Page 1

Turner OCTO® Assembly Guide

SECTION 1.

Assembly Guide

©Turner Access Ltd

65 Craigton Road, Glasgow, G51 3EQ, Scotland

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 1 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 2

Turner OCTO® Assembly Guide

SECTION 1. Contents

CONTENTS

1.1 Introduction............................................................................................................4

1.2 Pre-use Inspection & Selection............................................................................5

1.3 Components...........................................................................................................6

1.3.1 Basic Components....................................................................................6

1.3.2 Component Fixing Hints............................................................................7

1.3.3 Access Methods........................................................................................9

1.4 Safety Information................................................................................................11

1.4.1 General Safety Notes...............................................................................11

®

1.4.2 GuardAid

................................................................................................12

(i) User Instructions.................................................................................12

®

(ii) Wall Scaffold Assembly Procedure using GuardAid

.........................15

1.4.3 Fall Arrest.................................................................................................23

®

1.5 Assembly Procedures for Turner OCTO

System Scaffolds...........................24

1.5.1 Tied Wall Scaffold....................................................................................25

(i) Fully Boarded......................................................................................25

(ii) Top Lift...............................................................................................29

(iii) Corner Returns..................................................................................30

1.5.2 Independent Towers................................................................................34

(i) Fully Boarded......................................................................................34

(ii) Top Lift...............................................................................................35

(iii) Mobile................................................................................................36

(iv) Inspection & Maintenance Guidance Notes for Mobile Structures....37

1.5.3 Birdcages.................................................................................................39

(i) Linked Birdcage...................................................................................40

1.5.4 Freestanding Structures..........................................................................42

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 2 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 3

Turner OCTO® Assembly Guide

SECTION 1. Contents

1.5.5 Cantilever Brackets.................................................................................45

(i) Inside Boards.......................................................................................45

(ii) Cantilever Bracket with End Plate......................................................47

(iii) Cantilever Bracket with Cup..............................................................47

1.5.6 Circular Structures...................................................................................49

1.5.7 Suspended Scaffolds...............................................................................51

1.5.8 Pre Scaffold Handover Inspection...........................................................53

1.5.9 Maintenance............................................................................................53

1.5.10 Dismantling Procedure............................................................................54

1.6 Anchoring.............................................................................................................55

1.6.1 Tie Patterns for unclad scaffolds.............................................................55

1.6.2 Tie Loads.................................................................................................56

1.7 Maximum Heights................................................................................................57

1.7.1 Assembly Criteria - Unclad Tied Wall Scaffold Examples.......................58

1.7.2 Maximum Heights Unclad Tied Scaffolds (Foot Tied with Horizontal)....59

1.7.3 Maximum Heights Unclad Tied Scaffolds (Foot Tied with Guardrail)......60

1.7.4 Maximum Heights Unclad Tied Scaffolds (Non Foot Tied)......................61

1.8 Transport and Storage.........................................................................................62

1.9 References............................................................................................................63

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 3 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 4

1.1 INTRODUCTION

Turner OCTO® Assembly Guide

SECTION 1.1 Introduction

This Assembly Guide contains the necessary information required to correctly assemble

Turner OCTO

®

System Scaffolds in accordance with appropriate methods of safe assembly.

The provision and utilisation of collective protection equipment and methodology is

recommended where practicable for installers of Turner OCTO® System Scaffolding.

Installers / Dismantlers of Turner OCTO® System Scaffolding must also be competent,

relative to the type of scaffold to be erected, dismantled or altered.

This Assembly Guide provides instruction for foot tied, non-foot tied, and pedestrian

categories (as listed within the Assembly Guide) built from the ground or other suitable

foundation.

Types of Turner OCTO® System standard conguration included within this Assembly Guide

are detailed on the Contents Page and limited to the maximum heights as indicated in

Section 1.7 Maximum Heights (page 57).

This Assembly Guide should be used in conjunction with a suitable Risk Assessment and

Method Statement (by user) relative to the project to be undertaken. It must be noted that

all employers have a responsibility to ensure that work methods (practices) and adequate

facilities / resources (including work equipment) are provided to eliminate or minimise risks,

in accordance with current legislation.

A complete separate safe system of work (Method Statement) is required for all other types

of scaffold.

Sufcient training, combined with necessary experience, must also be considered and be

appropriate to achieve competency to build or dismantle a particular scaffold type in question.

Please ensure you read and fully understand the manual, and follow the content during

scaffold erection and ensure that the scaffold is complete prior to use and / or handover.

This Manual must be made available to the user / installer of the Turner OCTO® Scaffold

System at all times.

Only competent and qualied personnel should undertake assembly, dismantling and

alteration (and organisation, planning and supervision) of basic Turner OCTO® standard

congurations, and consideration should be given to providing additional (minimum) training

beforehand, if required.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 4 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 5

Turner OCTO® Assembly Guide

SECTION 1.2 Pre-use Inspection & Selection

1.2 PRE-USE INSPECTION & SELECTION

To ensure that a scaffold is assembled in a manner that prevents its component parts from

being accidentally displaced at any time, it is important that the following checks are carried

out:

• Ensure that all necessary components and safety equipment are available and

operational.

• Each component should be visually inspected prior to use and should be free from

defects.

• Steel components should be straight with no sign of corrosion, cracks or splits that

would impair strength or safety.

• Deck locks should be in good working order; hooks should be free of cracks and

corrosion, and bolts should be tight and locking nuts tted.

• Stiles or Ply inserts should not be punctured or worn to a degree that would impair

strength or safety.

Damaged or incorrect components must not be used.

Pre-use inspection should ONLY be carried out by a competent person.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 5 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 6

1.3 COMPONENTS

Turner OCTO® Assembly Guide

SECTION 1.3 Components

Turner OCTO

®

System components for basic use are described in this section for assembly,

dismantling and alteration of Turner OCTO® System standard congurations. For detailed

component information, refer to the Turner OCTO® Component Identication Guide.

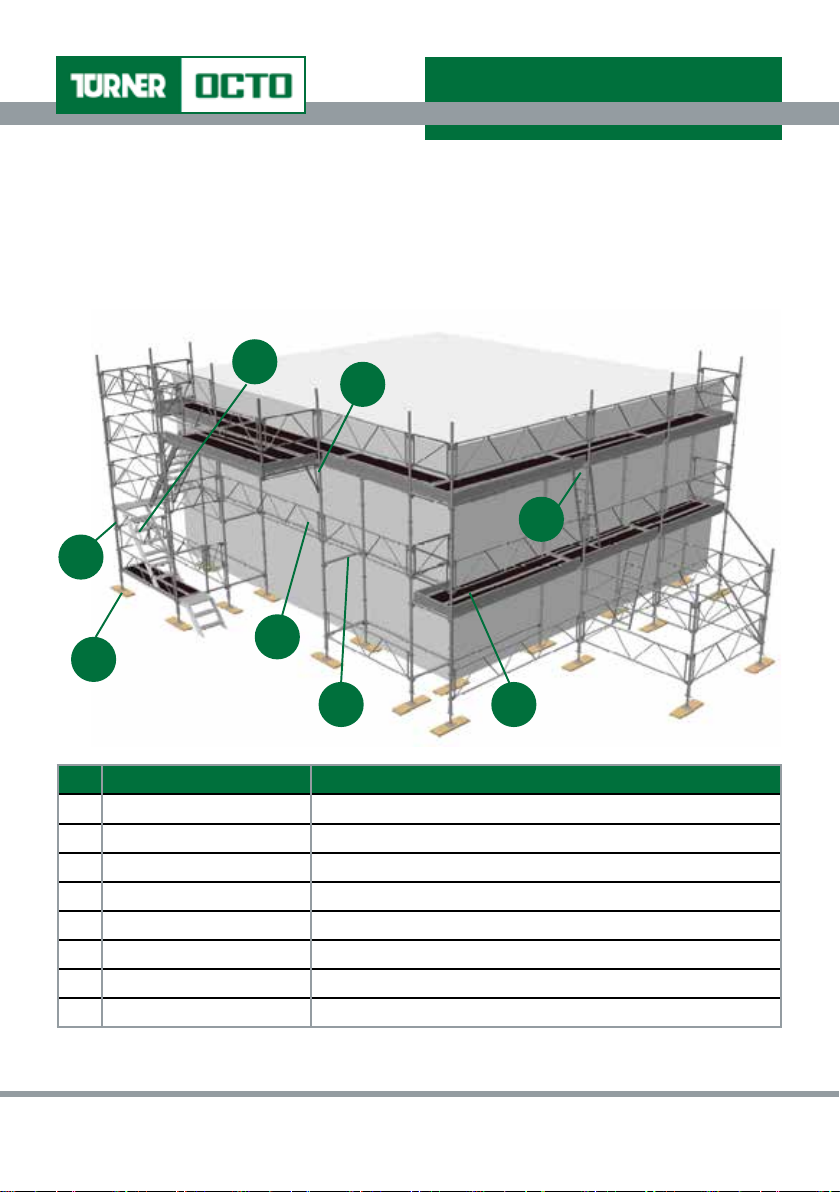

1.3.1 Basic Components

7

8

6

2

3

1

4 5

No. Component Details

1. Adjustable Base Jack Enables adjustment up to 500mm

2. Standard Sizes: 4m; 3m; 2m; 1m; 0.5m

3. Bracing Guardrail Sizes: 3.5m; 2.5m; 1.75m; 1.25m; 1m; 0.7m

4. Horizontal Sizes: 3.5m; 2.5m; 1.75m; 1.25m; 1m; 0.7m

5. Deck Sizes: 3.5m; 2.5m; 1.75m; 1.25m; 1m; 0.7m

6. Ladder Access Deck Sizes: 3.5m; 2.5m

7. Alloy Stair Stair access between working platform levels

8. Cantilever Bracket Sizes :1.25m; 1m; 0.7m; 0.45m; 0.30m; 0.1m

Note The sizes shown are basic sizes, other sizes available. Please ask for details.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 6 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 7

Turner OCTO® Assembly Guide

SECTION 1.3 Components

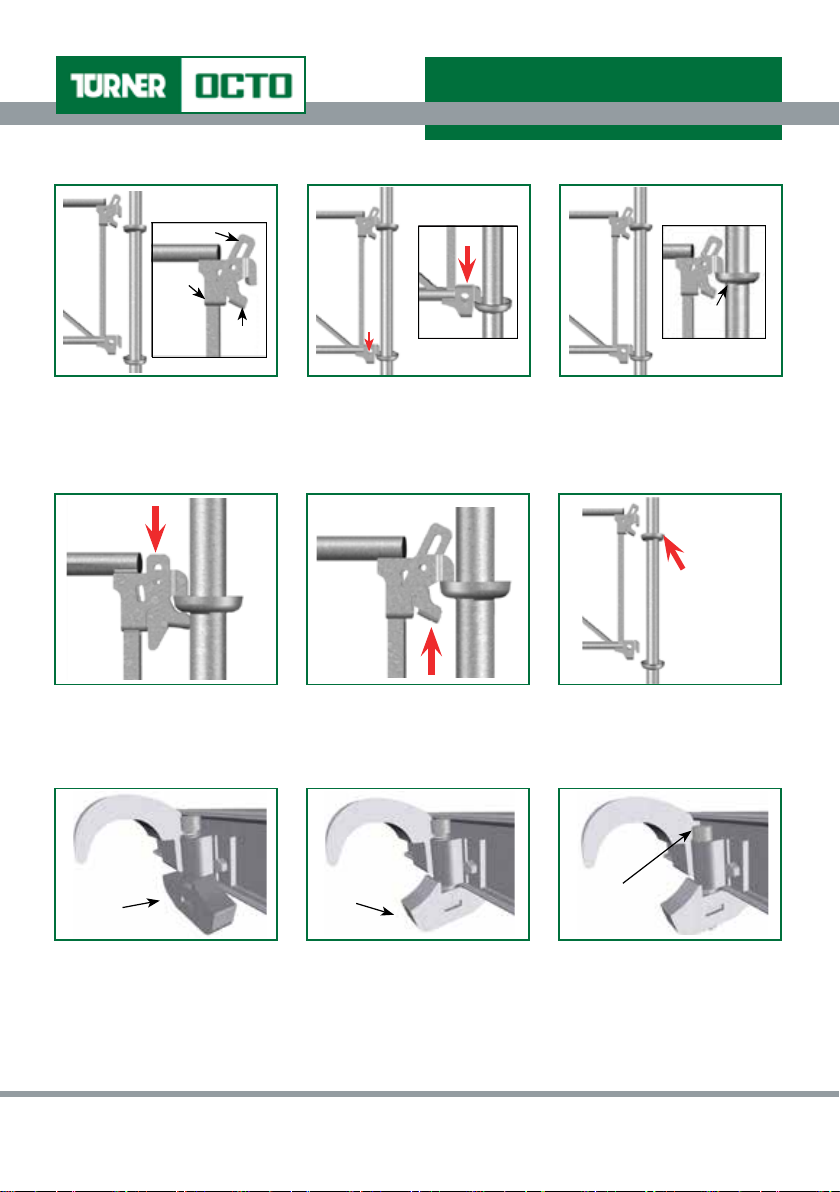

1.3.2 Component Fixing Hints

Horizontals

Saddle

Wedge

1. Turn the Horizontal upside

down at an angle of approx.

