Turin Networks MASTER series Quick Start Manual

MASTERseries

QUICK START GUIDE

Part Number: 002-0273-2010

Release: 7.0

October 2008

Copyright© 2008 Turin Networks. All rights reserved.

The information presented in this manual is subject to change without notice and does not represent a commitment on the

part of Turin Networks. The hardware and software described herein are furnished under a license or non-disclosure

agreement. The hardware, software, and manual may be used or copied only in accordance with the terms of this agreement.

It is against the law to reproduce, transmit, transcribe, store in a retrieval system, or translate into any medium - electronic,

mechanical, magnetic, optical, chemical, manual, or otherwise - any part of this manual or software supplied with

MASTERseries for any purpose other than the purchaser’s personal use without the express written permission of Turin

Networks.

The Turin Networks Logo is a registered trademark of Turin Networks. FLEXengine, FLEXmaster, MASTERseries and

OMC Companion are trademarks of Turin Networks. All other brand or product names are trademarks or registration

trademarks of their respective companies or organizations.

Corporate Contact Information:

Turin Networks, Inc.

1415 North McDowell Blvd.

Petaluma, CA 94954

Phone: +1-707-665-4400

Fax: +1-707-793-4935

www.TurinNetworks.com

Turin Technical Assistance Center:

E-mail: tech-support@TurinNetworks.com

Phone (US): 1-800-887-4638

Phone (International/Direct): 1-707-665-4355

Safety Information

CAUTION! ALWAYS USE CAUTION WHEN INSTALLING TELEPHONE LINES. READ THE CAUTIONS

BELOW FOR DETAILS ON SAFETY GUIDELINES TO PREVENT INJURY.

z The installation of a MASTERseries unit is to be performed by qualified personnel only.

z Never touch uninsulated telephone wires and terminals unless the telephone line has been

disconnected at the Network Interface (NI) as voltage potentials as high as 300 VAC may be

present across the transmit and receive pairs.

z Only use No. 26 AWG or larger telecommunication line cord, to reduce the risk of fire.

z Never install telephone wiring during a lightning storm.

z Never install telephone jacks in wet locations unless the jack is specifically designed for wet

locations.

PREFACE

Preface

z Refer to the installation section of this manual for a safe and proper installation procedure. All

wiring external to this equipment should follow the current provision of the National Electrical

Code.

Preface

Electrostatic Discharge (ESD) Precautions

Electrostatic Discharge (ESD) Precautions

ESD can damage processors, circuit cards, and other electronic components. Always observe the

following precautions before installing a system component.

1. Do not remove a component from its protective packaging until ready to install it.

2. Wear a wrist grounding strap and attach it to a metal part of the system unit before handling

components. If a wrist strap is not available, maintain contact with the system unit throughout

any procedure requiring ESD protection.

WARNING! INTEGRATED CIRCUITS (ICS) ARE EXTREMELY SUSCEPTIBLE TO ELECTROSTATIC

DISCHARGE. UNLESS YOU ARE A QUALIFIED SERVICE TECHNICIAN WHO USES TOOLS AND

TECHNIQUES THAT CONFORM TO ACCEPTED INDUSTRY PRACTICES, DO NOT HANDLE ICS.

The ESD warning label appears on packages and storage bags that contain

static-sensitive products and components.

4 MASTERseries - Release 7.0

QUICK START GUIDE

MASTERseries Quick Start Guide

In this Guide

Unpacking and Inspection

Installation Environment

2-Slot Chassis Installation

8-Slot Chassis Installation

Local Management - Logging in to the

FLEXmaster

Connectors

LEDs

NOTE: Multiple modules, master/slave functionality, and E1 functionality are not supported

in this release.

MASTERseries Quick Start Guide

Unpacking and Inspection

Unpacking and Inspection

WARNING! OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC DEVICES.

1. Inspect containers for damage during shipment. Report any damage to the freight carrier for

possible insurance claims.

2. Compare packing list with office records. Report any discrepancies to the office.

3. Open shipping containers, be careful not to damage contents.

4. Inspect contents and report any damage.

5. If equipment must be returned for any reason, carefully repack equipment in the original

shipping container with original packing materials if possible.

