OPERAT OR’S

MANUAL

MODEL 1305BC

BRUSH CUTTER

COPYRIGHT 2009 by

Turf Teq, LLC

Honey Brook, PA 19344 U.S.A.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmittedinanyformorbyanymeans,electronic,mechanical,photocopying,recording,orotherwise,

without prior written permission of Turf Teq, LLC.

DISCLAIMER: THE INFORMATION IN THIS MANUAL IS PROVIDED TO PROMOTE THE

SAFEUSE OF,ANDASSIST THEOPERATOR IN ACHIEVINGMAXIMUMPERFORMANCE

FROM THE MODEL 1305 BRUSH CUTTER AS DESCRIBED IN THIS MANUAL.

TABLE OF CONTENTS

INTRODUCTION 3......................................................................

OWNER ASSISTANCE 4................................................................

WARRANTY AND LIMITATION OF LIABILITY 6...........................................

SAFETY INFORMATION 10..............................................................

PERSONAL SAFETY 10..............................................................

MACHINE SAFETY 10................................................................

INTENDED USE 12.....................................................................

SURVEY THE AREA 12...............................................................

PERSONAL SAFETY DECALS 13........................................................

SAFETY DECAL INFORMATION 14......................................................

SERIAL NUMBER LOCATIONS 15.......................................................

TRACTOR SERIAL/MODEL NUMBER LOCATION 15....................................

ENGINE SERIAL NUMBER LOCATION 15..............................................

BRUSH CUTTER SERIAL NUMBER LOCATION 15......................................

CONTROL LOCATIONS - OVERVIEW 16.................................................

DAILY CHECKS TO PERFORM BEFORE STARTING THE ENGINE 17.......................

CHECK ENGINE OIL LEVEL 17.......................................................

CHECK FUEL LEVEL 17..............................................................

TRANSMISSION OIL LEVEL 17.......................................................

MAIN DRIVE BELT CONDITION 18....................................................

CHECK THAT ALL SHIELDS ARE IN PLACE AND HARDWARE IS TIGHT 18..............

CHECK TIRE PRESSURES 18........................................................

CHECK CLUTCH CABLE ADJUSTMENT 19............................................

CHECK BLADE SHARPNESS 19......................................................

CHECK BLADE NUT TORQUE 20.....................................................

GREASE MACHINE PIVOTS 20.......................................................

GENERAL CONTROLS 21...............................................................

PARK BRAKE (OPTIONAL EQUIPMENT) 21............................................

TRANSMISSION CONTROL LEVER (TOW VALVE) 22...................................

DIFFERENTIAL CONTROL 23.........................................................

BRUSH CUTTER SWING CONTROL 24................................................

PARKING THE MACHINE 27............................................................

ENGINE OPERATION 28................................................................

STARTING A COLD ENGINE 28.......................................................

STARTING A WARM ENGINE 29......................................................

STOPPING THE ENGINE 30..........................................................

1

OPERATING THE DIRECTIONAL SPEED CONTROLS 32..................................

PRELIMINARY STEPS TO MOVING THE MACHINE IN ANY

DIRECTION WITH ENGINE RUNNING 32...............................................

STOPPING MOVEMENT WITH ENGINE RUNNING 33...................................

VARIABLE SPEED CONTROL ADJUSTMENT 34........................................

ADJUSTING THE VARIABLE SPEED CONTROL 34.....................................

FORW ARD DIRECTION 35............................................................

REVERSE DIRECTION 35............................................................

OPERATING THE BRUSH CUTTER 36...................................................

STOPPING THE BRUSH CUTTER 36..................................................

SECURING THE BRUSH CUTTER FOR TRANSPORT 37..................................

BRUSH CUTTER SERVICE AND MAINTENANCE SCHEDULE 38...........................

SERVICE 39...........................................................................

ENGINE MAINTENANCE SEE ENGINE MANUFACTURES OWNER’S MANUAL...............

TRANSMISSION OIL LEVEL 39.........................................................

LUBRICATION 40......................................................................

LUBRICATE CONTROL CABLES 42...................................................

LUBRICATE PIVOT POINTS 42........................................................

MAIN DRIVE BELT 43..................................................................

CHECK MAIN DRIVE BELT CONDITION 43............................................

CHECK MAIN DRIVE BELT TENSION 44...............................................

REPLACING THE MAIN DRIVE BELT 45...............................................

INSTALLING THE MAIN DRIVE BELT 48...............................................

CLUTCH CABLE ADJUSTMENT 49...................................................

TRANSMISSION DRIVE BELT 52........................................................

CHECK AND ADJUST TRANSMISSION DRIVE BELT TENSION 52.......................

TRANSMISSION DRIVE BELT REPLACEMENT PROCEDURE 56.........................

REPLACING THE BLADE 63............................................................

BLADE INSTALLATION 65..............................................................

ATTACHING THE BRUSH CUTTER TO THE TRACTOR 66..................................

REMOVING THE BRUSH CUTTER FROM THE TRACTOR 81...............................

END OF SEASON STORAGE SERVICE 84................................................

SPECIFICATIONS 85...................................................................

TROUBLESHOOTING 86................................................................

2

INTRODUCTION

This manual is provided as a guide to help you safely operate the product and to achieve the maximum

performance from your Brush Cutter.

Before operating the Brush Cutter, thoroughly read the entire manual. It is important that you, the operator,

thoroughly understand how to operate the machine and adhere to all safety and operating procedures. Special

attention should be paid to all Safety Precautions which are detailed in this manual.

Instructions were written from the perspective that the operator is standing behind the machine grasping the

handlebars and facing the forward direction of travel.

Some pictures in this manual may show optional equipment installed or may not depict current production.

Please contact Turf Teq, LLC directly if, after reading the manual, you have questions about the safe operation

of this machine.

3

Thank you and congratulations on your purchase of a new Turf Teq Brush Cutter!

We are confident that your Brush Cutter will be one of the most gratifying pieces of equip-

ment you will ever own. As a result of your investment in the Brush Cutter, you will eliminate the need for manual back-breaking work and you will see an increase in productivity.

Your happiness is our goal, so please let us know of any questions or issues you may

have so that we may answer them or address them as quickly as possible. (Please have

your serial number available when you call us). We would also like to hear from you on

how much you enjoy your new Brush Cutter!

Turf Teq, LLC Toll Free (866) 503–TURF

4

Total Customer Satisfaction is our Goal

The Brush Cutter is designed to provide trouble-free operation. To ensure that you are

satisfied with your Brush Cutter, we offer the following Guarantee of Satisfaction:

• The Brush Cutter is GUARANTEED TO THE ORIGINAL PURCHASER FOR ONE

FULL YEAR against defects in materials and workmanship. If you feel that a part is defective, contact us and we replace the defective part and provide repair instructions as

required.

• The engine is guaranteed by the engine manufacturer:

Honda Engine: Two years in consumer use; two years in commercial use

• If your have questions or are not 100% satisfied with your Brush Cutter within the first

30 days of use, call us toll free at 1–866–503–TURF and we will work to answer your

questions and to resolve your concerns.

Please have the following information from your packing slip and from the Brush Cutter

available when contacting our customer service department:

Name of Purchaser

Tractor

Model

Serial Number

Date Purchased

Sales Order Number

Brush Cutter

Model

Serial Number

Date Purchased

Sales Order Number

5

Turf Teq, LLC

WARRANTY AND LIMITATION OF LIABILITY

(Customer Copy -- Page 1)

COVERAGE PROVIDED

Turf Teq, LLC, hereinafter called “Turf Teq” warrants to the original retail purchaser of each new Turf Teq

Product that Turf Teq will replace any part thereof found to be defective in materials or workmanship within

the time periods identified below.

DEFINITION

“Products” are machines, attachments, and Replacement Parts therefore supplied by Turf Teq.

WARRANTY

12 months from the date of first retail purchase.

Replacement Parts are warranted for 60 days or to the end of the Warranty Period, whichever is longer.

LIMITATIONS, INCLUDING DISCLAIMER OF IMPLIED WARRANTIES AND CONSEQUENTIAL

AGES

This warranty gives you specific legal rights and you may also have other rights that vary depending on

state or provincial laws.

Turf Teq does not authorize any person or Dealer to create for it any other obligation or liability in connection

with these Products. TO THE EXTENT ALLOWED BY LAW, ANY IMPLIED WARRANTY OF MERCHANT-

ABILITY OR FITNESS APPLICABLE TO THIS PRODUCT IS LIMITED TO THE STATED DURATION OF

THIS WRITTEN WARRANTY. TURF TEQ IS NOT LIABLE FOR LOSS OF THE USE OF THE PRODUCT,

LOSS OF TIME, INCONVENIENCE, COMMERCIAL LOSS OR CONSEQUENTIAL DAMAGES.

Some states and provinces do not allow limitations on how long an implied warranty will last or the exclusion

or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to

you.

The remedy of repair or replacement of a defective part during the warranty period herein specified shall be

the purchaser’s exclusive remedy.

RIGHT TO MAKE DESIGN

PERIOD

DAM-

CHANGES

Turf Teq reserves the right to make changes in the design and other changes in its Products at any time and

from time to time without notice and without incurring any obligation with respect to any product previously

ordered from it, sold or shipped by it.

6

Turf Teq, LLC

WARRANTY AND LIMITATION OF LIABILITY

(Customer Copy -- Page 2)

The warranty period will begin on the date of first retail sale.

The obligation of Turf Teq to purchase under this warranty is limited to the repair or replacement of

defective parts free of charge using genuine Turf Teq Replacement Parts. Repair or replacement in

accordance with this warranty shall constitute fulfillment of all liabilities of Turf Teq in respect to such

Products.

Your dealer shall review these warranty provisions with the purchaser prior to retail sale, secure his

acknowledgement of delivery of this warranty and record the date of first retail sale.

WHAT IS NOT COVERED BY THE WARRANTY?

This warranty shall NOT apply under the following conditions:

1. With respect to vendor warranty items such as engines, which shall be warranted by their manufacturer, or local representative

a. Honda Engines have a 2 YEAR WARRANTY that is covered by American Honda Motor

Corporation.

2. If the Product has been subject to misapplication, abuse, misuse, improper maintenance or other

negligence, fire or other accident.

3. If parts or attachments other than those made or marketed by Turf Teq have been used in connection with the Product, and in the sole judgment of Turf Teq such use affects its performance, stability

or reliability.

4. If the Product has been altered or repaired in a manner which, in the sole judgment of Turf Teq, affects its performance, stability or reliability.

5. Turf Teq shall have no liability for used equipment sold beyond the specified coverage period.

6. No warranty shall apply to damage resulting from accident or damage caused by environment (such

as exposure to corrosive material). Turf Teq shall not be responsible for any costs relating to rental

equipment used to replace the Product being repaired.