45° and shake.

4. Slide the Saddle over to the

Standard.

Wedge

....until the top of the Wedge

is level with the top of the

Horizontal.

Note If the Horizontal and Standard

are not level and plumb, the Wedge

may be difcult to drive.

2. The Wedge and Saddle will

then automatically fall back

into the preset position.

5. Lift Wedge and point

bottom of Wedge towards the

Standard.

7. To de-mount Horizontal,

drive Wedge vertically upwards

to loosen.

3. Position the Locking Head by

turning the Horizontal approx.

45° and rotate into the cup.

6. Drive Wedge down at an

angle of 45º initially towards

the Standard....

8. Lift the Wedge clear, slide

Saddle backwards and lift

Horizontal from cup.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 7 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 8

Guardrails

Turner OCTO® Assembly Guide

SECTION 1.3 Components

Wedge

Ledge

Cup

Saddle

1. Preset Guardrail by lifting

Wedge and resting it on ledge

within the Guardrail.

Note Saddle will hang loosely leaving

space to t hook into cup.

4. Drive vertically until level

with the top of the Guardrail.

Decks

Unlocked

1. Push Deck from below and

through bay, then slide back

along bay until the hooks are in

line with the Horizontal. Place

Deck onto Horizontal.

2. Locate top and bottom

hooks of Guardrail in cups

(0.5m apart). Hint Tap lower hook

with hammer to ensure that it is

properly located in cup.

5. To de-mount Guardrail, drive

Wedge vertically upwards to

loosen.

Locked

2. Ensuring that Deck ts

correctly in bay to be decked

out and there is no movement

in the Deck, lock in position.

3. Lift Wedge clear of ledge

within the Guardrail to the

Vertical position and allow to

drop and loosely engage.

6. Lift the Wedge clear, rest on

ledge and lift Guardrail from cup.

OCTO® Lock

3. The OCTO® Deck has the

added benet of being locked

permanently by fully engaging

the OCTO® Lock using the

appropriate OCTO® tool.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 8 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 9

Turner OCTO® Assembly Guide

SECTION 1.3 Components

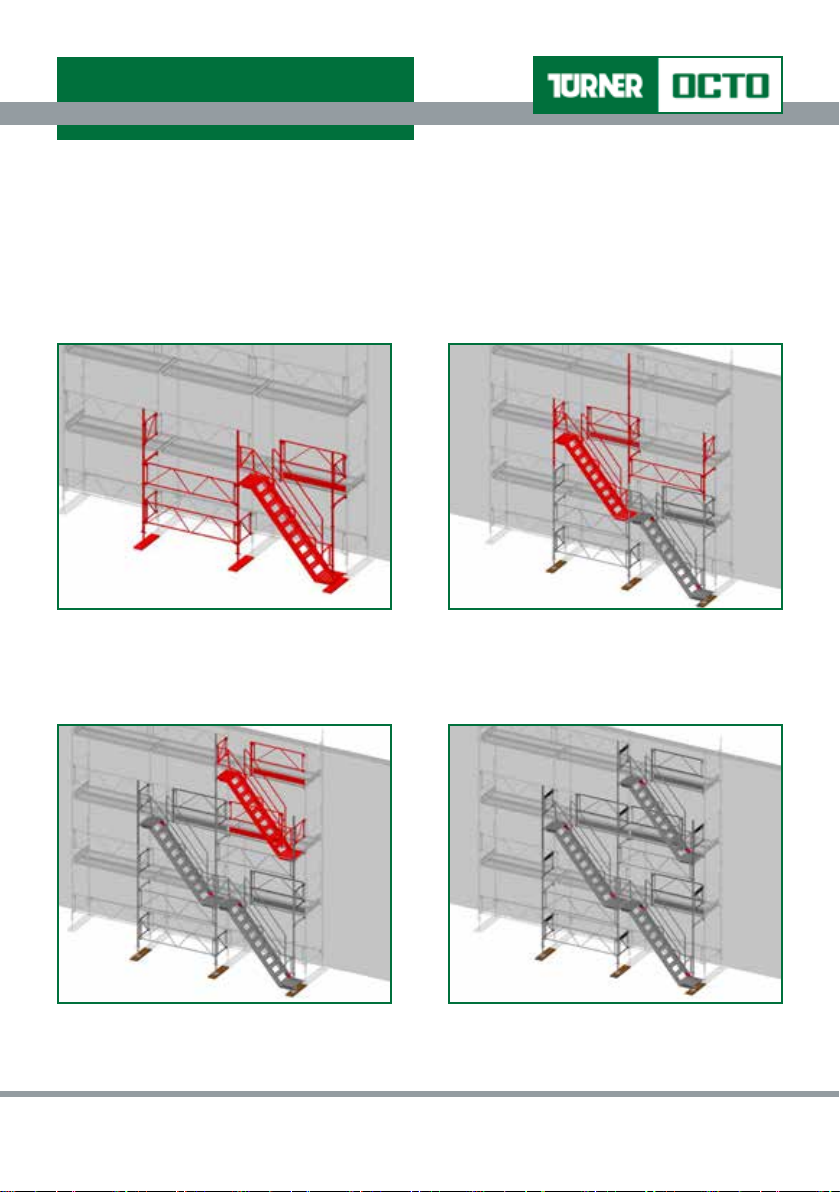

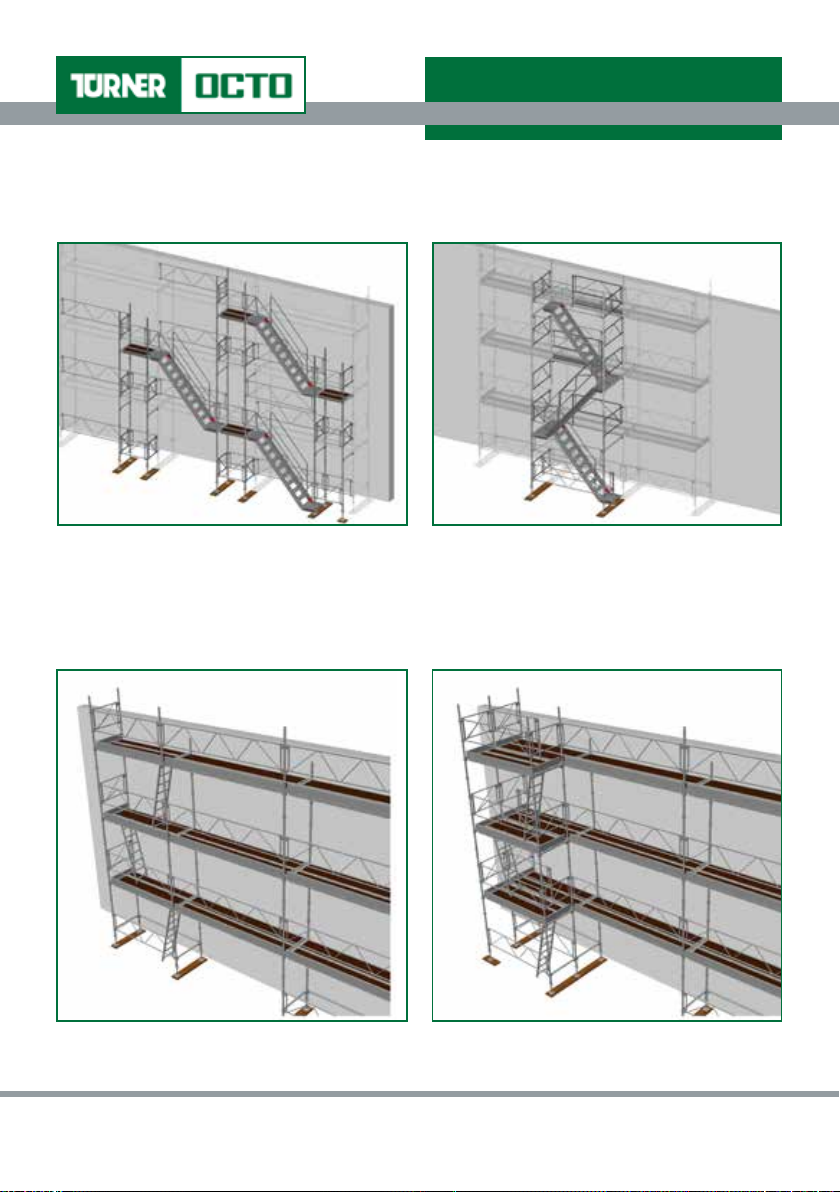

1.3.3 Access Methods

Stairway Access

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

• 0.7m External Stairway Access (2.5m bay)

1. Assemble 0.7m wide bay to external face

of facade scaffold. Fit Guardrail Post and

2. Continue to assemble next lift and t

Stair unit to 2nd lift.

1.75m Bracing Guardrail to allow walk off

from Stair unit when tted.

3. Fit Guardrail Post and 1.75m Bracing

4. Complete.

Guardrail to allow next lift Stair unit to be

placed.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 9 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 10

Turner OCTO® Assembly Guide

SECTION 1.3 Components

• 0.7m External Stairway Access

(3.5m bay)

• 1.25m External Stairway Access

(2.5m bay)

Ladder Access

• Internal Ladder Access with Hatches • External Ladder Access with Hatches

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 10 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 11

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

1.4 SAFETY INFORMATION

1.4.1 General Safety Notes

Only competent and qualied personnel should undertake assembly, dismantling and alteration

(and organisation, planning and supervision) of basic Turner OCTO

®

standard congurations,

and consideration should be given to providing additional (minimum) training beforehand, if

required.

Ensure that all necessary components and safety equipment are available and operational.

Inspect components for signs of damage or incorrect functioning prior to use. Damaged or

incorrect components should not be used.

Erect Exclusion Zone and t Warning Signs to comply with current legislation.

Before assembling the scaffold structure, check that the location for the structure does not

present any hazards during assembly, dismantling, moving and safe working with respect to

ground conditions, level and slope and obstructions.

Ensure the scaffolding is to be assembled on suitable foundations capable of withstanding

the loads imposed by the scaffolding and, where appropriate, adequate base boards to be

provided.

Fit toeboards on all working platforms.

DO NOT afx sheeting of any type to the scaffold structure without a proper Design.