6. If equipment is to be installed later, replace equipment in original shipping container and store

in a safe place until ready to install.

Installation Environment

The environment in which you are installing the Adit 600 must meet the following conditions:

z Operating temperature range: -40° to 149° F (-40° to 65° C)

z Storage temperature range: -40° to 158° F (-40° to 70° C)

z Maximum operating altitude: 10,000 ft. (3,048 m)

z Minimum operating altitude: 197 ft. (60 m) below sea level

z Maximum non-operating altitude: 40,000 ft. (12,192 m)

z Relative humidity (non-condensing) range: 0 to 95%

6 MASTERseries - Release 7.0

MASTERseries Quick Start Guide

Application

Application

Power Supply

Slot 2

Power Supply

Slot 1

Module Slot 1

Module Slot 2

19"

1.75"

10.2"

2-Slot Chassis Installation

2-Slot Chassis Installation

The 2-slot chassis has two application module slots and two power supply slots for redundant power.

Dimensions:

z 1.75 in (H) x 19 in (W) x 10.2 in (D).

z Maximum depth of the shelf, including cables, is 12 inches

z Rack Mounting: 19 or 23 inch rack

NOTE: Blank faceplates must be installed on each empty slot to be in compliance with

product emission standards.

Supported Configurations

The following table indicates the configurations supported by the 2-slot chassis.

Double

Fan

For information about configurations supported by the 8-slot chassis, see 8-Slot Chassis Installation on

page 20.