7. The warranty shall NOT apply to normal maintenance services, to normal replacement of service

items, or to normal deterioration due to use or exposure. Turf Teq shall not be responsible for normal replacement parts such as belts, chains, clutches, filters, oil, brushes, or other parts that are

worn out, unless they are determined by Turf T eq to be defective in material or workmanship.

Customer Signature _______________________

Date of Purchase _______________________

Date of Signature _______________________

Tractor Model Number _______________________

Tractor Serial Number _______________________

Brush Cutter Model Number _______________________

Brush Cutter Serial Number _______________________

7

Turf Teq, LLC

WARRANTY AND LIMITATION OF LIABILITY

(Turf Teq Warranty Registration Copy -- Page 1)

Important: This copy must be completed, signed and returned to Turf

Teq to register the product and activate the warranty.

COVERAGE PROVIDED

Turf Teq, LLC, hereinafter called “Turf Teq” warrants to the original retail purchaser of each new Turf Teq

Product that Turf Teq will replace any part thereof found to be defective in materials or workmanship within

the time periods identified below.

DEFINITION

“Products” are machines, attachments, and Replacement Parts therefore supplied by Turf Teq.

WARRANTY

12 months from the date of first retail purchase.

Replacement Parts are warranted for 60 days or to the end of the Warranty Period, whichever is longer.

LIMITATIONS, INCLUDING DISCLAIMER OF IMPLIED WARRANTIES AND CONSEQUENTIAL

AGES

This warranty gives you specific legal rights and you may also have other rights that vary depending on

state or provincial laws.

Turf Teq does not authorize any person or Dealer to create for it any other obligation or liability in connection

with these Products. TO THE EXTENT ALLOWED BY LAW, ANY IMPLIED WARRANTY OF MERCHANT-

ABILITY OR FITNESS APPLICABLE TO THIS PRODUCT IS LIMITED TO THE STATED DURATION OF

THIS WRITTEN WARRANTY. TURF TEQ IS NOT LIABLE FOR LOSS OF THE USE OF THE PRODUCT,

LOSS OF TIME, INCONVENIENCE, COMMERCIAL LOSS OR CONSEQUENTIAL DAMAGES.

Some states and provinces do not allow limitations on how long an implied warranty will last or the exclusion

or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to

you.

The remedy of repair or replacement of a defective part during the warranty period herein specified shall be

the purchaser’s exclusive remedy.

RIGHT TO MAKE DESIGN

PERIOD

DAM-

CHANGES

Turf Teq reserves the right to make changes in the design and other changes in its Products at any time and

from time to time without notice and without incurring any obligation with respect to any product previously

ordered from it, sold or shipped by it.

8

Turf Teq, LLC

WARRANTY AND LIMITATION OF LIABILITY

(Turf Teq Warranty Registration Copy -- Page 2)

The warranty period will begin on the date of first retail sale.

The obligation of Turf Teq to purchase under this warranty is limited to the repair or replacement of

defective parts free of charge using genuine Turf Teq Replacement Parts. Repair or replacement in

accordance with this warranty shall constitute fulfillment of all liabilities of Turf Teq in respect to such

Products.

Your dealer shall review these warranty provisions with the purchaser prior to retail sale, secure his

acknowledgement of delivery of this warranty and record the date of first retail sale.

WHAT IS NOT COVERED BY THE WARRANTY?

This warranty shall NOT apply under the following conditions:

1. With respect to vendor warranty items such as engines, which shall be warranted by their manufacturer, or local representative

a. Honda Engines have a 2 YEAR WARRANTY that is covered by American Honda Motor

Corporation.

2. If the Product has been subject to misapplication, abuse, misuse, improper maintenance or other

negligence, fire or other accident.

3. If parts or attachments other than those made or marketed by Turf Teq have been used in connection with the Product, and in the sole judgment of Turf Teq such use affects its performance, stability

or reliability.

4. If the Product has been altered or repaired in a manner which, in the sole judgment of Turf Teq, affects its performance, stability or reliability.

5. Turf Teq shall have no liability for used equipment sold beyond the specified coverage period.

6. No warranty shall apply to damage resulting from accident or damage caused by environment (such

as exposure to corrosive material). Turf Teq shall not be responsible for any costs relating to rental

equipment used to replace the Product being repaired.

7. The warranty shall NOT apply to normal maintenance services, to normal replacement of service

items, or to normal deterioration due to use or exposure. Turf Teq shall not be responsible for normal replacement parts such as belts, chains, clutches, filters, oil, brushes, or other parts that are

worn out, unless they are determined by Turf T eq to be defective in material or workmanship.

Customer Signature ______________________________________________

Date of Purchase __________________________________________________

Date of Signature __________________________________________________

Tractor Model Number _______________ Brush Cutter Model Number____________________

Tractor Serial Number ________________ Brush Cutter Serial Number____________________

Important: This copy must be completed, signed and returned to Turf Teq within

30 days of purchase to register the product and activate the warranty.

RETURN TO: Turf Teq, LLC

699 Todd Road

Honey Brook, PA 19344

9

SAFETY INFORMATION

PERSONAL SAFETY

SAFETY PRECAUTIONS

A careful operator is the best operator. Most accidents can be avoided by observing certain precautions. To

help prevent accidents, read and take the following precautions before operating the machine. Equipment

should be operated only by those who are properly trained.

GENERAL INFORMATION

1. Read the Operator’s Manual carefully before using the machine.

2. Only allow properly trained and qualified persons to operate the machine.

3. Keep safety decals clean.

4. Install shields before starting or operating the machine.

5. Make sure all shields are in place at all times.

6. Do not operate the Brush Cutter over cables, wires, pipes or other objects.

7. Keep people at least 75 feet away from the Brush Cutter when it is in operation.

PERSONAL PREPARATION AND ATTIRE

1. Wear safely glasses while operating the machine to protect your eyes.

2. Wear safety shoes with non-slip treads. Do not go barefoot or wearing open-toed shoes while operating

the machine.

3. Wear long pants

4. Use ear muffs or ear plugs to protect your hearing.

5. Wear gloves.

MACHINE SAFETY

MACHINE PREPARATION

1. Read the Operator’s manual for the machine and engine before operating the machine.

2. Become familiar with the controls BEFORE starting to operate the machine.

3. Inspect the area you will be working in for hidden objects such as large rocks, wires and other obstructions. Operating the machine over obstacles could damage the machine, cause property damage or

cause personal injury.

4. Wait for the engine to cool before refueling.

5. Fill the gasoline tank with the engine turned off and the machine outdoors.

6. Do not smoke while handling gasoline.

7. Keep any type of open flame away from the machine.

8. Make sure all shields are installed and secured.

9. Remove the spark plug wire from the spark plug before doing any work on the Brush Cutter.

10. Allow the engine and muffler to cool before working around the engine.

10

OPERA TING THE MACHINE SAFELY

1. Shut off the engine, place the transmission control lever in the transmission engaged position when the

machine is not in use. Engage the optional park brake if equipped.

2. Do not operate the machine engine in an enclosed building without adequate ventilation.

3. Make sure all shields are in place before starting the machine.

4. Do not leave the attachment in the raised position when the machine is parked.

5. Only allow properly trained personnel to operate the machine

6. Keep bystanders at least 75 feet away from the machine. The Brush Cutter can throw objects at great

speed and strike a bystander. Do not operate the machine when children or pets are in the area.

7. Disengage the main drive and stop the engine when a person or pet approaches the machine closer

then 75 feet.

8. Be sure the main drive and the hydrostatic control are disengaged before starting the engine.

9. NEVER operate the machine without all the shields installed.

10. NEVER reach under the shields when the engine is running.

11. ALWAYS shut off the engine and disconnect the spark plug wire before making any adjustments to the

machine.

12. ALWAYS shut off the engine and disconnect the spark plug wire before cleaning the machine.

13. Operate the machine during daylight hours.

14. Lower the attachment to the ground when the machine is turned off.

15. Keep the machine clean and do not allow combustible materials to accumulate on the machine.

16. Operate slowly on slopes and uneven terrain

17. DO NOT weld, cut, bend or otherwise modify your Turf Teq machine including any shielding. Altering or

modifying your machine will void the warranty and may make the machine unsafe.

18. Make sure you operate at a speed where you have 100% control of the machine at all times.

19. Do not backup unless there is adequate clear space to safely maneuver.

20. Engage the attachment drive before lowering the attachment to the ground and starting forward motion.

21. Keep feet and hands away from rotating components.

SERVICING THE MACHINE SAFELY

1. Stop the engine before performing any service on the machine.

2. Remove the spark plug wire when working on the machine.

3. Wait for the engine and muffler to cool before working around the engine area.

4. Wear thick gloves when checking, changing, sharpening or tightening the blade.

11

INTENDED USE

The Brush Cutter is a machine designed for cutting down large weeds, brush tall grass, saplings up to 1-1/2 inch

thick and other types of growth down to a height of 3-3/4 inches. Growth of 6 inches or less can be cut to 2-3/4

inches.

This machine is not a lawn mower and will not provide the quality of cut achieved with a lawn mower.

The Brush Cutter should not be used in tight confined spaces. It should be operated in rural settings or large

acreages.

WARNING: To prevent personal injury, make certain all tractor and Brush Cutter safety shields are in

place and secure before operating.

SURVEY THE AREA

Take a few minutes to walk around the job site. These few minutes are time well-spent because you can:

1. Look for obstructions. Walk around the job site to spot items that can damage your machine. Remove or

avoid rocks, roots, steel strapping, rope, wire, plastic wrapping, or anything that may hinder or damage your

machine. Remove these items before you start operating.

12

PERSONAL SAFETY DECALS

Thismanualshowsmachinedecals with safetymessageson,“WARNING,” and “DANGER.” Thesesafety messages are intended for your personal safety and those working with you. Please read the safety

messages and the specific information they contain.

WARNING: THE WORD “WARNING” IS USED WHERE THERE IS A POTENTIAL OR HIDDEN HAZARD

WHICH HAS THE POSSIBILITY FOR SERIOUS INJURYOR DEATH IF YOU DO NOT FOLLOW THE OPERATING INSTRUCTIONS FOR YOUR MACHINE. IT IS USED TO WARNOPERATORS AND OTHERS TO EXERCISE EVERY APPROPRIATE MEANS TO AVOID A SURPRISE INVOLVEMENT WITH MACHINERY.

DANGER:THEWORD“DANGER” ISUSEDWHEREYOU AREAT RISKOFBEINGKILLED ORSERIOUSLY

INJURED IF YOU DO NOT FOLLOW THE OPERATING INSTRUCTIONS IN CONNECTION WITH A SERIOUS HAZARD.