Turner OCTO® System Scaffolding is compatible and can be used with another similar type

of system scaffold; however, both types have different load bearing capacities. When the

components of both types are mixed, then the load bearing capacities of the compatible product

should be used instead of the data for Turner OCTO® System.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 11 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 12

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

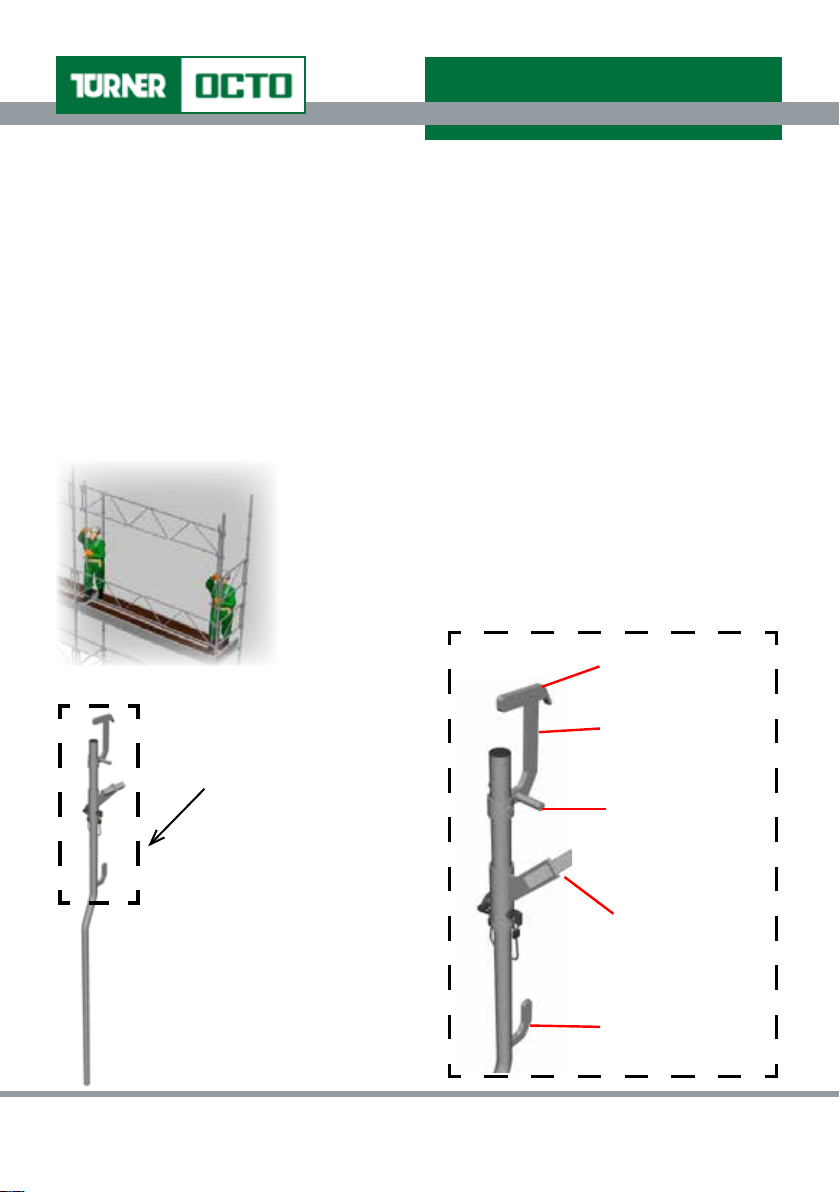

1.4.2 GuardAid

®

(i) User Instructions

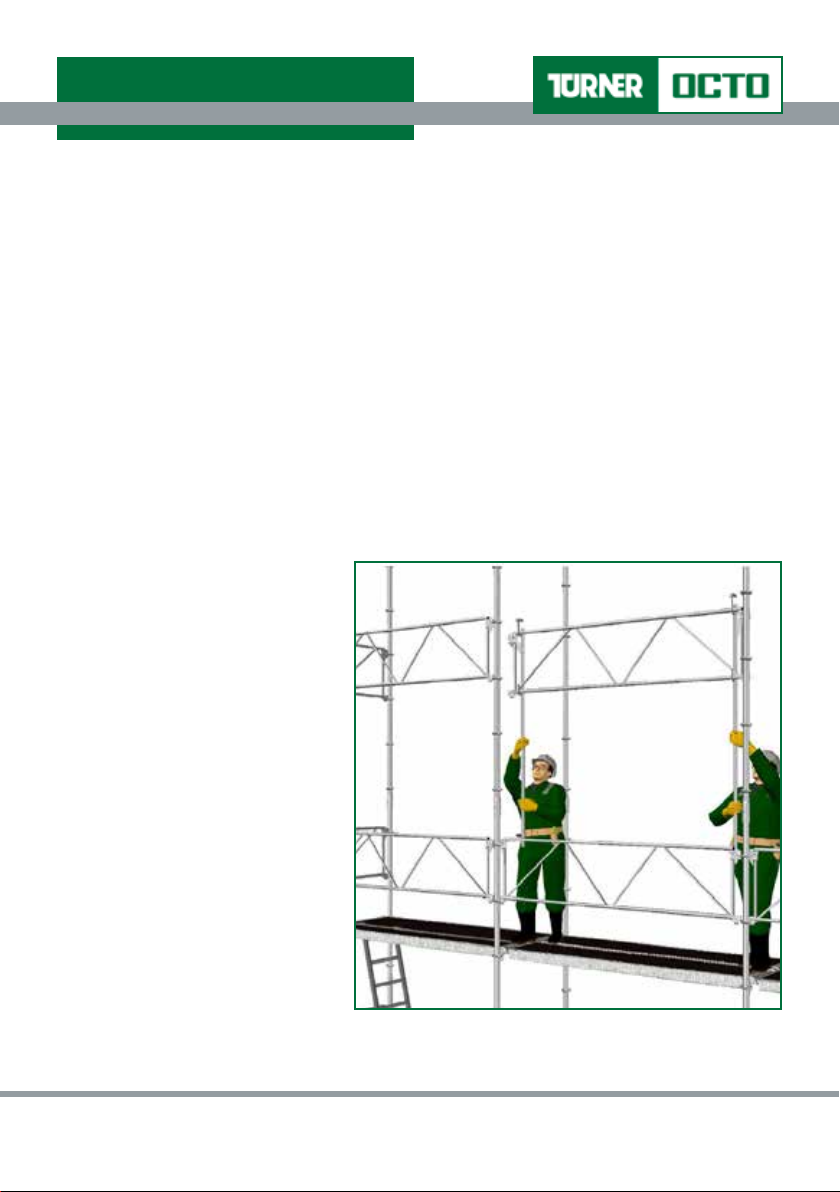

The GuardAid® Positional Tool (Figure 1) provides the scaffolder with integrated safety and

safe systems of work throughout scaffold assembly, dismantle and alteration; therefore,

eliminating the risk of fall from height and enabling compliance with current legislation.

GuardAid® is a scaffold tool used to position, while holding secure, a scaffolding guardrail,

before it is xed and locked into place.

GuardAid® enables existing components to be utilised as integral advance guardrails. This

is achieved by combining a sequence of steps; holding, securing, guiding and then enabling

automatic positioning, xing and locking the existing scaffold component.

To use the GuardAid® Positional Tool safely, each guardrail

component can be lifted into position by two operatives (one

at each end of the guardrail - as illustrated opposite).

The GuardAid

®

Positional Tool consists of various component

parts within the Tool Head (Detail ‘A’) that have different

functions for the scaffolder using the tool.

Detail ‘A’

Detail ‘A’

GuardAid® Positional Tool

Head

Figure 1 - GuardAid® Positional Tool

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Standard Cup Hook

Upper Chord Locator

Locking Pin for

Guardrail Wedge

Guardrail Wedge

Release

Lower Chord

Locator

Section 1 Page 12 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 13

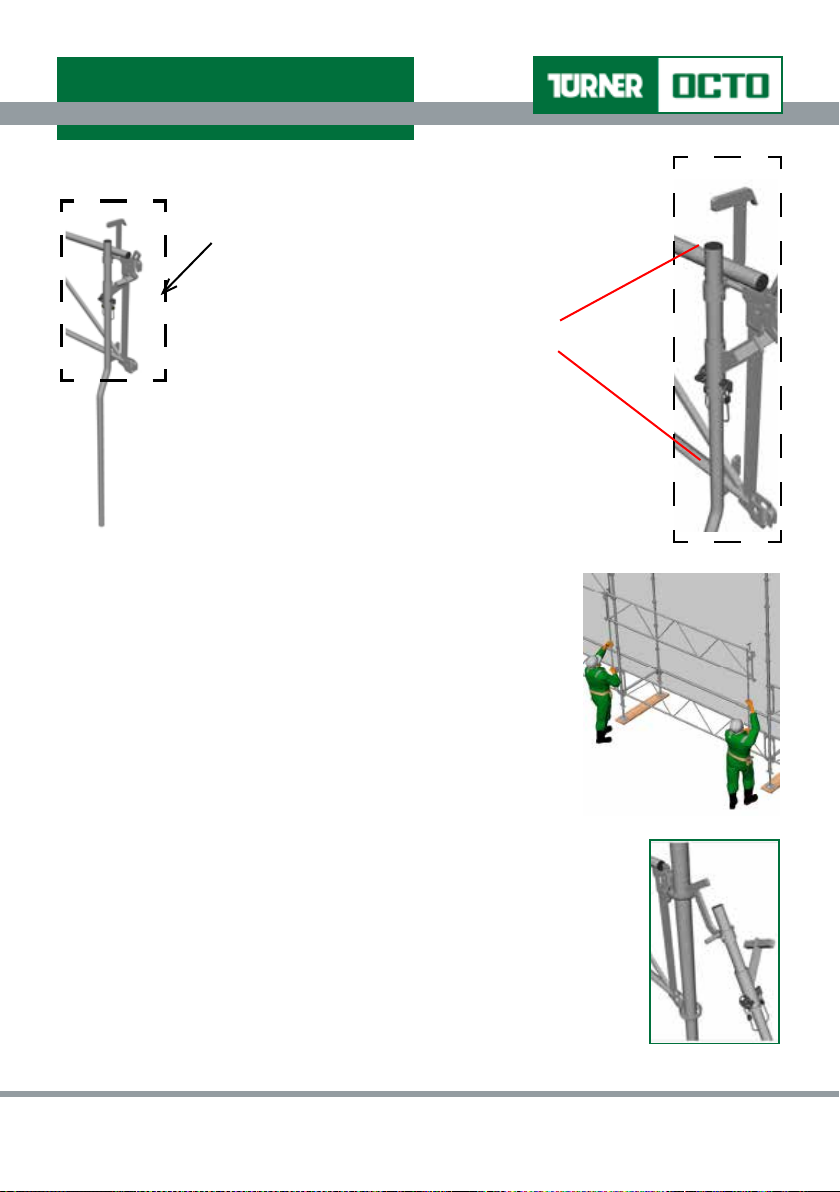

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

Upper and Lower Chord Locators

Detail ‘B’

Each operative must locate the guardrail

correctly (Figure 2) and ensure it is “seated”

properly in the Upper and Lower chord

locators of the GuardAid

Figure 2 - Using GuardAid

Positional Tool

®

®

tool (Detail B).

Detail ‘B’ - GuardAid®

Positional Tool Head

The operatives should then simultaneously raise the guardrail

and t the guardrail into the cups of the standard.

Detail ‘B’

Standard Cup Hook

Should the scaffold standards be slightly off the plumb then one

operative should locate one end of the guardrail into position

and locate in cups allowing wedge to drop and become loosely

engaged. This operative can then assist in locating the opposite

end of guardrail by using the Standard cup hook (of the GuardAid®

Tool) pulling the standard to the vertical (Figure 3); therefore,

allowing the guardrail to be tted correctly.