Triple

Fan

9

9

9

FM16

TDM

11*

FM16

ATM

11*

FM16

PWE

11*

Total Number

of Modules

MASTERseries - Release 7.0 7

MASTERseries Quick Start Guide

19-inch Mounting

Bracket

23-inch Mounting

Bracket

black green

+ -

black

+ -

2-Slot Chassis Installation

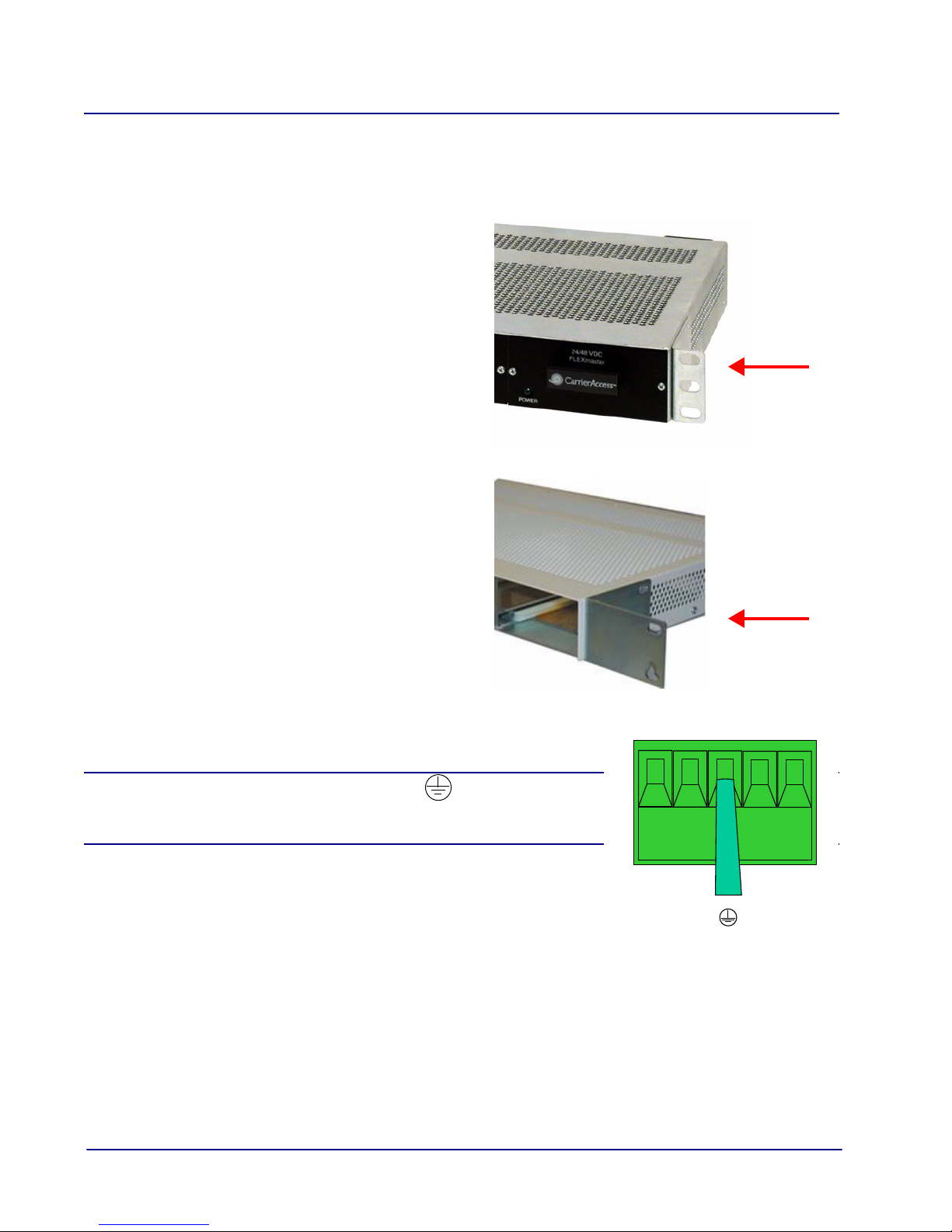

Rack Mount Installation

Mounting brackets for a 19-inch rack are installed on the chassis when shipped. If you want to install

the chassis in a 23-inch rack, you must purchase 23-inch mounting brackets from Turin Networks.

Installation of the 2-slot chassis is as follows:

1. To install the unit in a 19-inch rack, attach

the unit with the brackets to the rack using

the screws provided.

2. To install the unit in a 23-inch rack, remove

the 19-inch mounting brackets and replace

them with 23-inch mounting brackets

purchased from Turin Networks.

3. Ground the unit by attaching ground wire from the

terminal block to the frame ground.

WARNING! THE GROUND TERMINAL ON THE POWER

BLOCK MUST BE CONNECTED TO THE FRAME GROUND TO

PREVENT POSSIBLE DAMAGE TO THE EQUIPMENT.

8 MASTERseries - Release 7.0

MASTERseries Quick Start Guide

2-Slot Chassis Installation

Power Supply Installation and Cabling

DANGER! POSSIBLE SHOCK HAZARD EXISTS - PLEASE FOLLOW INSTRUCTIONS

CAREFULLY. ENSURE THAT NO POWER IS PRESENT ON POWER LEADS AND THAT

THE CHASSIS POWER SWITCH IS OFF WHEN PERFORMING THE PROCEDURES IN

THIS SECTION.

This section describes the power supplies used in the 2-slot chassis and provides instructions for

installing and setting up cabling for the power supplies.