FAILURE TO FOLLOW THE “WARNING” AND “DANGER INSTRUCTIONS MAY RESULT IN SERIOUS

BODILY INJURY OR DEATH.

13

SAFETY DECAL INFORMATION

The following safety decals were installed on the machine in the areas indicated. They are on the machine for

your safety.

Keep the decals clean and legible at all times.

Located on the control console. Located on the cutting deck.

Located on the cutting deck.

14

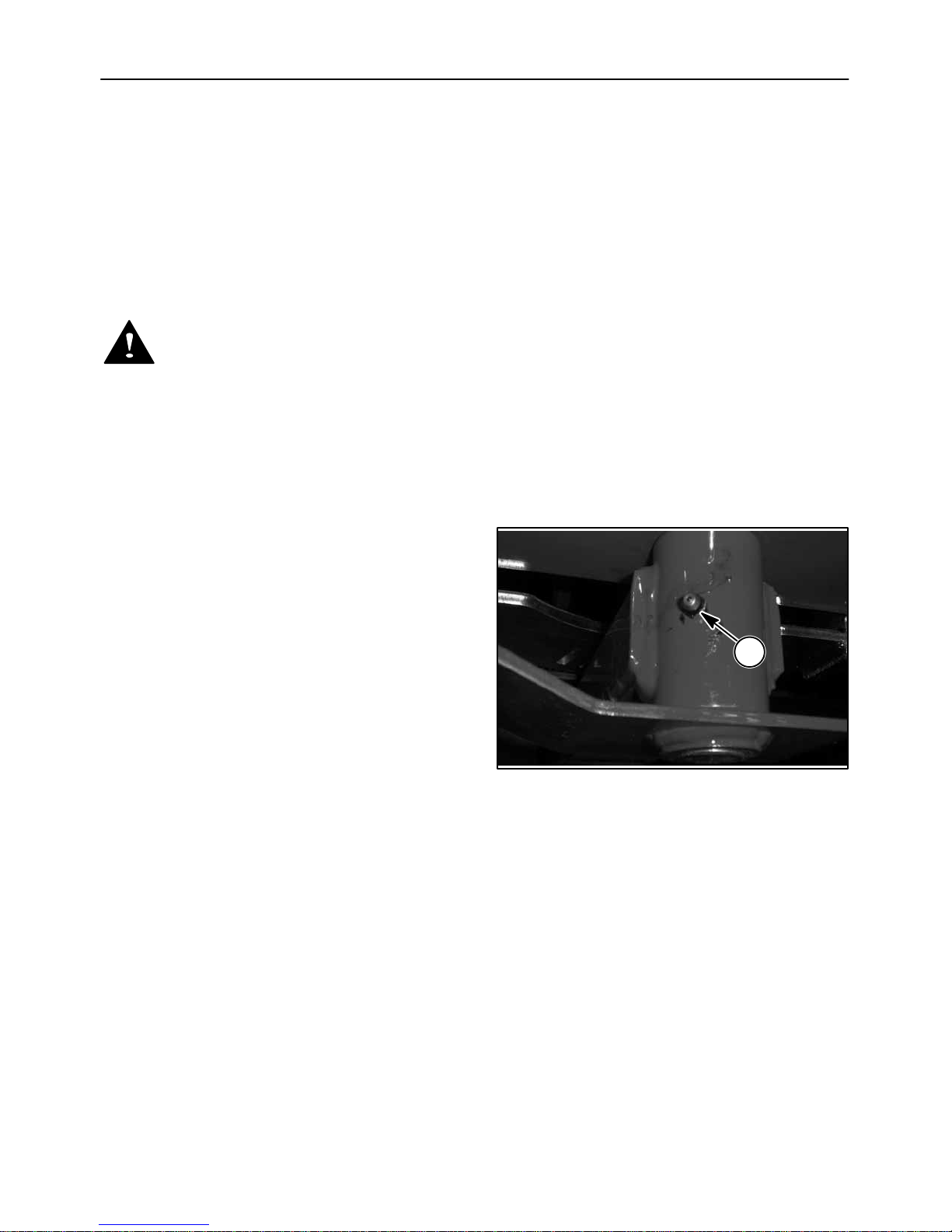

SERIAL NUMBER LOCATIONS

TRACTOR SERIAL/MODEL NUMBER

LOCATION

The serial and model numbers are located below the

control panel as shown.

The serial and model numbers will be required when

ordering parts.

For easy reference, enter Model and serial number

on the lines:

Model

Serial Number

ENGINE SERIAL NUMBER LOCATION

The Honda engine serial number is located on the

backside of the engine as shown.

The serial number will be required when ordering

parts.

For easy reference, enter the engine manufacturer

and the serial number on these line:

Manufacturer

Serial Number

BRUSH CUTTER SERIAL NUMBER

LOCATION

The serial number is located on the left side of the

attachment as shown.

1

2

The serial number will be required when ordering

parts.

For easy reference, enter Model and serial number

on the lines:

Manufacturer

Serial Number

3

15

CONTROL LOCATIONS -- OVERVIEW

B

D

C

E

G

H

A

A. Hydrostatic transmission control lever

B. Adjustable speed control

C. Throttle control

D. Attachment drive engage/disengage with

brake control lever

F

E. Swing control lever

F. Transmission engage/disengage (tow

valve) control lever

G. Park brake lever (Optional)

H. Differential lock control lever

16

DAILY CHECKS TO PERFORM BEFORE STARTING THE

ENGINE

NOTE:Perform allchecks with the machine on a flat,

level and hard surface

CHECK ENGINE OIL LEVEL

1. Remove the oil dipstick, A.

2. Check the oil level as indicated in the engine

owner’s manual and fill with the recommended

motor oil.

NOTE: OVERFILLING THE ENGINE OIL WILL

CAUSE LOSS OF POWER.

CHECK FUEL LEVEL

A

4

1. Remove the fuel tank cap, A.

2. Fill tank to the bottom of the fuel tank neck.

3. Use minimum of 86 octane gasoline.

4. Wipe any spilled fuel before staring the engine.

DO NOT OVERFILL THE FUEL TANK. OBSERVE

ALL SAFETY STATEMENTS LISTED IN THE

SAFETY INFORMATION SECTION

TRANSMISSION OIL LEVEL

1. Check that the oil level is to the full line, A, on the

reservoir bottle.

2. Add 10W30 API motor oil as described in the

“Service”sectiontothelevel oftheblacktiestrap.

DO NOT OVERFILL.

A

5

A

6

17

MAIN DRIVE BELT CONDITION

1. Remove the belt cover.

2. Inspect the belt for cuts, excessive wear or

damage.

3. Replace belt as required.

4. Replace the belt cover.

CHECK THAT ALL SHIELDS ARE IN PLACE

AND HARDWARE IS TIGHT

1. Check the hydrostatic drive belt shield, A.

2. Check the main drive belt shield, B.

3. Front deflector, C.

NOTE: DO NOT OPERATE THE MACHINE WITH

LOOSE OR MISSING SHIELDS. REPLACE MISSING SHIELDS IMMEDIATELY.

7

B

A

C

CHECK TIRE PRESSURES

Check tire pressures in the two rear tires and inflate

to 14 psi. The tires may have liquid in them so when

checking the tire pressure, the valve stem, A, should

be located at the top as shown or liquid will escape.

8

A

9

18

CHECK CLUTCH CABLE ADJUSTMENT

1. Measure the length of the spring in the

disengaged position.

2. Engage the attachment drive clutch.

3. Measure the length of the spring with the clutch

engaged.

4. The spring must be 1/2 inch longer in the

engaged position then in the disengaged

position.

5. Refer to the “Clutch Cable Adjustment” section

for details.

10

CHECK BLADE SHARPNESS

NOTE: WEAR HEAVYGLOVES WHEN WORKING

AROUND THE BLADE.

1. Checktheconditionofthebladeforanydamage.

2. Check the cutting edge for sharpness.

3. Replace or sharpen the blade as required.

Refer to “Replacing the Blade” Section for details.

Minimum 1/2 inch longer then disengaged.

11

12

19

CHECK BLADE NUT TORQUE

NOTE: WEAR HEAVYGLOVES WHEN WORKING

AROUND THE BLADE.

1. Check that blade nut torque is 90 lbs/ft.

Refer to “Blade Installation” Section for details and

torque procedure.

GREASE MACHINE PIVOTS

1. Grease Brush Cutter pivot points daily before

use.

2. Lubricate control cables daily before use.

Refer to the “Lubrication” Section for details.