Figure 3 - Using Standard Cup Hook

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 13 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

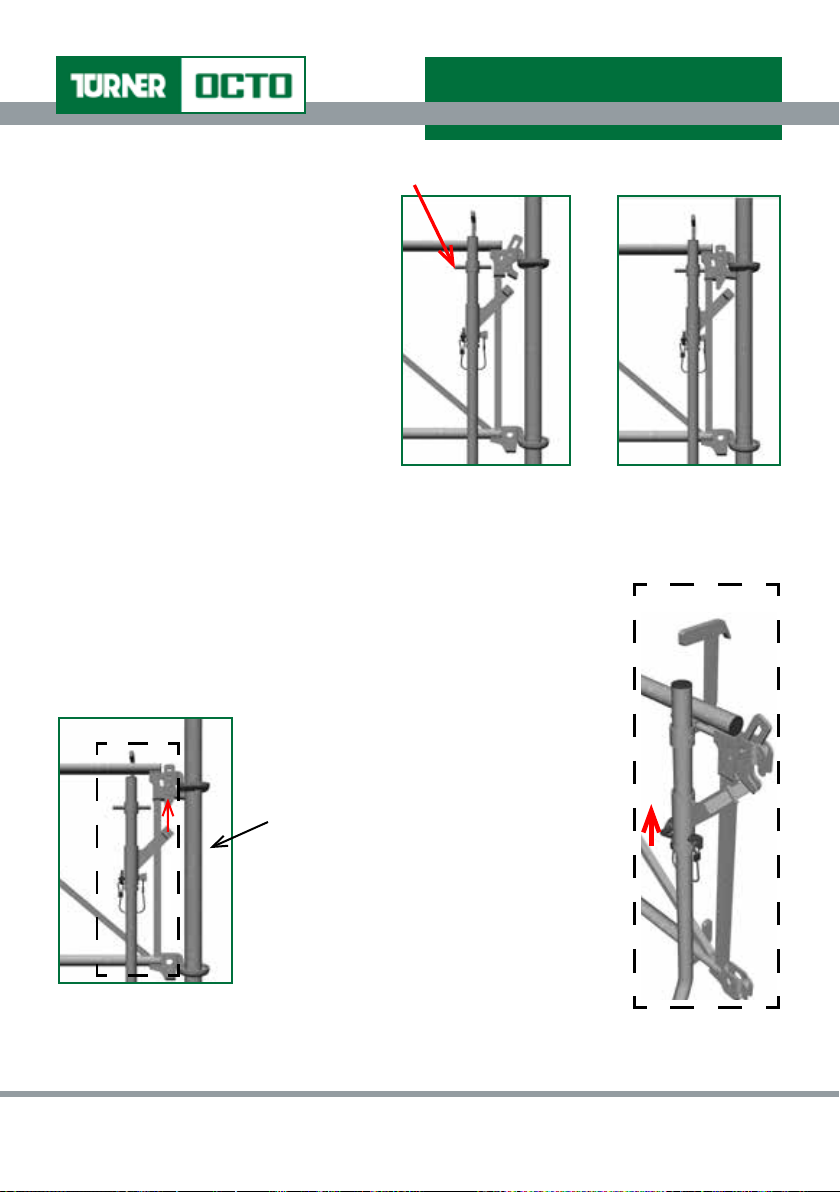

Page 14

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

Locking Pin for Guardrail Wedge

Locking Pin for Guardrail Wedge

Using the Guardrail Wedge Locking

Pin, push the wedge from its preset

condition (Figure 4) to the vertical

position and allow to drop and loosely

engage (Figure 5).

When all guardrails (including end

guardrails) are located in position on

the lift and platforms are placed and

locked then the scaffold operatives

should safely access the platform and

drive wedges home on all guardrails.

Guardrail Preset Condition

Figure 4 -

Guardrail loosely engaged

Guardrail Wedge Release

To de-mount the scaffold guardrails each operative must ensure that

the GuardAid® Positional Tool is located correctly in the guardrail prior

to it being removed.

It is then necessary for each operative to

drive the wedges on each end of the guardrail

vertically upwards to loosen (Figure 6).

Figure 5 -

Detail ‘C’

Detail ‘C’

This should be done using

the Guardrail Wedge Release

component part of the GuardAid

tool (Detail ‘C’)

Lift the wedge clear and rest the

wedge on inner ledge within the

guardrail and then both operatives

should simultaneously lift the

Figure 6 - De-Mounting Guardrail

using GuardAid® Positional Tool

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Guardrail clear of cups.

®

Detail ‘C’ - De-Mounting Guardrail

using GuardAid® Positional Tool

Section 1 Page 14 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 15

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

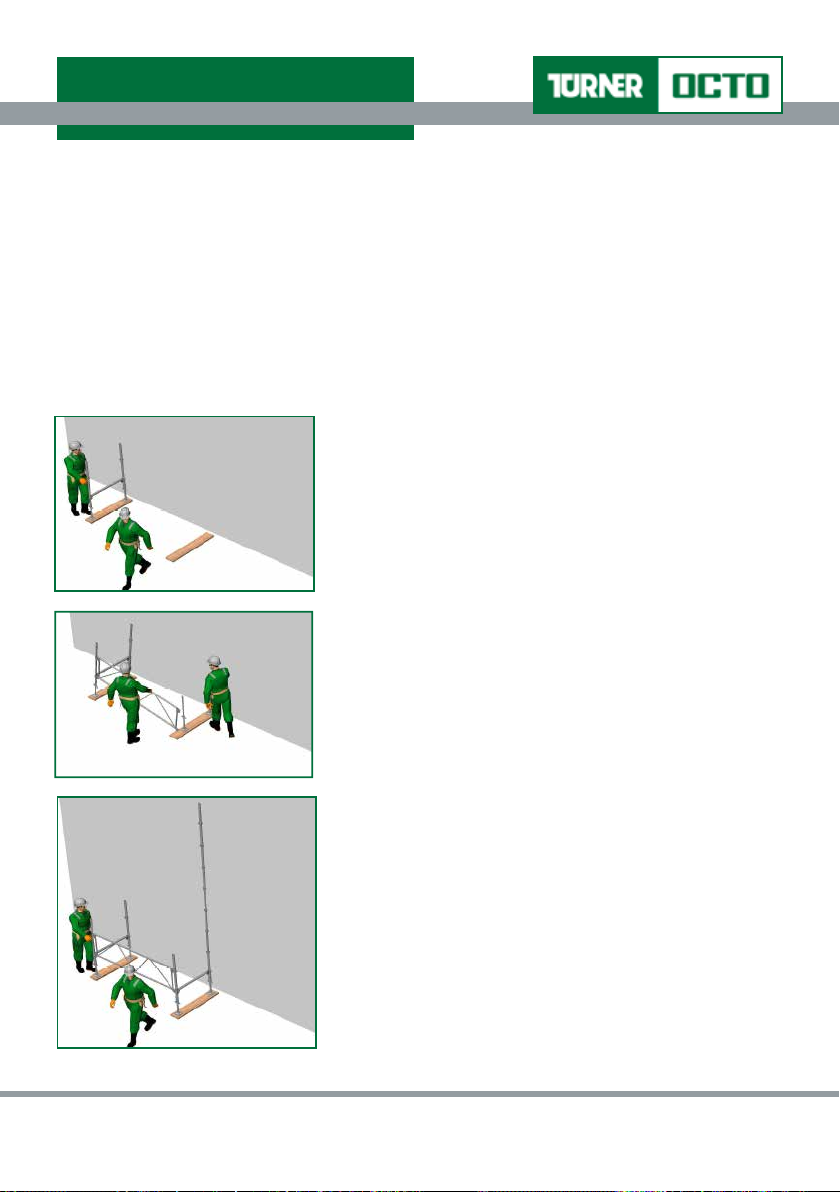

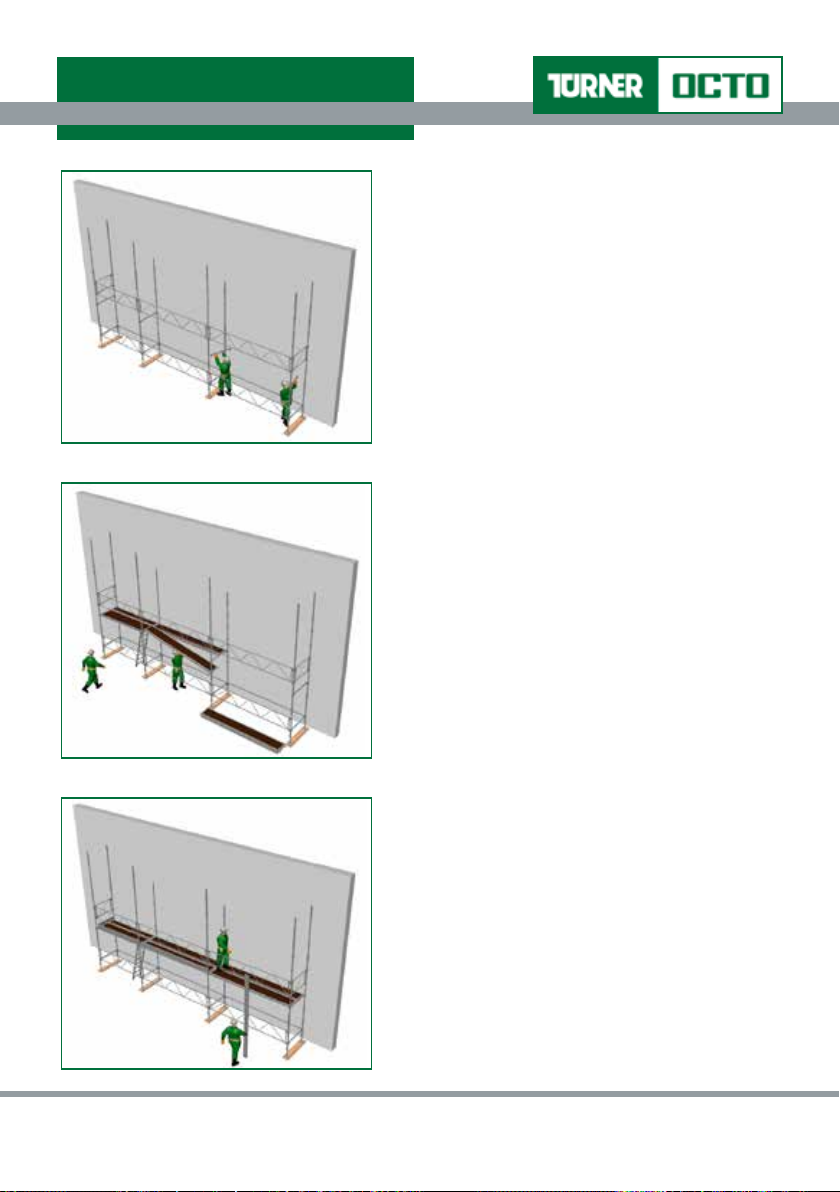

(ii) Wall Scaffold Assembly Procedure using GuardAid

®

This section shows the assembly procedure for a fully boarded tied wall scaffold using

the GuardAid® Positioning Tool; Turner’s recommended system of work for safe scaffold

assembly, dismantle and alteration.

Prior to the commencement of any scaffolding operations appropriate training is recommended.

Forward planning and organisation to ensure the amount and best utilisation of the correct

materials, before assembly procedures commence, will be rewarded throughout assembly

and in the nal scaffold constructed. Please refer to Section 1.5 Assembly Procedures for

further details.

1. Position two Jacks to approximate starting position

of rst bay (on base boards if required) and place

rst pair of appropriate Standards on Jacks then

connect transom (Horizontal) in lowest cups.

2. On outer Standard x Bracing Guardrail (to suit

required bay length) in direction of the length of the

scaffold.

3. Position next pair of Jacks and place Standard

on outer Jack. Connect Bracing Guardrail and x

transom to bottom cup.