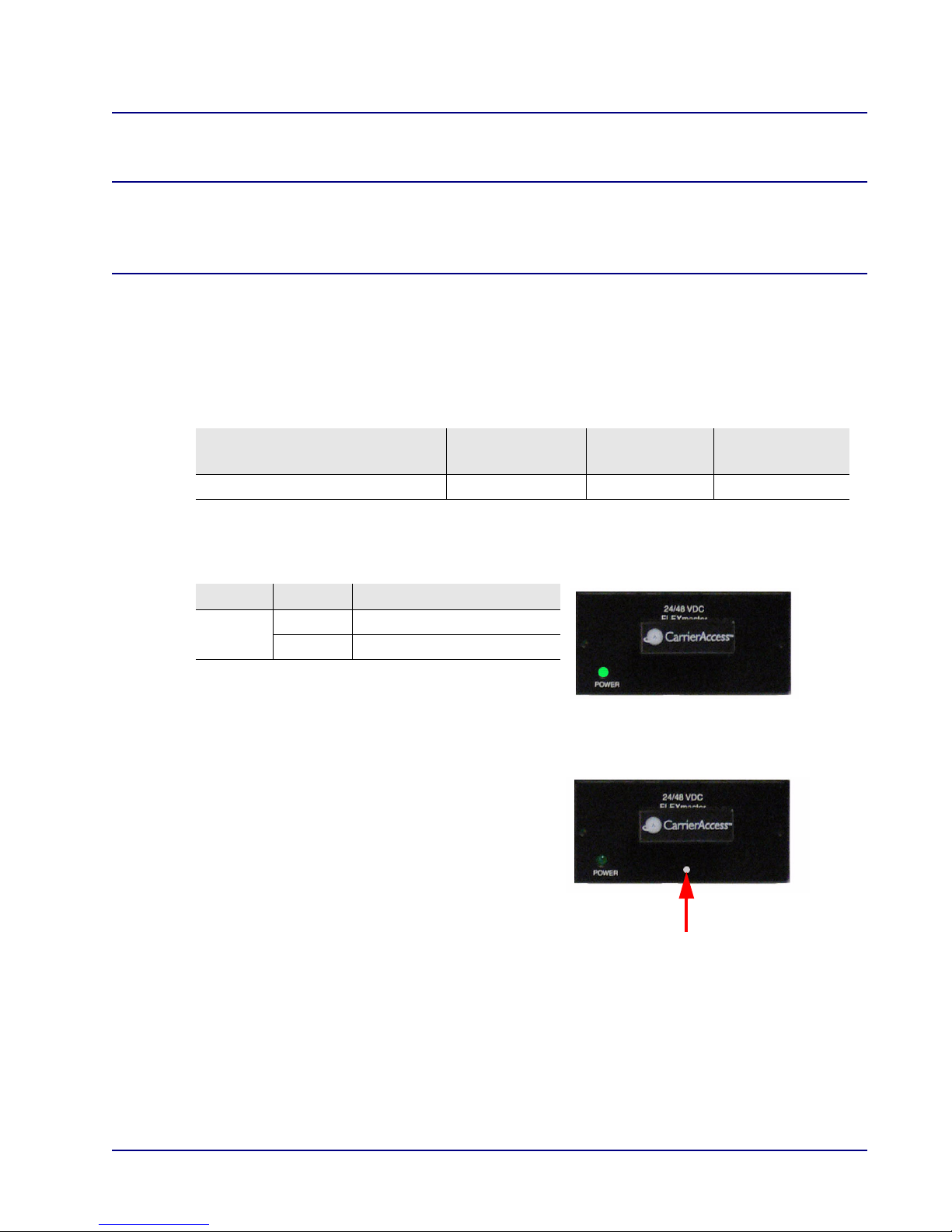

+24/-48 VDC Power Supply

FLEXmaster modules are powered by +24/-48 VDC power supplies. The power supplies are

redundant and load sharing.

DC Configuration

+24/-48VDC (24 – 65VDC input) 30W dual 3.15A

The LED states of the power supply are as follows

Power Supply

Wattage

:

Input Power

Feed(s)

Fuse

LED State Description

Power Off DC input missing or failure

Green DC input present

NOTE: MASTERseries Release 6.0 introduced a

new 24/-48 VDC power supply that is identified

by a small white dot on the faceplate.