13

14

20

GENERAL CONTROLS

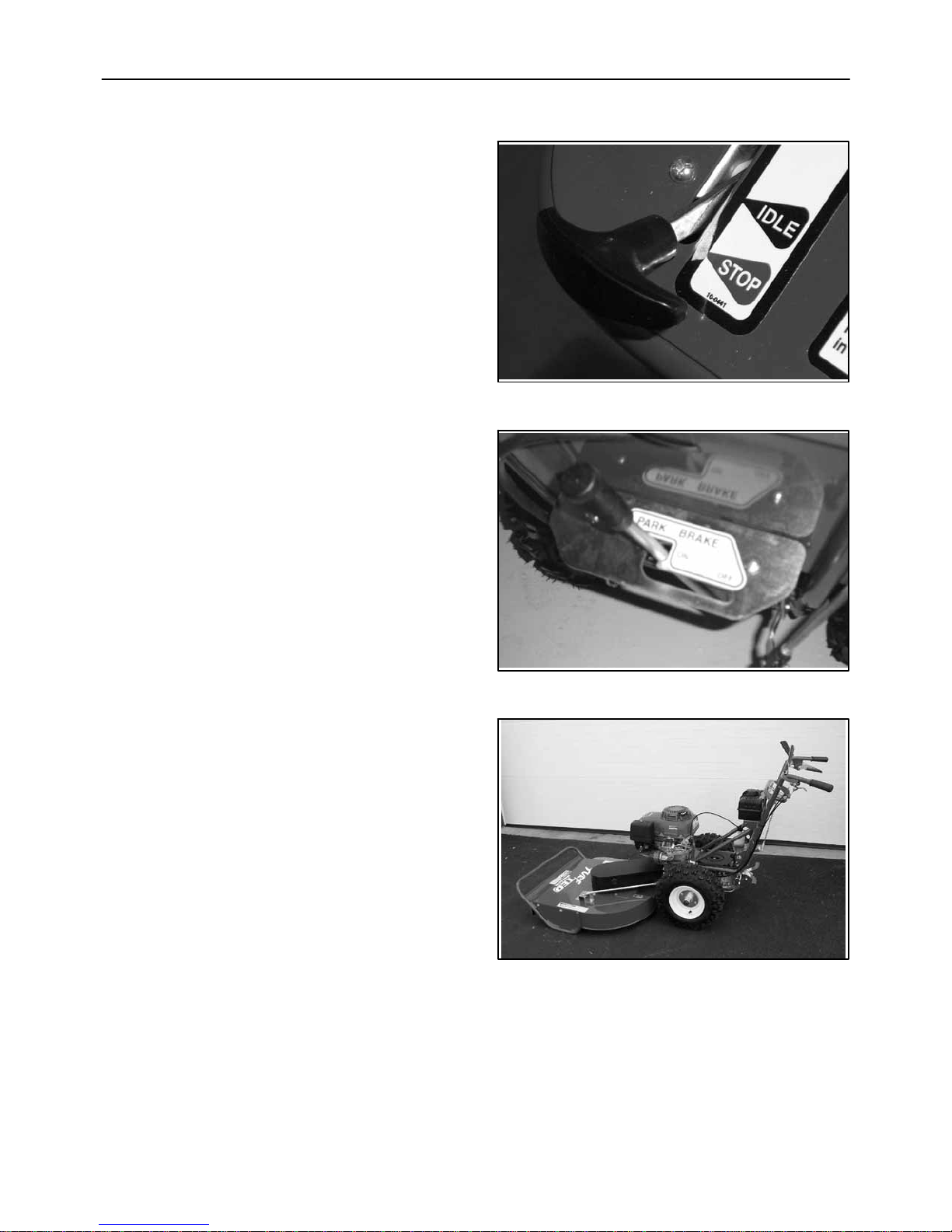

PARK BRAKE (OPTIONAL EQUIPMENT)

NOTE:TheParkBrakeisanoptionandwillnotbe on

every machine

When the Park Brake is engaged, the machine will

keep the machine from moving when the engine is

notrunning.WhentheParkBrake is disengaged, the

machine can be moved.

NOTE: The Park Brake must be disengaged before

moving the machine or the Park Brake and

transmission may be damaged.

Park Brake Engaged

1. To engage, place the Park Brake lever, A, to the

ON position. In this position the Park Brake will

keep the machine from moving when the engine

is not running.

A

Park Brake Disengaged

1. To disengage, place Park Brake lever, A, to the

OFF position. In this position the Park Brake is

disengaged and the machine can be moved.

15

A

16

21

TRANSMISSION CONTROL LEVER (TOW

VALVE)

The TRANSMISSION CONTROL LEVER engages

and disengages the transmission drive to the

engine. This feature makes it easy to position the

machine when the engine is not running.

NOTE:TheTransmissioncontrollevermustbeinthe

engaged position for the machine to move using

engine power.

Transmission Disengaged

When LEVER, A, is position forward as shown, the

machine can be pushed or pulled without the engine

running.

NOTE:IntheTransmission Disengaged position,the

transmissionwillnotpropelthemachinein forwardor

reverse when the engine is running and the

hydrostatic control lever is activated.

NOTE: Lever must be pushed to the detent position

at the end of the lever’s travel.

A

Transmission Engaged

When LEVER, A, is position rearward as shown, the

machine will be very hard to push or pull when the

engine is not running.

NOTE: In the Transmission Engaged position, the

transmission will propel the machine forward or

reverse when the engine is running and the

hydrostatic control lever is activated.

NOTE: Lever must be pushed to the detent position

at the end of the lever’s travel.

17

A

18

22

DIFFERENTIAL CONTROL

The differential control lever is used to position the

differential in either a unlocked or locked position.

The machine should be operated in the Unlocked

position until one tire starts to spin, then stop

machinetravelby placing the hydrostatic level in the

neutral position. Place the Differential Lock in the

Locked Position then resume machine travel.

NOTE: Only change the position of the Differential

Lock when machine travel is stopped.

Unlocked Position

In the Unlocked position, the wheels may drive at

different speeds depending on the traction available

at each wheel. This position may provide reduced

traction in certain ground conditions but will require

the least effort to steer the machine.

1. Place the foot control, A, in the unlocked position

by pushing down onthe rightside of the pedal,B,

until the pedal locks in place.

Locked Position

In the Locked position, both wheels will continuously

drive at the same speed regardless of the available

traction at each wheel. This position provides

maximum traction but will increase the effort needed

to steer the machine.

1. Placethefootcontrol,A,inthelocked position by

pushingdownontheleft side ofthepedal,C,until

the pedal locks in place.

A

B

19

A

C

20

23

BRUSH CUTTER SWING CONTROL

Positioning The Brush Cutter Angle

POSITION THE BRUSH CUTTER ATTACHMENT

STRAIGHT FORWARD FOR TRANSPORTING.

NOTE:OnlychangetheBrush Cutteranglewhenthe

machine is on a level surface.

NOTE: Left and right are determined by standing

behind the machine facing the direction of travel.

The Brush Cutter can be positioned as follows:

1. Straight ahead

2. Pivoted to the Left

21

22

24

Brush Cutter Swing Control Lever

The swing control lever is shown at A.

Adjusting Brush Cutter Angle

1. Lift up and hold the SWING CONTROL LEVER,

A.

A

23

A

2. Push forward on the left handlebar and at the

same time, pull rearward on the right handlebar

until the desired angle is achieved.

NOTE: Only change Brush Cutter position when the

machine is on a level surface.

24

25

25

3. Release the SWING CONTROL LEVER, A, and

itwilllocktheBrushCutter in thedesiredposition.

A

26

26

PARKING THE MACHINE

When parking the tractor, use the following

procedure.

1. Stop the engine by placing the throttle control to

the STOP position.

2. If equipped with the OPTIONAL PARK BRAKE,

put the brake to the ON position.

27

3. Park the machine on a level area with the deck

flat on the ground as shown.

28

29

27

ENGINE OPERATION

STARTING A COLD ENGINE

1. Place the throttle control to the CHOKE position.

2. Pull the starter rope slowly and with low force

until the slack is out of the rope and resistance is

felt.

3. Whenresistance isfelt,pulltheropewithenough

force to turn the engine fast enough to start the

engine. Return the pull rope gently to the

retracted position.

30

4. When the engine starts, position the throttle to

the RUN position for 30 seconds to allow the

engine to warm up.

31

32

28

5. Aftertheenginehaswarmedup,slowlyplacethe

throttle to the IDLE position.

6. Move the throttle to the RUN position when

operating the machine.

33

STARTING A WARM ENGINE

1. Place the throttle control slightly past the IDLE

position.

34

35

29

2. Pull the starter rope slowly and with low force

until the slack is out of the rope and resistance is

felt.

3. Whenresistance isfelt,pulltheropewithenough

force to turn the engine fast enough to start the

engine.

4. Move the throttle to the RUN position when

operating the machine.

36

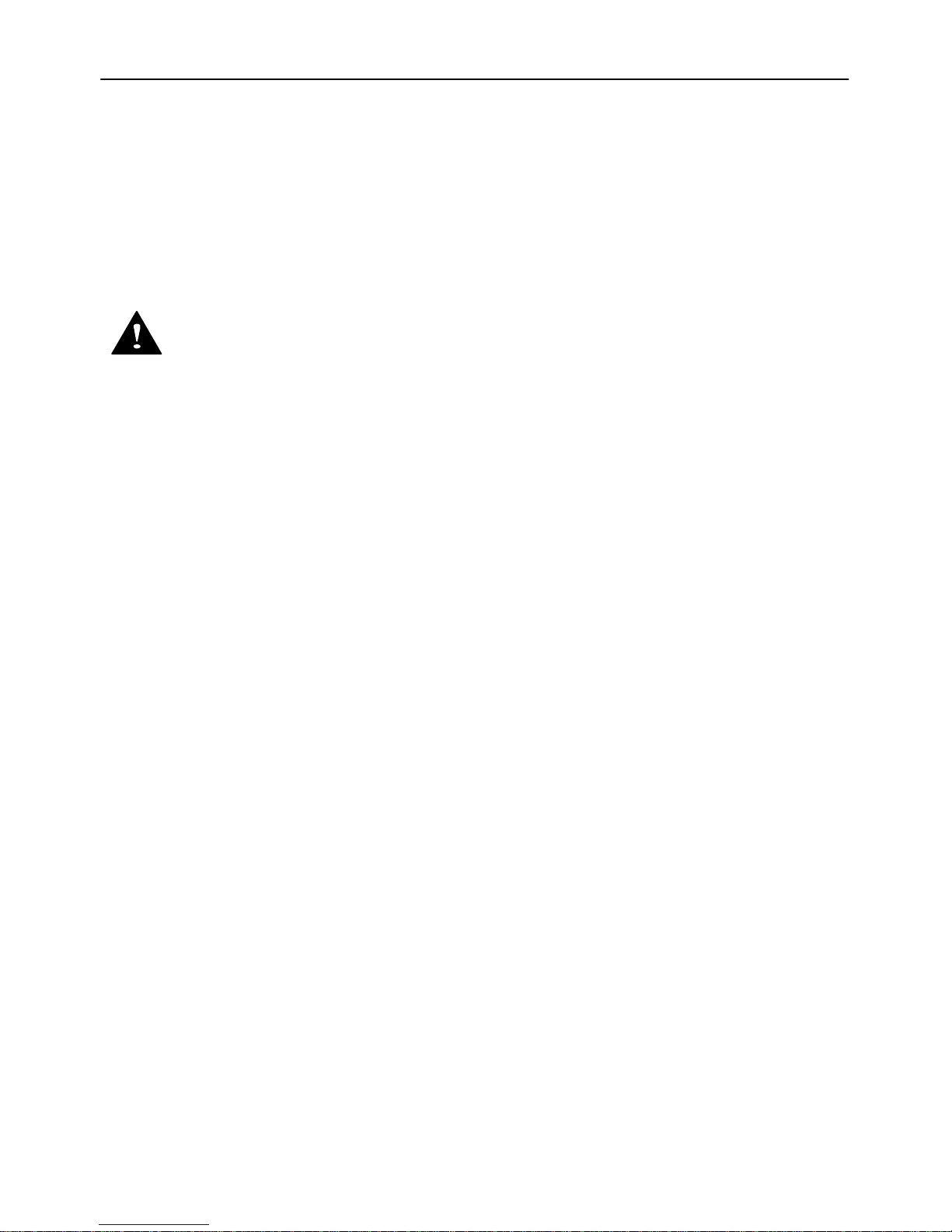

STOPPING THE ENGINE

1. Place the throttle to the IDLE position and allow

the engine to idle for 30 seconds.

