its operating mode to suit their application. These changes can be made using AirQWeb

or other programs and Apps. All sampling measurements must be stopped before any of the

instrument’s settings can be changed.

Operation of the instrument is controlled by the state of its Feature Flags and its Instrument

Settings. Its operational state is indicated by the Instrument Information table, Fault Flag

states and Diagnostic & Housekeeping Readings.

Please see Appendix of this document for full lists of the Feature Flags, Instrument Settings,

Fault Flags and Diagnostic readings.

The electrochemical cells used in iGAS need to be held under a constant bias voltage even when

the instrument is not being used. With 8 cells connected, this draws a current of about 10 mA

from the battery, WHICH MEANS THE BATTERY WILL BECOME EXHAUSTED AFTER ABOUT 10

DAYS.

If you intend not to use the iGAS instrument for several days, disconnect the battery by setting

the power isolator switch to O. Return the switch to 1 when you wish to start using the

instrument again. Note that the electrochemical cells may take several hours to recover after

powering down. Wait until their readings stabilize. You may also momentarily click the isolator

switch if, for whatever reason, you need to reboot the instrument.

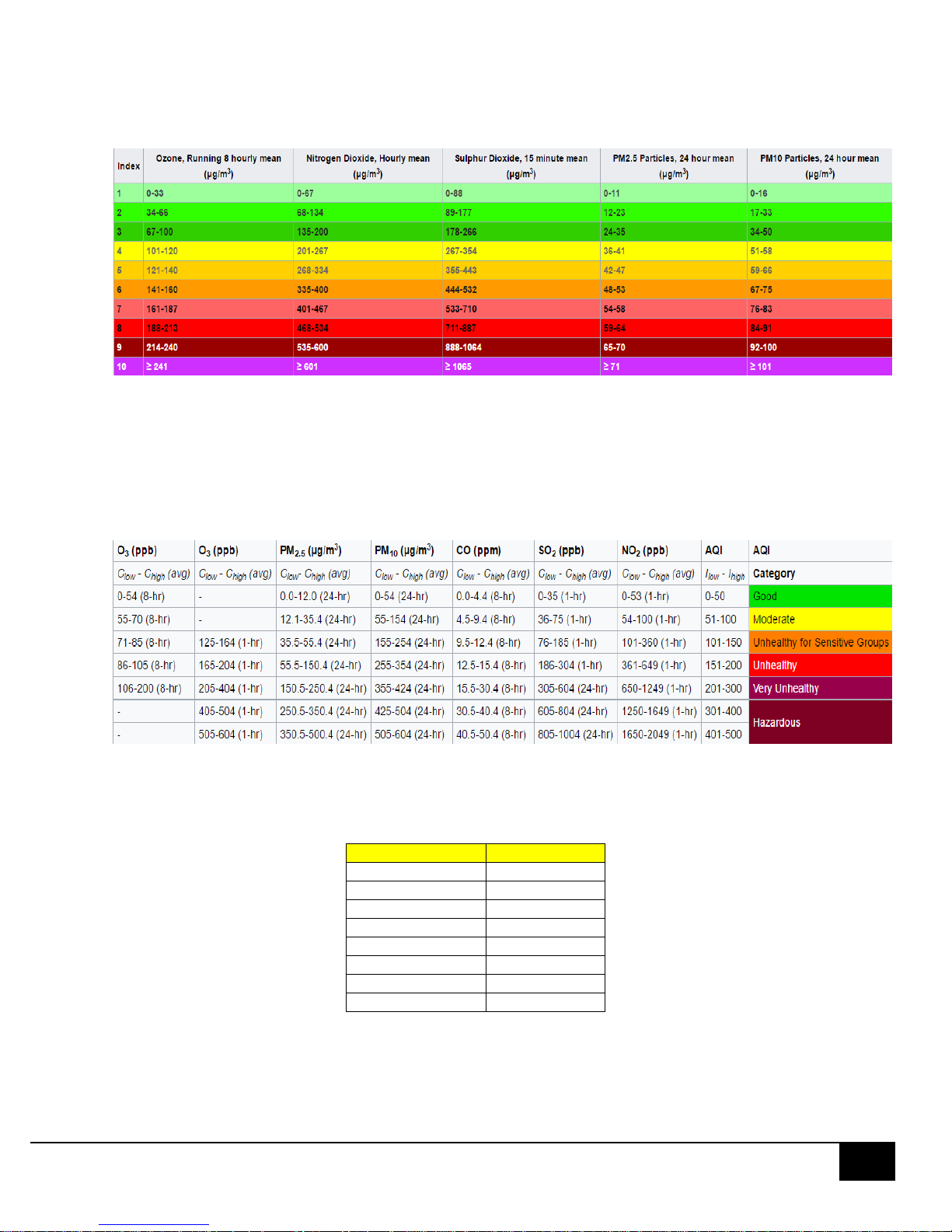

AIR QUALITY INDEX

The Air Quality Index (AQI) is based on the concentration of various gaseous and particulate

pollutants. Current values for the UK and USA are listed in the following tables: but be aware, the

UK index runs from 0 to 10, the USA one 0 to 500!