4. Place appropriate inner Standard and connect

transom between Standards.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 15 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 16

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

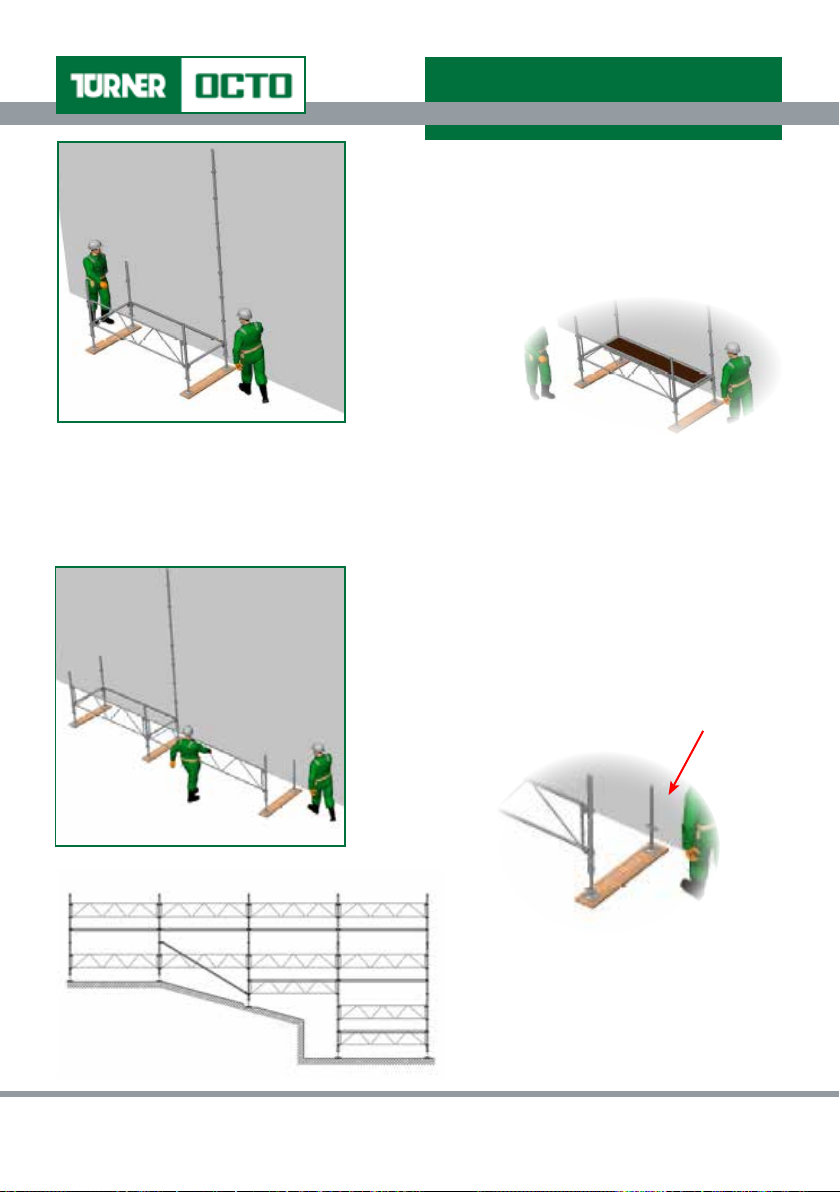

5. Fit Horizontal (ledger) between the inner

Standards (along length of bay) in bottom cups.

6. Check levels along 1st transom, ledger and nally

2nd transom and check that bay is square.

Note It may be advantageous to place a Deck in the bay to assist in “squaring” the bay. Place

an appropriate-sized Deck in the bay against the inside Horizontal (it should be parallel).

If required, make any adjustments and repeat as necessary.

7. Fix required Bracing Guardrail to outer Standard

and leave to “hang” in direction of length of

scaffold.

8. Place next Standard on Jack (set to minimum

height), lift into position and connect Guardrail.

Adjust Jack to sit under Standard.

Note On sloping ground, steps should

be cut to ensure the base boards lie at

and level.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 16 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 17

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

9. Fix transom to outer Standard then

place inner Standard on Jack, lift into

position and connect transom.

10. Fix ledger to inner Standards (bottom

cup) and level. Level along transom.

Repeat steps 7 to 10 until the desired

base length is complete.

Note Ensure that the entire base is

level and square. This will assist greatly

throughout the assembly of the remainder

of the structure.

11. Add additional and appropriate

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Standards on top of outer

Standards.

Section 1 Page 17 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 18

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

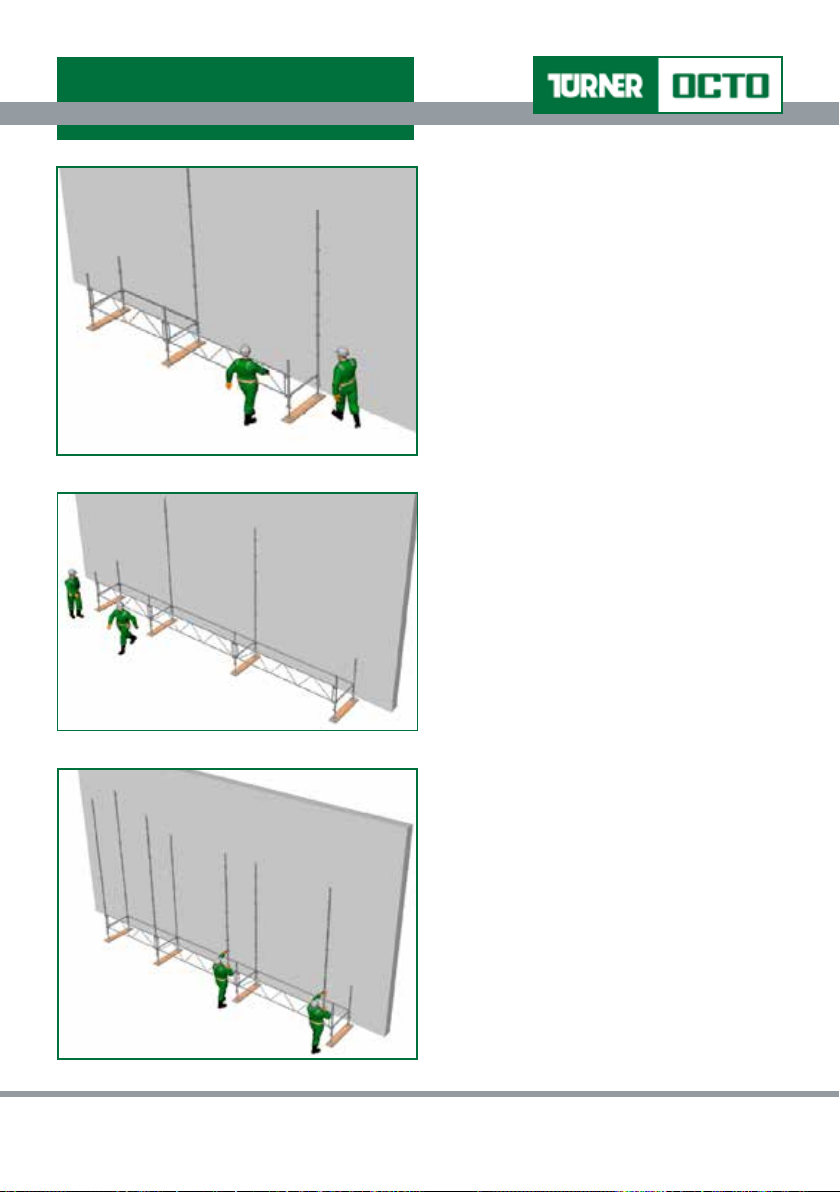

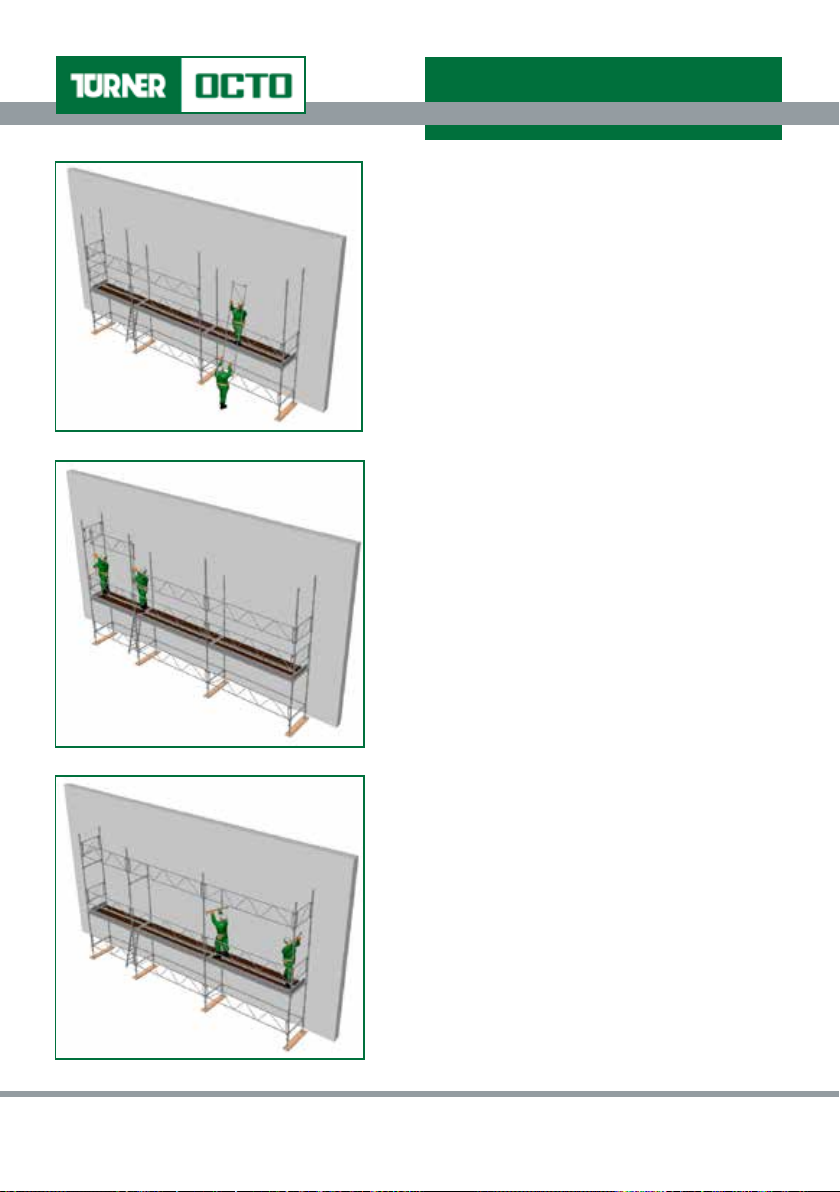

12. Place next lift Guardrails temporarily in cups

immediately above existing base Guardrails.

13. Using GuardAid® Positional Tool, raise

temporary Guardrails (placed at step 12)

into position to suit next lift platform and x

in position.

14. Continue to raise Guardrails from temporary

location into appropriate position to suit rst

lift platform using GuardAid

lift Guardrails are afxed.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

®

until entire next

Section 1 Page 18 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 19

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

15. Fix transoms at rst lift level (normally 4th

cup).

16. Select appropriate Decks and deck out

transoms (from below) until the lift is

complete (ensuring that locks on each end of

each Deck are in the locked position).

Note Place ladder access unit in one of the

bays to allow access to next lift.

17. Utilising ladder access unit, access can be

gained to Deck level and x Toeboards in

place.

Note Ensure that trapdoor is closed when

working on Deck.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 19 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 20

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

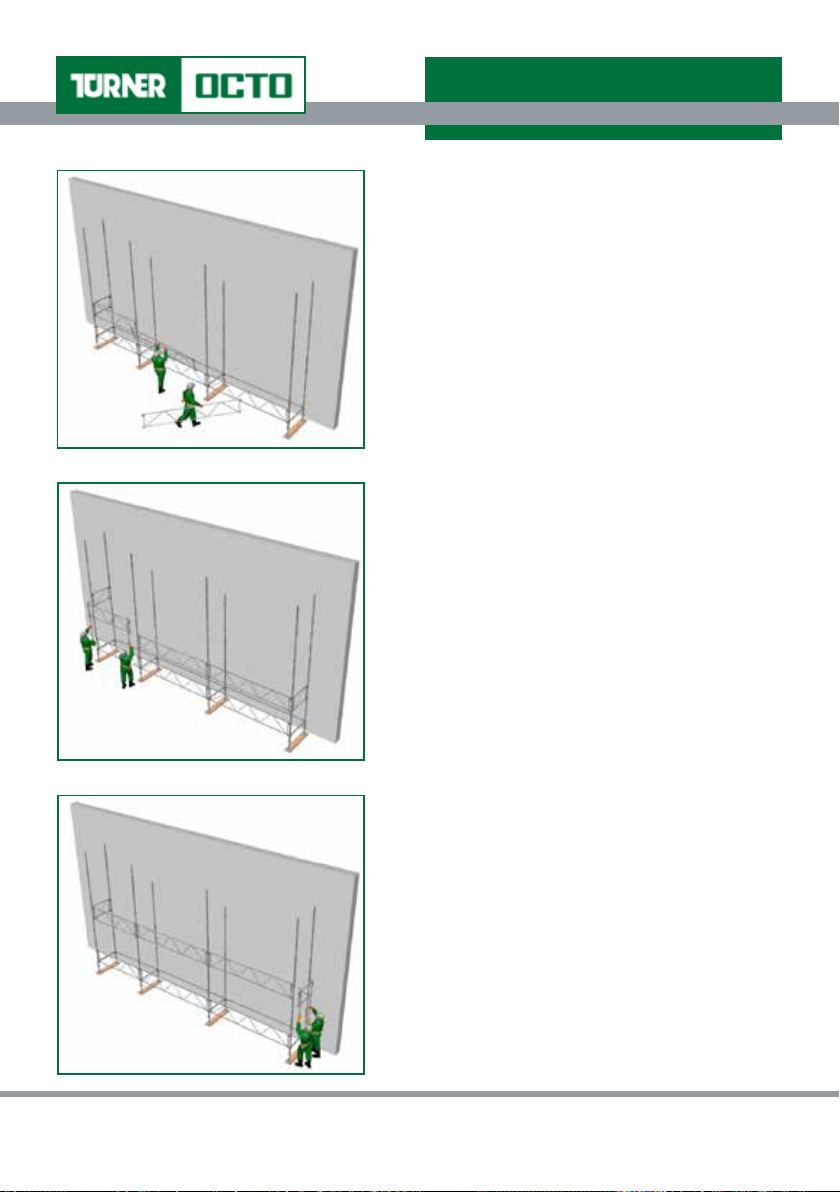

18. Place next lift Guardrails temporarily in cups

immediately above existing Deck Guardrails

and engage Wedge.