37

38

30

2. Place the throttle in the STOP position and the

engine should stop running.

NOTE: ENGINE COMPONENTS GET VERY HOT

DURING OPERATION. STOP THE ENGINE AND

ALLOWIT TO COOL BEFORE DOING ANY WORK

ON THE ENGINE.

39

31

OPERATING THE DIRECTIONAL SPEED CONTROLS

PRELIMINARY STEPS TO MOVING THE

MACHINE IN ANY DIRECTION WITH

ENGINE RUNNING

1. Place LEVER, A, in the TRANSMISSION

ENGAGED position as shown and described in

the “Transmission Control Lever” Section.

2. Start the engine using the procedure described

in the “Engine Operation” Section.

A

40

3. If equipped, place the OPTIONAL PARKBRAKE

in the OFF position.

41

42

32

STOPPING MOVEMENT WITH ENGINE

RUNNING

1. RELEASE the HYDROSTATIC CONTROL

LEVER, A. The lever will automatically go the

neutral position as shown.

2. When the hydrostatic lever is in the neutral

position the machine will stop and not move.

A

43

33

VARIABLE SPEED CONTROL

ADJUSTMENT

1. Adjust to slowest speed.

The maximum forward and reverse speeds can be

adjusted to meet specific operating conditions by

moving the Control Knob, A, in the adjustment slot.

B

WARNING: Adjust to slowest speed setting, B,

(fully to the rear of the slot) while learning to

operate the machine and when operating in

confined spaces.

NOTE: Only adjust the variable speed control when

the machine is stopped.

ADJUSTING THE VARIABLE SPEED

CONTROL

1. Loosen the control knob, A.

2. Move the VARIABLE SPEED CONTROL KNOB

forward to the FAST position to increase

maximum speed.

3. Move the VARIABLE SPEED CONTROL KNOB

rearward to the SLOW position to decrease

maximum speed. (Knob shown in slowest

position.)

4. Tighten control knob, A.

NOTE: The optimum location of the VARIABLE

SPEEDCONTROLKNOBallowsyoutofullyengage

thehydrostatic control lever toachieve acomfortable

operating speed for the ground conditions.

A

44

B

A

45

NOTE: Moving the VARIABLE SPEED CONTROL

KNOB toward the FAST position increases hydrostatic control level effort.

NOTE: Moving the VARIABLE SPEED CONTROL

KNOB toward the SLOW position decreases

hydrostatic control level effort.

34

FORW ARD DIRECTION

1. Complete the 4 steps in the PRELIMINARY

STEPS TO MOVING THE MACHINE if not

already completed.

2. SLOWLYapply pressure and gradually PULLUP

on the HYDROSTATIC CONTROL LEVER, A, to

provide a smooth start.

3. Forward speed is directly proportional to the

amount the hydrostatic control lever is moved.

4. The more the lever is pulled up, the faster the

forward ground speed will be.

CAUTION: When stopping, gradually release

pressure on the speed control level to provide a

smooth stop.

REVERSE DIRECTION

1. Complete the 4 steps in the PRELIMINARY

STEPS TO MOVING THE MACHINE if not

already completed.

2. SLOWLY apply pressure and gradually PULL

BACK on the HYDROSTATIC CONTROL

LEVER to provide a smooth start.

3. Reverse speed is directly proportional to the

amount the hydrostatic control lever is moved.

4. The more the lever is pulled back, the faster the

reverse ground speed will be.

5. Slowly release the lever to come to a smooth

stop.

A

46

47

35

OPERATING THE BRUSH CUTTER

1. Start the engine and place the throttle to the run

position as described in the “STARTING THE

ENGINE” section.

2. Depress the Brush Cutter DRIVE CONTROL

ANDBRAKELEVER,A,asshown.Thisreleases

the attachment drive brake and engages the

drive

.

48

A

CAUTION: Operating at excessive speeds can

causeexcessivewearordamageto the machine.

NOTE: Engage attachment drive before entering the

area to be cut.

STOPPING THE BRUSH CUTTER

1. Release the Brush Cutter DRIVE CONTROL

AND BRAKE LEVER, A, as shown. This will

disengage the drive and apply the brake to stop

the blade from turning.

NOTE: Apply and release the drive control lever in a

smooth quick motion.

NOTE:Donotallowtheclutchslowlyoritwillslipand

overheat causing premature failure.

49

A

50

36

SECURING THE BRUSH CUTTER FOR TRANSPORT

1. Position the Brush Cutter on a trailer or other

vehicle.

2. Stop the engine.

3. Lower the Brush Cutter until the skids rest on the

trailer deck.

4. Use the corner of the front push bar, A, to secure

the front of the machine.

A

5. Secure the rear of the tractor using the tie down

loops, B, as shown.

NOTE: Do not over tighten the tie down straps or the

frame or tires may be damaged.

B

51

52

37

BRUSH CUTTER SERVICE AND MAINTENANCE

SCHEDULE

Area Check Interval Action

Engine oil level Daily when in use See engine manual

Engine maintenance Daily when in use See engine manual

Transmission oil level Daily when in use Fill as required

Lubricate grease zerks Daily when in use Grease

Lubricate control cables Daily when in use Lubricate

Lubricate pivot points Daily when in use Lubricate

Check mian drive belt condition Daily when in use Check condition/tension

Check clutch cable adjustment Daily when in use Check/adjust spring length

Check blade condition Daily when in use Check/sharpen/change

Check blade nut torque Daily when in use Torque as required

38

SERVICE

ENGINE MAINTENANCE

See engine manufactures owners manual.

TRANSMISSION OIL LEVEL

1. Checktheoillevelwhenthetransmission is cool.

2. The oil level should be to the full line, A, on the

reservoir ,B.

3. Use 10W30 API motor oil to fill the reservoir.

4. Add oil by removing cap, A, then remove foam

element, B.

5. Add oil as required.

6. Replace foam element and replace cap.

B

A

53

A

B

54

39

LUBRICATION

Lubricate the following grease points every 10 hours

or on an annual basis whichever comes first.

Use a SAE all weather, high temperature, multipurpose grease.

Add grease to the fittings until there is a slight increase in effort needed to operate the grease gun

handle.

CAUTION: Worn grease fittings that will not hold

thegun,andfittings with astuckcheck ball,must

be replaced.

Items not equipped with grease fittings (linkages,

cables, pins, levers, etc.) should be lubricated with

SAE 30 oil before the start of each operating day, or

more frequently as conditions require.

Attaching pivot located at the pivot located under the

frame below the engine. Apply grease to zerk, A.

A

55

40

Deck pivot point. Apply grease to zerk, A.

Idler pivot point. Apply grease to zerk, A.

A

56

A

Deck attaching pivot. Apply grease to zerk, A.

57

A

58

41

LUBRICATE CONTROL CABLES

Lubricate cables with WD 40, silicone or 10 weight

motor oil.

Add lubrication between the cable and the sheath.

LUBRICATE PIVOT POINTS

Lubricate all pivot points with WD 40, silicone or 10

weight motor oil.

Add lubrication to pivot points.

59

60

42

MAIN DRIVE BELT

The main drive belt transfers power from the engine

to the Brush Cutter. It is automatically tensioned by

a spring attached to the idler assembly.

WARNING: Before starting any work:

1. Allow the engine and muffler to cool before

starting work.

2. Remove the spark plug wire from the spark

plug.

3. Place thethrottlecontrolto theStopposition.

CHECK MAIN DRIVE BELT CONDITION

1. Allow the engine and muffler, A, to cool before

workingaroundtheengineortoremovethemain

belt shield, B.

A

B

2. Remove the spark plug wire, A, from the spark

plug, B.

61

A

B

62

43

3. Remove the two shield attaching knobs, A.

4. Remove the shield to access the belt.

5. Checktheconditionofthebelt and thetensioning

spring.

6. Replace the belt if worn or stretched.

7. Check belt tension.

8. Reinstall all shields.

A

A

63

CHECK MAIN DRIVE BELT TENSION

The main drive belt transfers power from the engine

to the Brush Cutter. It is tensioned by a spring, A,

attached to the idler.

The belt is automatically tensioned by the spring, A.

NOTE: No adjustment is required. Replace the belt

if it starts to slip.

64

A

65

44

REPLACING THE MAIN DRIVE BELT

1. Allow the engine and muffler, A, to cool before

workingaroundtheengineortoremovethemain

belt shield, B.

2. Remove the spark plug wire, A, from the spark

plug, B.

A

B

66

A

3. Remove the two shield attaching knobs, A.

B

67

A

A

68

45

4. Remove the shield to access the belt.

5. Pull on idler arm to remover belt tension.

6. Remove belt from pulley.

69

7. Remove spring from anchor arm, A.

70

A

71

46

8. Slide belt under the idler.

9. Push the belt guide, A, to the unlatched position

as shown.

72

A

10. Remove the belt by sliding it between the pulley

and the frame.

73

74

47

INSTALLING THE MAIN DRIVE BELT

1. Install the belt by reversing the removal

procedure.

2. Reinstallthebeltshieldandtighten the twoshield

attaching knobs, A.

75

A

A

3. Install the spark plug wire, A, on the spark plug,

B.

76

A

B

77

48

CLUTCH CABLE ADJUSTMENT

NOTE: Before checking clutch cable adjustment,

check that when the clutch handle released is

released, the clutch spring must not have tension on

itandthelever,A,must bewithin1/4inchof theclutch

housing as shown.

78

A

1. Measure the length of the spring in the

disengaged position as shown.

NOTE: The spring must not have tension on it in the

released position.

79

80

49

2. Engage the attachment clutch lever.

3. Measure the length of the spring in the engaged

position. It should be at least 1/2 inch longer than

your measurement in the disengaged position.

81

4. Adjust the clutch cable nuts to obtain 1/2 inch

stretch of the spring.

NOTE: Adjust the clutch cable nuts clockwise to

increase spring tension.

Minimum 1/2 inch longer then disengaged.

82

83

50

NOTE: After adjusting the clutch cable, check that

when the clutch handle is released the clutch spring

hasnotensiononitandthelever,A,iswithin1/4inch

of the clutch housing as shown.

A

84

51

TRANSMISSION DRIVE BELT

The belt delivers power from the engine to the

transmission.

The best does not need attention unless it starts to

slip.

NOTE: If the belt starts to slip check belt tension as

described below. If the tension is correct, the belt

MUST be replaced.

NOTE: Do not over tighten the belt. Over tightening

the belt will cause damage to the engine and/or

transmission.

WARNING: Before starting any work:

1. Allow the engine and muffler to cool before

starting work.

2. Remove the spark plug wire from the spark

plug.