3

iGAS Operating Instructions, Issue 6, Apr 2018

EU and UK DEFRA

The Daily Air Quality Index (DAQI) in the leftmost column tells you about levels of air pollution

and provides recommended actions and health advice. The index is numbered 1-10 and divided

into four bands, low (1) to very high (10), to provide detail about air pollution levels in a simple

way, similar to the sun index or pollen index.

USA EPA

The carbon monoxide (CO) readings are in ppm (parts per million). The UK readings are given in

µg/m3, the USA EPA in ppb (parts per billion). The conversion between the two is given by the

following table, iGAS can record results either in ppb or µg/m3 (see Feature Flags)

1 ppb

µg/m3

SO2

2.62

NO2

1.88

NO

1.25

O3

2.0

CO

1.15

H2S

1.47

VOC

2.29

CO2

1.80

4

iGAS Operating Instructions, Issue 6, Apr 2018

ZERO GAS AND SAMPLE FILTERS

iGAS is fitted with a pair of air filters, one of which is used to generate a zero gas. The air

sample is selectively drawn through these filters by a pair of ultra-quiet pumps. The humidity

and temperature in both air sample streams is equalized using Nafion drier tubes. Looking at

the instrument door, the larger Zero Filter is on the left, the Sample Filter on the right.

The Zero Filter uses a standard AXP3 respirator filter with Rd40 thread.

For iGAS we specify AXP3 Rd40 respirator cartridges. These contain a P3 particle filter and AX

micro-porous activated coconut charcoal only. They contain no impregnated charcoal. There is

some evidence that metal impregnated charcoal may increase the catalytic reduction of water

vapour to H2 and CO by the charcoal.

All charcoal filters will catalytically reduce water vapour to create ppb levels of hydrogen and

carbon monoxide. The activity increases with increasing temperature and the Filter Shield

protects the Zero Filter from sudden temperature changes. Since hydrogen can have a

significant effect on electrochemical cells, especially SO2 and H2S, iGAS incorporates special

sensors to compensate for the effect.

The Sample Filter is a 1 micron PTFE membrane filter which is used simply to prevent ambient

dust particles being drawn into the instrument when sampling. A PTFE membrane is used to

minimize absorption of sample gases, especially ozone. Note that most P3 respirator filters

absorb ozone and acidic gases, especially SO2, and are not suitable.

The AXP3 Zero Filter contains about 300g of pure activated charcoal which absorbs most

polluting gas species. Note that this Zero Filter will not absorb carbon monoxide and iGAS is

factory configured to exclude CO from the zero correction scheme. This is feasible because the

CO sensor is stable at ppm levels of pollution and, therefore, does not need zero correction.

It is recommended that the filters are changed at 3 monthly intervals but the actual lifetime of

the Zero Filter will depend on the level of ambient pollution, humidity, and the zeroing scheme

used. The Continuous Zeroing scheme (see below) uses the Zero Filter most and draws about 10

litres of air per hour through it. Filter breakthrough is unlikely to occur before 1 gram of

pollutant gas has been absorbed, equivalent to about 106 ppm litres of flow if 1ppb=1µg/m3.

This corresponds to < 1% of the weight of the activated charcoal.

5

iGAS Operating Instructions, Issue 6, Apr 2018

ZEROING SCHEMES

There are three zeroing schemes which may be selected to compensate for temperature and

humidity drift in the sensors. Use the Feature Flags to set the zeroing scheme you require. The

Continuous Zero is the factory default. Any of the sensors in the Manifold may be excluded

from the zeroing process by setting the SEDs accordingly.

Continuous Zeroing: Air is alternatively drawn through the Zero Filter and then the Sample

Filter, the actual reading is the difference between the two measurements. The length of the

Zero Phase determines how long the air is drawn through each filter and measurements are

taken for 10 seconds at the end of each phase. The shortest (default) phase time is 1 minute,

meaning the air is alternatively drawn through the Zero Filter for 1 minute and then through

the Sample Filter for 1 minute. If Use Rise Time is selected, the 90% response time (T90) of the

cell is taken into account when the results are calculated.

Continuous Zeroing overrides all other zeroing schemes and is the recommended mode of

operation. Use to acclimatize a new Zero Filter.

Periodic Zeroing: Measures the sensor offsets at the Zeroing Interval specified in the

Instrument Settings. If the Zeroing Interval is zero, the offsets are just measured at the start of

the sample. Each offset measurement takes three Zero Phases, make sure you select the

feature Use Periodic Zeros to actually apply those offsets. The advantage of this method is the

zeroing takes place only infrequently allowing a faster reporting interval to be used. It also

maximizes the lifetime of the Zero Filter but may give rise to more offset drift between

successive zeros. However, unless there are significant changes in temperature or humidity, this

will be small on the AQI scale.

Temperature Zeroing: If neither of the above Feature Flags are set, the instrument will measure

the sensor offsets whenever the Manifold Temperature has changed by the amount specified

by the Zero Trigger temperature specified in the Instrument Settings. Again, select Use Periodic

Zeros to apply the measured offsets.

In all cases the default zero phase length is 1 minute.

Loading...

Loading...