19. Using GuardAid® Positional Tool, raise

temporary Guardrails (step 18) into position

to suit next deck lift and x in position.

20. Continue to raise Guardrails into appropriate

position using GuardAid

Guardrails are afxed.

21. Fix transoms at rst lift level (normally 4th

cup from lower deck).

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

®

until entire next lift

Section 1 Page 20 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 21

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

22. Select appropriate Decks and deck out

transoms (from below) until the lift is

complete (ensuring that locks on each

end of each Deck are in the locked

position).

Note Place ladder access unit in one of

the bays to allow access to next lift.

23. Utilising ladder access unit, access can

be gained to Deck level and x Toeboards

in place.

Note Ensure that trapdoor is closed when

working on platform.

24. Add additional and appropriate Standards

on top of inner and outer Standards (if

required).

25. Place next lift Guardrails temporarily in

cups immediately above existing deck

Guardrails and engage Wedge.

26. Using GuardAid® Positional Tool, raise

temporary Guardrails (step 24) into

position to suit next lift platform and x in

position and engage Wedge.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 21 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 22

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

27. Continue to raise Guardrails into appropriate

position using GuardAid® until entire next lift

Guardrails are afxed.

28. Fix transoms at rst lift level (normally 4th

cup from lower platform).

29. Select appropriate Decks and deck out

transoms (from below) until the lift is

complete (ensuring that locks on each end

of each Deck are in the locked position).

Note Place ladder access unit in one of the

bays to allow access to next lift.

30. Utilising ladder access unit, access can be

gained to deck level and x Toeboards in

place.

Note Ensure that trapdoor is closed when

working on Deck.

Repeat steps 24 to 30 until desired platform

height is reached.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 22 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 23

Turner OCTO® Assembly Guide

SECTION 1.4 Safety Information

1.4.3 Fall Arrest

If lanyards are to be used in the installation of Turner OCTO

®

System Scaffolds, rather than

Turner best and recommended practice using GuardAid®, then double lanyards must be

used.

The attachment points shown below must be used. Only use the specified attachment points.

At no point in the installation should you attach the lanyard to Guardrails or Horizontals. The

positions indicated below are shown and numbered for maximum resistance against fall.

Connections

1 - 6 On the vertical Standard directly above the decked level

on the inside or outside face of the scaffold

7 - 9 On the vertical Standard 1.0m above the deck (2nd cup

above deck level) on the outside face only

10 & 11 On the vertical Standard at 2.0m above working deck

(4th cup above deck level) but ONLY when a transverse

horizontal has been installed beforehand as shown in

diagram above

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 23 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 24

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5 ASSEMBLY PROCEDURES FOR TURNER OCTO® SYSTEM SCAFFOLDS

Read this section in conjunction with Section 1.4.1 General Safety Notes on Page 11.

Prior to the commencement of any scaffolding operations appropriate training is recommended.

Forward planning and organisation to ensure the amount and best utilisation of the correct

materials, before assembly procedures commence, will be rewarded throughout assembly

and in the nal scaffold constructed. Careful consideration of the scaffold to be assembled

is required to ensure that it will meet working requirements and is designed to carry the

necessary loads.

The scaffold and the system of work chosen to assemble, dismantle and alter it, must also

comply with the requirements of current legislation, and further ensure that members of the

public are not put at risk.

It is necessary to erect Exclusion Zones and t Warning Signs prior to scaffold assembly.

Ensure the scaffolding is to be assembled on suitable foundations capable of withstanding

the loads imposed by the scaffolding and, where appropriate, adequate base boards to be

provided.

Where the foundation is a soft ground, the soil should be excavated to a rm base or,

alternatively, a larger base board used.

On sloping ground, steps should be cut to ensure the base boards lie at and level.

All components, including GuardAid® components (if used), should be available and

operational.

All components should be closely inspected before use (see Section 1.2 Pre-Use Inspection

& Selection page 5).

Ties should be xed as the scaffold rises (see Tie Pattern on Page 55).

Suitable access should also be used to achieve safe assembly and dismantling at all times.

This Assembly Guide should be issued to all operatives that will assemble, dismantle or alter

Turner OCTO® scaffolds and referred to if required.

Where this symbol appears, a risk of fall is present. However, this is only

applicable if using fall arrest equipment (does not apply when using GuardAid®

methodology to provide collective protection measures).

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 24 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 25

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5.1 Tied Wall Scaffold

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

(i) Fully Boarded

1. Position two Jacks to approximate

starting position of rst bay (on base

boards if required) and place 1st pair

of appropriate Standards on Jacks.

2. On outer Standard x Bracing

Guardrail (to suit required bay

length) in direction of the length of

the scaffold.

Connect transom (Horizontal) in

lowest cups.

3. Position next pair of Jacks and place

5. Fit Horizontal (ledger) between the

Standard on outerJack, connect

Bracing Guardrail and x transom to

bottom cup.

6. Check levels along 1st transom,

4. Place appropriate inner Standard

and connect transom between

Standards.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

inner Standards (along length of

bay) in bottom cups.

ledger and nally 2nd transom and

check that bay is square.

Section 1 Page 25 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 26

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

Note It may be advantageous to place a

Deck in the bay to assist in “squaring” the

bay. Place an appropriate sized Deck in the

bay against the inside Horizontal (it should

be parallel).

If required, make any adjustments and

repeat as necessary.

9. Fix transom to outer Standard then place

inner Standard on Jack, lift into position

and connect transom.

10. Fix ledger to inner Standards (bottom

cup) and level. Level along transom.

Repeat steps 7 to 10 until the desired base

length is complete.

7. Fix required Guardrail to outer

Standard and leave to “hang” in

direction of length of scaffold.

8. Place next Standard on Jack (set to

minimum height), lift into position and

connect Guardrail. Adjust Jack to seat

under Standard.

Note Ensure that the entire base is

level and square. This will assist greatly

throughout the assembly of the remainder

of the structure.

11. Add additional and appropriate

Standards on top of outer Standards.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 26 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 27

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

Note Ensure that the entire base is level

and square before proceeding with rst

lift height.

13. Add additional and appropriate-sized

Standards on top of the existing

outer Standards (as necessary)

to allow placing of the next lift of

scaffolding.

12. Place appropriate-sized Decks,

Bracing Guardrails and all

Horizontals to complete rst lift

safely. Ensure that ladder access

unit is situated in one of the bays to

allow access to next lift.

14. Repeat placement of appropriatesized Decks, Bracing Guardrails,

Horizontals and ladder access unit to

complete the second lift.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 27 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 28

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

15. Position inner Standards as

necessary and continue to next lift.

17. Fit Toeboards to each working lift.

16. Repeat sequence until desired

height is reached.

18. Completed scaffold.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 28 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 29

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

(ii) Top Lift

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

To assemble top lift only scaffolds, simply remove Decks from the bays that do not require

to have a working platform below the top lift (leaving ladder access bay in place).

1. Add Bracing Guardrails between

outer and inner Standards to provide

2. Remove Decks from the remaining

bays (from below).

protection to the ladder access bay

prior to removing Decks.

3. Fit Toeboards. 4. Completed scaffold.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 29 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 30

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

(iii) Corner Returns

External / Internal

Construction of the scaffold structure with corner returns should begin at a corner of the

building allowing for either corner return options 1 to 3 to be built correctly. Option 4 return

may be required in a corner to complete the scaffold run.

Option 1: 3 Legged Return

External

Constructed using 3 legs built

from base level.

Internal

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 30 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 31

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

Option 2: 4 Legged (core) Return

External

Built from a complete bay of scaffold where inside Standard is placed at corner and a run

of scaffold is constructed in both direction away from the corner along the building façade.

Internal

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 31 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 32

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

Option 3: Corner Return with inside boards

External

Two runs of scaffolding linked by a bay at the corner identical in size to the inside boards

allowing for Decks to be placed from the bay in one direction and placed on inside Cantilever

Brackets in the other direction. This allows for movement of the inside boards without

interfering with the scaffold construction.

Internal

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 32 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 33

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

Option 4: Fly By Return

Two runs of scaffolding that meet at a corner but cannot form one of the returns as shown

previously. Therefore, it is necessary to let one scaffold “y by” the other to maintain scaffold

run platform width. It will be necessary to close the gap with handrailing and Toeboards to

protect users.

In all cases, ensure that Bracing Guardrails are tted on inside faces of the scaffold

structure if the gap between the building and the scaffold structure exceeds 225mm (or local

regulations, if different).

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 33 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 34

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5.2 Independent Towers

Prior to the commencement of any scaffolding operations,

please refer to Sections 1.4.1 General Safety Notes and 1.5

Assembly Procedures.

(i) Fully Boarded

1. Base out structure

according to base out

procedure in Section 1.5.1

Tied Wall Scaffold Fully

Boarded steps 1 to 11.

Note Ensure that the entire

base is level and square before

proceeding with rst lift height.

2. Place appropriate-sized

Decks (incl. ladder unit

to one side of tower),

Bracing Guardrails

and all Horizontals to

complete rst lift safely.

4. Repeat placement of appropriate-sized

Decks, ladder access, Bracing Guardrails &

Horizontals to complete subsequent lifts.

5. Fit Toeboards.

3. Add additional and

appropriate-sized

Standards on top of

existing Standards to

allow placing of the next

lift of scaffolding.

6. Completed

Scaffold.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 34 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 35

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

(ii) Top Lift

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

1. Add Bracing Guardrails between

outer and inner Standards to provide

protection to the ladder access bay

2. Using Bracing Guardrail to Bracing Guardrail

Connector component, close off ladder

access units leaving them safe to use.

prior to removing decks.

3. Fit toeboards.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 35 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 36

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

(iii) Mobile

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

The following drawings show the base out procedure for a mobile tower. On completion of

the base out, proceed using steps 2 - 6 on Page 34.

1. Position four Castor

Wheel Jacks and

four Horizontals to

approximate starting

position of rst bay.

4. Place third Standard on

Jack and connect third

2. Ensure wheels are

locked, then place rst

Standard on Jack and

connect Horizontal in

3. Place second Standard

on Jack and connect

second Horizontal in

lowest cup.

lowest cup.

5. Continue until all Horizontals are connected. Check

levels along Horizontals and check that bay is square.

Horizontal in lowest cup.

Note Please refer to the Inspection & Maintenance Guidance Notes for Mobile Structures

on Page 37 when moving Turner OCTO

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

®

scaffold structures.

Section 1 Page 36 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 37

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

(iv) Inspection & Maintenance Guidance Notes for Mobile Structures

All mobile structures should be inspected prior to any moves to determine the integrity of the

structures has not been compromised. All components should be securely fastened.

Upon completion of your operations, all tools, materials, debris, etc. should be removed

and all platforms left in this condition. Before usage of structure and prior to structure being

moved, all platforms should be checked to ensure that they are free of any loose items.