3. Place thethrottlecontrolto theStopposition.

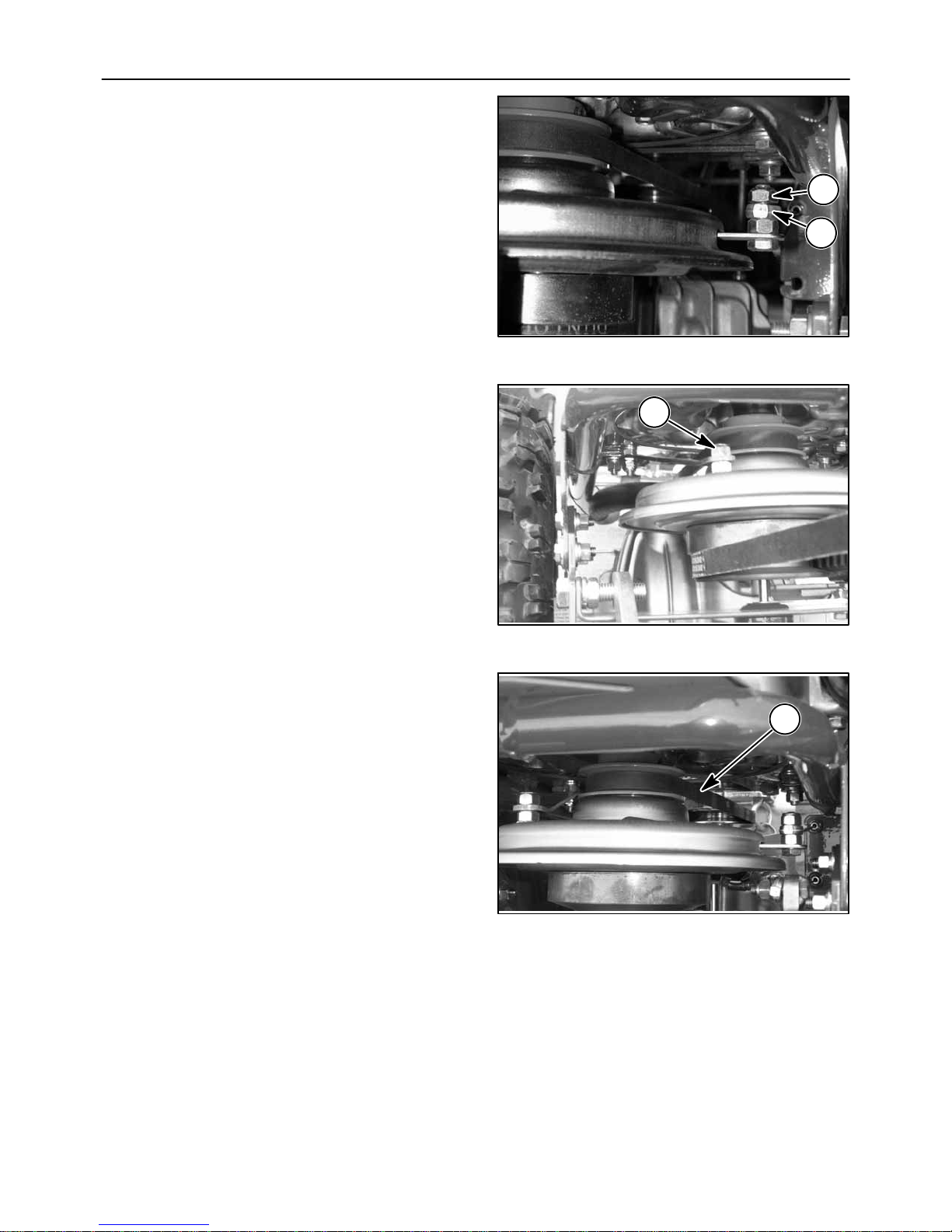

CHECK AND ADJUST TRANSMISSION

DRIVE BELT TENSION

1. Remove the spark plug wire, A, from the spark

plug, B.

2. Remove transmission shield, A, after removing

two bolts, B.

B

A

85

B

B

A

86

52

3. Check the belt for glazed belt edges, cracks or

missing pieces. Replace the belt if any of the

previous conditions are found. Proceed to the

“Belt Replacement” section.

4. Check that the distance at A, from the frame to

the center of the transmission input shaft, is

between 3-5/8 to 3-3/4 inches as shown.

ATTENTION:

If the distance is less then 3-5/8 inches, proceed to

step 5.

If the distance is 3-3/4 inches or greater, proceed to

the “Belt Replacement” section.

5. Loosen the two retaining bolts, A, that attach the

left axle to the frame. Also, loosen the two

retaining bolts securing the right axle to the

frame.

A

87

6. Loosen bolt, A, that attaches the transmission to

the support

.

A

A

88

A

89

53

7. Adjust dimension at A, from the frame to

centerline of the transmission shaft to 3-5/8 to

3-3/4 inches.

8. Tighten the two axle to frame attaching bolts, A,

for the left axle. Tighten the two axle to frame

bolts on the right axle.

A

90

9. Tighten attaching bolt, A.

A

A

91

A

92

54

10. Installthetransmissionshield,A,andsecurewith

bolts, B.

11. Install the spark plug wire, A, on the spark plug,

B.

B

B

A

93

B

A

12. Start the engine and check for proper operation.

Correct any issues before using the machine.

94

55

TRANSMISSION DRIVE BELT

REPLACEMENT PROCEDURE

Belt Removal

1. Remove the spark plug wire, A, from the spark

plug, B.

2. RemovetheBrushCuttermain drive belt, A, from

the engine pulley as described in the “Remove

Main Drive Belt” section.

B

A

95

3. Remove transmission shield, A, after removing

two bolts, B.

A

96

B

B

A

97

56

4. Loosen the two retaining bolts, A, that attach the

left axle to the frame. Also, loosen the two

retaining bolts securing the right axle to the

frame.

5. Loosen bolt, A, that attaches the transmission to

the rear frame support

.

A

A

98

A

99

6. Remove the clutch brake cable jam nut, A, then

remove the cable yoke, B, from the stud.

A

B

100

57

7. Remove nut, A, that hold the clutch brake torque

strap then remove the strap from the stud and

swing the strap toward the frame.

8. Remove the transmission belt, A, from the

engine and transmission pulleys and from the

tractor as shown.

A

101

A

9. Adjust dimension at A, from the frame to

centerline of the transmission shaft to 3-5/8 to

3-3/4 inches.

102

A

103

58

10. Tighten the two axle to frame attaching bolts, A,

for the left axle. Tighten the two axle to frame

bolts on the right axle.

11. Tighten attaching bolt, A.

A

A

104

A

105

Belt Installation

12. Installthenew transmission belt, A, and place on

the engine sheave.

A

106

59

13. Place the belt on the transmission pulley as

shown.

14. Slowly pull on the engine starter rope to place the

belt on the pulley.

NOTE: Spark plug wire must be removed from the

spark plug.

107

15. After the belt has seated on the pulley, pull the

starterrope4timesandcheckthatthebelt is fully

seated on the pulleys, running straight, not

contacting any objects and is not damaged.

Correct as required.

108

109

60

16. Install cable yoke, B, on the stud. Put two drops

ofredLocktite#271onthe threads of thejamnut,

A, then tighten on the stud until there is 1/64 inch

clearance between the jam nut and the yoke.

17. Reinstall the clutch brake torque strap. Put two

drops of red Locktite #271 on the threads of the

jam nut, A, then tighten securely.

A

B

110

A

18. Check that the transmission drive belt, A, is

trackingcorrectly andnotcontactinganyobjects.

111

A

112

61

19. Installthetransmissionshield,A,andsecurewith

bolts, B.

20. InstalltheBrushCutterdrivebelt,A,asdescribed

in the “Replace Main Drive Belt” section.

B

B

A

113

21. Install the spark plug wire, A, on the spark plug,

B.

22. Start the engine and check for proper operation.

Correct any issues before using the machine.

A

114

B

A

115

62

REPLACING THE BLADE

1. Remove the spark plug wire from the spark plug.

2. Support the deck on two jack stands as shown.

116

3. Remove the belt shield and hold the top pulley

with a suitable wrench.

CAUTION: Wear thick gloves when working

around the blade. The blade is sharp and can cut

you.

117

118

63

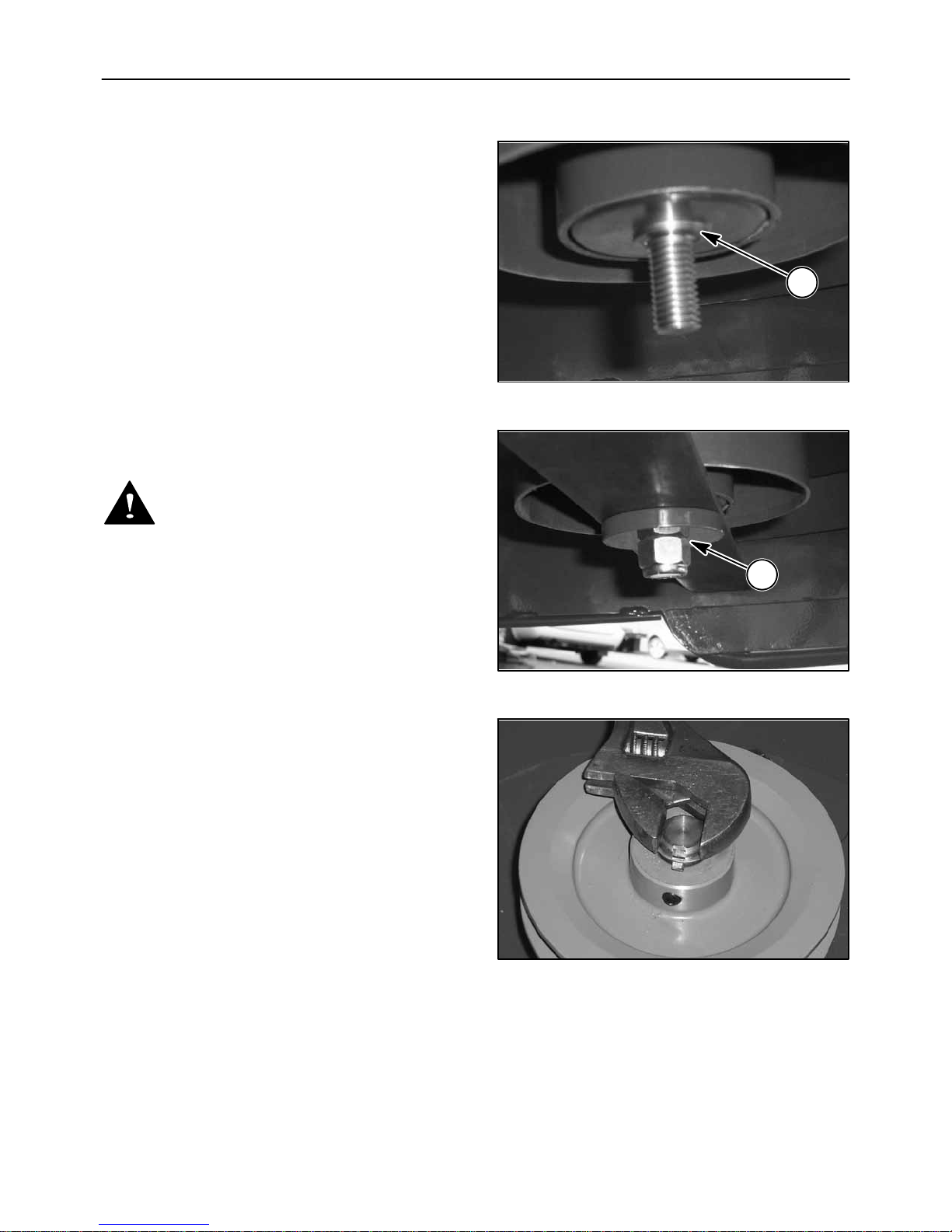

4. Remove the nut and spacer, A, using a 15/16

wrench.