MASTERseries - Release 7.0 9

MASTERseries Quick Start Guide

Fan Power Connector

2-Slot Chassis Installation

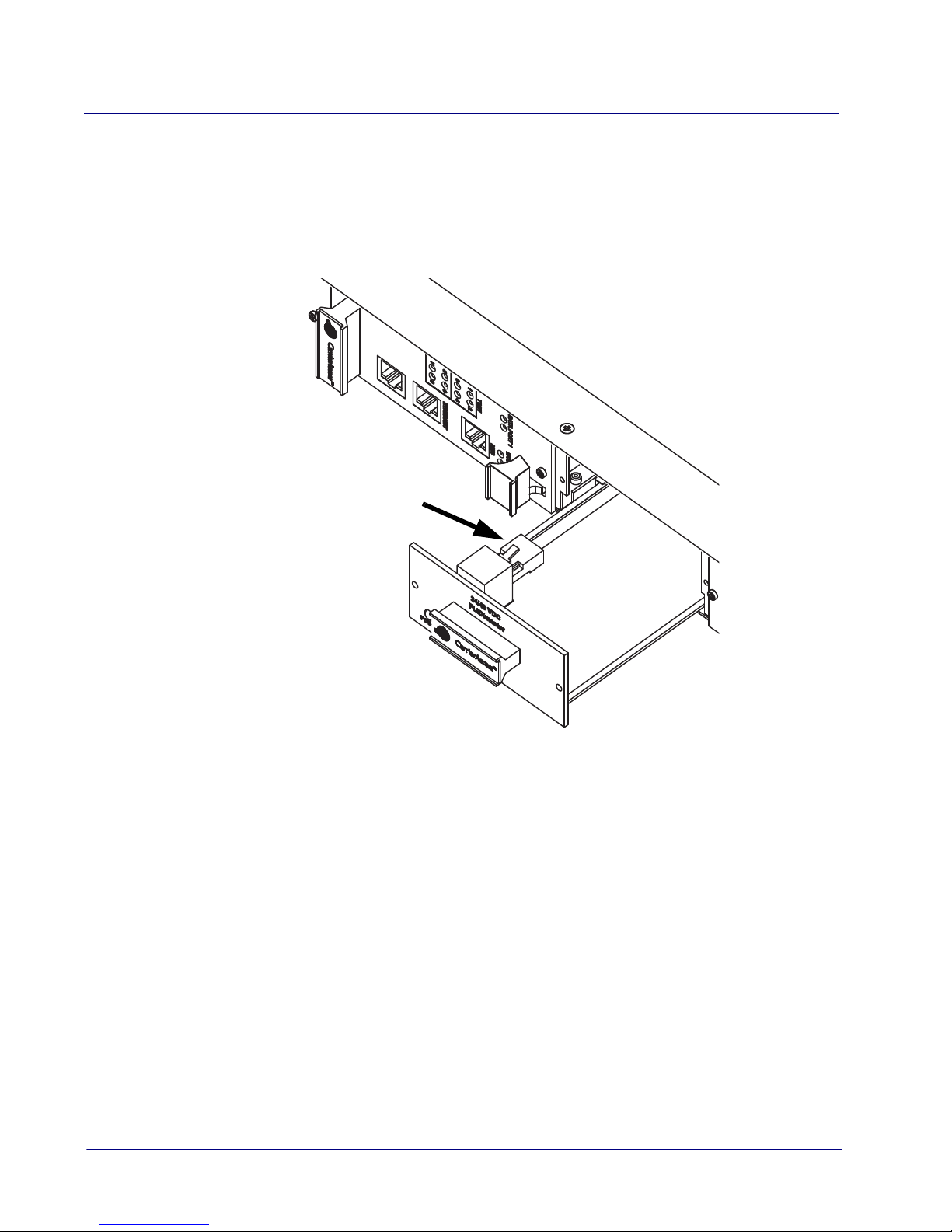

Power Supply Installation

To install the first power supply:

1. Remove the blank faceplate from power supply slot 2.

2. Slide the power supply halfway into the empty slot, and plug the fan’s power connector into

the power supply.

3. Slide the power supply the rest of the way into the slot. Press firmly to make full contact

with the connector at the back of the chassis.

4. Insert and tighten the screws on the front of the power supply.

5. For redundant systems, install a second power supply into power supply slot 1 following

the same procedure (except for connecting the fan).