All personnel should be clear of structure prior to movement of that structure. However, if

it has been determined by the person in charge that it will be necessary to have personnel

on board the structure to assist in the safe passage of the structure then the following is

necessary:-

i. Check with Turner OCTO® Design Dept. to ensure that personnel can be positioned on

board the structure.

If Item (i) has been afrmed then temporary guardrails have to be placed in position to

protect those on board when the structure is moved.

It is absolutely necessary to ensure that brake locks are in the off position during all

movements of the structure to avoid unnecessary damage occurring to the Castor wheel

and Jack arrangements or “at spots” appearing on the wheel.

When the structure has been successfully moved to its required location, and is stationary,

all brake locks must be on.

Protruding items are potentially hazardous and may cause injury to personnel or damage to

surrounding areas. To prevent such incidents occurring all protrusions should be removed, if

possible, or protective measures deployed before movement of structure.

If structure is to be stored outside, said structure should be adjoined to other such structures

in storage area to add stability and suitable anchorage / ties utilised to prevent overturn

or movement due to prevailing weather conditions. Deck locks should be on and further

supplemented by other means such as cable ties especially if exposed conditions are

expected.

When structure is stored and not in use, access to the structure should be restricted by any

means necessary at all access points on all structure.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 37 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 38

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

The following checks and procedures must be followed prior to and during all moves (refer

to Guidance notes):

TICK

( ) All structures and components are securely in place.

( ) All platforms have been checked and are clear of any debris and / or all loose items.

( ) All personnel are cleared from structure to be moved.

If it has been deemed necessary by the Client that personnel are required to be stationed

on board the structure to provide guidance whilst it is being moved then the following

checks are to be included.

( ) Design check has been requested.

( ) Temporary guardrails are in position.

( ) All brake locks are off prior to and during all movements of structure.

( ) All brake locks are on when structure is stationary and in required position (location).

( ) All protruding items are removed or protective measures deployed.

( ) Is structure to be stored outside?

If yes;

( ) All necessary measures have been taken to prevent movement when stored.

( ) All access to structure has been restricted when stored.

Signed…………………………………………. Date…………………

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 38 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 39

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5.3 Birdcages

A Turner OCTO® system birdcage scaffold creates a large at platform that can cover a great

expanse of work area overhead.

The procedure for assembling the birdcage is similar to building a series of towers. Each

tower is constructed from the tower next to it.

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

1. Base out structure according to base

out procedure in Section 1.5.1 Tied

Wall Scaffold Fully Boarded steps 1

to 11.

Note Ensure that the entire base is level

and square before proceeding with rst

lift height. It may be advantageous to t

temporary bracing guardrails to determine the

positioning of second structure and to assist

in levelling overall structure.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

2. Place appropriate-sized Decks,

Bracing Guardrails, Horizontals and

Standards to complete each lift.

3. Repeat sequence until desired height

is reached.

4. Fit Toeboards to working lift.

Completed Scaffold.

Section 1 Page 39 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 40

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

To assemble top lift only birdcage scaffolds,

remove Decks from the bays that do not

require to have a working platform below the

top lift (leaving ladder access bay in place).

Add Bracing Guardrails between outer and

inner Standards to provide protection to the

ladder access bay prior to removing Decks.

Remove Decks from the remaining bays

(from below).

Fit Toeboards.

(i) Linked Birdcage

Birdcage scaffolds can also be constructed by linking 2 runs of scaffolding using Bracing

Guardrails as the assembly procedure progresses until nal lift height is achieved and the

full platform is completed.

The bay sizes and links can be

any OCTO® system modular

size from 0.7m to 3.5m.

Bay Length / Width ‘x-x’ = 0.70m to 3.50m

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 40 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 41

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1. Base out structure according to base

out procedure in Section 1.5.1 Tied Wall

Scaffold Fully Boarded steps 1 to 11.

2. Fit temporary Bracing Guardrails to

protect the scaffold run platforms when

working from them. Bracing Guardrails

should be used to create the link between

the scaffold runs.

Note Ensure that the entire base is level and

square before proceeding with rst lift height. It

may be advantageous to t temporary Bracing

Guardrails to determine the positioning of second

structure and to assist in levelling overall structure.

3. Place appropriate-sized Decks, Bracing

4. Fit Toeboards to each working lift.

Guardrails, and Horizontals to complete

rst (ladder access unit) lift safely.

To assemble top lift only birdcage scaffolds, remove Decks

from the bays that do not require a working platform below

the top lift (leaving ladder access bay in place).

Add Bracing Guardrails between outer and inner Standards

to provide protection to the ladder access bay prior to

removing Decks. Remove Decks from the remaining bays

(from below). Fit Toeboards.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 41 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 42

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5.4 Freestanding Structures

The stability of freestanding structures is created using buttressing.

The example below is formed using full box type buttressing extended to the lift below the

full height of the structure (platform level) and tied back to the wall scaffold using plan braces

enabling each leg of the wall scaffold to be connected to the buttress.

This type of buttress provides the greatest stability to the wall scaffold structure.

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

For freestanding structures ensure all standards are pinned (using Standard Pins).

1. Base out wall scaffold to 1st lift height

3. Position Jacks to approximate starting

according to base out procedure in

Section 1.5.1 Tied Wall Scaffold Fully

Boarded steps 1 to 11.

2. Determine correct positioning for

buttress and x bracing guardrails (to

suit correct size of buttress) from outer

4. Fit plan bracing from buttress Standard

Standards and leave to “hang” in the

direction of buttress.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

position of rst bay (on base boards

if required) and place rst pair of

appropriate standards on Jacks then

connect transom (horizontal) in lowest

cups.

to tie back to wall scaffold and afx to

wall scaffold (in cup).

Section 1 Page 42 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 43

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

5. Place appropriate-sized Decks (incl.

ladder unit to one side of tower),

Bracing Guardrails and all Horizontals

to complete rst lift safely.

8. Repeat placement of appropriate-sized

Decks, ladder access, Bracing Guardrails

and Horizontals to complete subsequent

lifts of the buttress.

6. Add additional and appropriatesized Standards on top of existing

Standards to allow placing of next lift

of scaffolding.

7. Fix bracing guardrails and plan

bracing from buttress standard to tie

back to wall scaffold and afx to wall

scaffold (in cup).

9. Completed scaffold.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 43 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 44

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

Buttress Examples

Due to the complexity of any freestanding structure i.e. whether a structure is to be

sheeted or netted; if there is enough space to provide a full buttress, will the structure be

exposed to wind or other such important factors, then the structure may require additional

stability measures (ballast) to be employed and should therefore be designed prior to any

works commencing.

The following examples are illustrative only and may be subject to specic design criteria.

Tower Buttress Examples

Wall Scaffold Buttress Examples

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 44 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 45

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5.5 Cantilever Brackets

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

(i) Inside Boards

1. Base out structure according to base

out procedure in Section 1.5.1 Tied Wall

Scaffold Fully Boarded steps 1 to 11.

Note Ensure that the entire base is level and

square before proceeding with rst lift height.

3. Add additional and appropriate-sized

Standards on top of the existing outer

Standards (as necessary) to allow

placing of the next lift of scaffolding.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

2. Place appropriate-sized Decks,

Bracing Guardrails, Horizontals and

Cantilever Brackets to complete rst

lift safely. Ensure that ladder access

unit is situated in one of the bays to

allow access to next lift.

4. Repeat placement of appropriatesized Decks, Bracing Guardrails,

Horizontals and ladder access unit to

complete the second lift.

Section 1 Page 45 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 46

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

5. Position inner Standards as necessary

and continue to next lift.

7. Fit Toeboards to each working lift

(ends at additional inside cantilver

brackets).

6. Repeat sequence until desired height

is reached.

8. Completed scaffold.

Tied Wall Scaffold with Bridge - Example of Cantilever Brackets in use.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 46 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 47

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

(ii) Cantilever Brackets with End Plate

Cantilever brackets with end plate (0.10m to 1.20m) are used as inside cantilever brackets

to minimise the gap between the scaffold structure and the building.

They may also be used (in some instances) as hop up brackets and moved as works

progress.

(iii) Cantilever Brackets with Cup

Cantilever brackets with cup (0.50m to 1.25m) can be used to the inside, outside or end

faces of the scaffold structure.

Additional scaffold materials can be built from this cantilever bracket (in accordance with

design) useful in bridging over lower level projections (for example) or increasing platform

width if necessary in certain applications.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 47 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 48

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

To provide additional loading capacity to the cantilever bracket with cup then the bracket

should be located 0.5m (1 cup in normal circumstances) below the platform level to allow

diagonal face braces to be tted as a raker.

Additional Horizontals (transoms) must be tted below the existing platform adjacent to the

cantilever bracket and also at the lift below where the diagonal face brace ts in the cup.

Note When using this arrangement, refer to design.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 48 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 49

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5.6 Circular Structures

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

The circular scaffold structure is a series of towers that are linked together.

1. Base out structure according to base

out procedure in Section 1.5.1 Tied Wall

Scaffold Fully Boarded steps 1 to 11.

2. Ensure that the inside Horizontals

(ledgers) have free passage and do not

foul the structure.

3. Place appropriate sized Decks, Bracing

Guardrails and Horizontals in the towers

(including a ladder access unit in at least

one tower) and link between the towers

(in accordance with the design) ensuring

Bracing Guardrails are tted too.

Should the minimum handrail height fall

below regulated heights then an additional

ledger should be added above the Bracing

Guardrail (handrail).

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 49 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 50

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

4. Repeat placement of appropriate-sized

Decks, ladder access units, Bracing

Guardrails and Horizontals to complete

subsequent lifts.

5. Fit Toeboards.

6. Completed Scaffold.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 50 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 51

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5.7 Suspended Scaffolds (Hanging Scaffolds)

Prior to the commencement of any scaffolding operations, please refer to Sections 1.4.1

General Safety Notes and 1.5 Assembly Procedures.

There are many variations in the design and construction of hanging scaffolds. The following

instructions are intended as an example only of one type based on the nal design of the

hanging structure.

All hanging scaffolds are subject to design and verication of that design prior to scaffolding

works commencing.

Note When constructing a hanging scaffold structure you MUST pin the standards using

high tensile M16 Nuts and Bolts.

1. Assemble the tower structure using

additional Base Jacks upturned in the

Standards that can then be adjusted

to t tight against the underside of the

oor above. This provides structural

stability.

This should be carried out in strict

accordance with design drawings and

appropriate plan bracing tted.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

2. Fit connecting Horizontals (transoms)

from tower structure to allow connection

of hanging Standards.

3. Fit Guardrails and Horizontals (ledgers)

and tie Standards back to the tower

structure using diagonal face braces

ensuring all components are securely

locked.

4. Fit Decks.

Section 1 Page 51 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 52

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

5. Create hanging bay using Standards,

Bracing Guardrails, Horizontals,

Cantilever Brackets and Decks.

6. Tie outside Standards back to tower

structure using diagonal face braces.

7. Fit hanging Standards to complete the

bay and pin using high tensile M16

Nuts and Bolts.

8. Fit appropriate Bracing Guardrails,

Horizontals and Decks to complete

bay.

Ensure that a ladder access unit is tted

to gain access to lower level.

9. Fit Toeboards. 10. Complete Scaffold.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 52 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 53

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5.8 Pre Scaffold Handover Inspection

The scaffold should be visually inspected to make certain that all components used have

been installed correctly and secured to prevent accidental displacement.

Check that all necessary scaffold ties (if required) have been installed in accordance with

the tie pattern on page 55 and that all Guardrails and Toeboards have been tted to the

working platforms.

1.5.9 Maintenance

®

All Turner OCTO

Scaffolds, in common with all types of scaffolding, should be regularly

inspected (at least once per week) and recorded, in accordance with current legislation.

The statutory regulations of each state or country should be observed and/ or the type of

work to be carried out on the scaffolding or the environment in which the scaffolding is to be

used, or the position (if moved) may also determine the frequency of inspections required.

However, it is good safety practice to inspect the structure before every working shift and

any defects or misuse reported and corrected, as soon as possible, by a competent person.