NOTE: The nut is a right hand thread nut.

5. Check the condition of the threads on the shaft

and nut. Replace if there is thread damage or if

the nut is a lose fit on the shaft.

6. Check the pilot lip, A, for damage. Replace shaft

if the lip is damaged.

A

119

A

120

64

BLADE INSTALLATION

1. Install the blade over the pilot lip, A.

2. Install the spacer and nut, A.

3. Torque nut to 90 lbs/ft.

DANGER:Blademustfitoverthepilotlipandnut

must be torqued to 90 lbs/ft. or the blade may

come loose.

A

121

A

4. Hold the flat sides of the shaft with a suitable

wrench as shown while you torque the blade nut

to 90 lbs/ft.

NOTE: Failure to hold the shaft will result in the nut

not being torqued properly.

5. Install spark plug wire and main belt shield.

6. Run the mower.

122

123

65

NOTE: If the mower vibrates or you hear unusual

noisestop themachine immediately.Findthenrepair

the cause of the problem before operating the

mower.

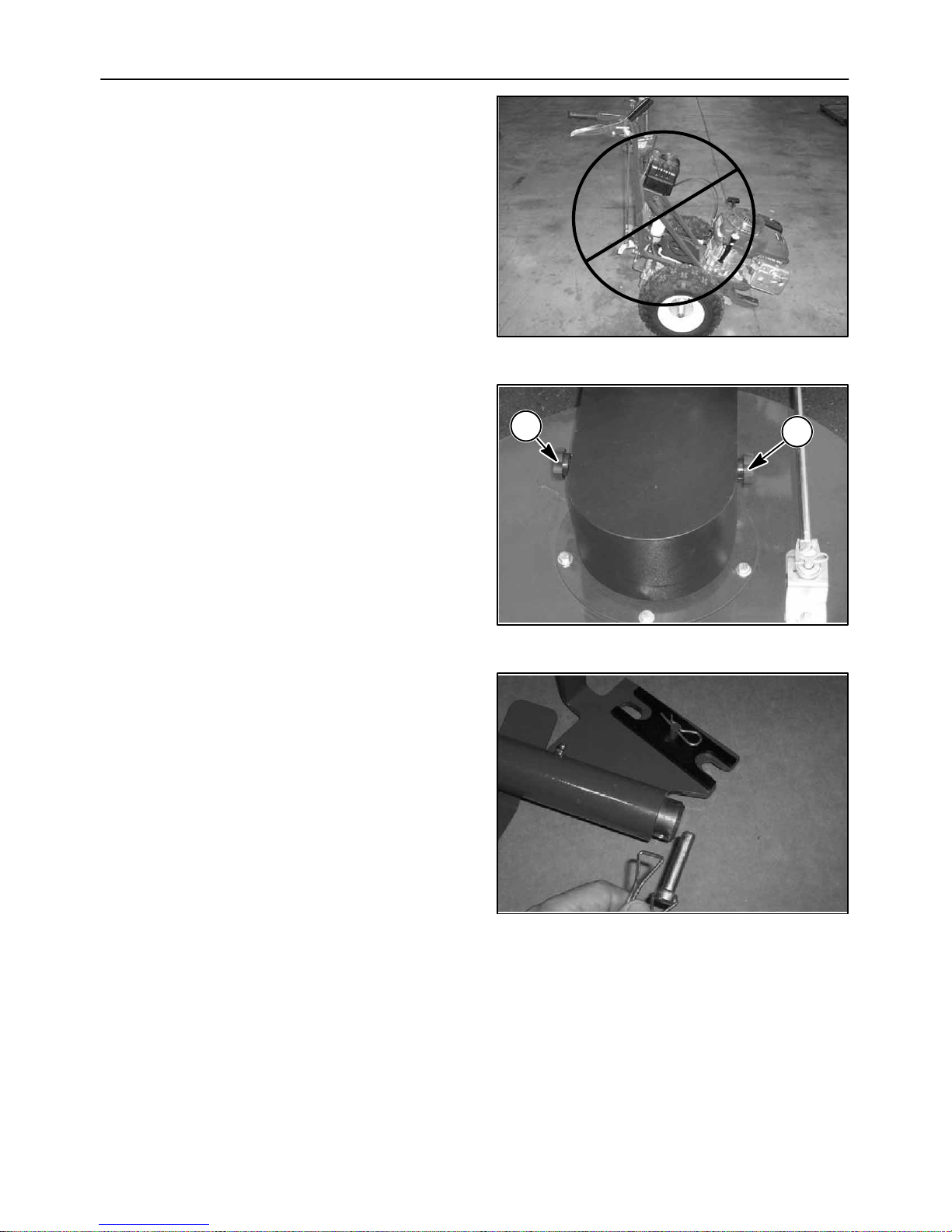

ATTACHING THE BRUSH CUTTER TO THE TRACTOR

SAFETY NOTES

WARNING: Read the entire operator’s manual

before starting any work.

124

Read these instructions thoroughly before

starting any work.

Place the machine on a flat, level and hard

surface.

Wearappropriate protectiveclothing,glovesand

eye protection.

CAUTION: Do not work on the machine when the

muffler is hot.

125

126

66

1. Allow the engine and muffler, A, to cool before

workingaroundtheengineortoremovethemain

belt shield, B.

2. Remove the spark plug wire, A, from the spark

plug, B.

A

B

127

A

3. Remove any attachment from the tractor.

4. Place blocking under the tractor as shown.

B

128

129

67

NOTE: Do not park the tractor resting on the tongue.

Oil will fill the cylinder causing the engine to smoke.

5. Remove the two shield attaching knobs, A.

130

6. Remove the pin.

A

A

131

132

68

7. Slide the tube off the rod.

8. Remove pin.

133

9. Slide the mount bracket from the tube.

134

135

69

10. Install the receiver, A, on the tongue.

11. Torque the rear bolt and the front nut to 65 lbs/ft.

A

136

12. Install the lock plate, A, as shown over the bolts.

Note:Ifthelockplatedoesnotfit over the bolt heads,

tighten the hardware until the lock plate fit the

hardware.

137

A

138

70

13. Install the hair pin as shown.

14.Placea2x4under the deck as shown.

139

15. Disconnect the transmission by placing the lever

fully forward as shown.

140

141

71

16. Push the tractor forward and inset the deck pin

fully in the receiver.

17. Insert the pin to lock the deck to the receiver.

142

18. Slide belt under the idler.

143

144

72

19. Position the white belt idler toward the belt until

the spring pulls it overcenter.

20. Installthebeltbyslidingitbetween the pulley and

the frame.

145

21. Attach the spring to the anchor arm as shown.

146

147

73

22. Pull on idler arm to remove belt tension.

23. Install the belt on the pulley.

24. Releasetheidlerarmand check the belt ifseated

in the pulley.

148

25. Check that your frame has the two holes, A, as

shownforthebrackettoattach.

Note: Iftheholesare notpresent proceed to the next

step.

Note: If the holes are present proceed to step 33.

149

A

150

74

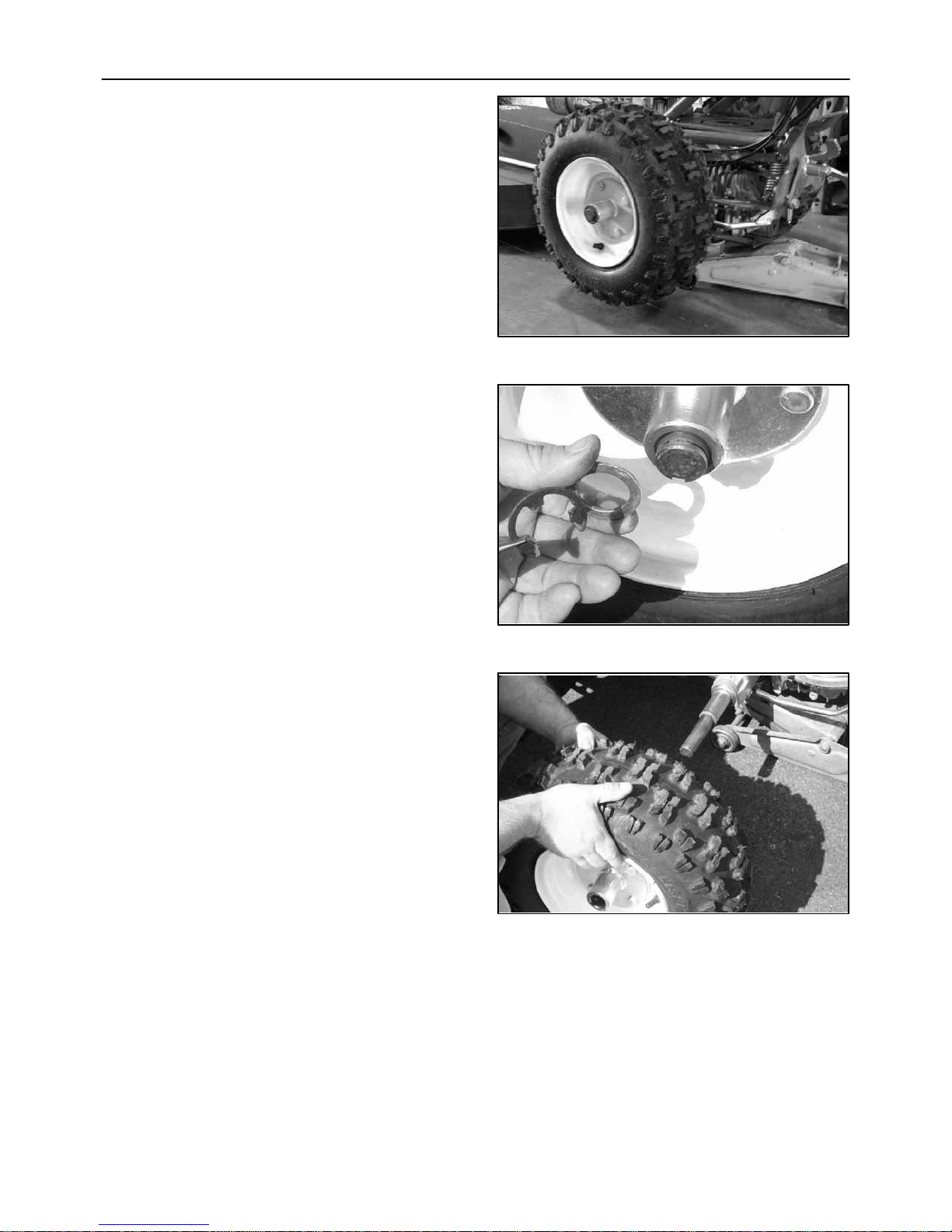

26. Jack up the left side of the tractor.

Note: Useajack stand or blocking under the left axle

housing to support the tractor.