10 MASTERseries - Release 7.0

MASTERseries Quick Start Guide

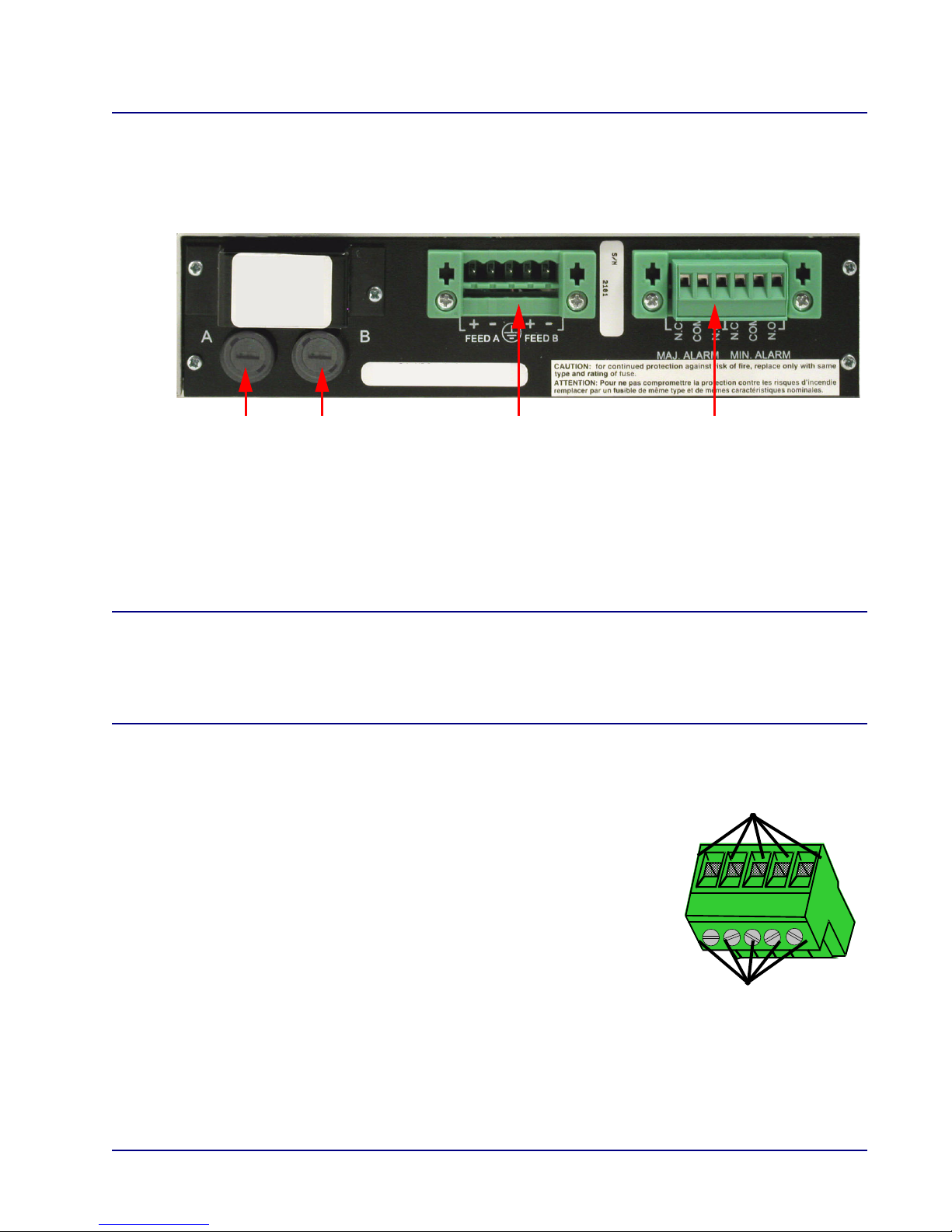

Power Entry Module Alarm Terminal Block

DC Line Input Fuses

(A and B feeds)

Connect 16-18

Wire Securing Screws

Gauge Wire Here

2-Slot Chassis Installation

Power Lead Connection

The +24/-48 VDC power entry module provides DC power protection and isolation when the leads

are properly attached.

Each input has its own return. The labels of the power entries vary based on what version of the

chassis you have:

z FEED A (IN A/RTN A) operates power supply A

z FEED B (IN B/RTN B) operates power supply B

DANGER! POSSIBLE SHOCK HAZARD EXISTS - PLEASE FOLLOW INSTRUCTIONS

CAREFULLY.

ENSURE THAT NO POWER IS PRESENT ON THE POWER LEADS TO BE CONNECTED

AND THAT THE CHASSIS POWER SWITCH IS OFF.

To connect the power leads:

1. Remove the power terminal block for easier lead attachment by

prying off the block with a screwdriver.

2. Strip the two wires from the power source so that approximately

5/16 inch of bare wire is exposed. 16 or 18 AWG insulated

copper wire is recommended for power connections.

3. Attach leads to the appropriate terminals using the screws on the

block to secure them. The illustrations on the following page

show the positioning of the leads.

4. Be sure to attach the ground wire as described in Rack Mount

Installation on page 8.

5. Ensure that no bare wire shows after the wires are installed.

6. IMPORTANT: Do not connect power yet.

MASTERseries - Release 7.0 11

Loading...

Loading...