Examples of misuse are as follows (but not limited to):

• Overloading of platforms

• Removal of Components; in particular, decking, guardrails, toeboards and ties

• Undermining of foundations

• Sheeting xed to structure without approval

• Electrical Hazards

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 53 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 54

Turner OCTO® Assembly Guide

SECTION 1.5 Assembly Procedures

1.5.10 Dismantling Procedure

The dismantling procedure should simply be a reversal of the steps explained for the

assembly of the various types of standard congurations.

However, several safety procedural steps should be considered before dismantling

operations begin.

1. Refer to your Risk Assessment – a separate Risk Assessment should be carried out

prior to any dismantling operations.

2. Visually check the scaffold from ground level for any obvious hazards that may have

developed or been created (by the user) that may not be listed on the Risk Assessment.

Such hazards may include:

• Debris left on the scaffold

• Overhead wires on or touching the scaffold

• Obvious removal of scaffold ties (check number of ties tted on Hand Over Certicate to

assist in determining whether ties may have been removed).

• Removal of structurally important components, e.g. Decks and Bracing Guardrails.

This list is not exhaustive and other hazards may exist. If in any doubt and you can see

hazards that have not been notied on the Risk Assessment, seek consultation before

proceeding to the next step.

3. Erect an exclusion zone and t Warning signs in accordance with current legislation

prior to scaffold dismantle taking place.

4. Commence dismantling operations and continue to visually inspect scaffold at close

proximity throughout the dismantling procedure for any unforeseen hazards.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 54 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 55

Turner OCTO® Assembly Guide

SECTION 1.6 Anchoring

1.6 ANCHORING

1.6.1 Tie Patterns for unclad scaffolds

3500 max. 3500 3500 35003500

200020002000200020002000200020002000200020002000

24000

Denotes Tie Location

4270 max.

Every standard to be tied at top lift except where platform is greater than 1500mm from eaves.

• End ties to be tied at maximum 4000mm crs

• All ties to be within 300mm of standard - transom joint

• Good practice is to x all ties to inner and outer standards. A minimum requirement is for all end ties to be xed to

inner and outer standards and other ties xed to inner standard only.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 55 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 56

1.6.2 Tie Loads

Turner OCTO® Assembly Guide

SECTION 1.6 Anchoring

Unclad Scaffold 24m x 1m with 0.7m (max) cantilevers; Load Class 3

WIND LOAD CRITERIA

BS EN 12810 - 1 EDGE End standards > 2.0m from edge of building

• South East England EDGE(II) End standards ≤ 2.0m from edge of building

• Distance <100m from sea INTERIOR Any Internal standards

• 300m land altitude TOP Top platform level > 2.0m from eaves of building

• Open Country TOP(II) Top platform level ≤ 2.0m from eaves of building

BS 6999 - 2 EDGE End standards > 2.0m from edge of building

• West of Scotland EDGE(II) End standards ≤ 2.0m from edge of building

• Distance <100m from sea INTERIOR Any Internal standards

• 300m land altitude TOP Top platform level > 2.0m from eaves of building

• Open Country TOP(II) Top platform level ≤ 2.0m from eaves of building

MAXIMUM

TIE LOADS

1000 CB060

DESCRIPTION

1000 CB060 1000 CB060 1000 CB060

CONFIGURATIONS

C1 & C2

(kN)

C3 & C4

(kN)

3.1 2.9

6.2 5.8

5.7 5.6

3.0 3.0

5.6 5.5

4.3 3.9

8.4 7.7

7.6 7.5

4.0 3.8

7.3 7.2

Max. 24.0m

Bracing guardrails & Transoms @ 2.0m c/c

Max. 4.27m to rst Tie Location

C1 C3C2 C4

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 56 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 57

Turner OCTO® Assembly Guide

SECTION 1.7 Maximum Heights

1.7 MAXIMUM HEIGHTS

1.7.1 Assembly Criteria - Unclad Tied Wall Scaffold Examples

FOOT TIED FOOT TIED NON FOOT TIED

COMPONENTS

(Horizontal as

Base Transom

Member)

Max Bay Length 3500mm 3500mm 3500mm

(Guardrail as

Base Transom

Member)

TRANSOMS

LEDGERS

(Inside Face)

GUARDRAILS

(Outside Face)

Max. Height to rst

transom

Max. Subsequent

vertical spacing

Horizontal Spacing In End Bays + minimum every 2nd Bay

Max. Height to rst

ledger

Max. Subsequent

vert. spacing

Horizontal Spacing In End Bays + minimum every 2nd Bay

Max. Height to

bottom chord of 1st

guardrail

Max. Subsequent

vert. Spacing c/c

800mm 800mm 2700mm

2000mm 2000mm 2000mm

800mm 800mm 800mm

2000mm 2000mm 2000mm

Ledgers not required where locked Turner System decks

are in place

800mm 800mm 800mm

2000mm 2000mm 2000mm

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 57 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 58

Turner OCTO® Assembly Guide

SECTION 1.7 Maximum Heights

The following examples of Unclad Tied Wall Scaffolds are SYSTEM CONFIGURATIONS in

accordance with BS EN 12810-1:2003 (7.2 The standard set of system congurations).

They note the maximum computed leg load for the congurations built to their maximum

height to top platform level. Where this computed height is higher than 24m it is noted that

the Max. Height to Platform is 24.0m.

LIVE LOAD

The loading congurations are in accordance with BS EN 12811-1:2003(6.1.3 Load

Classes).

See Turner Fabrication interpretation of Load Class Table below.

LOAD CLASS DUTY

1

Inspection &

Very Light Duty

UDL ON

PLATFORM

kN/m

0.75 1 @ 100% (0.75) & 1 @ 50% (0.375)

MAX. NUMBER OF PLATFORMS IN

2

USE (UDL KN/M2)

2 Light Duty 1.50 1 @ 100% (1.50) & 1 @ 50% (0.75)

3

General

Purpose

2.00 1 @ 100% (2.00) & 1 @ 50% (1.00)

4 Heavy Duty 3.00 1 @ 100% (3.00) & 1 @ 50% (1.50)

The cantilevers are rated at the same capacity as the main platforms in all cases.

Scaffolds other than those noted in the SYSTEM CONFIGURATION must be designed

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 58 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 59

Turner OCTO® Assembly Guide

SECTION 1.7 Maximum Heights

1.7.2 Maximum Heights Of Unclad Tied Scaffolds (Foot Tied With Horizontal)

1000 CB060 1000 CB060

Bracing guardrails & Transoms @ 2.0m c/c

1000

Drawing 1

LEG LOADS

Inner

Outer

(kN)

(kN)

10.75 24.24 24*

Drawing 2

LEG LOADS

Inner

Outer

(kN)

(kN)

11.03 22.91 24*

Drawing 3

LEG LOADS

Inner

Outer

(kN)

(kN)

34.4 34.11 24*

Max Height

to Platform

(m)

Max Height

to Platform

(m)

Max Height

to Platform

(m)

Load Class

to BS EN

12811-1

3

0.8m MAX.

1 2 3

*Height restricted to 24m. Leg Loads given for maximum height achieved in this conguration.

• Based on 3.5m bay lengths.

• Tie pattern arrangement shown separately

• Scaffolds other than those noted in System Congurations (BS EN 12810-1:2003 - 7.2) require

design.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 59 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 60

Turner OCTO® Assembly Guide

SECTION 1.7 Maximum Heights

1.7.3 Maximum Heights Of Unclad Tied Scaffolds (Foot Tied With Guardrail)

1000 CB060

Bracing guardrails & Transoms @ 2.0m c/c

1000 CB060 1000

Drawing 1

LEG LOADS

Inner

Outer

(kN)

(kN)

11.74 29.5 24*

Drawing 2

LEG LOADS

Inner

Outer

(kN)

(kN)

13.79 29.79 24*

Drawing 3

LEG LOADS

Inner

Outer

(kN)

(kN)

39.64 38.95 24*

Max Height

to Platform

(m)

Max Height

to Platform

(m)

Max Height

to Platform

(m)

Load Class

to BS EN

12811-1

3

0.8m MAX.

1 2 3

*Height restricted to 24m. Leg Loads given for maximum height achieved in this conguration.

• Based on 3.5m bay lengths.

• Tie pattern arrangement shown separately

• Scaffolds other than those noted in System Congurations (BS EN 12810-1:2003 - 7.2) require

design.

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 60 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 61

Turner OCTO® Assembly Guide

SECTION 1.7 Maximum Heights

1.7.4 Maximum Heights Of Unclad Tied Scaffolds (Non Foot Tied)

1000 CB060 1000 CB060 1000

Drawing 1

LEG LOADS

Outer

(kN)

8.21 20.73 20

LEG LOADS

Outer

(kN)

8.35 18.41 14

Max Height

to Platform

Inner

(kN)

Drawing 2

Max Height

to Platform

Inner

(kN)

(m)

(m)

Bracing guardrails & Transoms @ 2.0m c/c2.3m MAX.

Drawing 3

LEG LOADS

Outer

(kN)

20.7 19.91 24*

Load Class

to BS EN

12811-1

Inner

(kN)

3

Max Height

to Platform

(m)

1 2 3

First lift restricted to 1kN per m

2

* Height restricted to 24m. Leg Loads given for maximum height achieved in this conguration.

• Based on 3.5m bay lengths.

• Tie pattern arrangement shown separately

• Scaffolds other than those noted in System Congurations (BS EN 12810-1:2003 - 7.2) require

design.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 61 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 62

Turner OCTO® Assembly Guide

SECTION 1.8 Transport and Storage

1.8 TRANSPORT AND STORAGE

The Transportation Rack is fully galvanised and used for the safe transportation to/ from

site and storage in Yard (Compound) areas.

Racks can be stacked either empty or full to minimise the area required for storage.

Sample loads for the Transportation Rack:

Item Approx. No. per Rack

S400 to S125 Standards 4,00 m to 1,25 m 75

S100 + S100FT Standards 1,00 m + Standards 1,00 m with ush top 150

S050 Standards 0,50 m 225

BG350 to BG125 Bracing Guardrails 3,50 m to 1,25 m 25

BG100 to BG070 Bracing Guardrails 1,00 m to 0,70 m 50

BG050 Bracing Guardrails 0,50 m 75

H350 to H125 Horizontals 3,50 m to 1,25 m 100

H100 to H070 Horizontals 1,00 m to 0,70 m 200

HB125 to HB100 Horizontal Beam 1,25 m to 1,00 m 90

HB350 to HB150 Horizontal Beam 3,50 m to 1,50 m 64

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 62 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 63

Turner OCTO® Assembly Guide

SECTION 1.9 References

1.9 REFERENCES

• BRITISH STANDARD BS EN 12811 (2003): Parts 1 & 2 Temporary Works Equipment

• BRITISH STANDARD BS EN 12810 (2003): Parts 1, 2 and 3 Façade Scaffolds made

of Prefabricated Components

®

• Assessment of the OCTO

System for Access Scaffold Applications by A.W. Irwin,

B.Sc.(Eng.), PhD., C. Eng., M.I.C.E., M.I. E. MASA.

• Work at Height Regulations (2005)

• Construction (Lifting Operations and Lifting Equipment) Regulations (LOLER), 1998:

Provision and Use of Work Equipment Regulations 1998

• Personal Protective Equipment at Work Regulations 1992

• Management of Health & Safety at Work Regulations 1999

• Construction (Design & Management) Regulations 1994

• Construction (Health, Safety & Welfare) Regulations 1996

• Manual Handling Operations Regulations 1992

• BRITISH STANDARD BS 1139 Pt.5 1990

• (HD 1000:1988) Metal Scaffolding Part 5: Specication for Materials: Dimensions,

design loads and safety requirements for service and working scaffolds made of

prefabricated elements.

T: +44 (0) 141 309 5555 F: +44 (0) 141 309 5436 www.turner-octo.com

Section 1 Page 63 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Page 64

Turner OCTO® Assembly Guide

For more information, please contact Turner Access Design Department on T: +44 (0) 141 309 5555

©Turner Access Ltd 65 Craigton Road, Glasgow, G51 3EQ, Scotland

Section 1 Page 64 TA3/01/50/01_Iss1Rev3

Rev.No.Jan17/Rev3

Loading...

Loading...