27. Remove the C clip that holds theleftwheelonthe

axle.

151

28. Remove the left wheel and tire.

152

153

75

29. Mark the hole locations as shown.

30. Drill two 11/32 inch holes where the lines

intersect.

31. Reinstall the left wheel, and secure with the C

clip.

2--3/8”

2--3/8”

154

32. Remove the jack and blocking.

155

156

76

33. Installthebracket and tighten the hardware to 25

lbs/ft.

34. Install a flat washer as shown.

35. Install the link arm over the pin.

157

36. Install a flat washer.

37. Inserttheslippin asshowntosecurethelinkarm.

158

159

77

38. Grease the deck pivot point at the zerk shown.

Apply grease until grease pushes out between

the joint.

39. Grease the idler pivot point until grease pushes

out between the joint.

160

40. Grease the deck pivot zerk until grease pushed

out of the joint.

161

162

78

41. Installthebeltshieldandtightenthe two securing

knobs, A.

42. Attach the spark plug wire to the spark plug.

A

A

163

43. Position the transmission level full rearward in

the engaged position detent.

164

165

79

WARNING: Read the entire operator’s manual

before operating the Brush Cutter.

Operate the Brush Cutter and make sure

everything is operating properly.

Correct any problem before using the Brush

Cutter.

166

80

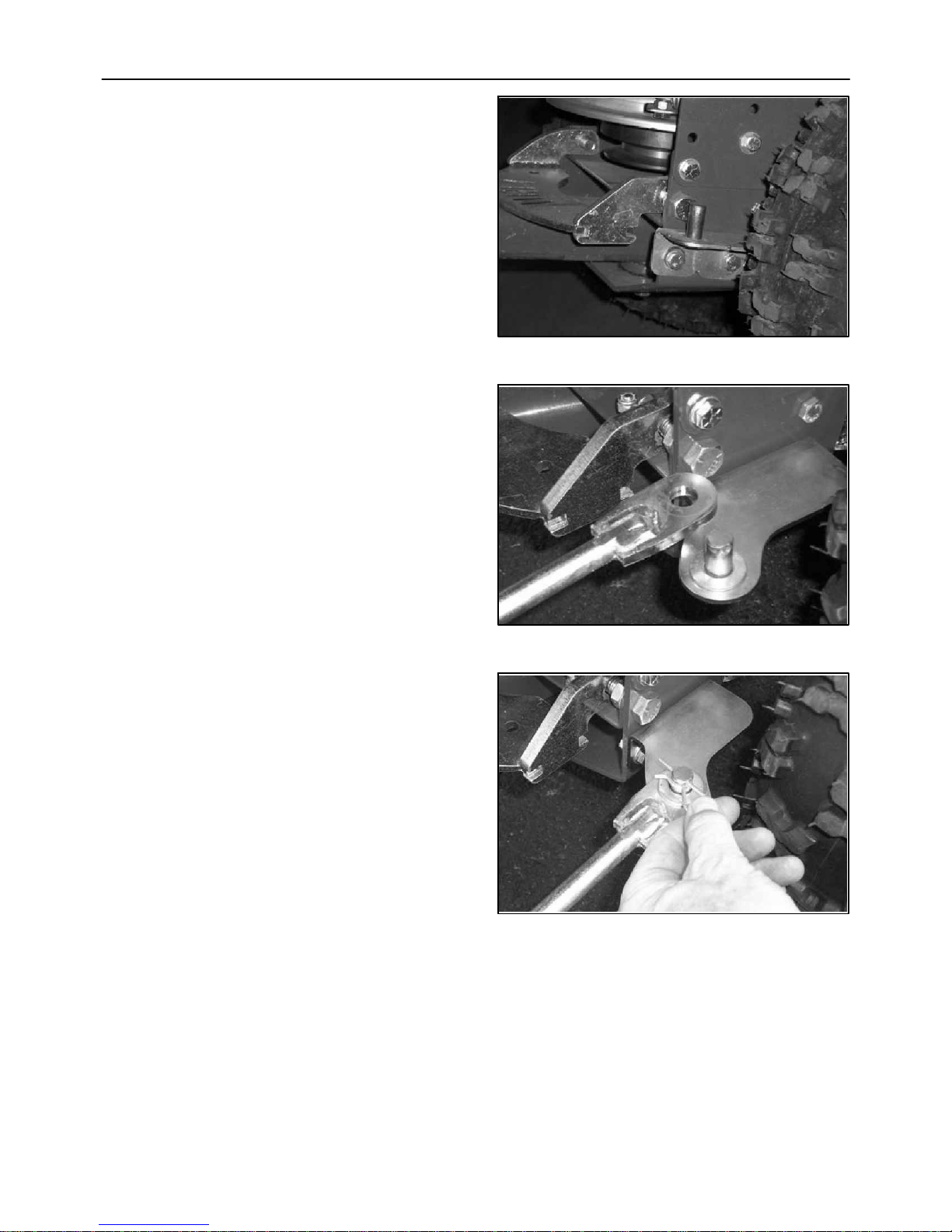

REMOVING THE BRUSH CUTTER FROM THE TRACTOR

WARNING: Read the entire operator’s manual

before starting any work.

Removing the Brush Cutter is the reverse of

installation.

167

1. Allow the engine and muffler, A, to cool before

workingaroundtheengineortoremovethemain

belt shield, B.

2. Remove the spark plug wire, A, from the spark

plug, B.

A

B

168

A

B

169

81

3. Remove the main drive belt as described in the

“Replace Main Drive Belt” section.

4. Support the rear of the deck with blocking.

170

5. Remove the pin from the link arm.

171

172

82

6. Disconnect the link arm from the pin.

7. Remove the pin form the rear of the deck

attaching rod.

173

8. Pullthetractor away from the deck until deck pin,

A, is out of the receiver, B.

174

B

A

175

83

END OF SEASON STORAGE SERVICE

CLEAN THE ENTIRE MACHINE AND

ENGINE

Thoroughly clean the machine and engine then blow

dry with 50 PSI compressed air.

ENGINE SERVICE

1. Refer to the engine manufactures manuals for

specific recommendations and procedures.

2. Drain the fuel tank.

3. Run the engine until the carburator runs out of

fuel and the engine stops running.

MACHINE SERVICE

1. Lubricate all grease point as shown in the

Lubrication Section.

2. Lubricate all linkage pivot points.

3. Spray exposed cables with a fluid lubricant to

prevent binding and rust.

4. Examine belt for damage and replace as

required.

5. Check the condition of all shields and replace as

required.

6. Check safety decals and replace as required.

7. Check all bearing for bearing condition. Replace

any loose bearings.

8. Check condition of the blade and replace as

required.

9. Clean the bottom of the deck to prevent the deck

from rusting.

84

SPECIFICATIONS

ENGINE Honda – GXV390K1 13.0 HP

FUEL TANK 1.0 US Gallon

OPERATING SLOPE Maximum operating slope 20 degrees

TRANSMISSION Hydrostatic infinite variable control

GROUND SPEED 0–4.2mph

WEIGHT 380 Lbs.

DIMENSIONS 42” W x 45” H x 76” L

BLADE WIDTH 26”

DECK WIDTH 28”

CUTTING HEIGHT 2-3/4” or 3-3/4”

DECK OSCILLATING 12 degrees right and left

SKIDS AND PUSH BAR Adjustable for cut height

Replaceable

DRIVES Engine mounted clutch/brake

TIRES Rear = 18 x 6.5 heavy 4-Ply lugged

ATTACHMENT ARM Variable angle 0 to 18 degrees to the left

Deck can be positioned up to 12 inches outside the left handle bar

CONTROLS Variable speed control lever

Implement positioning lever

Differential lock

Park Brake – optional

FRAME Heavy formed tube mainframe

85

BEFORE EACH USE

AFTER EACH USE

1. Check brush cutter daily for loose, bent, broken,

or missing parts.

2. Observe brush cutter’s general condition, noting

points that may need attention.

3. Check blade to be sure no foreign objects such

as wire or weeds are wrapped around it.

4. Make certain drive line shields are in place and

in good condition.

5. During operation, listen for abnormal sounds

which might indicate loose parts, damaged

bearings or other damage. Correct any problem

immediately.

1. Clean all debris from brush cutter especially on

the blade and deck.

2. To prevent rusting, touch up any spots where

paint may have worn off.

3. Store in a clean, dry place.

TROUBLESHOOTING

SYMPTOM POTENTIAL CAUSE REMEDY

Blade does not turn. Tractor attachment clutch is not engaged. Engage tractor Attachment

Drive.

Control and Brake Lever

Obstruction jammed between the rotor and

frame.

Blade stalls too easily. Cutting height too deep. Increase cutting height.

Ground speed too fast. Reduce ground speed.

Clear obstruction from the blade

as detailed in the manual.

Main Drive Belt is slipping. Replace Main Drive Belt.

Blade not sharp. Sharpen blade.

Blade installed backward so blunt end of blade

enters crop first.

Blade not tight on shaft. Tighten nut to 90 LBS/FT.

Main drive clutch is slipping. Adjust main drive clutch cable

Install blade so cutting portion of

the blade enters crop first.

tension.

86

BC02--1009

Printed in U.S.A.

Loading...

Loading...